Patents

Literature

140results about How to "Improve anti-sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

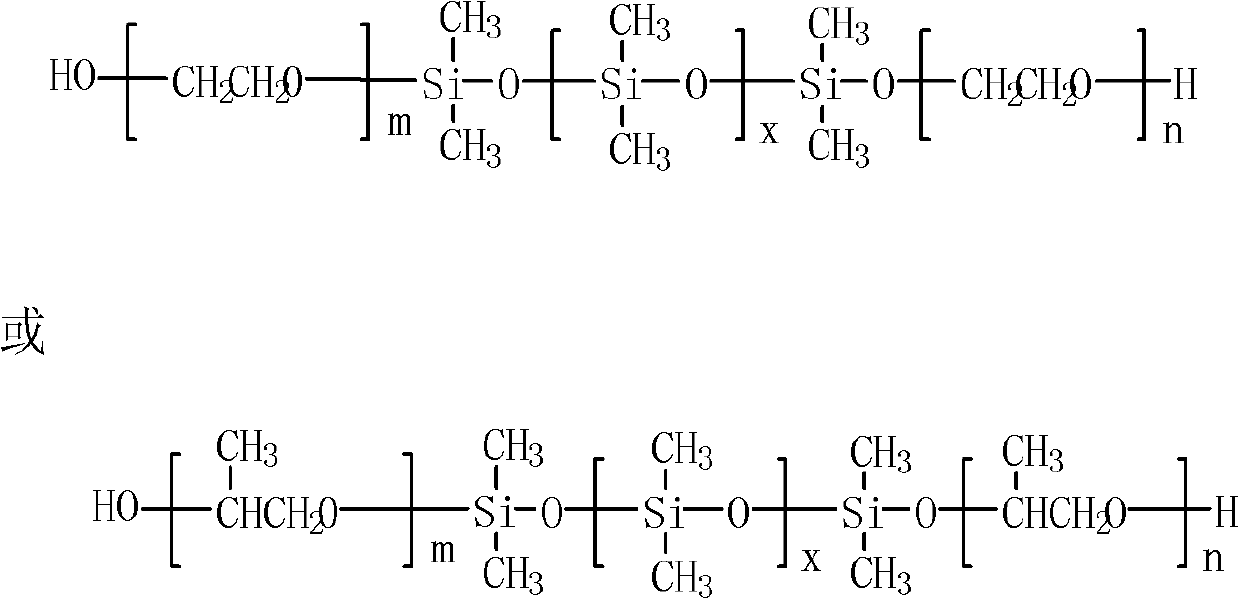

Organic silicon-modified polyurethane resin for synthetic leather and preparation method thereof

The invention designs organic silicon-modified polyurethane resin for synthetic leather and a preparation method thereof, which relates to the field of processing of the synthetic leather and aims at solving the technical problems of poor anti-sticking property, water resistance, wear resistance and other properties of the existing synthetic leather. The organic silicon-modified polyurethane resin disclosed by the invention is characterized by comprising the following raw material ingredients in percentage by weight: 2%-30% of diisocyanate, 5%-40% of polyester or polyether type polylol, 0.5%-20% of hydroxyl-terminated organic silicon, 0%-10% of small molecular polylol chain extender, 0%-13% of small molecular polyamine chain extender, 0.01%-1% of catalyst and the balance of solvent, wherein the hydroxyl-terminated organic silicon adopts a polyether-polysiloxane copolymer with two ends which are of hydroxyl groups, and a polyether chain segment is of polyoxyethylene or polyoxypropylene. The glossiness and transparency of the polyurethane resin after modification can not be affected by the organic silicon, and the anti-sticking property, surface smoothness, wear resistance and waterresistance are obviously improved simultaneously.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

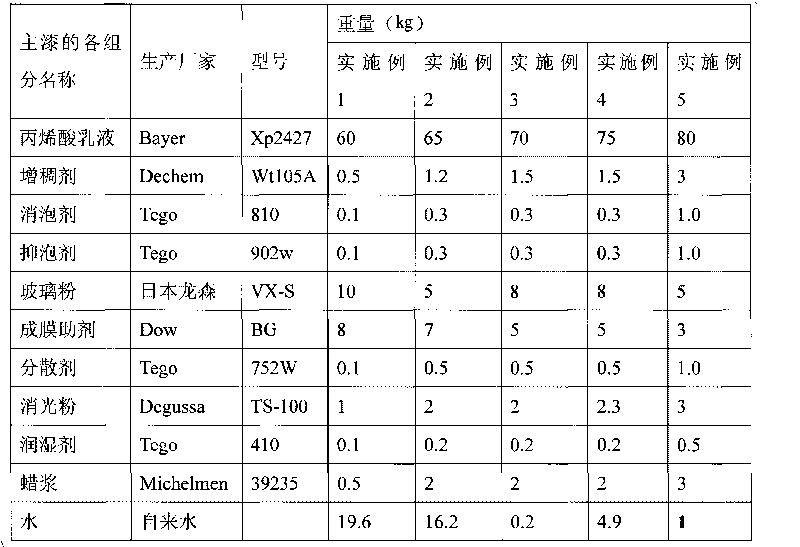

Aqueous dull finishing coat, preparation method and use method thereof

InactiveCN101717603AGood chemical resistanceHigh hardnessPolyurea/polyurethane coatingsDefoaming AgentsMaterials science

The invention relates to an aqueous dull finishing coat with scratch resistance, a preparation method and a use method thereof. Main varnish is prepared from the following components in parts by weight: 60-80 parts of acrylic acid emulsion, 0.5-3 parts of thickening agent, 0.1-1.0 part of defoaming agent, 5-10 parts of glass powder, 0.1-1.0 part of foam inhibitor, 3-8 parts of filming auxiliary agent, 0.1-1.0 part of dispersant, 0.1-0.5 part of wetting agent, 1.0-3.0 parts of extinction powder, 0.5-3.0 parts of wax pulp and 1-20 parts of water; a curing agent of the aqueous dull finishing coat is mixed by 80 parts by weight of aliphatic polyisocyanate and 20 parts by weight of propylene glycol methyl ether acetate; and the ratio of curing agent NCO to main varnish OH is 2.5. The main varnish is prepared by the steps of adding the acrylic acid emulsion into a container, adding the thickening agent, the defoaming agent, the foam inhibitor and the dispersant under stirring, and dispersing at 500RPM for 5-8 minutes till being uniform; afterwards, after adding the extinction powder, the glass powder and the wax pulp under stirring, dispersing at 1000RPM for 15 minutes till the fineness is not more than 25mum; and then, adding the wetting agent, the filming auxiliary agent and the water, dispersing at 500RPM for 10 minutes till being uniform and filtering by a sieve with 100 meshes so as to obtain the aqueous dull finishing coat. The aqueous dull finishing coat is used by mixing in the weight mixture ratio of the main varnish to the curing agent to tap water being 100:50:20. A varnish film has very good hardness, toughness, scratch resistance, abrasion resistance and weather resistance, can be recoated without blanching and has especially good chemical resistance.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

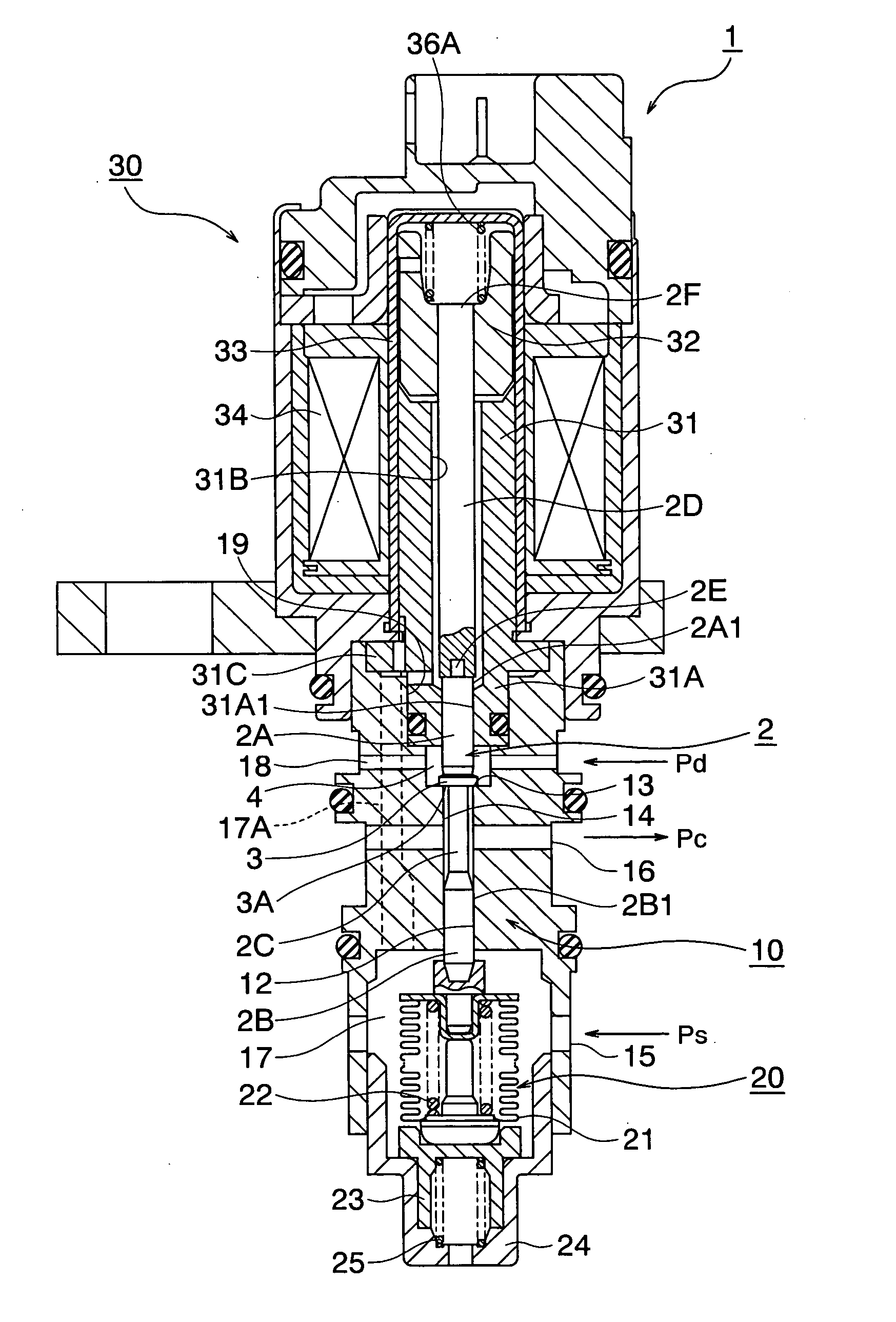

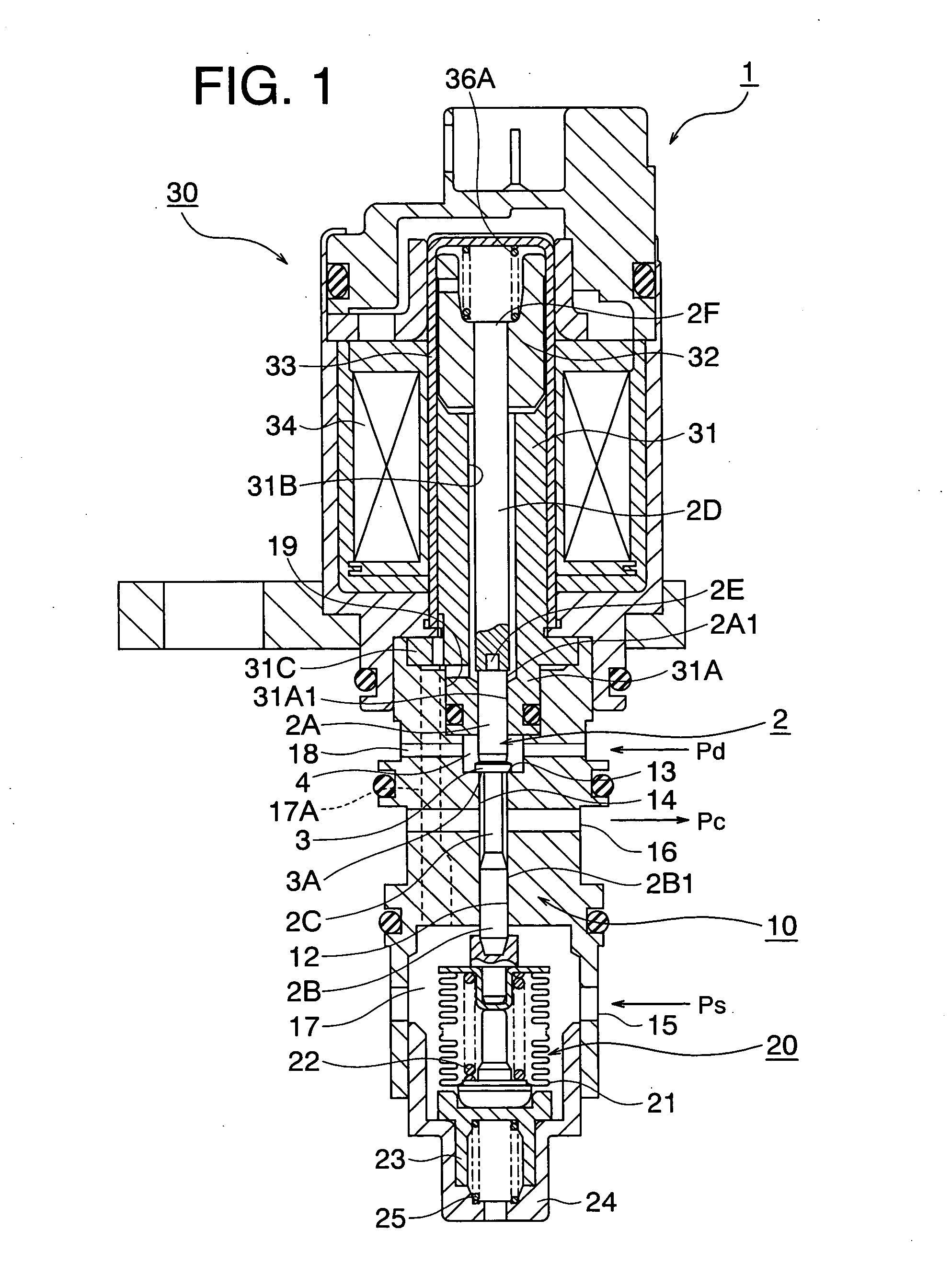

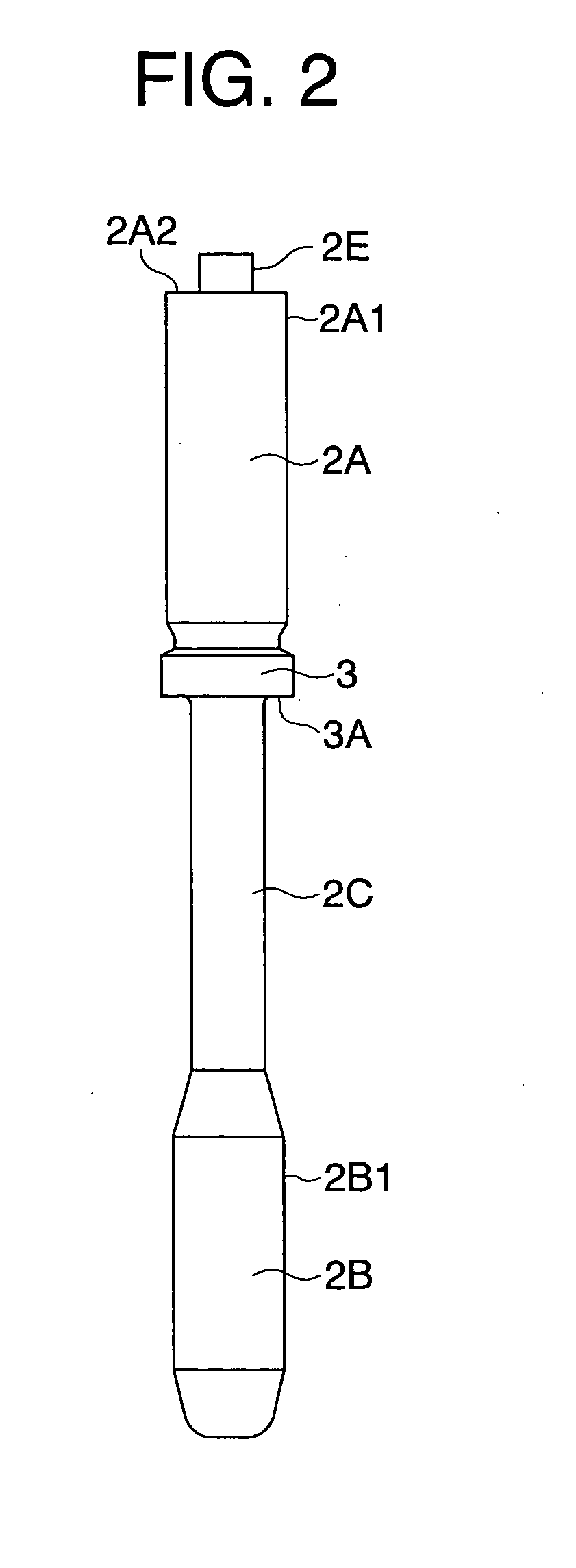

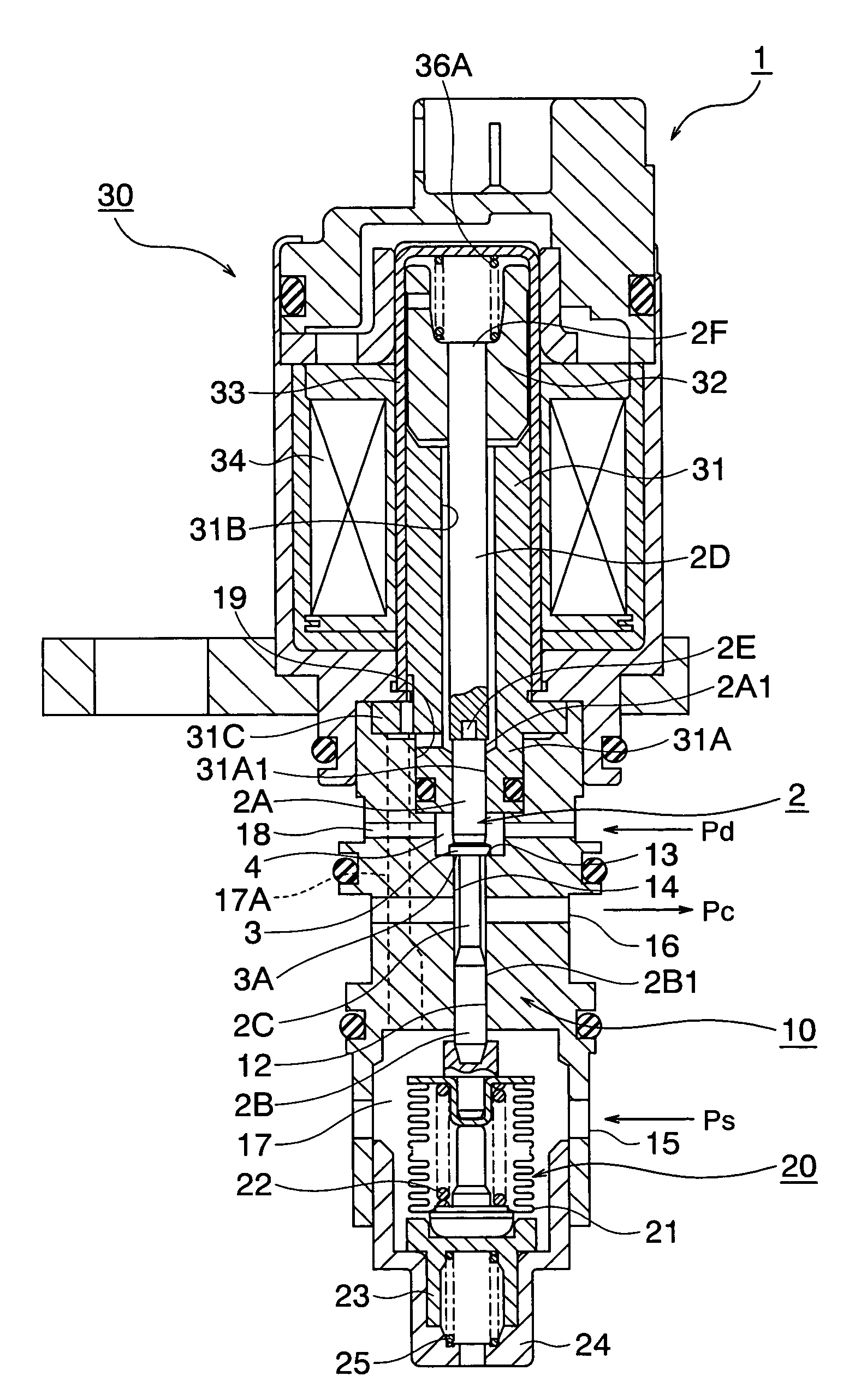

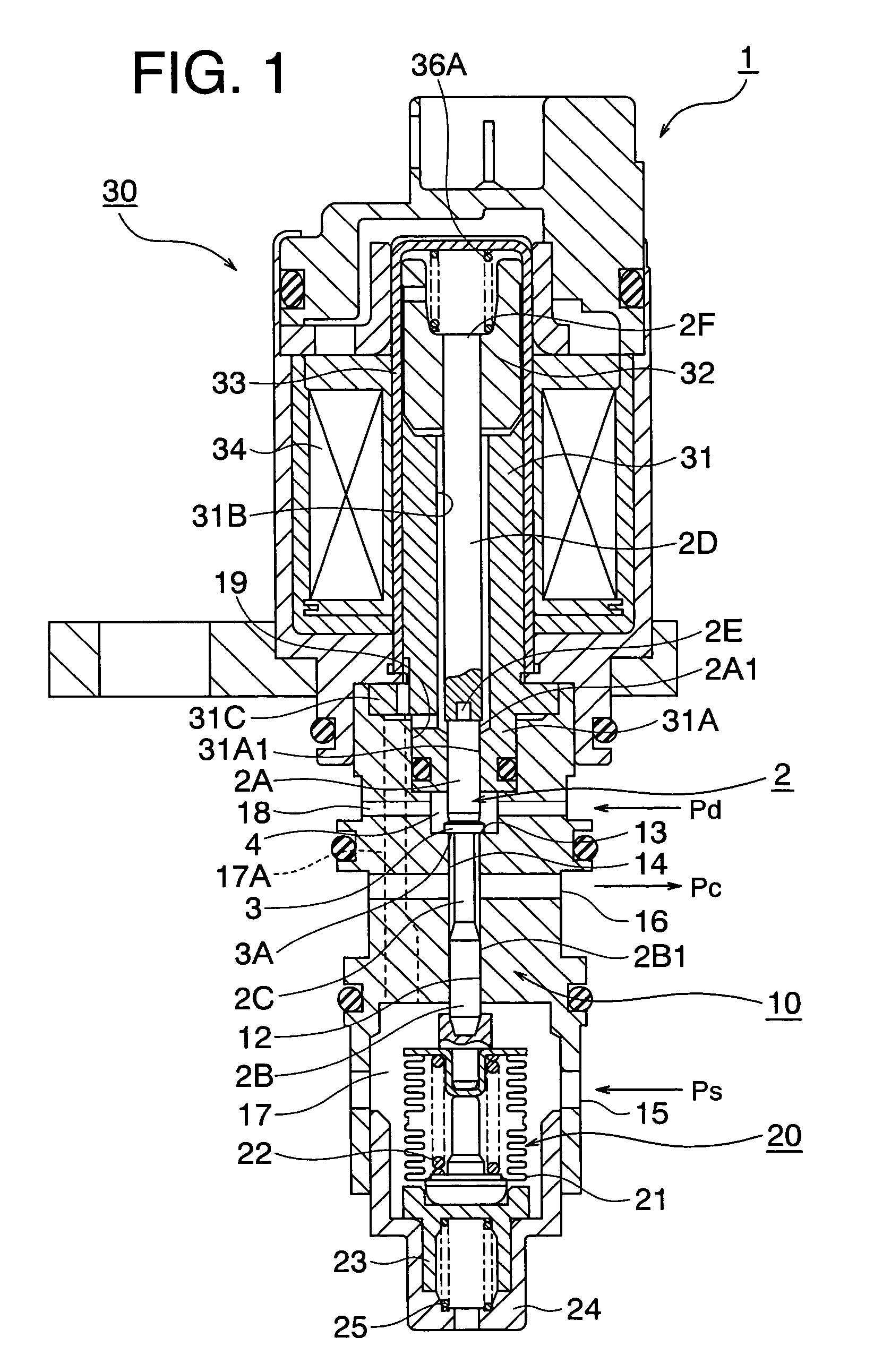

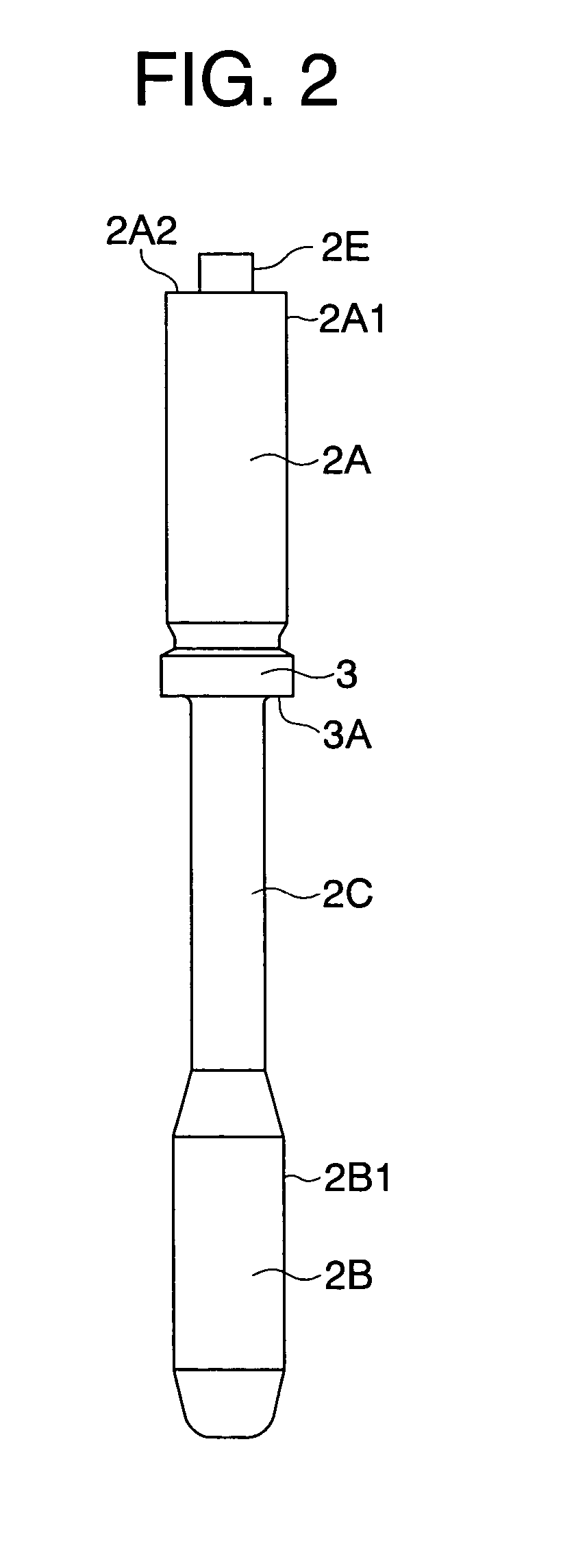

Capacity control valve

ActiveUS20050035321A1Reduce surface roughnessSmall overall deformationPipe supportsAir-treating devicesNuclear engineeringControl valves

An object of the present invention is to improve an anti-abrasive property of an operating rod by using a surface hardening heat treatment without a post finishing process and to enhance a response of the operating rod by preventing powders from being attracted to a sliding surface of the operating rod. Another object is to decrease a machining cost of the operating rod. The capacitive control valve is comprised of a solenoid rod portion communicating with a moveable core of the solenoid portion, an operating rod connected with the solenoid rod portion, a valve body defined in the operating rod and opening or closing a control fluid passage hole and a fixed core oppositely arranged relative to the moveable core, the fixed core retaining a guide hole, the guide hole guiding the operating rod in freely moveable a manner which longitudinally extends through an internal bore wherein the operating rod is processed at no more than 500° C. by a low temperature surface hardening treatment.

Owner:EAGLE INDS

Hard alloy sintered antisticking coating

The invention aims to provide a hard alloy sintered antisticking coating which is mainly prepared from tween, aluminium oxide powder or zirconium oxide powder, titanium carbide, graphite powder, methylcellulose, polyethylene glycol and the rest of water. The hard alloy sintered antisticking coating is rational and scientific in formula and has the advantages of simplicity in preparation, high-temperature resistance, high attachment to a graphite boat, environment friendliness and the like; sticky phases such as nickel and cobalt in a hard alloy are separated from the graphite boat; the problem of sticky boat and carbon penetration which cannot be completely solved by the existing coating and antisticking method is solved; the one-time success rate of sintering the large sticky phase hard alloy product is increased; and the hard alloy sintered antisticking coating is outstanding in performance and has prominent practical characteristics and obvious advancement.

Owner:GUANGXI WUZHOU GANGDE HARD ALLOY MFG

Capacity control valve

ActiveUS7533687B2Reduce surface roughnessSmall overall deformationPipe supportsOperating means/releasing devices for valvesControl valvesHeat treated

Owner:EAGLE INDS

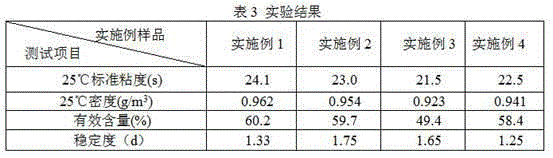

Asphalt separant and preparation method thereof

The invention provides an asphalt separant and a preparation method thereof. The asphalt separant is uniform light yellow emulsion and comprises, by weight, 4-10 parts of dimethyl silicone, 1-2 parts of surface active agents, 4-10 parts of glycerol, 40-80 parts of plant oil, 20-60 parts of water, 0.5-0.8 part of preservative and 0.2-0.3 part of aromatic. The preparation method includes the following steps that all the components are pre-heated to 60-80 DEG C, the dimethyl silicone oil, the glycerol and the plant oil are sequentially added into a reaction kettle with the constant temperature of 60-80 DEG C, the surface active agents and the water are added after stirring is carried out for 10-20 min, then stirring is carried out for 10-20 min, high-speed shearing emulsifying are carried out for three times through a colloid mill at the rotation speed of 1000-6000 r / min, and the preservative and the aromatic are added in the emulsifying process, and the asphalt separant is prepared. The asphalt separant has the advantages of being environmentally friendly and free of pollution, and is soluble to water, good in chemical stability, excellent in high temperature and low temperature resistance, little in use amount and excellent isolation efficiency. Influences to performance of asphalt mixed materials are small, and the asphalt separant can be used for adhesion resistance of various mechanical devices in asphalt mixed material conveying and construction, and is wide in application range.

Owner:XIAN HIGHWAY INST

Stick-proof anti corrosion paint for internal wall of water steam pipeline

InactiveCN1724601ALow water vapor permeabilityRegular structureCorrosion preventionAnti-corrosive paintsEpoxyAlcohol

The invention discloses a method to manufacture anti-sticking antisepsis coating material used in water or gas pipeline. It is made up of film forming resin, filling, assistant agent, dispersing agent, and compounding solution. The main ingredients in film forming resin are epoxy resin, chlorinated rubber, and phenol-formaldehyde resin. The filling is made up from iron red, and talcum powder. The assistant agent is gas phase SiO2. And the compounding solution is made up from ethanol, cyclohexanol, butyl alcohol. The coating material has the advantages of easy to be manufactured, strong adhesive force, good tenacity, steady capability, and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Organosilicon coating agent and preparation method thereof

InactiveCN106398523AStrong UV resistanceImprove antioxidant capacityCoatingsChemical reactionUltraviolet

The invention provides an organosilicon coating agent and a preparation method thereof. According to the invention, an organosilicon material is used as a basic raw material which is allowed to have a film forming function through a normal-temperature chemical reaction; an organosilicon material film is allowed to be firmly bonded with the surface of an object in virtue of the action of an adhesion promoter and a diluent, so the effect of long-lasting anti-adhesion effect is obtained; meanwhile, the organosilicon coating agent provided by the invention has good ultraviolet resistance and antioxidation capability and is suitable for brush coating of an external surface. The organosilicon coating agent can be applied onto the surfaces of decorative coatings and exterior coatings; after curing, the organosilicon coating agent has good adhesion, is hard to fall, enables the surfaces of the coatings to be bright and smooth and shows excellent anti-adhesion effect; with the organosilicon coating agent, advertisement labels cannot be firmly bonded on the surfaces of the coatings and can be easily taken off, and marks written on the surfaces of the coatings by marking pens can be directly erased without solvent or water; and the organosilicon coating agent has long-lasting anti-adhesion effect and presents good anti-adhesion effect after having been coated on the surfaces for one year.

Owner:湖北新四海化工股份有限公司

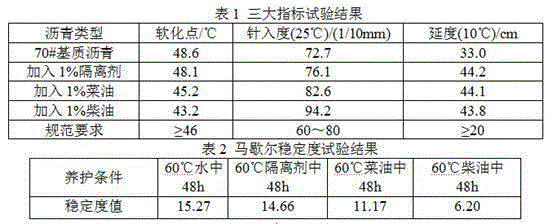

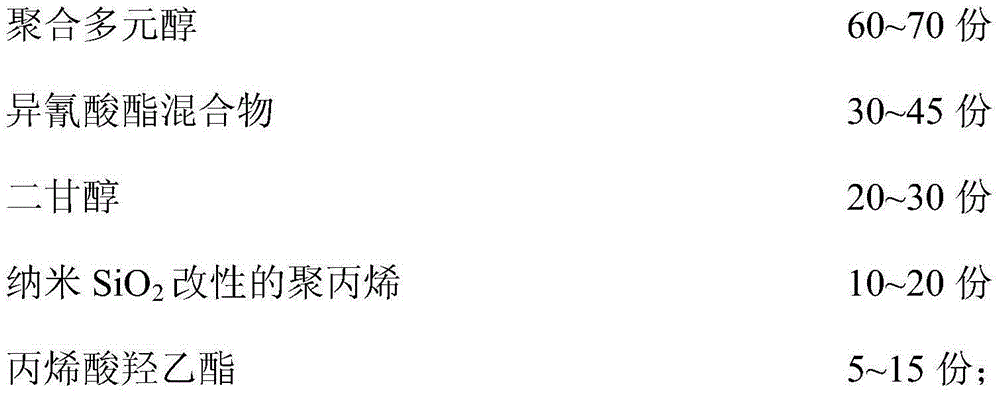

Rolling level thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a rolling level thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer is mainly prepared of the following components in parts by weight: polymeric glycol, isocyanate mixture, diethylene glycol, nano SiO2 modified polypropylene and hydroxyethyl acrylate, wherein the polymeric glycol is a polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol mixture; the isocyanate mixture is a toluene diisocynate and hexamethylene diisocyanate mixture. Under the synergistic effect of polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol and the synergistic effect of toluene diisocynate and hexamethylene diisocyanate, the prepared rolling level thermoplastic polyurethane elastomer is high in processing performance and resilience performance due to nano SiO2 modified polypropylene and hydroxyethyl acrylate serving as a crosslinking agent; meanwhile, the phenomenon of roll bonding can be avoided in a working process.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Dedicated thread compound for casing drilling

ActiveCN1804014AGuaranteed tightnessPrevent looseningAdditivesDrilling compositionGas phaseSilicon dioxide

The invention relates to a screw-thread grease for casing well drilling, wherein the constituents include (by weight percent): molybdenum disulfide composite lithium-based grease 10-50%, expanded graphite 10-30%, copper powder 1-10%, zinc powder 0-30%, lead powder 0-40%, magnesium sulfonate 0.1-5%, SP-80 0.1-8%, dimethyl silicon oil 0.1-5%, polytetrafluoroethylene 0-12%, gas phase silicon dioxide 1-15%. The screw-thread grease is prepared by using thickened mineral oil as carrying agent, charging solid substance, bulking agent, expanded graphite sealing material, then carrying out homogenization.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Super-slide type biaxial tension polypropylene thin film for easy-quit package retraction tobacco

The invention relates to a super-smooth type dual-direction extension polypropylene film used by a retractable cigarette with the package easy to be taken down, comprising a structure of an upper layer, an intermediate layer and a lower layer. The upper layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene biopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The intermediate layer is added with hydrogen oil resin accounting for 10 to 30 percent of the total weight of the polypropylene basal material as erection strengthening agent and 0.2-1.0 percent of alkyl (C14-18) double (2-hydroxyethyl group) amine as anti-static agent. The lower layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene triopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The film has small internal friction and good erection and static electricity prevention, and can enable the cigarette package to be easily taken down from the film.

Owner:江苏恒创包装材料有限公司

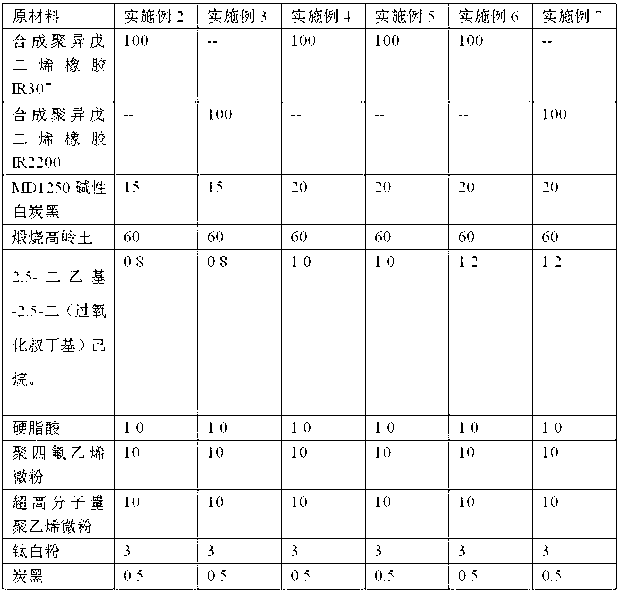

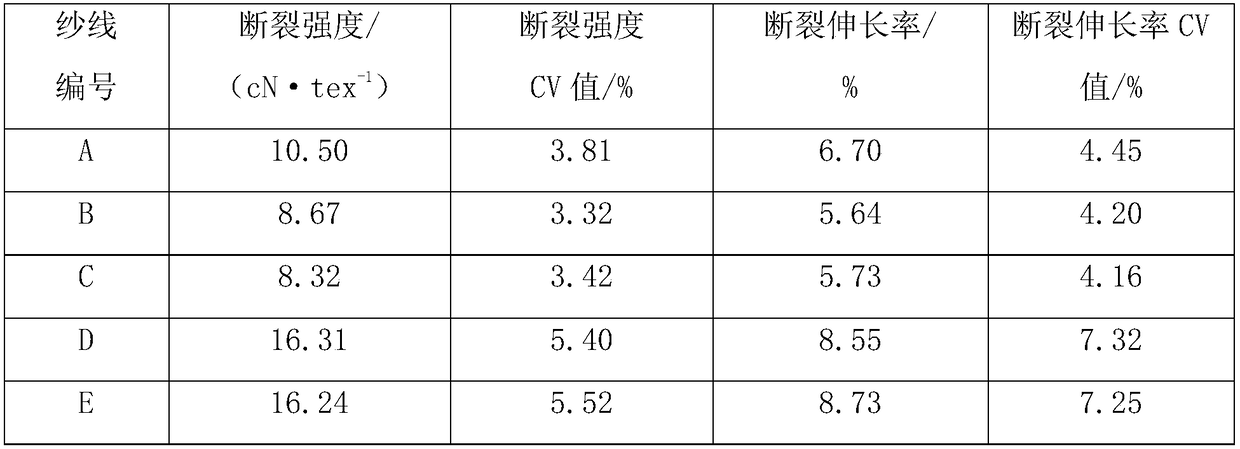

Rubber syringe needle protective cap for pre-encapsulation injection syringe and production method thereof

ActiveCN103232623AIncreased degree of vulcanizationSpeed up vulcanizationPolymer scienceSmell problems

The invention discloses a rubber syringe needle protective cap for a pre-encapsulation injection syringe. The protective cap is prepared from the following raw materials in parts by weight: 100 parts of synthesized polyisoprene rubber, 5-30 parts of alkaline white carbon black, 20-70 parts of calcined kaolin, 0.3-1.2 parts of peroxide, 0.5-1.0 part of stearic acid, 5-20 parts of polytetrafluoroethylene micro powder, 5-20 parts of ultra-high molecular weight polyethylene micro powder, 1-5 parts of titanium dioxide and 1-3 parts of carbon black. The rubber syringe needle protective cap has the obvious characteristics that a clean and simple peroxide sulfuration system is adopted, and a conventional complicated sulfur and zinc oxide promotion system is avoided. Special alkaline fillers are adopted, the sulfuration degree and speed of rubber are improved, and a smell problem caused by adopting the peroxide to sulfurate the polyisoprene rubber is reduced. The polytetrafluoroethylene micro powder and the ultra-high molecular weight polyethylene micro powder with good inertness and dispersibility are added into a formula, the lubricity and chemical inertness of the rubber are improved, and the viscous resistance of a rubber syringe needle protective cap product is improved.

Owner:郑州翱翔医药科技股份有限公司

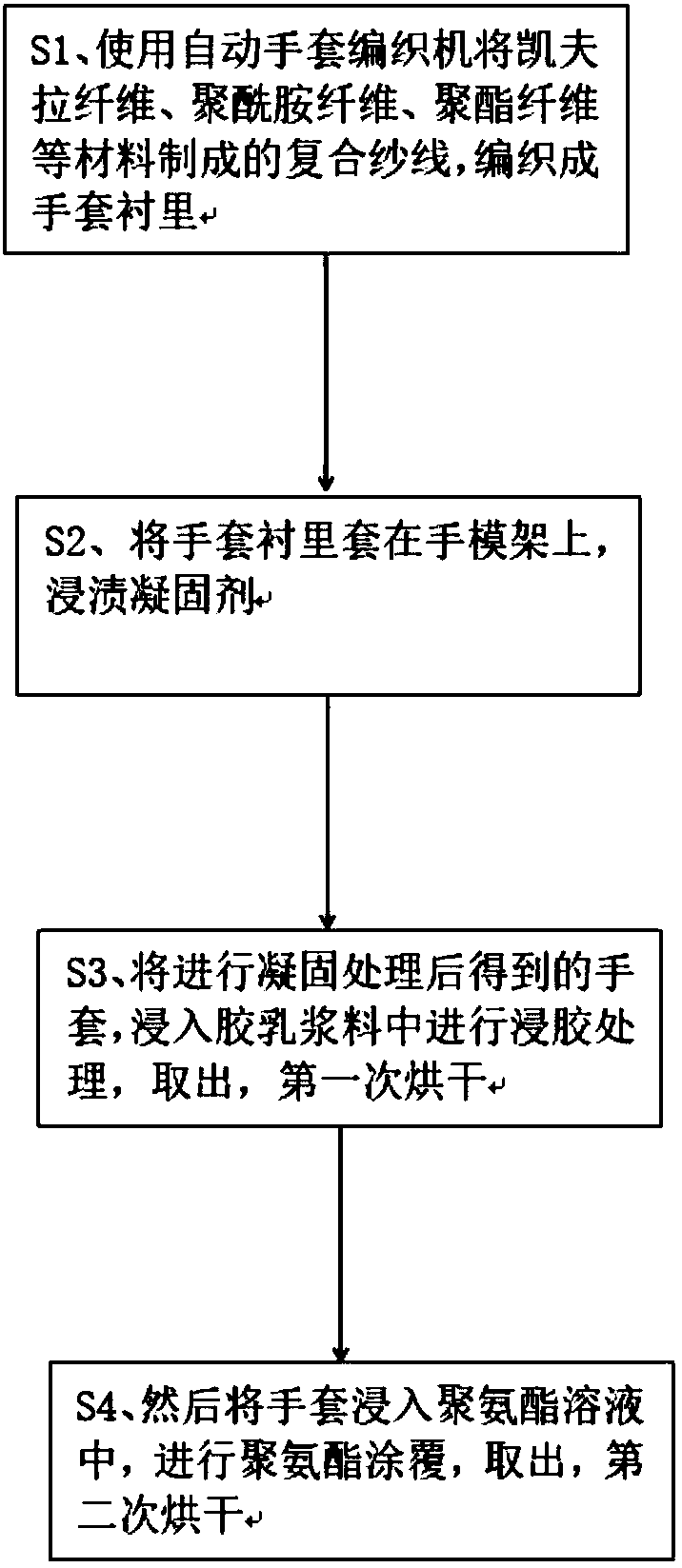

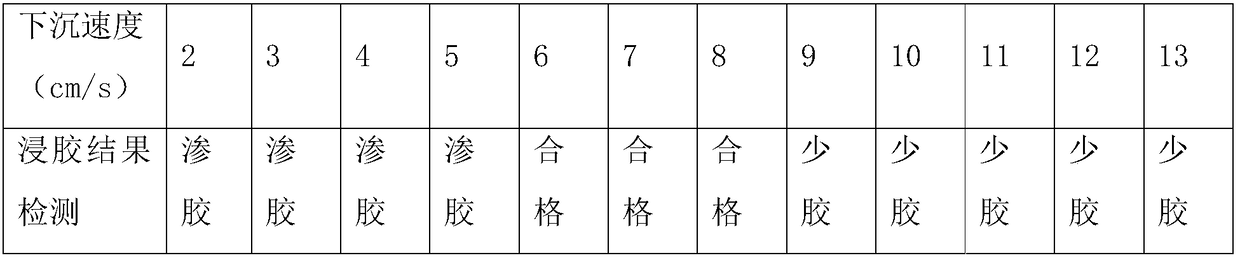

Manufacturing method for latex labor-protective gloves

The invention relates to a manufacturing method for latex labor-protection gloves and belongs to the technical field of labor protection gloves. The method comprises the steps of S1, using an automatic glove knitting machine to weave composite yarn prepared from Kevlar fiber, polyamide fiber, polyester fiber and the like into a glove lining; S2, sleeving a hand mold frame by the glove lining, andconducting impregnating by a coagulant; S3, immersing the gloves obtained after coagulation treatment in a latex slurry for dipping treatment, and taking out the immersed gloves out, and conducting first drying; and S4, then dipping the gloves into a polyurethane solution for polyurethane coating, taking the gloves out, and conducting second drying. In the method, traditional cotton materials arereplaced by a new material, the production industry cost is reduced, and an advanced production process is improved, so the production efficiency is improved.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

Silk fibroin based antibacterial nano-fibers and preparation method thereof

InactiveCN108385182AHigh antibacterial effect and antibacterial rateImprove stabilityMonocomponent protein artificial filamentArtifical filament manufactureChemistryAntibacterial effect

The invention provides silk fibroin based antibacterial nano-fibers. The silk fibroin based antibacterial nano-fibers are prepared from the following components in parts by weight: 100 to 150 parts ofsilk fibroin, 4 to 8 parts of titanium dioxide, 20 to 30 parts of chitosan, 10 to 15 parts of nano copper oxide and 10 to 15 parts of polyethylene oxide. The invention further provides a preparationmethod of the silk fibroin based antibacterial nano-fibers; the silk fibroin based antibacterial nano-fibers, prepared by the preparation method, have good biocompatibility, anti-sticking performance,good antibacterial effect and excellent color fixing effect.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

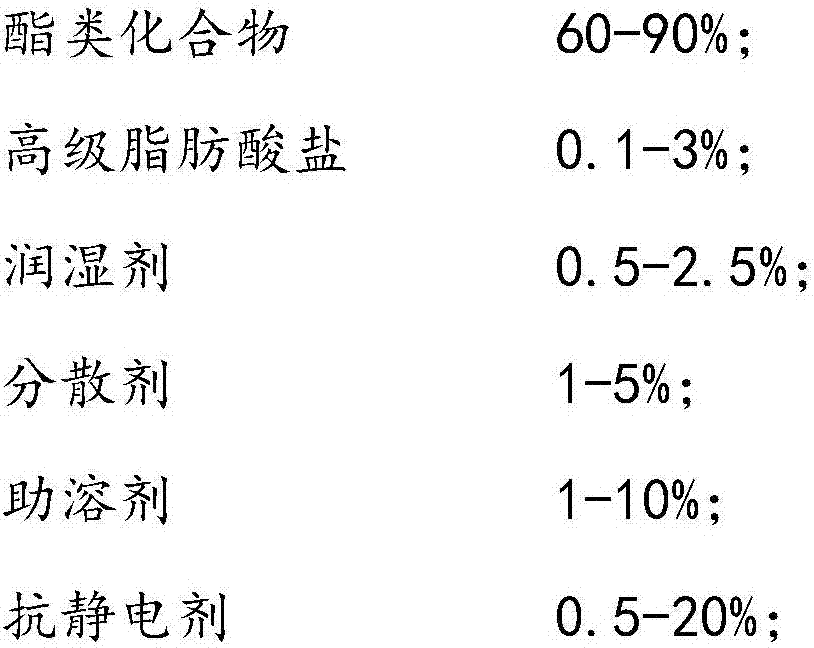

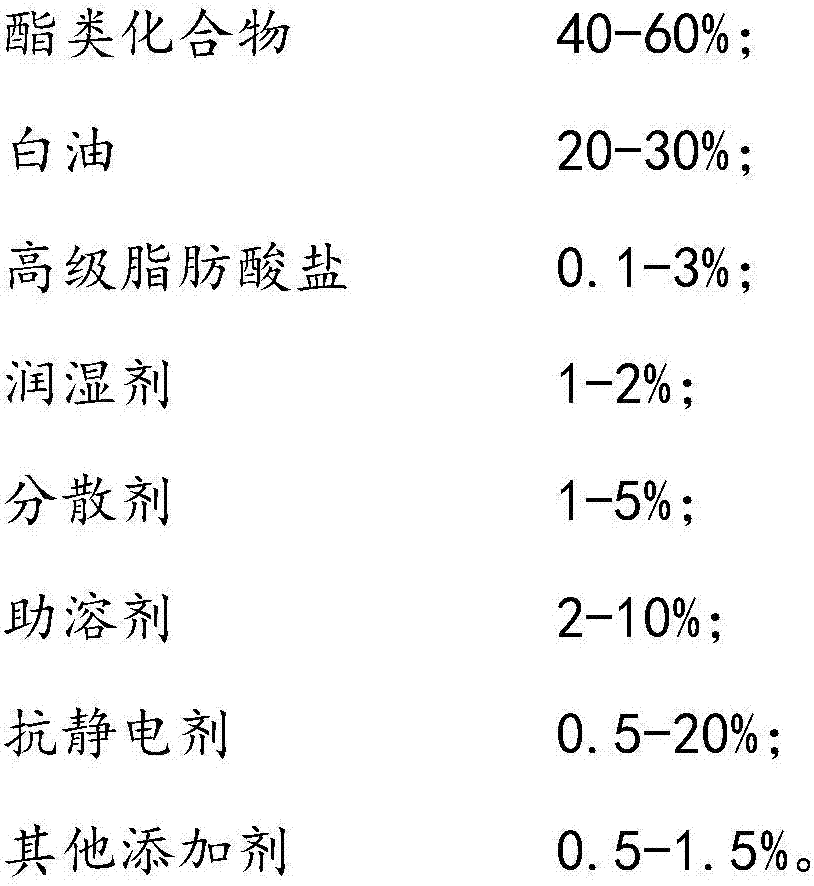

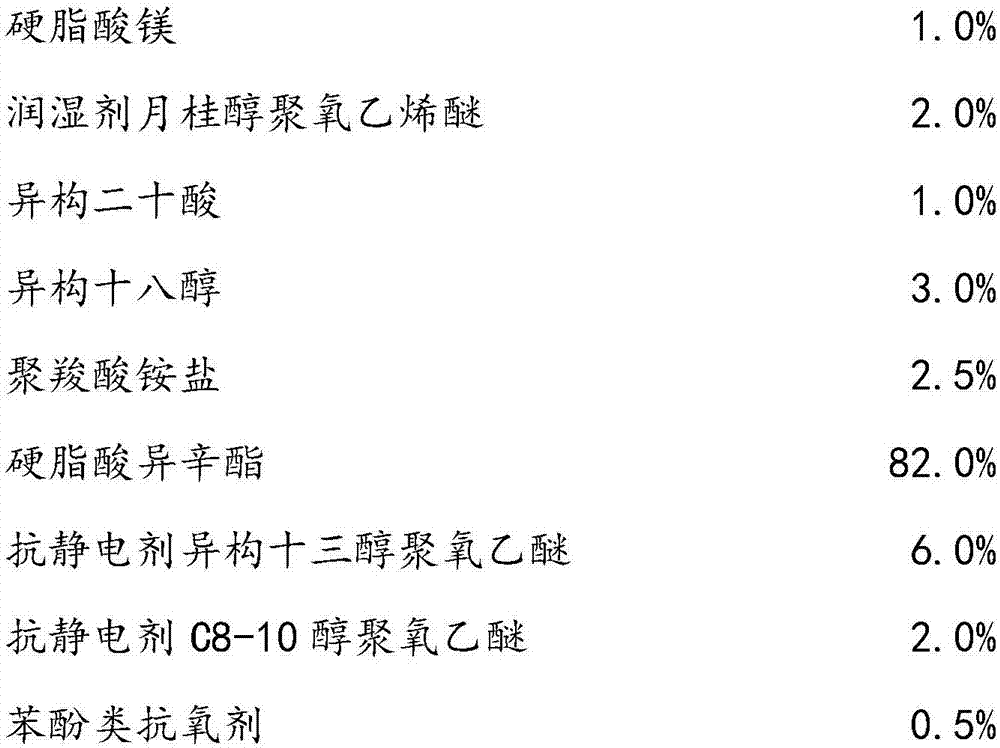

Spandex dry spinning oil agent not containing organosilicone and preparation method thereof

The invention relates to a spandex dry spinning oil agent not containing organosilicone and a preparation method thereof. The spandex dry spinning oil agent comprises 60 to 90% of ester type compound, 0.1 to 3% of higher fatty acid salt, 0.5 to 2.5% of wetting agent, 1 to 5% of dispersant, 1 to 10% of dissolving additive, and 0.5 to 20% of anti-static agent. The spandex dry spinning oil agent has the advantages that (1) the oil agent adhered onto fiber can be easily removed, and the oil-applied spandex yarn can be laminated, compounded and adhered, and be easily and uniformly dyed; (2) by adopting the formula compounding and technology optimizing, the dispersion of metal magnesium is small, and the nanometer level can be reached; the spandex fiber has good anti-adhering and isolation properties, the anti-adhering and adhering-preventing effects are good, and the unwinding property of inner layer and outer layer is excellent; the smoothness is proper.

Owner:烟台锐泽化学品有限公司

Superficial treatment process of high abrasion resistance metallic film synthetic leather

ActiveCN101445840AImprove surface wear resistanceStrong adhesionComposite leathersPretreated surfacesPolymer scienceMetal

The invention relates to a superficial treatment process of a high abrasion resistance metallic film synthetic leather, which is characterized that the superficial treatment process comprises the following steps: coating a colorless film on the metallic film surface of the metallic film of the metallic film synthetic leather; thermally sealing a colorless film release paper and the metallic film synthetic leather by using the colorless film and the metallic film; stripping the separated paper after being cooled; and then completing the preparation of the high abrasion resistance metallic film synthetic leather. The invention can not only effectively avoid stripping and surface decoloring, but also improve the product quality.

Owner:ANHUI ANLI MATERIAL TECH

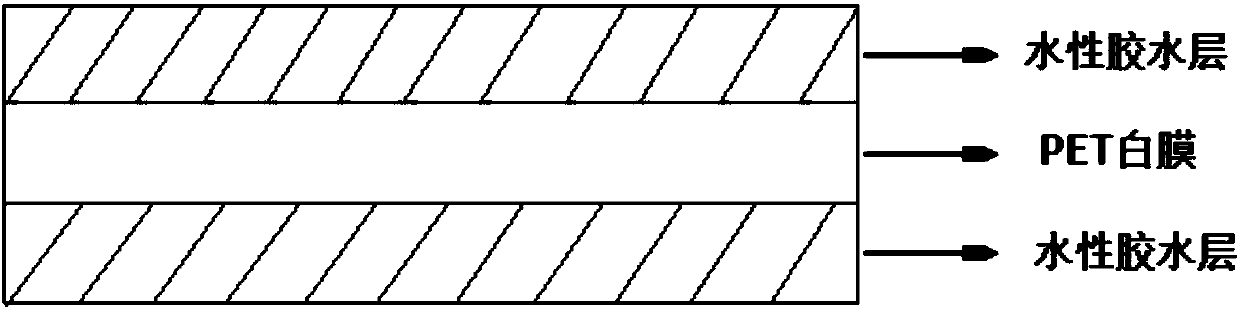

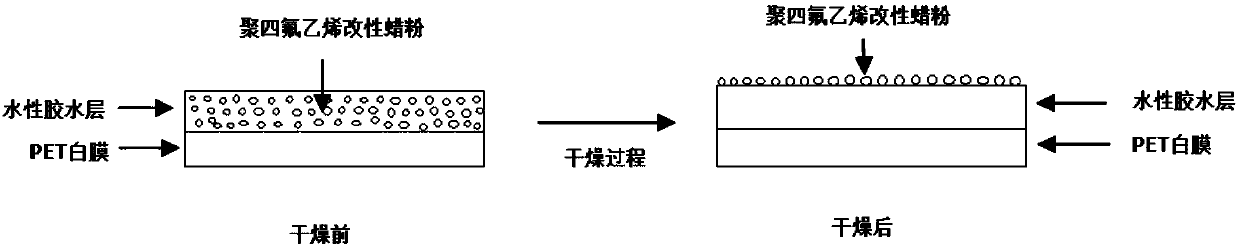

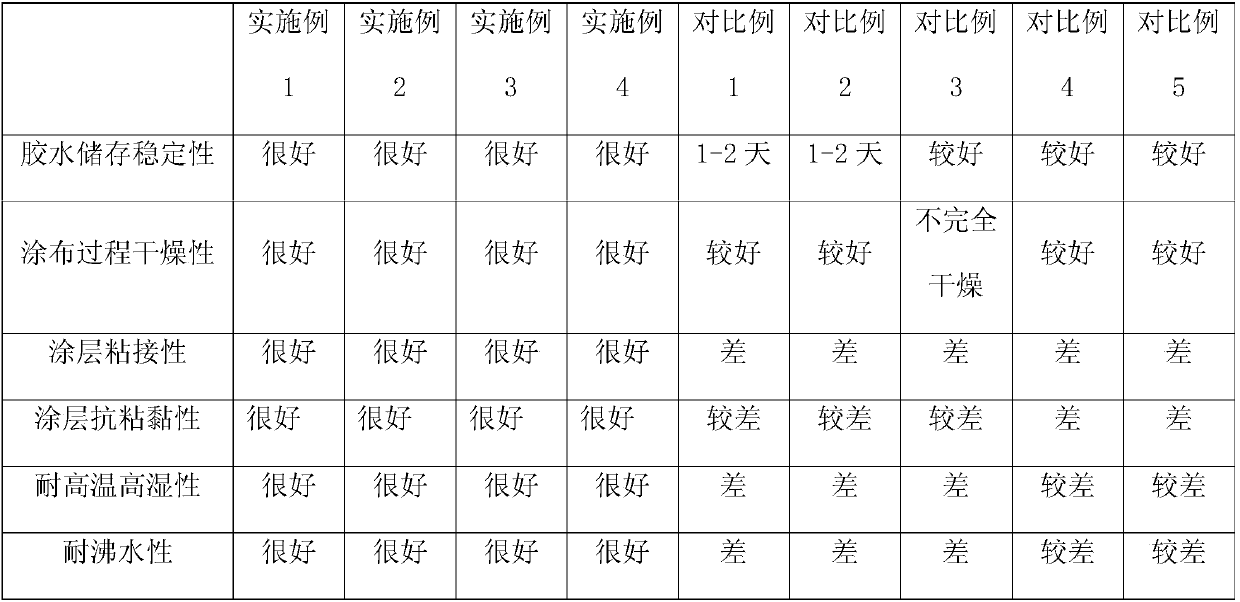

PET card film and preparation method thereof

InactiveCN107699152AImprove adhesionImprove aging resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesWater basedPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a PET card film and a preparation method thereof. By selecting aliphatic waterborne polyurethane, thecohesive property and the ageing resistance of water-based glue coated to form a white PET film can be effectively improved; by selecting a flatting agent, the later printing requirements of a coating can be effectively met; by adding water-based polytetrafluoroethylene, bonding resistance of the coating in a storage layer can be improved; by adding a blocked isocyanates curing agent, the adhesive force, the stability, the water resistance and the high temperature and humidity resistance of the coating can be obviously improved, so that the PET card film capable of meeting the using requirements is prepared.

Owner:常州勤邦新材料科技有限公司

High-quality molding sand and preparation method thereof

InactiveCN105057565AGood air permeabilityGood plasticity and yieldFoundry mouldsFoundry coresHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses high-quality molding sand and a preparation method thereof. The molding sand is prepared from, by weight, 180-200 parts of fused ceramite, 20-30 parts of forsterite, 5-10 parts of black corundum, 40-50 parts of bentonite, 8-10 parts of heavy calcium carbonate powder, 1-2 parts of pulverized coal, 2-4 parts of tung oil, 3-4 parts of phosphate, 2-3 parts of sodium hexametaphosphate and 4-6 parts of hydroxypropyl methyl cellulose. The molding sand has good breathability, strength and heat resistance. The plasticity and deformability are also good. The surfaces of manufactured castings are smooth and bright, the phenomena of shrinkage cavities, bubbles and deformation are reduced, and the rate of finished products is high. Besides, the manufacturing technology is simple, and production pollution can be lowered.

Owner:HEFEI CITY TENVER PRECISION CASTING

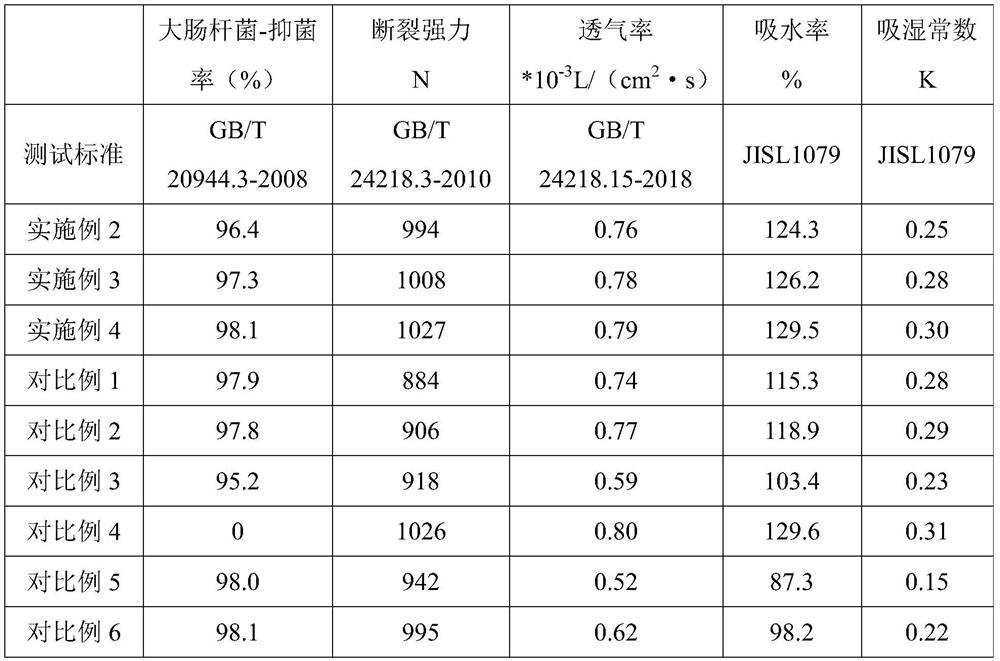

Antibacterial PP spun-bonded non-woven fabric and preparation method thereof

InactiveCN113106633AImprove antibacterial propertiesImprove breathabilityConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolyethylene glycol

The invention discloses an antibacterial PP spun-bonded non-woven fabric and a preparation method thereof. The antibacterial PP spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight of 55 to 65 parts of polypropylene, 30 to 37 parts of an ethylene-methyl methacrylate copolymer, 16 to 20 parts of polyethylene glycol monomethyl ether, 2 to 4 parts of maleic anhydride grafted polypropylene, 3 to 4.2 parts of large-aperture hollow silicon dioxide nanoparticles, 2.6 to 3.2 parts of nano silver-loaded titanium dioxide and 5 to 8 parts of a filler. The antibacterial PP spun-bonded non-woven fabric disclosed by the invention is good and lasting in antibacterial effect, high in air permeability, large in moisture-absorbing constant, high in water absorption rate, good in moisture-absorbing and air-permeable performance, good in skin-friendly performance and high in use comfort level; and in addition, the antibacterial PP spun-bonded non-woven fabric is high in breaking strength, good in mechanical property, good in durability, excellent in comprehensive performance index, good in comprehensive use performance and wide in market application prospect.

Owner:福建澳杰无纺布科技有限公司

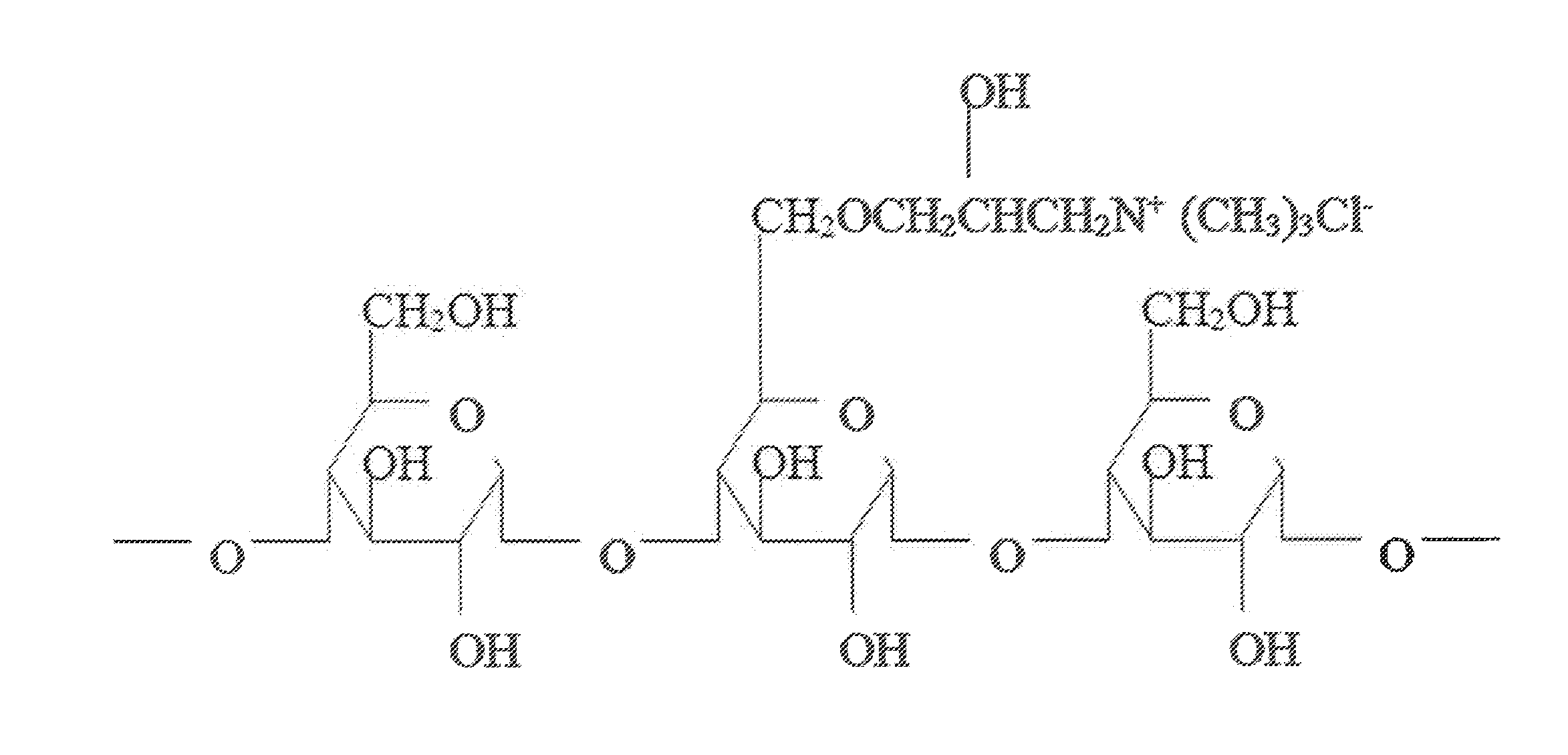

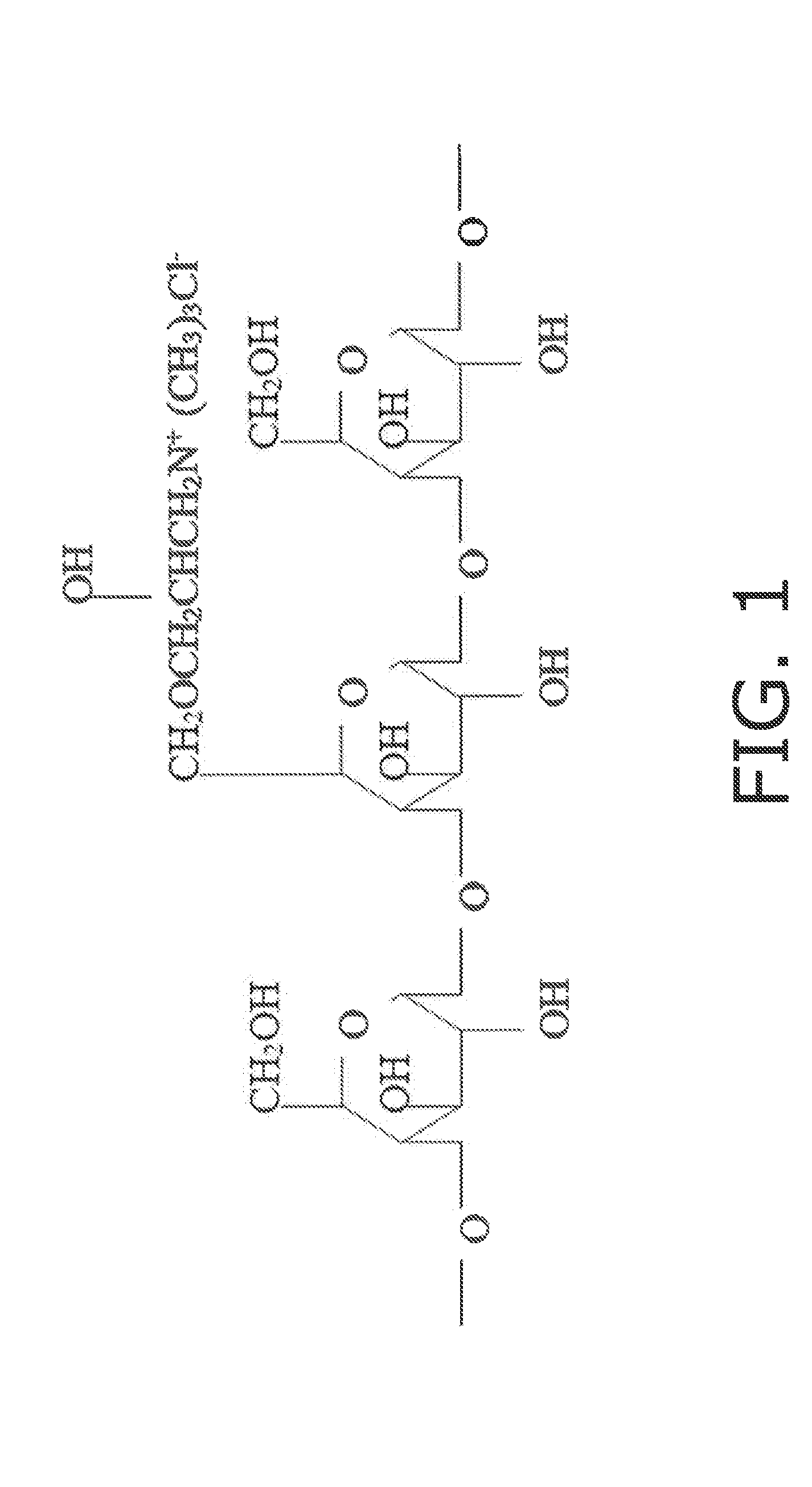

Composition and processfor removing impurities from a circulating water system

ActiveUS20140251921A1Improve anti-stickingEasy to separateWater/sewage treatment by centrifugal separationWater treatment parameter controlWater basedAluminium chlorohydrate

The invention provides methods and compositions for a composition and / or a method for treating impurities in a circulating water system. The circulating water system impurities may be oversprayed paint in paint spray booth applications. The composition includes an aqueous solution of a cationized starch, a polybasic aluminum salt such as aluminum. chlorohydrate or polyaluminum chloride and a solution of a medium to high MW aqueous flocculant. The composition is particularly useful when added to recirculating scrubber water in paint spray booths for effectively treating both water based and solvent based paints.

Owner:ECOLAB USA INC

Method for preparing double-component and double-layer nano lubrication thin film by taking nano-particle array as template

ActiveCN102584331AOvercome reunionStrong bondDecorative surface effectsChemical vapor deposition coatingSelf-assemblyLubrication

The invention discloses a method for preparing a double-component and double-layer nano lubrication thin film by taking a nano-particle array as a template. The double-component and double-layer nano lubrication thin film is prepared on the surface of hydroxylated monocrystalline silicon by taking the nano-particle array as the template according to a liquid phase method and a gas phase method; and components of the double-component and double-layer nano lubrication thin film can be controlled according to the concentration of a nano-particle solution or a lifting speed. The prepared double-layer nano film consists of a self-assembly film formed on the surface of the monocrystalline silicon by bonding alkyl carboxylic acid with high lubrication performance and perfluorocarboxylic acid through a chemical key so as to be integrated with the dual advantages of the long service life of the alkyl carboxylic acid and the surface antisticking performance of the perfluorocarboxylic acid; therefore, the obtained double-component and double-layer nano lubrication thin film has relatively high friction performance and high lubrication; the bearing capacity, the antisticking performance and the anti-abrasion performance of the single self-assembly single-molecule film are improved greatly; and the application of the self-assembly single-molecule film is expanded.

Owner:GUANGXI UNIV

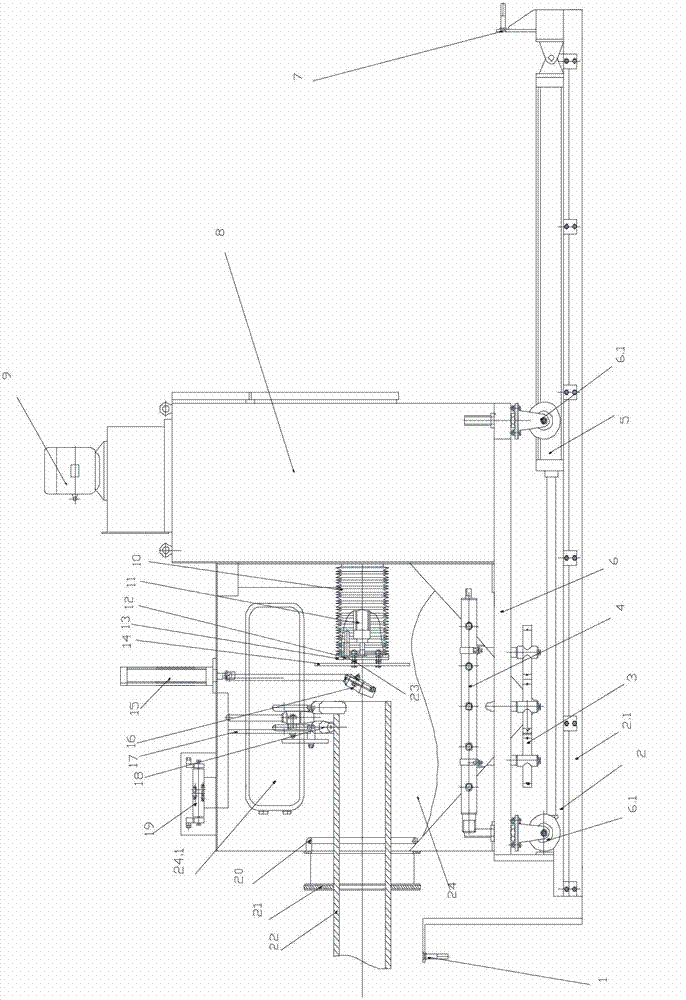

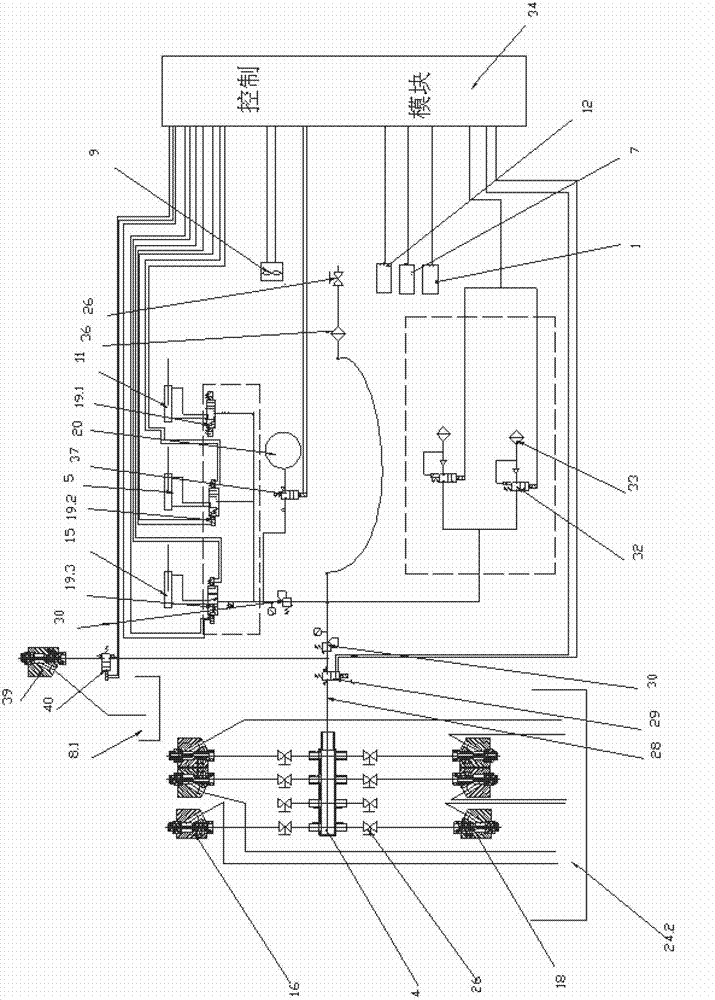

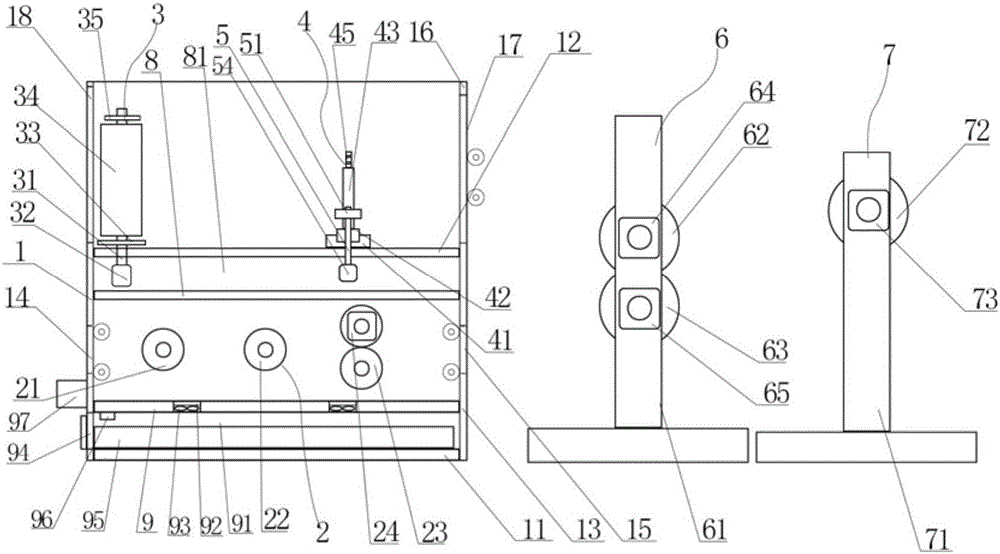

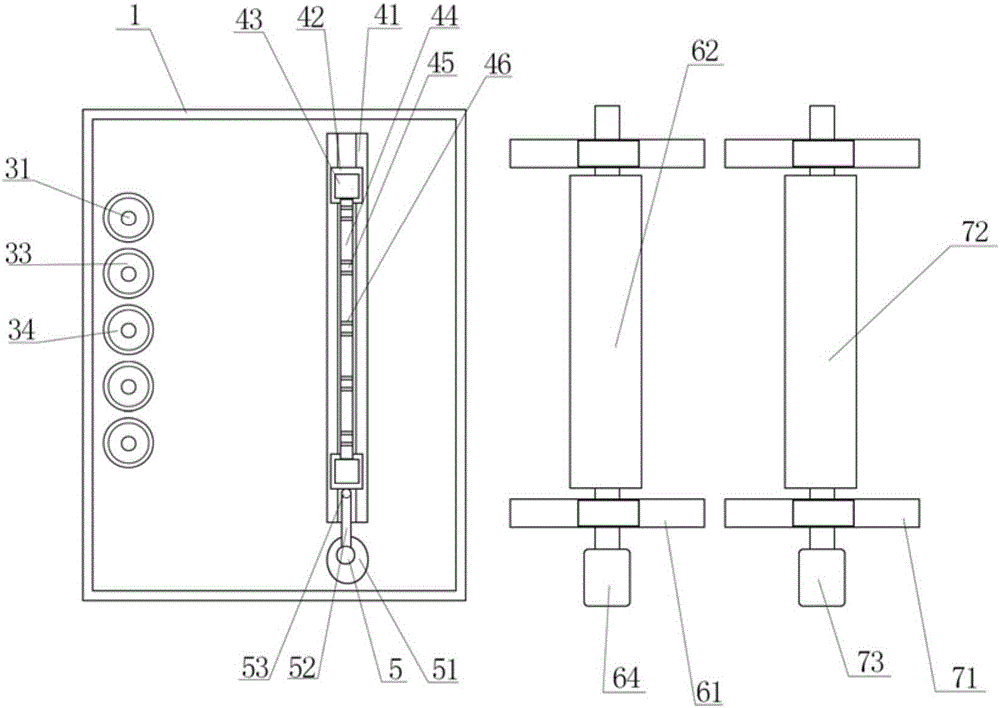

Automatic pipe end thread sandblasting machine

ActiveCN102729154ACompact structureReduce volumeBlast gunsAbrasive machine appurtenancesSteel tubeGalling

The present invention provides an automatic pipe end thread sandblasting machine. The sandblasting machine comprises an online automatic pipe end sandblasting machine comprising a mechanical part, a pneumatic part and an electric apparatus control part. The sandblasting machine of the present invention has the following benefits that: anti-galling and anti-corrosion of the thread portion of the steel pipe are improved. The sandblasting machine of the present invention has characteristics of simple structure, easy maintenance, small size, low pollution, and easy use, and is suitable for online pipe end sandblasting treating. In addition, the sandblasting machine has the following advantages that: the sandblasting machine has effects of other blasting ways, and provides good sandblasting effects after the actual production, the work efficiency is high, the processing cost is significantly reduced. With the actual production practices, the production output is increased by 40%, and the qualified rate of the product is improved by 5%.

Owner:TIANJIN PIPE GROUP CORP

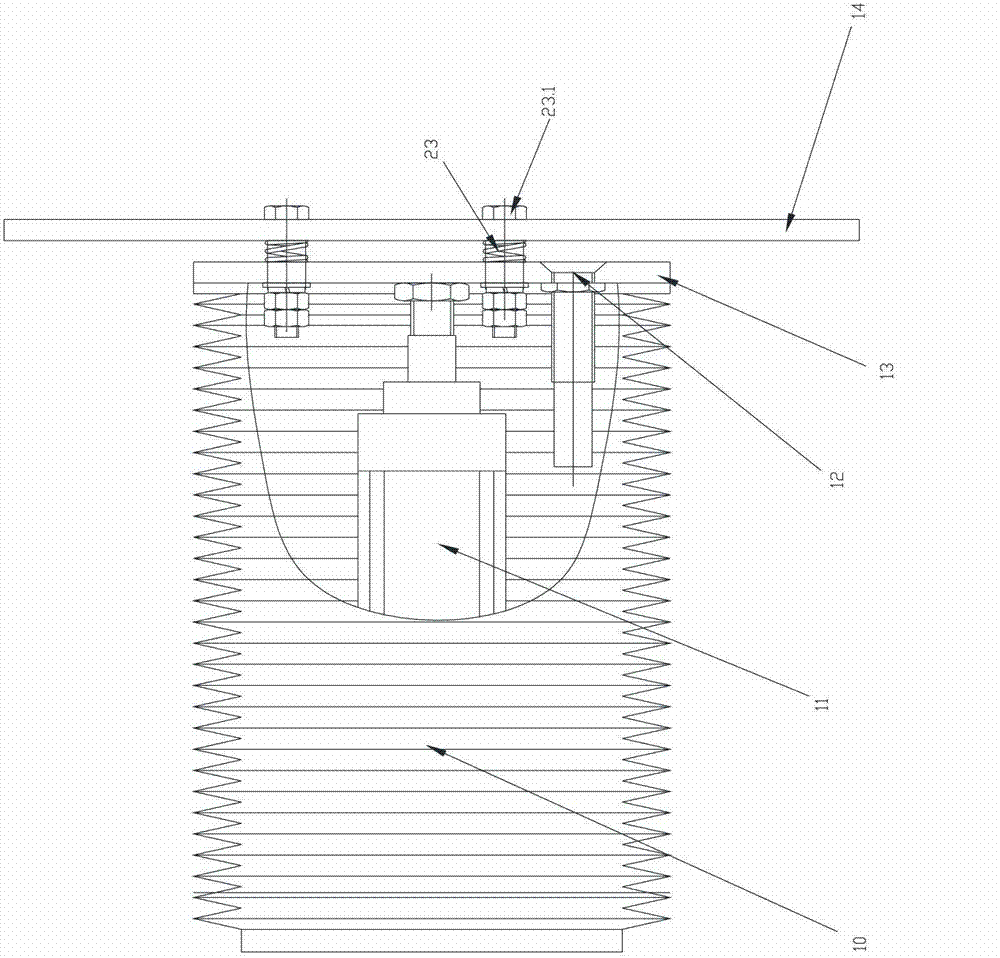

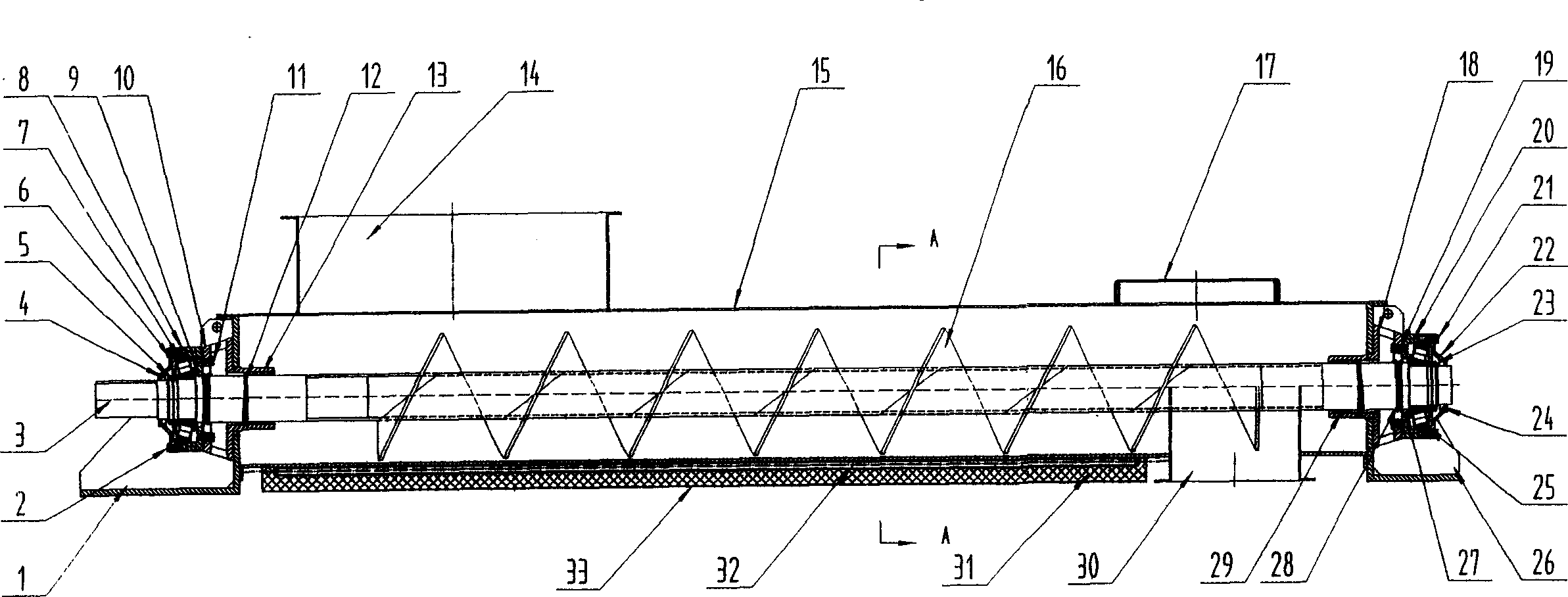

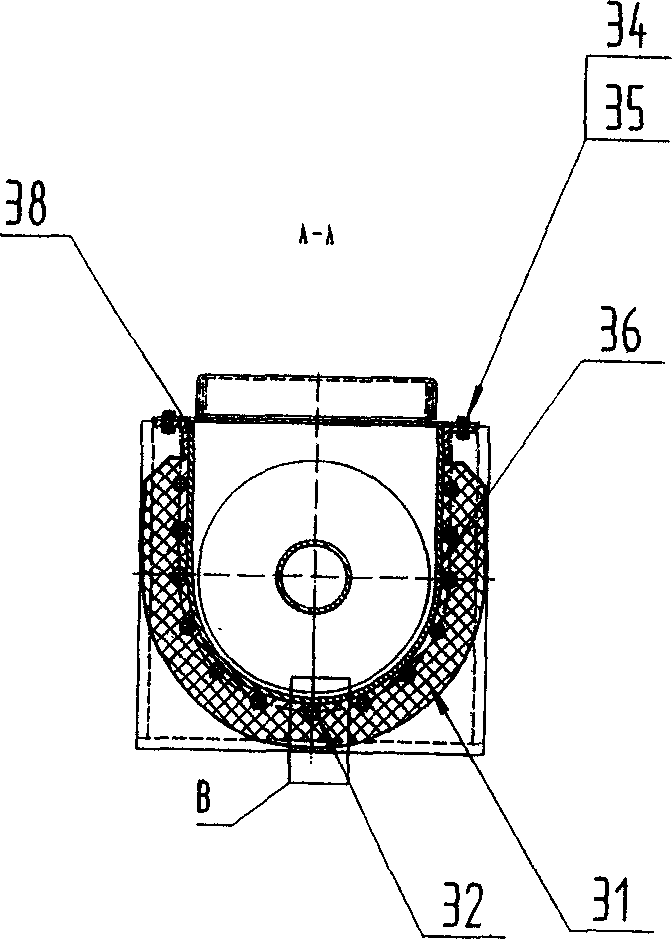

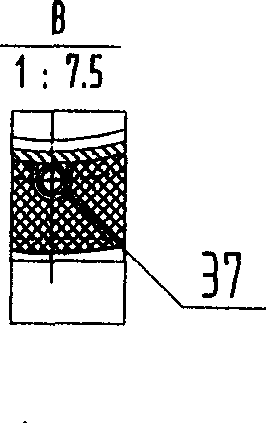

Heating type screw conveyor

InactiveCN1861354AChange temperature flowAchieve heat preservationMixing operation control apparatusHeat carrierEngineering

A screw conveyer with heating function is composed a casing, left and right supporters at both ends of said casing, a screw body installed in the bearing holes, the heat carrier pipelines fixed to the supporting frame and installed at the arc part and both sides of said casing, and the installing wool layer and metal jacket sequentially surrounding said heat carrier pipelines. It features that the heat exchange between heat carrier and casing is used for heating, warming or cooling material to be conveyed.

Owner:WUXI XITONG ENG MACHINERY

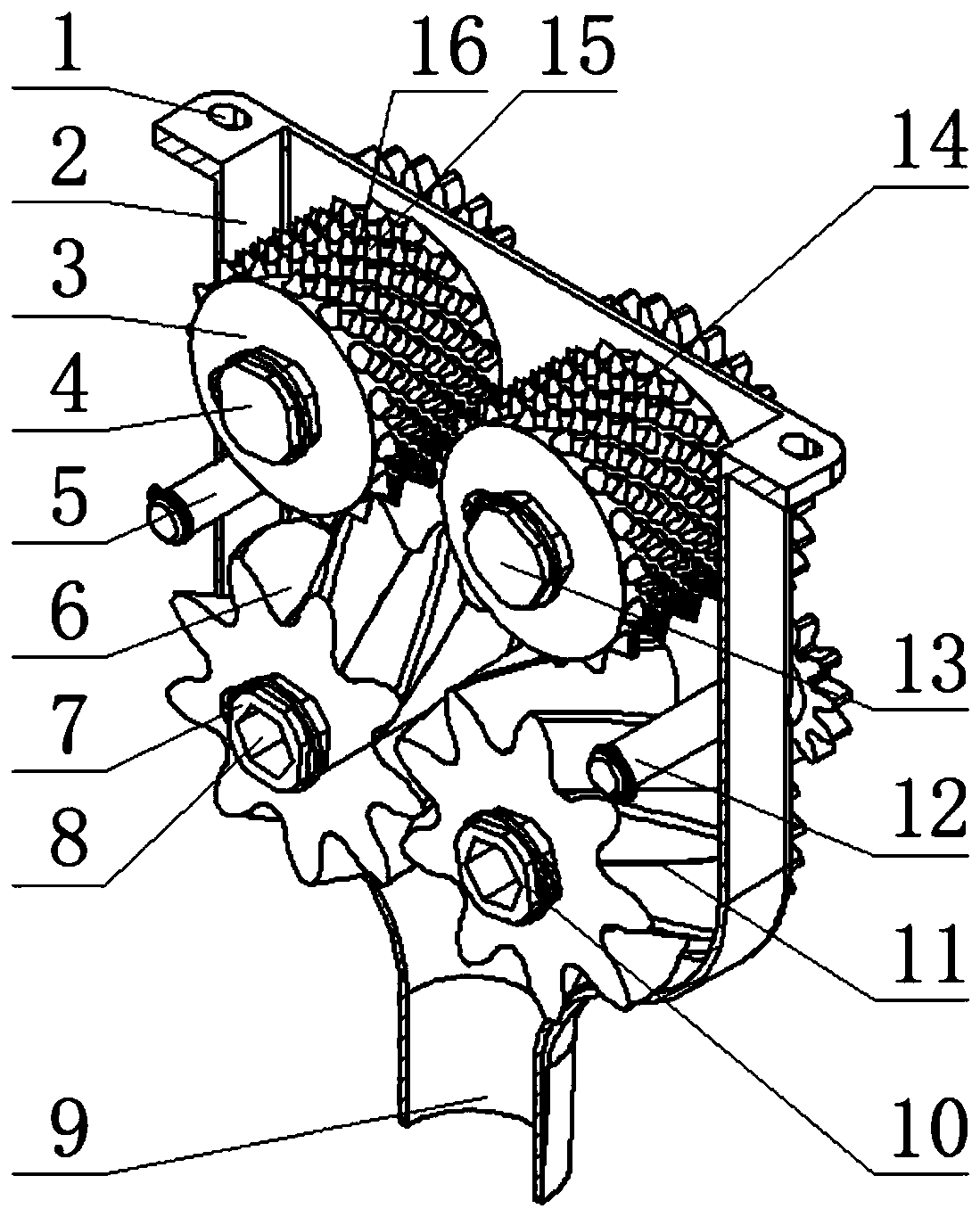

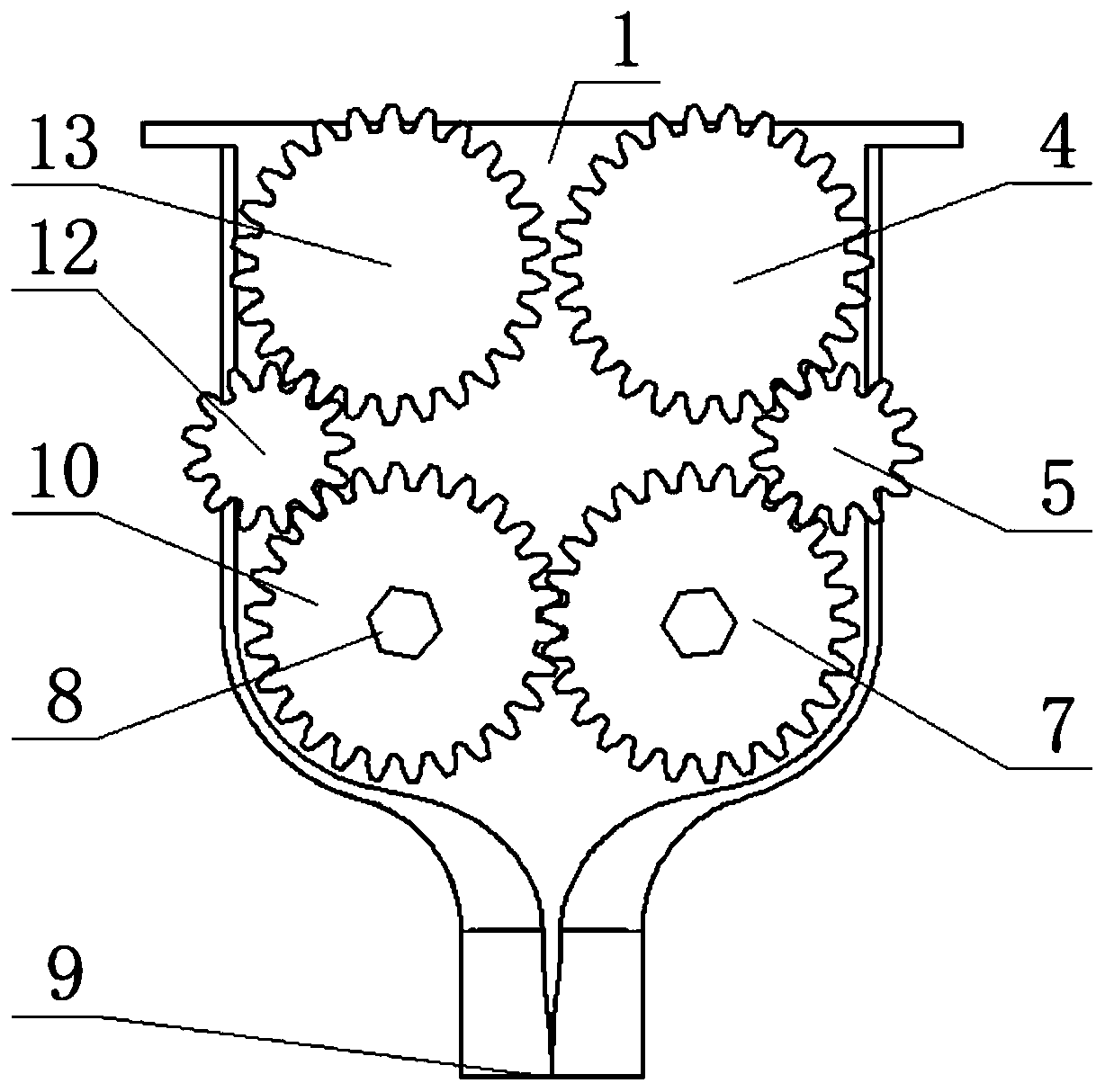

Breaking anti-blockage uniform application fertilizer apparatus with multi-stage breaking function

PendingCN110038681AImprove anti-stickingImprove crushing effectFertiliser distributersGrain treatmentsAgricultural engineeringSpiral line

The invention discloses a breaking anti-blockage uniform application fertilizer apparatus with a multi-stage breaking function, and belongs to the agricultural machines. A left driving gear shaft anda right driving gear shaft which are engaged are rotatably assembled on the lower portion of a shell and transfer motion to a left driven gear shaft and a right driven gear shaft through a left transition gear shaft and a right transition gear shaft, a left rotation involute fertilizer discharging gear and a right rotation involute fertilizer discharging gear are fixedly arranged in the middles ofthe left and right driving gear shafts, right rotation cone ridge breaking rollers with spiral anti-sticking breaking cone ridges evenly distributed in the circumferential direction are fixedly arranged in the middles of the left and right driven gear shafts, the spiral anti-sticking breaking cone ridges which are in right rotation spiral line shapes are composed of cone faces and saddle faces which are alternatively arranged, and the centering gap of the right rotation cone ridge breaking roller is larger than the side wall gap. Through impact circular rotation roll extruding breaking effectof the breaking roller, large block fertilizer is broken into small fertilizer and bulk fertilizer, inner circular flow is used for further breaking, an inclined tooth involute fertilizer discharginggear is used for carrying out fertilizer secondary breaking, and then discharging is achieved in a uniform and constant manner. Meanwhile, the fertilizer apparatus is novel in structure, high in reliability and high in adaptation.

Owner:NORTHEAST FORESTRY UNIVERSITY

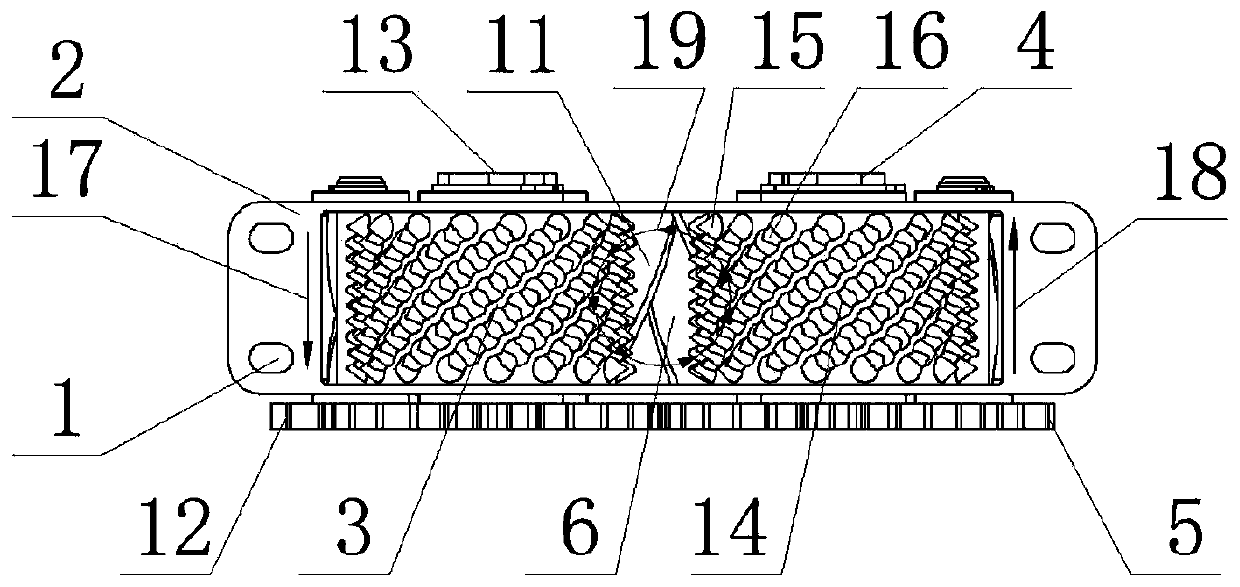

Cotton cloth attachment anti-adhesion yarn winding device

InactiveCN106516877AIncrease the area of actionImprove anti-stickingFilament handlingYarnEngineering

The invention discloses a cotton cloth attachment anti-adhesion yarn winding device. The cotton cloth attachment anti-adhesion yarn winding device comprises a rack. The bottom of the rack is provided with a bottom plate. The middle of the rack is provided with a transverse plate. A partition plate is horizontally arranged below the transverse plate. An accommodating cavity is formed between the partition plate and the transverse plate. A cotton roll conveying assembly is arranged above the bottom plate. A yarn unwinding assembly is arranged on the transverse plate. One side of the yarn unwinding assembly is provided with a swing mechanism. One side of the rack is provided with a pressing mechanism and a winding mechanism. A cleaning plate is horizontally arranged above the bottom plate. A cleaning cavity is formed between the cleaning plate and the bottom plate. The cleaning plate is uniformly provided with four cleaning holes which communicate with the cleaning cavity. Each cleaning hole is internally provided with a negative pressure draught fan. The side surface of the cleaning cavity is provided with a rectangular opening. A drawer is arranged in the cleaning cavity through the rectangular opening. One side of the bottom of the cleaning plate is provided with a water injection nozzle. The side surface of the rack is provided with a water tank which is connected with the water injection nozzle.

Owner:苏州市朗润纺织科技有限公司

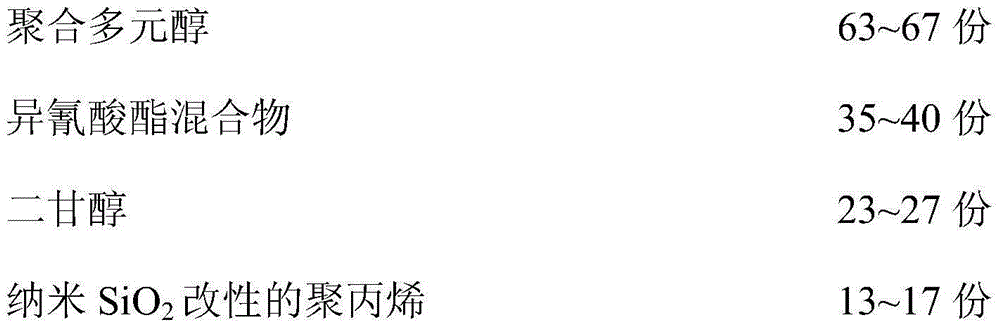

Calendaring high-performance thermoplastic polyurethane elastomer and preparation method thereof

The invention provides a calendaring high-performance thermoplastic polyurethane elastomer and a preparation method thereof. The calendaring high-performance thermoplastic polyurethane elastomer provided by the invention is prepared from specific diisocyanate and polyhydric alcohol, and together with polyvinyl alcohol resin, the components act and coordinate with one another in a specific amount ratio, so that the prepared polyurethane is good in mechanical property and machinable property and good in elasticity, and the stick resistance can be improved. Tests show that the tensile strength of the polyurethane elastomer is greater than 90MPa, the breaking elongation of the polyurethane elastomer is up to 980%, the rebound rate of the polyurethane elastomer is greater than 88%, the adhesion property is grade 0, no adhesion can be caused when the polyurethane elastomer is left to stand for 8 hours at 80 DEG C, the polyurethane elastomer is applicable to calendaring, and the polyurethane elastomer is not adhered to metal devices in the calendaring process.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

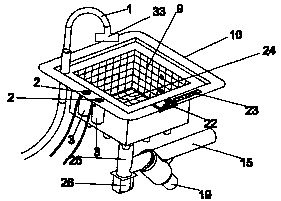

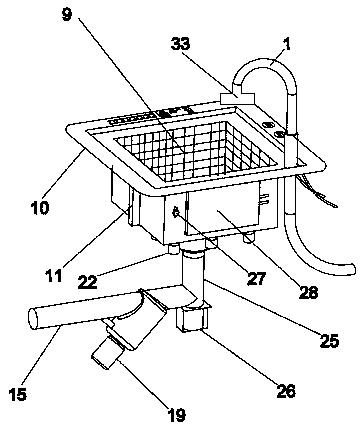

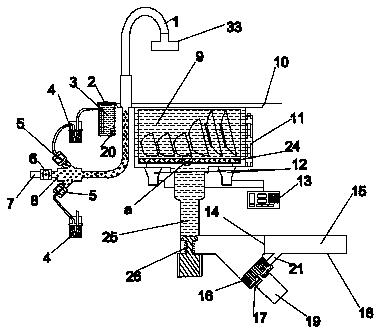

Tea set ultrasonic cleaning device

InactiveCN107595222AUniform cleaning effectEffect of cleaning effectTableware washing/rinsing machine detailsEngineeringBottle

The invention discloses a tea set ultrasonic cleaning device comprising a cleaning pool. A faucet is connected to the side portion of the cleaning pool, a filter is arranged at a water outlet of the faucet, and a cleaning basket is arranged in the cleaning pool. A rubber pad is arranged between the cleaning basket and the pool bottom of the cleaning pool, a water level sensor is arranged on the side face of the cleaning pool, and an ultrasonic energy converter is placed on the bottom face of the cleaning pool. A water draining pipe is connected to the middle of the bottom face of the cleaningpool, the side face, provided with the faucet, of the cleaning pool is connected with a bottle, and the lower portion of the bottle is connected with a liquid pumping pump through a water pipe. The liquid pumping pump is connected with a second electromagnetic valve through a water pipe, the second electromagnetic valve is connected with a diluter, the diluter is connected with the tail of the faucet through a water pipe, and the rear portion of the diluter is connected with a tap water feeding pipe through a first electromagnetic valve. According to the tea set ultrasonic cleaning device, thecleaning speed is high, the effect is good, the cleanliness is high, damage to the surface of a cleaned object is avoided, the inner wall of the cleaning pool is coated with an anti-sticking coating,and stains are not prone to being stuck, so that the cleaning effect of the device is improved, and the service life of the device is prolonged.

Owner:兰溪市拜瑞珂科技服务有限公司

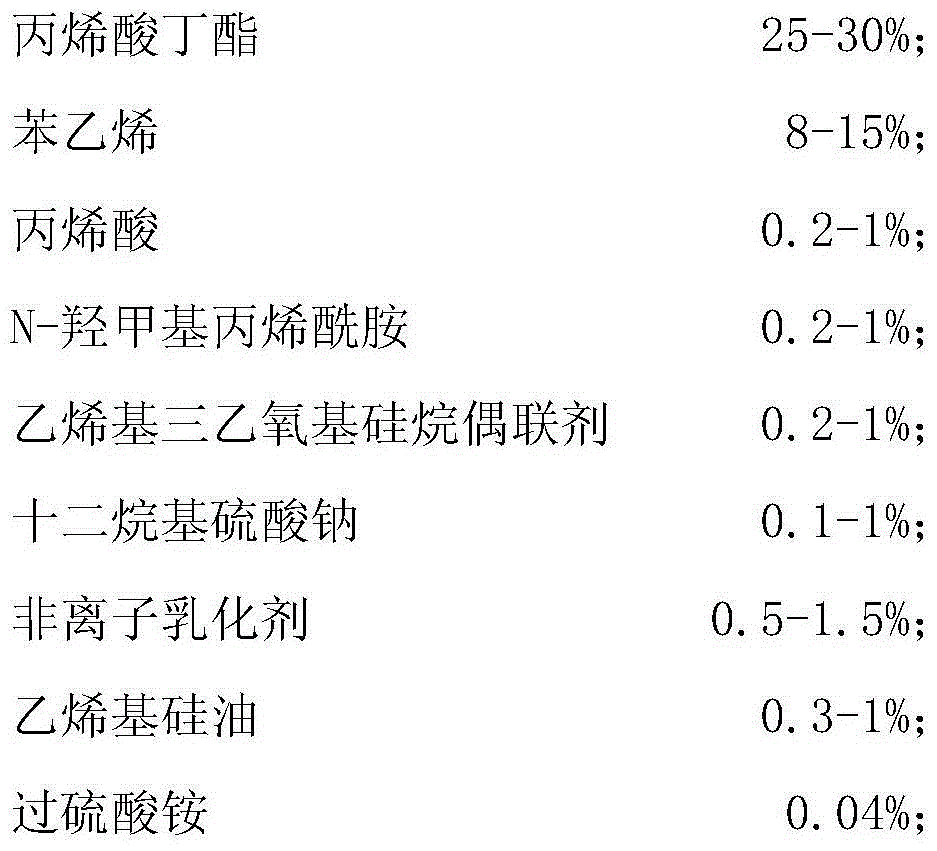

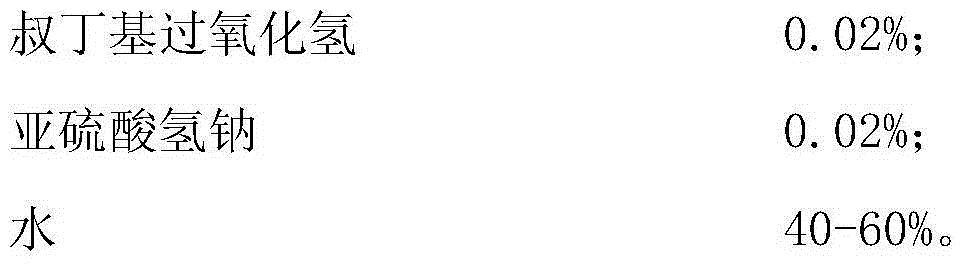

Anti-stick mucilage resin and preparation method thereof

The invention discloses anti-stick mucilage resin and a preparation method thereof. The mucilage resin comprises butyl acrylate, styrene, vinyl silicone oil and the like. The preparation method of the anti-stick mucilage resin comprises the steps of pre-emulsification, initial adding, dropwise adding, postprocessing and the like. The vinyl silicone oil is used as a functional monomer to take apart in a reaction so as to achieve crosslinking with resin macromolecules in the polymerization process, so that the finally-obtained mucilage resin has the characteristics of the vinyl silicone oil, and therefore the stick resistance of the dried mucilage resin is improved.

Owner:HEFEI JUHE RADIAL CHEM TECH

Waterborne anti-doodling coating

The invention discloses a waterborne anti-doodling coating. The waterborne anti-doodling coating is characterized by comprising the following components in parts by weight: 50-80 parts of pure acrylate emulsion, 0.5-1 part of wax emulsion, 0.05-0.1 part of fluoride additive, 15-20 parts of filler, 0.1-0.2 part of dispersant, 0.05-0.1 part of wetting agent and 1.0-2.0 parts of coalescing agent. The waterborne anti-doodling coating disclosed by the invention has excellent antifouling and anti-doodling functions and contaminants can be easily cleaned.

Owner:关锦池

Laser strengthening technology for surface of steel rail of railway

The invention discloses a laser strengthening technology for the surface of a steel rail of a railway. The laser strengthening technology includes the steps that the surface of the steel rail is quenched through lasers, and then a tempering technology is carried out on the steel rail through lasers. Microscopic structures of the steel rail are tempered martensite structures and are optimized with a laser processing technology, evenly-refined sorbite-or-troostite-similar tempered structures with the thickness of 0.8 mm to 1 mm can be obtained on the surface of the steel rail, high rigidity (HRC35-50) and high abrasion resistance are achieved, and meanwhile high bending strength and high fatigue strength are achieved; the sticking resistance, the creeping resistance, the squashing resistance, the side abrasion resistance and the corrugation resistance of the steel rail are improved accordingly. By means of the laser strengthening technology, corrugation, side abrasion and block falling of the steel rail are remarkably reduced on the premise that the mechanical performance such as bending strength, breaking tenacity and fatigue strength of the whole steel rail is guaranteed, the stability and the corrosion resistance of the steel rail are remarkably improved, the service life of the steel rail is remarkably prolonged, the replacement time of the steel rail is prolonged, the maintenance cost of the steel rail is saved, driving resistance is reduced, fuel is saved, and the service period of the steel rail of the railway is prolonged.

Owner:WUHAN TUANJIE DIANJIN LASER MFG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com