Flame-retardant heat-conducting double-side adhesive

A technology of heat-conducting double-sided adhesive and heat-conducting adhesive, which is applied in the field of double-sided adhesive, can solve the problems of not being able to meet the needs of market competition, reduce production efficiency, and inconvenient use, and achieve mechanical and manual winding, increased electric shock resistance, and cathode The effect of peeling heightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

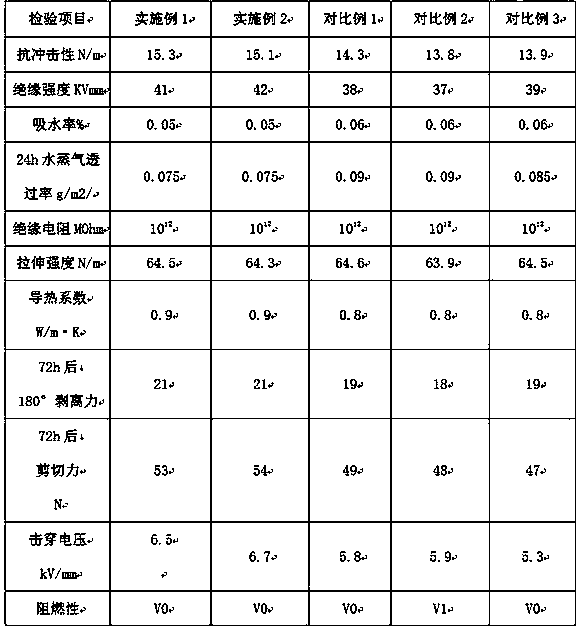

Examples

Embodiment 1

[0021] The object of the present invention is to provide a flame-retardant and heat-conducting double-sided adhesive to solve the existing problems.

[0022] A flame-retardant and heat-conducting double-sided adhesive, including two parts, the base material is made of basalt fiber fireproof cloth; the flame-retardant and heat-conducting adhesive layer is a layer of flame-retardant and heat-conducting adhesive layer coated on the surface of the base material layer by scraper transfer coating Glue, the flame-retardant heat-conducting adhesive is epoxy resin pressure-sensitive adhesive, chlorosulfonated polyethylene, silicone rubber, terpene resin, flame retardant, polytetrafluoroethylene micropowder, ceramic micropowder, nano flake graphite, coupling agent , a mixture of barium titanate whiskers and boron nitride nanosheets; the components of the flame-retardant thermally conductive adhesive are by weight: 80 parts of epoxy resin pressure-sensitive adhesive, 17 parts of chlorosul...

Embodiment 2

[0033] The object of the present invention is to provide a flame-retardant and heat-conducting double-sided adhesive to solve the existing problems.

[0034] A flame-retardant and heat-conducting double-sided adhesive, including two parts, the base material is made of basalt fiber fireproof cloth; the flame-retardant and heat-conducting adhesive layer is a layer of flame-retardant and heat-conducting adhesive layer coated on the surface of the base material layer by scraper transfer coating Glue, the flame-retardant heat-conducting adhesive is epoxy resin pressure-sensitive adhesive, chlorosulfonated polyethylene, silicone rubber, terpene resin, flame retardant, polytetrafluoroethylene micropowder, ceramic micropowder, nano flake graphite, coupling agent , barium titanate whiskers, and a mixture of boron nitride nanosheets; the components of the flame-retardant thermally conductive adhesive are by weight: 85 parts of epoxy resin pressure-sensitive adhesive, 31 parts of chlorosu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com