A kind of permeable brick and preparation method thereof

A permeable brick and cement technology, which is applied in the field of building materials, can solve the problems of not preparing permeable bricks, lack of rock resources, and large environmental burdens, and achieve the effects of widening utilization channels, high solid waste utilization rate, and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

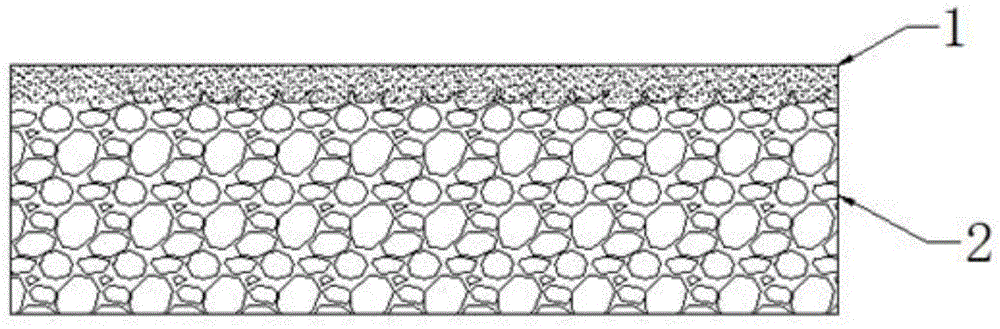

Image

Examples

Embodiment 1

[0041] Preparation of non-fired ceramsite for building silt:

[0042] ①Weigh the following formula proportion raw materials according to the proportion:

[0043] Solid content: building silt 76%, cement 3%, quicklime 3%, perlite 3%, desulfurization gypsum 4%, fly ash 5%, water glass 6%. The amount of water used is 50% of the total mass of the above-mentioned solid content.

[0044] ②Preparation method: 1) materials such as construction silt, cement, quicklime, desulfurized gypsum, perlite and fly ash are uniformly mixed by a mixer, and then put into a disc granulator;

[0045] 2) Put the water glass into the water, and after the dissolution is uniform and complete, start the disc granulator, and within 20 minutes, spray all the prepared solution into the powder of the granulator, and continue to run the disc granulator. The pellet machine can be formed into balls in 40 minutes;

[0046] 3) After curing the pelletized ceramsite in fresh water at 18-22°C for 24 hours, take it o...

Embodiment 2

[0064] Preparation of non-fired ceramsite for building silt:

[0065] ①Weigh the following formula proportion raw materials according to the proportion:

[0066] Solid content: building silt 75%, cement 4%, quicklime 4%, perlite 6%, desulfurization gypsum 5%, fly ash 7%, water glass 9%. The amount of water used was 55% of the total mass of the above-mentioned solid content.

[0067] ② The preparation steps are the same as the preparation method of the non-fired ceramsite for building silt in Example 1.

[0068] The obtained ceramsite samples are tested: the bulk density of ceramsite is 510kg / m 3 , the cylinder compressive strength is 1.2Mpa.

[0069] Preparation of permeable bricks:

[0070] ①Weigh the following formula proportion raw materials according to the proportion:

[0071] Surface composition: ceramic sand: 70%, desalinated sea sand: 15%, cement: 15%. The water consumption is 55% of the total cement mass.

[0072] Base composition: building silt unburned cerams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com