Polymer concrete nanometer damping material for reducing vibration and lowering noise

A vibration and noise reduction, polymer technology, applied in the field of polymer concrete, can solve the unresolved problems of strength and damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

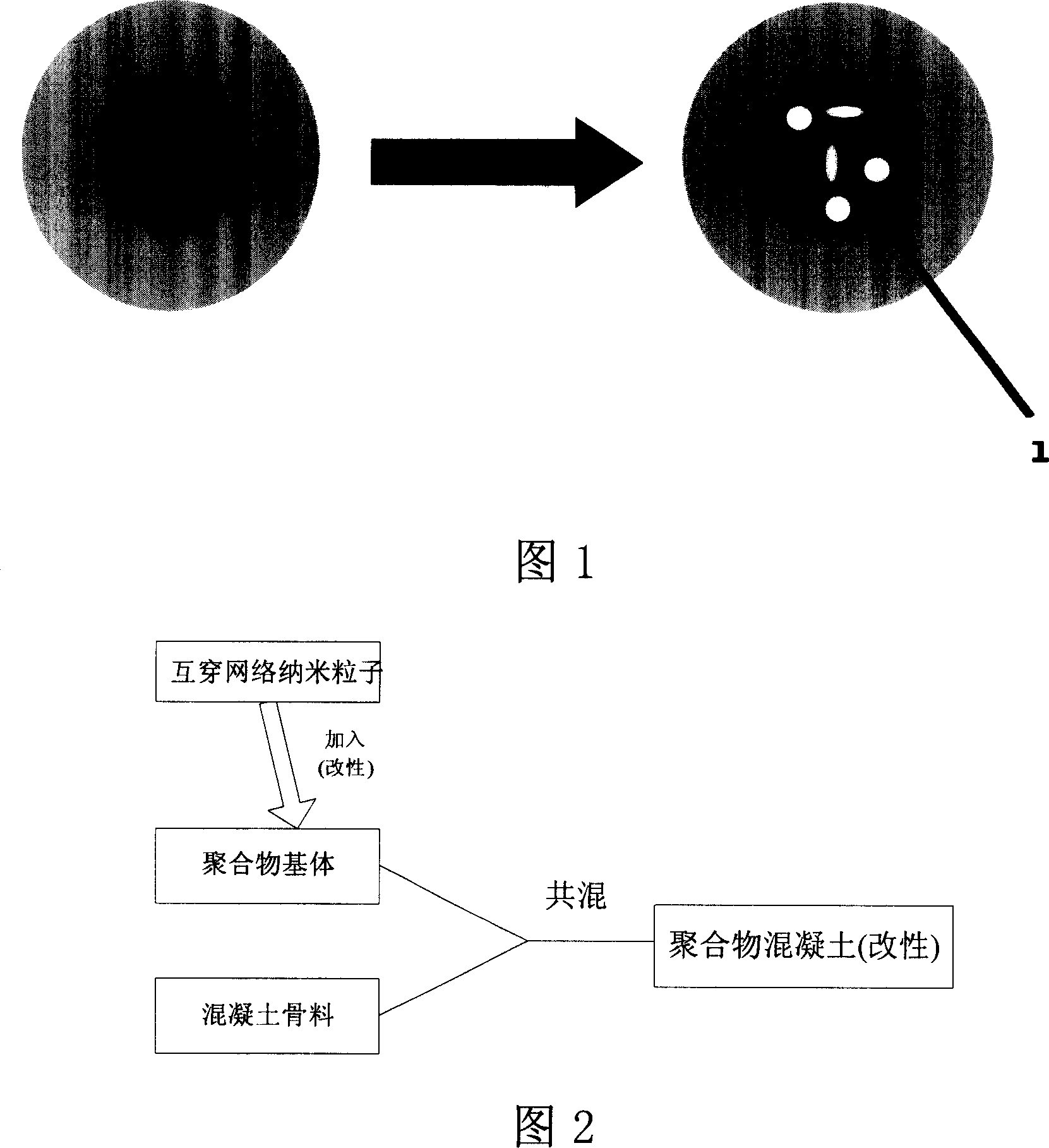

[0077] The preparation method of polymer concrete of the present invention comprises the steps:

[0078] Provide 1 weight part of interpenetrating network nanoparticles with a particle size of 50nm-100nm; 11-31 weight parts of polymer matrix; 58-174 weight parts of concrete aggregate, and mix the above components to obtain the concrete.

[0079] Preferably, the interpenetrating network nanoparticles are dispersed in an organic solvent to obtain dispersed interpenetrating network nanoparticles, and the obtained dispersed interpenetrating network nanoparticles are used for mixing with other components. More preferably, the organic solvent is ethanol. Preferably, the dispersion temperature is 50-90°C.

[0080] For example, specifically: first, the nanoparticles are dissolved in ethanol at an appropriate temperature, and blended with the polymer matrix, thereby well solving the problem of uniform dispersion of the nanoparticles in the polymer matrix of the concrete.

[0081] The...

Embodiment 1

[0089] Preparation:

[0090] The nanocomposite material for vibration and noise reduction consists of the following components by weight:

[0091] 1 part of nanoparticles composed of 1:1 mole fraction of styrene and n-butyl acrylate as the matrix (the particles shown are core-shell structure. Styrene is the core, and n-butyl acrylate is the shell);

[0092] 13 parts of polymer matrix, said polymer matrix is epoxy resin E44 (Shanghai Resin Factory): 10 parts, curing agent 651 (Shanghai Kailin Paint Factory): 3 parts;

[0093] Diluent: 2.5 parts of ethanol above 95%;

[0094] Aggregate: 40 parts of 8mm quartz sand, 32 parts of 3mm quartz sand.

[0095] Blending method:

[0096] 1. Dissolve the above-mentioned amount of nanoparticles in 1 part of alcohol at 50°C to 80°C, and mix for 3 minutes;

[0097] 2. Blend epoxy resin E44: 10 parts, curing agent 651: 3 parts; 1.5 parts 99% alcohol for 3 minutes to form a polymer matrix;

[0098] 3. Add the fused nanoparticles to the b...

Embodiment 2

[0102] Adopt the same technical scheme as Example 1, the difference is that the weight components are different; the weight components are as follows:

[0103] 1 part of nanoparticles composed of 1:1 mole fraction of styrene and n-butyl acrylate as the matrix (the particles shown are core-shell structure. Styrene is the core, and n-butyl acrylate is the shell);

[0104] 26 parts of polymer matrix, described polymer matrix is epoxy resin E44 (Shanghai Resin Factory): 20 parts, curing agent 651 (Shanghai Kailin Paint Factory): 6 parts;

[0105] Diluent: 5 parts of ethanol above 95%;

[0106] Aggregate: 80 parts of 8mm quartz sand, 3mm quartz sand: 64 parts.

[0107] Blending method:

[0108] 1. Dissolve the above-mentioned amount of nanoparticles in 2 parts of alcohol at 50°C to 80°C, and mix for 3 minutes;

[0109] 2. Blend epoxy resin E44: 20 parts, curing agent 651: 6 parts; 3 parts of 99% alcohol for 3 minutes to form a polymer matrix;

[0110] 3. Add the fused nanopar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com