Patents

Literature

87results about How to "Guaranteed flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

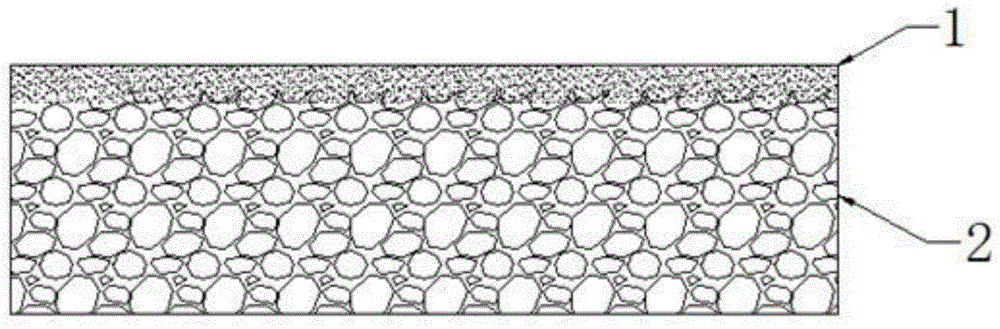

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

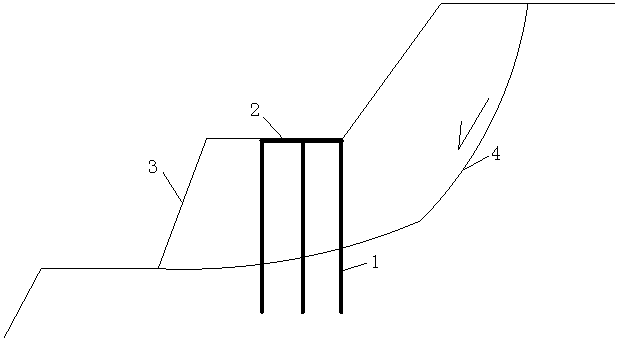

Structural design method for load-bearing section of miniature anti-slip compound pile

InactiveCN103225310AIncreased bending stiffnessReduce in quantityExcavationsBulkheads/pilesThrust bearingGeological survey

The invention discloses a structural design method for a load-bearing section of a miniature anti-slip compound pile. The method comprises the following steps: 1, performing a field geological survey, and determining mechanical properties of a geotechnical slope body through tests; 2, evaluating the stability of a slope, and calculating the residual slide thrust of the slope; 3, considering the adjustment and the distribution of the slide force among piles of the miniature anti-slip compound pile, and determining the distribution ratio of the slide force under each pile; 4, calculating to obtain the residual slide thrust borne by each pile; 5, calculating the bending moment, the shearing force, corners and the displacement of the load-bearing section of each pile; 6, performing reinforcement design on the miniature anti-slip pile according to the calculated bending moment; and 7, rechecking designed reinforcing bars according to the calculated shearing force. According to the design method, the residual slope slide thrust distribution conditions of each pile of the miniature anti-slip compound pile are determined, the reinforcing function of each pile body in the combined pile consisting of multiple piles is determined, the distribution of the anti-slip effect on each pile is obtained, the structure effect and the pile-soil action effect of the miniature anti-slip compound pile are considered, and the internal force calculation result is accurate and scientific, so that the bending resistance, the shearing resistance and the safety of the miniature anti-slip compound pile are guaranteed.

Owner:CENT SOUTH UNIV

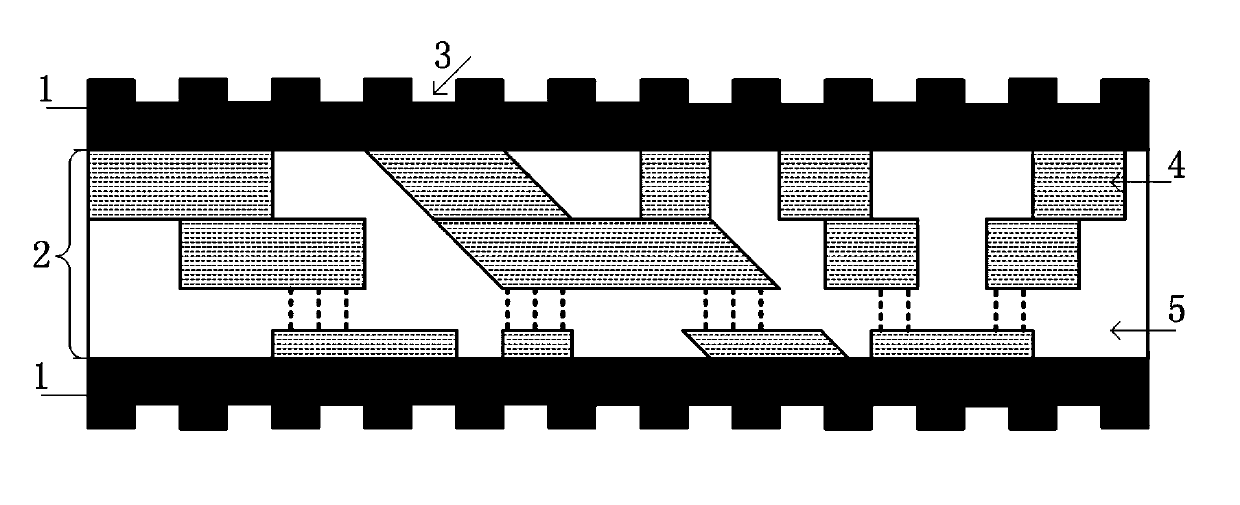

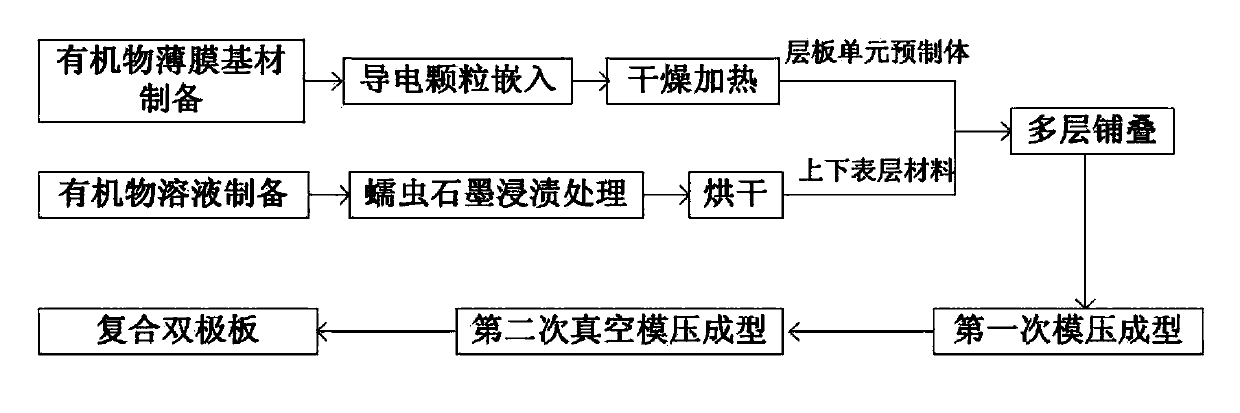

Composite bipolar plate for PEM (proton exchange membrane) fuel battery and preparation method thereof

ActiveCN103746131AGood effectImprove air tightnessFinal product manufactureCell electrodesSurface layerProton

The invention discloses a composite bipolar plate for a PEM (proton exchange membrane) fuel battery and a preparation method thereof. The bipolar plate comprises an upper and lower surface layers prepared by using vermicular graphite as a base material, and a plurality of laminated plate unit preforms prepared by embedding conductive particles in organic substance films, wherein every two adjacent laminated plate unit preforms are provided with one or a plurality of conductive particle overlay areas to form one or a plurality of zigzag conductive paths. The preparation method comprises the following steps: sequentially laying the lower surface layer material, the laminated plate unit preforms and the lower surface layer material in a die, and carrying out die pressing twice to obtain the bipolar plate for a PEM fuel battery. The method enhances the production efficiency of the composite bipolar plate for a PEM fuel battery, and lowers the manufacturing cost; and the composite bipolar plate has the advantages of high bending strength, favorable conductivity and favorable air tightness.

Owner:CHINA THREE GORGES UNIV

Aluminium based interlayer alloy for liquid phase diffusion weld

InactiveCN1569385AReduce welding costsShorten the timeWelding/cutting media/materialsSoldering mediaRare earthCopper

The invention discloses an aluminum base middle-layer alloy for liquid phase diffusion welding. The weight percentage of each element is: aluminum 60-95%, silicon 0.5-10%, copper 0.5-35%, magnesium 0.5-10%, gallium 0.001-1%, rare earth 0.001-0.1%. It can be applied to the weld of each kind of aluminum and aluminum alloy product.

Owner:SHANDONG HUADIAN ENERGY SAVING TECH

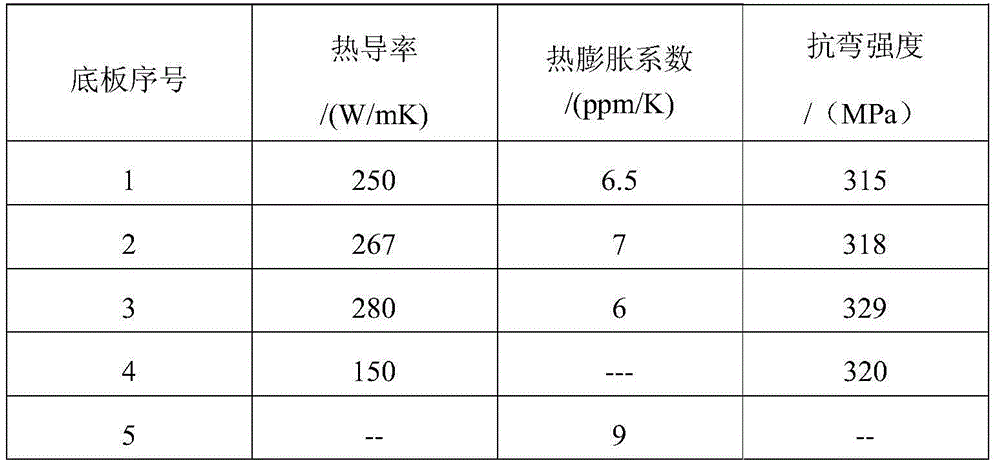

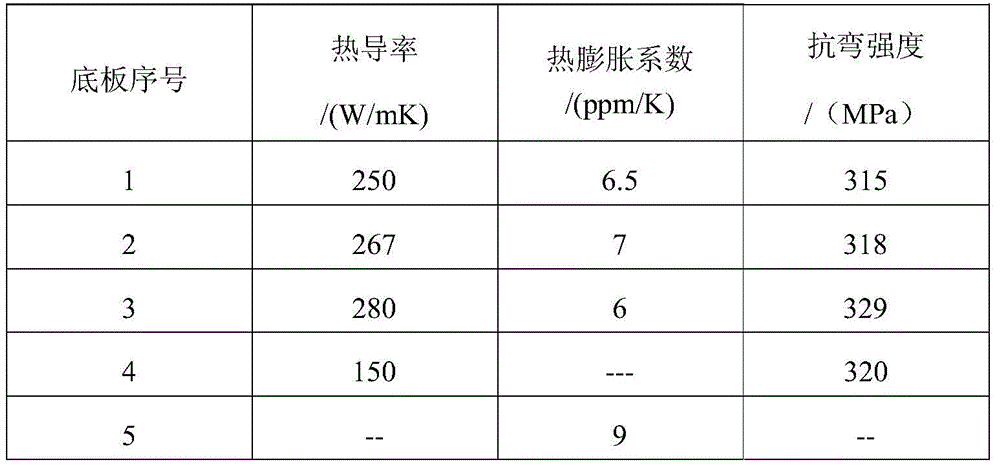

Preparation method for aluminum silicon carbide, aluminum silicon carbide obtained with method and electronic component packaging substrate

ActiveCN104658920AAvoid scourUniform internal organizationSemiconductor/solid-state device detailsSolid-state devicesAluminum substrateElectronic component

The invention provides a preparation method for aluminum silicon carbide and aluminum silicon carbide obtained with the method. The preparation method for aluminum silicon carbide comprises powder filling and aluminization, wherein in the powder filling step, a groove of an aluminum substrate is filled with powder and a powder plate is formed; an aluminum foil with the depth being 0.5 mm is laid on the surface of the powder plate; other additives except aluminum and silicon carbide are not added into aluminum silicon carbide. According to the preparation method for aluminum silicon carbide, the aluminum foil with the depth of 0.5 mm is laid on the surface of the silicon carbide powder and then aluminization is carried out, so that scouring of molten aluminum to a silicon carbide layer in an aluminization process can be prevented and an aluminum silicon carbide material obtained after the aluminization step is guaranteed to be uniform in internal structure. Moreover, the method provided by the invention keeps the bending resistance of the aluminum silicon carbide material under a condition that no additive is added, so that the thermal conductivity of the obtained aluminum silicon carbide material is increased to 250-280 W / mK.

Owner:HUNAN HARVEST TECH DEV

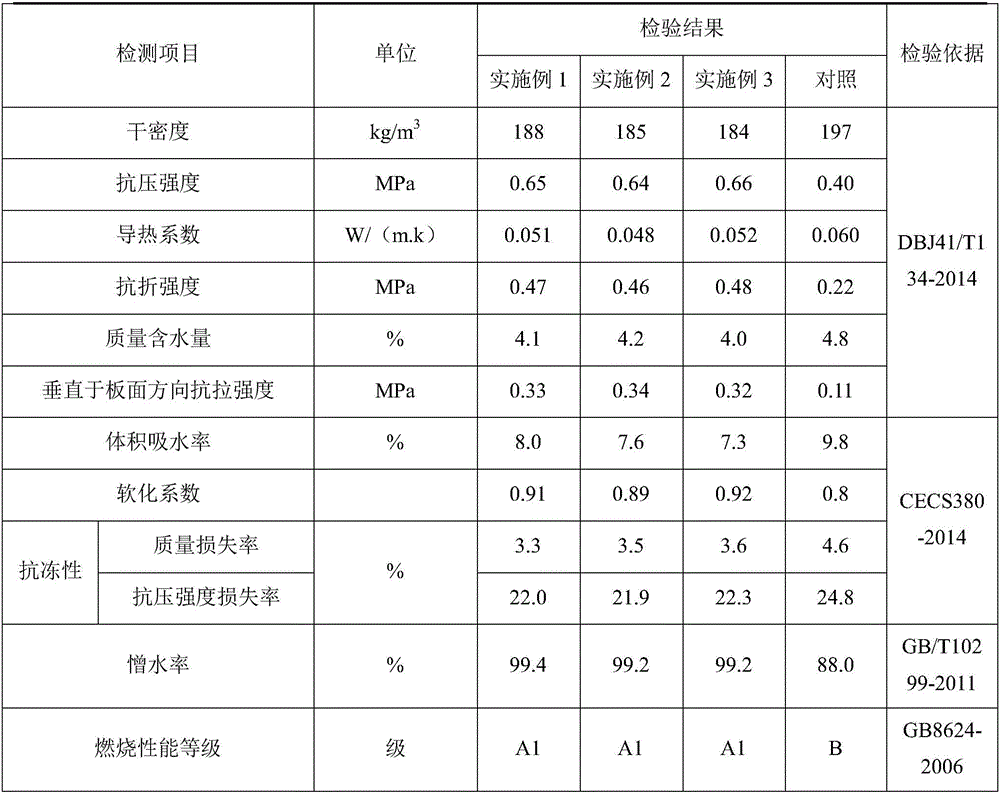

Hydrophobic modified expanded perlite thermal insulation board and production method thereof

ActiveCN105948638AExcellent fire performanceImprove fire performanceSolid waste managementCeramic shaping apparatusSodium silicateEmulsion

The invention discloses a polyacrylate enhanced modified expanded perlite thermal insulation board and a production method thereof. The modified expanded perlite thermal insulation board comprises the following components, by weight: 25-40 parts of cement, 5-8 parts of fly ash, 2-5 parts of triethoxysilane, 5-10 parts of polyacrylate emulsion, 50-70 parts of modified expanded perlite, 0.7-2.9 parts of sodium dodecylbenzenesulfonate, 5-10 parts of additives, 1-3 parts of quicklime, 0.1-0.5 parts of PP fiber, 0.5-2 parts of carbon fiber, 5-10 parts of diatomite, 4-10 parts of sodium silicate and 10-20 parts of water. According to the modified expanded perlite thermal insulation board, cement, fly ash, diatomite, PP fiber and other organics and inorganics are adopted as raw materials, such that industrial and mining waste materials are effectively utilized, and no toxic or harmful substance is added. Therefore, the modified expanded perlite thermal insulation board is green and environment-friendly. The modified expanded perlite thermal insulation board has the advantages of wide raw material source and low cost. The production process is simple and is easy to operate. With the thermal insulation board, requirements by different building materials can be satisfied, and good social and economic benefits are provided.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

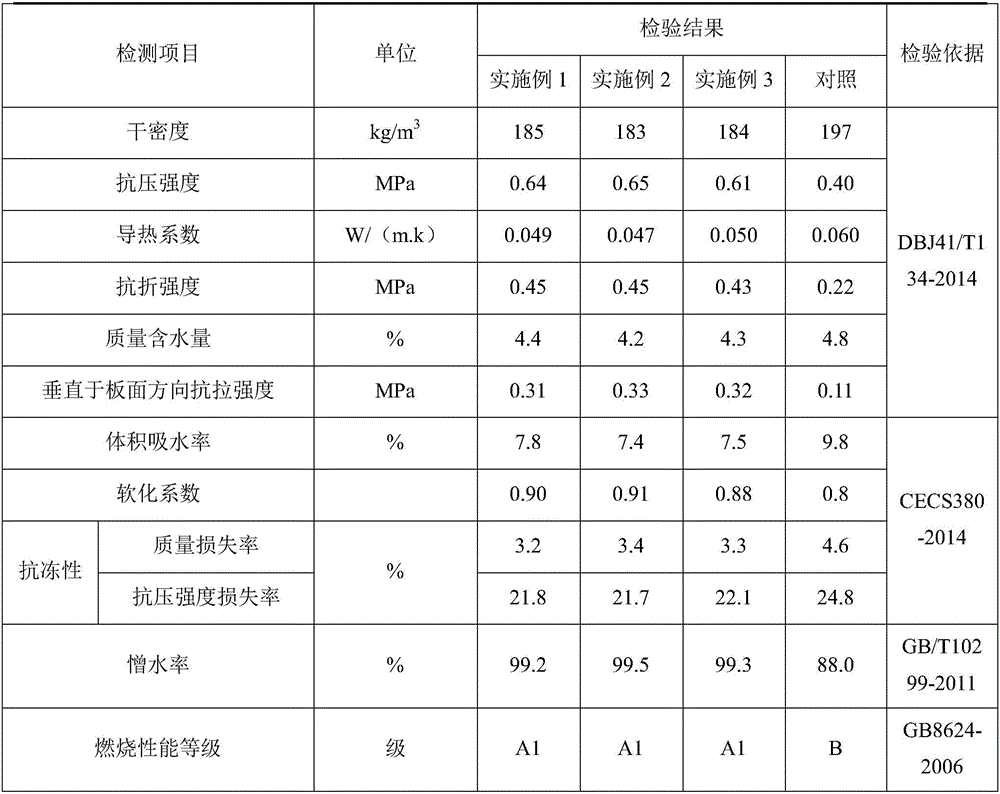

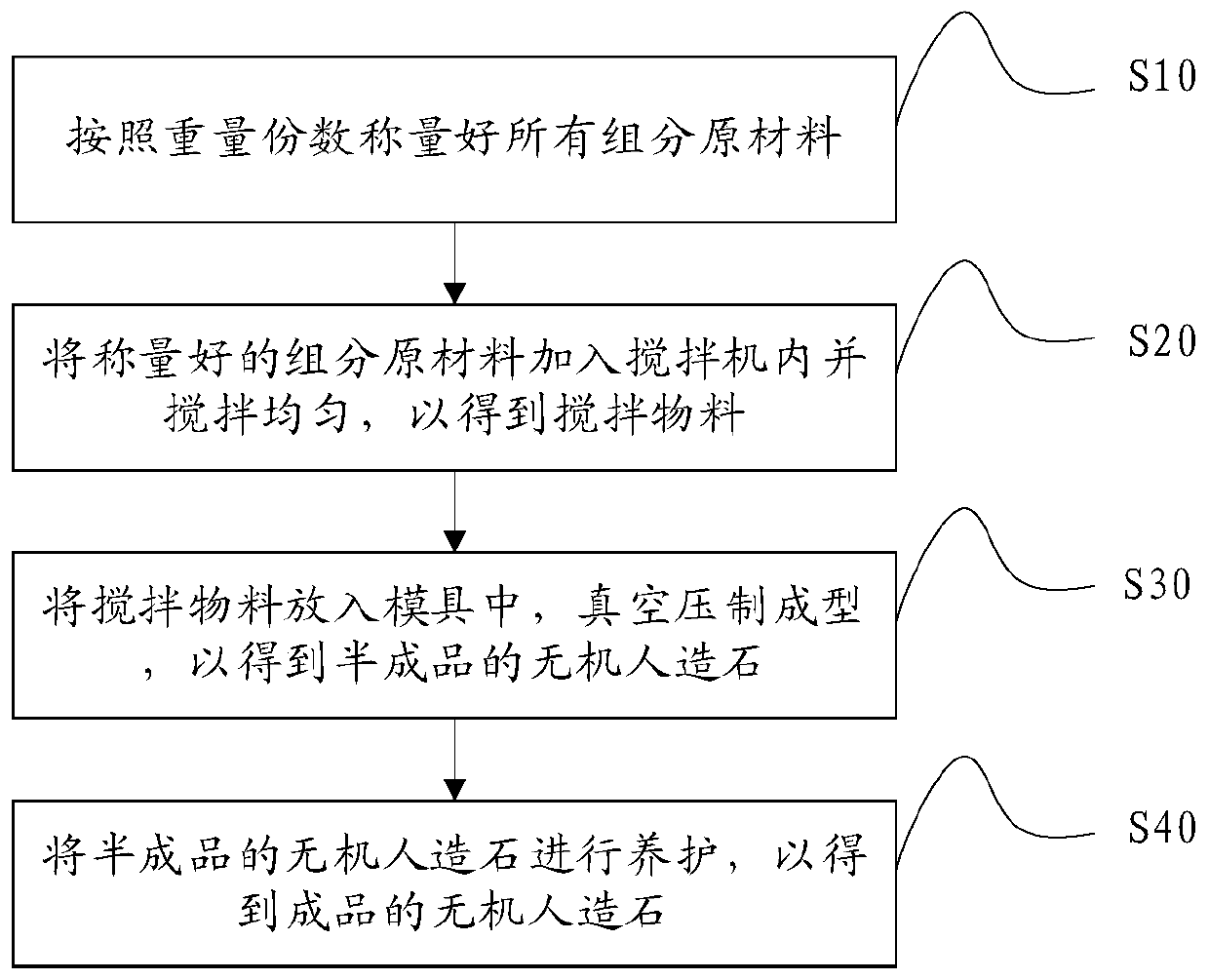

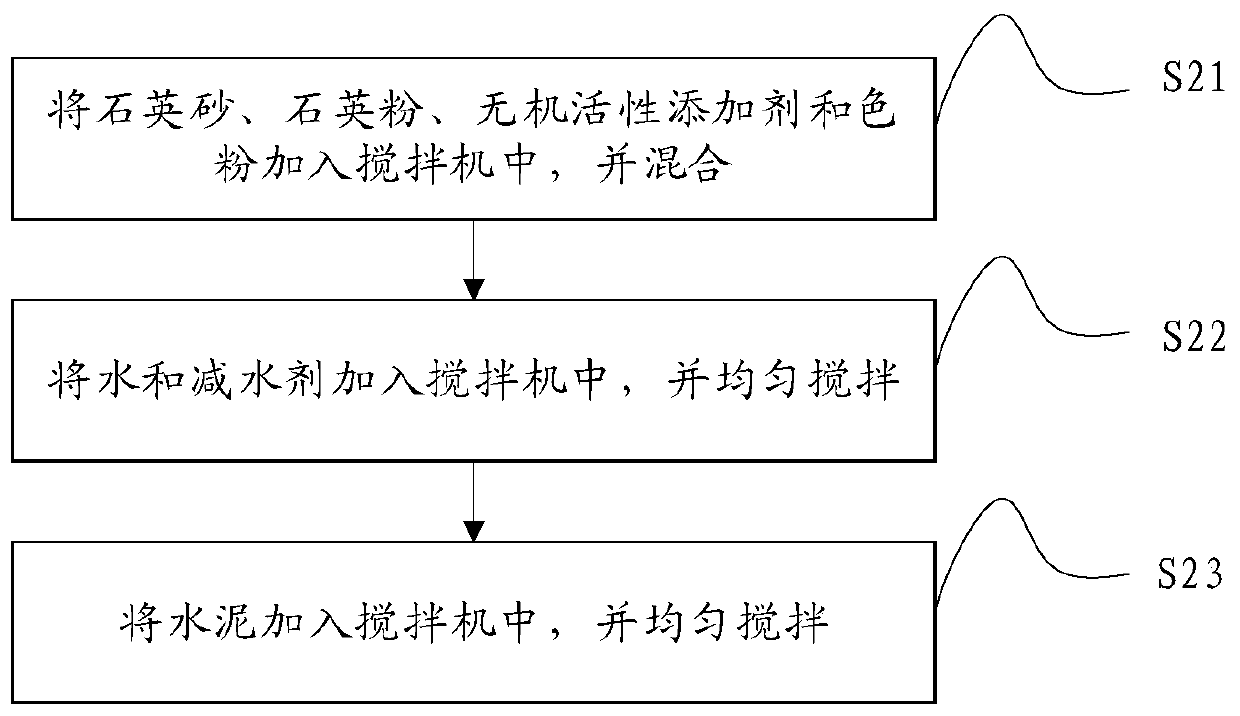

High-strength inorganic artificial stone and manufacturing method thereof

The invention discloses a high-strength inorganic artificial stone and a manufacturing method thereof. The high-strength inorganic artificial stone comprises the following components: 60-70 parts of quartz sand, 5-10 parts of quartz powder, 22-25 parts of cement, 2.5-4 parts of an inorganic active additive, 0.5-1.5 parts of a water reducing agent and 2-4 parts of water. According to the high-strength inorganic artificial stone provided by the invention, the inorganic artificial stone is prepared by completely using inorganic raw materials, so that the environmental pollution caused by the inorganic artificial stone in use is avoided; and the inorganic active additive is used as a preparation material, so that the flexural strength of the inorganic artificial stone is ensured to meet the use requirements.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

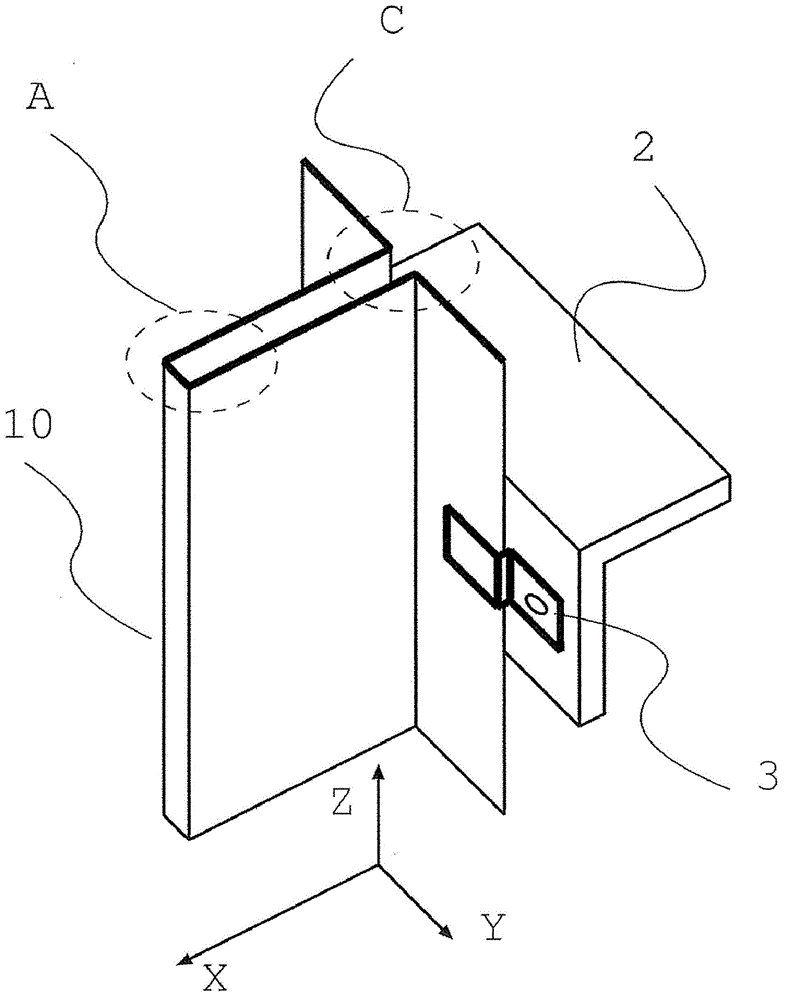

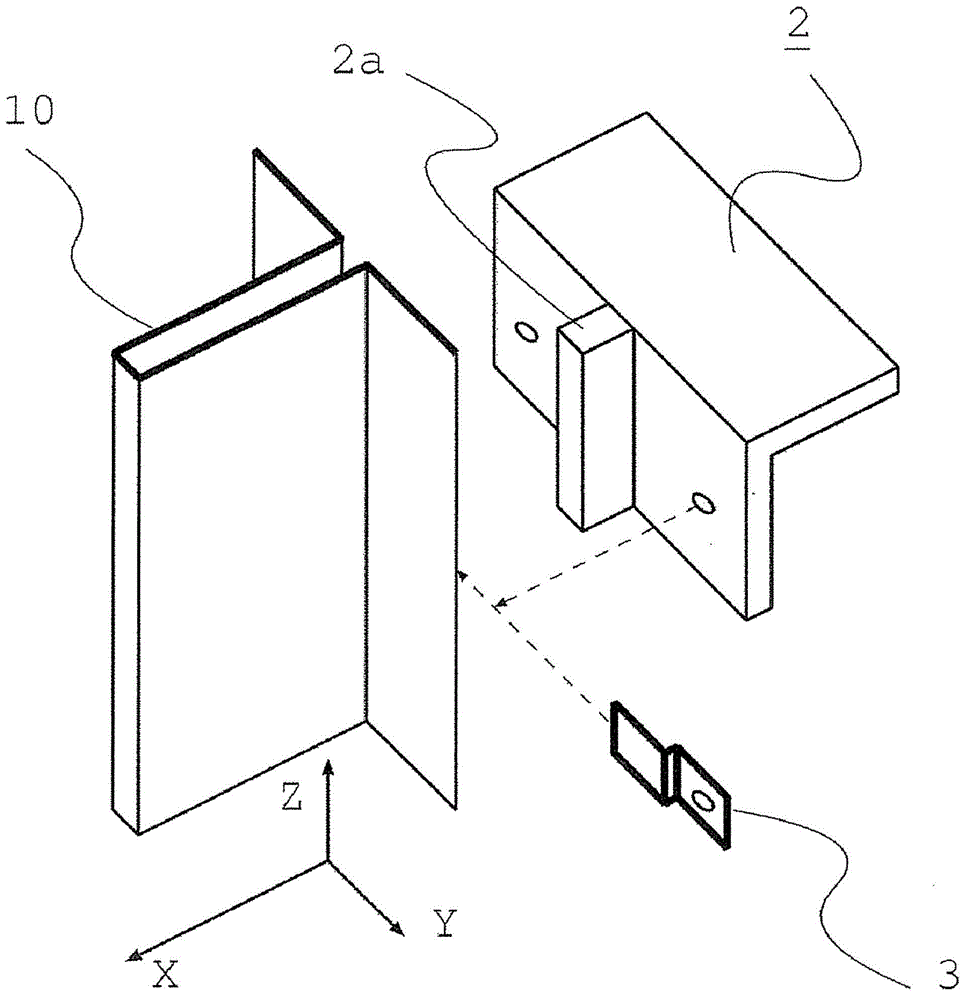

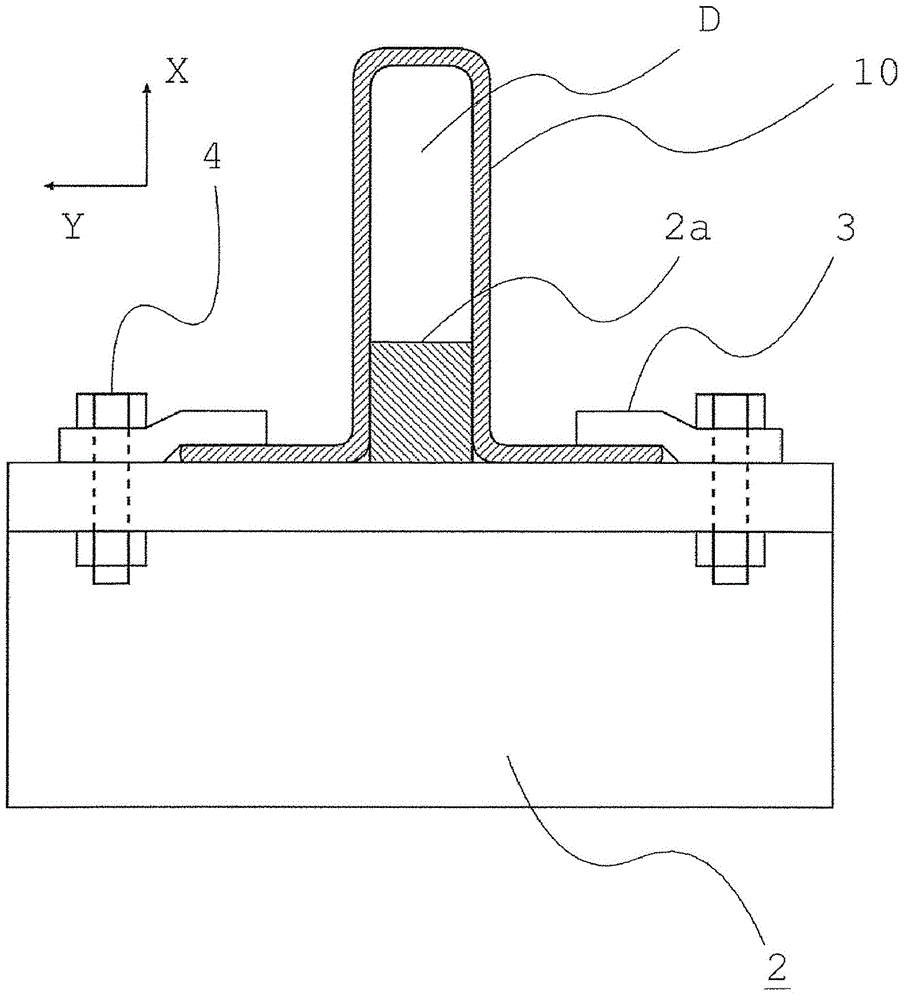

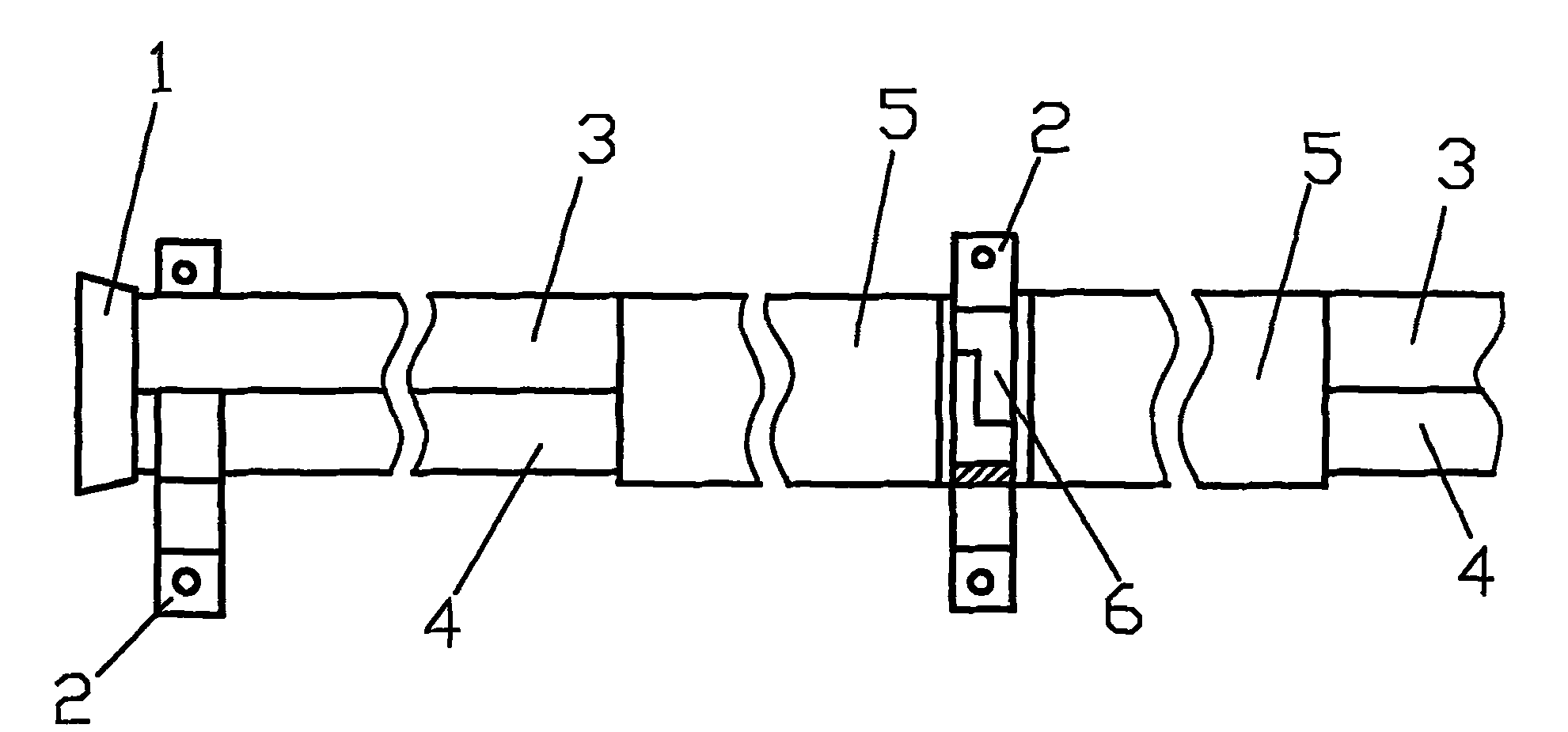

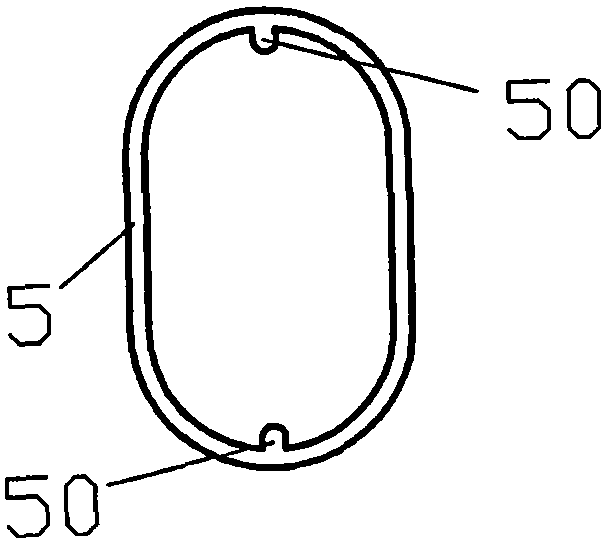

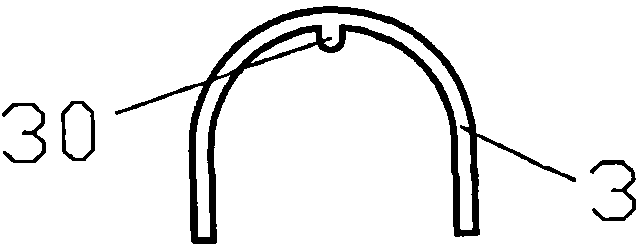

Supporting structure of elevator guide rail

The invention provides a supporting structure of an elevator guide rail. In the prior art, if the up-down interval of a carrier becomes longer, the horizontal load of an elevator car and a counterweight, when an earthquake happens, may result in the bending of the guide rail, and then the bending strength cannot be ensured. Therefore, if a guide rail having a larger cross section is required, the problem of higher cost of the guide rail arises. The supporting structure of the elevator guide rail includes a steel plate forming guide rail provided with a U-shaped forming part, and a carrier supporting the steel plate forming guide rail, wherein one face of the steel plate forming guide rail and one face of the carrier are defined in that the surfaces of the faces are contacted with each other in the plane determined by the head direction of the steel plate forming guide rail and the axial direction of the steel plate forming guide rail.

Owner:MITSUBISHI ELECTRIC CORP

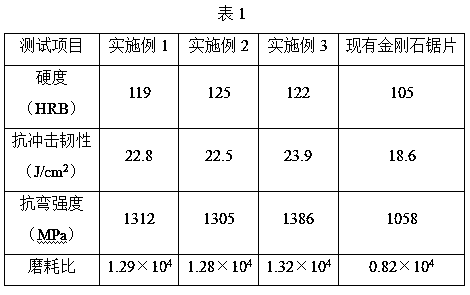

High-performance diamond saw blade and preparation method thereof

ActiveCN109175388AHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderBoron carbide

The invention discloses a high-performance diamond saw blade and a preparation method thereof. A tool bit of the high-performance diamond saw blade comprises a first cutting area and a second cuttingarea. The first cutting area comprises, by weight part, 8-14 parts of polycrystalline diamond particles, 48-55 parts of iron powder, 25-32 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-5 parts of tungsten carbide and titanium carbide mixture powder and 0.4-0.7 part of lanthanum pentanickel powder. The second cutting area comprises, by weight part, 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, 27-33 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder and 0.4-0.7 part of lanthanum pentanickel powder. The high-performance diamond saw blade is excellent in comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

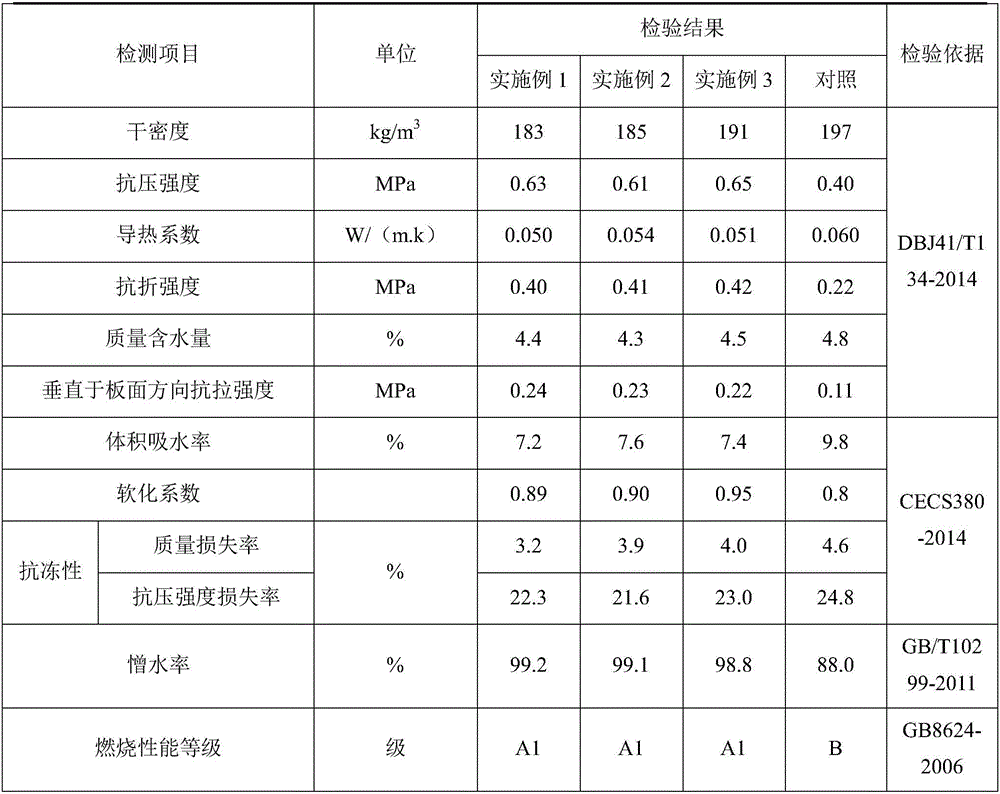

Lightweight waterproof modified expanded perlite insulation board and production method thereof

The invention discloses a lightweight waterproof modified expanded perlite insulation board and a production method thereof. The modified expanded perlite insulation board comprises the following components in parts by weight: 25 to 40 parts of cement, 5 to 8 parts of fly ash, 2 to 5 parts of methyltrimethoxysilane, 5 to 10 parts of a polyacrylate emulsion, 50 to 70 parts of modified expanded perlite, 0.7 to 2.9 parts of sodium dodecyl benzene sulfonate, 5 to 10 parts of an additive, 1 to 3 parts of quicklime, 0.1 to 0.5 part of PP fiber, 0.5 to 2 parts of carbon fiber, 5 to 10 parts of kaolin, 4 to 10 parts of water glass and 10 to 20 parts of water. The modified expanded perlite insulation board provided by the invention uses cement, fly ash, kaolin, PP fiber and organic and inorganic matters as raw materials, so industrial and mineral waste materials are effectively utilized; meanwhile, no toxic and harmful substance is added, so greenness and environmental protection are achieved. The modified expanded perlite insulation board provided by the invention has the advantages of extensively available raw materials, low cost, simple production process, facilitation to operation, capability of meeting the demands of different building materials, and good social and economic benefits.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

Modified-expanded-perlite insulation board and production method therefor

The invention discloses a modified-expanded-perlite insulation board and a production method therefor. The modified-expanded-perlite insulation board is prepared from the following ingredients in parts by weight: 18-25 parts of cement, 5-8 parts of fly ash, 2-5 parts of triethoxysilane, 5-10 parts of polyacrylate emulsion, 50-70 parts of modified expanded perlite, 0.7-2.9 parts of sodium dodecylbenzene sulfonate, 5-10 parts of additive, 0.1-0.5 part of PP fibers and 10-20 parts of water. According to the modified-expanded-perlite insulation board disclosed by the invention, the cement, the fly ash and other organic and inorganic matters serve as raw materials, so that wastes of industry and mining are put into effective use; and hazardous and noxious substances are not added, so that the modified-expanded-perlite insulation board is green and environment-friendly. The modified-expanded-perlite insulation board disclosed by the invention is wide in source of raw materials, low in cost, simple in production process and easy in operation, can meet the requirements of different building materials and has good social and economic benefits.

Owner:XINYANG CITY OF CRYSTAL ENG MATERIALS CO LTD

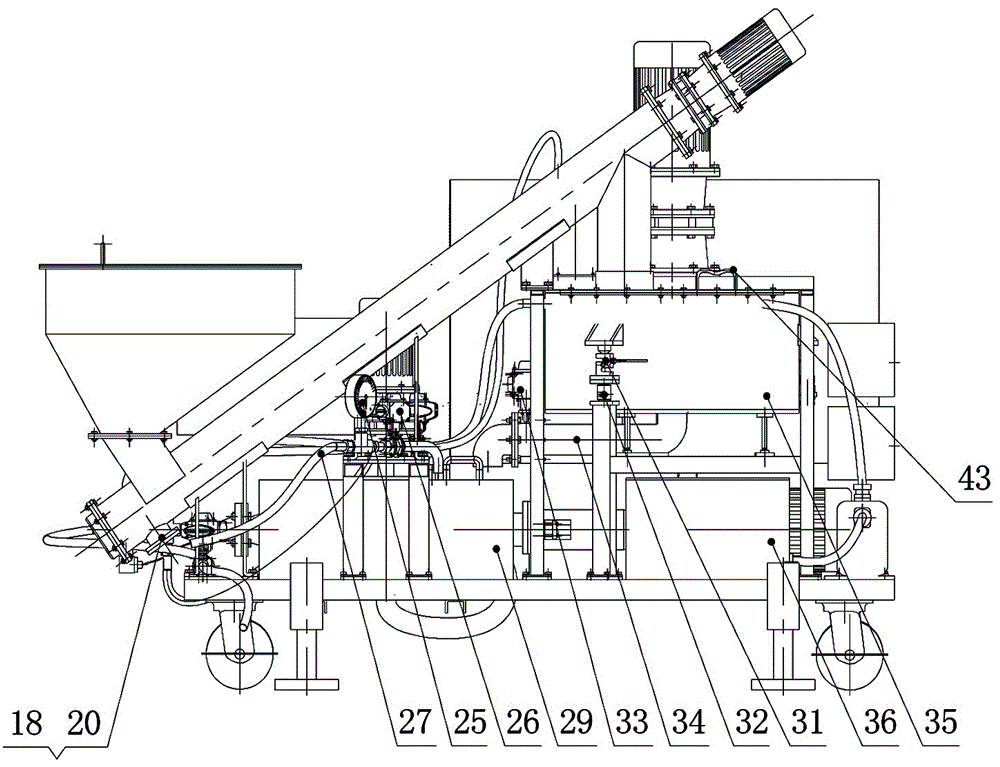

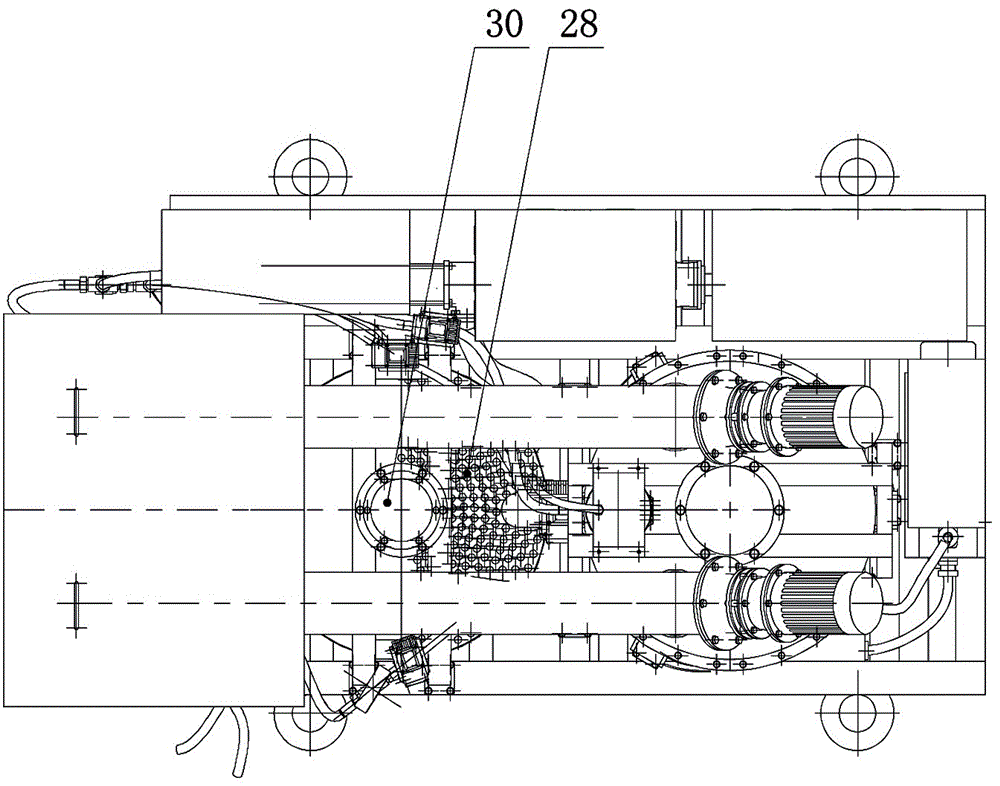

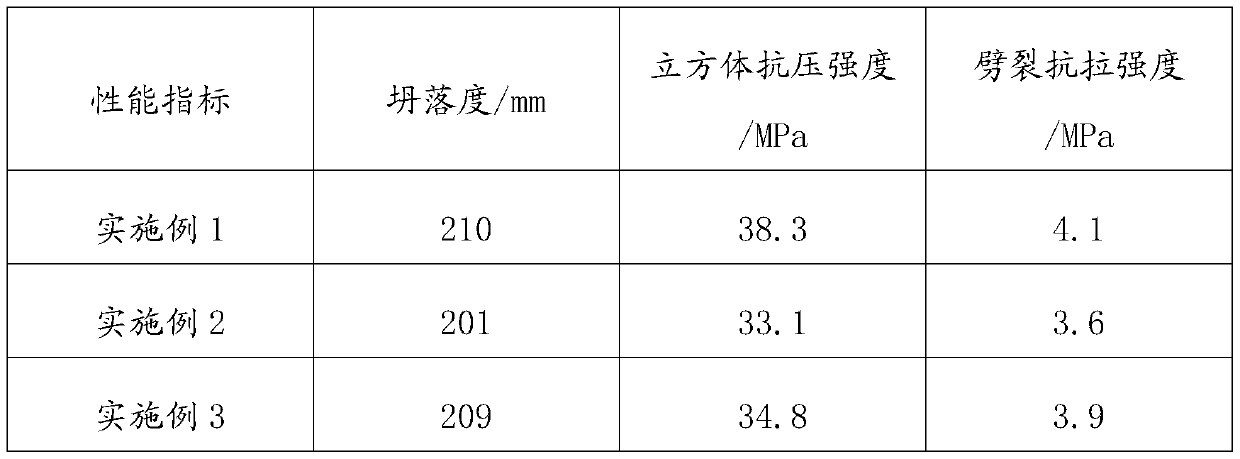

Intelligent large grouting equipment

InactiveCN106638317AControl mix ratioGuaranteed compressive strengthBridge erection/assemblyMicrocomputerFlexural strength

The invention discloses intelligent large grouting equipment, comprising an automatic feeding system, a grout liquidity auto-detection system, a weighing system, a control center system, a high-speed stirring system, a low-speed stirring system, an automatic grouting system, a cleaning system, an automatic water-adding system and a grout circulating loop system; a grouting agent charging tank is connected to the lower portion of a grouting agent feeding pipe, and cleaning outlet II is positioned below the grouting agent feeding pipe; a high-speed stirring barrel is fixed to a triangular frame through a weighing sensor and is measured and controlled via a microcomputer; the large grouting equipment also comprises a backup power system and a cleaning system. The intelligent large grouting equipment has the function of automatically metering raw material in static discharging state, accurate control for grout matching ratio is ensured, and effective guarantee is provided for grout compressive strength, flexural strength and performance indexes; the system can automatically detect the liquidity of grout, an operator needs to carry out irregular detection in non-fixed batches, and unqualified grout is avoided being pressed into a beam duct.

Owner:柳州市邱姆预应力机械有限公司

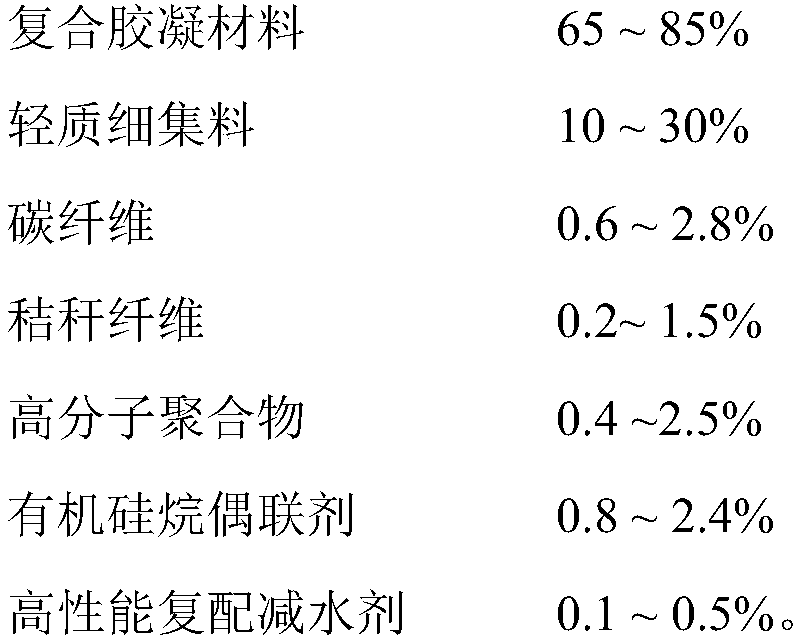

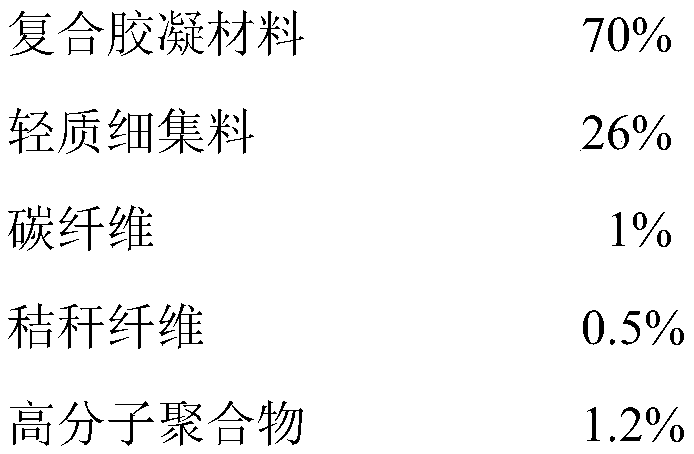

Straw fiber-reinforcing spraying-type phosphorus gypsum-based fireproof mortar as well as preparation method and application thereof

The invention discloses a straw fiber-reinforcing sprayspraying-type phosphorus gypsum-based fireproof mortar as well as a preparation method and application thereof, which belongs to the technical field of construction materials. The straw fiber-reinforcing sprayspraying-type phosphorus gypsum-based fireproof mortar is prepared from the following raw materials by weight percentage: 65 to 85 percent of composite cementing material, 10 to 30 percent of light-weight fine aggregates, 0.6 to 2.8 percent of carbon fibers, 0.2 to 1.5 percent of straw fibers, 0.4 to 2.5 percent of macromolecular polymer, 0.8 to 2.4 percent of an organic silane coupling agent, and 0.1 to 0.5 percent of a high-performance compound water reducing agent. The straw fiber-reinforcing spraying-type phosphorus gypsum-based fireproof mortar is characterized in thatBy adopting the technical scheme of the invention, the fireproof capability of the mortar can be effectively improved, so that the fire risk of the steel structural building can be reduced, and the mortar material is convenient in construction and application and firm in combination with the steel structural building.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Biochar, preparation method thereof, foam concrete and preparation method of foam concrete

PendingCN113955738AImprove mechanical propertiesReduce heavy metal leachingSolid waste managementCarbon preparation/purificationChemistryEnvironmental geology

The invention relates to the technical field of concrete, and concretely relates to a biochar, a preparation method thereof, a foam concrete and a preparation method of the foam concrete. The biochar with excellent performance is prepared, and the foam concrete is prepared by taking the biochar and sludge incineration ash as raw materials. The preparation method of the foam concrete comprises the following steps: premixing the ash, cement and biochar to obtain a dry mixture; carrying out wet mixing on the obtained dry mixture and water to obtain a wet mixture; mixing the wet mixture with a water reducing agent to obtain a mixture; mixing the obtained mixture with foam to obtain slurry; and pre-curing and curing the obtained slurry in sequence to obtain the foam concrete. According to the embodiment of the invention, the sludge incineration ash is successfully recycled, so that the sludge incineration ash is recycled, and the fixation of the carbon element is realized. The obtained concrete is uniform in pore size distribution, and the physical properties including compression resistance, fracture resistance, dry density, water resistance, heat conductivity coefficient and the like all meet the building industry standard foam concrete (JG / T 266-2011).

Owner:SHANGHAI JIAO TONG UNIV

Cobalt leaching solution system, hard alloy cobalt leaching method and blade with diamond coating

ActiveCN105803419AReasonable configurationReasonable setting of cobalt removal stepsChemical vapor deposition coatingAlloyCobalt

The invention provides a cobalt leaching solution system which comprises an acid solution A and an alkaline solution B. The acid solution A comprises H2SO4 or HNO3, H2O2 and H2O, and the alkaline solution B comprises K3[Fe(CN)6], H2O and NaOH or KOH. The invention further provides a method for cobalt leaching of hard alloy through the cobalt leaching solution system, and a blade with a diamond coating, and the blade with the diamond coating is formed by settling a diamond layer on a hard alloy base body which is subjected to cobalt leaching through the hard alloy cobalt leaching method. The cobalt leaching solution system is easy to prepare and good in cobalt leaching effect. The method is reasonable in step arrangement and easy to operate. A blade base body and the blade surface coating of the obtained blade with the diamond coating have high bonding strength.

Owner:FUNIK ULTRAHARD MATERIAL

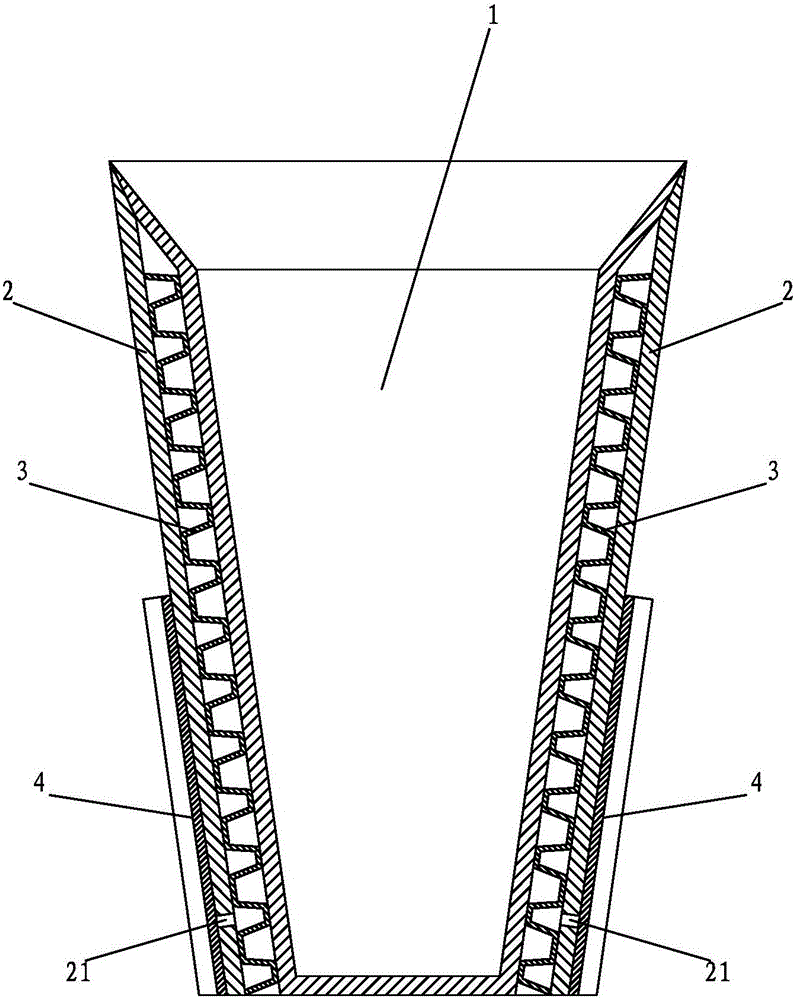

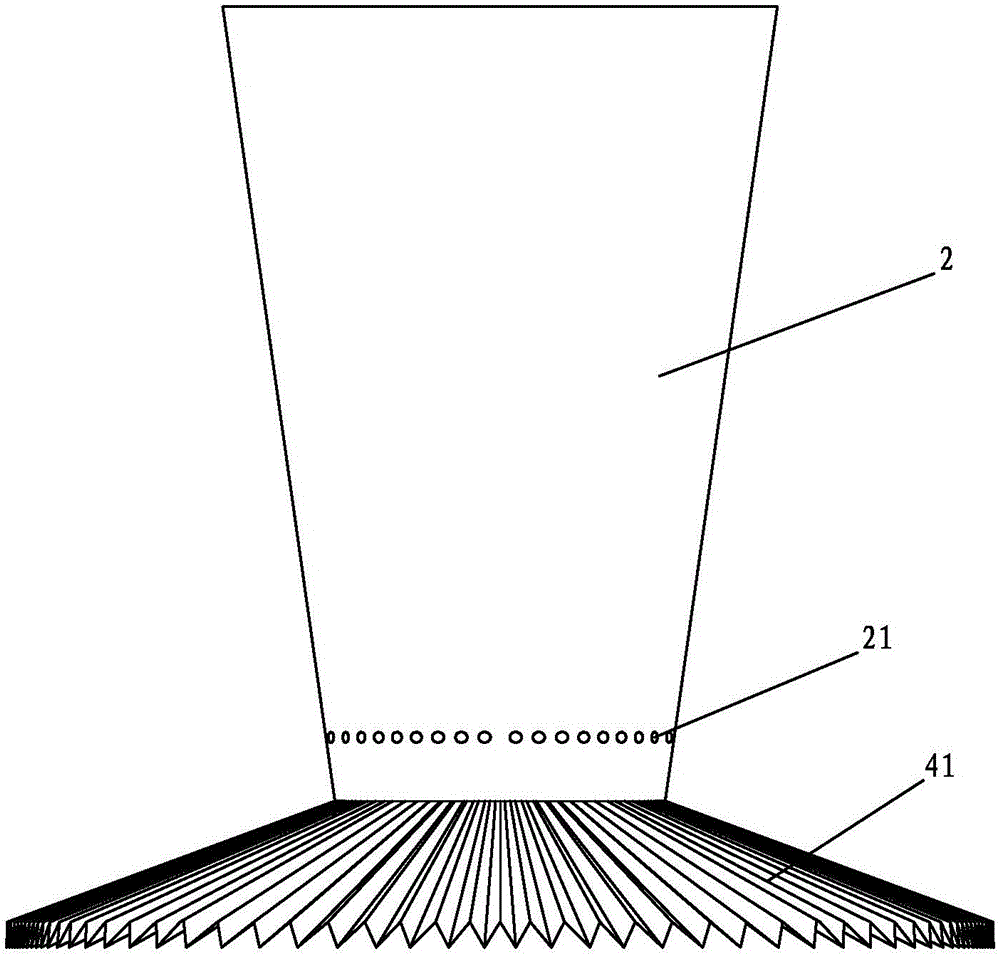

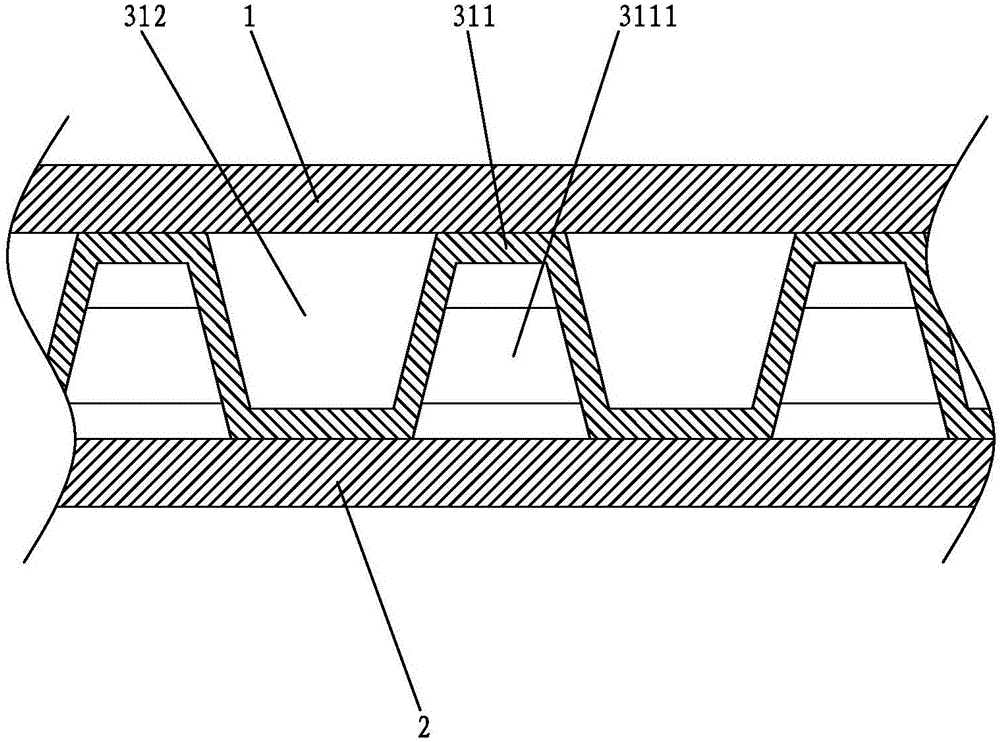

Corrugated paper cup

ActiveCN105775300AAvoid bending deformationWill not bendVenting meansRigid containersAir cyclePaper based

The invention discloses a corrugated paper cup. An isolation cavity is formed by a corrugated paper layer, so that the fact that the hand of a user is scalded by a hot beverage in a paper cup main body; longitudinal corrugated structures are laterally supported and restrained by horizontal corrugated structures; the horizontal corrugated structures are laterally supported and restrained by the longitudinal corrugated structures; and the sidewalls of the longitudinal corrugated structures and the sidewalls of the horizontal corrugated structures do not easily curve laterally. The longitudinal corrugated structures and the horizontal corrugated structures can perform bending resistance supporting, so that the defect of a traditional corrugated paper cup that a crease is formed along a corrugated structure extension direction, so that bending deformation is formed in the direction vertical to corrugated structures is overcome. The upper surfaces and the lower surfaces of the longitudinal corrugated structures and the horizontal corrugated structures all form planar surfaces, so that the contact area of the paper cup main body and an outer paper layer is enlarged, and the longitudinal corrugated structures and the horizontal corrugated structures are favorably glued onto the paper cup main body and the outer paper layer. A communication ventilation web is formed by the whole corrugated paper layer, and the corrugated paper layer communicates with the outside to perform cold and hot air circulation; and the hot beverage in the paper cup main body is subjected to rapid and natural heat dissipation and cooling. An annular corrugated paper base can be overturned up and down to perform stable and stretched support or to be folded.

Owner:FUJIAN WENSONG COLOR PRINTING

C30 carbon fiber broken brick recycled concrete and preparation method thereof

The invention discloses C30 carbon fiber broken brick recycled concrete. The concrete is prepared from the following raw materials in parts by weight: 380-400 parts of cement, 200-220 parts of water,650-670 parts of river sand, 610-630 parts of broken bricks, 7-9 parts of carbon fibers, 80-120 parts of fly ash, 40-60 parts of silica fume, 6-8 parts of a water reducing agent, 10-12 parts of an exciting agent, 0.9-1.2 parts of a dispersing agent and 0.6-0.7 part of a defoaming agent. The invention also provides a preparation method thereof. The materials available in the market are utilized inthe concrete; an improved concrete stirring process is adopted, and carbon fibers, silica fume, fly ash, hydroxypropyl methyl cellulose, chemical additives and the like are doped, so that the defectsof low strength, high brittleness, easiness in cracking and the like of broken brick recycled concrete are overcome, and the carbon fiber concrete with excellent workability, relatively high ductilityand a C30 strength grade is prepared.

Owner:NANYANG NORMAL UNIV

Laser strengthening technology for surface of steel rail of railway

The invention discloses a laser strengthening technology for the surface of a steel rail of a railway. The laser strengthening technology includes the steps that the surface of the steel rail is quenched through lasers, and then a tempering technology is carried out on the steel rail through lasers. Microscopic structures of the steel rail are tempered martensite structures and are optimized with a laser processing technology, evenly-refined sorbite-or-troostite-similar tempered structures with the thickness of 0.8 mm to 1 mm can be obtained on the surface of the steel rail, high rigidity (HRC35-50) and high abrasion resistance are achieved, and meanwhile high bending strength and high fatigue strength are achieved; the sticking resistance, the creeping resistance, the squashing resistance, the side abrasion resistance and the corrugation resistance of the steel rail are improved accordingly. By means of the laser strengthening technology, corrugation, side abrasion and block falling of the steel rail are remarkably reduced on the premise that the mechanical performance such as bending strength, breaking tenacity and fatigue strength of the whole steel rail is guaranteed, the stability and the corrosion resistance of the steel rail are remarkably improved, the service life of the steel rail is remarkably prolonged, the replacement time of the steel rail is prolonged, the maintenance cost of the steel rail is saved, driving resistance is reduced, fuel is saved, and the service period of the steel rail of the railway is prolonged.

Owner:WUHAN TUANJIE DIANJIN LASER MFG TECH

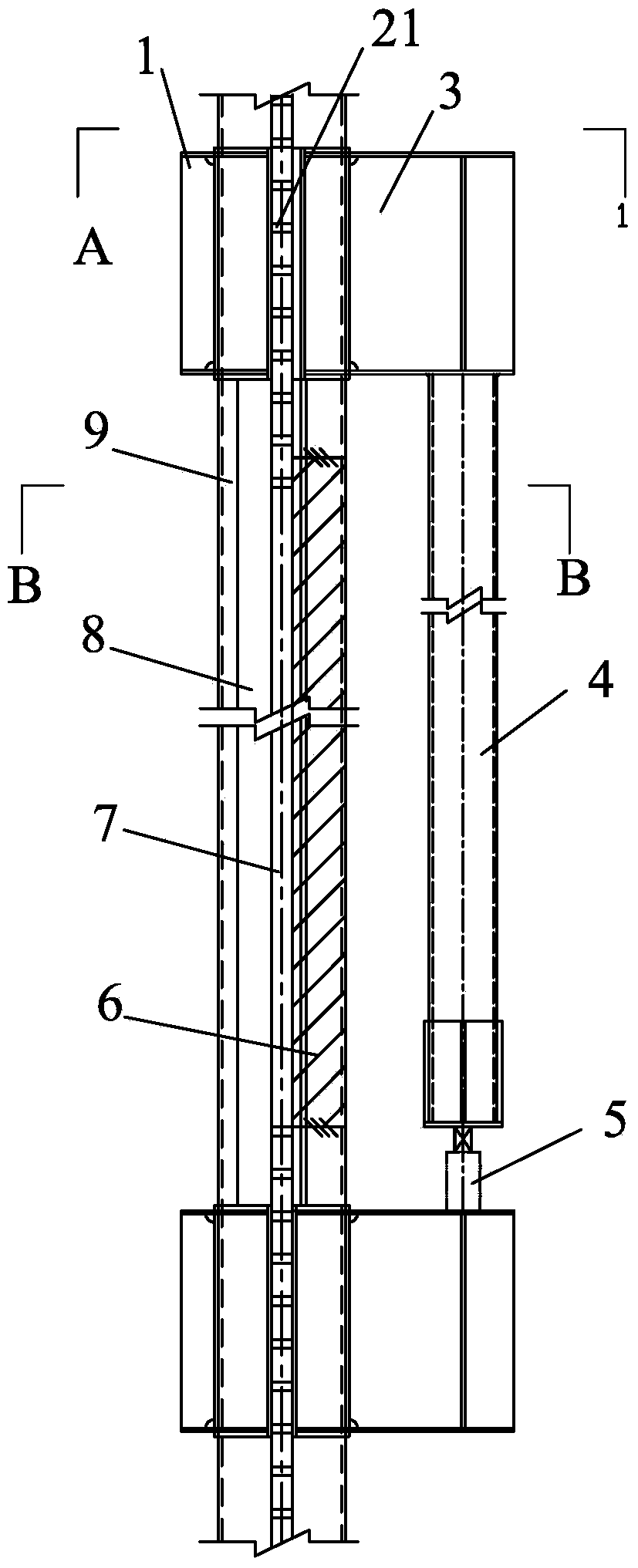

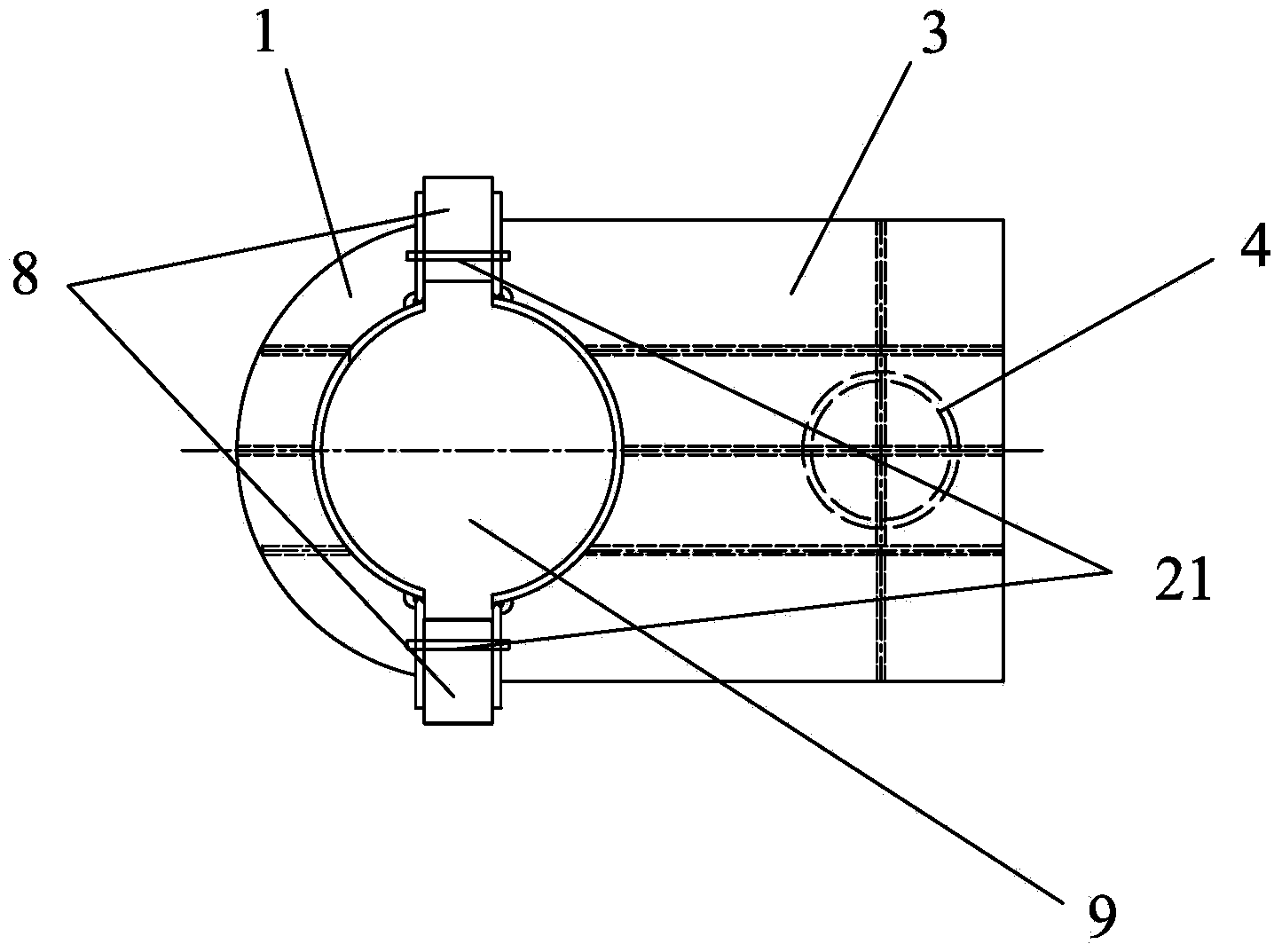

Replacing device of self-elevating type platform truss spud leg semicircular plate and replacing method thereof

ActiveCN104005392AAffect constructionEven by forceArtificial islandsUnderwater structuresEngineeringChanging equipment

The invention discloses a replacing device of a self-elevating type platform truss spud leg semicircular plate. The replacing device comprises an upper sheath assembly and a lower sheath assembly, the back portion of the outer side sheath of each sheath assembly is fixedly provided with a supporting seat 3, and a supporting steel tube assembly 4 and a vertical jack 5 are arranged between the upper supporting seat 3 and the lower supporting seat 3; moreover, a tooth-shaped complementary plate 8 is arranged in a mode of being in tooth-shaped matched with the broadside of a spud leg main string tube 9, and the tooth-shaped complementary plate 8 is fixed by a bolt 21; the two sides, between the upper supporting seat 3 and the lower supporting seat 3, of the tooth-shaped complementary plate 8 are fixedly provided with anti-bending backboards in a welded mode. The invention further provides a replacing method needed when the self-elevating type platform truss spud leg semicircular plate deforms and is damaged, the construction period can be greatly shortened, the number of lifting work times and construction amount are lowered, the safety work coefficient is increased, so that convenient, safe and reliable replacing is achieved, on the basis of guaranteeing construction safety and quality, the construction period can be effectively shortened, and the construction cost is lowered.

Owner:大连船舶重工集团海洋工程有限公司

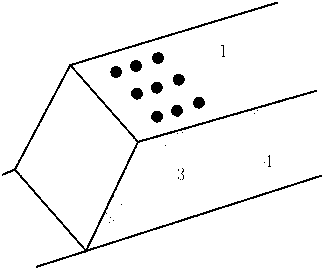

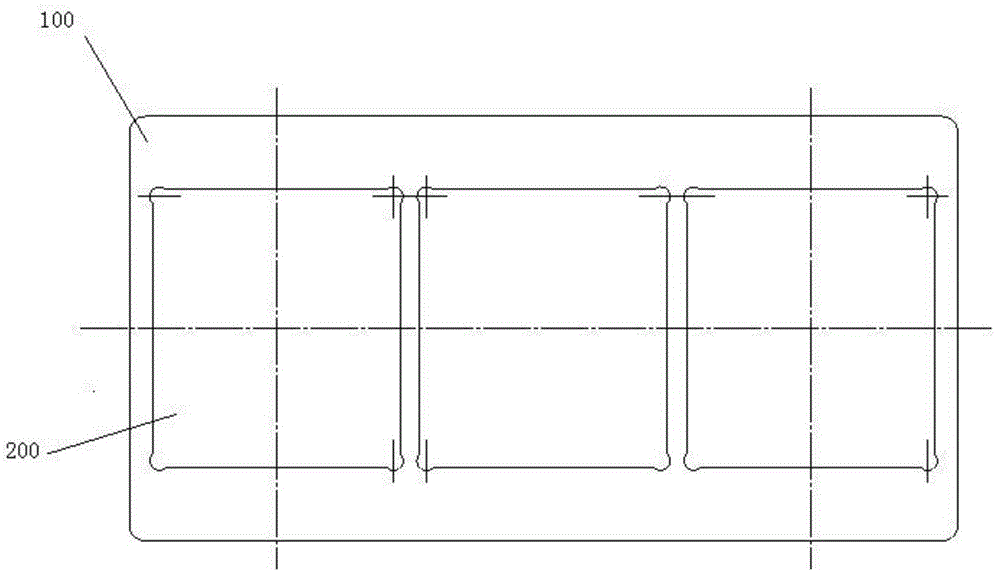

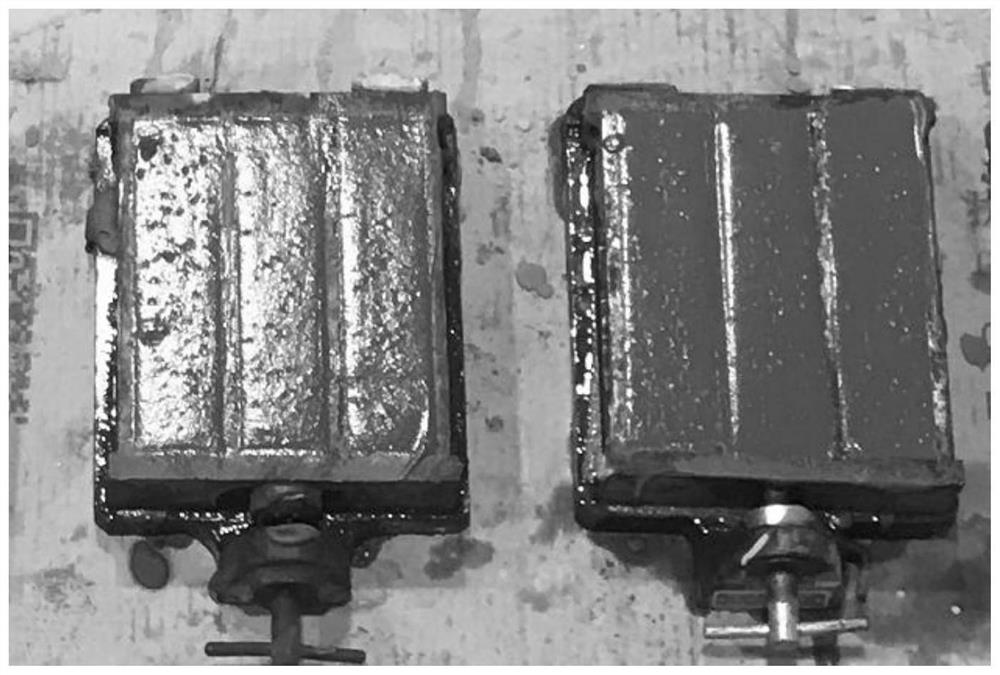

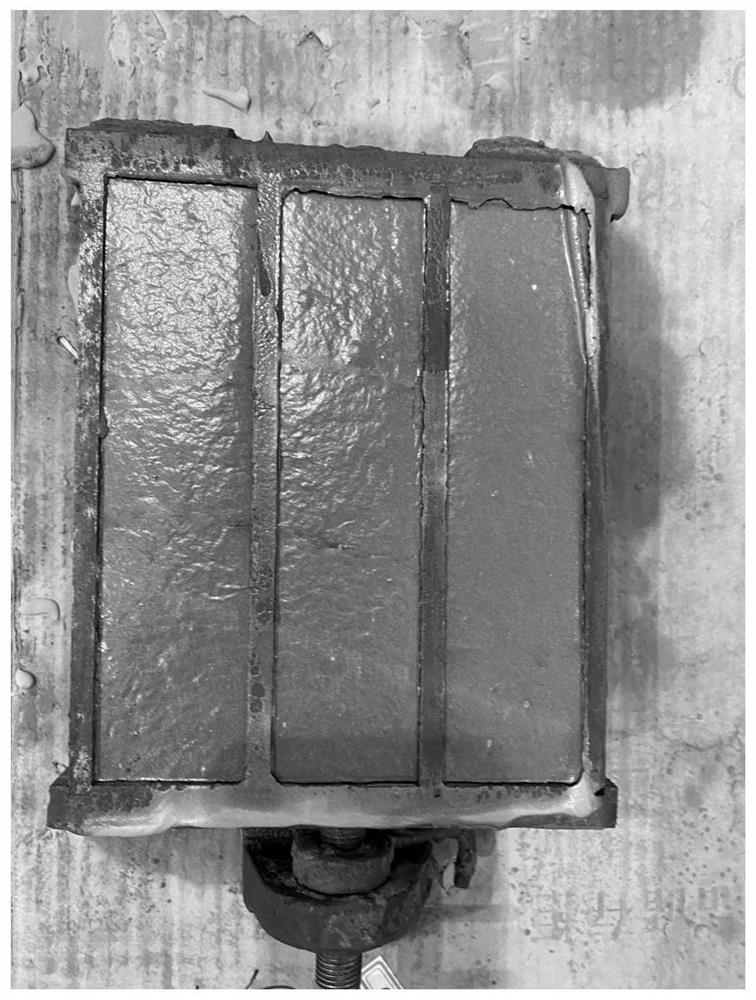

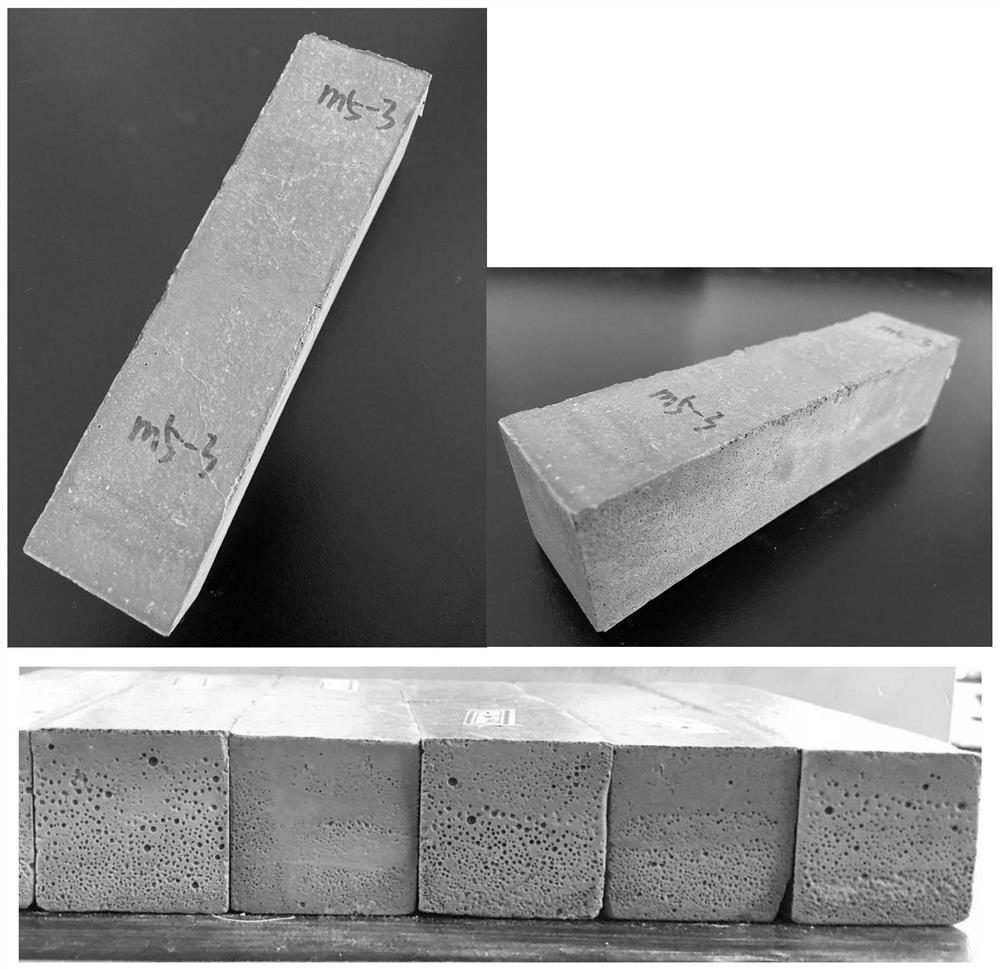

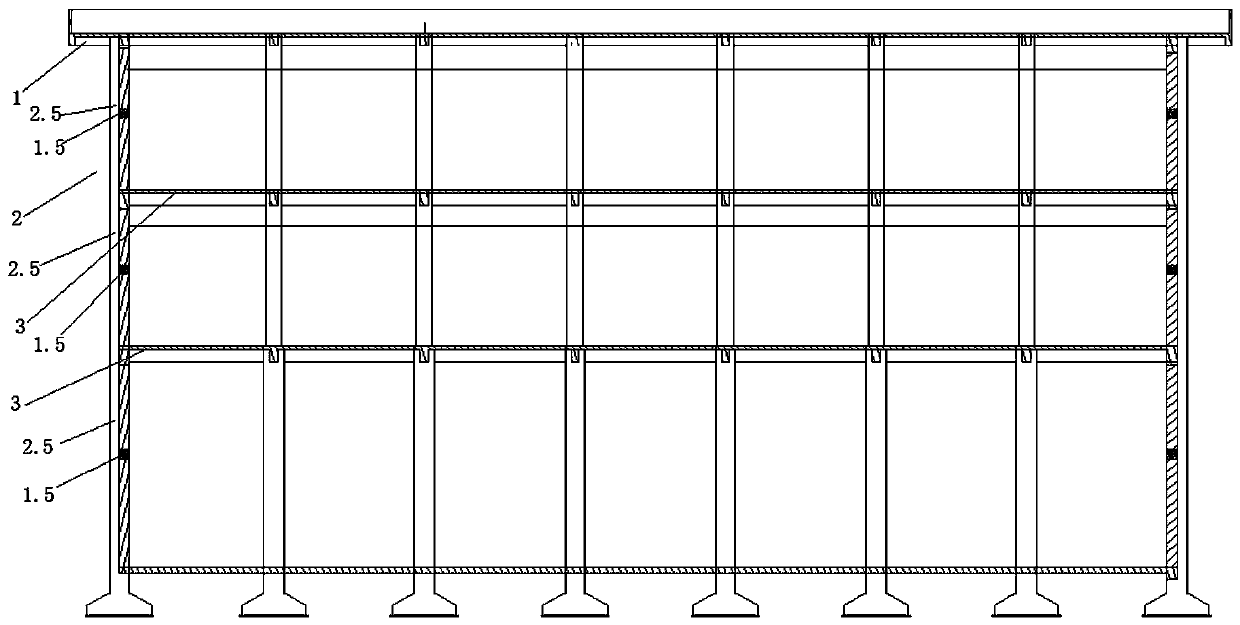

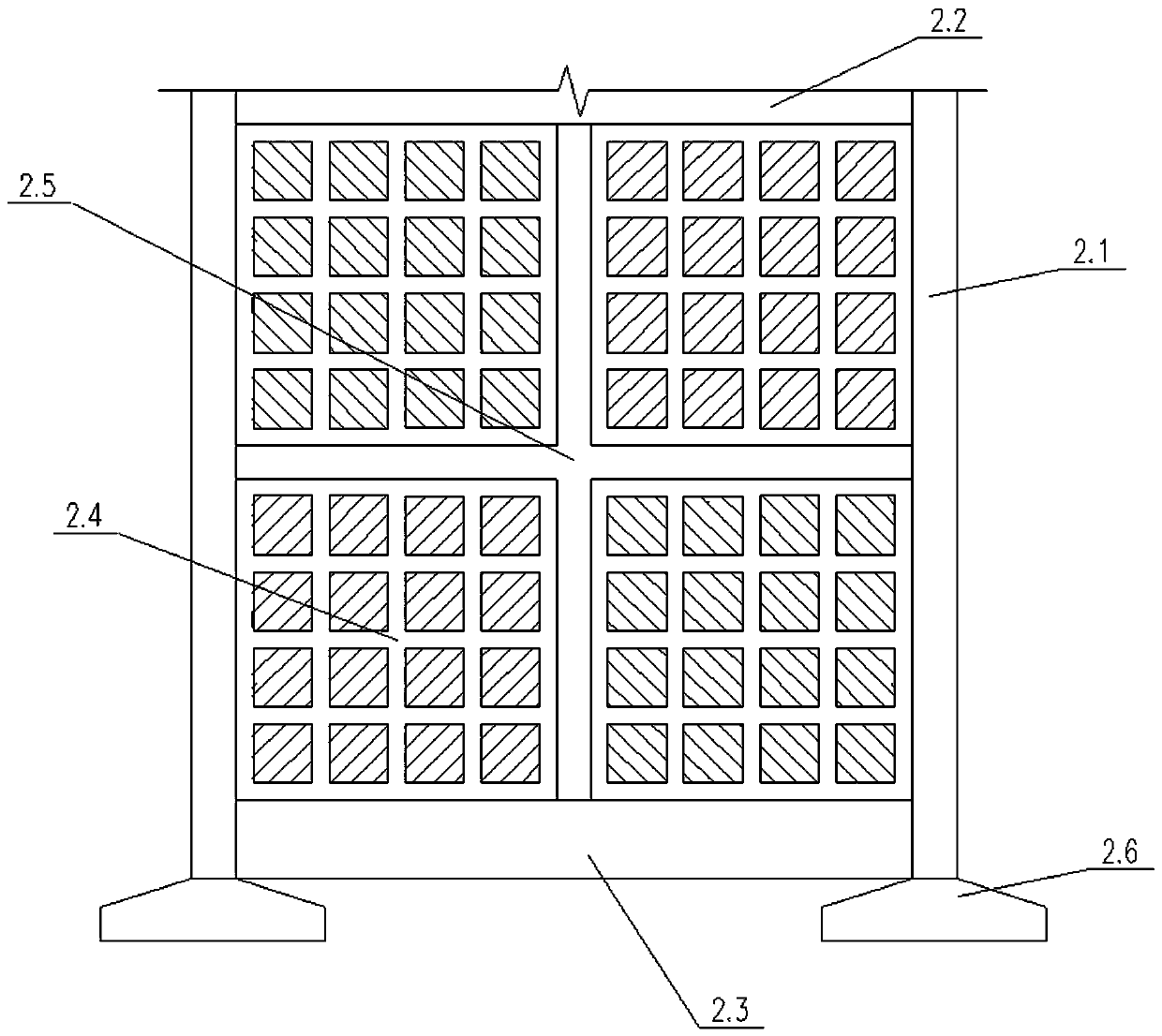

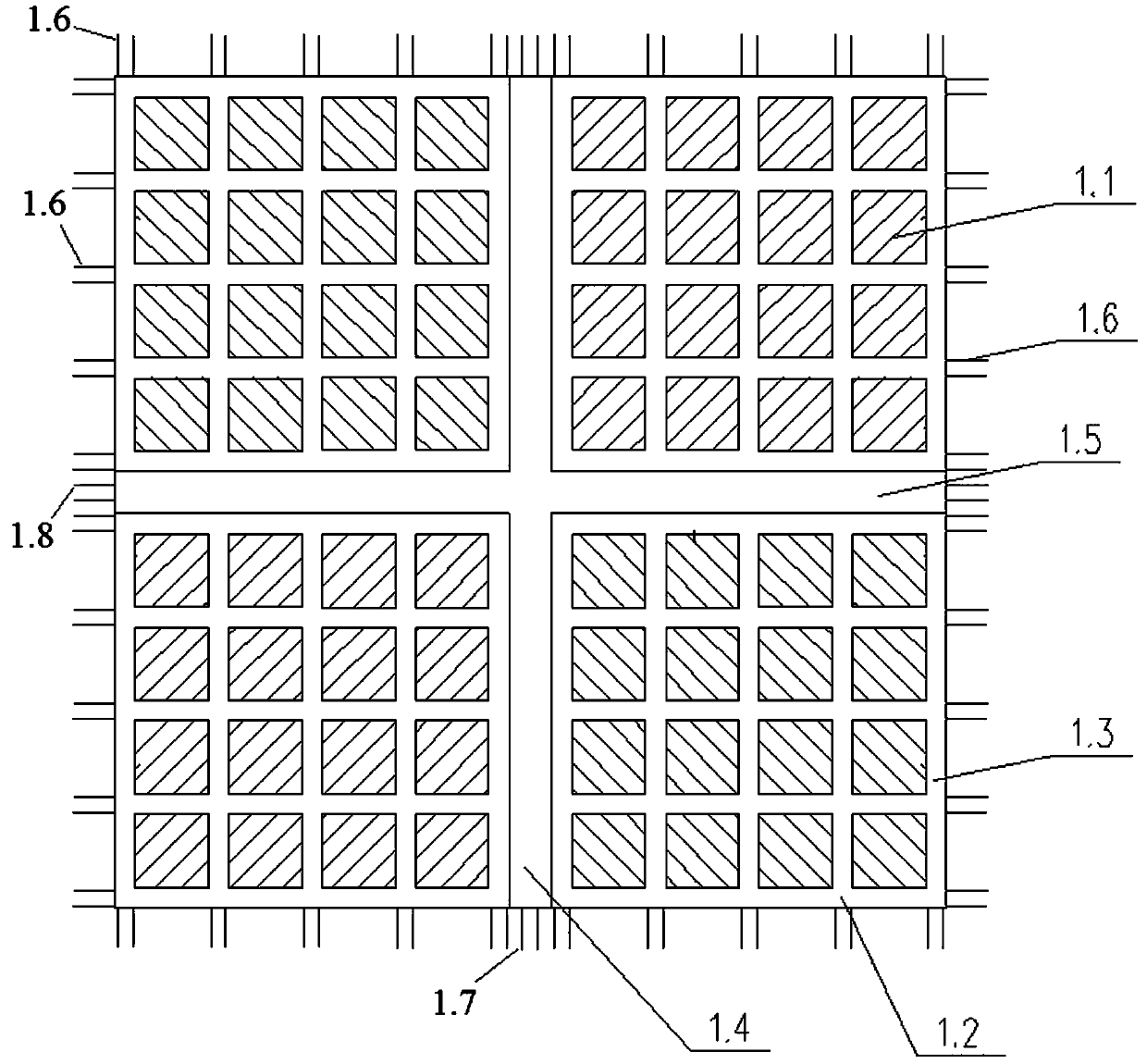

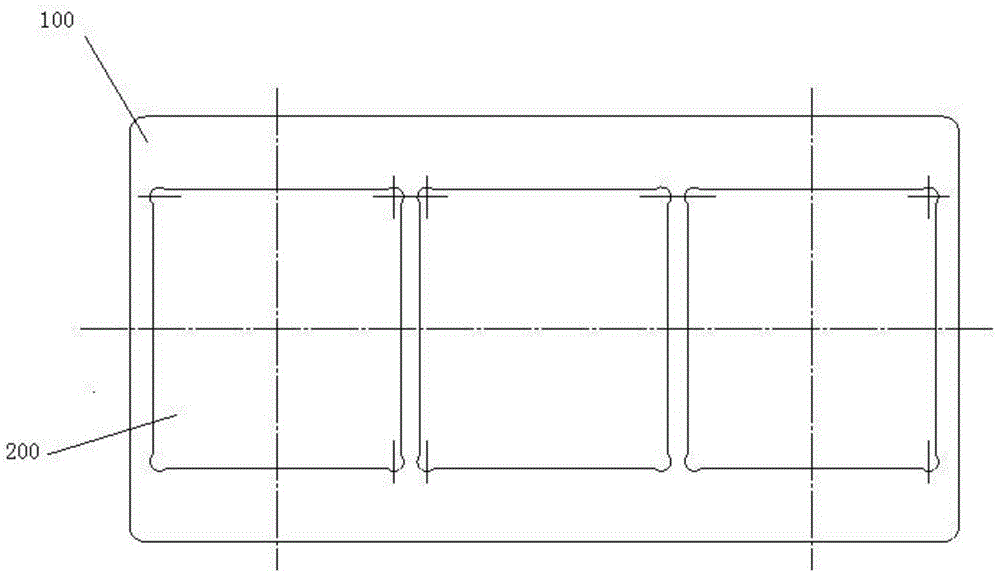

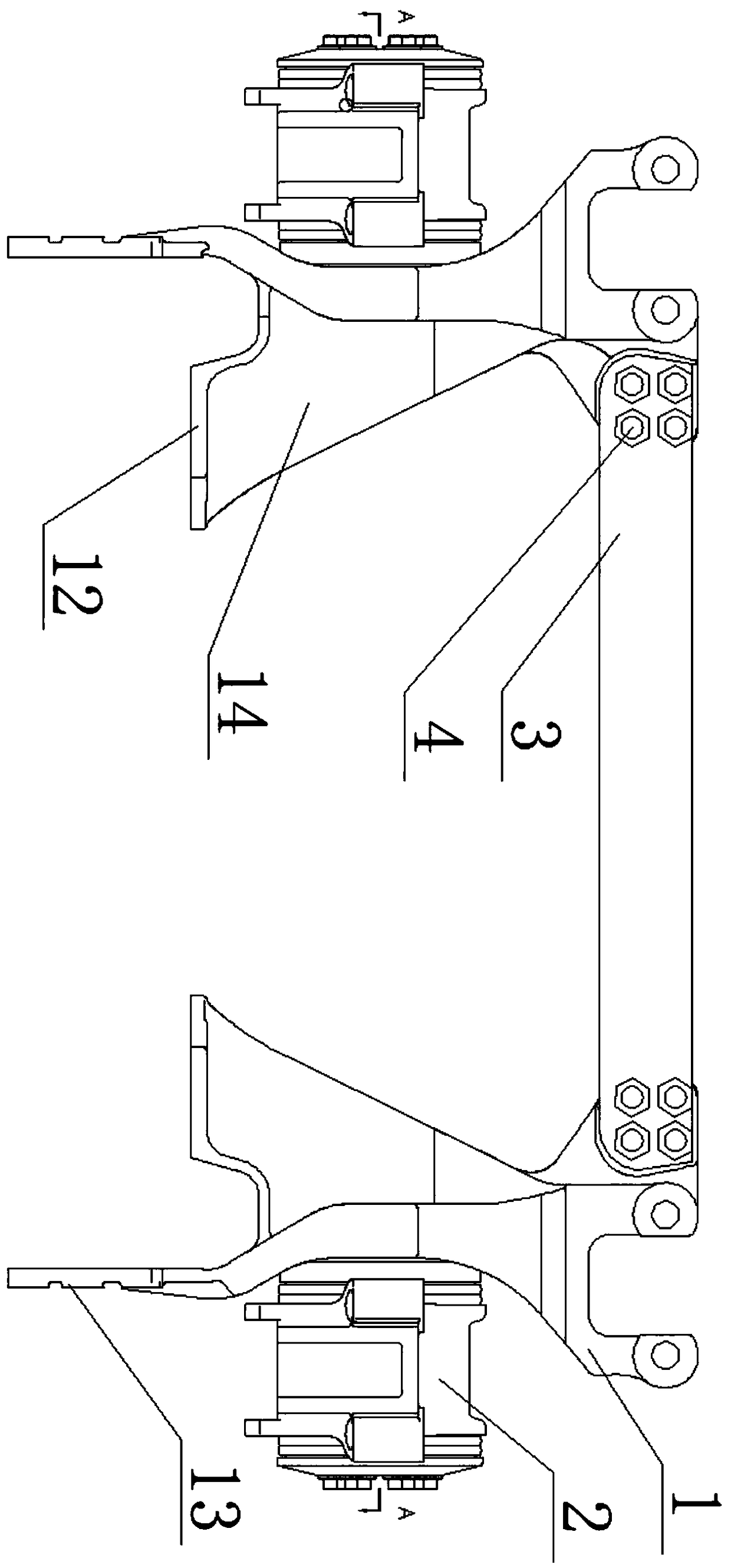

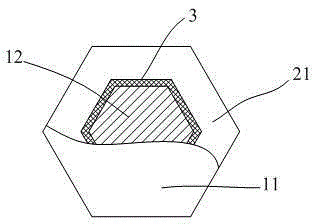

Multi-storied warehouse, multi-storied warehouse wall and manufacturing method of multi-storied warehouse wall

InactiveCN110107133AGuaranteed stiffnessGuaranteed flexural strengthWallsBulk storage containerBrickStructural engineering

The invention relates to a multi-storied warehouse, a multi-storied warehouse wall and a manufacturing method of the multi-storied warehouse wall. The multi-storied warehouse wall comprises frame vertical columns, frame crossbeams are arranged between the frame vertical columns, composite wallboards are arranged between the adjacent frame vertical columns and the corresponding adjacent frame crossbeams, and the composite wallboards comprise hidden columns and hidden beams, wherein the hidden columns and the hidden beams are arranged in a vertically and transversely crossing mode; the compositewallboards further comprise composite wallboard units arranged between the hidden columns and the hidden beams which are adjacent, and the composite wallboard units comprise ribbed columns and ribbedbeams, wherein the ribbed columns and the ribbed beams are arranged in a vertically and transversely crossing mode; and a plurality of grid holes are formed between the ribbed columns and the ribbedbeams, and each grid hole is internally provided with a concrete block of an integrated structure. Through the multi-storied warehouse, the multi-storied warehouse wall and the manufacturing method ofthe multi-storied warehouse wall, the problems that in the prior art, the spaces between vertical columns and crossbeams are filled with solid brick walls, the solid brick walls are low in rigidity and low in bending strength, and environment pollution is caused in the production process are solved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

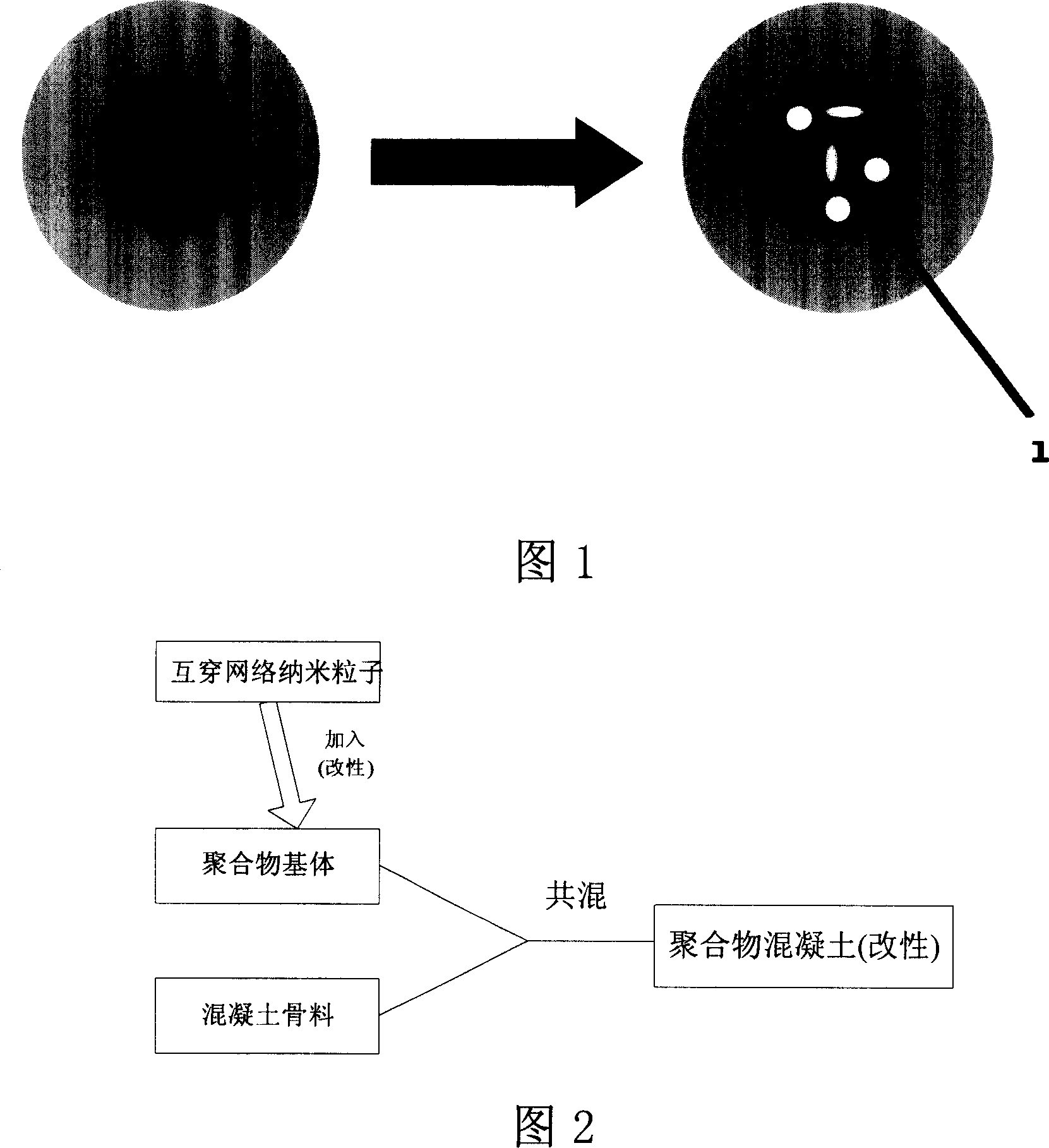

Polymer concrete nanometer damping material for reducing vibration and lowering noise

ActiveCN100999397AIncrease dampingGuaranteed flexural strengthPolymer concreteUltimate tensile strength

This invention provides a combinations used in polymer concrete. The combinations mentioned include the following components: interpenetrating polymer networks (IPN) nano-particles one weight share; described IPN nano-particle size of the 50nm - 100nm; Polymer matrix weight of 11 ~ 31 copies; Concrete Aggregate 58 ~ 174 copies. The invention of the combination can be used to obtain polymer concrete that not only have the necessary strength and could improve the damping loss factor, but also for industrial application.

Owner:SHANGHAI QIYAO HEAVY IND CO LTD

Preparation method of aluminum silicon carbide, obtained aluminum silicon carbide and electronic component packaging bottom plate

ActiveCN104658920BAvoid scourUniform internal organizationSemiconductor/solid-state device detailsSolid-state devicesCarbide siliconAluminum substrate

The invention provides a preparation method for aluminum silicon carbide and aluminum silicon carbide obtained with the method. The preparation method for aluminum silicon carbide comprises powder filling and aluminization, wherein in the powder filling step, a groove of an aluminum substrate is filled with powder and a powder plate is formed; an aluminum foil with the depth being 0.5 mm is laid on the surface of the powder plate; other additives except aluminum and silicon carbide are not added into aluminum silicon carbide. According to the preparation method for aluminum silicon carbide, the aluminum foil with the depth of 0.5 mm is laid on the surface of the silicon carbide powder and then aluminization is carried out, so that scouring of molten aluminum to a silicon carbide layer in an aluminization process can be prevented and an aluminum silicon carbide material obtained after the aluminization step is guaranteed to be uniform in internal structure. Moreover, the method provided by the invention keeps the bending resistance of the aluminum silicon carbide material under a condition that no additive is added, so that the thermal conductivity of the obtained aluminum silicon carbide material is increased to 250-280 W / mK.

Owner:HUNAN HARVEST TECH DEV

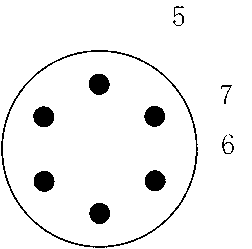

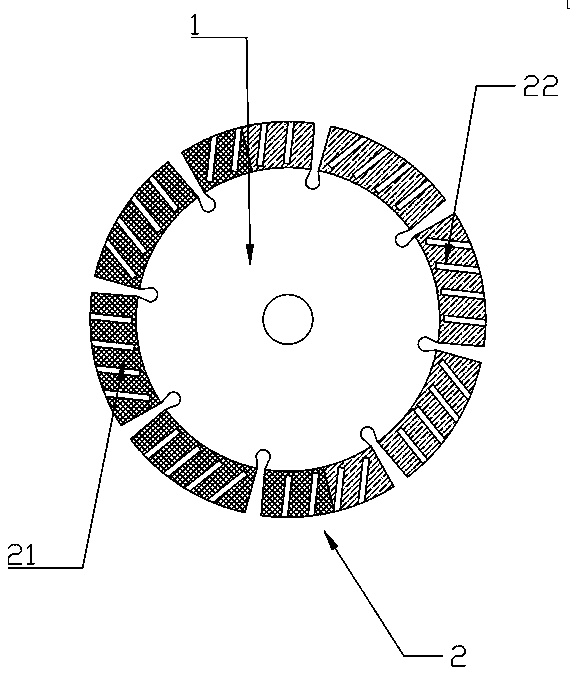

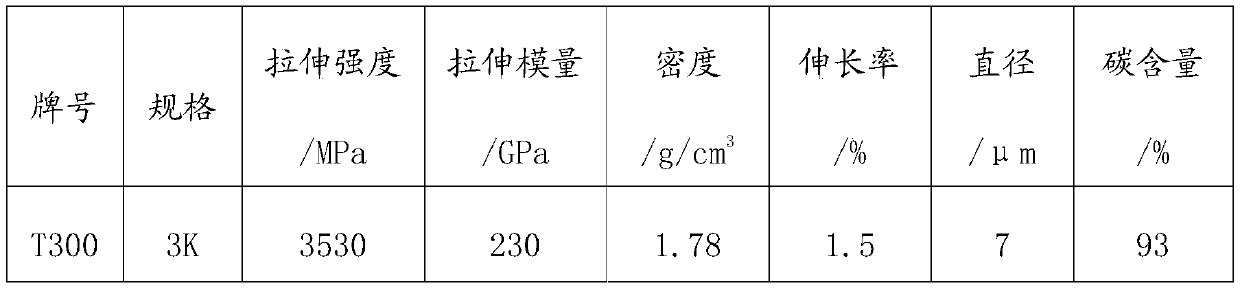

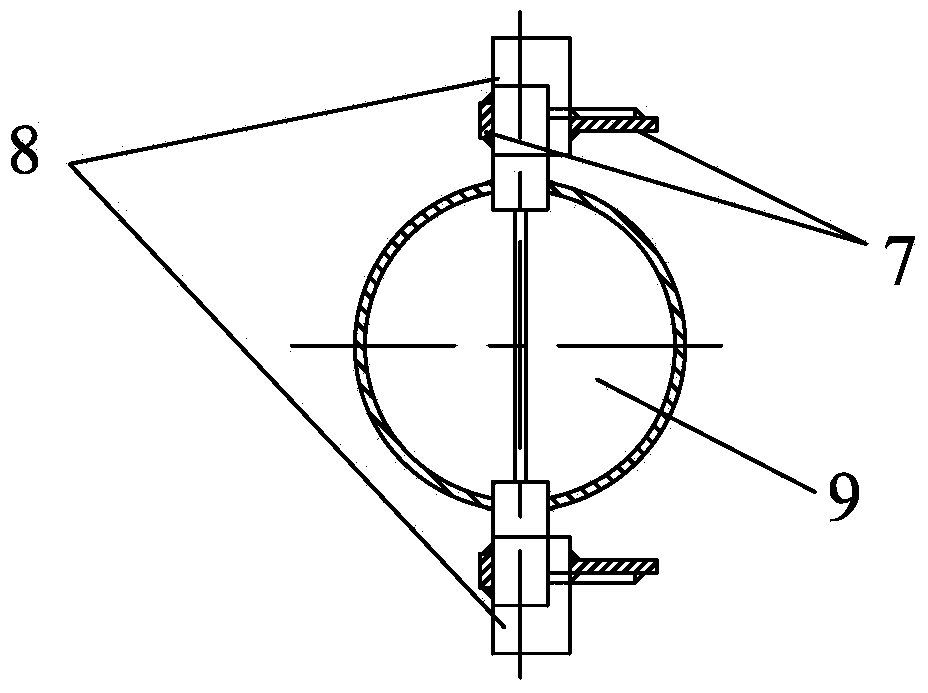

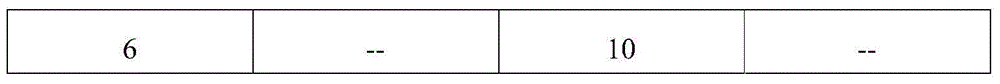

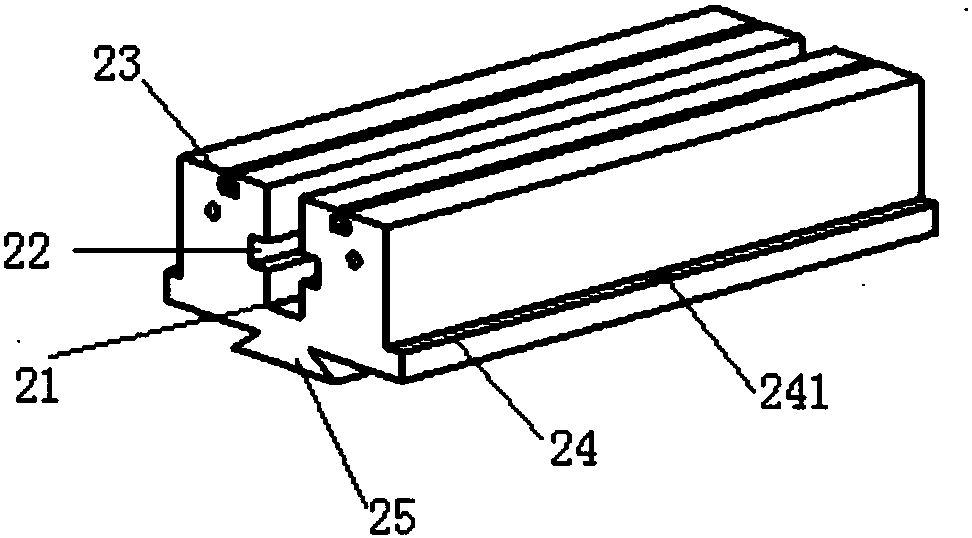

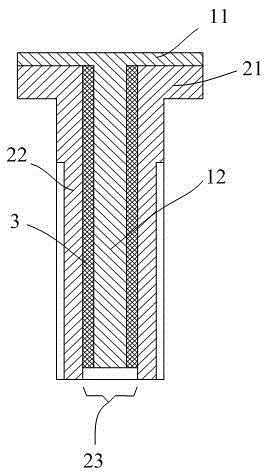

Magnetic treatment device and method for modification of hot pressing coring type iron-based diamond drill bit

ActiveCN107630138AImprove wear resistanceImprove flexural strengthDrill bitsUltrasound attenuationWear resistance

The invention discloses a magnetic treatment device for modification of a hot pressing coring type iron-based diamond drill bit. The magnetic treatment device comprises a U-shaped magnet; the U-shapedmagnet is arranged in a sliding platform; the sliding platform is arranged on a bottom plate, and can slide along the bottom plate; the U-shaped magnet consists of an L-shaped iron core and a reversed-T-shaped iron core; the reversed-T-shaped iron core and the L-shaped iron core each comprises a horizontal section and a vertical section; the bottom surface of the horizontal section of the reversed-T-shaped iron core is in close contact with the top surface of the horizontal section of the L-shaped iron core, and can move along the horizontal section of the L-shaped iron core; the lower partsof the vertical sections of the reversed-T-shaped iron core and the L-shaped iron core are in the sliding platform and are in close contact with the sliding platform; the upper part of the vertical section of the reversed-T-shaped iron core is wound by a first coil; the upper part of the vertical section of the L-shaped iron core is wound by a second coil; and the first coil and the second coil are connected with a programmable power supply in series. The abrasive resistance and the bending strength of a drill bit billet can be improved; and the magnetic treatment device is applicable to drillbits in different external diameters, and rapid attenuation of the magnetic induction intensity is avoided.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

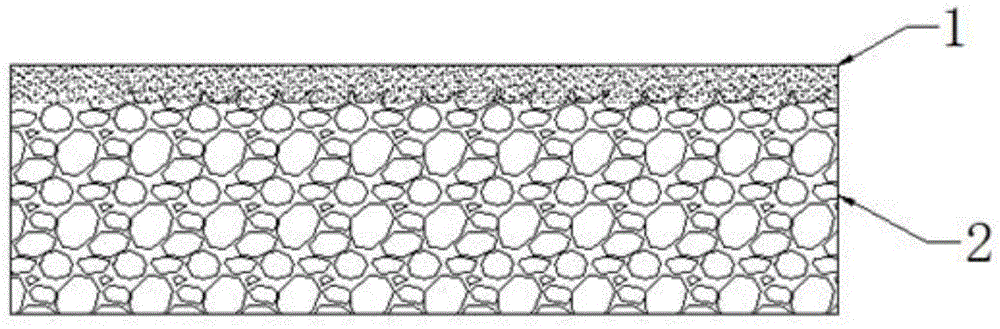

A kind of permeable brick and preparation method thereof

ActiveCN104452525BSimple componentsImprove bending resistanceSolid waste managementSidewalk pavingsSolid componentSurface layer

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

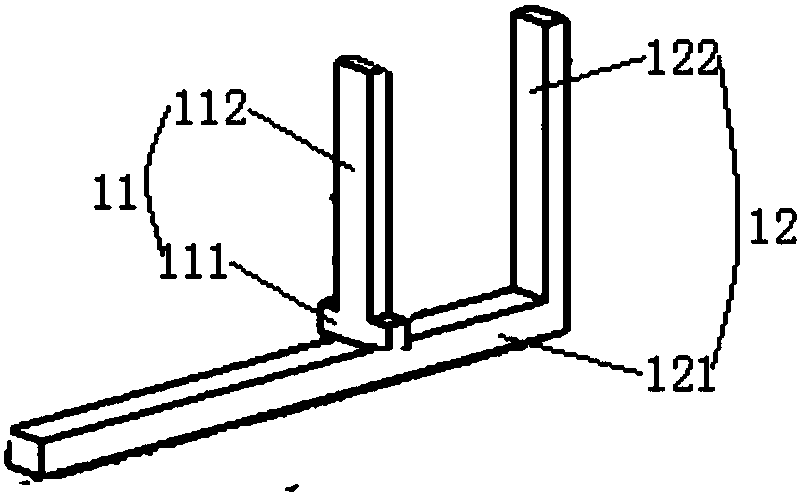

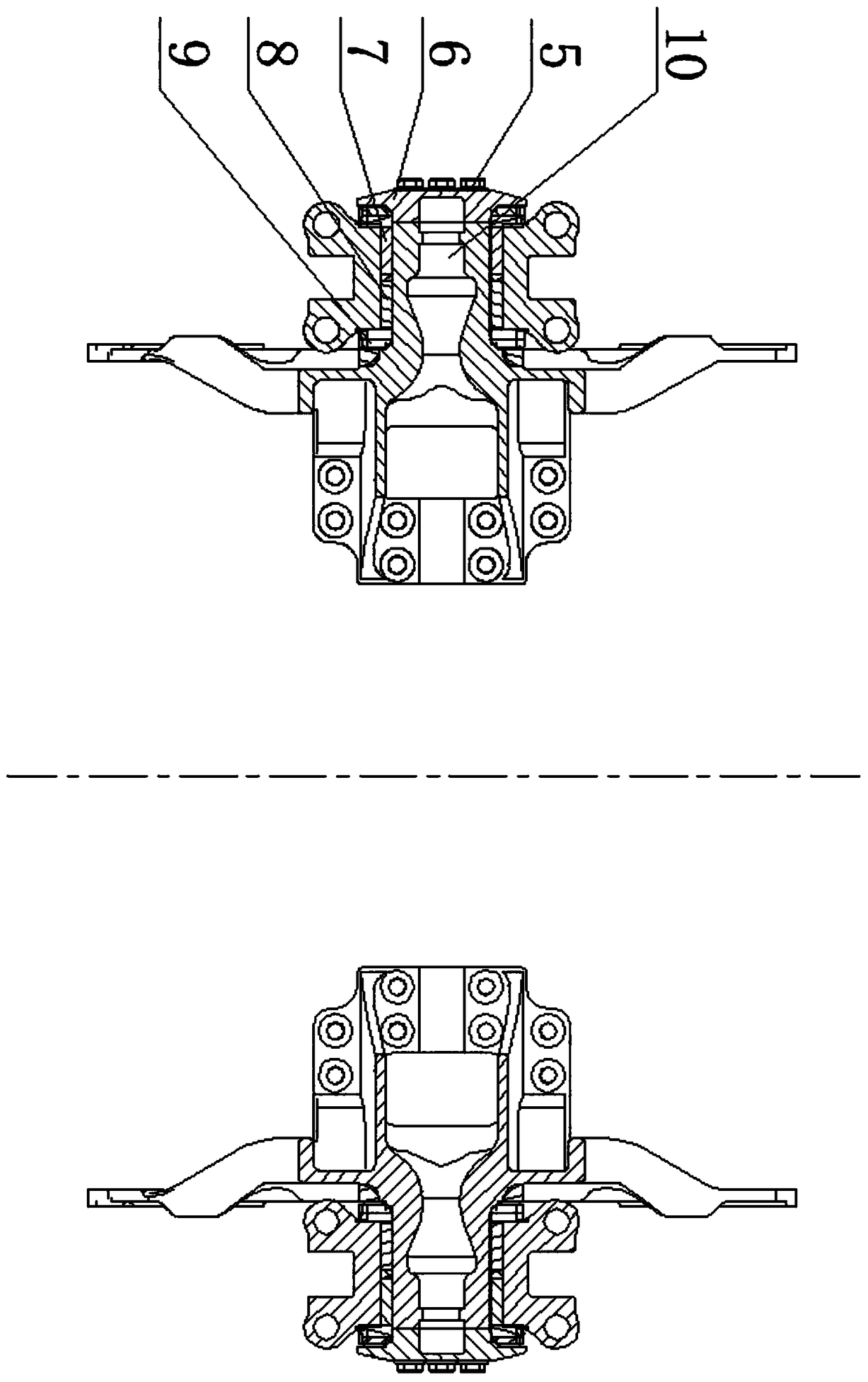

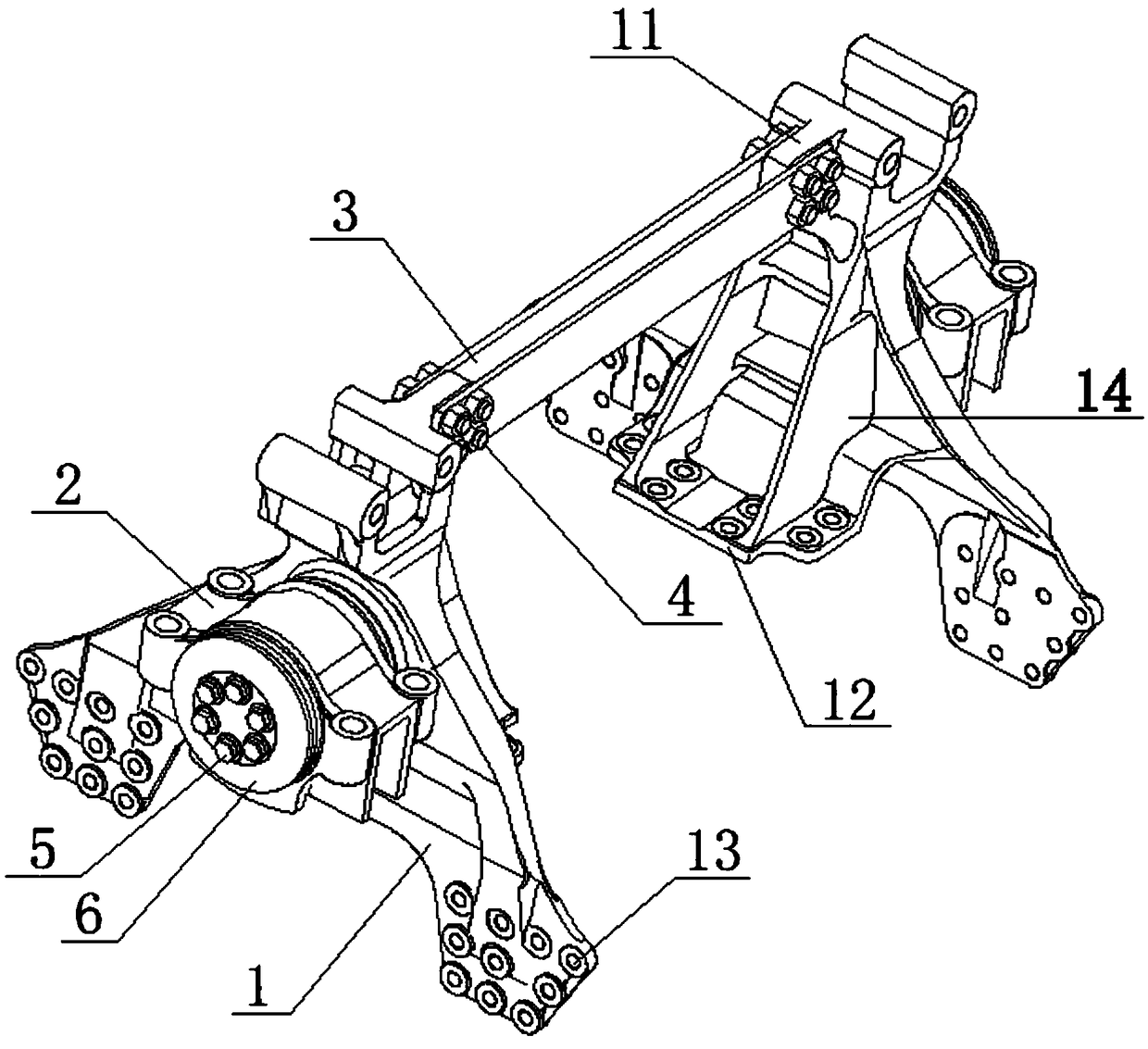

Light weight and high strength balance bridge

PendingCN109278484AEasy to use and maintainEasy to replaceLeaf springsResilient suspensionsEconomic benefitsEngineering

The invention provides a light weight and high strength balance bridge. The light weight and high strength balance bridge comprises two connecting brackets, balance shafts in clearance fit with the connecting brackets and integral type plate spring seats mounted on the balance shafts. Bolt mounting plates are fixedly connected to the corresponding positions of the upper ends of the two connectingbrackets, a plurality bolt holes are formed in the surfaces of the bolt mounting plates, connecting plates are arranged on the two sides of the bolt mounting plates, the two connecting plates are straight plates with a same size, and bolt holes matched with the bolt mounting plates are formed in the two ends of the two connecting plates. Under a premise of not changing the loading capacity of a whole vehicle and the whole strength of parts, oil consumption of the whole vehicle is reduced, a detachable structure and maintenance-free bearings are convenient to use and maintain, the using cost islower, the economic benefit of the whole vehicle using is improved, and the problems that an existing driving bridge balanced suspension system is heavier and maintenance and replacement are inconvenient are solved.

Owner:ANHUI FUMA AUTO PARTS GRP CO LTD

Ceramic tile prepared from waste materials and preparation method of ceramic tile

PendingCN113788668AAchieve re-useReduce manufacturing costCeramic materials productionClaywaresSlurryWaste material

The invention relates to the technical field of ceramics, and discloses a ceramic tile prepared from waste materials and a preparation method of the ceramic tile, and the preparation method comprises the following steps: carrying out filter pressing on artificial stone polishing residues and ceramic polishing residues, conducting soaking in a resin dispergator, conducting precipitating, carrying out filter pressing, and conducting uniform stirring to obtain artificial stone treatment residues and ceramic treatment residues; mixing the plastic raw material, the waste residue, a non-plastic raw material, a reinforcing auxiliary material and water, and carrying out ball milling and aging to obtain slurry; carrying out spray granulation on the slurry to obtain powder, carrying out compression molding, and conducting drying to obtain a ceramic green body; and carrying out silk-screen printing and ink-jet printing on the ceramic green body, conducting glazing and then conducting firing to obtain the ceramic tile manufactured by utilizing the waste materials. The ceramic polishing slag, the artificial polishing stone and the filter pressing mud in the waste slag are used as one of the main preparation raw materials of the ceramic green body, so that the solid waste material is recycled, the energy is saved, the environment is protected, the production cost is reduced, meanwhile, the influence on the performance of a ceramic tile finished product is small, and the breaking strength and the water absorption rate are better improved.

Owner:FOSHAN CITY GANI CERAMICS CO LTD

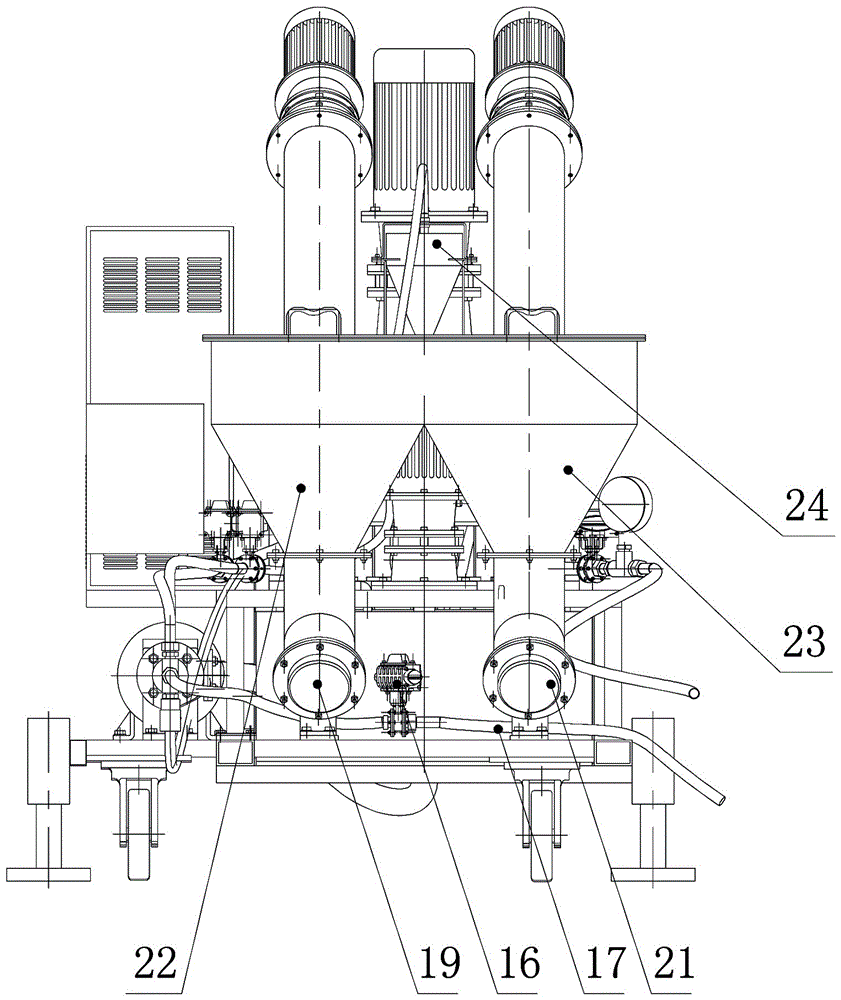

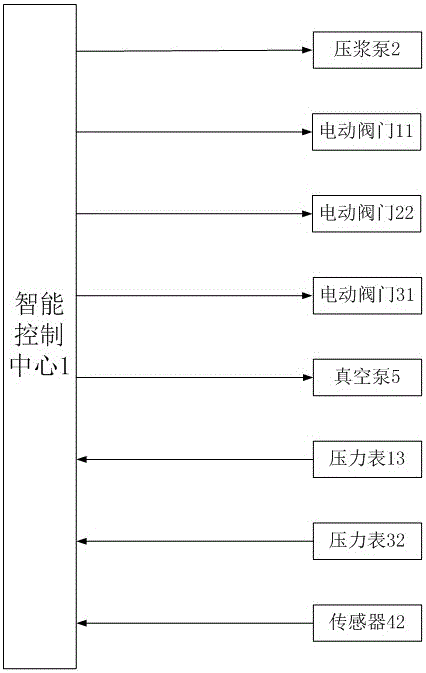

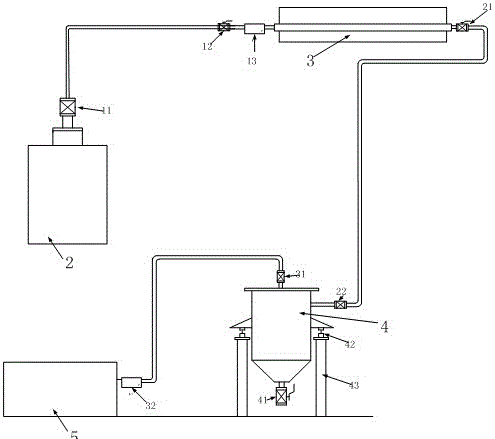

Intelligent vacuum grout release machine and intelligent vacuum grout release method

InactiveCN105756351AGuaranteed compressive strengthGuaranteed flexural strengthBuilding material handlingAutomatic controlControl engineering

The invention discloses an intelligent vacuum grout release machine which comprises an intelligent center, a grout pressing pump, a pre-stress pipeline, a weighing and metering bucket and a vacuum pump, wherein the intelligent center is responsible for controlling operation of the whole intelligent vacuum grout release machine; the intelligent control center is used for controlling operation of the vacuum pump and the grout pressing pump and opening and closure of electronic valves according to pressure gauges in pipelines and signals fed back from the sensor on the weighing and metering bucket, thereby achieving the purpose of intelligent automatic grout release. By adopting the intelligent vacuum grout release machine, air in the weighing and metering bucket can be eliminated, then grout can be relatively easily released, meanwhile due to intelligent automatic grout release control, a function of automatically detecting a static discharge state of a raw material can be achieved, the material metering error can be strictly controlled within 1%, accurate control on grout-water mixing proportioning is ensured, and the pressure resistance, the breaking strength and the performance indexes of the grout are effectively ensured. Problems that manual grout release is large in error, inconvenient to operate and the like can be solved.

Owner:崔建军

Aluminium based interlayer alloy for liquid phase diffusion weld

InactiveCN1274458CGuaranteed flexural strengthImprove wettabilityWelding/cutting media/materialsSoldering mediaRare earthCopper

Owner:SHANDONG HUADIAN ENERGY SAVING TECH

Assembled type telescopic curtain supporting rod

InactiveCN103892678AArbitrarily adjust the length of useGuaranteed load capacityCurtain suspension devicesBreaking strengthButt joint

An assembled type telescopic curtain supporting rod is formed by one or two telescopic curtain supporting rod sets and three curtain supporting rod fixing frames, and is characterized in that each telescopic curtain supporting rod set is formed by two telescopic curtain supporting rod bodies, and the telescopic curtain supporting rod bodies of each telescopic curtain supporting rod set are oppositely symmetric with a butt-joint piece with buckled ends as the center; each telescopic curtain supporting rod body is formed by assembling a main rod, an inner rod, an upper attachment rod, one butt-joint piece and a decoration end, wherein the inner rod, the upper attachment rod, the butt-joint piece and the decoration end are matched with the main rod; or each telescopic curtain supporting rod body is formed by assembling a clean inner wall main rod, a groove inner rod, a convex rail upper attachment rod, one butt-joint piece and a decoration end, wherein the groove inner rod, the convex rail upper attachment rod, the butt-joint piece and the decoration end are matched with the clean inner wall main rod. The three curtain supporting rod fixing frames serve as supporting points, the distance between the supporting points at two ends can be adjusted according to actual installation requirements, and the lengths of the telescopic curtain supporting rod bodies fixed among the supporting points can be adjusted at will. The assembled type telescopic curtain supporting rod has the advantages that the lengths of the telescopic curtain supporting rod bodies can be adjusted at will within a set range in use, so that the telescopic curtain supporting rod is quite convenient to carry and construct; it is guaranteed that hanging rings on curtains can slide smoothly; bearing capacity and breaking strength of the telescopic curtain supporting rod can be guaranteed.

Owner:周高超

Bolt capable of being taken out rapidly after being broken

The invention discloses a bolt capable of being taken out rapidly after being broken. The bolt comprises a bolt head and a screw rod integrally formed with the bolt head. A through hollow cavity is formed from the end of the bolt head to the end of the screw rod. The cross section of the hollow cavity is in a hexagonal shape. The bolt further comprises a center rod. The center rod comprises a center rod head with the section identical with that of the bolt head and a center rod pillar with the section identical with that of the wall of the hollow cavity. The center rod pillar is in sliding fit with the hollow cavity, and the center rod head is attached to the bolt head in a sealed manner. The bolt has the beneficial effects that the bolt is applied to connection of objects, when the bolt breaks, the broken bolt can be rapidly taken out through a hexagon wrench, and the time for taking out the bolt is effectively saved.

Owner:CHONGQING JINYOUYUAN BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com