Production equipment for seepage-proofing permeable plate-shaped sand products and matching production method thereof

A technology for production equipment and air-permeable panels, which is applied in the directions of manufacturing tools, climate sustainability, sustainable waste treatment, etc., and can solve the problems of lack of plate-shaped product equipment and supporting production methods for anti-permeation air sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

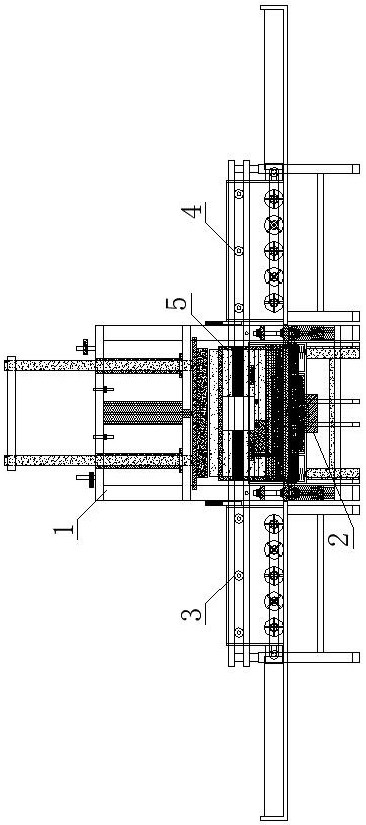

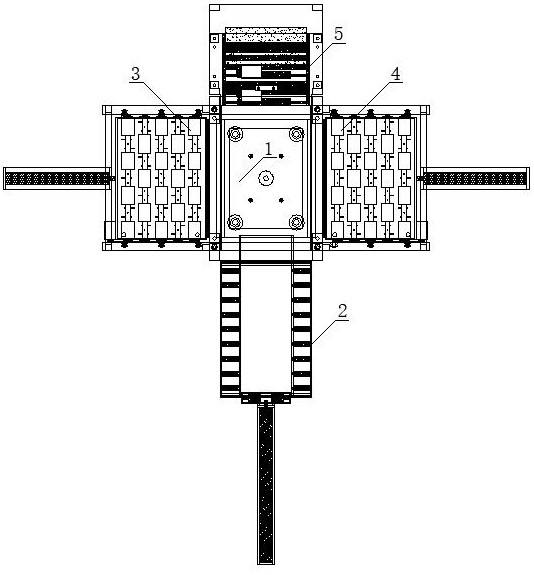

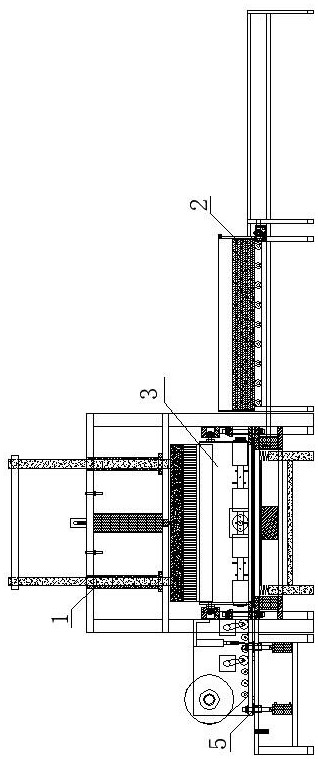

[0136] As shown in the accompanying drawings, a production equipment for anti-permeable air plate-shaped sand products is characterized in that it includes a push plate device 2 connected around the molding machine 1, a bottom material distribution device 3, a top material distribution device 4, a grid Cloth supply device 5, air compressor, automatic control system 7. The front of the molding host 1 is the grid cloth supply device 5; the rear of the molding host 1 is the push plate device 2; the left side of the molding host 1 is the bottom material distribution device 3; the right side of the molding host 1 is the top material distribution device 4; the bottom material distribution The positions of the device 3 and the top material distributing device 4 are interchangeable.

[0137] The molding machine 1 includes a vibrating device 11, a demoulding cylinder 12, a molding bottom plate 13, a molding mold 14, a molding pressure head 15, a pressure head lifting device 16, a moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com