White carbon black dispersant for rubber and preparation method of white carbon black dispersant

A technology of white carbon black and dispersant, which is applied in the field of white carbon black dispersant for rubber and its preparation, can solve the problems of complex use of silane coupling agent and dispersant, serious environmental pollution, and inconspicuous effect, etc., and achieve Improve processing safety performance, control product quality, and reduce prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

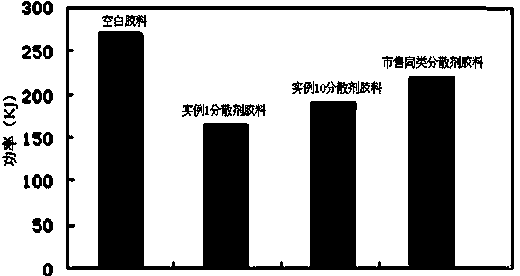

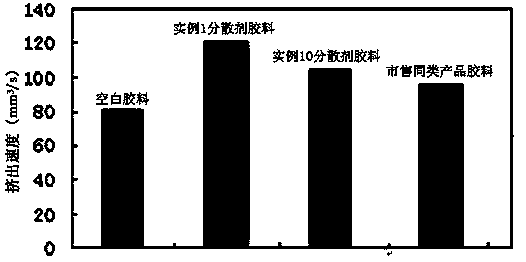

Examples

Embodiment 1

[0045] The formula of the white carbon black dispersant for rubber of the present invention is: 60 parts of stearic acid amide, 25 parts of pentaerythritol tetraester stearate, and 15 parts of plasticizer A (saturated and unsaturated mixed fatty acid zinc soap).

[0046] The preparation method is as follows: Stir and melt fatty acid soap salt and fatty acid ester at 100°C, then add fatty acid amide or fatty acid amine at 115°C and stir to melt, pour out and cool to form tablets or melt and granulate to obtain new white rubber for rubber Carbon black dispersant. The preparation process flow chart is shown in Figure 5 .

Embodiment 2

[0048] The formulation of the white carbon black dispersant for rubber of the present invention is: 50 parts of stearic acid amide, 30 parts of pentaerythritol tetraester stearate, and 20 parts of plasticizer A (saturated and unsaturated mixed fatty acid zinc soap). The preparation method is the same as in Example 1.

Embodiment 3

[0050] The formulation of the white carbon black dispersant for rubber of the present invention is: 55 parts of stearic acid amide, 25 parts of pentaerythritol tetraester stearate, and 15 parts of plasticizer A (saturated and unsaturated mixed fatty acid zinc soap). The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com