Biochar, preparation method thereof, foam concrete and preparation method of foam concrete

A technology of foam concrete and biochar, applied in the field of concrete, can solve the problems of heavy weight, high density, poor thermal insulation performance and thermal conductivity, etc., and achieve the effect of reducing the leaching of heavy metals and strengthening mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

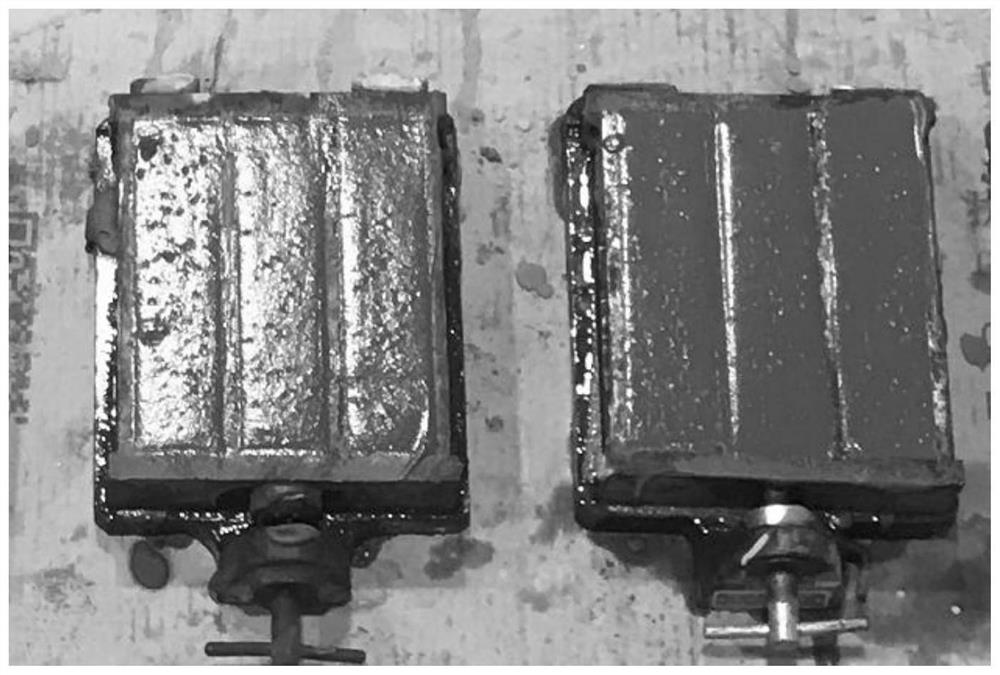

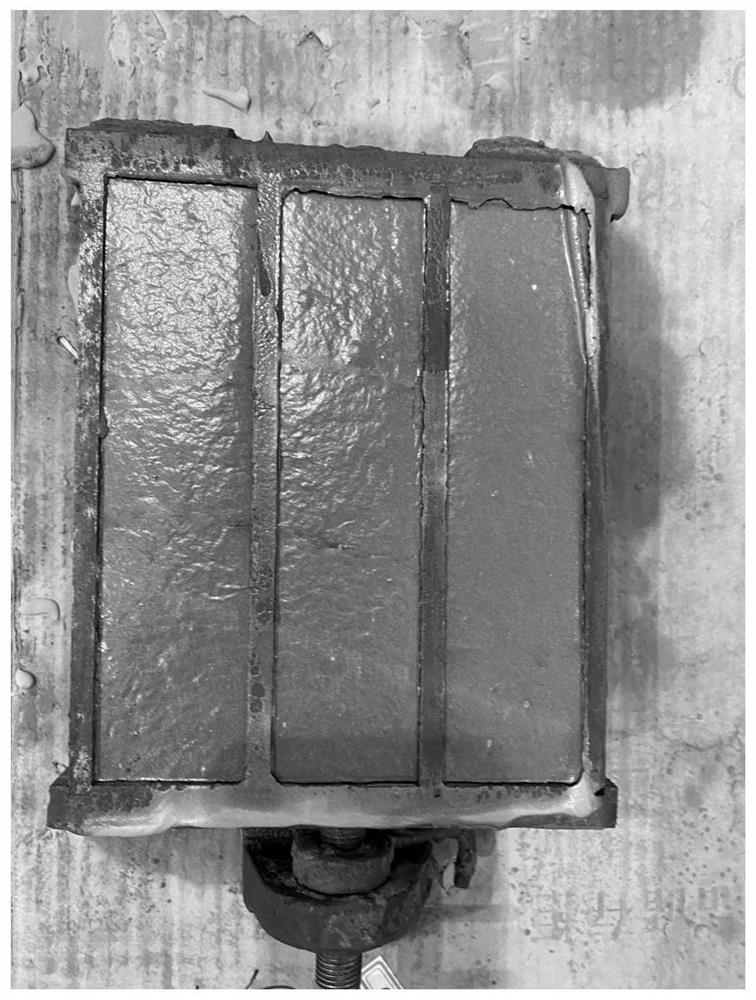

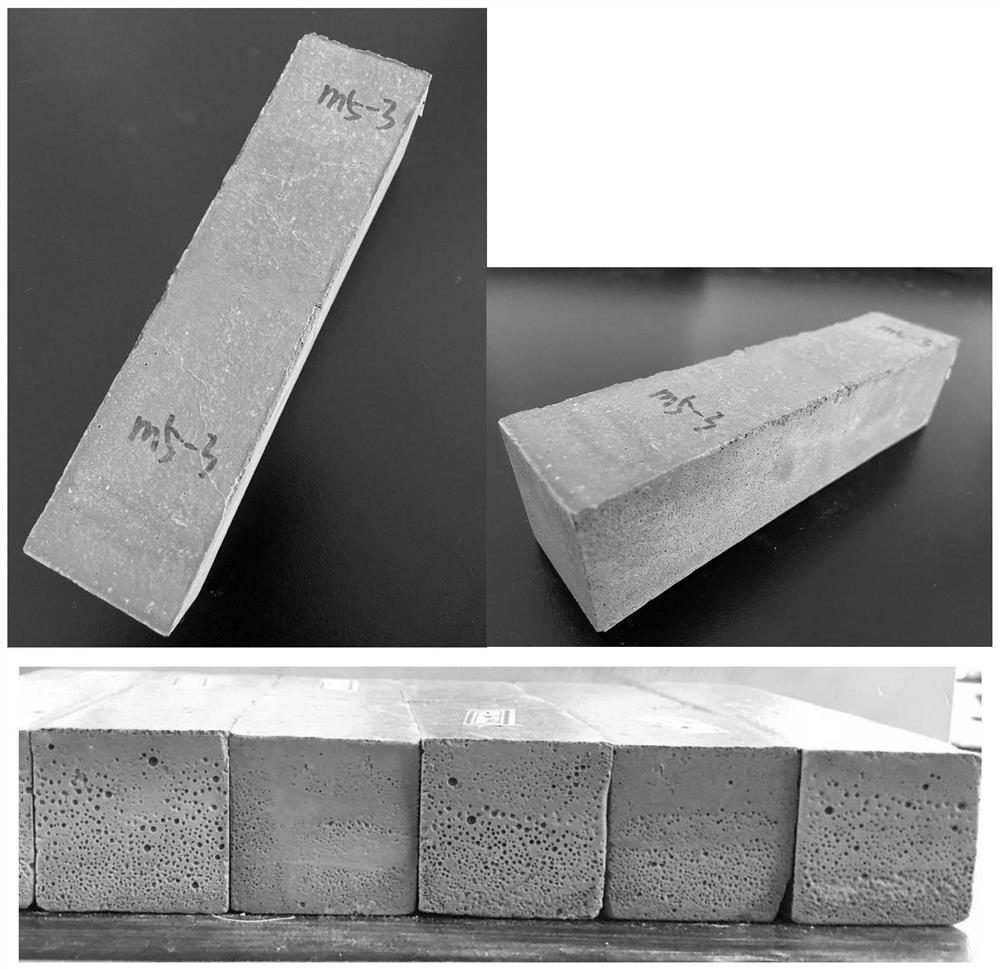

Image

Examples

preparation example Construction

[0038] The invention provides a kind of preparation method of biochar, comprises the following steps:

[0039] Crushing plant-based biomass to obtain biomass particles;

[0040] The biomass particles are carbonized and pyrolyzed to generate the biochar.

[0041] In the present invention, the plant-based biomass includes one or more of barley grass, sawdust, straw, branches and peanut shells, preferably peanut shells; the particle size of the biomass particles is 2 to 5 mm, or It can be 3 to 4 mm.

[0042] In the present invention, the temperature of the carbonization and pyrolysis is 470-530°C, may also be 480-520°C, and further may be 500-510°C; the time of the carbonization and pyrolysis is 1-2h; The heating rate of the solution temperature is 10-15° C. / min, and may also be 10-12° C. / min.

[0043] In the present invention, biochars prepared at different pyrolysis temperatures have different properties such as porosity, carbon content, and carbon stability. The biochar ob...

Embodiment 1

[0071] After the peanut shells are crushed to a particle size of 2-5mm, the temperature is raised to 500°C at a heating rate of 10°C / min, and the carbonization and pyrolysis is carried out at this temperature for 1 hour. The carbonized pyrolysis product is crushed to 50-500 μm to obtain biochar pyrolyzed at 500° C.

Embodiment 2

[0073] After the peanut shells are crushed to a particle size of 2-5mm, the temperature is raised to 700°C at a heating rate of 10°C / min, and the carbonization and pyrolysis is carried out at this temperature for 2.5 hours. The carbonized pyrolysis product is pulverized to 50-500 μm to obtain biochar pyrolyzed at 700° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com