Patents

Literature

58results about How to "Low water vapor permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenated block copolymer having alkoxysilyl group and use therefor

InactiveUS20130244367A1High glass transition temperatureImprove heat resistanceNon-fibrous pulp additionAluminium compoundsHigh humidityPolymer science

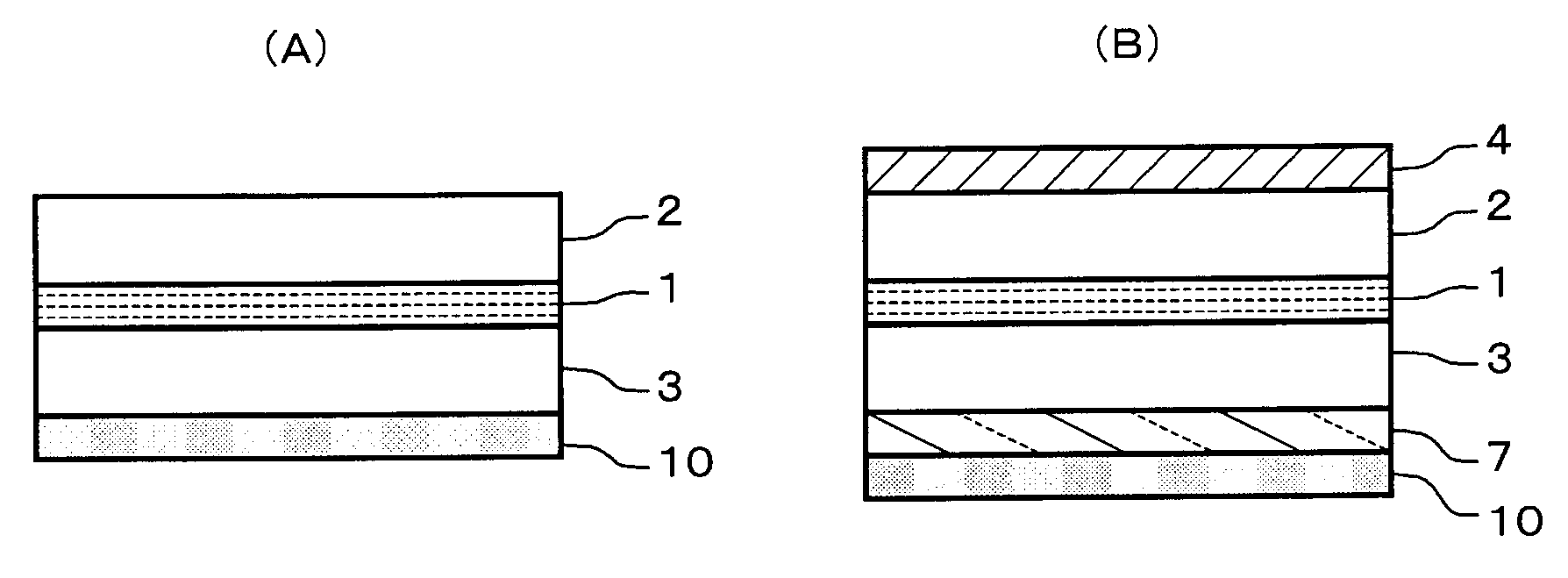

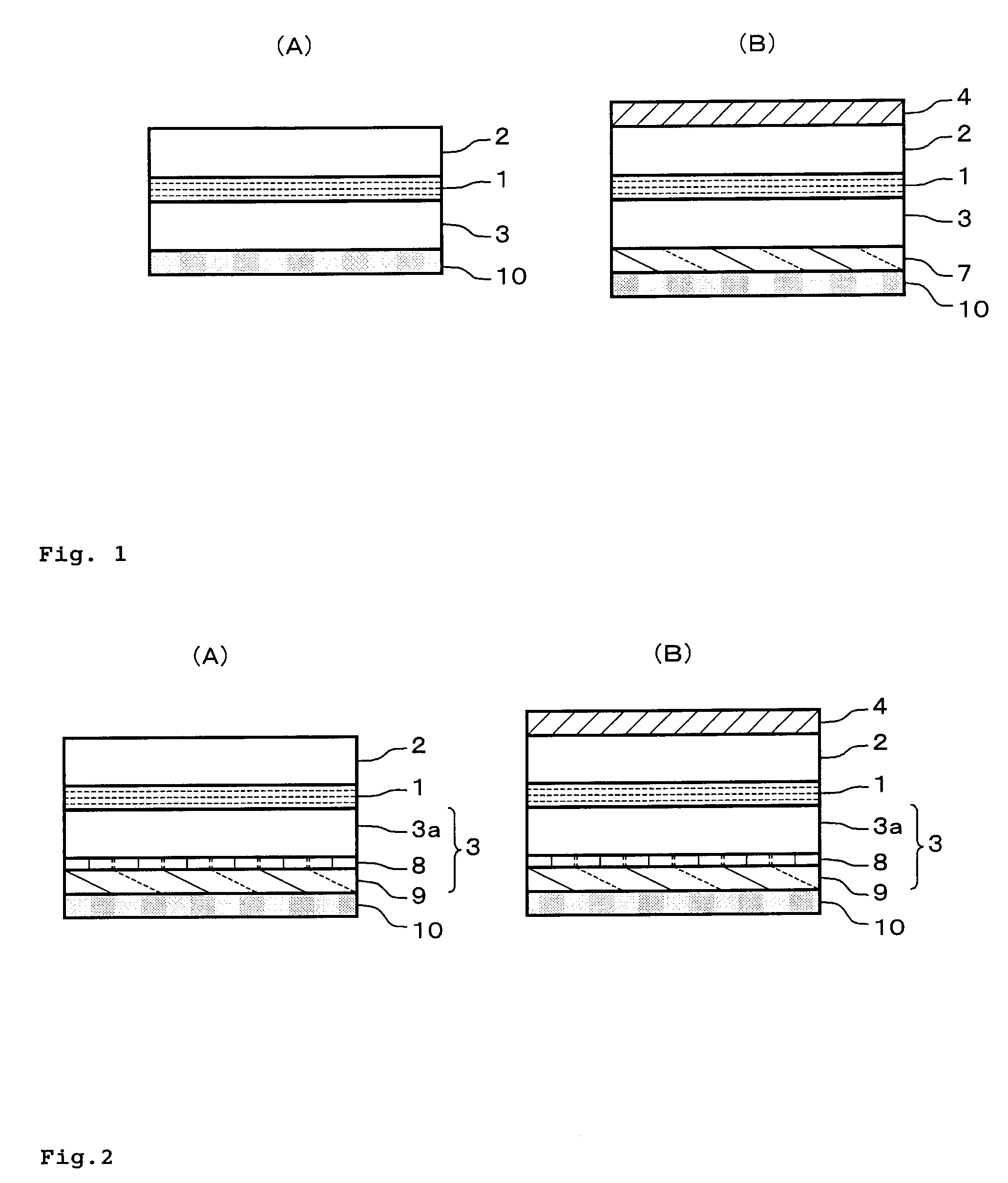

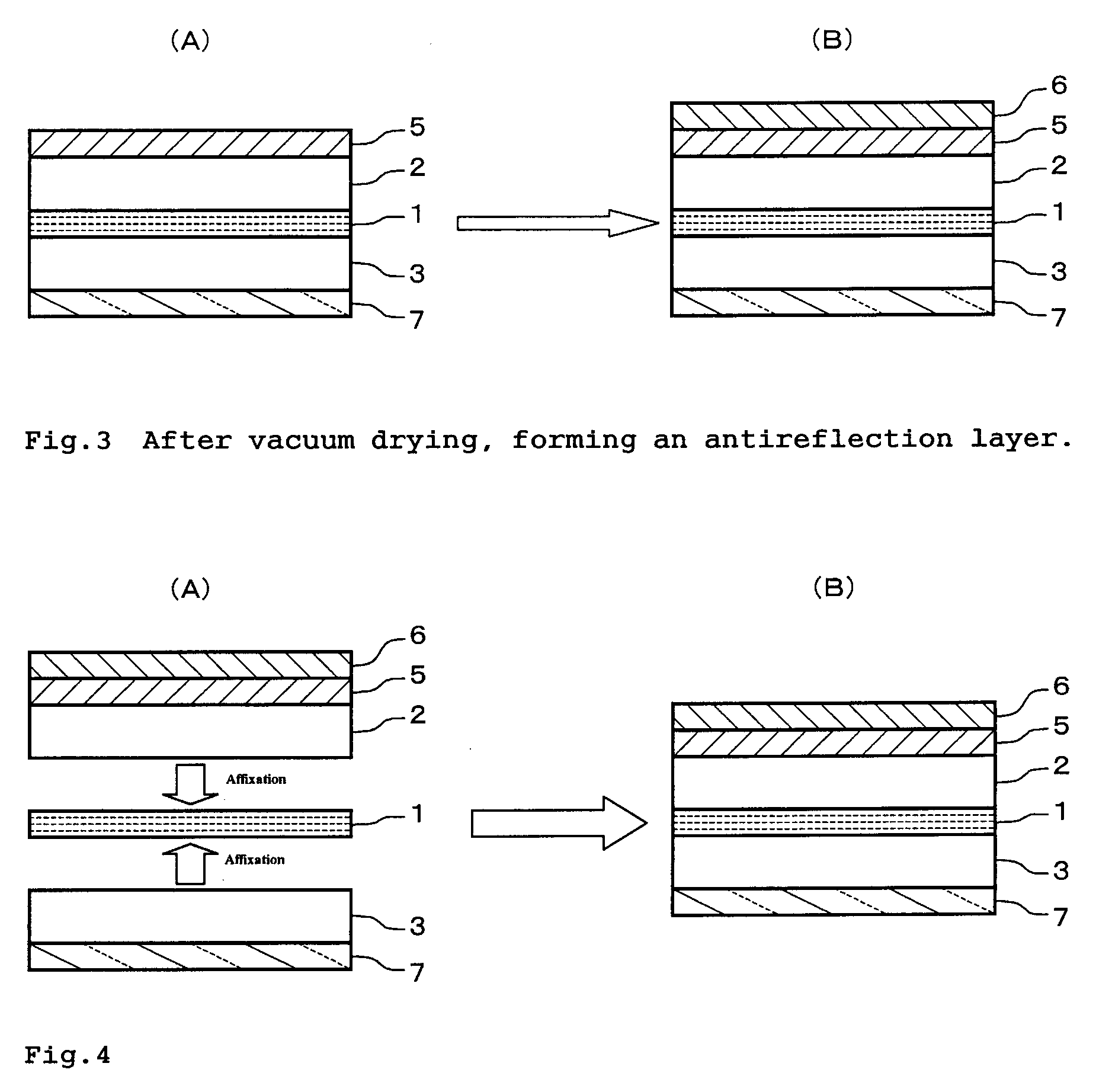

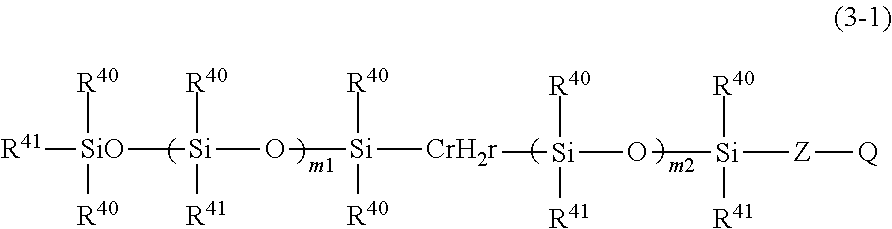

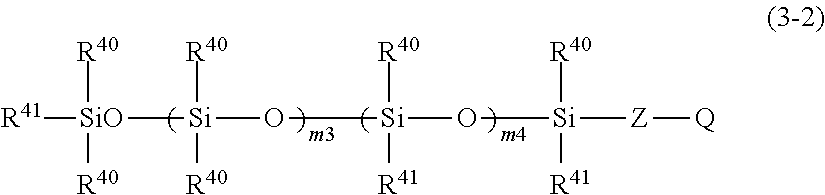

Provided are: an alkoysilyl group-containing hydrogenated block copolymer produced by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer that includes at least two polymer blocks [A] and at least one polymer block [B], the polymer block [A] including a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block [B] including a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer to a weight fraction wB of the polymer block [B] in the block copolymer being 20:80 to 60:40; a method for producing the same; a solar cell element encapsulating material; a sheet, a laminated sheet; a multilayer sheet; and a method for encapsulating a solar cell element. The alkoxysilyl group-containing hydrogenated block copolymer exhibits low hygroscopicity, a low water vapor permeability, transparency, weatherability, and flexibility, maintains excellent adhesion to glass even when exposed to a high-temperature / high-humidity environment for a long time, and can encapsulate a solar cell element without applying a special waterproof treatment.

Owner:ZEON CORP

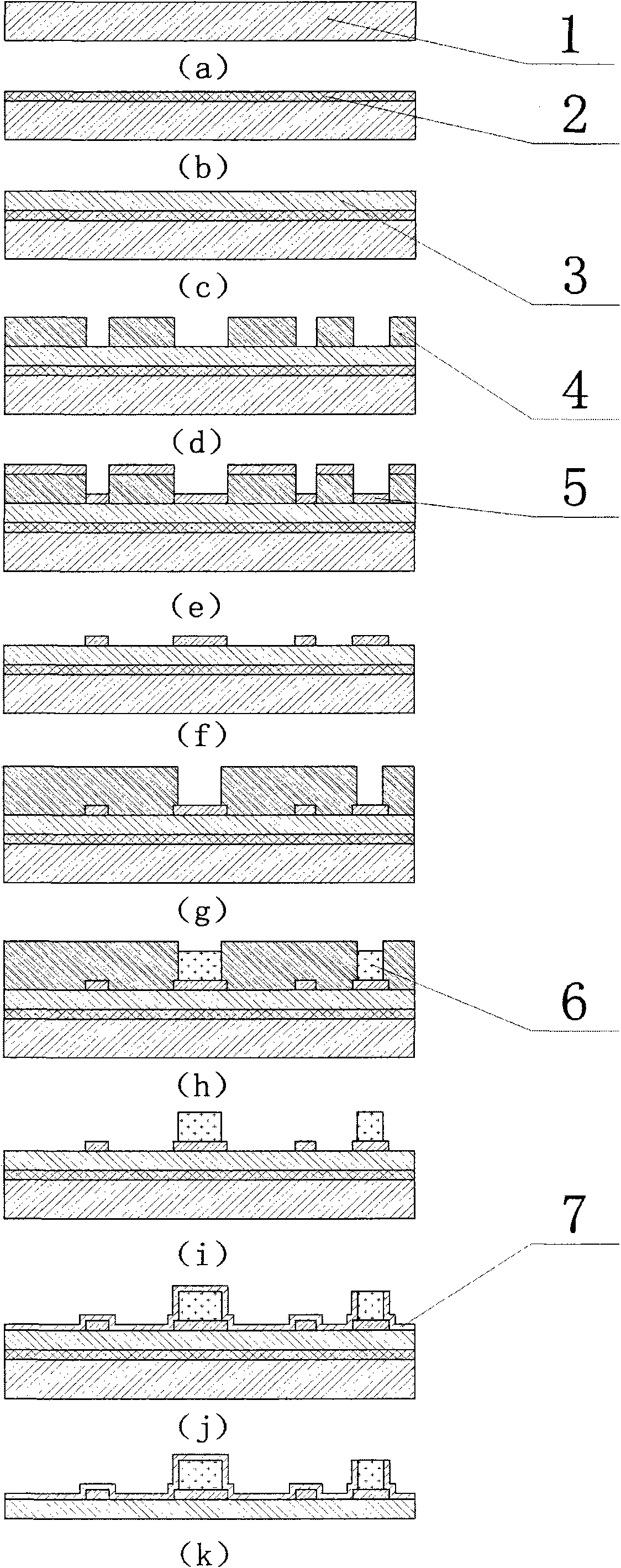

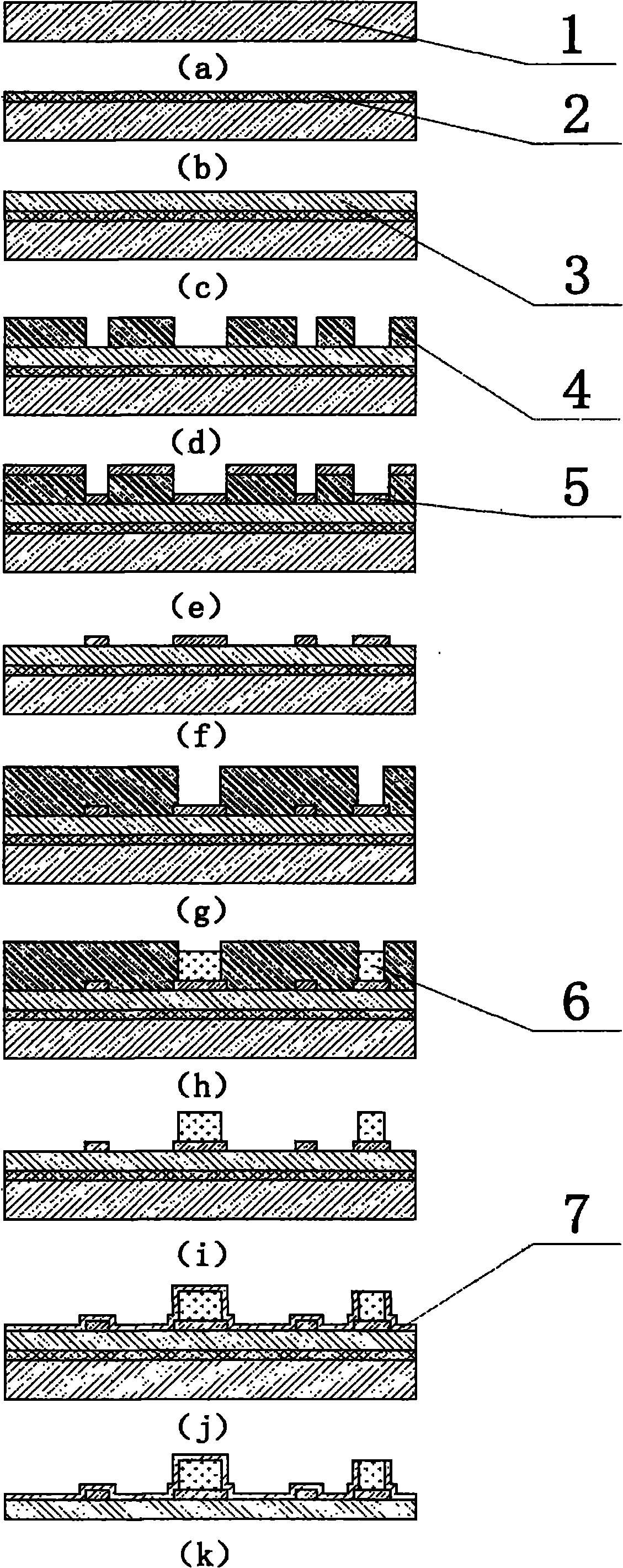

Manufacturing method of flexible heat-sensitive thin film resistor array

ActiveCN101950644AGood applicabilityGood insulation performanceNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsPrepolymerSheet resistance

The invention discloses a manufacturing method of a flexible heat-sensitive thin film resistor array, which belongs to the field of micro-electromechanical systems (MEMS). The method comprises the following steps: firstly depositing a sacrificial layer on a silicon chip; spin-coating a PI prepolymer on the sacrificial layer, and forming a PI thin film by thermocuring; then spin-coating photoresist, carrying out lithographic patterning, and sputtering a required metal heat-sensitive thin film layer; adopting the stripping method to obtain a pattern of the heat-sensitive thin film layer; then spin-coating the photoresist, carrying out the lithographic patterning, and then electroplating for forming an electrical connection metal layer; removing the photoresist, and then carrying out heat treatment on heat-sensitive resistors; and finally depositing a parylene protective layer, removing the sacrificial layer and then obtaining the flexible thin film resistor array. The flexible heat-sensitive thin film resistor array has simple process, more reliable connectivity of the heat-sensitive resistors, and small interference of conductor resistance, and can greatly improve the measurement precision when being used as a sensing element of a sensor, and be applied in moist, underwater and other environments under the condition of ensuring the sensitivity of the sensor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Thermal transfer image-receiving sheet

InactiveUS6165938AReduce the temperatureEasy to superviseSynthetic resin layered productsAblative recordingImaging qualityWater vapor

A thermal transfer image-receiving sheet is provided which causes none of a dimensional change, curling, misregistration of image and can produce a printed image having satisfactory image quality and density. The thermal transfer image-receiving sheet comprises: a paper substrate; and a dye-receptive layer provided on one side of the substrate, a water vapor barrier layer composed mainly of a resin being provided on at least the side of the thermal transfer image-receiving sheet remote from the dye-receptive layer.

Owner:DAI NIPPON PRINTING CO LTD

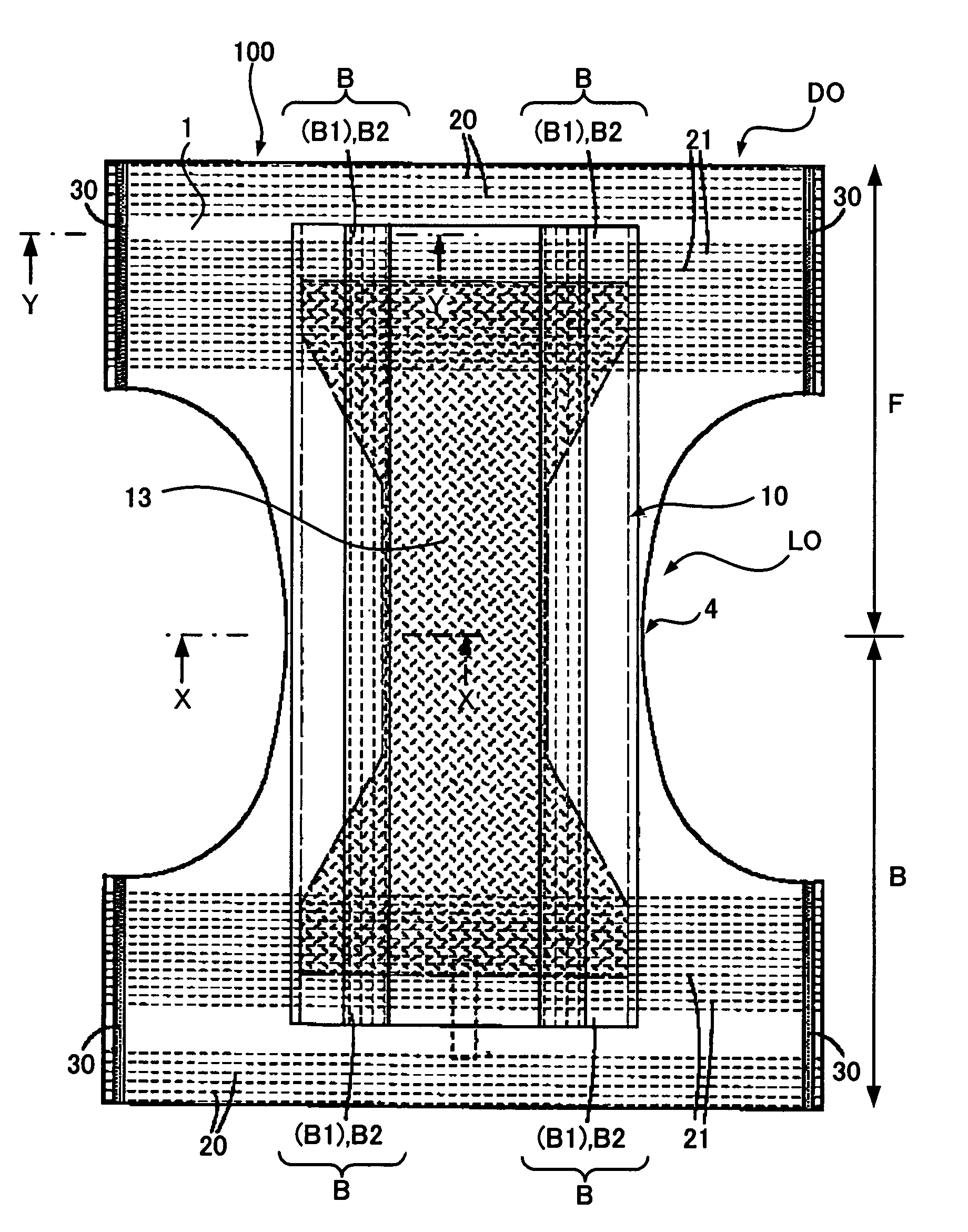

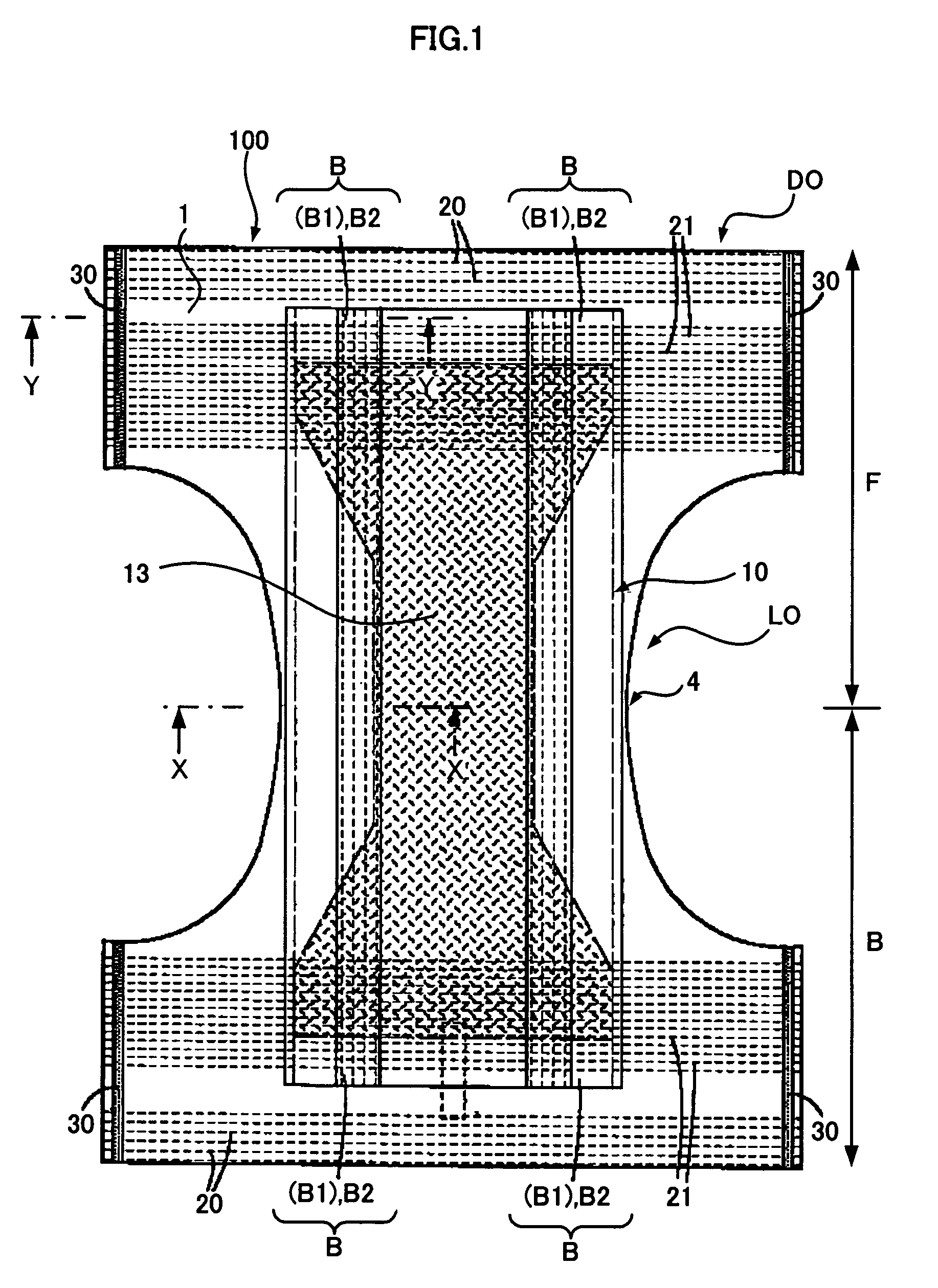

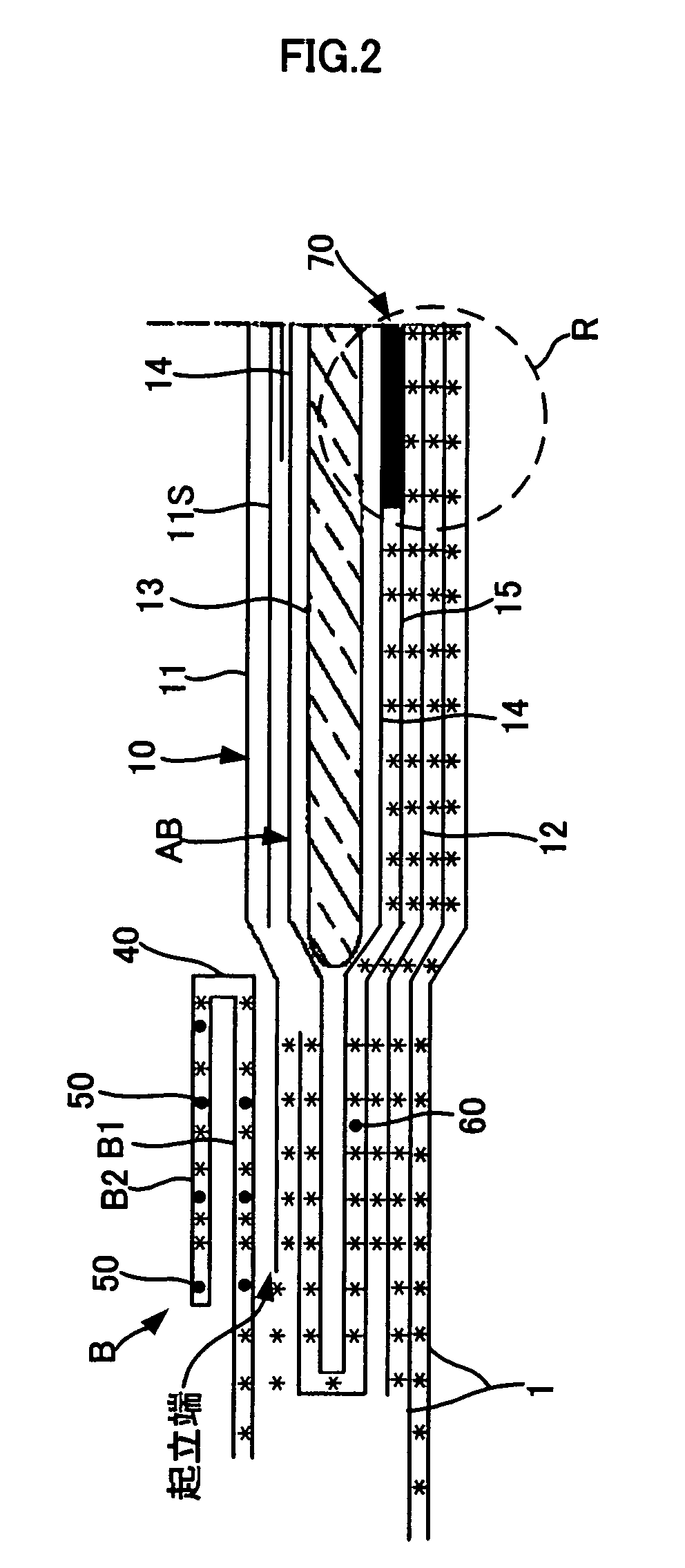

Absorbent Article

In an absorbent article structured by integrally forming at least a liquid permeable top sheet, an absorbent, a water vapor permeable waterproof sheet, and a liquid impermeable back sheet in this order, a water content indicator is provided on an inner surface of the water vapor permeable waterproof sheet, the water content indicator being constituted by a hydrophilic resin coating layer and an information mark provided on an inner surface of the hydrophilic resin coating layer.

Owner:DAIO PAPER CORP

Highly durable polarization plate and liquid crystal display

InactiveUS20070092662A1Improve moisture resistanceRetain its optical qualityLiquid crystal compositionsPolarising elementsTectorial membraneLiquid-crystal display

The present invention provides a polarizer comprising a polarizing film, a first transparent protective film and a second transparent protective film, the polarizing film being between the first transparent protective film and the second transparent protective film, wherein the first transparent protective film has a water-vapor permeability of 50 g / m2·24 hours or less at 40° C. under a relative humidity of 90 % and a water content of the polarizer is 2.0% by weight or less.

Owner:SUMITOMO CHEM CO LTD

Granulate or powder for producing coating or binding agents for medicaments

InactiveUS7175857B2Reduce dust generationLow water vapor permeabilityPowder deliveryFibre treatmentFood supplementMeth-

The invention relates to a process for the production of granules or powders, suitable as coating agents and binders for oral or dermal pharmaceutical forms, for cosmetics or food supplements, consisting essentially of (a) a copolymer, consisting of free radical-polymerized C1- to C4-esters of acrylic or methacrylic acid and further (meth)acrylate monomers which contain functional tertiary amino groups, (b) 3 to 25% by weight, based on (a), of an emulsifier having an HLB of at least 14, (c) 5 to 50% by weight, based on (a), of a C12- to C18-monocarboxylic acid or of a C12- to C18-hydroxyl compound, where the components (a), (b) and (c) are simultaneously or successively blended or mixed with one another, optionally with addition of a pharmaceutical active compound and / or further customary additives, fused in a heatable mixer, mixed, the melt is cooled and comminuted to give granules or powders.

Owner:EVONIK OPERATIONS GMBH

Curable Silicone Composition, And Semiconductor Sealing Material And Optical Semiconductor Device Using The Same

InactiveUS20150252220A1High refractive indexImprove heat resistanceCoatingsLuminescent compositionsHydrogen atomHydrogen

A curable silicone composition comprising: an organopolysiloxane represented by the average unit formula: (R13—SiO1 / 2)a(R12SiO2 / 2)b(R2SiO3 / 2)c(SiO4 / 2)d (wherein the R1 moieties are alkyl groups, alkenyl groups, phenyl groups, or hydrogen atoms; the R2 moieties are groups represented by R1, condensed polycyclic aromatic groups, or groups including a condensed polycyclic aromatic group, provided that at least one of the R1 and R2 moieties in the molecule is an alkenyl group or hydrogen atom and at least one R2 moiety in the molecule is a condensed polycyclic aromatic group or a group having a condensed polycyclic aromatic group; and a, b, c, and d are numbers satisfying the relationship: 0.01≦a≦0.8, 0≦b≦0.5, 0.2≦c≦0.9, 0≦d<0.2, and a+b+c+d=1); and metal oxide microparticles with an average particle size of at most 500 nm and a refractive index of at least 1.55.

Owner:DOW CORNING TORAY CO LTD

Stick-proof anti corrosion paint for internal wall of water steam pipeline

InactiveCN1724601ALow water vapor permeabilityRegular structureCorrosion preventionAnti-corrosive paintsEpoxyAlcohol

The invention discloses a method to manufacture anti-sticking antisepsis coating material used in water or gas pipeline. It is made up of film forming resin, filling, assistant agent, dispersing agent, and compounding solution. The main ingredients in film forming resin are epoxy resin, chlorinated rubber, and phenol-formaldehyde resin. The filling is made up from iron red, and talcum powder. The assistant agent is gas phase SiO2. And the compounding solution is made up from ethanol, cyclohexanol, butyl alcohol. The coating material has the advantages of easy to be manufactured, strong adhesive force, good tenacity, steady capability, and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

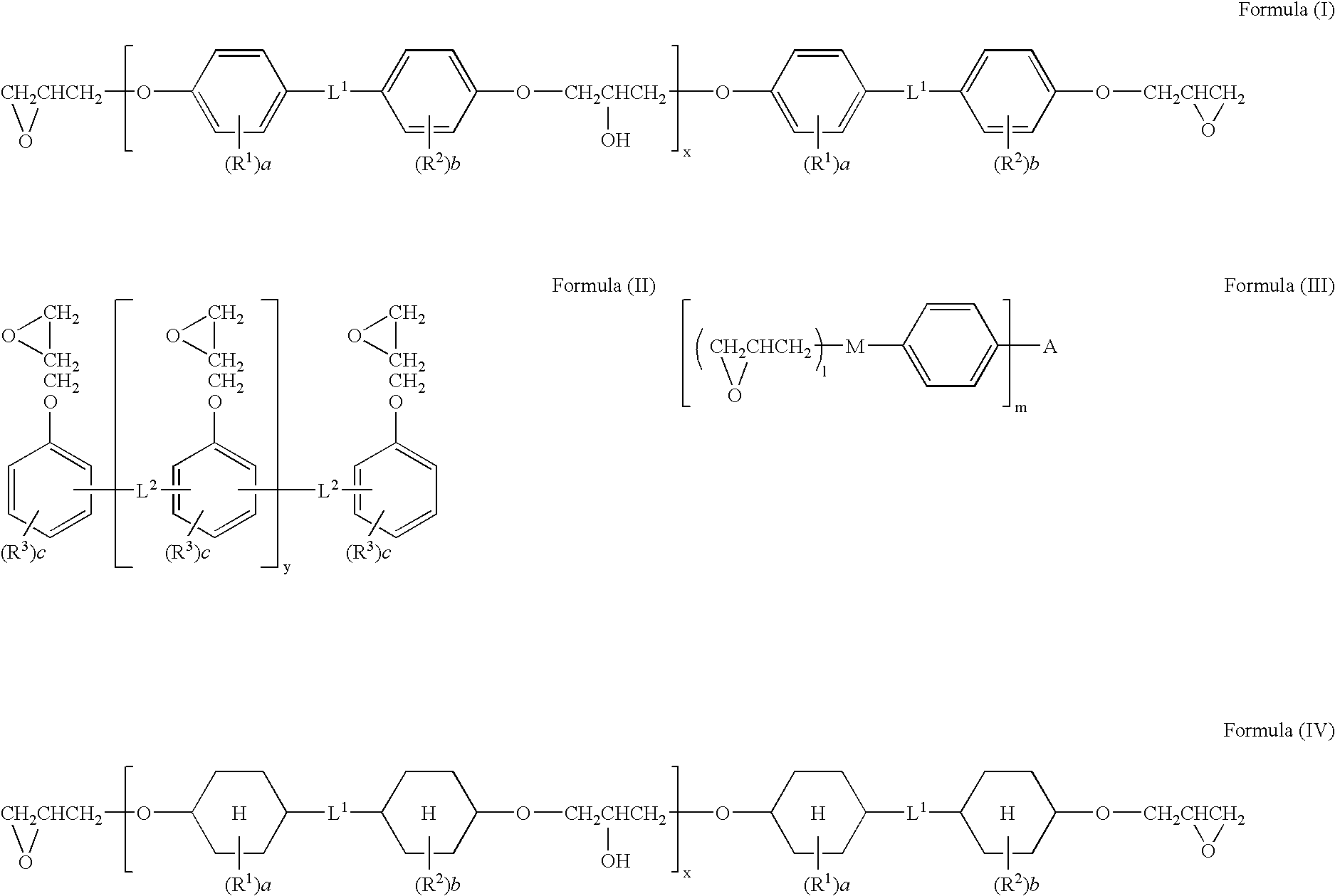

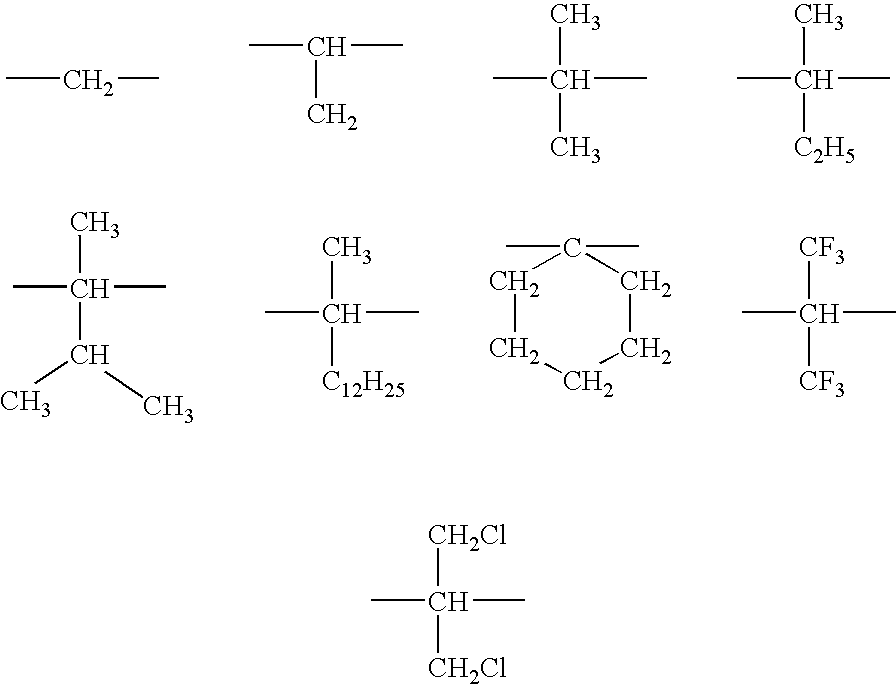

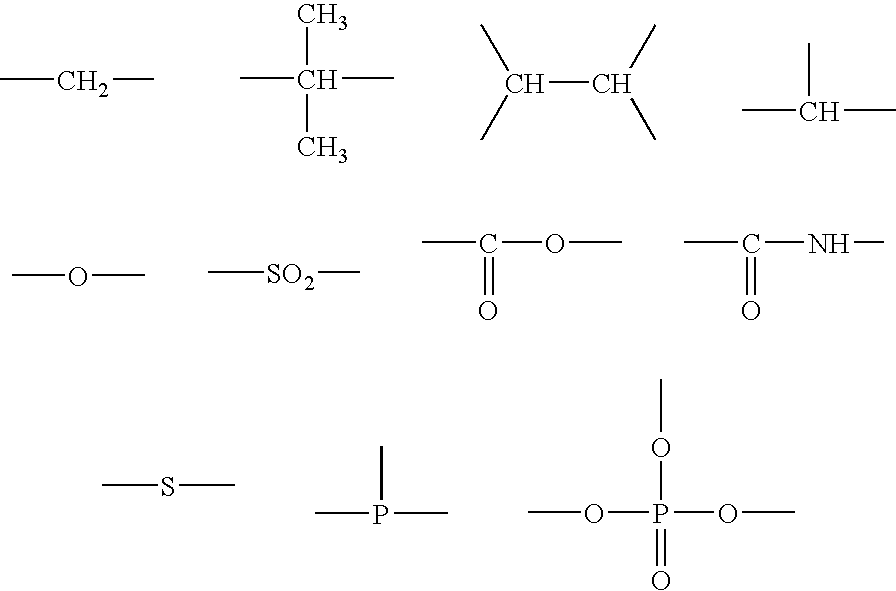

Resin composition and molded article comprising same

ActiveUS20150329750A1High transparencyImprove adhesionAdhesivesPhotovoltaic energy generationPolymer scienceCopolymer

A resin composition including an alkoxysilyl group-containing hydrogenated block copolymer [3], and a hydrocarbon-based polymer [4] having a number average molecular weight of 300 to 5000, the resin composition including the hydrocarbon-based polymer [4] in an amount of 1 to 50 parts by weight based on 100 parts by weight of the alkoxysilyl group-containing hydrogenated block copolymer [3], the alkoxysilyl group-containing hydrogenated block copolymer [3] being obtained by introducing an alkoxysilyl group into a hydrogenated block copolymer [2] that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer [1] that includes at least two polymer blocks [A] and at least one polymer block [B], and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer [1] to a weight fraction wB of the polymer block [B] in the block copolymer [1] being 30:70 to 65:35.

Owner:ZEON CORP

Gas barrier film and organic device using the same

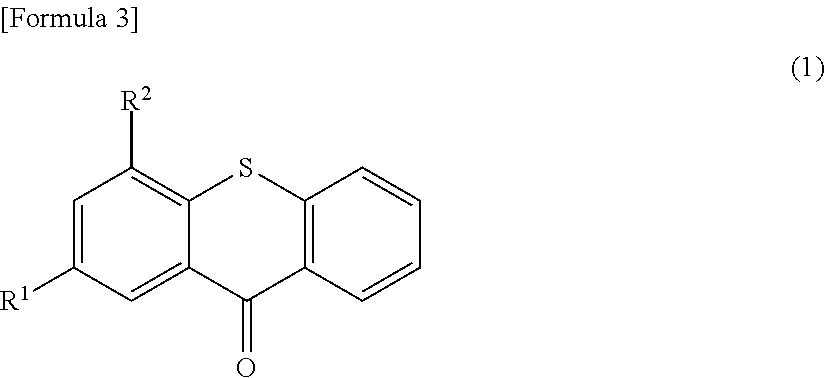

InactiveUS20080303431A1AdhesionLow gas permeabilityDischarge tube luminescnet screensLamp detailsArylPolymer

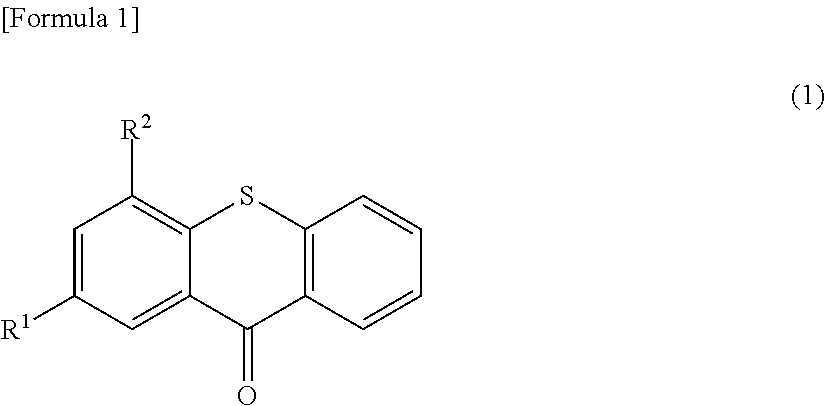

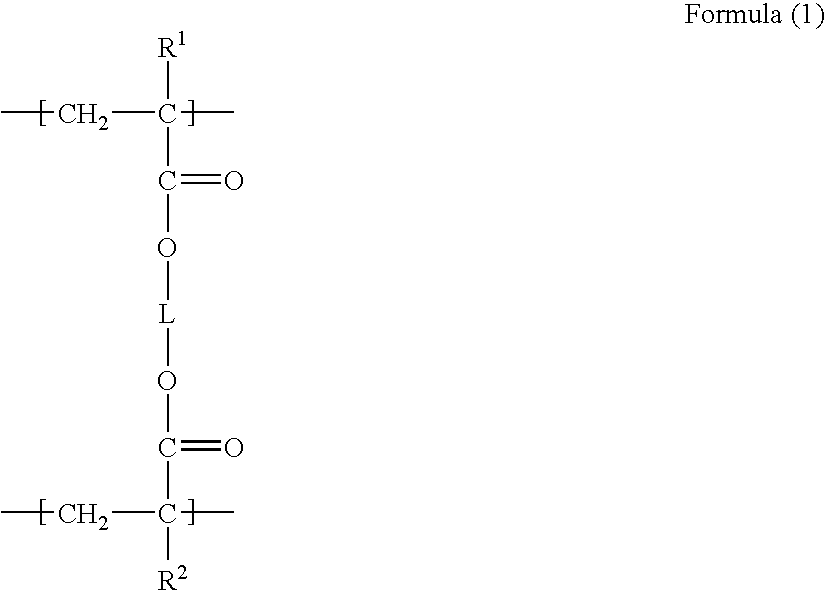

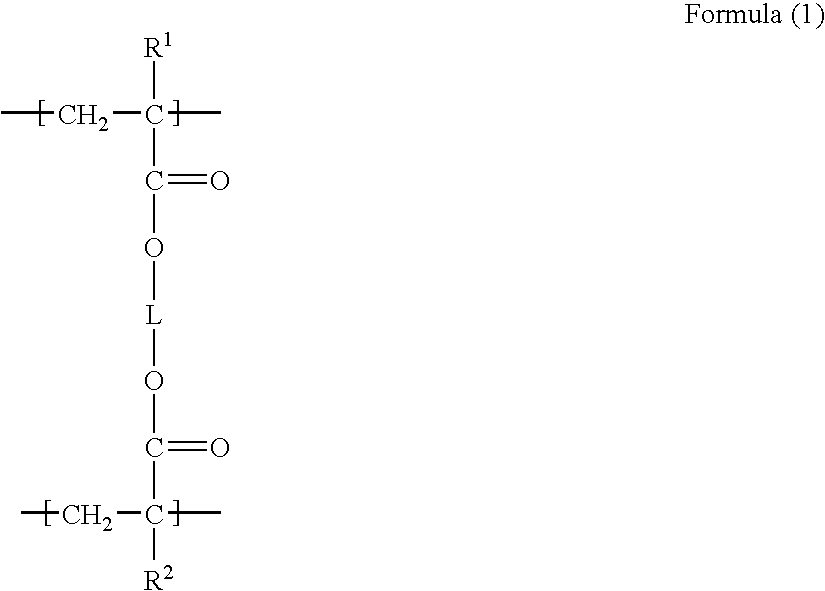

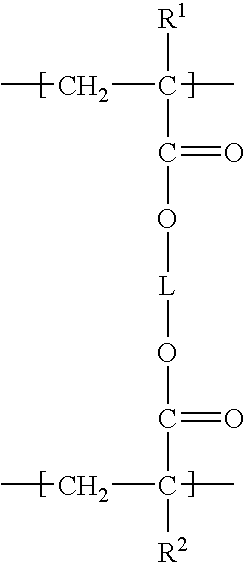

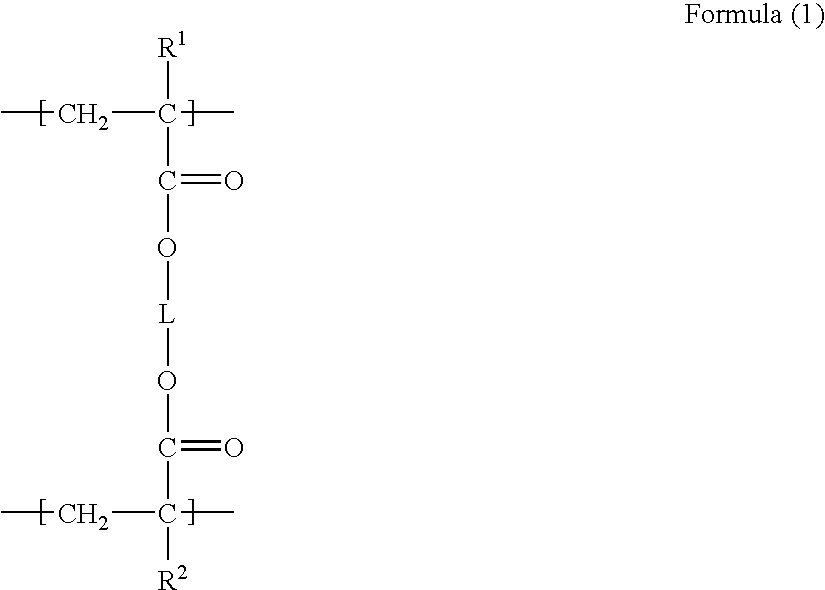

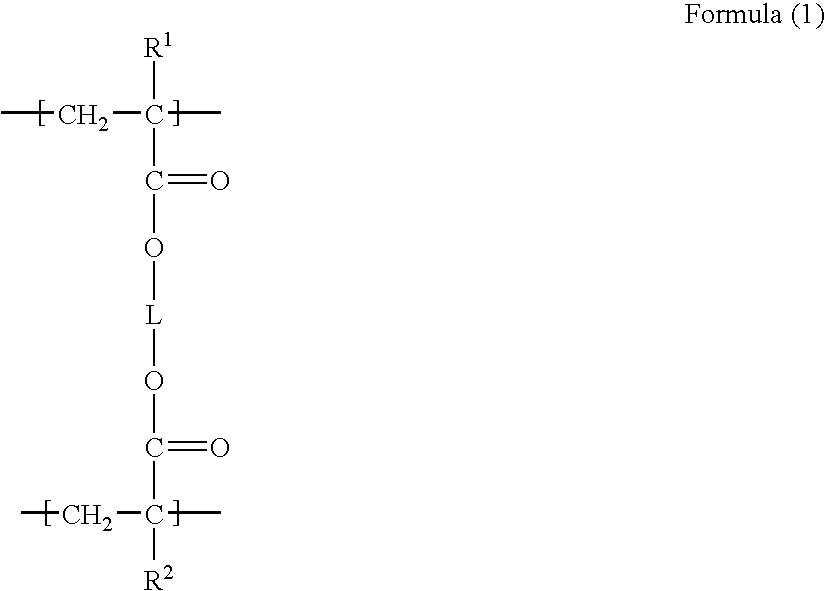

A gas barrier film having an inorganic layer and an organic layer containing a polymer compound and a non-polymerizable compound represented by the formula (1):wherein R1 and R2 represent an alkyl group having 1-20 carbon atoms or an aryl group having 6-20 carbon atoms. The gas barrier film has high barrier properties.

Owner:FUJIFILM CORP

Polarized film, optical film, and image display device

InactiveUS20150049380A1Resists change in resistanceReduce penetrationLamination ancillary operationsOptical filtersWater vapor permeabilityPolarizer

A polarizing film, comprising a polarizer; transparent protective films with a water-vapor permeability of 150 g / m2 / 24 hours or less provided on both sides of the polarizer; and adhesive layers each interposed between the polarizer and one of the transparent protective films, wherein the adhesive layers are formed by applying an active energy ray to an active energy ray-curable adhesive composition containing a radically polymerizable compound, and the transparent protective films are bonded to the polarizer with the adhesive layers.

Owner:NITTO DENKO CORP

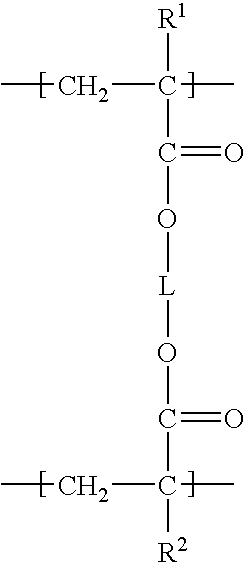

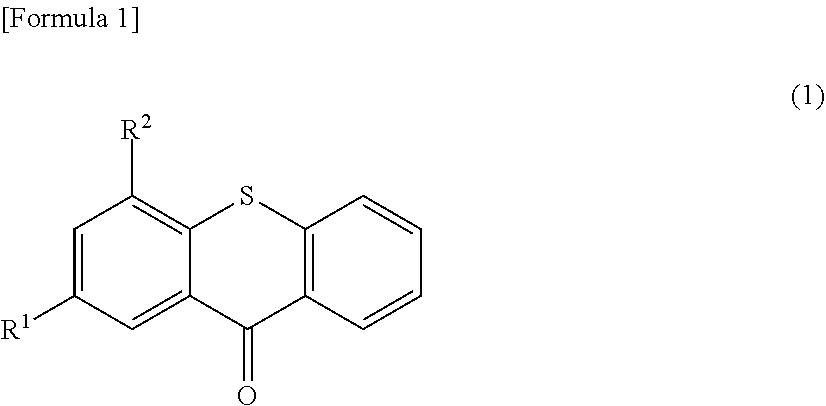

Barrier laminate, barrier film substrate, methods for producing them, and device

InactiveUS20080305350A1Increased durabilityImprove adhesionElectroluminescent light sourcesSynthetic resin layered productsHydrogen atomSulfur

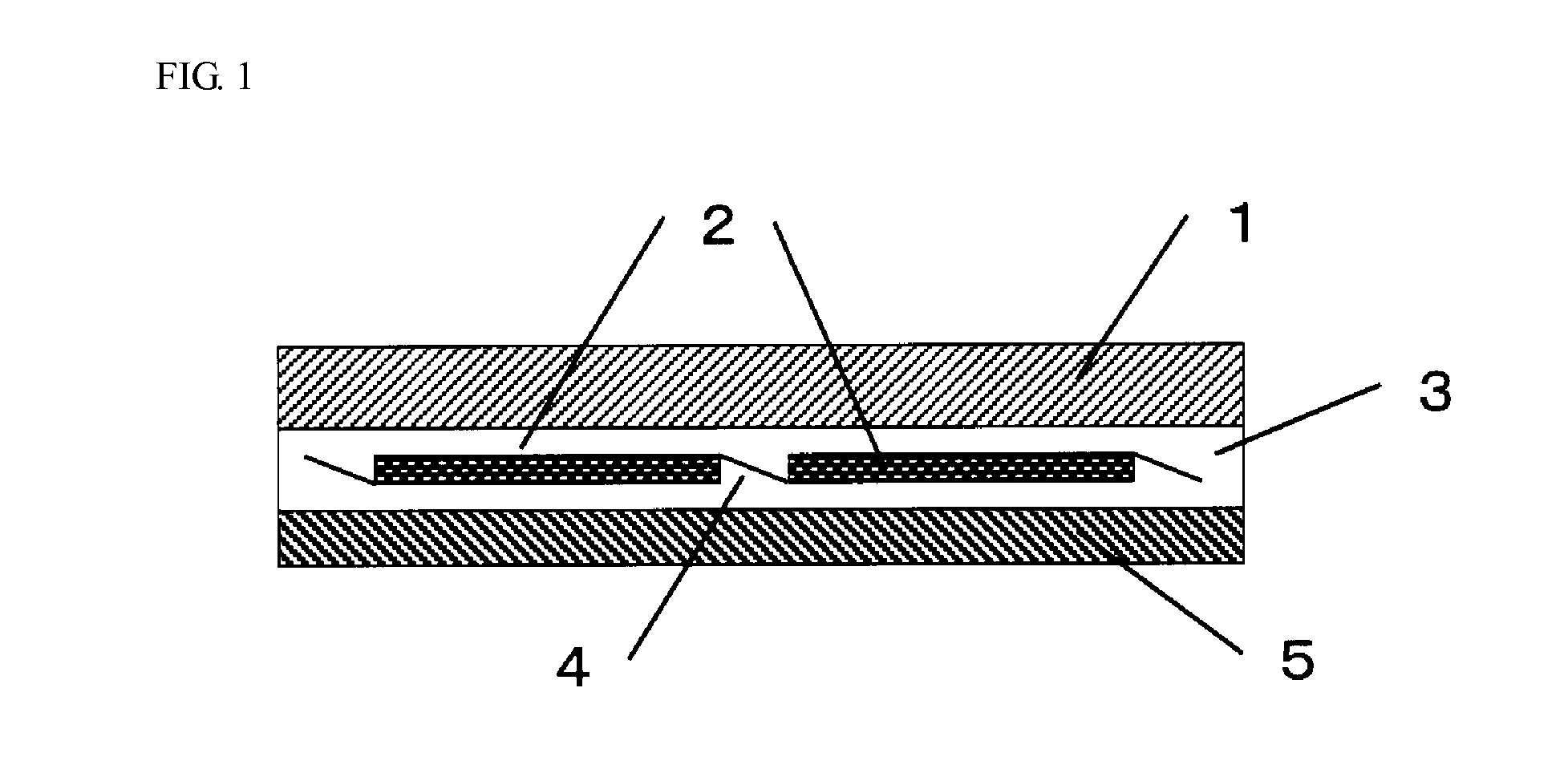

A barrier laminate comprising at least one organic layer and at least one inorganic layer, in which the organic layer comprises a polymer having a structural unit of the following formula:wherein R1 and R2 represent a hydrogen atom or a methyl group; L represents an open-chain alkylene group having at least 8 carbon atoms and not containing an oxygen atom, a nitrogen atom and a sulfur atom.

Owner:FUJIFILM CORP

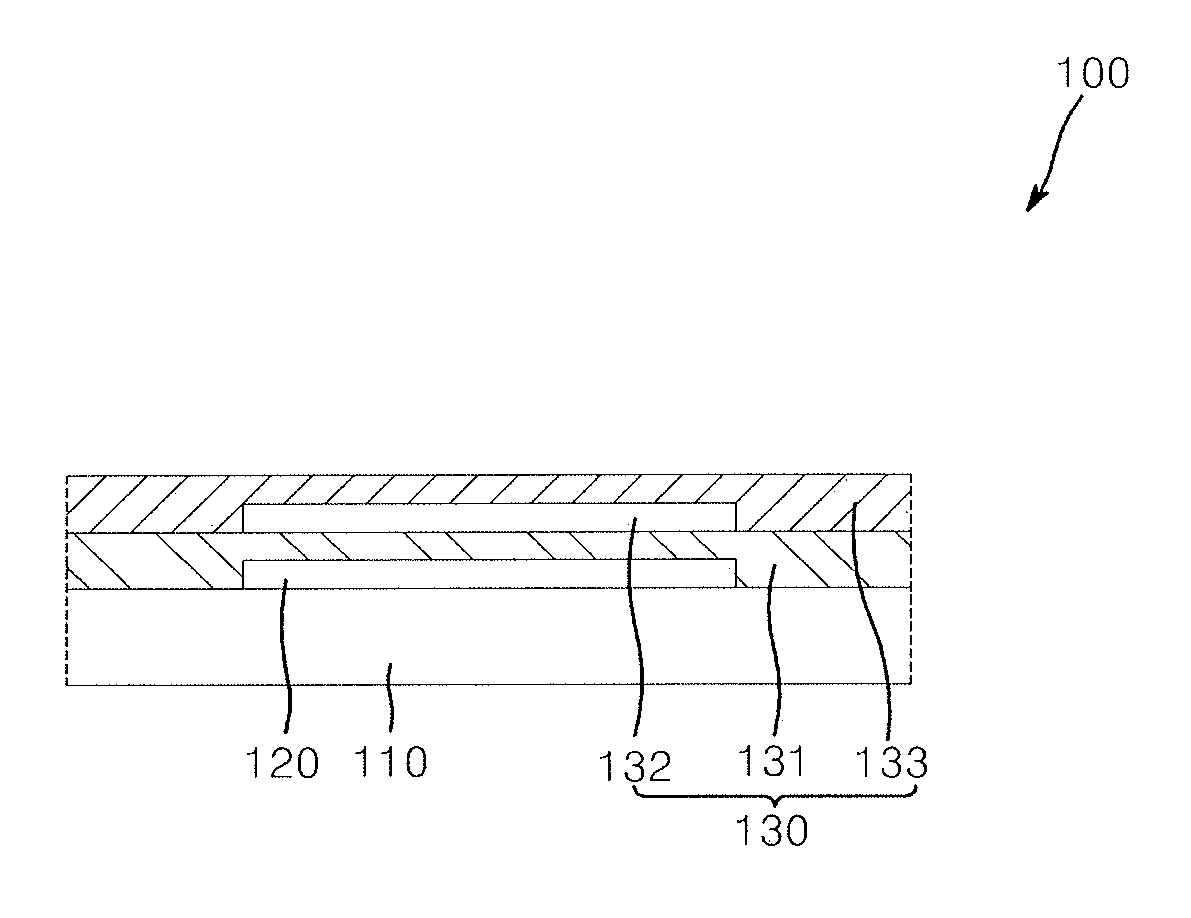

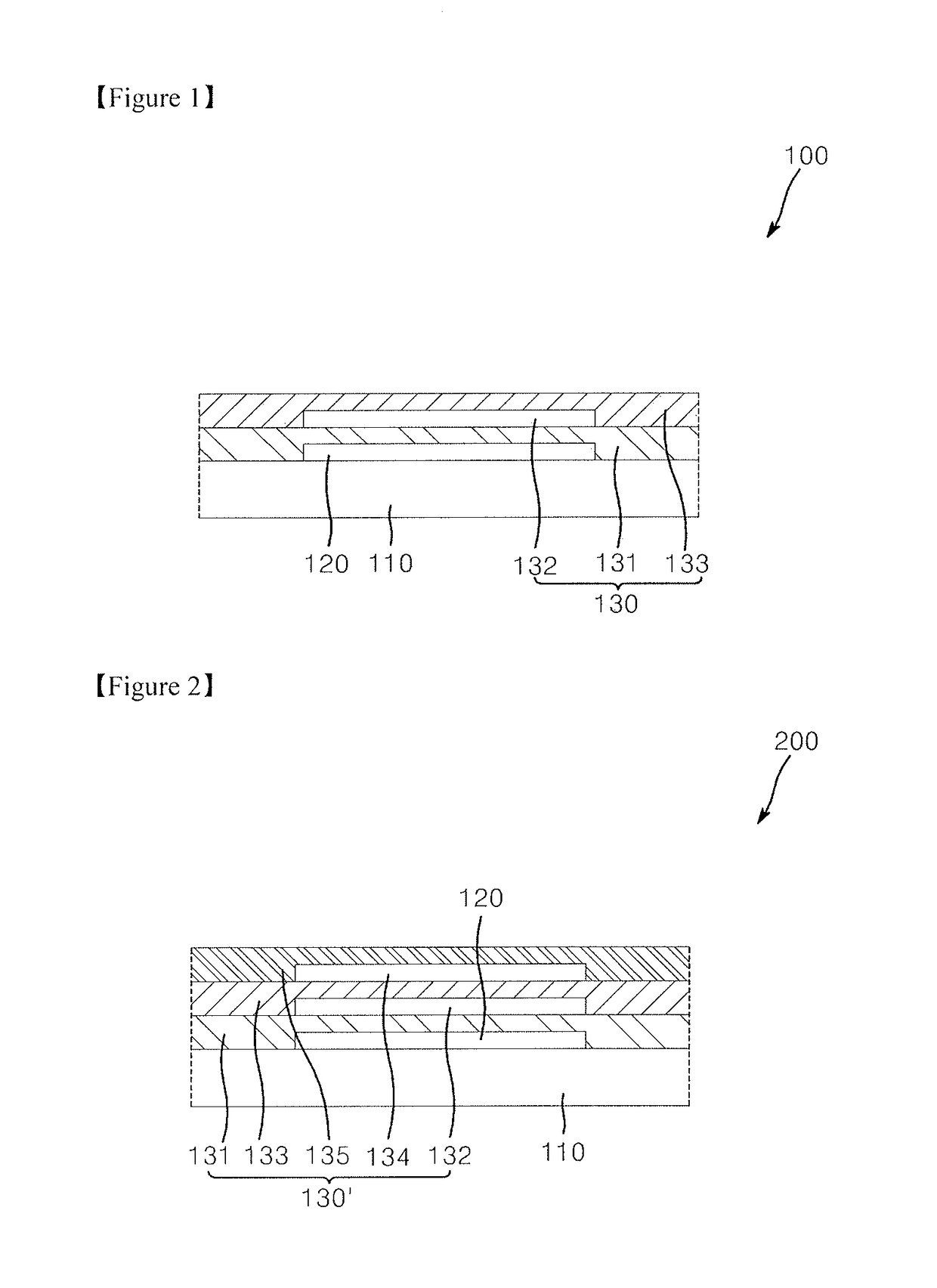

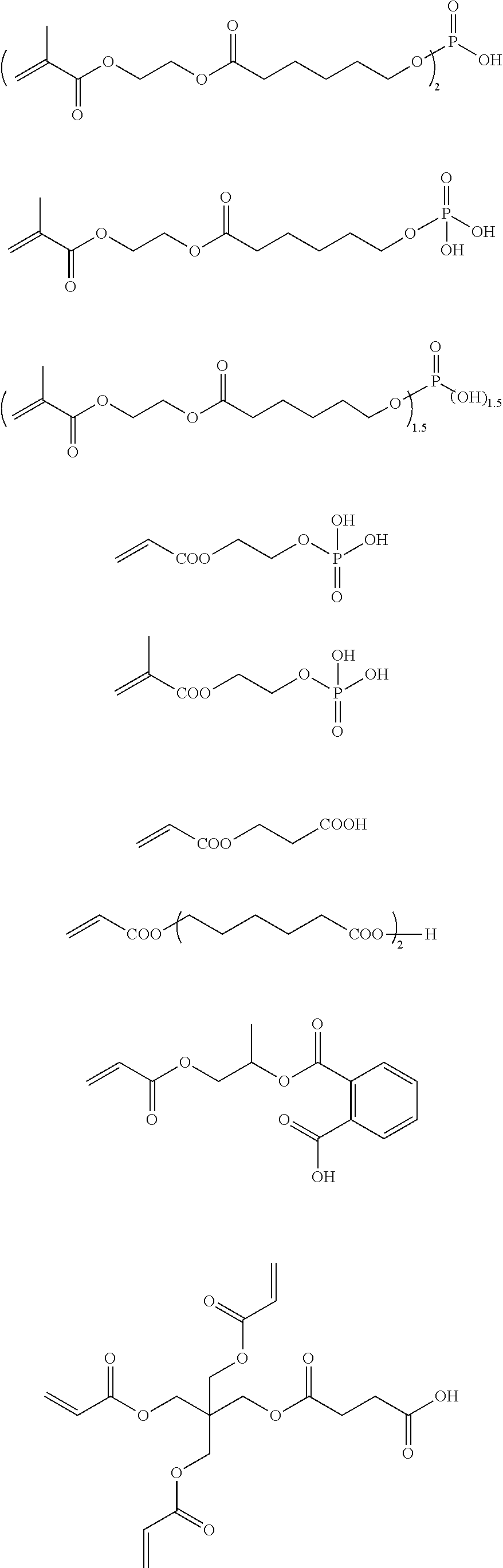

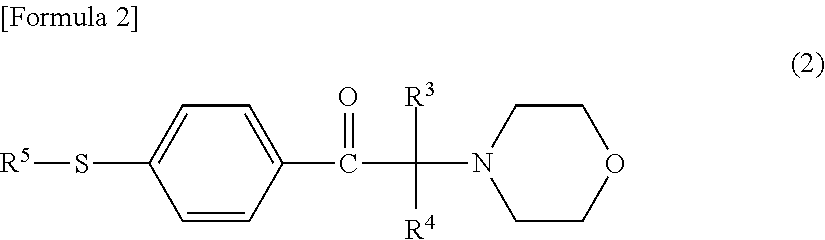

Organic light emitting display

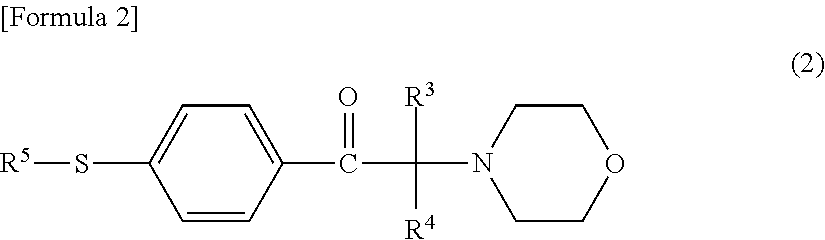

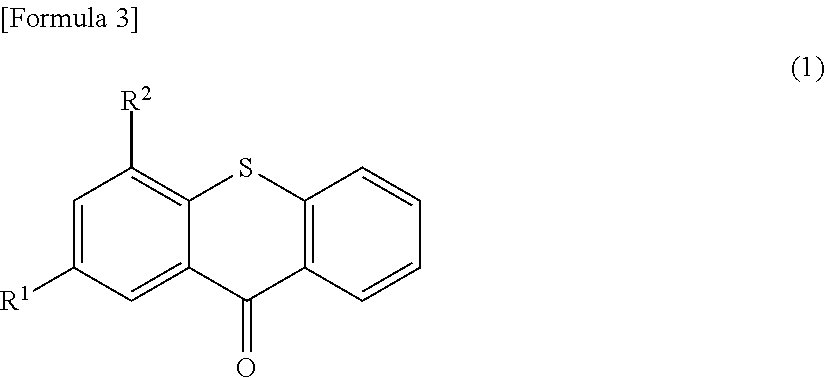

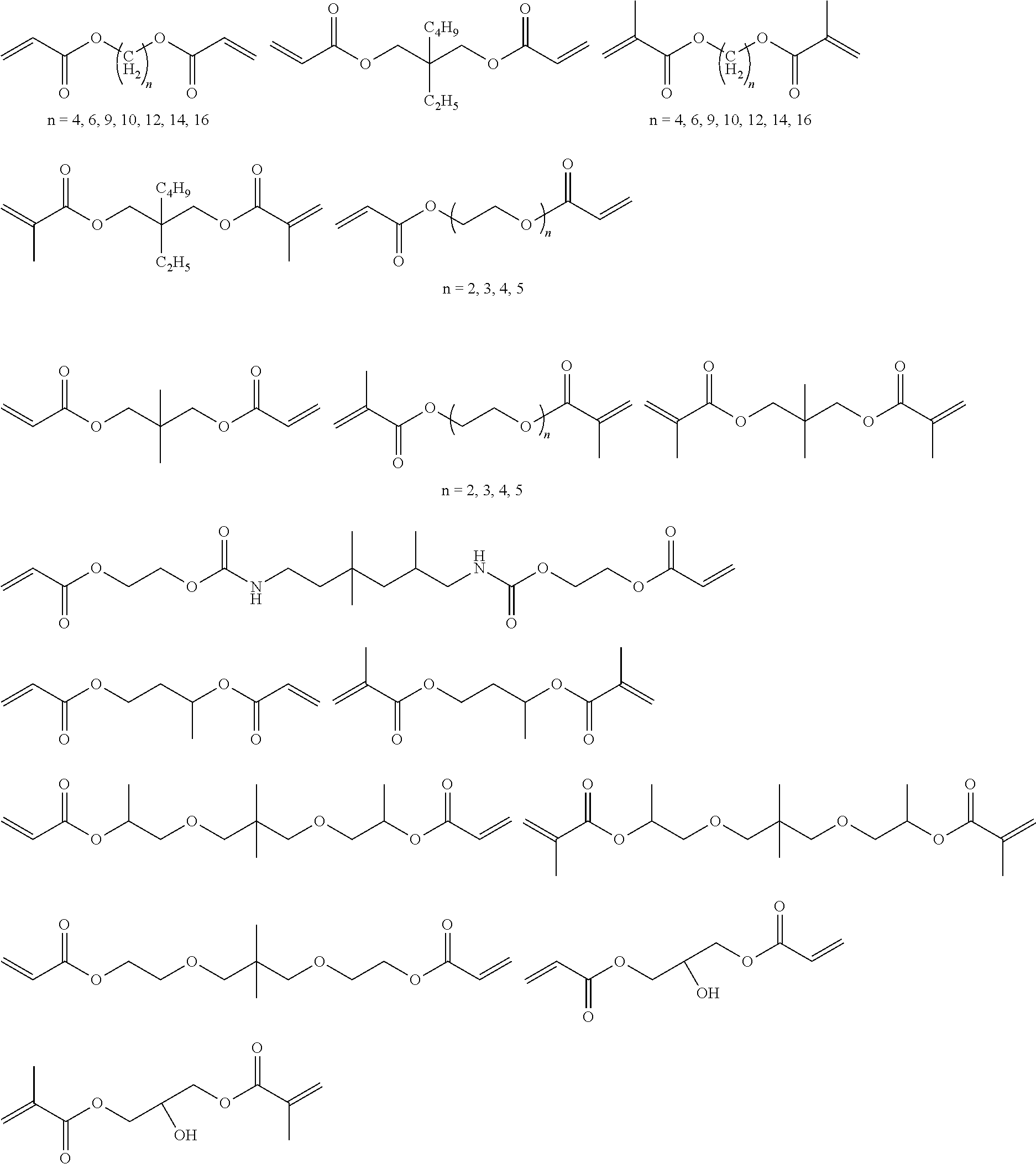

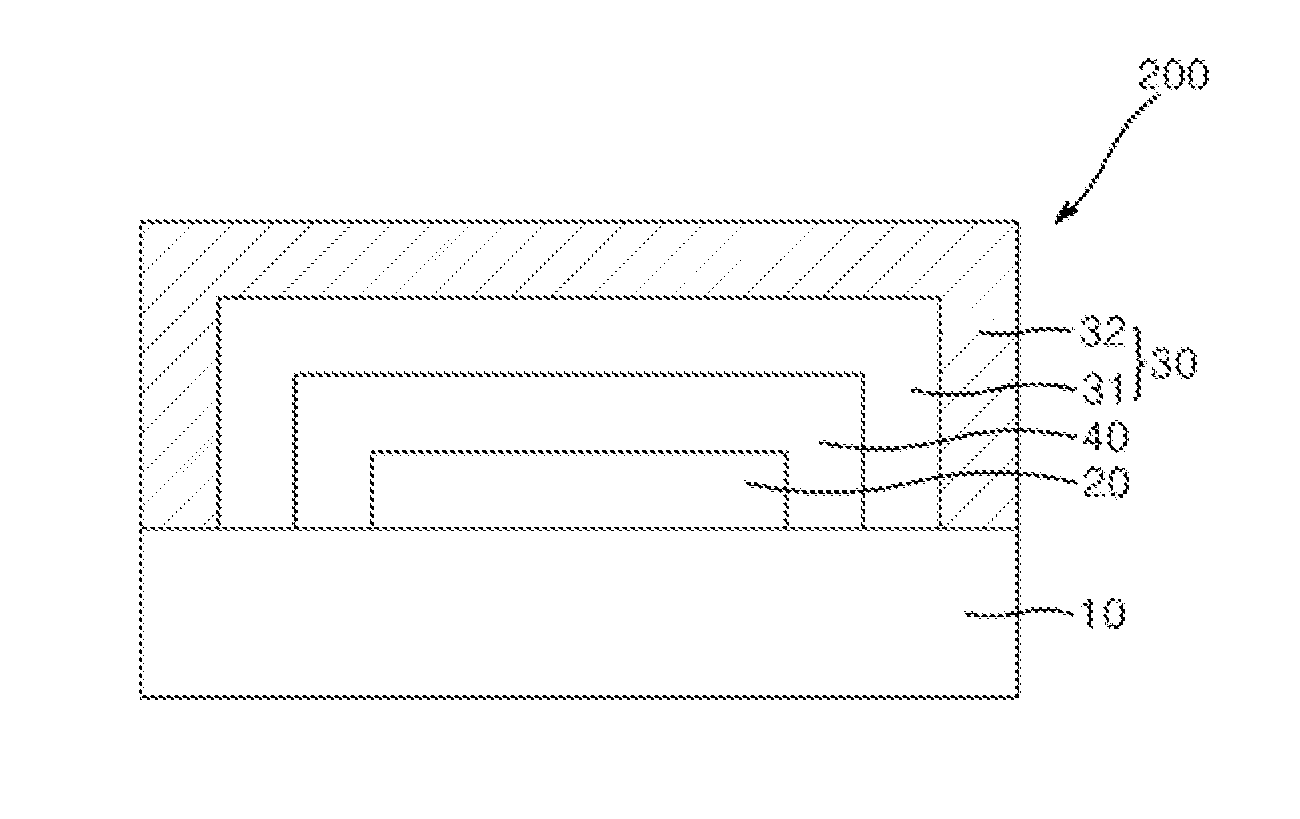

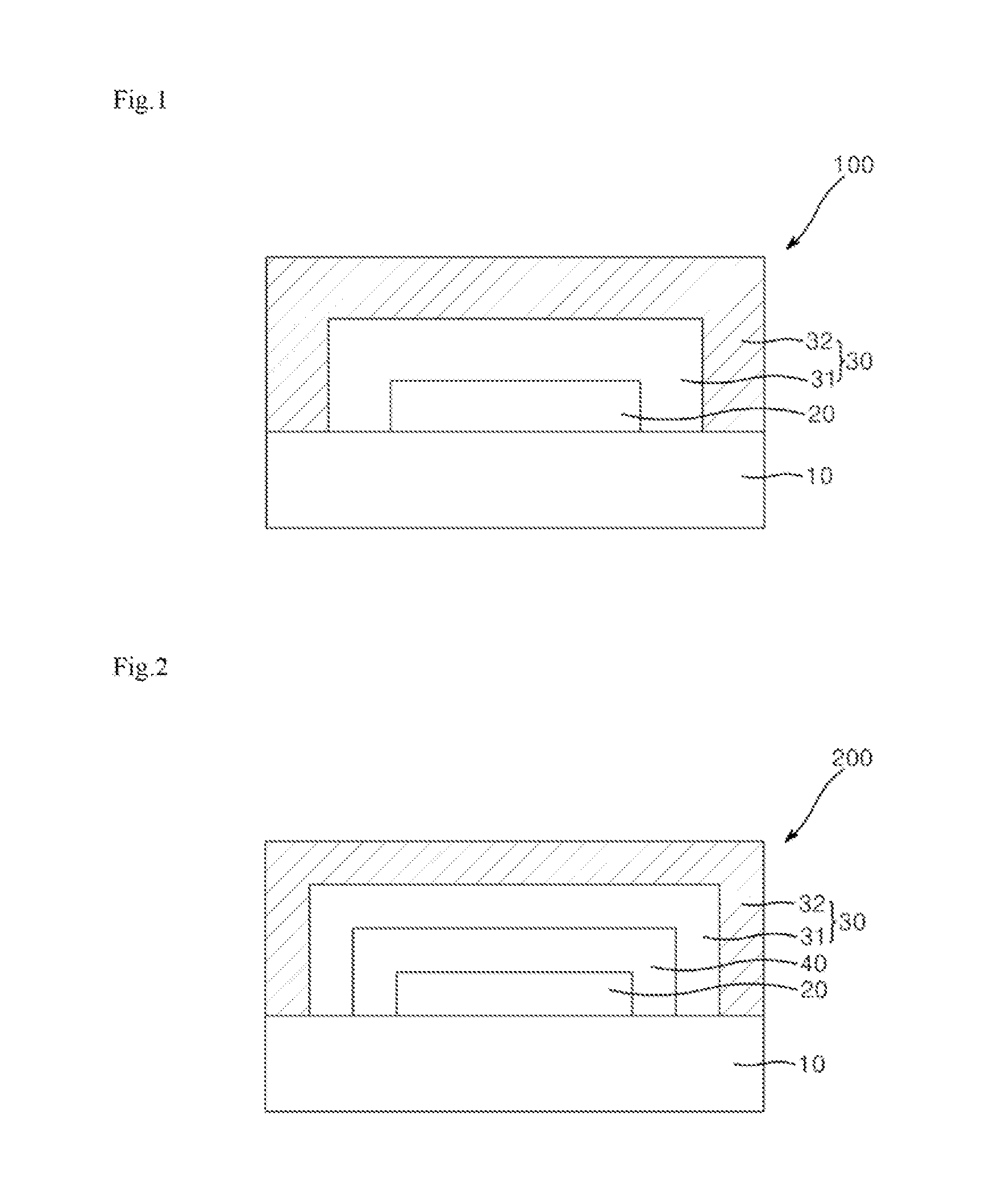

ActiveUS20180158880A1High plasma resistanceLow water vapor permeabilitySemiconductor/solid-state device detailsSynthetic resin layered productsPhysicsPhenyl group

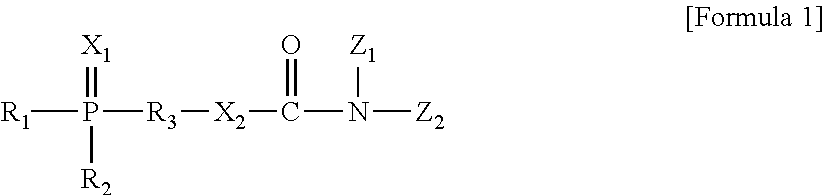

Disclosed is an organic light emitting diode display apparatus including: a substrate; an organic light emitting diode disposed on the substrate; and an encapsulation layer encapsulating the organic light emitting diode. The encapsulation layer has a structure in which two or more inorganic layers and one or more organic layers are alternately stacked one above another, two adjacent inorganic layers at least partially contact each other, and the organic layers are formed of an encapsulating composition. The encapsulating composition includes a photocurable monomer and a photopolymerization initiator. The photocurable monomer includes a monomer containing no aromatic hydrocarbon group; and a monomer having two or more substituted or unsubstituted phenyl groups represented by Formula 1. The photocurable monomer includes about 5 wt % to about 45 wt % of the monomer having two or more substituted or unsubstituted phenyl groups and about 55 wt % to about 95 wt % of the monomer containing no aromatic hydrocarbon group.

Owner:SAMSUNG SDI CO LTD

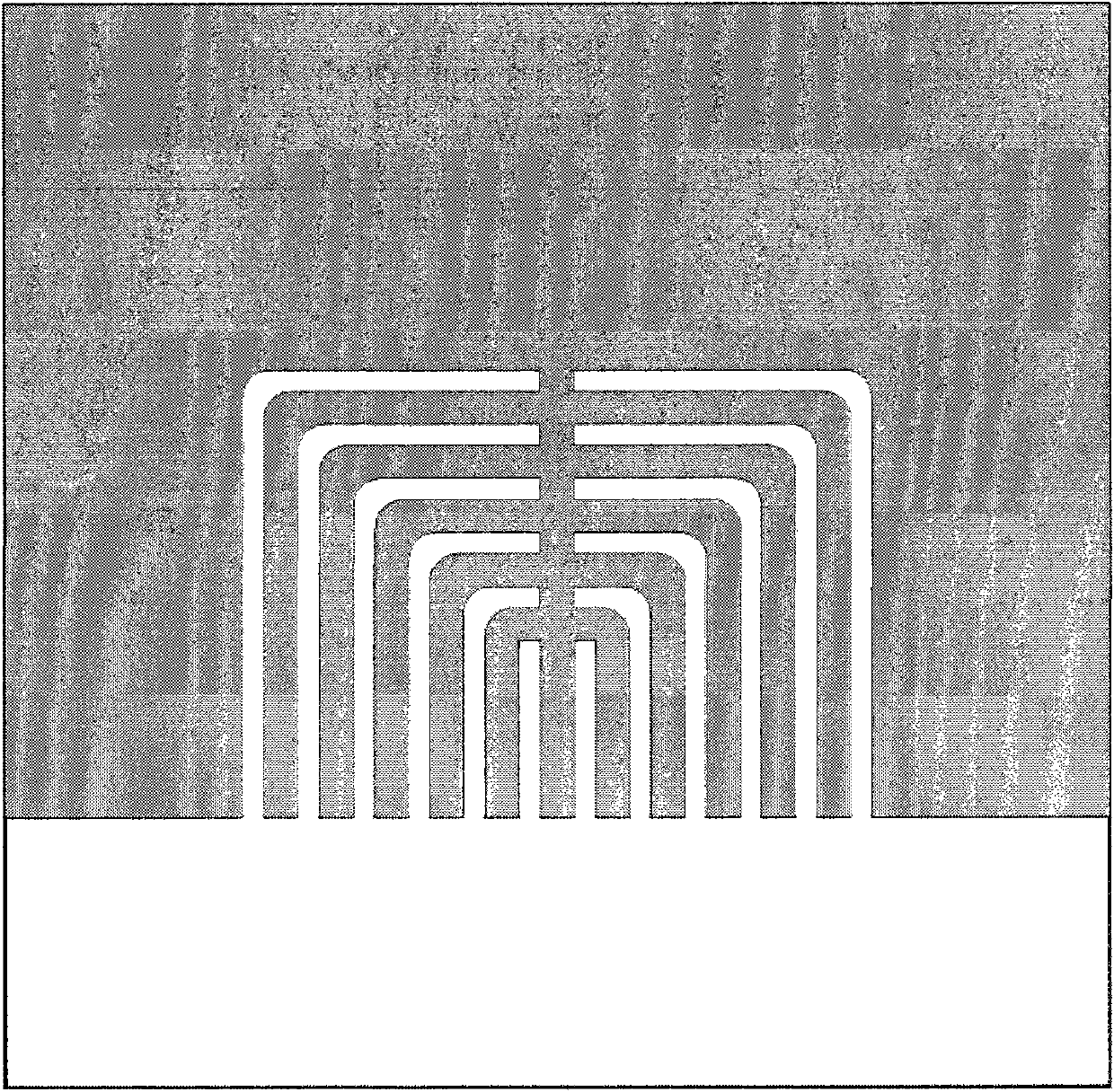

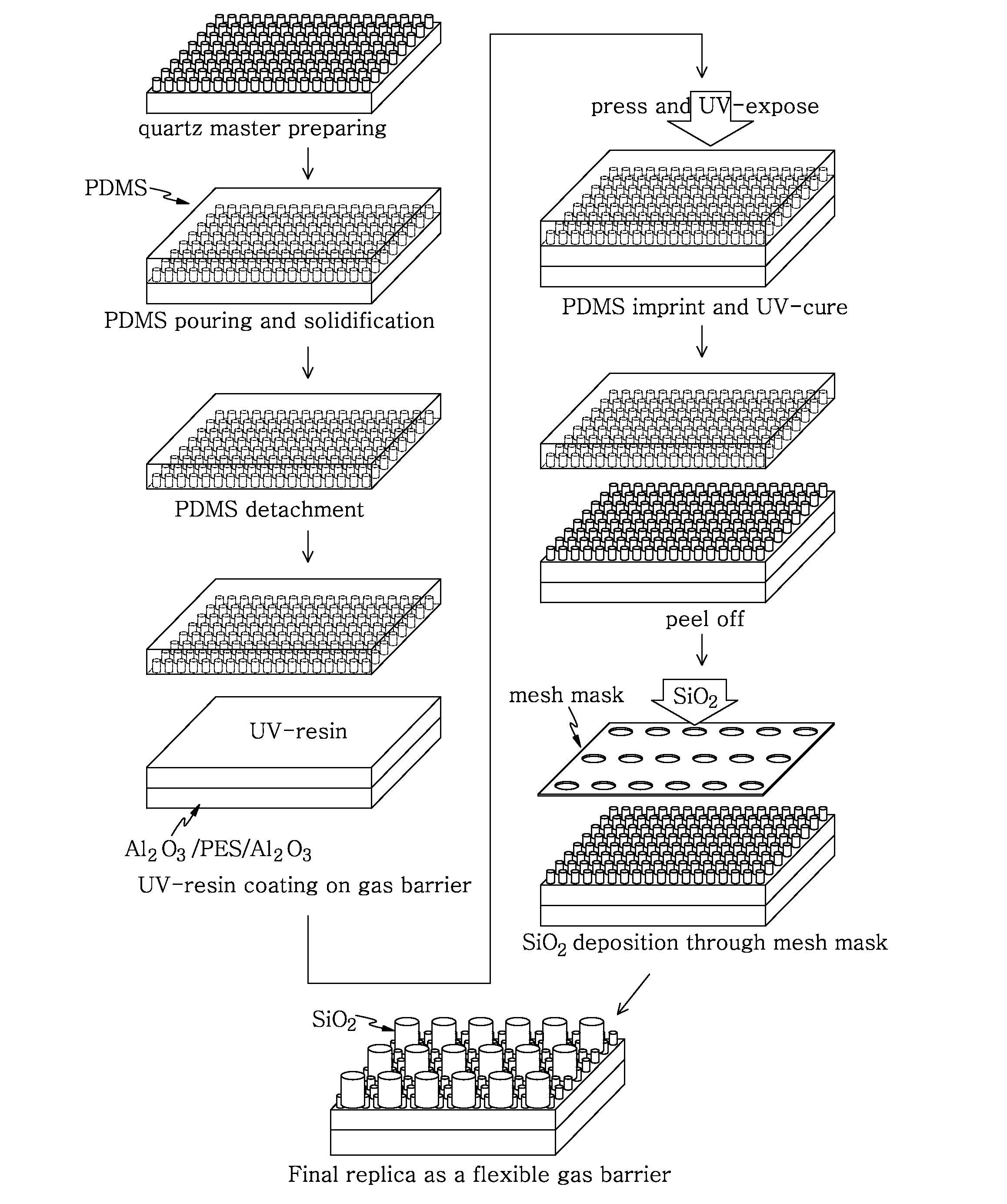

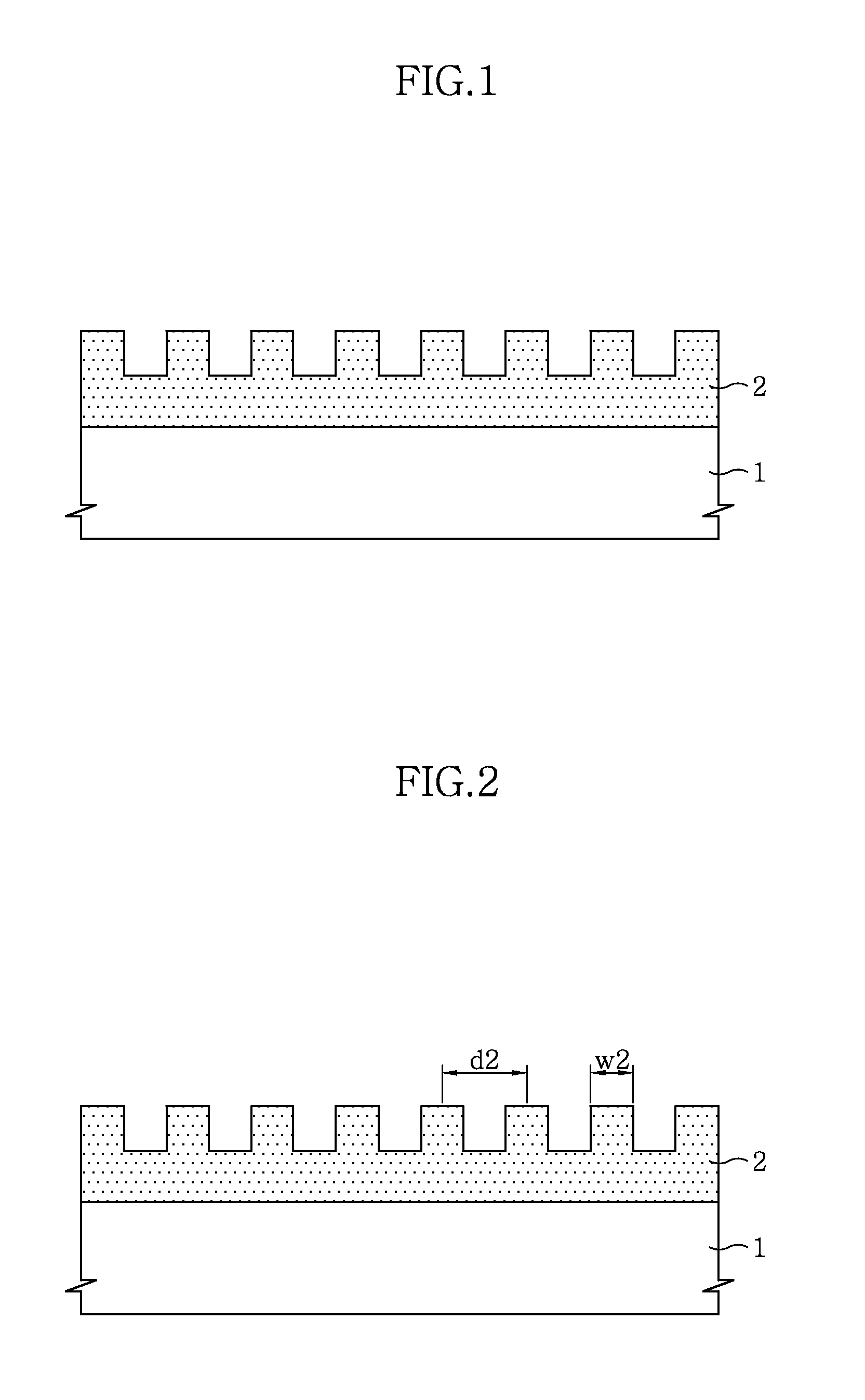

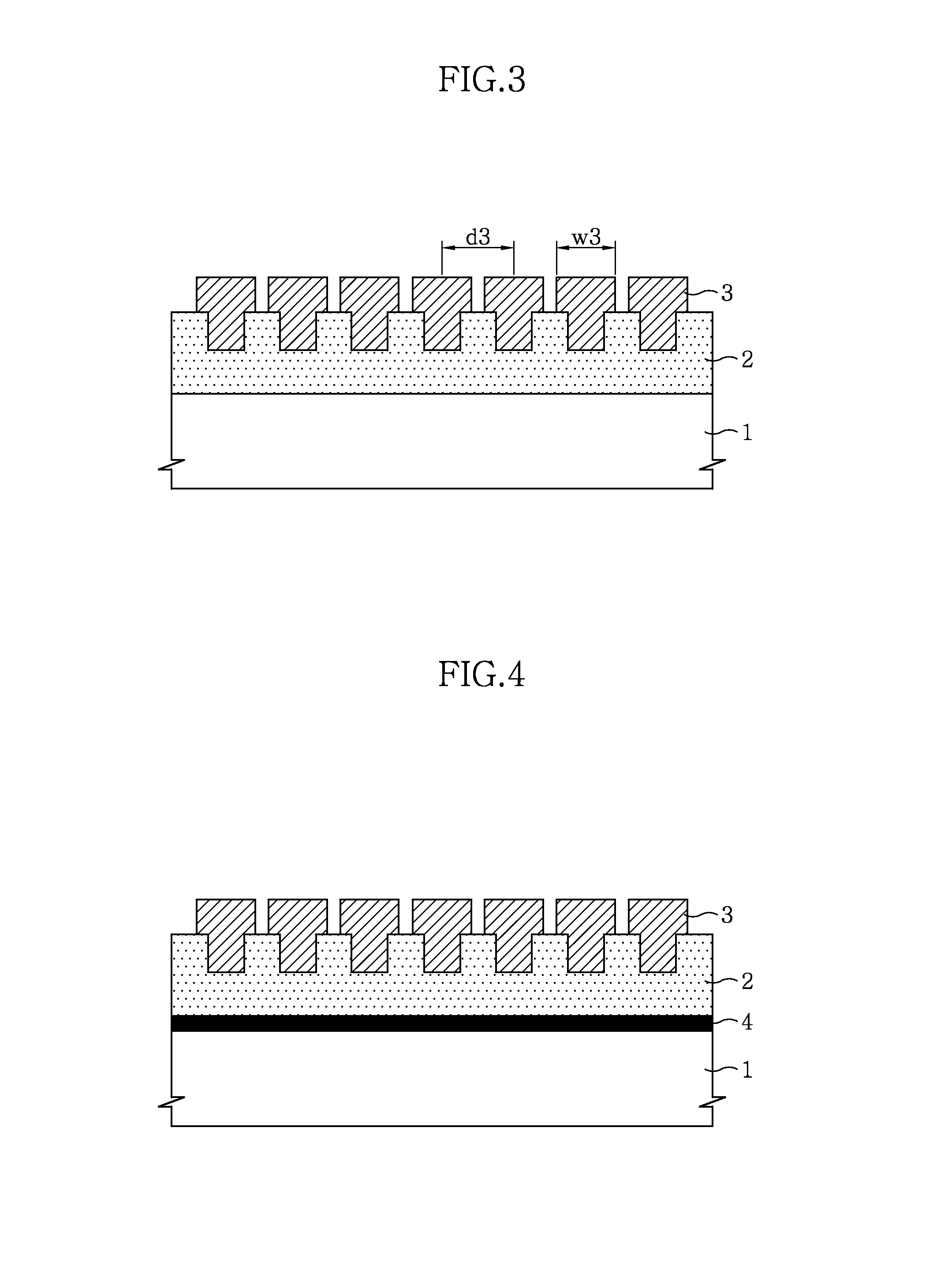

Flexible gas barrier film, method for preparing the same, and flexible display device using the same

InactiveUS20120114910A1Low water vapor permeabilityWithout increasing production costLayered productsNanoinformaticsWater vapor permeabilityFlexible display

The present invention provides a flexible gas barrier film including: a transparent base film; and a hydrophobic pattern layer formed on the base film. The flexible gas barrier film is capable of maximizing hydrophobicity and effectively reducing water vapor permeability by patterning the hydrophobic layer.

Owner:KOREA UNIV RES & BUSINESS FOUND

Barrier laminate, method of manufacturing the laminate, gas barrier film and device

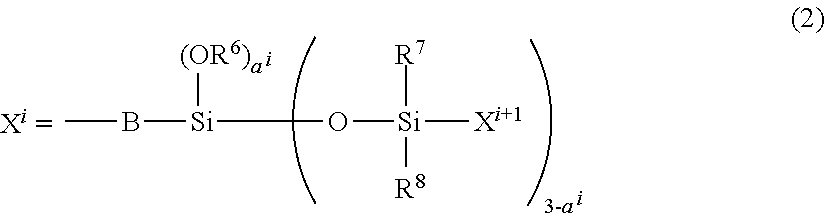

InactiveUS20110236674A1AdhesionImprove the immunityLamination ancillary operationsSynthetic resin layered productsOligomerSilanes

A method of manufacturing a barrier laminate including forming a first organic layer by laminating and hardening a composition containing (A) a polymerizable acidic compound, oligomer or polymer, (B) a polymerizable compound, and (C) a silane coupling agent on a first inorganic layer; forming a second organic layer by laminating and hardening a composition containing (D) a polymerizable compound and (E) a silane coupling agent on the first organic layer; and forming a second inorganic layer on the second organic layer by a plasma deposition method.

Owner:FUJIFILM CORP

Photocurable composition and device including barrier layer formed from composition

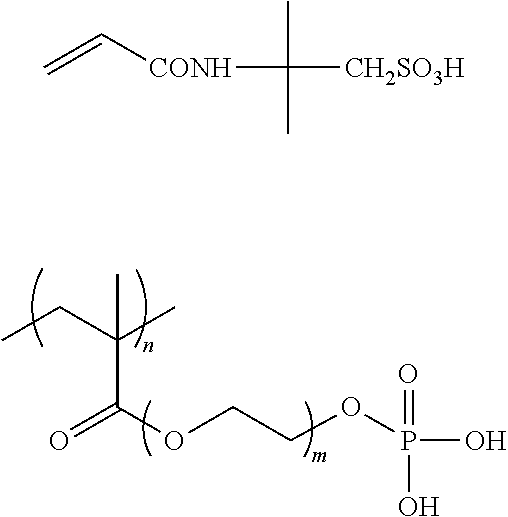

ActiveUS20150318482A1Low water vapor permeabilityPerformance deteriorationOther chemical processesSolid-state devicesPolymer sciencePolymer chemistry

The present invention relates to: a photocurable composition containing (A) a photocurable monomer and (B) a monomer containing phosphorus and an amide group; and a device including a barrier layer formed of the composition.

Owner:CHEIL IND INC

Process for producing raw sausage with shortened ripening time

ActiveUS20100047417A1Short timeMature fastThermoplastic sausage casingsMeat/fish preservationThermoplasticWater vapor permeability

A process accelerating the ripening of raw sausages by incorporating a casing having a water vapor permeability of less than 600 g / m2 d at a relative humidity of less than 60%. Preferably, the process employs casings having a water vapor permeability of 50 to 400 g / m2 d, more preferably 70 to 300 g / m2 d, particularly preferably 80 to 200 g / m2 d. The process concerns, in particular, single-layered or multilayered casings made of thermoplastics, optionally also coated textile fiber skins or cellulose fiber skins.

Owner:KALLE AG

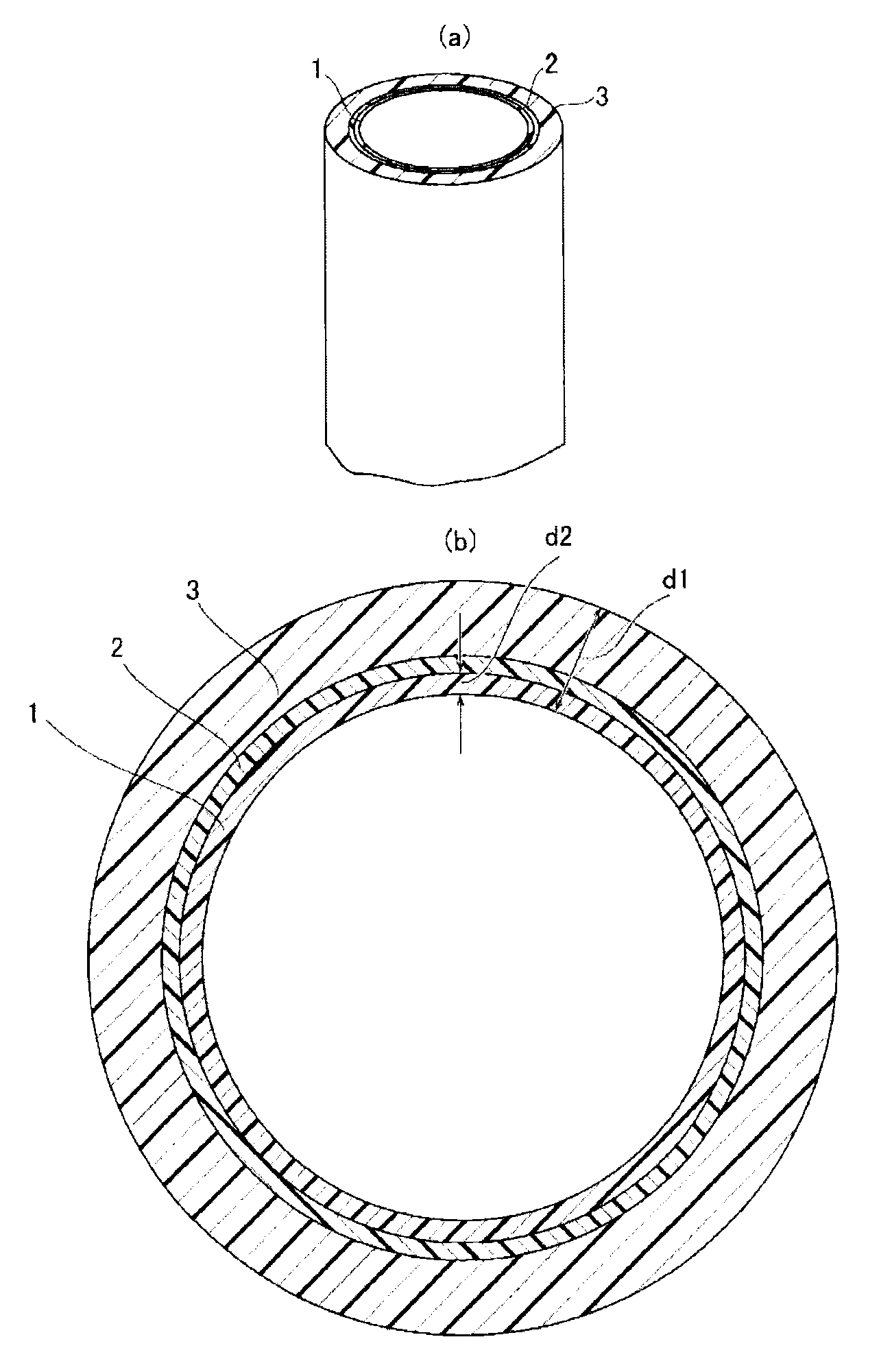

Composite hollow fiber membrane and hollow fiber membrane module

InactiveUS20150122129A1Suppress generationIncrease volumeMembranesSemi-permeable membranesHollow fibre membraneFiber

This composite hollow fiber membrane comprises a gas-permeable non-porous homogeneous layer which has a polyolefin resin (A) as the main component and a porous support layer which is made of a polyolefin resin (B) and which supports said non-porous homogeneous layer, and the composite hollow fiber membrane is characterized in that the polyolefin resin (A) of non-porous homogeneous layer is a block copolymer of ethylene units and at least one type of olefin unit selected from α-olefin units having a carbon number of 3-20. By this means, a gas-permeable composite hollow fiber membrane is provided which has good gas permeability, reduces the impact of condensate on the performance of a gas dissolving module, and has excellent elution properties.

Owner:MITSUBISHI CHEM CORP

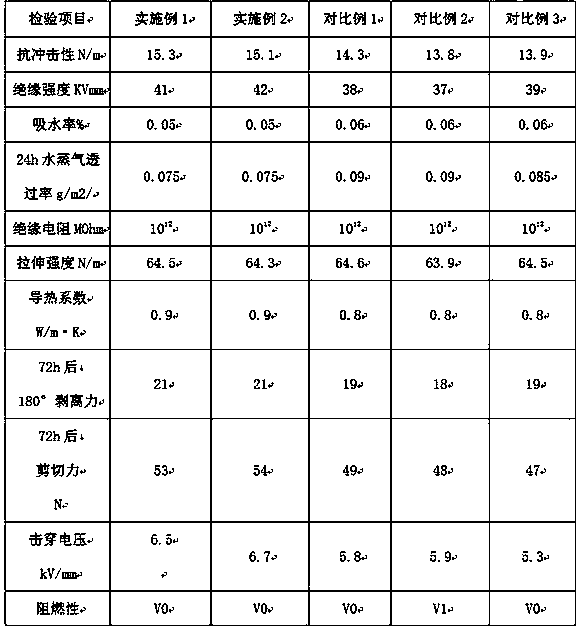

Flame-retardant heat-conducting double-side adhesive

InactiveCN109161351AUniform thicknessImprove liquidityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a flame-retardant heat-conducting double-side adhesive. The flame-retardant heat-conducting double-side adhesive is prepared from a mixture of an epoxy resin pressure-sensitiveadhesive, chlorosulfonated polyethylene, organic silicon rubber, terpene resin, a flame retardant, polytetrafluoroethylene micro powder, ceramic micro powder, nano flake graphite, a coupling agent, barium titanate whisker and boron nitride nanosheets, and a substrate of basalt fiber fireproof cloth. The flame-retardant heat-conducting double-side adhesive has high heat conductivity and insulationas well as the properties of softness, compression, fitness and strong adhesion, is large in applicable temperature range, is capable of filling up uneven surfaces, can be tightly and solidly adheredto a heat source device and a heat radiation fin, is capable of rapidly conducting out heat, is good in heat conductivity and stability, long in service life, excellent in adhesion property and simple in preparation process, and has very good application prospects in fields such as electronic packaging and power wires, and a polymer substrate is filled with inorganic granules with excellent heatconductivity.

Owner:阜南县力韦包装材料有限公司

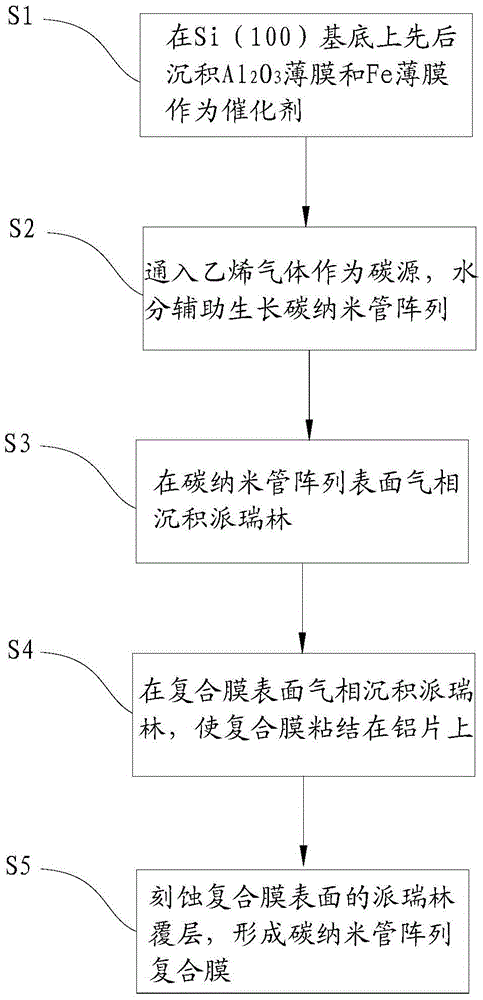

Preparing method of carbon nano tube array composite film and heat exchanger

ActiveCN105463404AImprove thermal conductivityWith high temperature and low temperature resistanceChemical vapor deposition coatingLaminated elementsComposite filmGas phase

The invention provides a preparing method of a carbon nano tube array composite film and a heat exchanger. The method comprises the following steps that S1, an Al2O3 film and a Fe film are sequentially deposited on a substrate of monocrystalline silicon (100) to serve as catalysts; S2, vacuum chemical vapor deposition equipment is heated to 830 DEG C to 850 DEG C, ethylene gas is led in to serve as a carbon source, and a carbon nano tube array grows under assistance of water; S3, paracyclophane is deposited on the surface of the nano tube array in a vapor manner to form an even composite film; S4, the composite film is transferred to an aluminum sheet from the substrate of the monocrystalline silicon (100), paracyclophane is deposited on the surface of the composite film in a vapor manner, and a composite film is bonded on the aluminum sheet; and S5, a paracyclophane coating on the surface of the composite film is etched to form the carbon nano tube array composite film. The prepared carbon nano tube array composite film has high temperature and low temperature resistance, corrosion resistance, heat conduction and super hydrophobicity, and therefore when a unit carries out refrigeration, heat exchanger fins are not prone to condensation; and during heating, frosting is not prone to happening, the heat exchange performance of the heat exchanger is improved, and therefore the running performance of the unit is improved.

Owner:GREE ELECTRIC APPLIANCES INC

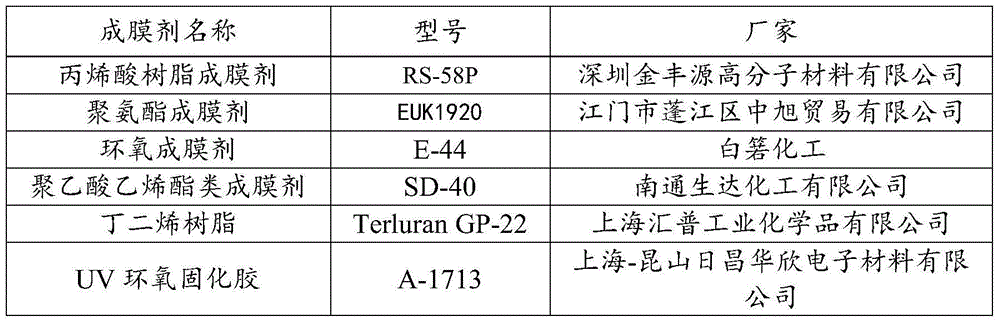

Organic light emitting diode device encapsulation drying agent and encapsulation application method thereof

ActiveCN104409655AEasy to operateEasy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingMoisture absorptionKetone

The invention relates to the field of organic light emitting diode device encapsulation and provides an organic light emitting diode device encapsulation drying agent and an encapsulation application method thereof. The drying agent is characterized by comprising, by weight, 4-7 parts of chloride, nano calcium oxide microcrystal, and 15-70 parts of film forming agent. The molar ratio of the chloride to the nano calcium oxide microcrystal is 1:1-10. When the drying agent is used for encapsulating an OLED device, the drying agent is dissolved by ketone or alcohol to form coating liquid, the coating liquid is used to coat the inner surface of the cover plate of the OLED device in a spun manner, and film thickness is 2-10 micrometers. Compared with traditional drying pieces, the drying agent and the coating liquid thereof are simple to operate, convenient to prepare, cheap in raw material, easy in raw material acquiring, convenient to store and good in stability. Compared with other thin film drying agent, the drying agent and the coating liquid thereof has the advantages that the nano calcium oxide particles are doped in the coating liquid, specific surface area is increased, moisture absorption capability is increased, and good drying effect is achieved.

Owner:北京大学包头创新研究院

Polarized film, optical film, and image display device

InactiveUS9829605B2Low water vapor permeabilityResists change in resistanceLamination ancillary operationsOptical filtersMoisture permeabilityPolarizer

A polarizing film, comprising a polarizer; transparent protective films with a water-vapor permeability of 150 g / m2 / 24 hours or less provided on both sides of the polarizer; and adhesive layers each interposed between the polarizer and one of the transparent protective films, wherein the adhesive layers are formed by applying an active energy ray to an active energy ray-curable adhesive composition containing a radically polymerizable compound, and the transparent protective films are bonded to the polarizer with the adhesive layers.

Owner:NITTO DENKO CORP

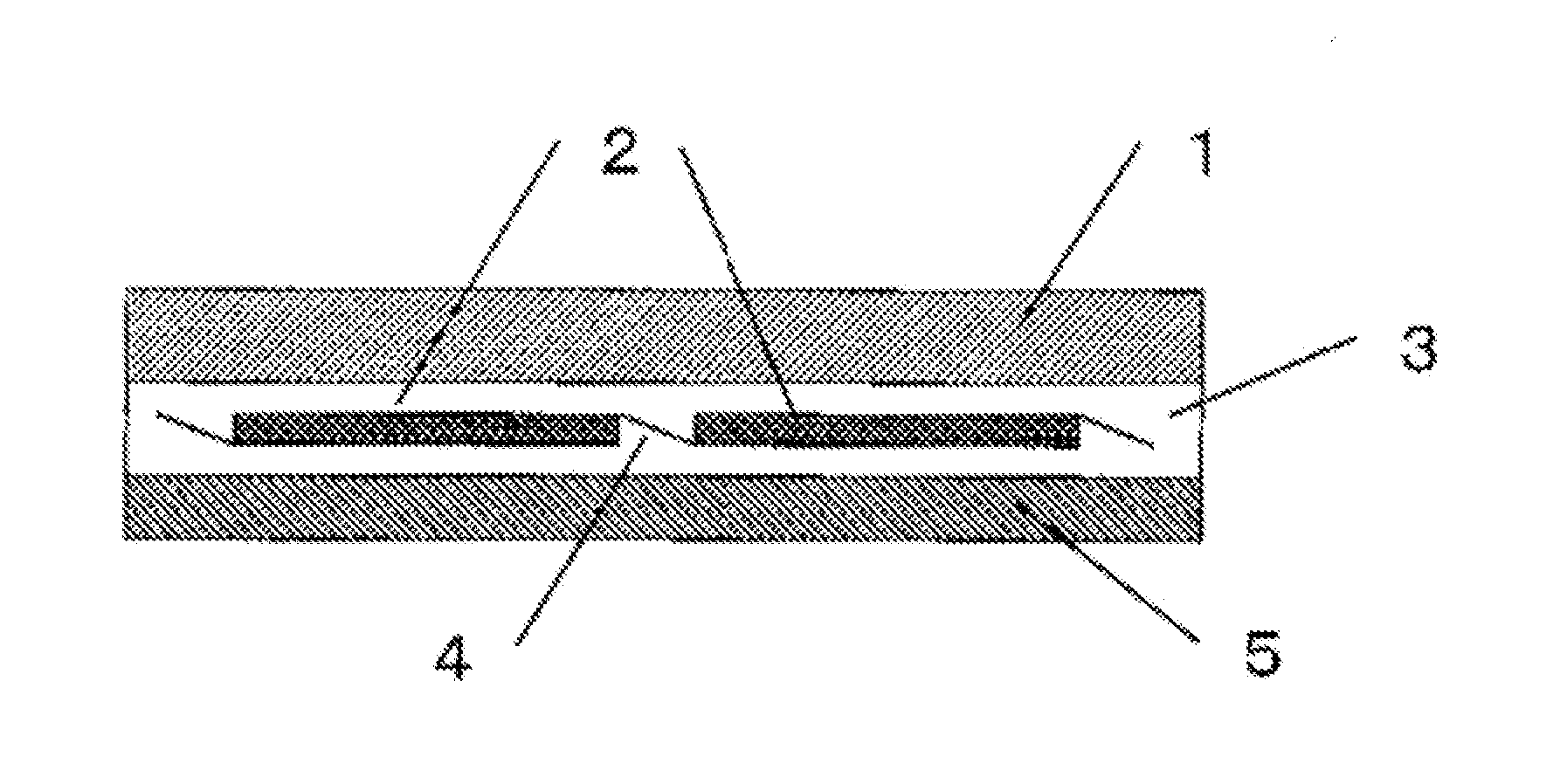

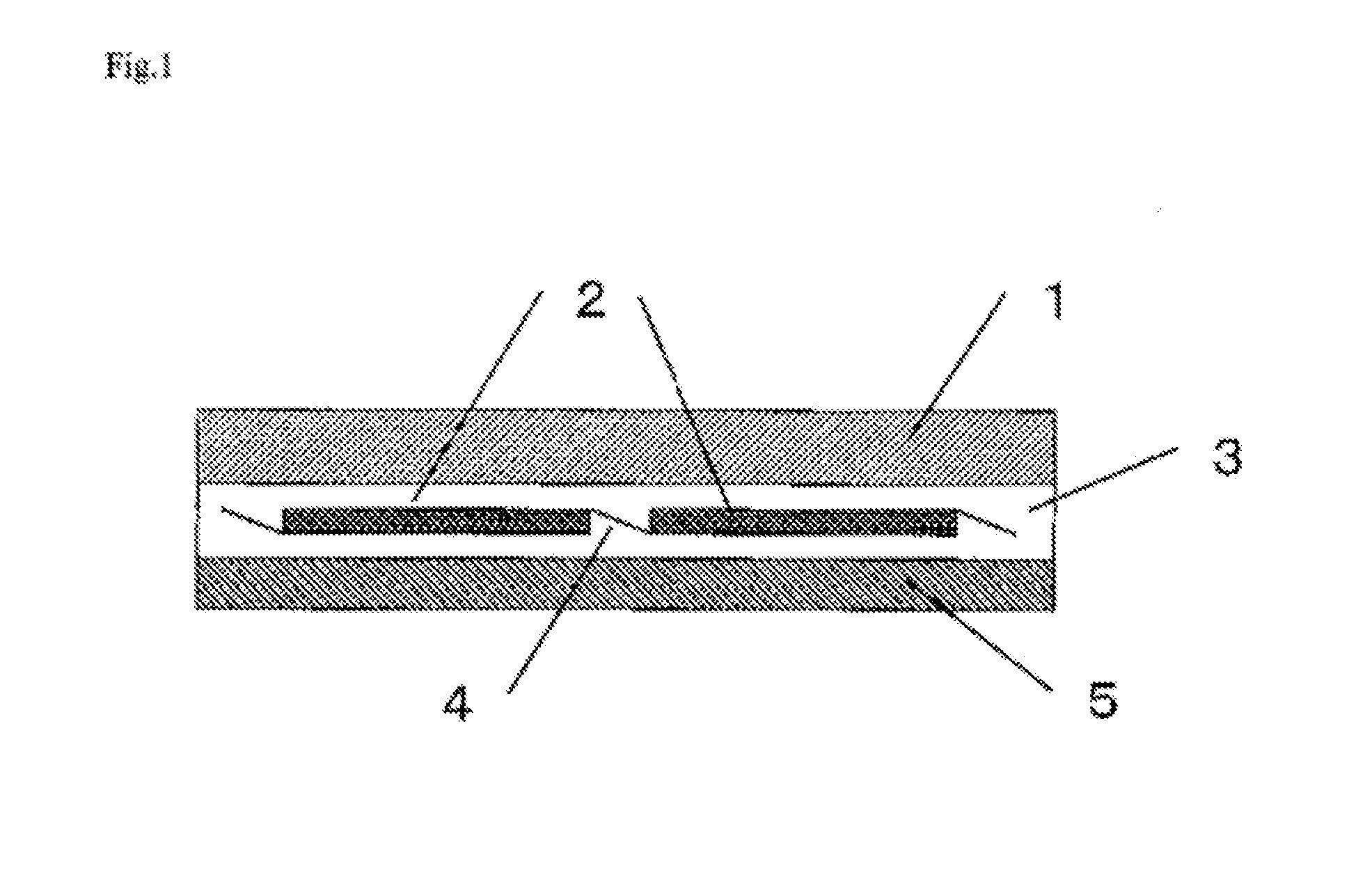

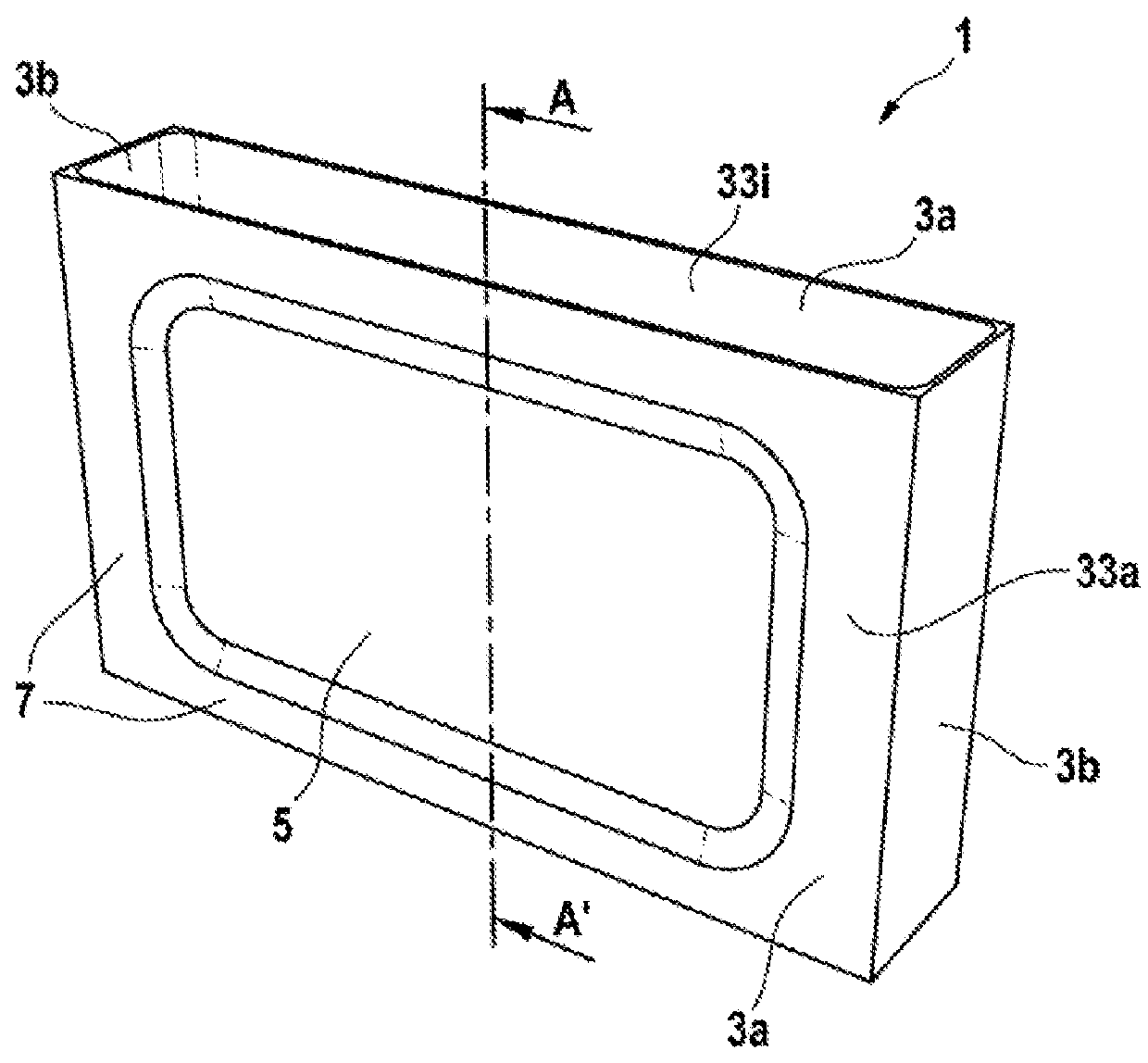

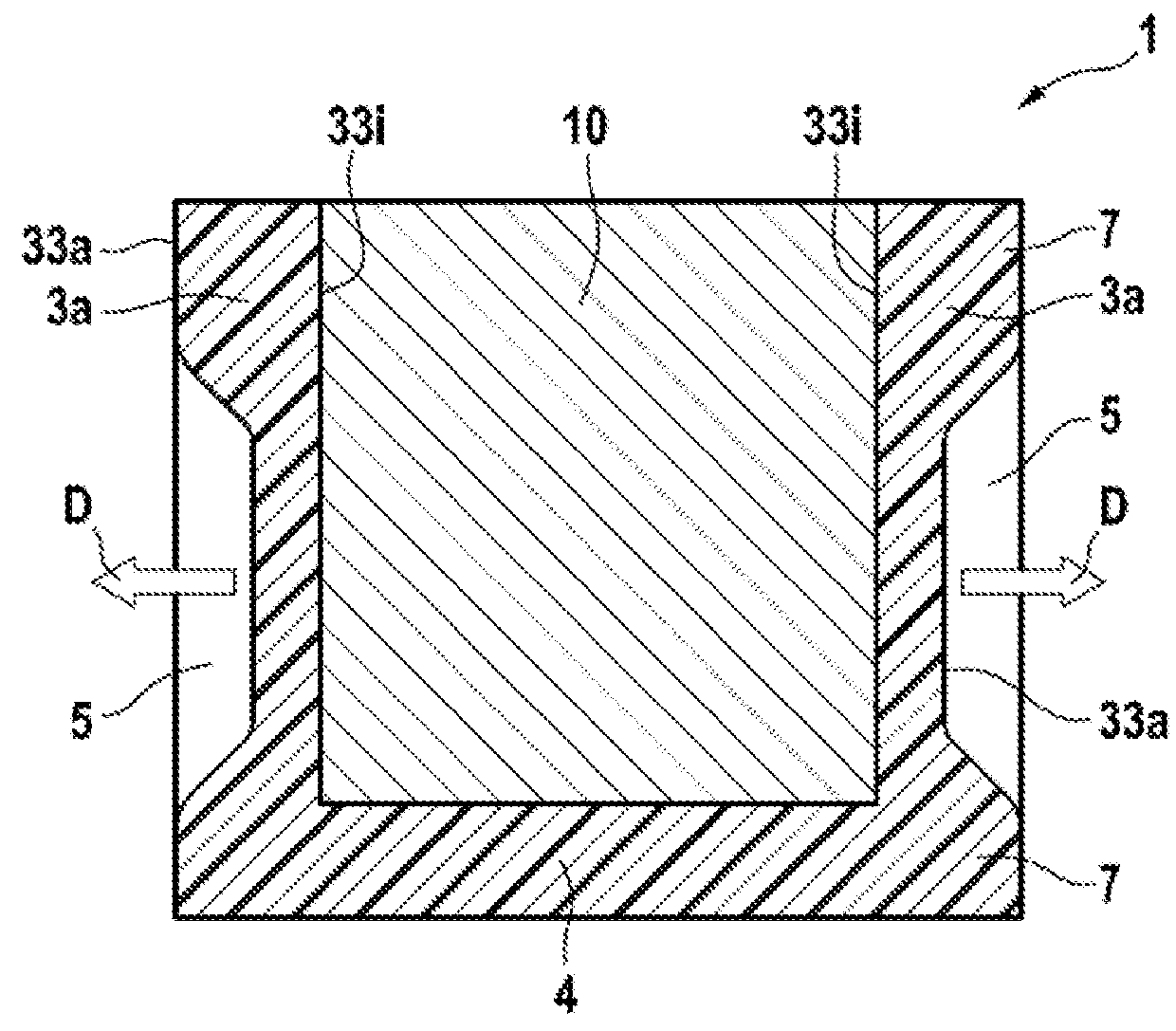

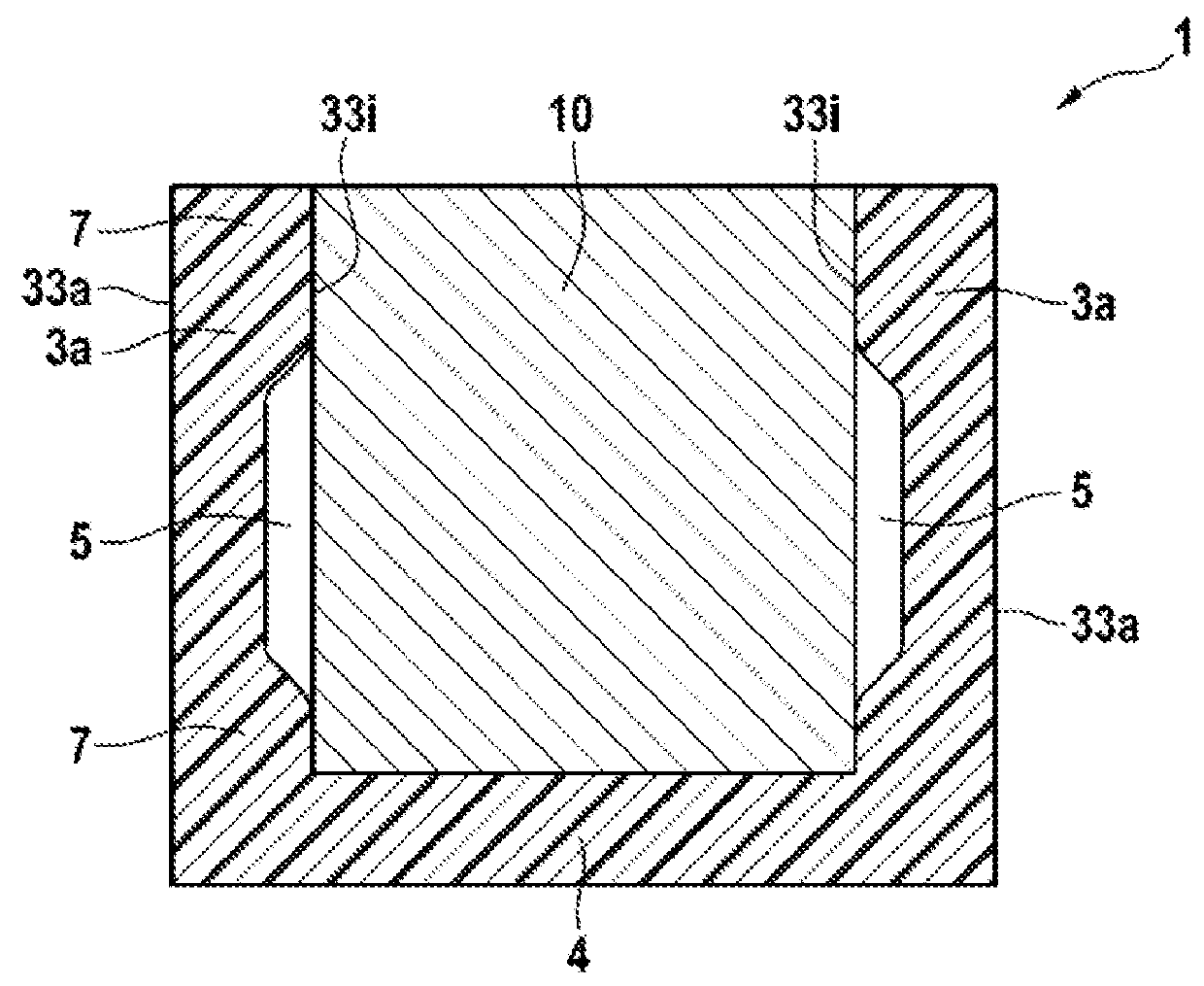

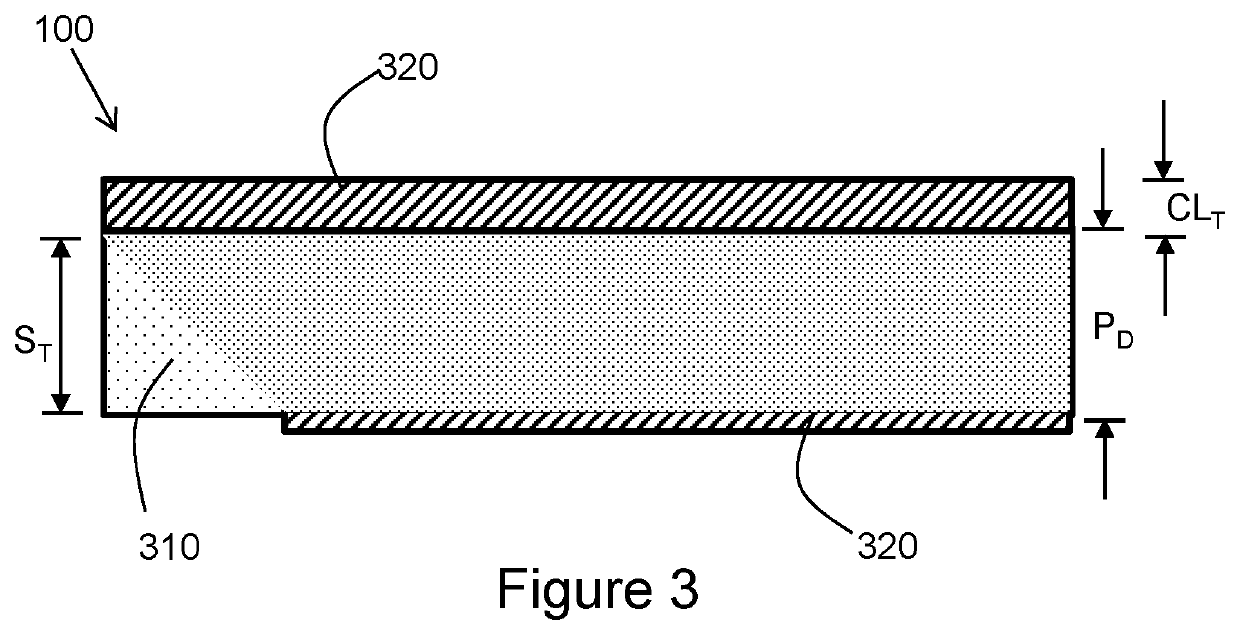

Insulating molding for a battery cell

ActiveUS20180097209A1Great distensionOptimum of distensionFinal product manufactureSecondary cellsEngineeringLithium-ion battery

An insulating molding (1) for a housing of at least one battery cell is disclosed, specifically for a housing of at least one lithium-ion battery cell, wherein, on at least one molding sidewall (3a, 3b) of the insulating molding (1), a depression (5) is configured, which is constituted by means of a reduced wall thickness, in order to reduce the force acting on the battery cell.

Owner:ROBERT BOSCH GMBH

Method for producing laminate, barrier film substrate, device and optical member

ActiveUS7901767B2Low water vapor permeabilityIncreased durabilitySynthetic resin layered productsSolid-state devicesPolymer scienceMethyl group

A method for producing a laminate having a structure of an organic layer and an inorganic layer laminated thereon, which comprises polymerizing a mixture that contains a monomer of the following formula (1) wherein m is 2 and a monomer of the following formula (1) wherein m is 3 or more, thereby forming the organic layer:wherein R1 represents a hydrogen atom or a methyl group; and L represents an m-valent linking group.

Owner:FUJIFILM CORP

Barrier laminate, barrier film substrate, methods for producing them, and device

InactiveUS8197946B2Increased durabilityImprove adhesionElectroluminescent light sourcesSynthetic resin layered productsPolymer scienceMethyl group

A barrier laminate comprising at least one organic layer and at least one inorganic layer, in which the organic layer comprises a polymer having a structural unit of the following formula:wherein R1 and R2 represent a hydrogen atom or a methyl group; L represents an open-chain alkylene group having at least 8 carbon atoms and not containing an oxygen atom, a nitrogen atom and a sulfur atom.

Owner:FUJIFILM CORP

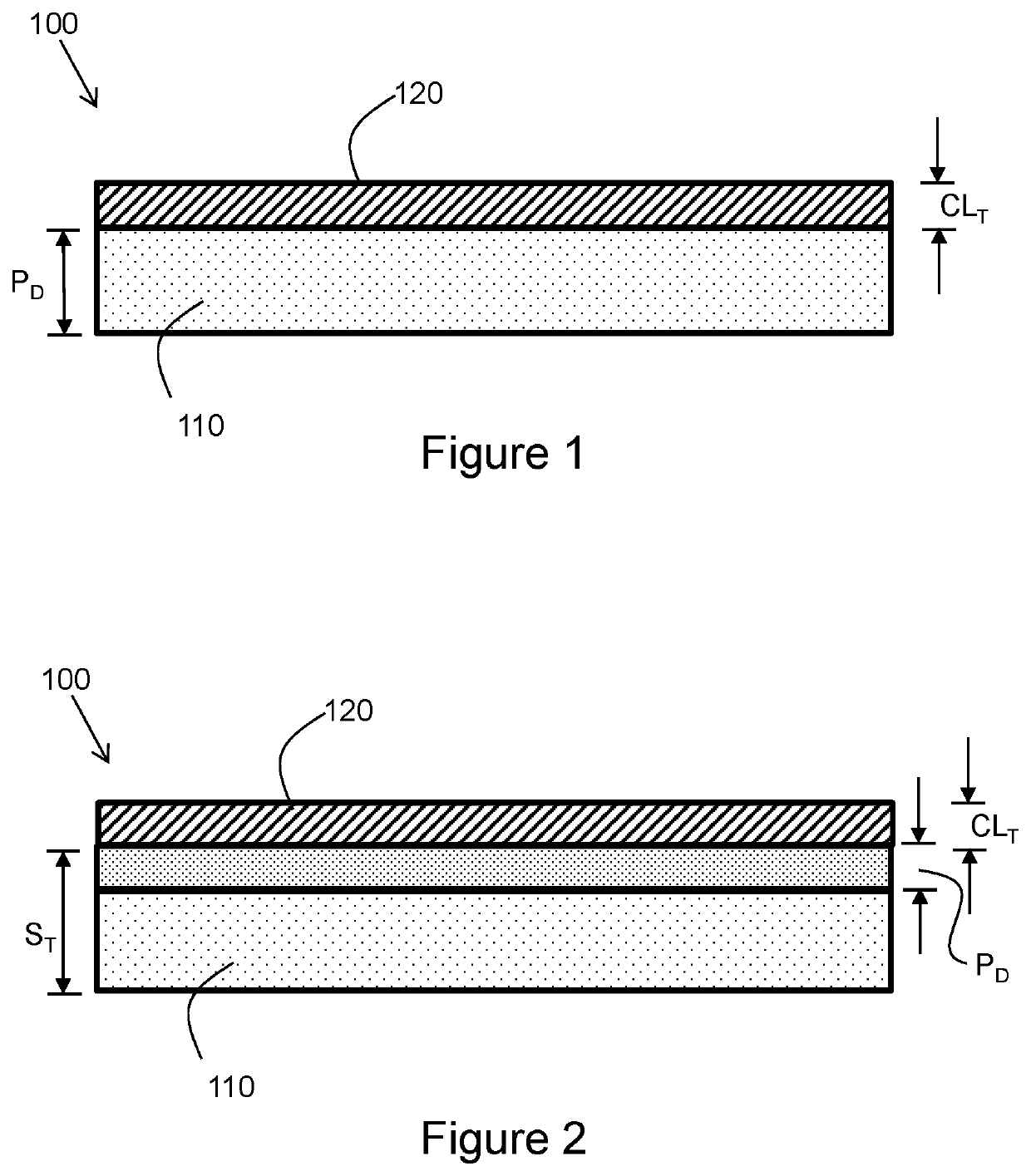

Vapor retarding building materials and methods for making them

ActiveUS11136755B2Low water vapor permeabilityExcellent water vapor permeabilitySynthetic resin layered productsConjugated diene hydrocarbon coatingsHydrophobic polymerWater vapor

The present disclosure relates generally to vapor retarding building materials and methods for making them. The present inventors have found simple and cost-efficient materials that have low water vapor permeability at low relative humidities and that can be provided as a coating on a building material substrate. Notably, in many embodiments, the materials can have high water vapor permeability at high relative humidities. In one embodiment, the disclosure provides vapor retarding articles comprising a building material substrate; and a polymeric coating layer coated on the building material substrate, the polymeric coating layer comprising an inorganic hydrophilic particulate filler dispersed in a continuous organic phase comprising a hydrophobic polymer, wherein the content of the filler is from about 30% to about 85% by weight of the polymeric coating layer, the vapor retarding article configured to have a water vapor permeance of no more than about 1 Perm at 25% relative humidity.

Owner:CERTAIN TEED LLC

Cellulose Ester Film. Polarizing Plate and Liquid-Crystal Display Device

InactiveUS20080160219A1Deterioration of planarityLow water vapor permeabilityLiquid crystal compositionsCellulosic plastic layered productsCellulose ester membraneLiquid-crystal display

A cellulose ester film comprising a cellulose ester and a reaction product between at least one epoxy compound and at least one polymerization accelerator; a polarizing plate using the cellulose ester film as a protective layer of a polarizer; and a liquid crystal display device using either the cellulose ester film or the polarizing plate.

Owner:FUJIFILM CORP

HYDROGEN PEROXIDE FORMULATIONS IN BARRIER LAYER FILMS WITH A SIOx LAYER"

ActiveUS20200360246A1Easy accessHigh mechanical strengthCosmetic preparationsHair cosmeticsFiberPolymer science

The present disclosure concerns a cosmetic product for modifying the natural colour of keratinous fibres, in particular human hair, comprising at least one packaging (VP) and a cosmetic composition (KM) contained in this packaging (VP). The packaging is made of a multilayer film (F) containing at least two polymer layers (P1) and (P2) and at least one barrier layer (BS). The cosmetic composition comprises at least one oxidizing agent, at least one C8-C30-alcohol, at least one specific anionic surfactant, at least one non-ionic surfactant and at least one acrylic acid-based thickener. The use of the packaging (VP) in combination with the cosmetic composition (KM) surprisingly does not lead to an inflation of the packaging or an excessive loss of water of the agent (KM) during storage.

Owner:HENKEL KGAA

EPDM Composition

InactiveUS20090088522A1Excellent in low outgassing propertyLow gas permeabilityEngine sealsSpecial tyresPolymer scienceWater vapor permeability

The present invention is to provide an EPDM composition from which molding material excellent in low outgassing property and low gas permeability (low water vapor permeability) can be obtained even if the EPDM composition contains a mass of plasticizer blended in.The present invention relates to an EPDM composition including ethylene-propylene-non-conjugated diene terpolymer (EPDM polymer) as main element, B) plasticizer at 50-200 part by weight per the EPDM polymer of 100 part by weight, C) filler at 100-450 part by weight per the EPDM polymer of 100 part by weight, and D) vulcanizing agent at 1-10 part by weight per the EPDM polymer of 100 part by weight.

Owner:NOK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com