A solution to the emptying of bridge bearings

A bridge bearing and solution technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as labor and time-consuming, and achieve the effects of avoiding uneven force, reducing lifting difficulty, and reducing bridge diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the existing bridge with support void disease as an example, the specific implementation steps of the disease solution are as follows:

[0026] (1) Remove the original support pad and clean it up;

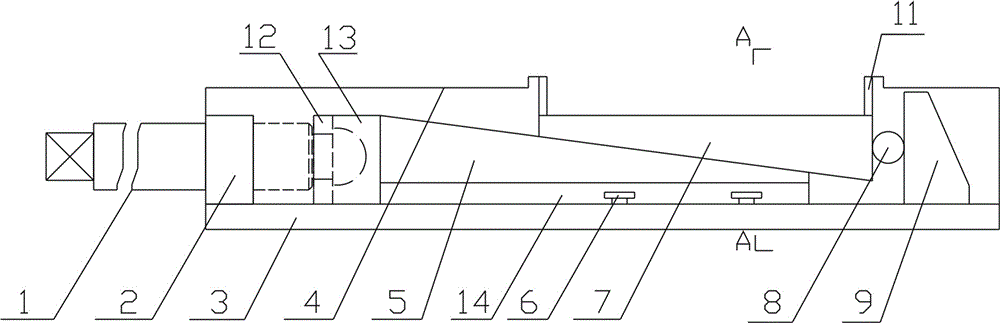

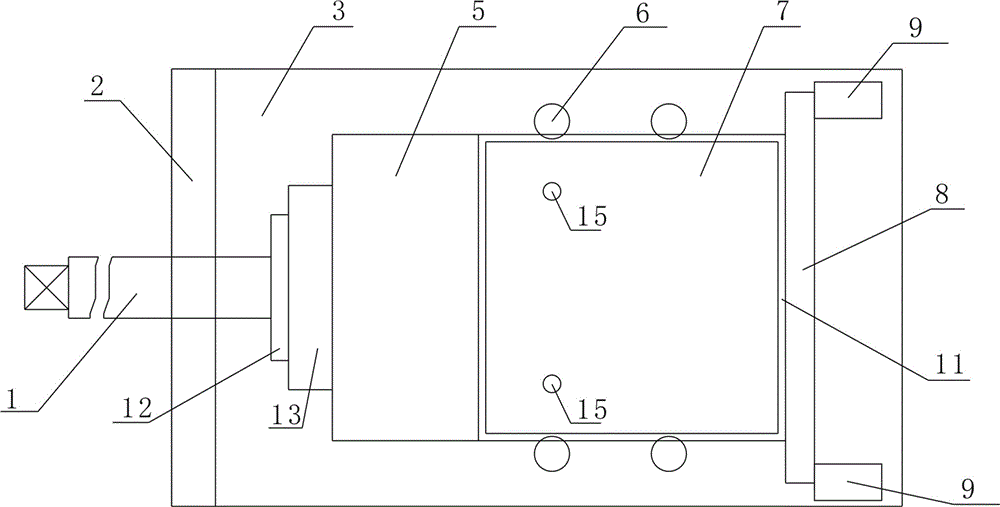

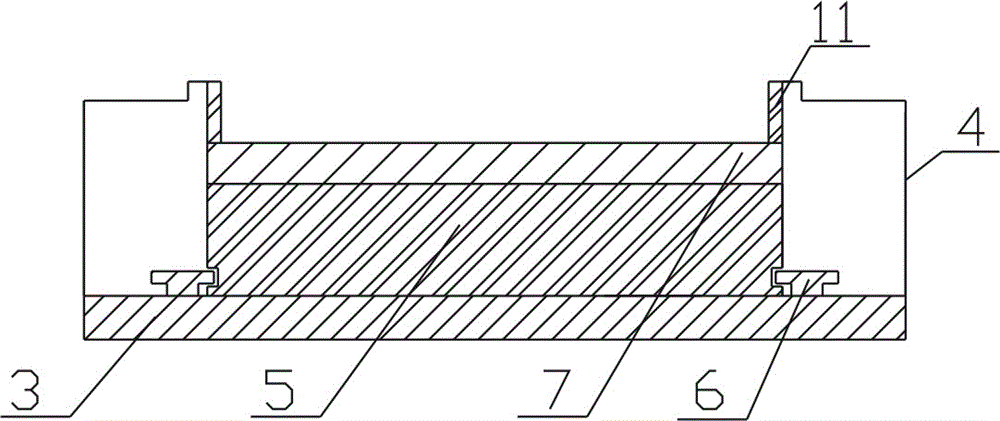

[0027] (2) Install adjustable support pad stones at the original support pad stones (epoxy mortar can be laid for preliminary adjustment of elevation according to the actual situation); if Figure 1-6 As shown, the adjustable bridge support pad stone: includes a round head screw 1 and a base 3, and the inner wire steel plate 2, the stop pressure plate 12, the pressure bearing plate 13, and the sliding device 5 are placed on the base 3 in sequence from left to right , and the anti-resistance pressure plate 12, the pressure-receiving plate 13, and the sliding device 5 are sequentially connected, the inner wire steel plate 2 is placed at intervals with the anti-resistance pressure plate 12, and the center position of the left end of the pressure-receiving plate 12 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com