C-N-O supersaturated solid solution martensitic stainless steel powder, preparation method and cladding method

A martensitic stainless steel and powder technology, which is applied in the field of laser additive and remanufacturing, can solve the problems of many heat treatment processes, high powder preparation cost, unsuitable for on-site working conditions, etc., and achieves uniform powder particle size, excellent molding quality, and reduced The effect of crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

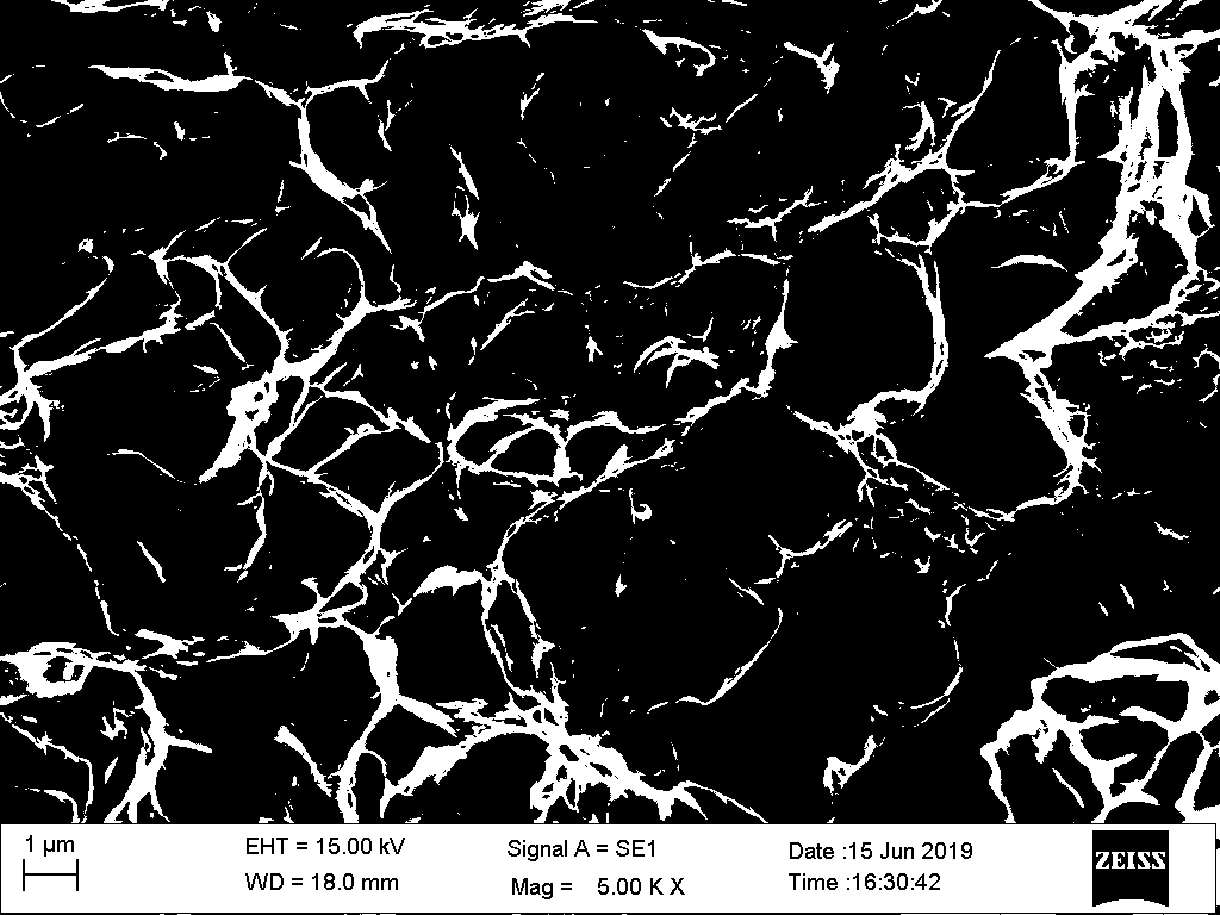

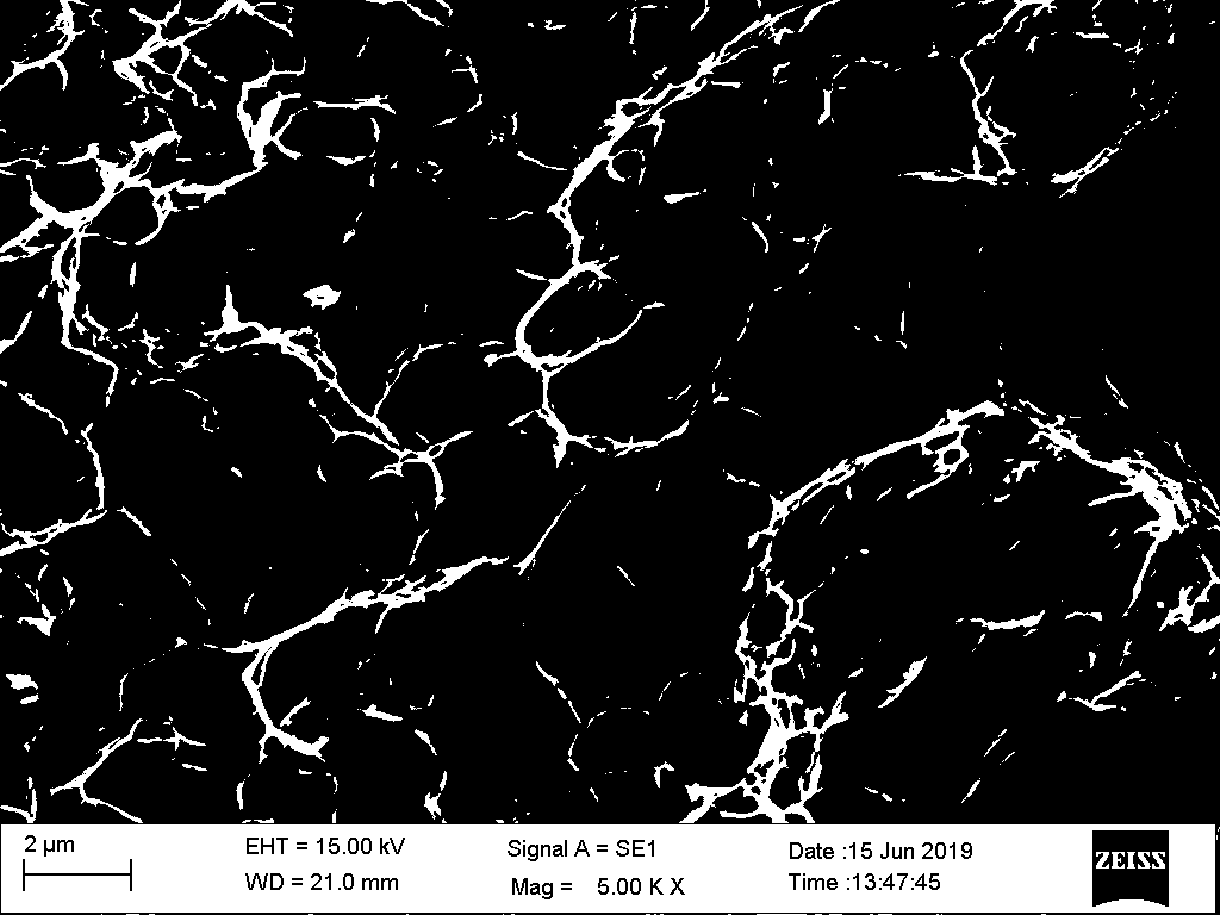

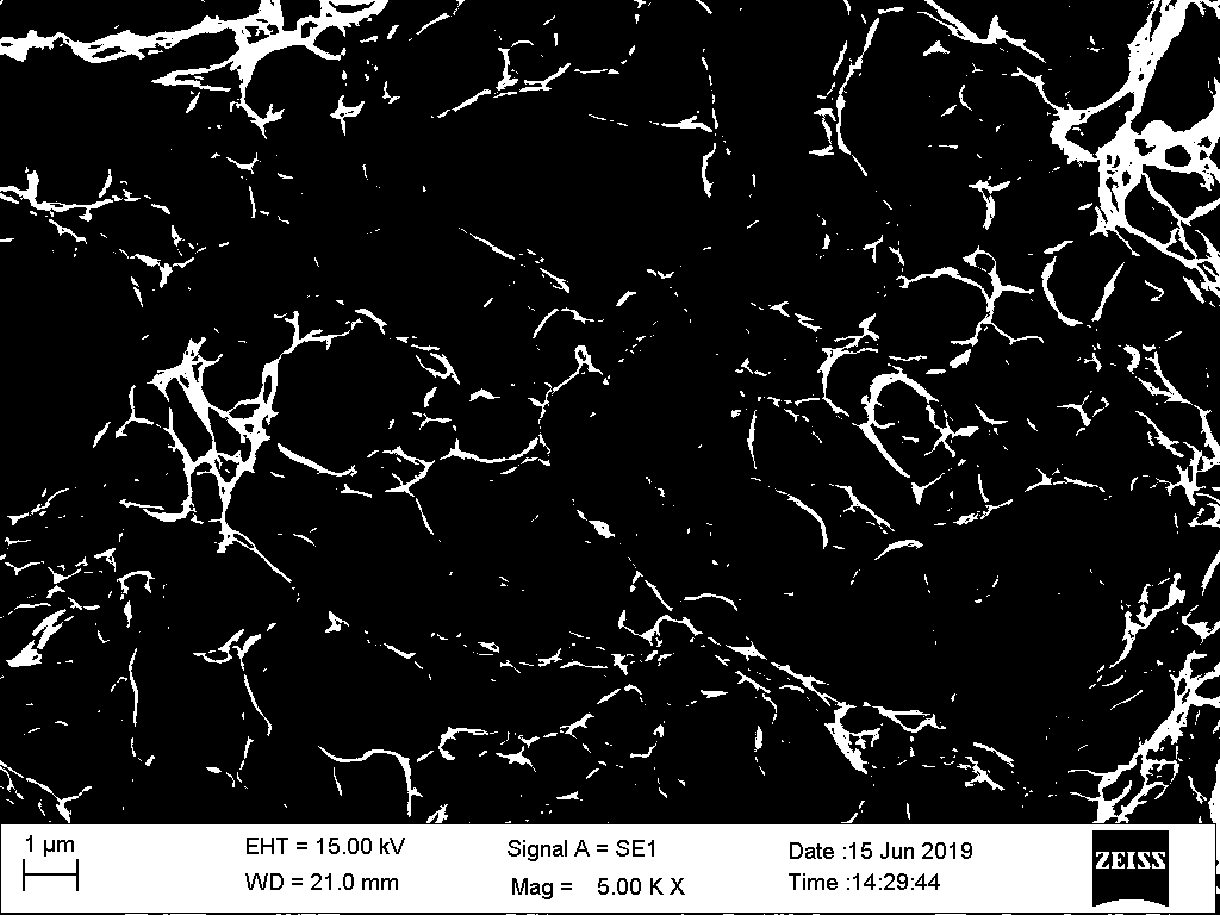

Image

Examples

Embodiment 1

[0062] C-N-O supersaturated solid solution martensitic stainless steel powder, the elements contained in it and the parts by weight of each element are as follows: C: 0.18 parts; N: 0.09 parts; Si: 0.75 parts; Cr: 12.0 parts; Mn: 0.80 parts; Ni : 1.3 parts; Al: 0.45 parts; V: 0.22 parts; O: 0.045 parts; Fe: 84.16 parts.

Embodiment 2

[0064] C-N-O supersaturated solid solution martensitic stainless steel powder, the elements contained in it and the parts by weight of each element are as follows: C: 0.19 parts; N: 0.11 parts; Si: 0.80 parts; Cr: 13.09 parts; Mn: 0.91 parts; Ni : 1.51 parts; Al: 0.5 parts; V: 0.25 parts; O: 0.045 parts; Fe: 82.64 parts.

Embodiment 3

[0066] C-N-O supersaturated solid solution martensitic stainless steel powder, the elements contained in it and the parts by weight of each element are as follows: C: 0.23 parts; N: 0.12 parts; Si: 0.90 parts; Cr: 14.0 parts; Mn: 0.95 parts; Ni : 1.80 parts; Al: 0.55 parts; V: 0.30 parts; O: 0.045 parts; Fe: 81.1 parts.

[0067] Briefly describe the preparation method of C-N-O supersaturated solid solution martensitic stainless steel powder of the present invention:

[0068] S01, according to the elements contained in C-N-O supersaturated solid-solution martensitic stainless steel powder and the parts by weight of each element, select iron-carbon master alloy, iron-silicon master alloy, iron-chromium master alloy, iron-manganese master alloy, iron-aluminum master alloy, Iron-vanadium master alloy and pure nickel are made into alloy mixture.

[0069] S02, use a vacuum induction furnace to smelt the alloy mixture into alloy liquid with qualified composition, and then inject the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com