C30 carbon fiber broken brick recycled concrete and preparation method thereof

A technology of recycled concrete and carbon fiber, which is applied in the field of building materials, can solve the problems of low strength, high brittleness, and easy cracking of recycled concrete from broken bricks, and achieve the effect of dense internal structure of concrete, improvement of interface bonding, and promotion of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

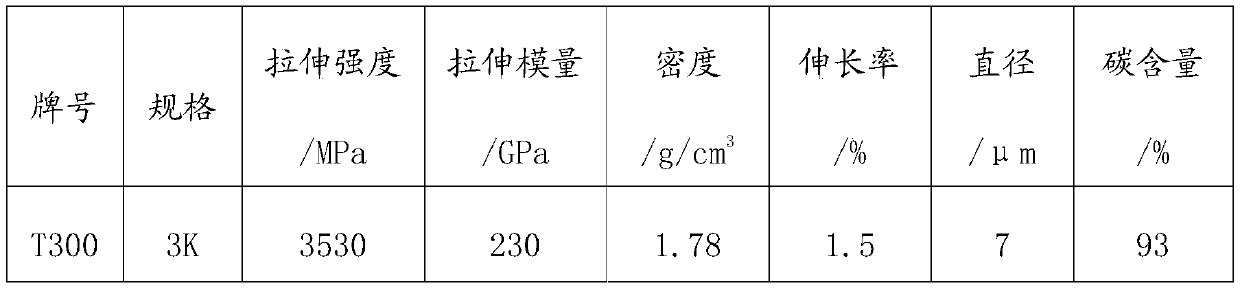

Method used

Image

Examples

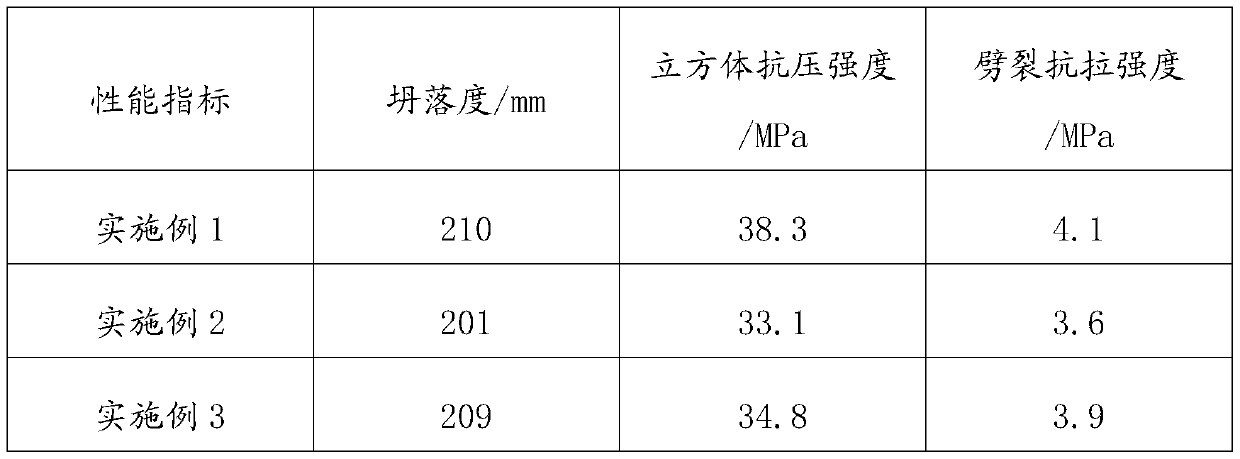

Embodiment 1

[0069] In the carbon fiber broken brick recycled concrete of C30 strength grade in this embodiment, the proportioning content of each component in the carbon fiber broken brick recycled concrete is calculated as follows in parts by weight: 394 parts of cement, 212 parts of water, 660 parts of river sand, and 622 parts of broken brick , 8 parts of carbon fiber, 100 parts of fly ash, 45 parts of silica fume, 7.2 parts of water reducer, 11 parts of activator, 1.1 parts of dispersant, and 0.62 parts of defoamer.

Embodiment 2

[0071] The carbon fiber broken brick recycled concrete of the C30 strength grade in this embodiment, the proportioning content of each component in the carbon fiber broken brick recycled concrete calculated in parts by weight is as follows: 380 parts of cement, 200 parts of water, 650 parts of river sand, 610 parts of broken brick , 7 parts of carbon fiber, 80 parts of fly ash, 40 parts of silica fume, 6 parts of water reducer, 10 parts of activator, 0.9 part of dispersant, and 0.6 part of defoamer.

Embodiment 3

[0073] In the carbon fiber broken brick recycled concrete of C30 strength grade in this embodiment, the proportioning content of each component in the carbon fiber broken brick recycled concrete is calculated as follows in parts by weight: 400 parts of cement, 220 parts of water, 670 parts of river sand, and 630 parts of broken brick , 9 parts of carbon fiber, 120 parts of fly ash, 60 parts of silica fume, 8 parts of water reducer, 12 parts of activator, 1.2 parts of dispersant, and 0.7 part of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com