Preparation method for aluminum silicon carbide, aluminum silicon carbide obtained with method and electronic component packaging substrate

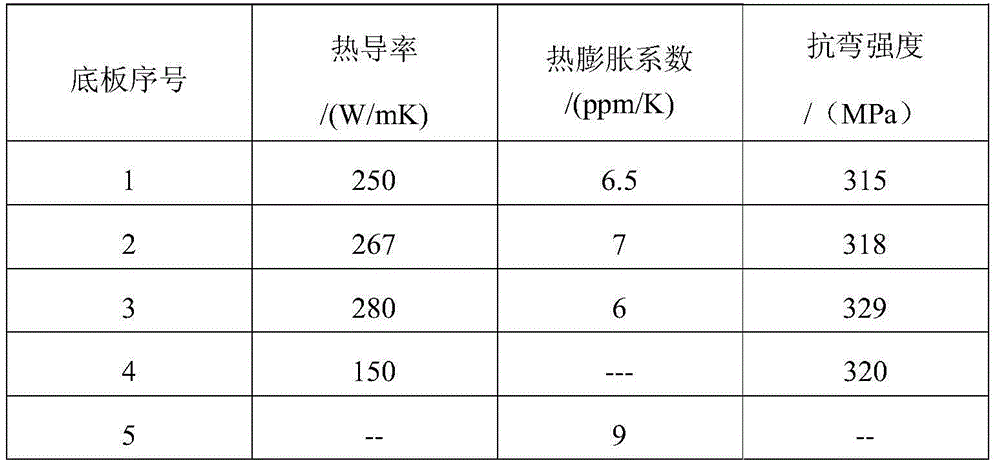

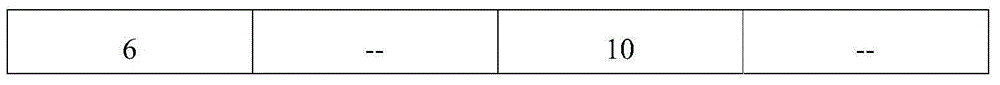

A technology of aluminum silicon carbide and silicon carbide powder is applied in the field of aluminum silicon carbide and electronic component packaging bottom plates, and aluminum silicon carbide preparation fields, which can solve the problem of difficult to meet the use requirements of high-power power electronic devices, and reduce the performance and impact of electronic device packaging bottom plates. Device reliability and other issues, to achieve the effect of improving thermal conductivity, uniform internal structure, and maintaining flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of aluminum silicon carbide provided by the invention includes the steps of powder filling and aluminizing. The contents not particularly limited in these steps can be carried out according to conventional steps. The powder filling step includes filling the powder into the aluminum substrate to obtain a powder board. The powder plate is filled with silicon carbide powder into the depression on the surface of the aluminum plate. The recessed shape is of any depth, but cannot penetrate the aluminum plate.

[0024] In the existing aluminizing step, if no aluminum foil is laid on the surface of silicon carbide, when the aluminum liquid submerges the silicon carbide powder, the filled silicon carbide powder will be washed by the aluminum liquid and partially piled up. Lay aluminum foil with a thickness of 0.5 mm on the surface of the compacted silicon carbide powder. By arranging the aluminum foil of this thickness on the surface of the silicon carb...

Embodiment 1

[0038] 1. Powder blending: Mix 10μm spherical silicon carbide powder and 70μm spherical silicon carbide powder at a volume ratio of 1:3, and fully stir in a mixer until the powder is evenly mixed, and then pass through a 50-mesh sieve.

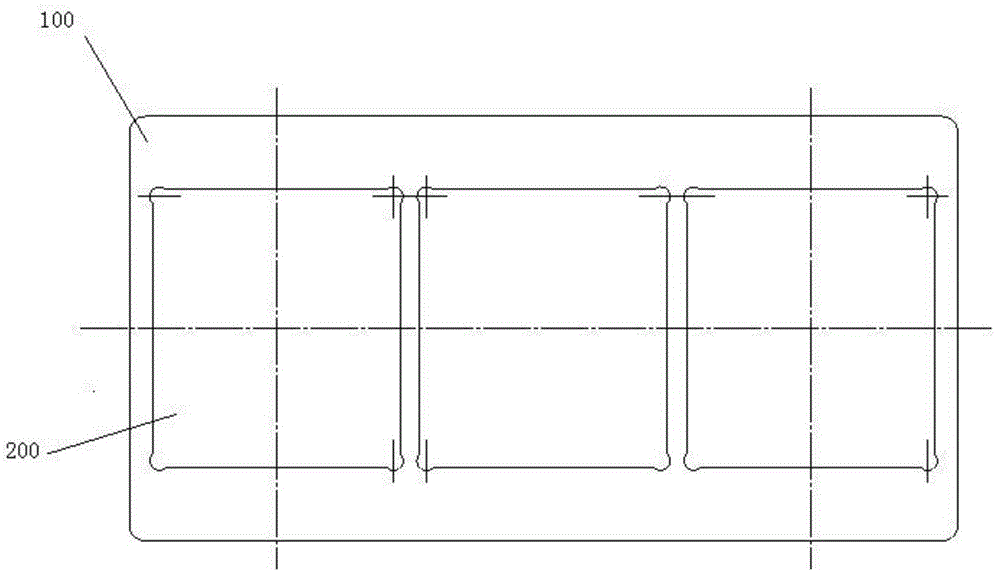

[0039] 2. Preparation of aluminum substrate: mill out 3 square grooves with a depth of 3mm on one side of a square aluminum block (210mm×110mm×5mm) with a thickness of 5mm;

[0040] 3. Powder filling: fill the mixed powder obtained in step 1 into the three square grooves of the aluminum substrate in step 2, compact it under 100MPa to obtain a powder plate, and cover the powder with aluminum foil with a thickness of 0.5mm surface;

[0041]4. Aluminizing: Put the powder plate covered with aluminum foil obtained in step 3 into the mold, then immerse it in molten aluminum at 750°C, vacuumize to 700Pa at room temperature, and then pressurize to 5MPa for 10 minutes , to obtain an electronic packaging base plate embedded with aluminum silicon carbid...

Embodiment 2

[0045] 1. Powder blending: Mix 15μm spherical silicon carbide powder and 80μm spherical silicon carbide powder at a volume ratio of 1:3, and fully stir in a mixer until the powder is evenly mixed, and then pass through a 50-mesh sieve.

[0046] 2. Preparation of aluminum substrate: mill out three square grooves with a depth of 3mm on one side of a square aluminum block (210mm×110mm×5mm) with a thickness of 5mm;

[0047] 3. Powder filling: fill the mixed powder obtained in step 1 into the three square grooves of the aluminum substrate in step 2, compact it under 100MPa to obtain a powder plate, and cover the powder with aluminum foil with a thickness of 0.5mm surface;

[0048] 4. Aluminizing: Put the powder plate covered with aluminum foil obtained in step 3 into the mold, then immerse it in molten aluminum at 750°C, vacuumize to 700Pa at room temperature, and then pressurize to 5MPa for 10 minutes , to obtain an electronic packaging base plate embedded with aluminum silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com