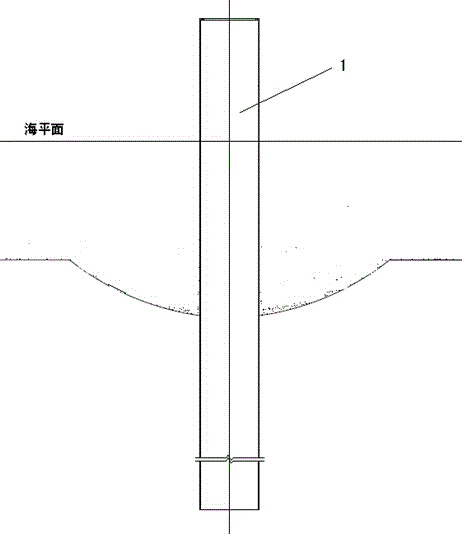

Anti-scouring construction method for single-pile foundations of offshore wind power

A single-pile foundation and construction method technology, which is applied in basic structure engineering, protection devices, buildings, etc., can solve the problems of large amount of rock dumping, crushed stone damage, poor controllability of wind turbine support stability, etc., and achieves improved stability. performance, avoid damage, and save the amount of riprap works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

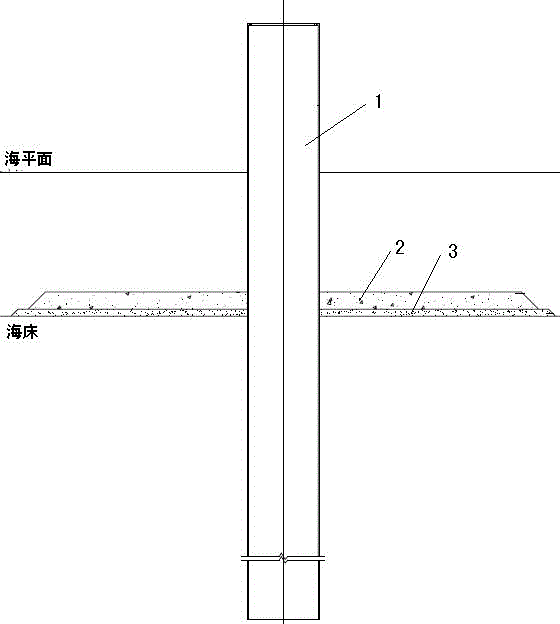

other Embodiment approach

[0036] In other embodiments, according to the diameter and load-carrying conditions of the single pile foundation, the thicknesses of the filter layer 3 and the protective layer 2 are adaptively adjusted, as long as the thickness of the filter layer 3 is between 300-800mm, The thickness of the protective layer 2 is between 500-1500 mm, and the protective diameter of the scouring protection area where the anti-scouring material layer is laid is 6-12 times the diameter of the single pipe pile 1, all of which belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com