Patents

Literature

106results about How to "Speed up vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881AIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

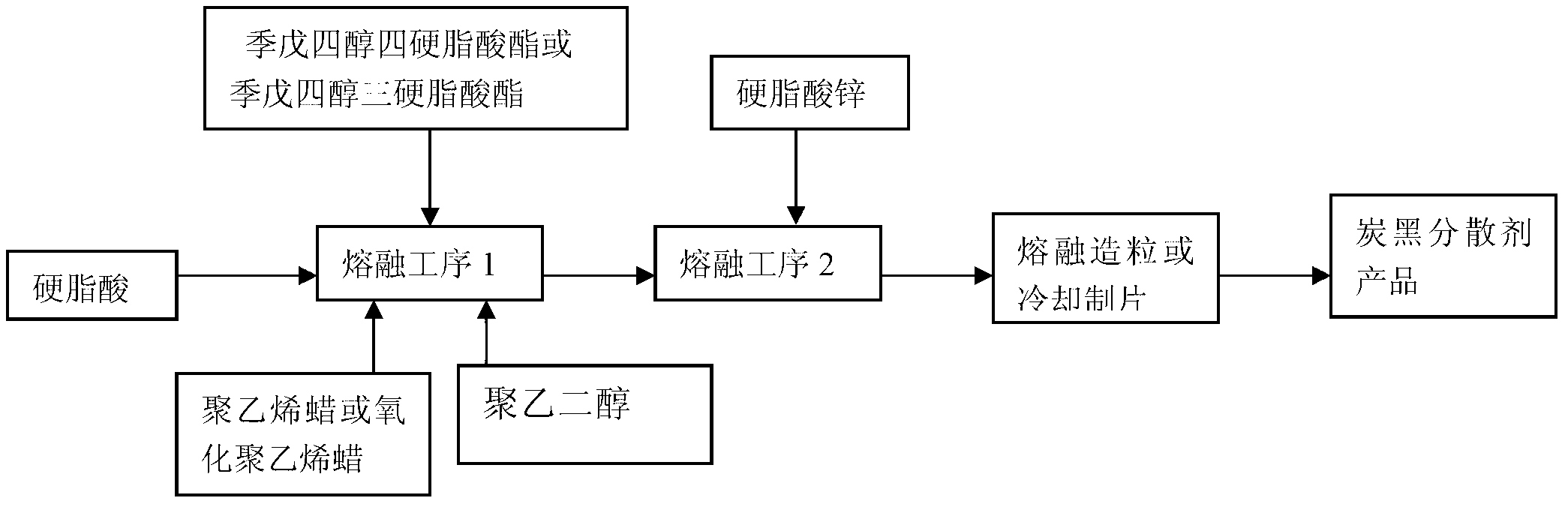

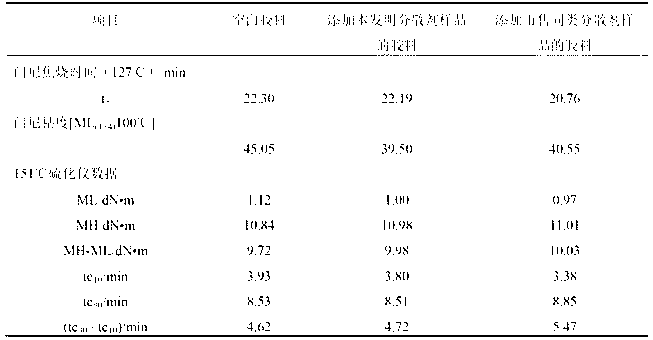

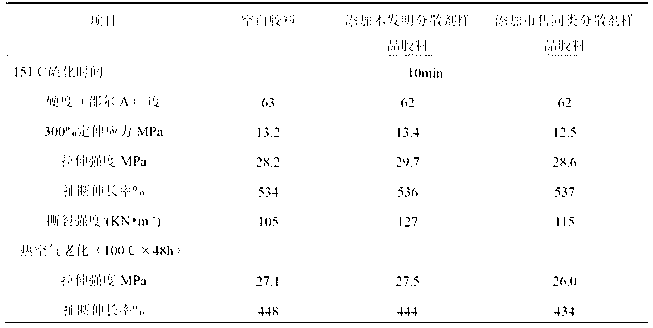

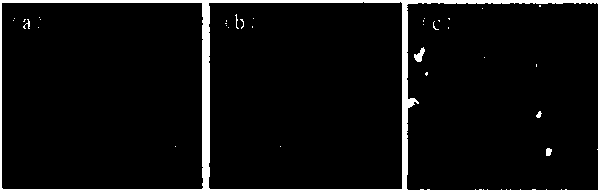

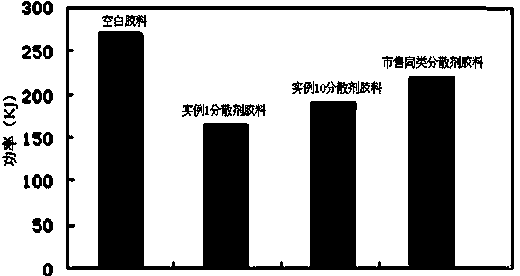

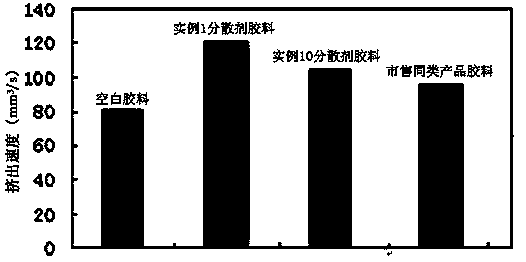

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

White carbon black dispersant for rubber and preparation method of white carbon black dispersant

ActiveCN103450504AIncreased process safetyImprove mechanical propertiesRubber materialPolymer science

The invention discloses a white carbon black dispersant for rubber. The white carbon black dispersant is characterized by comprising the following raw materials in parts by weight: 30-70 parts of fatty acyl amide / acid amide, 10-30 parts of fatty acid ester and 0-30 parts of fatty acid soap salt. The invention also discloses a preparation method of the white carbon black dispersant. The preparation method is simple and rapid; and the obtained white carbon black dispersant has multiple functions such as dispersion, lubrication and chemical modification, can be used for improving the processing safety performance as well as physical and mechanical properties of a rubber material and increasing the curing speed of the rubber material and is remarkable in effect.

Owner:SHANDONG YANGGU HUATAI CHEM

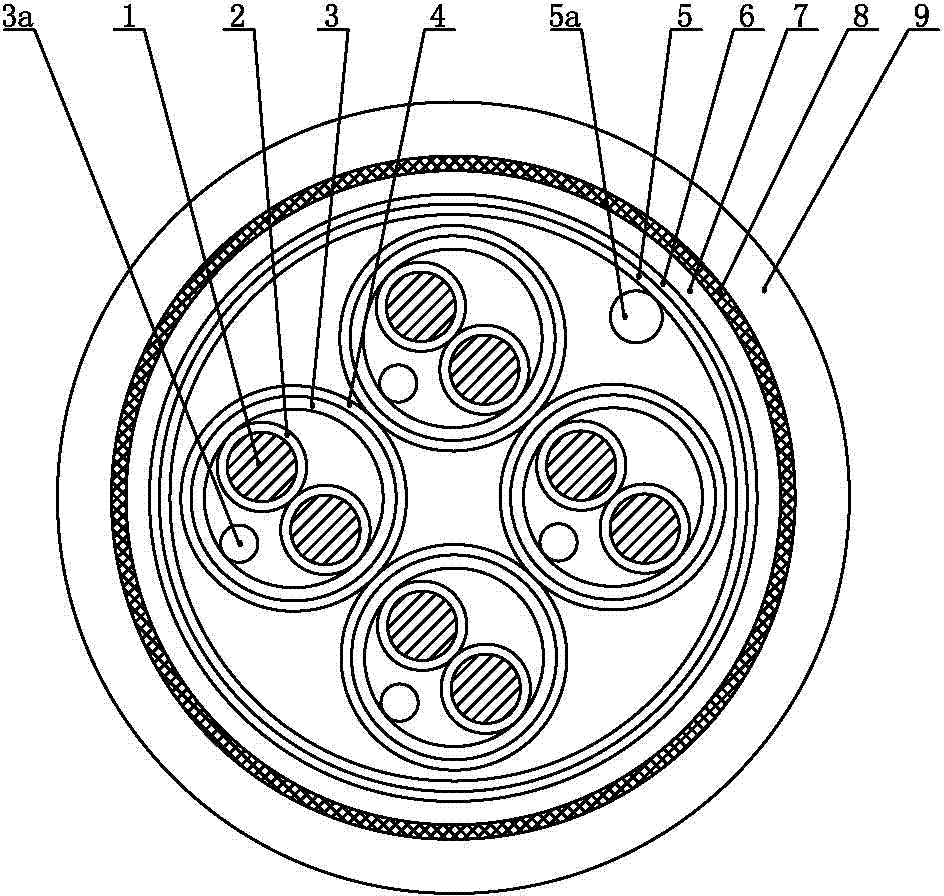

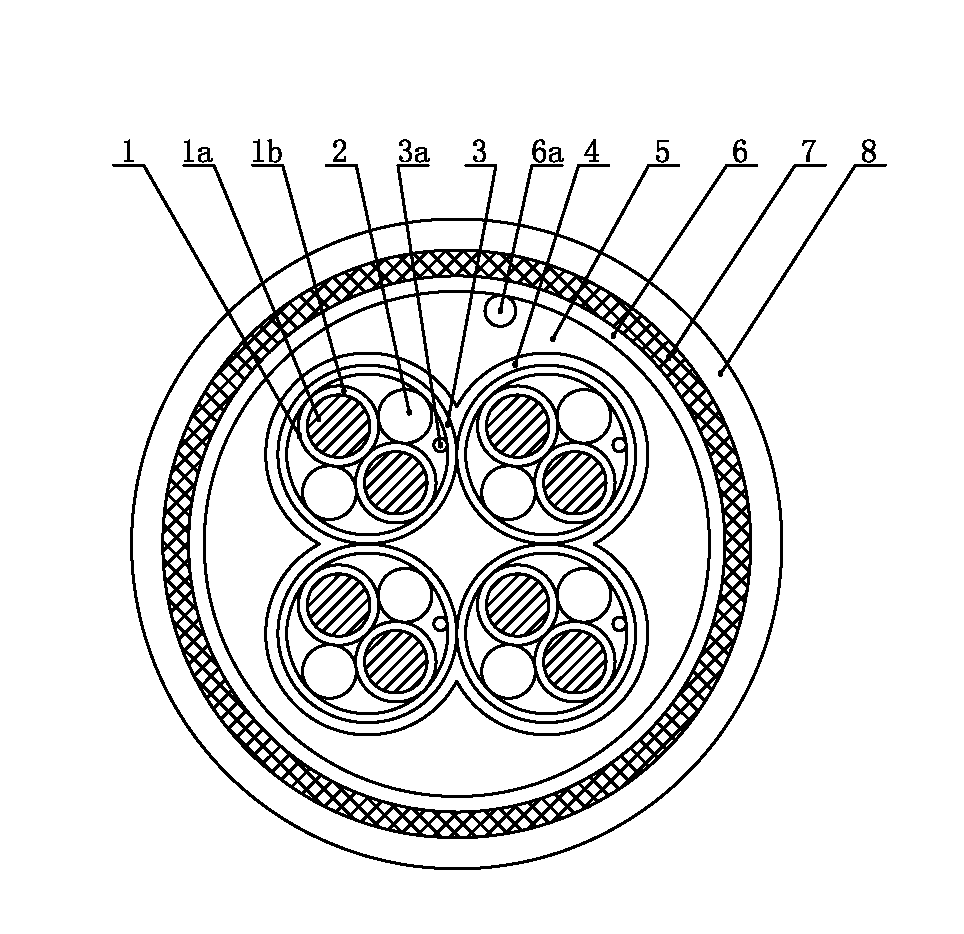

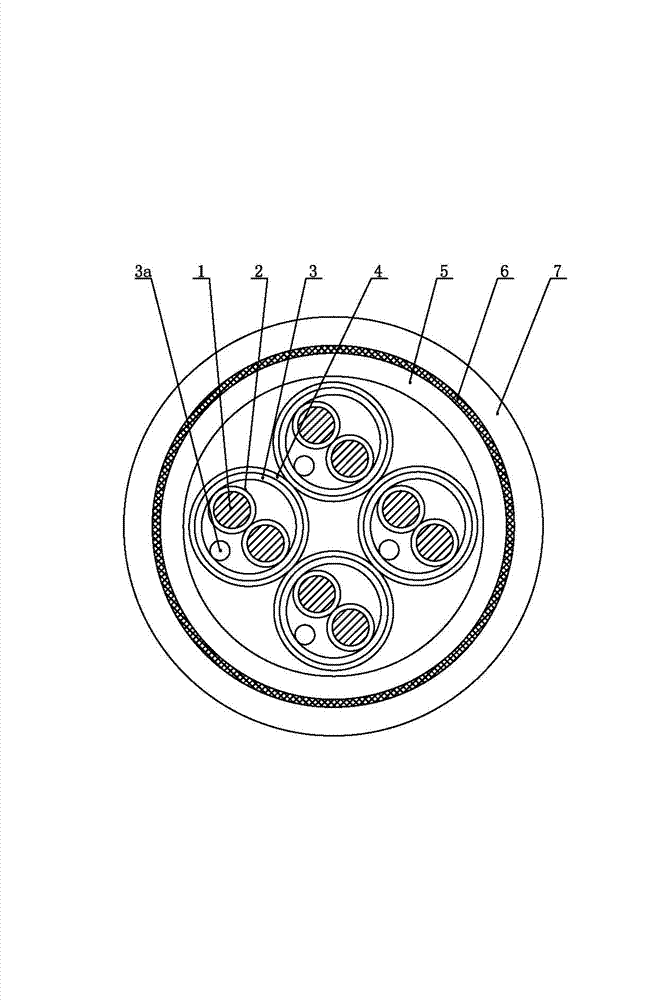

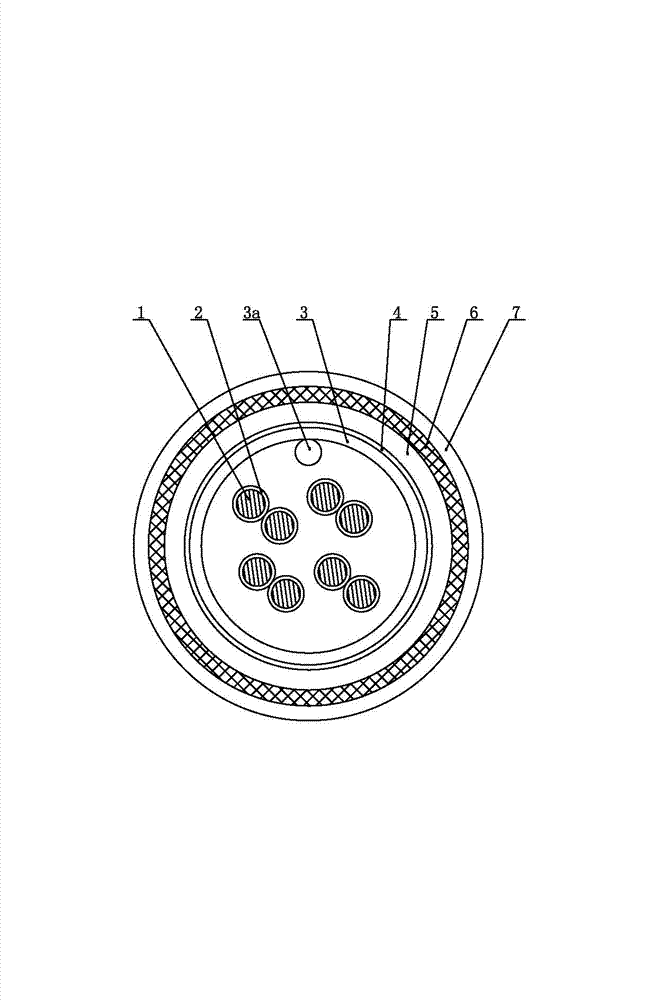

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-abrasion-resistance anti-aging tire rubber material

The invention discloses a high-abrasion-resistance anti-aging tire rubber material. The high-abrasion-resistance anti-aging tire rubber material is prepared from the following raw materials in parts by weight: 45-55 parts of epichlorohydrin rubber, 35-40 parts of ethylene propylene diene monomer, 20-25 parts of butadiene styrene rubber, 10-15 parts of chloroprene rubber, 1.5-2 parts of zircoaluminate coupling agent TL-5, 3-3.5 parts of 1,1,3,3-tetramethylperoxyphenoxybutyl acetate, 1.3-1.6 parts of 3,3-bis(tertiary pentylperoxy)ethyl butyrate, 2-4 parts of potassium carboxylacrylate, 4-7 parts of divinyl benzene, 10-12 parts of magnesium oxide, 25-30 parts of channel black, 20-30 parts of superfine hollow microspheres, 10-15 parts of lignin fiber, 25-30 parts of nano sepiolite powder, 20-25 parts of nano boron nitride, 30-40 parts of zinc borate, 2-3 parts of calcium stearate, 4-6 parts of barium stearate, 5-8 parts of phenyl petroleum sulfonate, 1-3 parts of antiager TMDQ and 2-4 parts of antiager NBC.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

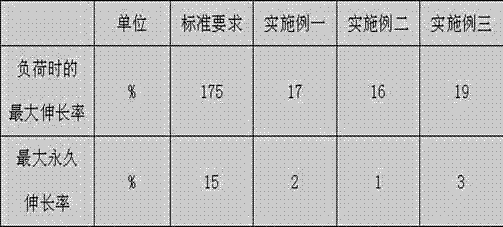

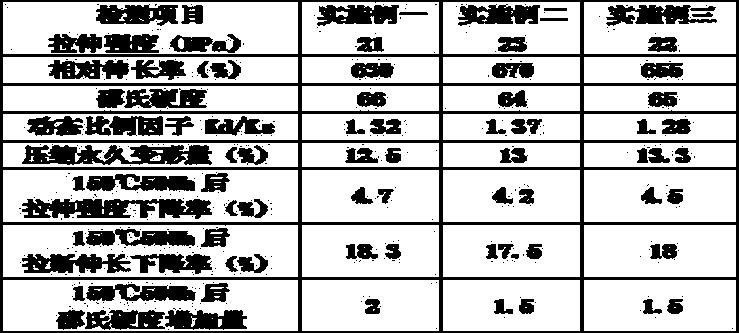

High-strength high-elongation flame retardant rubber insulated cable material and preparation process thereof

ActiveCN103232630AOvercome the difficulty of swinging glueImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesElastomerParaffin wax

The invention discloses a high-strength high-elongation flame retardant rubber insulated cable material and a preparation process thereof. The high-strength high-elongation flame retardant rubber insulated cable material comprises the following components in parts by weight: 8-14 parts of chlorinated polyethylene (CPE), 15-21 parts of ethylene-octylene copolymer elastomer (POE), 3-6 parts of fumed silica, 15-19 parts of aluminium hydroxide, 13-18 parts of calcined clay, 5-8 parts of 800# paraffin base rubber oil, 0.5-1 part of active magnesium oxide, 4-7 parts of superfine talcum powder, 1-2 parts of zinc oxide, 0.3-0.6 part of environmental stabilizer, 1-2 parts of microcrystalline wax, 0.5-1 part of titanium dioxide, 0.5-0.8 part of 4,4' bis(alpha, alpha dimethyl benzyl) diphenylamine, 1-2 parts of dicumyl peroxide and 1-1.5 parts of triallyl cyanurate. By adopting the high-strength high-elongation flame retardant rubber insulated cable material, uniform addition of inorganic powder is facilitated, a process range is wide, higher elongation at break is still maintained when a continuous vulcanizing temperature is 190-210 DEG C, a fire retardant and a high reinforced filler are added without reducing electrical property, and tensile strength and oxygen index are greatly increased; and cost is greatly reduced.

Owner:JIANGSU HENGTONG POWER CABLE

Method for preparing fluorine-containing rubber for automobile rubber pipe

ActiveCN102516438AImprove vulcanization speed and fluidityImprove oil resistance, acid and alkali resistanceRigid pipesSolventWeight distribution

The invention relates to a method for preparing a fluorine-containing rubber for an automobile rubber pipe, which comprises the following steps of: (1) adding deionized water into a reaction kettle, and reserving 30-50% space; (2) evacuating the reaction kettle and removing oxygen; (3) adding emulsifier into the reaction kettle, and then adding initial mixing monomers of tetrafluoroethylene, vinylidene fluoride and perfluoropropylene till the pressure is 0.7-5.0MPa, and adding triggers, chain transfer agents and pH value regulators, and performing polymerization reaction; (4) during a reaction process, replenishing the initial mixing monomers of tetrafluoroethylene, vinylidene fluoride and perfluoropropylene, and keeping the constant pressure of the reaction kettle, thereby obtaining a perfluoroethylene-propylene copolymer; and (5) vulcanizing the copolymer, thereby obtaining the fluorine-containing rubber for the automobile rubber pipe. The rubber for the automobile rubber pipe prepared according to the method provided by the invention has the advantages of excellent molecular weight distribution, excellent solvent resistance and wider industrial application prospect.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

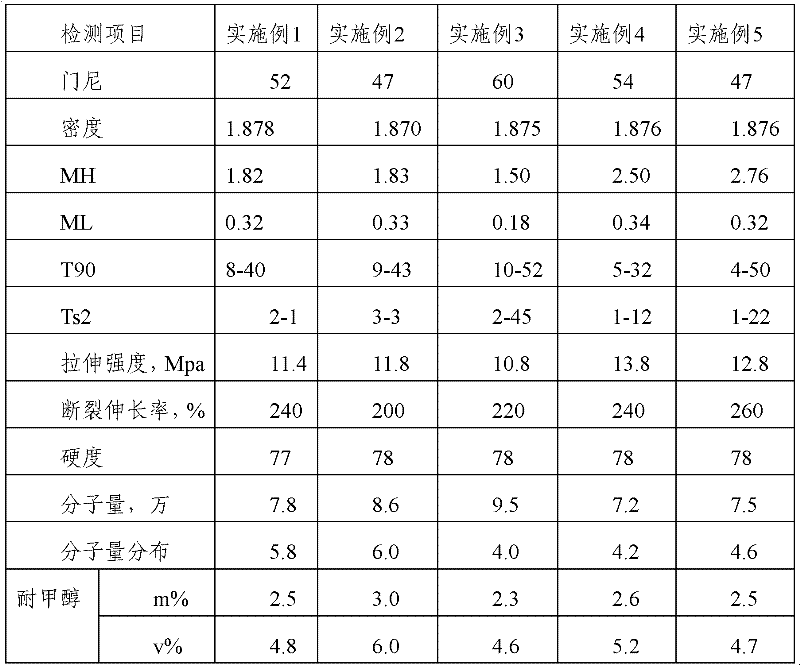

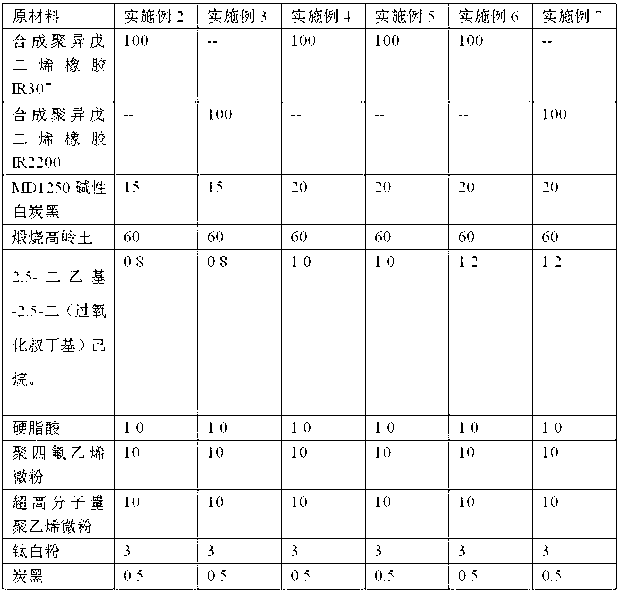

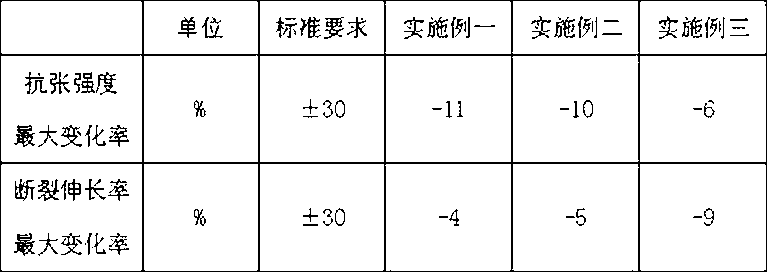

Rubber syringe needle protective cap for pre-encapsulation injection syringe and production method thereof

ActiveCN103232623AIncreased degree of vulcanizationSpeed up vulcanizationPolymer scienceSmell problems

The invention discloses a rubber syringe needle protective cap for a pre-encapsulation injection syringe. The protective cap is prepared from the following raw materials in parts by weight: 100 parts of synthesized polyisoprene rubber, 5-30 parts of alkaline white carbon black, 20-70 parts of calcined kaolin, 0.3-1.2 parts of peroxide, 0.5-1.0 part of stearic acid, 5-20 parts of polytetrafluoroethylene micro powder, 5-20 parts of ultra-high molecular weight polyethylene micro powder, 1-5 parts of titanium dioxide and 1-3 parts of carbon black. The rubber syringe needle protective cap has the obvious characteristics that a clean and simple peroxide sulfuration system is adopted, and a conventional complicated sulfur and zinc oxide promotion system is avoided. Special alkaline fillers are adopted, the sulfuration degree and speed of rubber are improved, and a smell problem caused by adopting the peroxide to sulfurate the polyisoprene rubber is reduced. The polytetrafluoroethylene micro powder and the ultra-high molecular weight polyethylene micro powder with good inertness and dispersibility are added into a formula, the lubricity and chemical inertness of the rubber are improved, and the viscous resistance of a rubber syringe needle protective cap product is improved.

Owner:郑州翱翔医药科技股份有限公司

Outsole sizing material for protective boots

ActiveCN105713267AFast vulcanizationImprove scorch performanceSolesChemistryButadiene-styrene rubber

The invention discloses an outsole sizing material for a pair of protective boots. Raw materials of the outsole sizing material comprise chloroprene rubber, butadiene-acrylonitrile rubber, styrene-butadiene rubber, a composite accelerator, organic montmorillonite, N-methylene carboxyl-2-benzothiazole sulfenamide, sulphur, high aromatic hydrocarbon oil, ethylene thiourea, mica powder, low-temperature calcined kaolin, diethylene glycol, an anti-aging agent, a liquid ethylene-propylene-terpolymer and a flame retardant. All the components are synergistic, compatibility is good, interface bonding strength is strong, insulating effect is excellent, flame retardant property is excellent, and high-low temperature resistance and waterproof and antiskid properties are relatively good, acid and alkali resistance, oil resistance and corrosion resistance are greatly improved, heat insulating property and permeability are strong, so that the outsole sizing material is soft, wear-resistant and nondeformable and also has comfort and strong generality under the premise that functional requirements are met.

Owner:JIHUA 3539 SHOE MAKING

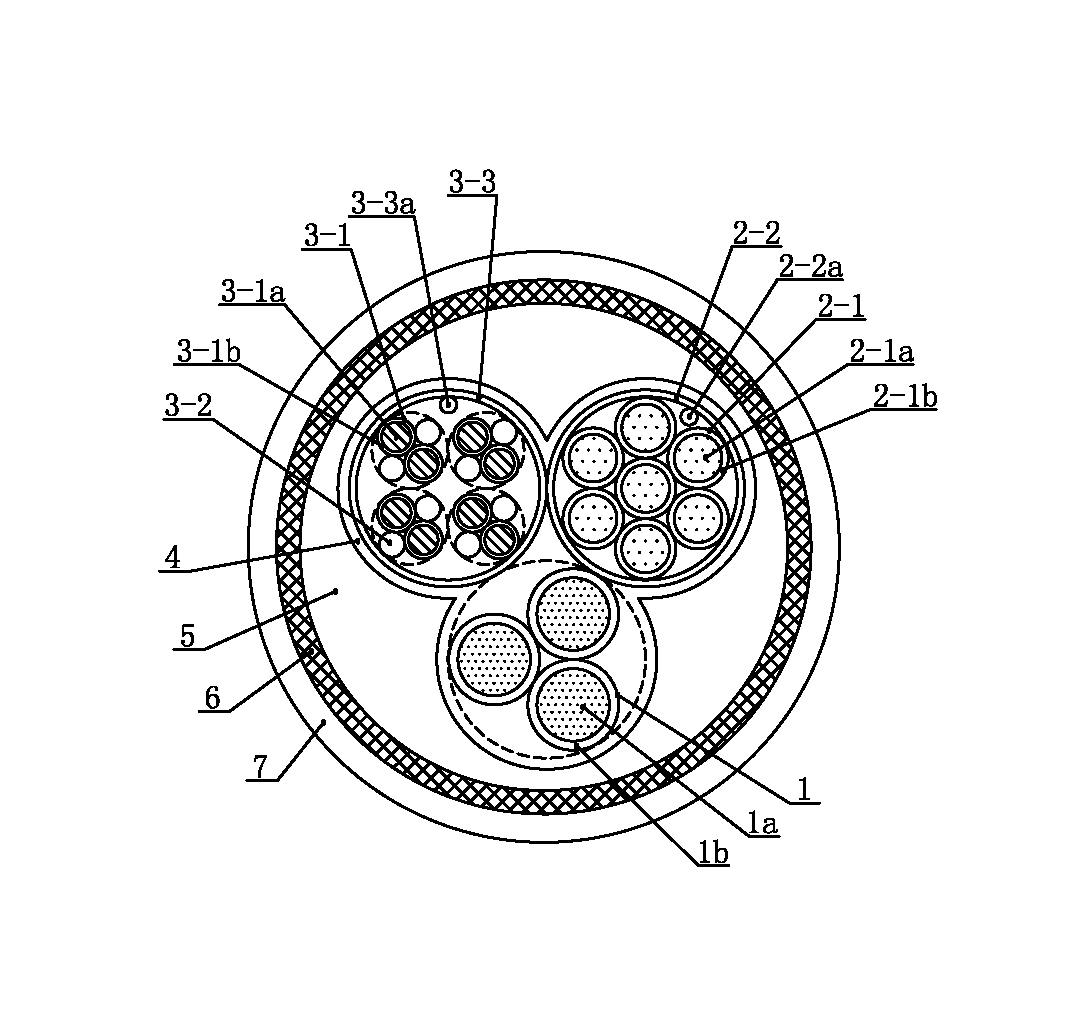

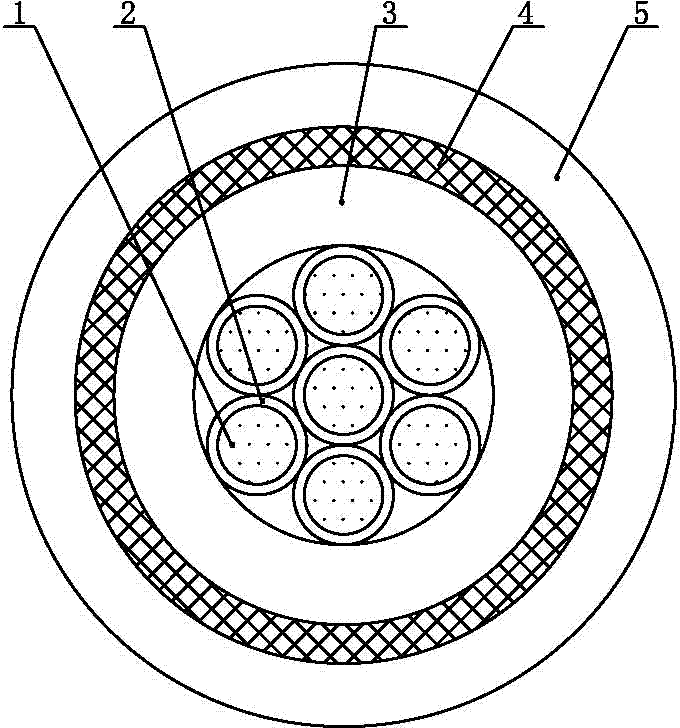

Composite cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103226992AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsPower cableEngineering

The invention relates to a composite cable for a flame-retardant fireproof boat and a manufacturing method thereof. A power cable core, a control cable core and an instrument cable core are stranded into a composite cable core; the periphery of the composite cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The low-intensity non-woven fabric longitudinally-covered layer is completely in fit with each insulated conductor in shape, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards; and meanwhile, the inner jacket and the insulated cores are guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

Rubber composition and pneumatic tire using the same

InactiveUS7795356B2Reduce dispersionShorten speedSpecial tyresOrganic dyesSilicon dioxideMethyl group

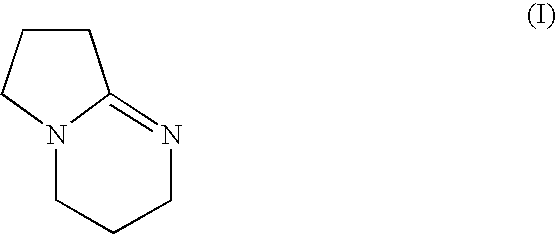

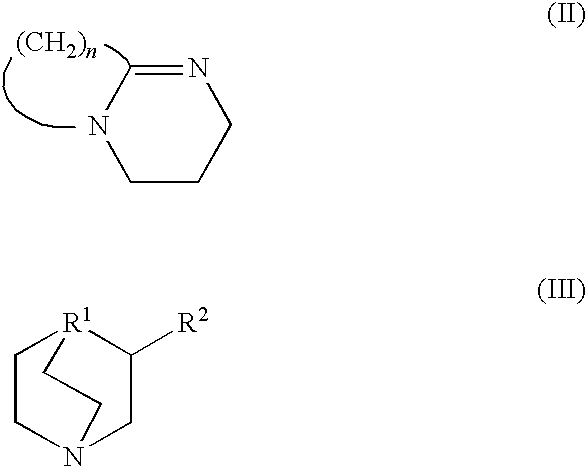

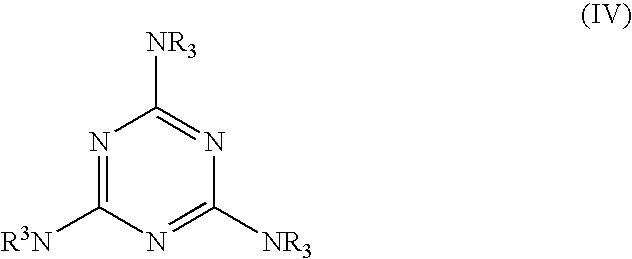

A rubber composition containing 100 parts by weight of a diene-based rubber, 20 to 120 parts by weight of silica, 3 to 15% by weight, based upon the weight of silica, of a sulfur-containing silane coupling agent and (A) 1,5-diazabicyclo[4,3,0]nonene-5 (DBN) having the formula (I):and / or a salt thereof or (B) 0.1 to 3.0 parts by weight of a compound having a piperidine skeleton having the formula (II) or a salt thereof and / or formula (III):wherein n indicates 3 or 5, R1 indicates CH or N and R2 indicates H or OH when R1 is CH, or H when R1 is N, and a melamine derivative of formula (IV):wherein R3 is a methoxymethyl group (—CH2OCH3) or methylol group (—CH2OH), the number of methoxymethyl groups is 3 to 6, and the number of methylol groups is 0 to 3, and / or polymer or copolymer resins of the same and a pneumatic tire using the same.

Owner:THE YOKOHAMA RUBBER CO LTD

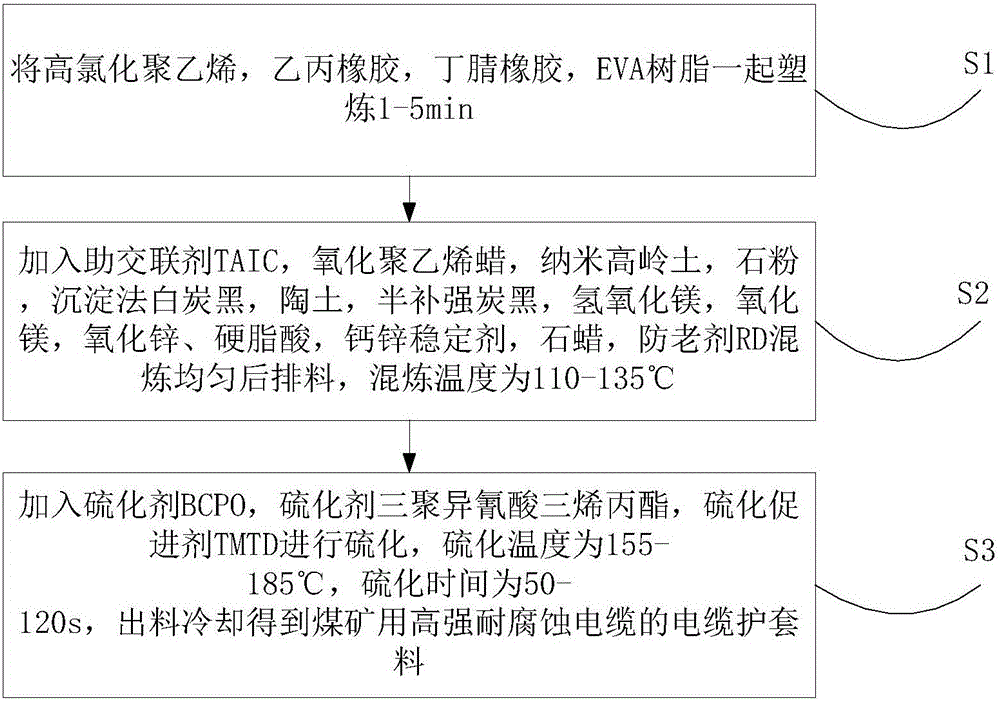

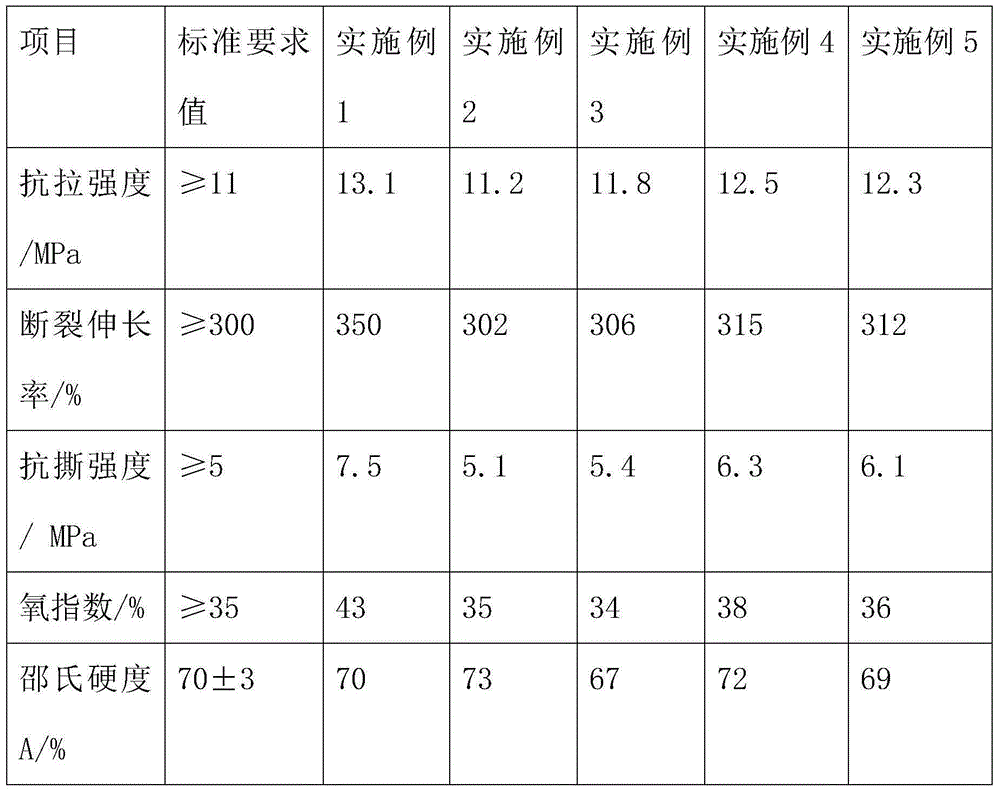

High-strength corrosion-resistant cable for coal mine

InactiveCN105153558AExcellent resistance to atmospheric agingGood chemical resistancePlastic/resin/waxes insulatorsWaxCorrosion resistant

The invention provides a high-strength corrosion-resistant cable for a coal mine. The cable comprises a cable core, an insulating layer and a sheath layer, wherein the sheath layer comprises the raw materials in parts by weight: 65 parts of highly chlorinated polyethylene, 50 parts of ethylene propylene rubber, 35 parts of nitrile rubber, 35 parts of EVA resin, 2.0 parts of a vulcanizing agent BCPO, 1.5 parts of a vulcanizing agent triallyl isocyanurate, 0.5 part of a vulcanizing accelerant TMTD, 1.0 part of an assistant crosslinking agent TAIC, 4 parts of oxidized polyethlene wax, 18 parts of nano kaolin, 10 parts of mountain flour, 5 parts of precipitated white carbon black, 6 parts of argil, 12 parts of semi-reinforced carbon black, 25 parts of magnesium hydrate, 4.0 parts of magnesium oxide, 3.5 parts of zinc oxide, 1.5 parts of stearic acid, 4.0 parts of a calcium and zinc stabilizer, 3.5 parts of paraffin and 2.0 parts of an anti-aging agent RD. The invention further provides a preparation method for the high-strength corrosion-resistant cable for the coal mine. The cable provided by the invention has temperature-resisting and corrosion-resisting properties, and is extremely excellent in tear resistance.

Owner:ANHUI HUAYU CABLE GRP

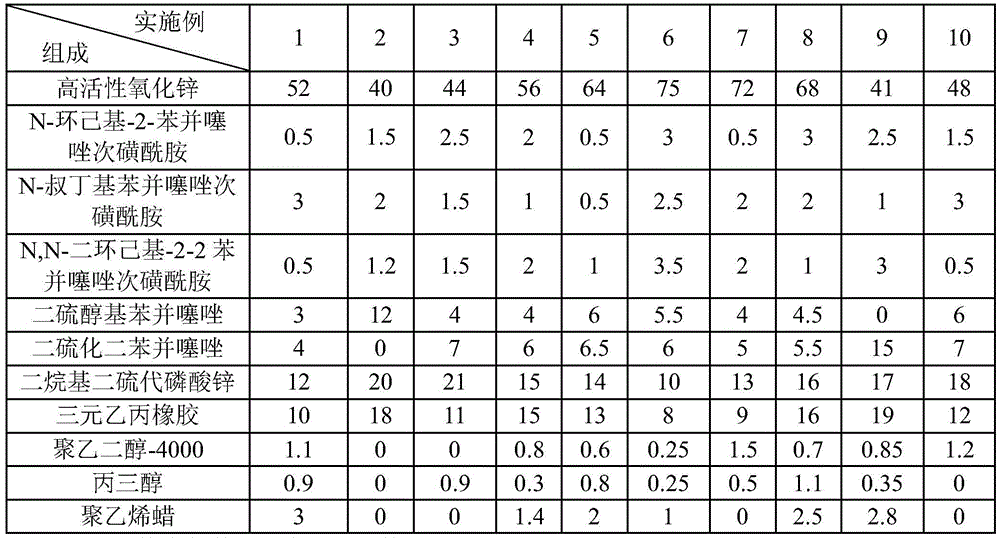

Rubber comprehensive accelerator and method for preparing same

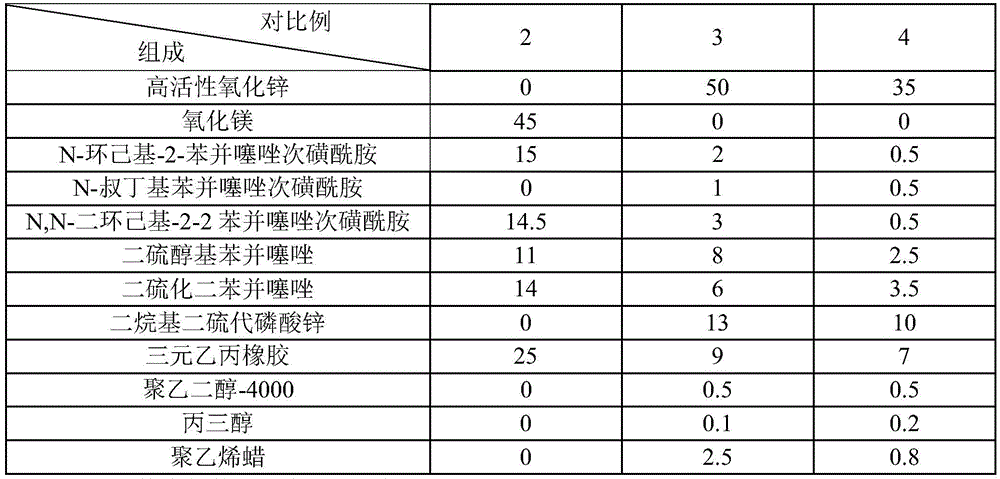

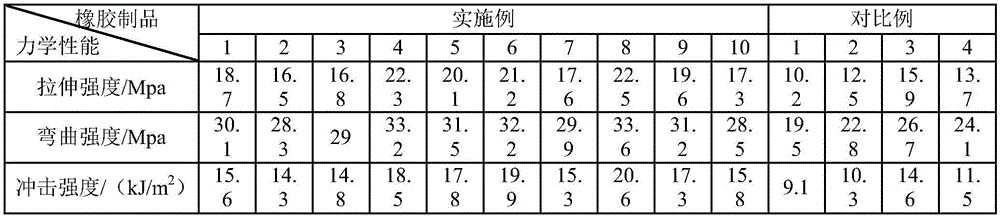

The invention discloses a rubber comprehensive accelerator and a method for preparing the same.The rubber comprehensive accelerator mainly comprises, by weight, 40-75 parts of high-activity zinc oxide, 2-9 parts of after-effectiveness sulfenamide accelerators, 7-15 parts of thiazole accelerators, 10-21 parts of ultrahigh-speed accelerators and 8-19 parts of macromolecular carriers.The rubber comprehensive accelerator and the method have the advantages that different types of additives can be sufficiently mixed with one another by the aid of a step-by-step adding process, accordingly, the rubber comprehensive accelerator is excellent in aging resistance and yellowing resistance, and mechanical properties of rubber products further can be improved.

Owner:YONGJIA WEICHENG RUBBER IND & TRADE CO LTD

Wear-resisting and oil-resisting oil pipe rubber material

The invention discloses a wear-resisting and oil-resisting oil pipe rubber material. The wear-resisting and oil-resisting oil pipe rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of epichlorohydrin rubber, 25-30 parts of chlorinated natural rubber, 15-20 parts of butadiene styrene rubber, 10-15 parts of carboxylic acrylonitrile butadiene rubber, 2-5 parts of 1,1-di(t-butylperoxy)-3,3,5-trimethylsiloxane, 1-1.5 parts of bis-2,4-dichlorobenzoyl peroxide, 0.3-0.6 part of 2,5-dimethyl-2,5-di(tert-butyl peroxy)hexane, 4-6 parts of sulfur powder, 2-4 parts of triethanolamine, 5-7 parts of zinc oxide, 25-30 parts of channel black, 20-30 parts of superfine hollow microspheres, 15-20 parts of fumed silica, 25-30 parts of nano calcined kaolinite, 20-25 parts of nano-titanium nitride, 30-40 parts of magnesium hydroxide, 2-3 parts of barium stearate, 4-6 parts of trioctyl trimellitate, 1-3 parts of antiager MB and 2-4 parts of antiager NBC.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

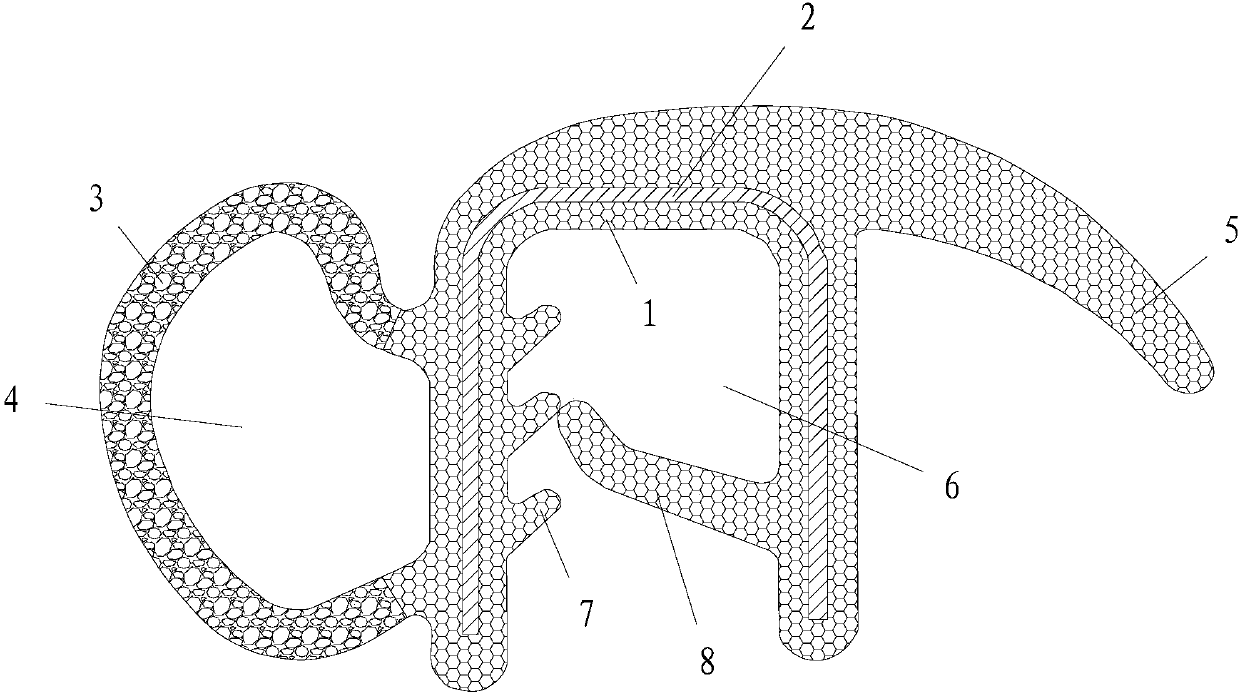

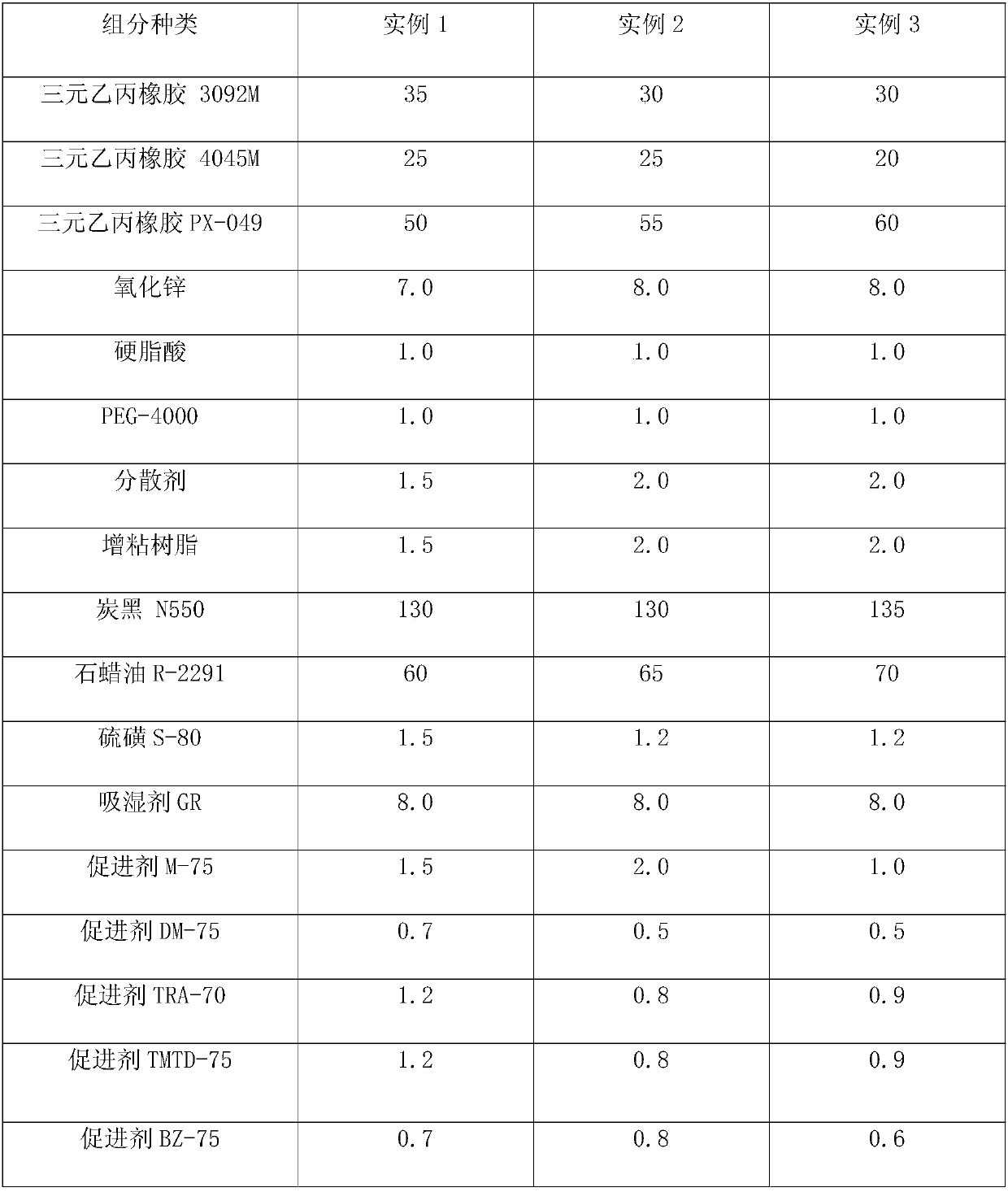

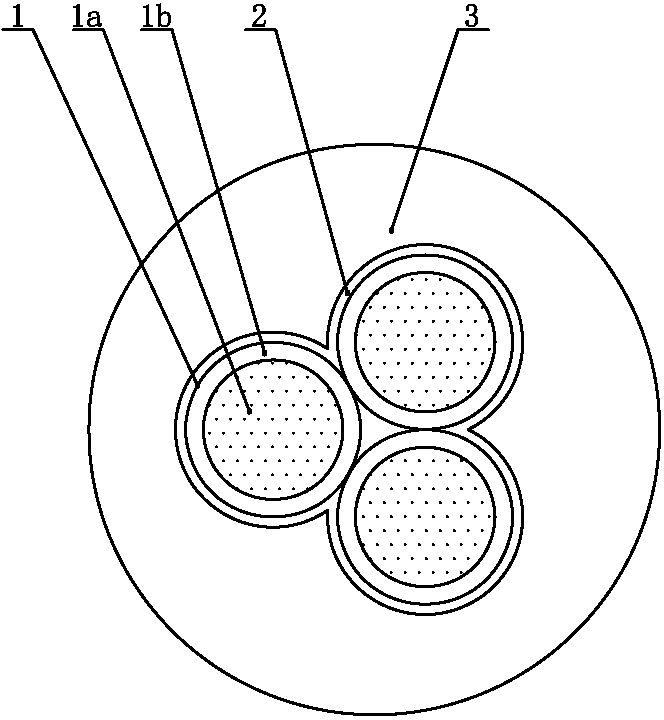

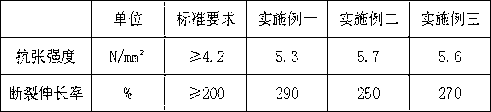

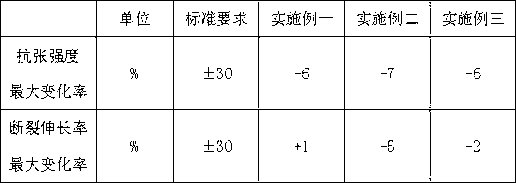

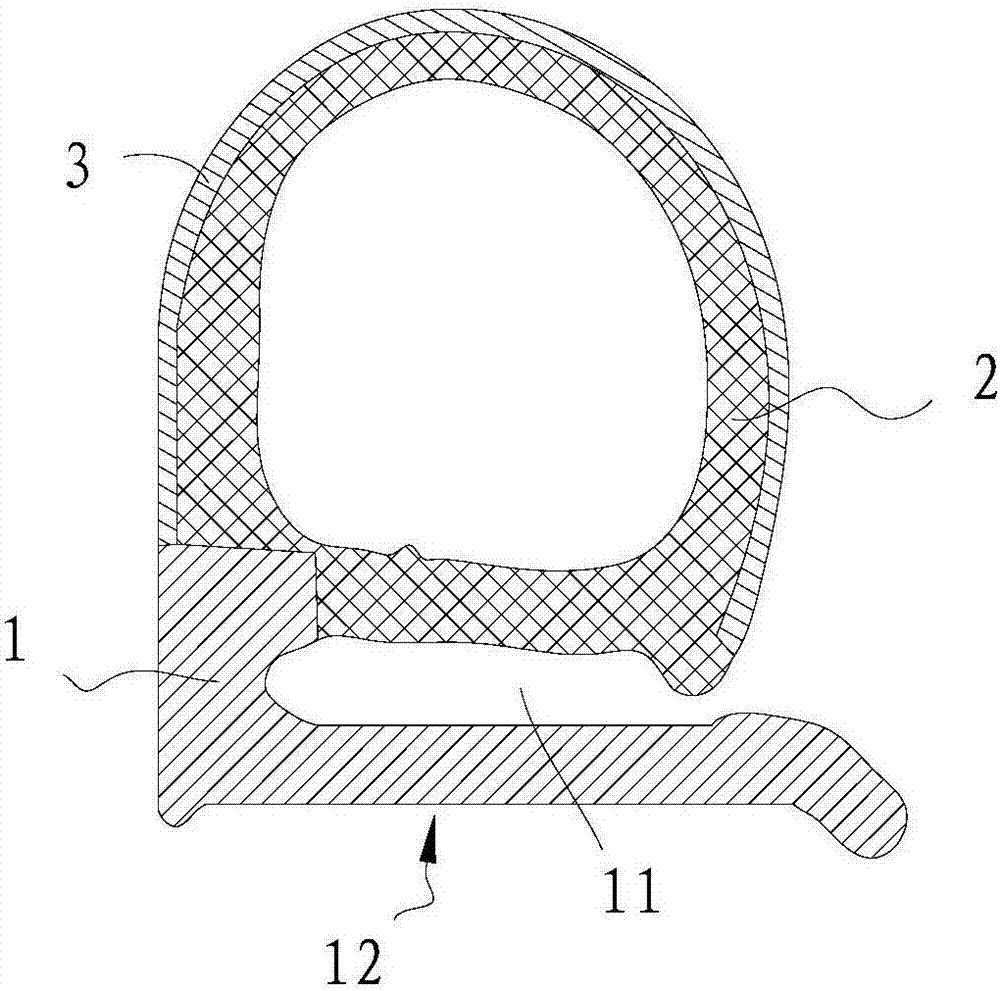

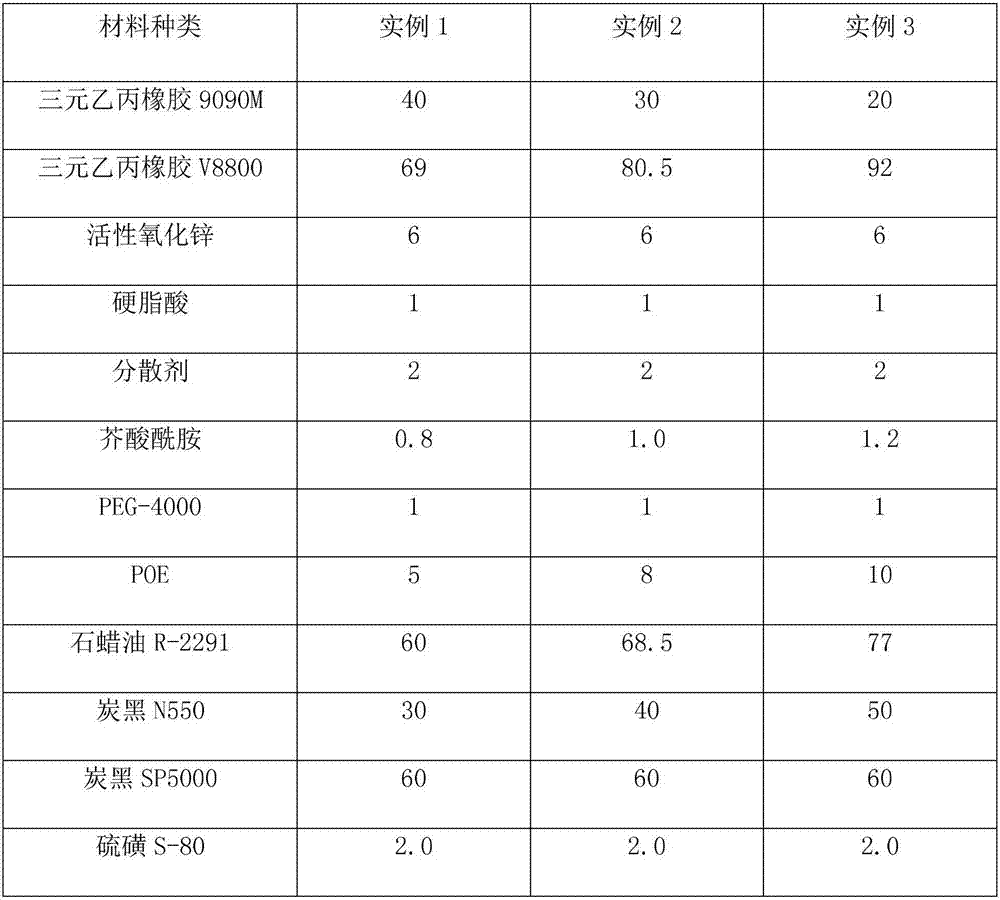

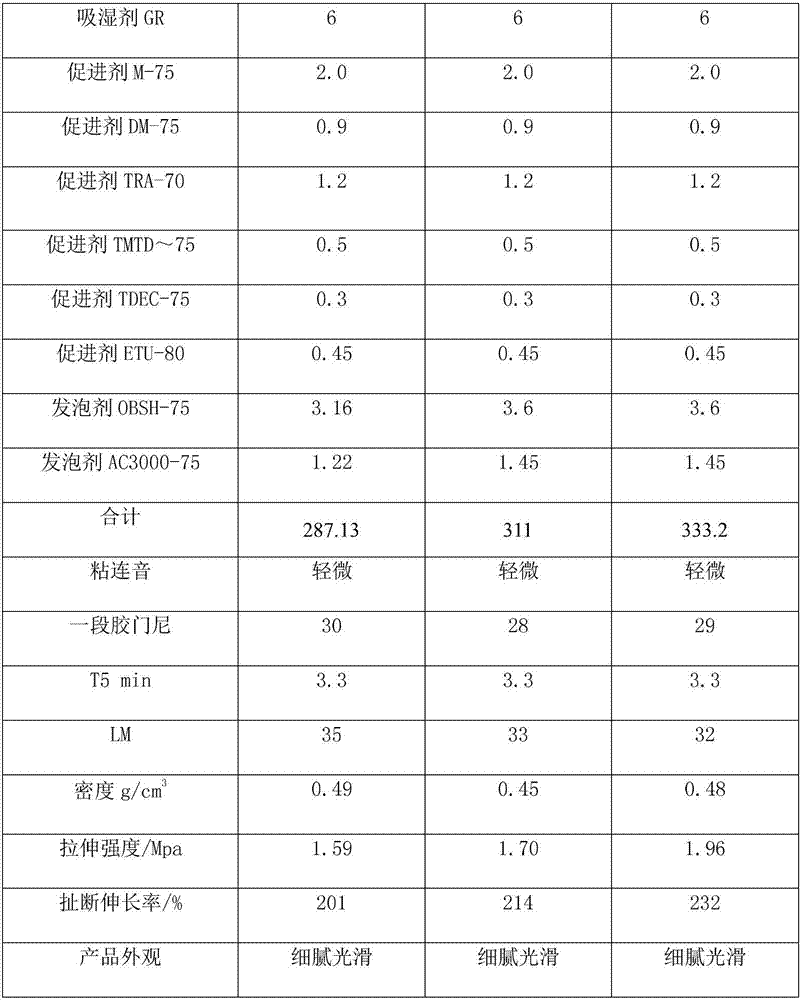

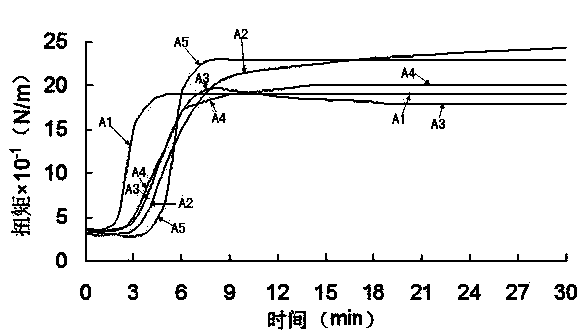

Sealing strip cladding sizing material and preparation method thereof as well as car door sealing strip and preparation method thereof

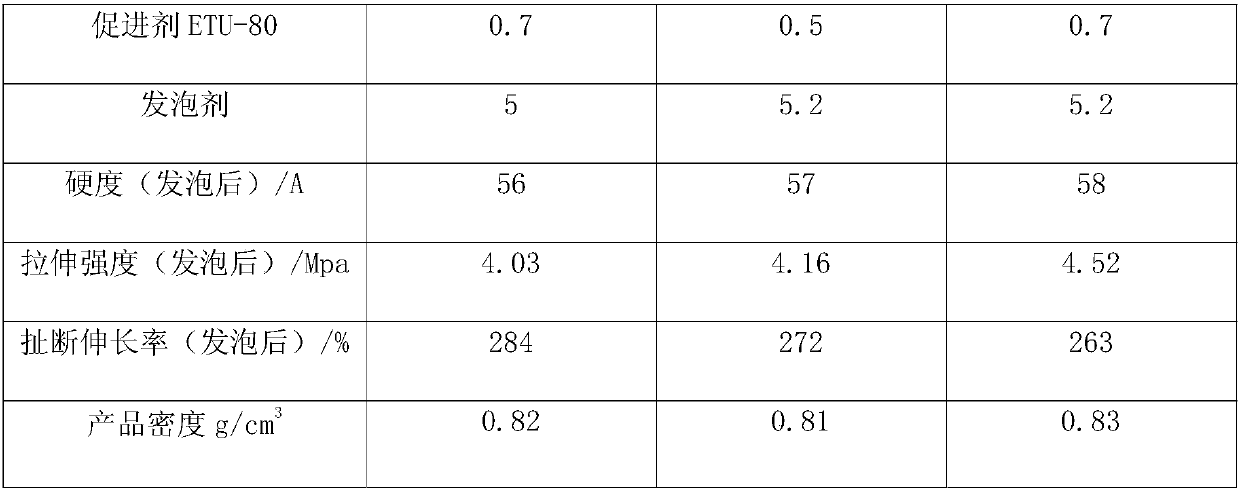

The invention provides a sealing strip cladding sizing material and a preparation method thereof as well as a car door sealing strip and a preparation method thereof. The sealing strip cladding sizingmaterial of the invention is prepared from the following components: EPDM (Ethylene-Propylene-Diene Monomer) 3092M, EPDM 4045M, EPDM PX-049, zinc oxide, stearic acid, PEG-4000, a dispersing agent, tackifying resin, paraffin oil R-2291, carbon black N550, sulfur S-80, a moisture absorbent GR, an accelerant M-75, an accelerant DM-75, an accelerant TRA-70, an accelerant TMTD-75, an accelerant BZ-75,an accelerant ETU-80, and a microsphere foaming agent EWE-60GE. The sealing strip cladding sizing material of the invention can implement the light-weight design of a sealing strip product, also hasrelatively good physical properties such as processability and surface quality, and can improve the quality of a sealing strip utilizing the sealing strip cladding sizing material.

Owner:NUOBO RUBBER PRODION

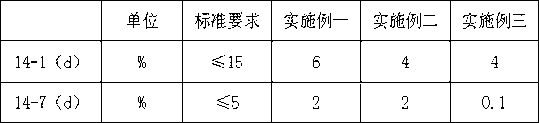

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

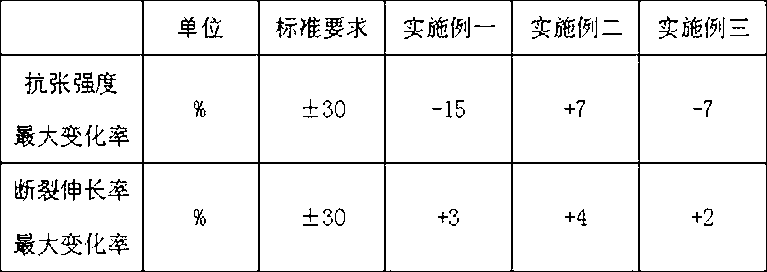

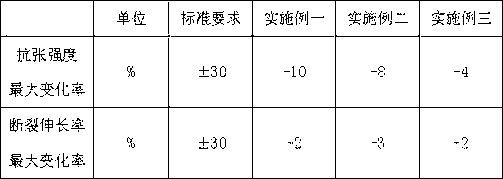

Salt corrosion resistance twisted cable insulation rubber used for ocean wind power and preparation method thereof

ActiveCN103224669AIncrease working temperatureAnti-aging propertiesPlastic/resin/waxes insulatorsInsulated cablesRubber materialVulcanization

The invention discloses salt corrosion resistance twisted cable insulation rubber used for ocean wind power and a preparation method of the salt corrosion resistance twisted cable insulation rubber. By weight, raw materials comprise 8 parts of Keltan5508, 12 parts of DutralTER4044, 5-7 parts of EP-20, 0.5-0.7 part of DCP, 0.3-0.5 part of TAC, 0.2-0.4 part of HVA-2, 0.2-0.4 part of RD, 0.2-0.4 part of MB, 0.2-0.4 part of KH-550, 2.1-2.5 part of hydration zinc borate, 1-1.5 parts of antimony trioxide, 25-40 parts of aluminum hydroxide, 0.8-1.2 part of red lead, 0.5-1 part of stearic acid, 1.5-2 parts of nan-zinc oxide, 2-5 parts of paraffin oil Sunpar2280, 0.5-1 part of chlorinated paraffin-52, and 1-3 parts of hydration silicon dioxide. According to the method, firstly, the EPDM rubber Keltan5508, the DutralTER4044 and the EP-20 are mixed for 1-1.5 minutes, and then other components except for a vulcanizing agent and a co-vulcanization agent are added. After mixing is carried out for 7-8 minutes, discharging and airing are carried out for more than 24 hours. Then the rubber materials are mixed for 2-3 minutes, the vulcanizing agent and the co-vulcanization agent are added at the last 20 seconds, and the mixed materials are loaded on an open mill for milling, triangular injection molding and square injection molding and then sheeted. The insulation rubber is good in mechanical performance, anti-corrosion performance and anti-aging performance and long in service life.

Owner:浙江华威设备制造有限公司

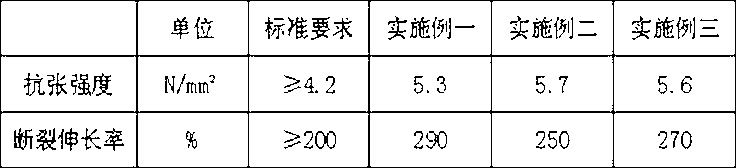

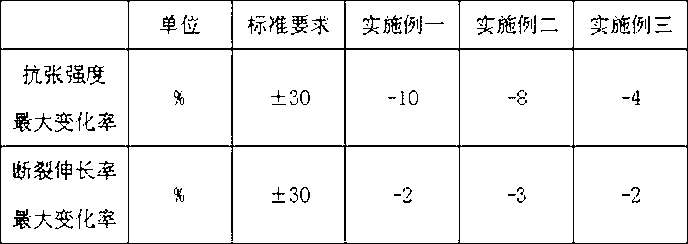

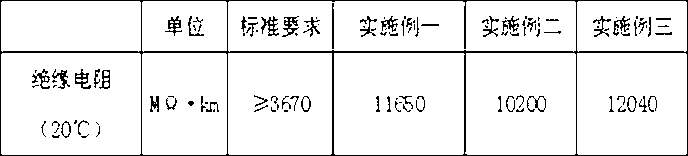

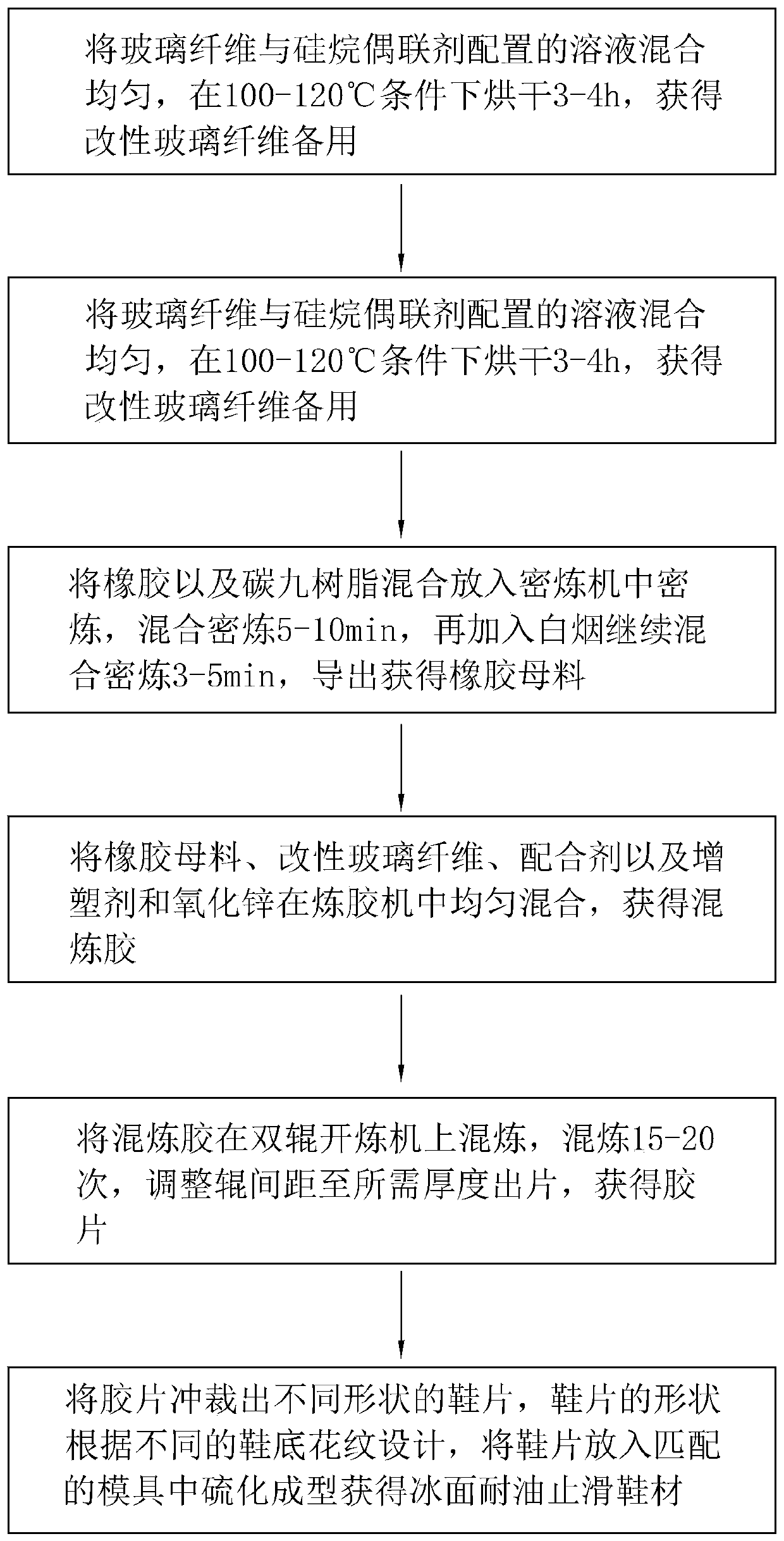

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

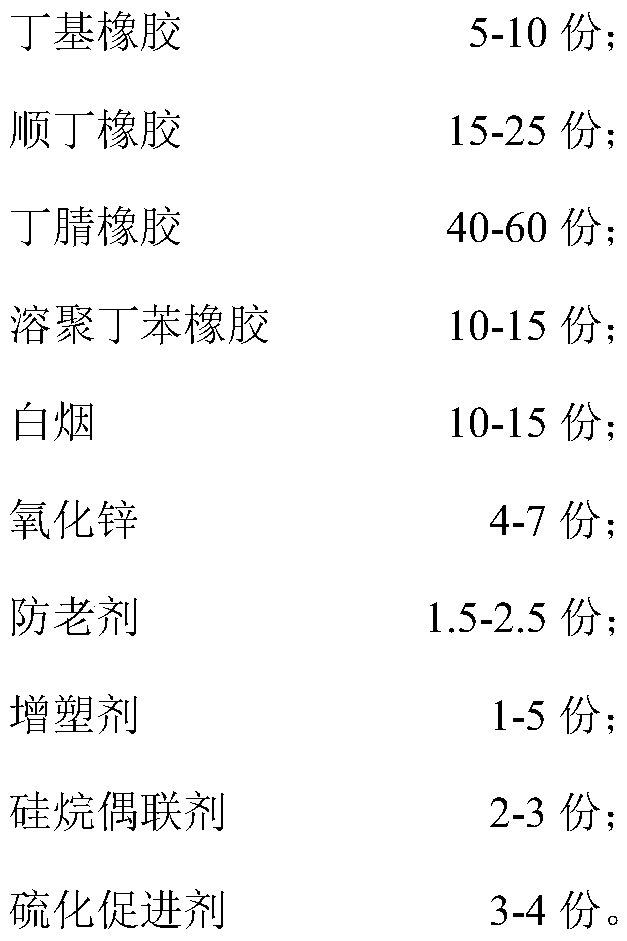

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

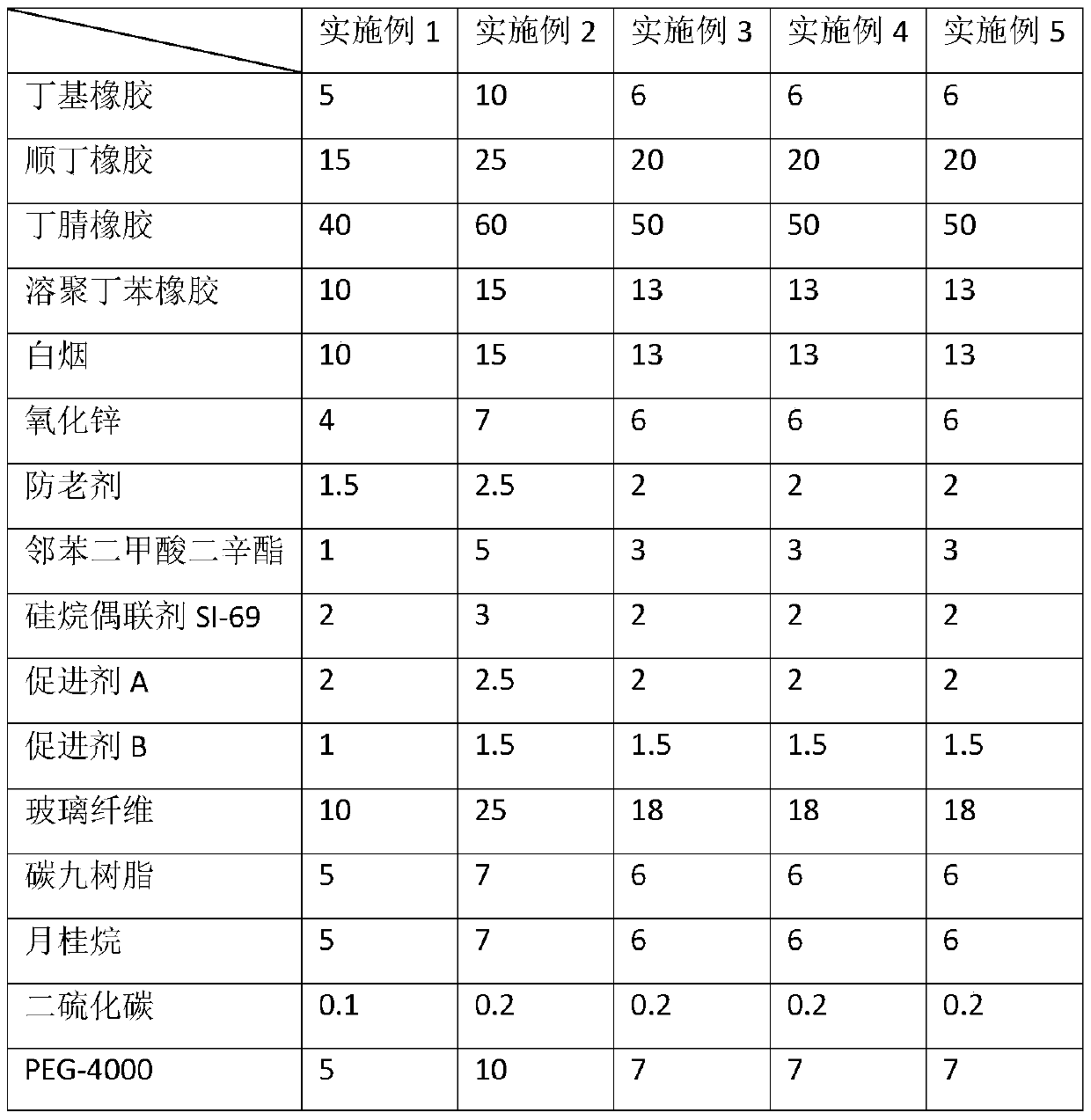

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

Application of zinc isoocatanoate in reduction on agglomeration of white carbon black, white carbon black dispersing agent containing zinc isoocatanoate and preparation method thereof

The invention provides application of zinc isoocatanoate in reduction on agglomeration of white carbon black. According to research, the inventor discovers that the polarity of a silanol group on the surface of white carbon black can be reduced by zinc isoocatanoate so as to play a role in dispersing white carbon black. Under the support of the function, zinc isoocatanoate can be used in the application field of multiple white carbon blacks. The invention also provides a white carbon black dispersing agent containing zinc isoocatanoate and a preparation method thereof. The method is simple, free of pollution, energy-saving and environment-friendly; the obtained dispersing agent has functions of physical dispersion and chemical dispersion, and is suitable for dispersing sizing materials with high filling amount of white carbon black, so that the dispersibility of the white carbon black can be improved, the processing performance of the sizing material also can be improved, the mixing time is shortened, the smoothness and dispersion uniformity of the sizing material is increased, the flowability of the sizing material in the processing and mixing stage is increased, and the Mooney viscosity is reduced; moreover, the white carbon black dispersing agent has a strengthening effect, and the mechanical property of vulcanized rubber is improved.

Owner:SHANDONG YANGGU HUATAI CHEM

High-performance rubber for generator shock pad and preparation process thereof

ActiveCN103627043AIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

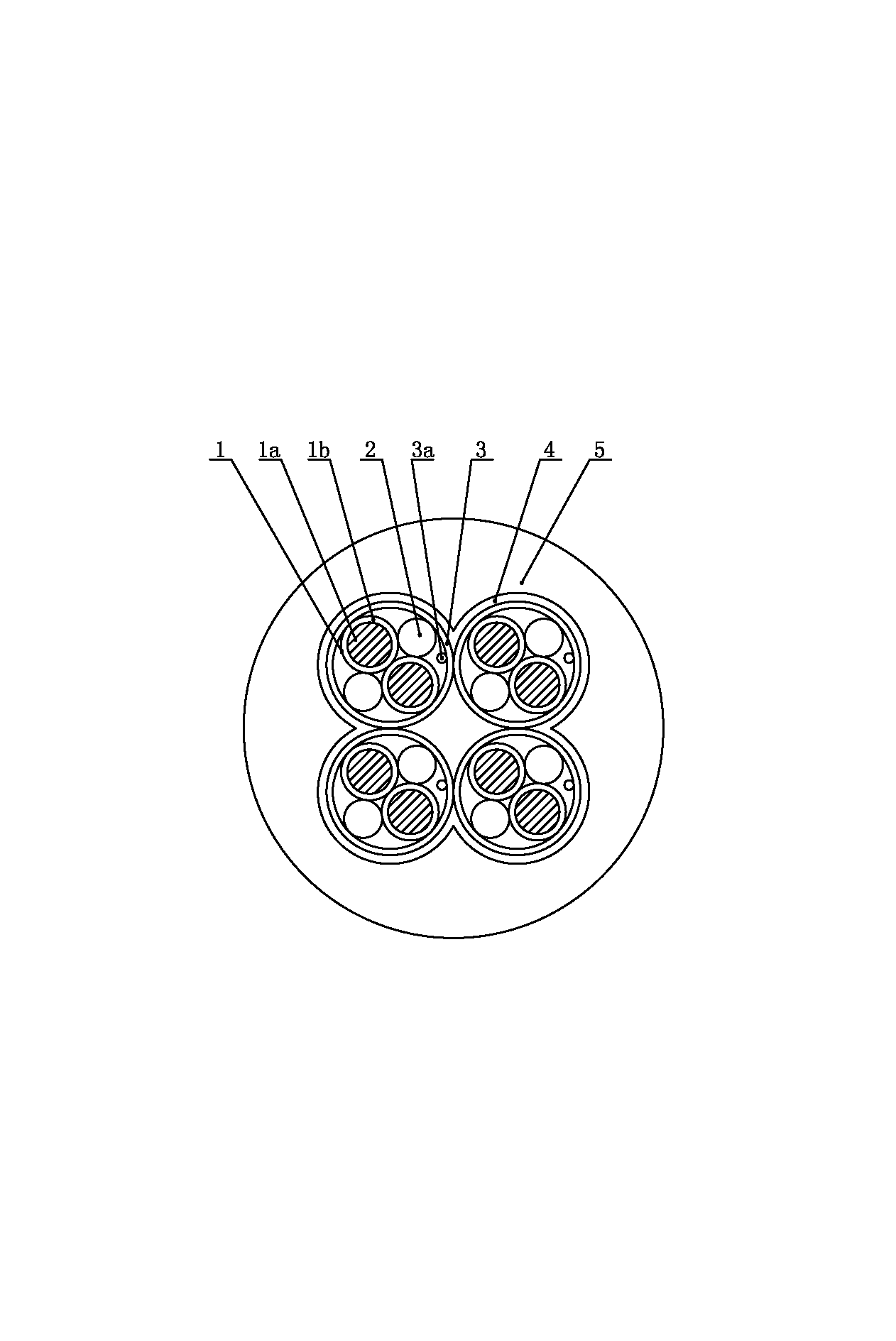

Double-shielded instrument cable for flame-resistant and fire-resistant ship and manufacture method thereof

ActiveCN103187126AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsFiberCopper conductor

The invention relates to a double-shielded instrument cable for a flame-resistant and fire-resistant ship and a manufacture method of the double-shielded instrument cable. The periphery of a twisted copper conductor is extruded and packed with a flame-resistant and fire-resistant ethylene propylene rubber insulating layer to form insulated cable cores, the insulated cable cores are twisted with one another two by two to form a twisted conductor pair, a gap of each twisted conductor pair is filled with a flame-resistant non-absorbent fiber filling core, and the periphery of each set of the twisted conductor pairs is warped with twisted conductor pair copper foil shield layers to form pair twist sets; and the plurality of sets of pair twist sets are twisted with one another to form a cable core, and the periphery of the cable core is sequentially packed with a low-intensity non-woven fabric lengthways-packed layer, an inner jacket, a cable core copper foil shield layer, an armor weaving layer and an outer jacket. The low-intensity non-woven fabric lengthways-packed layer is completely matched with the shape of the insulated cable core, so that gaps between the low-intensity non-woven fabric lengthways-packed layer and the insulated cable core can be eliminated, and the flame can not inwards extend conveniently; and the non-stickiness between the inner jacket and the insulated cable core can be guaranteed, and the insulated cable core can be hardly damaged when the jackets are stripped during construction.

Owner:嘉兴君宏汽车配件有限公司

Marine independent screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969048AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesUltraviolet lightsEngineering

The invention relates to a marine independent screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, a copper foil polyester composite belt screening layer is lapped at the periphery of each group of stranded wire pair, copper foil surfaces are inward, tin-plating stranded steel drainage wires are arranged on the inner sides of the copper foil polyester composite belt screening layers, penetrate through the full length of each stranded pair and cling together with the copper foil surfaces; and a polyester belt is lapped at the periphery of each copper foil polyester composite belt screening layer to form a stranded group; and the all stranded groups are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, an inner protecting bush is extruded at the periphery of the cable core, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The independent screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

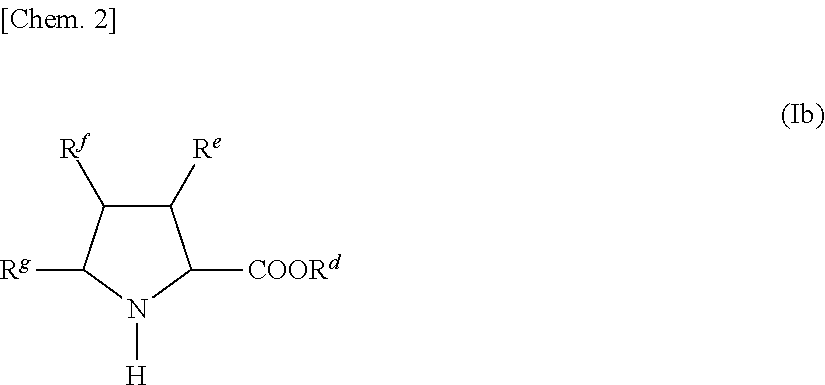

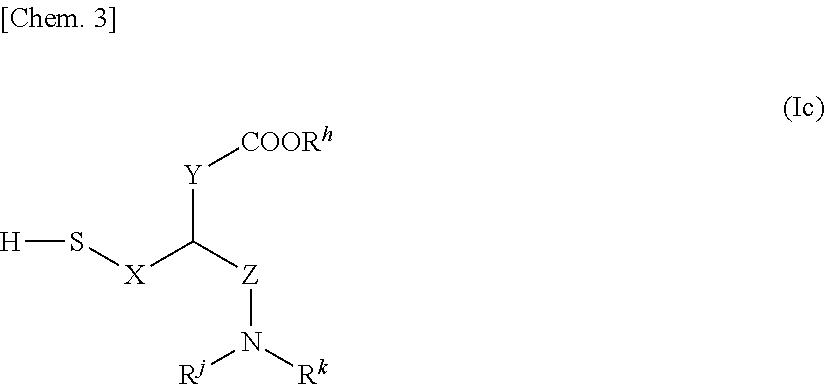

Rubber composition and method for producing rubber composition

ActiveUS20150031821A1Improve propertiesSpeed up vulcanizationSpecial tyresPolymer scienceVulcanization

The present invention provides a rubber composition comprising, as blended, a rubber component (A), an amino acid derivative (B) and a filler containing an inorganic filler (C), and further containing, as incorporated therein, at least one selected from sulfur and a sulfur compound. The vulcanization rate of the rubber composition is accelerated and the low-heat-generation property thereof is excellent.

Owner:BRIDGESTONE CORP

Rubber material for rubber shoe sole and preparation method thereof

The invention discloses a rubber material for a rubber shoe sole and a preparation method thereof. The rubber material is prepared from the following raw materials in parts by weight: 45 to 65 parts of nitrile rubber, 35 to 45 parts of organosilicone rubber, 5 to 10 parts of rubber and plastic alloy, 4 to 8 parts of modified vinyl resin, 3 to 6 parts of modified rare earth oxide, 1 to 4 parts of vulcanizing agent, 3 to 7 parts of tetrasulphide dipentyl methylene thiuram, 2 to 6 parts of diisopropyl peroxide, 4 to 8 parts of maleic anhydride-grafted polyethylene, 2 to 4 parts of zinc methacrylate, 5 to 10 parts of dibutyl phthalate, 3 to 6 parts of pentaerythritol stearate, 10 to 20 parts of modified nanometer wear-resistant filler, 3 to 7 parts of zinc ricinoleate, 2 to 5 parts of activator, 1 to 3 parts of softener, 0.5 to 1.5 parts of rubber accelerant, and 0.4 to 0.8 part of anti-aging agent. The rubber material for the rubber shoe sole has the advantages that the elasticity is high, the abrasion-resistant property is high, the tensile property and compressive property are realized without damage, the corrosion-resistant property is realized, and the weather-resistant property is good.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

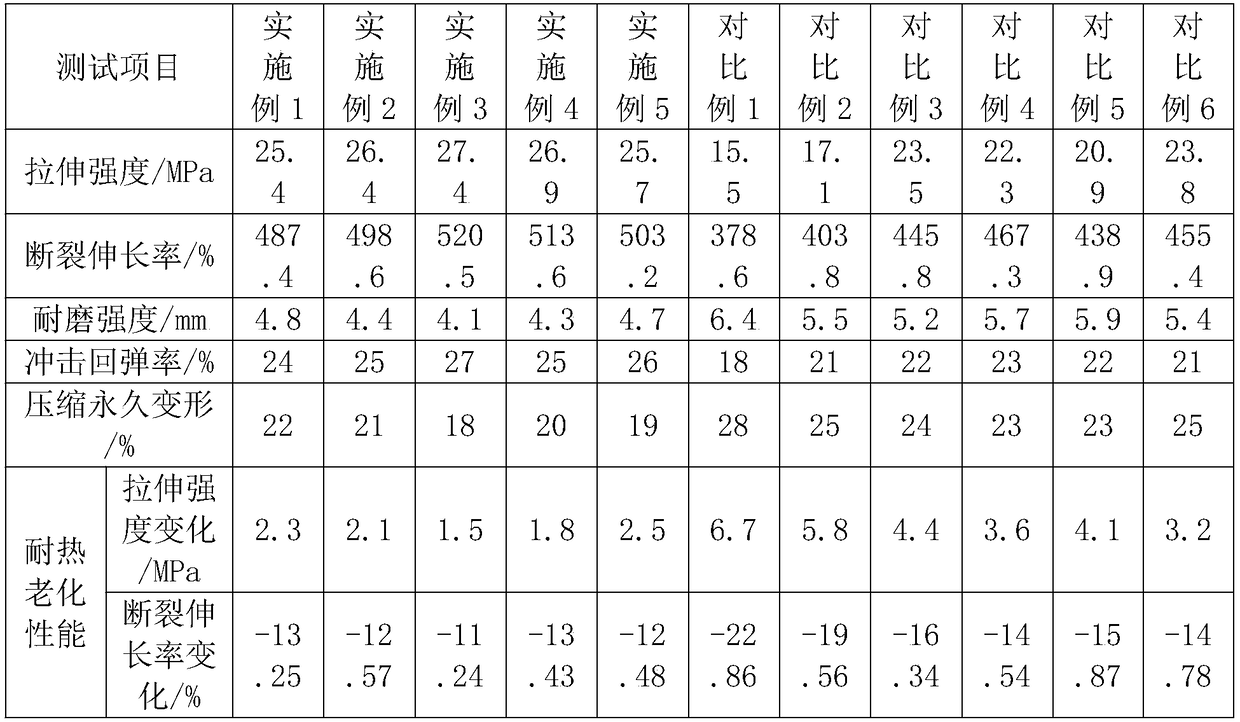

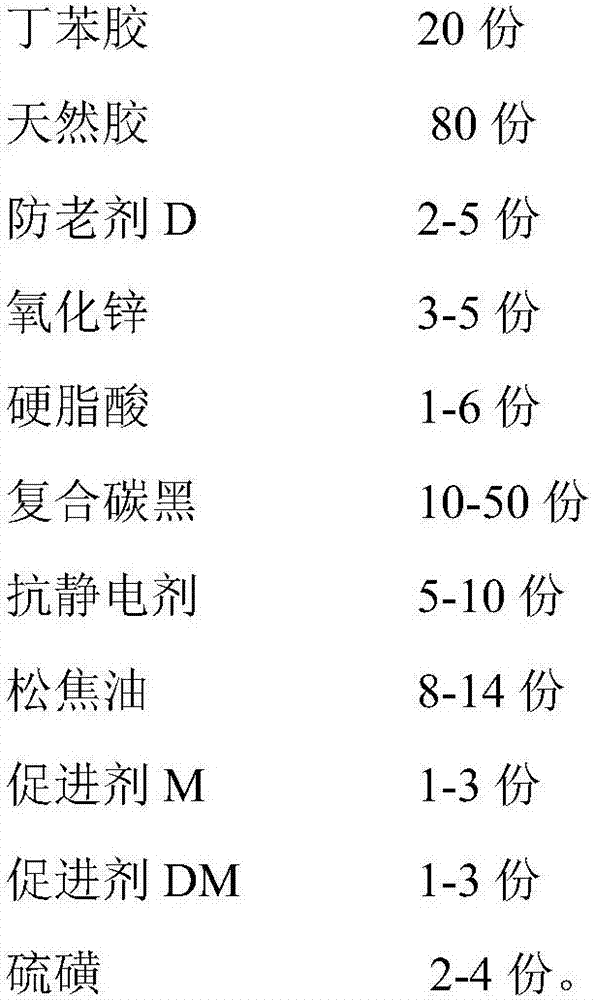

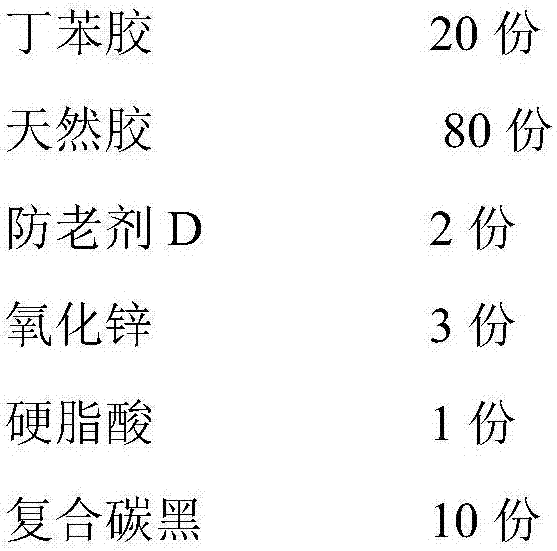

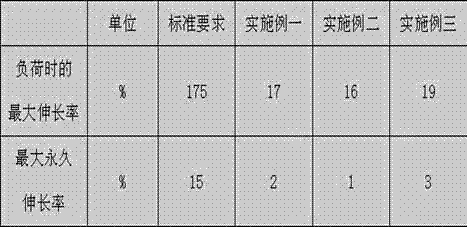

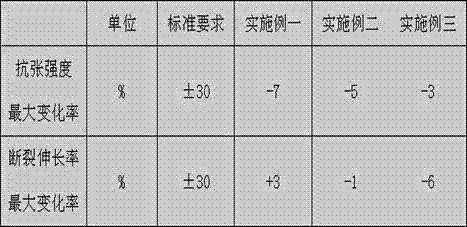

Anti-static rubber and preparation method thereof

InactiveCN107417991AEasy to processImprove wear resistanceBuilding insulationsAntistatic agentHardness

The invention discloses an anti-static rubber and a preparation method thereof and belongs to the field of rubber manufacturing. The anti-static rubber and the preparation method thereof aim at solving the problems of anti-static deficiency, poor physical performance and low heat generation rate in the prior art. The anti-static rubber is a compound conductive carbon black composition combined with anti-static agent, thereby effectively guaranteeing anti-static effects, improving wear resistance; compounded carbon black is low in heat value during operation and can ensure hardness and ductility of the anti-static rubber. By means of a two-section plastifying manner and through synergistic effects of the compounded carbon black and the anti-static agent, the anti-static rubber achieves good anti-static effects, excellent physical performance, good hardness and tensile strength, low heat value and simple production processes.

Owner:MAANSHAN TIANXIN ROLL IND

Marine integral screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969056AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesCopper foilScreening instrument

The invention relates to a marine integral screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, the all stranded wire pairs are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, a copper foil polyester composite belt screening layer is lapped at the periphery of the cable core, a copper foil surface is inward, a tin-plating stranded steel drainage wire is arranged on the inner side of the copper foil polyester composite belt screening layer, penetrates through the full length of each stranded pair and clings together with the copper foil surface; and a polyester belt is lapped at the periphery of the copper foil polyester composite belt screening layer, an inner protecting bush is extruded at the periphery of the polyester belt, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The integral screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

Whitening ultraviolet-proof ethylene-propylene rubber insulation control cable for ships and manufacturing method thereof

InactiveCN102969057AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation control cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a 0.35-2.5mm<2> tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 part of TAIC, 0.5-0.8 part of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid, 1-1.5 parts of rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of an ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

A kind of high-performance rubber for generator shock absorber and its preparation process

ActiveCN103627043BIncreased shear strengthImprove anti-aging propertiesRubber materialPolymer science

The invention discloses high-performance rubber for a generator shock pad and a preparation process thereof. Raw materials of the rubber comprise: natural rubber, DBD (Dibromodulcitol), 100-mesh zinc oxide, stearic acid, CTP (Cytidine Triphosphate), spraying carbon black, DCP (Dicalcium Phosphate), BMI (Bismaleimide Resin), TMTD (Thiram), CZ (Citrazinic Acid), m-phenylenediamine and bisphenol A type epoxy resin; and the preparation process comprises: premixing, mixing and vulcanizing. A rubber material is fully activated by mixing to improve the heat resistance, aging resistance and deformation resistance of the rubber material, the m-phenylenediamine and the BMI are pre-mixed before the vulcanizing procedure to improve the toughness of the BMI, the bisphenol A type epoxy resin is added with the m-phenylenediamine, the three components are compatible and perforative to improve the shearing strength and the aging resistance of the rubber, the CZ and the TMTD are added to further improve the curing speed and the scorch resistance, and the finally obtained rubber has good breaking strength and breaking elongation, proper hardness, excellent high temperature resistance and good damping effect.

Owner:STATE GRID CORP OF CHINA +1

Heat-resistant weather-resistant flame-retarding rubber insulating cable material

InactiveCN104761802AOvercome the difficulty of swinging glueImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxElastomer

The invention discloses a high-strength high-elongation flame retardant rubber insulated cable material and a preparation process thereof. The high-strength high-elongation flame retardant rubber insulated cable material comprises the following components in parts by weight: 8-14 parts of chlorinated polyethylene (CPE), 15-21 parts of ethylene-octylene copolymer elastomer (POE), 3-6 parts of fumed silica, 15-19 parts of aluminium hydroxide, 13-18 parts of calcined clay, 5-8 parts of 800# paraffin base rubber oil, 0.5-1 part of active magnesium oxide, 4-7 parts of superfine talcum powder, 1-2 parts of zinc oxide, 0.3-0.6 part of environmental stabilizer, 1-2 parts of microcrystalline wax, 0.5-1 part of titanium dioxide, 0.5-0.8 part of 4,4' bis(alpha, alpha dimethyl benzyl) diphenylamine, 1-2 parts of dicumyl peroxide and 1-1.5 parts of triallyl cyanurate. By adopting the high-strength high-elongation flame retardant rubber insulated cable material, uniform addition of inorganic powder is facilitated, a process range is wide, higher elongation at break is still maintained when a continuous vulcanizing temperature is 190-210 DEG C, a fire retardant and a high reinforced filler are added without reducing electrical property, and tensile strength and oxygen index are greatly increased; and cost is greatly reduced.

Owner:JIANGSU HENGTONG POWER CABLE

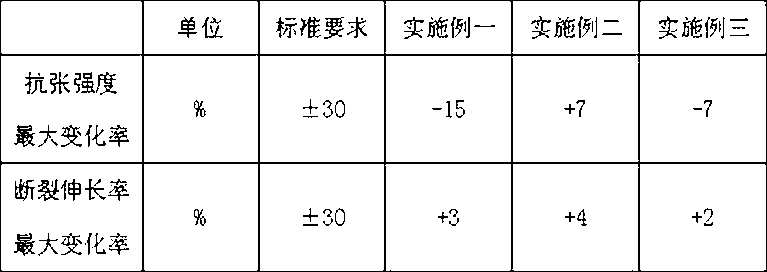

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com