Patents

Literature

37results about How to "Aids in demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881AIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

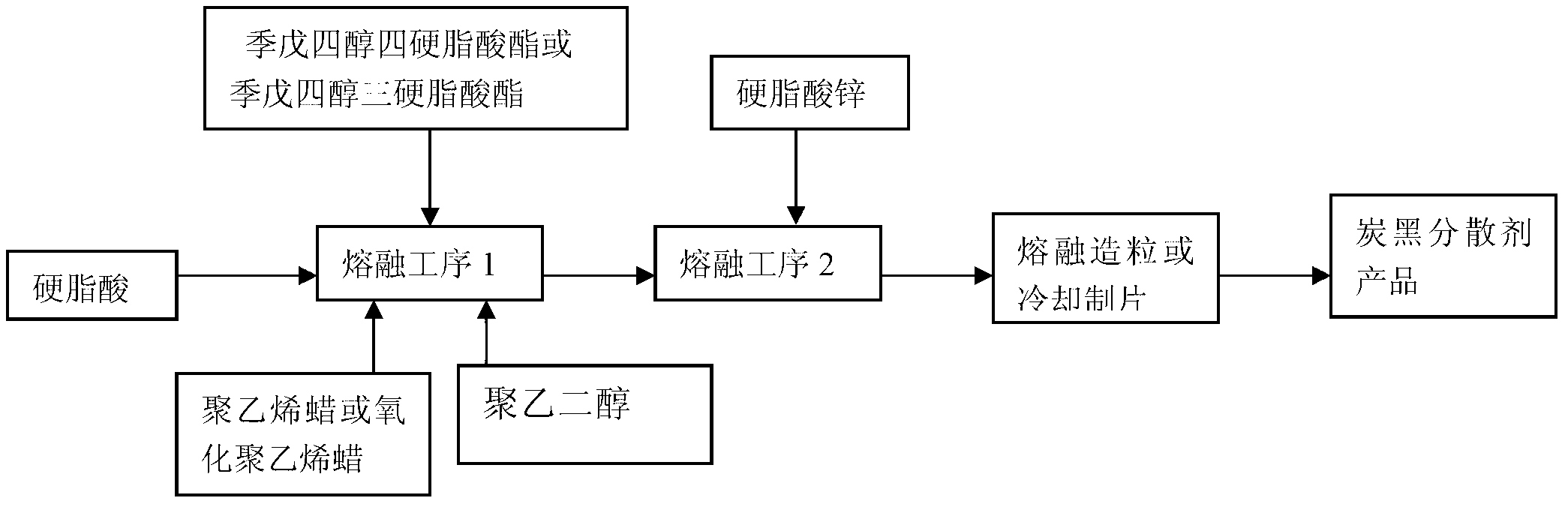

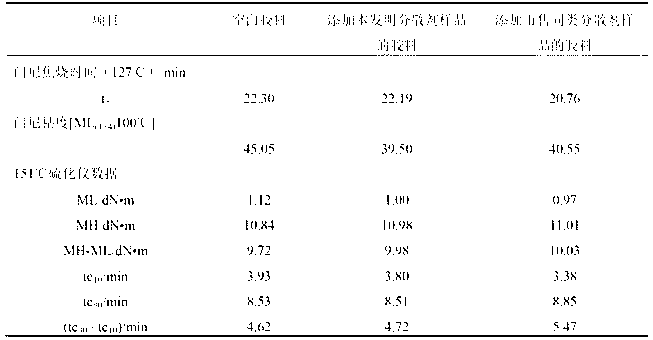

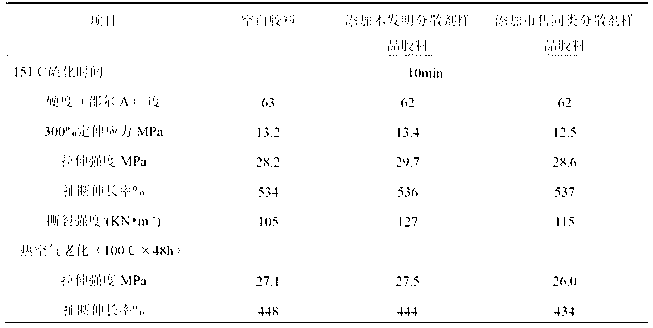

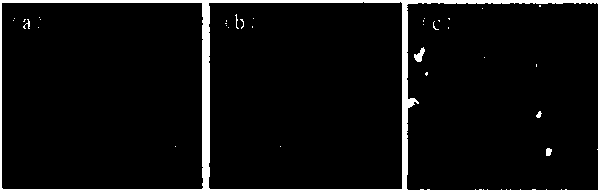

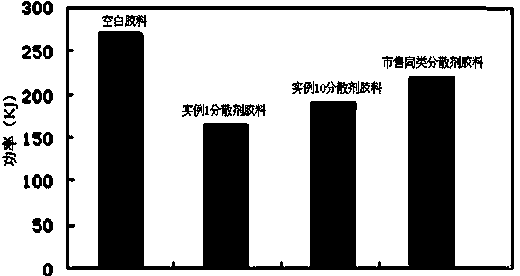

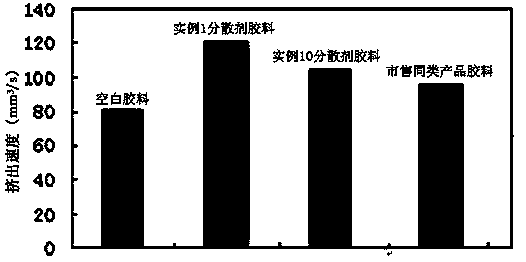

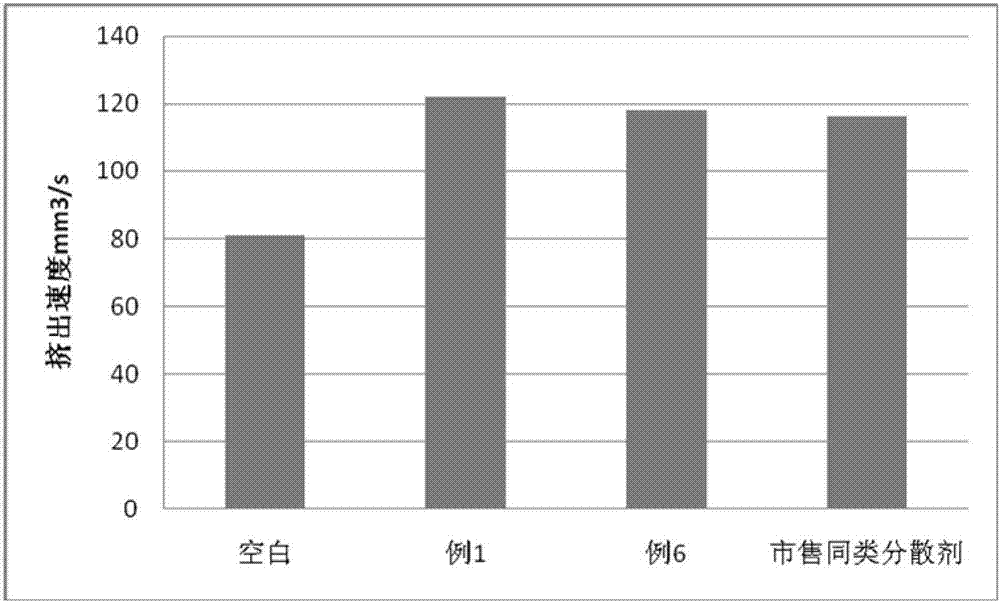

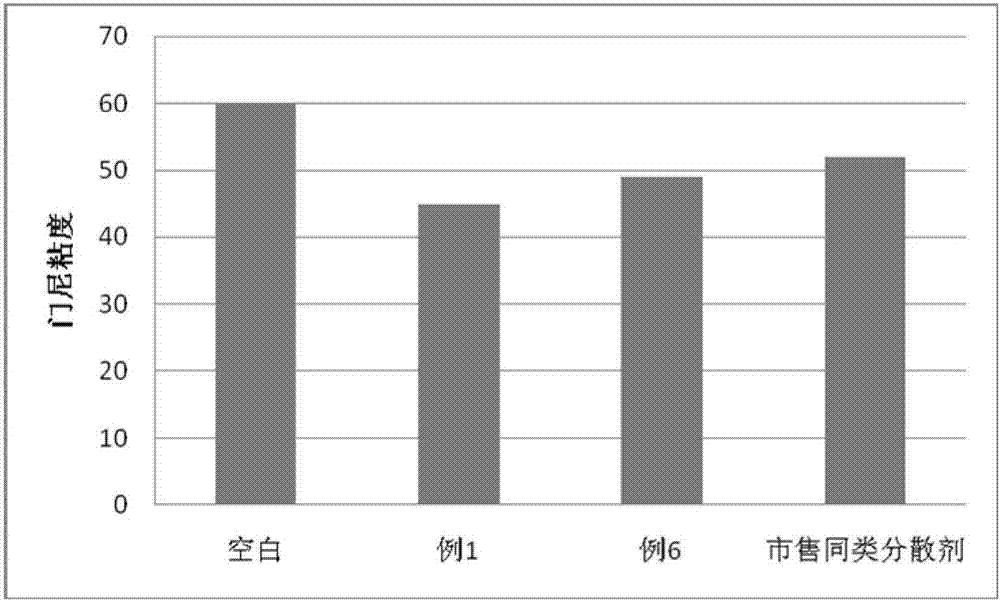

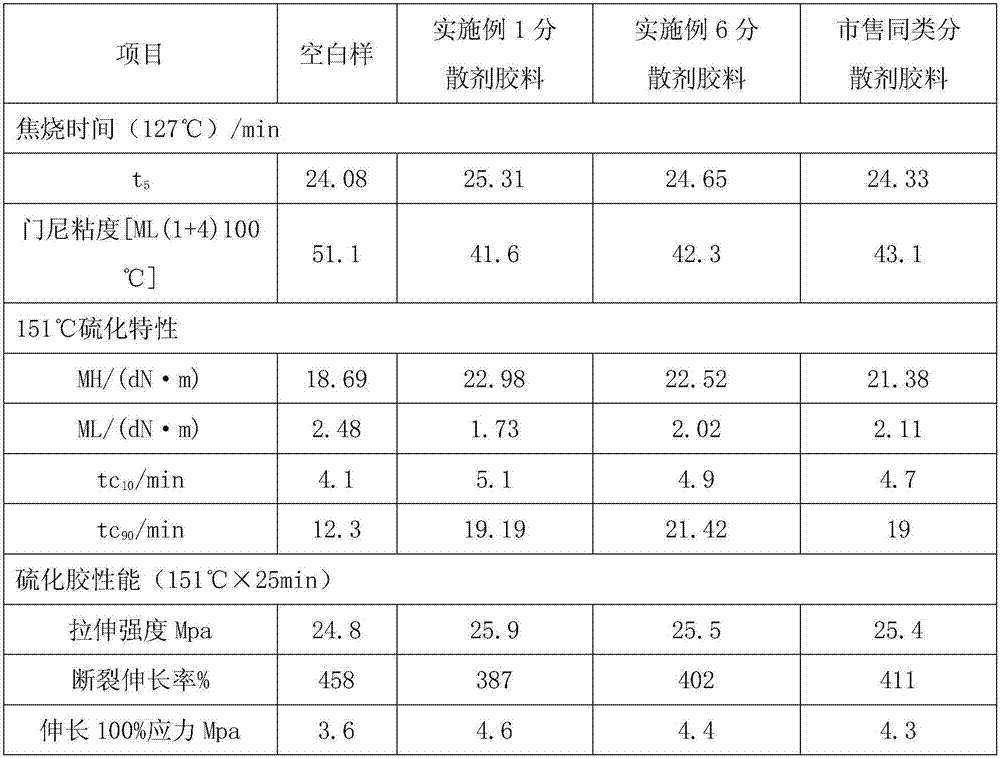

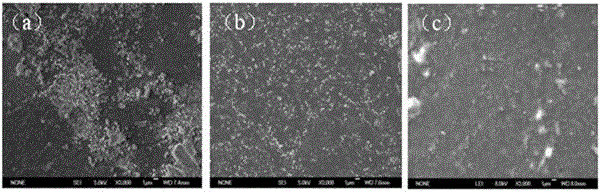

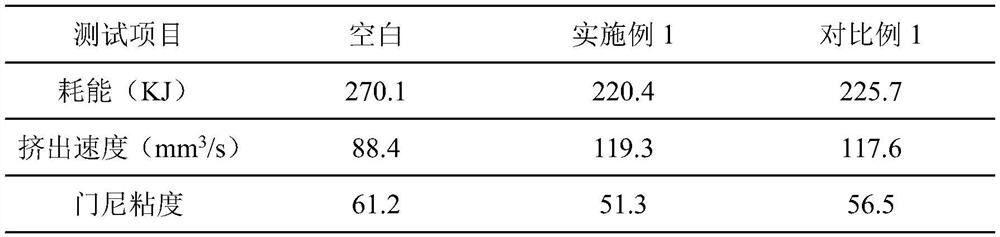

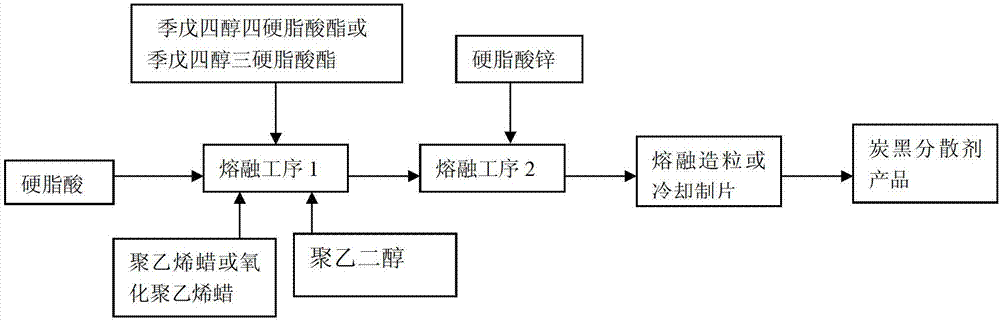

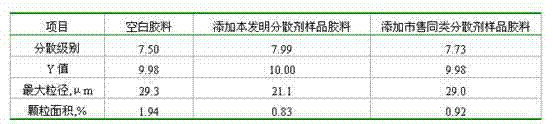

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

White carbon black dispersant for rubber and preparation method of white carbon black dispersant

ActiveCN103450504AIncreased process safetyImprove mechanical propertiesRubber materialPolymer science

The invention discloses a white carbon black dispersant for rubber. The white carbon black dispersant is characterized by comprising the following raw materials in parts by weight: 30-70 parts of fatty acyl amide / acid amide, 10-30 parts of fatty acid ester and 0-30 parts of fatty acid soap salt. The invention also discloses a preparation method of the white carbon black dispersant. The preparation method is simple and rapid; and the obtained white carbon black dispersant has multiple functions such as dispersion, lubrication and chemical modification, can be used for improving the processing safety performance as well as physical and mechanical properties of a rubber material and increasing the curing speed of the rubber material and is remarkable in effect.

Owner:SHANDONG YANGGU HUATAI CHEM

Preparation method for SMC composite material

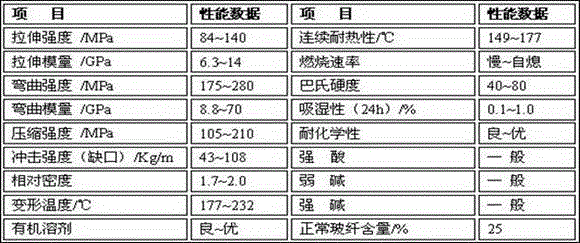

InactiveCN106519620AIncrease brightnessImprove mechanical propertiesSynthetic resin layered productsThermoplasticFiber

The invention relates to a preparation method for an SMC composite material. The preparation method comprises the following steps: successively adding 18 to 25 parts of unsaturated resin, 18 to 22 parts of a low-profile shrinking agent, 6 to 9 parts of thermoplastic, 0.4 to 0.6 part of an auxiliary agent, 0.3 to 0.6 part of a curing agent, 2 to 4 parts of an internal release agent, 0.15 to 0.3 part of a polymerization inhibitor, 34 to 38 parts of an inorganic filling material, 6 to 9 parts of PE powder and 0.8 to 1 part of a thickening agent so as to prepare a resin paste; uniformly coating a high-density polyethylene film with the prepared resin paste in a scraping manner, cutting 24 to 26 parts of glass fiber into the glass fiber with a length of 2 to 3 CM, uniformly dispersing the cut glass fiber between upper and lower high-density polyethylene films, and allowing the resin paste and the alkali-free glass fiber to be completely impregnated so as to form a sheet material; thickening the sheet material at 40 to 45 DEG C for 6 to 12 hours so as to obtain an SMC sheet material molded plastic; and placing sheared SMC sheet material molded plastic into a mold, carrying out mold molding at a temperature of 145 to 155 DEG C, maintaining pressure for a period of time, and carrying out processes like mold closing, demolding and trimming so as to obtain a final product. The preparation method provided by the invention prepares an SMC product with low density, good mechanical properties and high gloss surface.

Owner:常州日新模塑科技有限公司

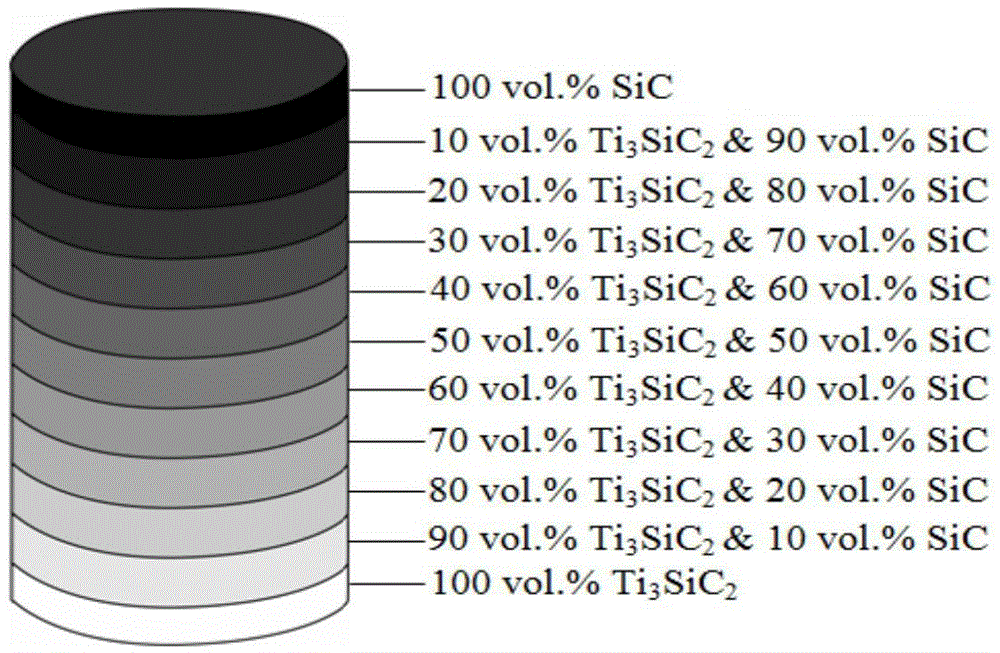

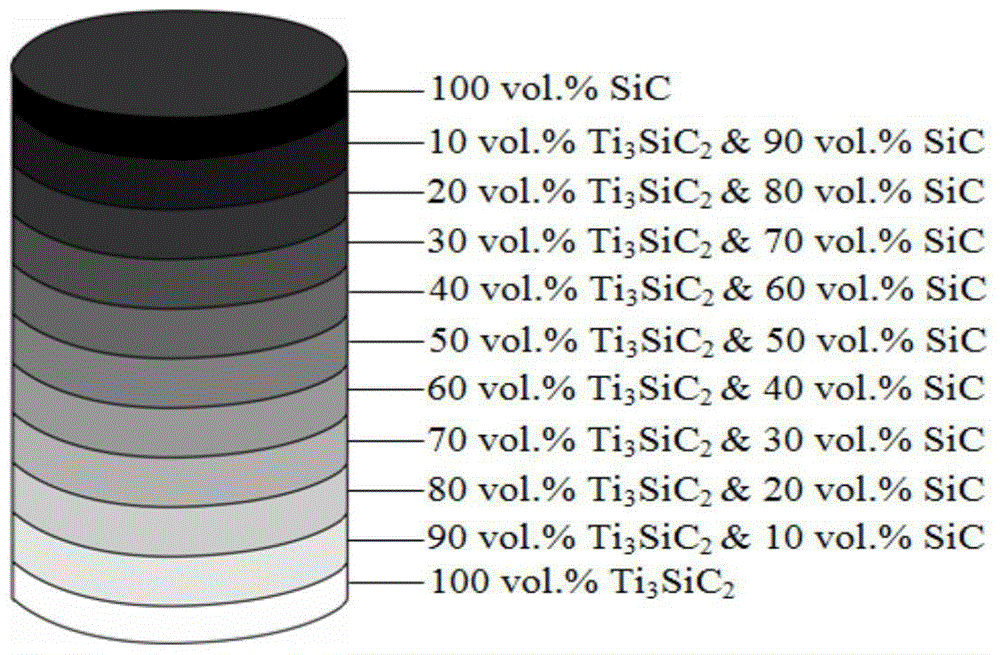

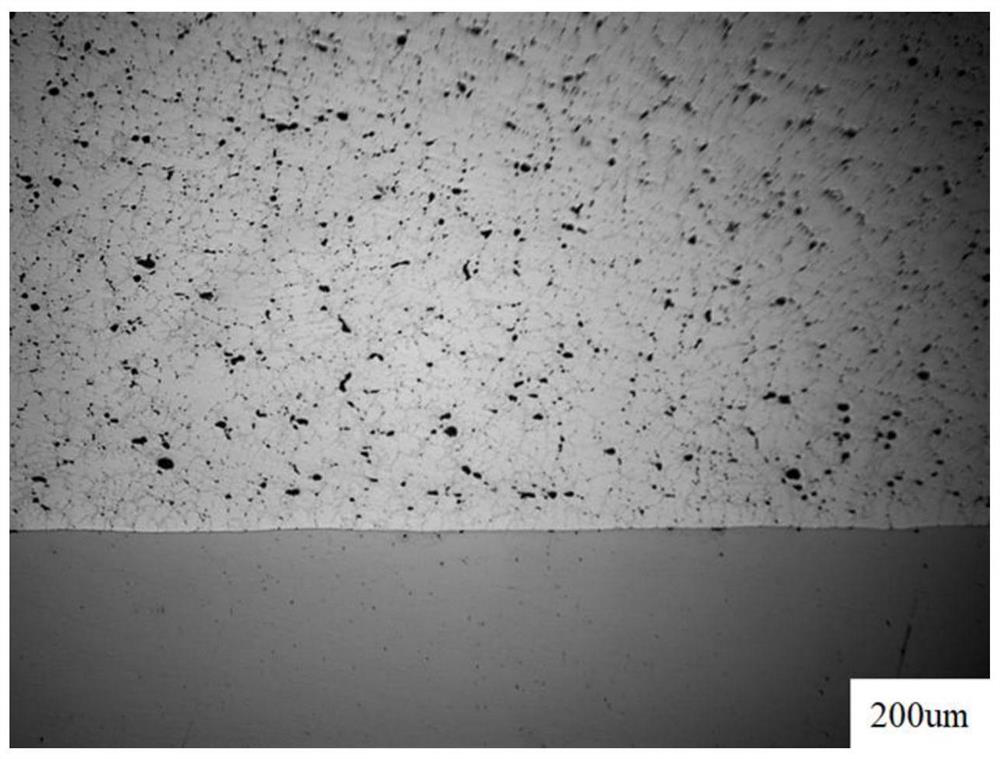

Preparation method of Ti3SiC2/SiC functionally gradient material

ActiveCN105541331AUniform and dense structureModerate combinationOxidation resistantFunctionally gradient material

The invention discloses a preparation method of a Ti3SiC2 / SiC functionally gradient material, comprising the steps of mixing Ti3SiC2 powder and SiC powder in a die layer by layer in a gradient way, then preparing a blank, performing vacuum hot-pressing sintering on the blank to obtain a green body, and sequentially performing dipping densification and pyrolysis treatment on the green body; the SiC powder comprises micron beta-SiC powder and nanometer beta-SiC powder; the vacuum hot-pressing sintering temperature is 1600-1700 DEG C, and is kept for 3-5h, and the maximum pressure is 25MPa; the dipping densification comprises performing dipping densification on gradient layers containing 60-100 vol. percent of SiC in the green body subjected to the hot-pressing sintering in polycarbosilane liquid. The Ti3SiC2 / SiC functionally gradient material prepared by the method is high in compactness, contains multiple gradient layers along the thickness direction from Ti3SiC2 to SiC (designing can be performed as required), the structure is uniform and compact in each gradient layer, interfaces among the gradient layers are moderately combined, the mechanical strength is high, the breaking tenacity is good, under high temperature, the oxidation resistance and the thermal shock resistance are good, and the Ti3SiC2 / SiC functionally gradient material having 11 gradient layers and the thickness of 8-15mm can be prepared.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

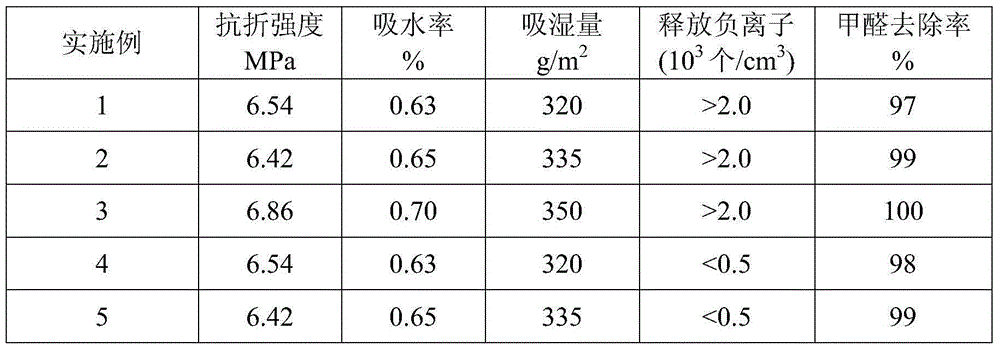

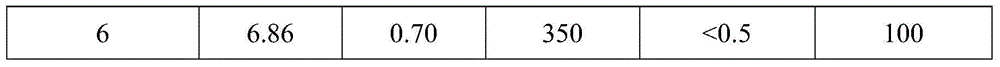

Diatomaceous earth breathing brick with high humidifying harm-reduction function and production method thereof

A diatomaceous earth breathing brick with a high humidifying harm-reduction function and a production method thereof are disclosed, through improvement of a formula, slurry with excellent performances can be prepared, a molding material is prepared by a spray granulation process, and the molding problem is overcome. The formula comprises, (wt%), 80%-90% of diatomaceous earth; 4%-14% of clay; 0.5%-1.5% of talc; 0.5%-1% of a ceramic body enhancer; 1%-2% of a ceramic sintering aid agent; 0.5%-1% of a superplasticizer; 0.5%-1.5% of nano titanium dioxide and 0.5%-1.5% of tourmaline powder. The production method is as follows: the raw materials are prepared into the slurry by adding of water, and by spray granulation, material distribution, molding and firing, the diatomaceous earth breathing brick with the high humidifying harm-reduction function is obtained. Compared with the prior art, the formula and the molding process are improved, the use amount of the diatomaceous earth is significantly increased, body cracking, deformation, stratification and other phenomena caused by inappropriate moisture content of raw materials, uneven material distribution and excessive local stress of a green body can be avoided, and the diatomaceous earth breathing brick has a higher humidifying harm-reduction function.

Owner:LIAONING SILICATE RES INST

Resin paint surface nursing emulsion and preparation method thereof

InactiveCN102174292AEasy to useNo excretionOrganic detergent compounding agentsWax coatingsWaxEmulsion

The invention discloses resin paint surface nursing emulsion, which consists of the following components in part by weight: 10 to 50 parts of stearic acid, 20 to 80 parts of ester, 90 to 150 parts of polyol, 80 to 100 parts of alcohol amine, 50 to 80 parts of solvent oil, 30 to 60 parts of wax and 400 to 500 parts of distilled water. A preparation method comprises the following steps of: uniformly mixing the polyol, the alcohol amine and the distilled water to obtain a component A; heating and stirring the stearic acid, the ester, the solvent oil and the wax at the temperature of between 85 and 95 DEG C, and mixing for 30 to 40 minutes to obtain a component B; and uniformly mixing the component A and the component B. The emulsion can completely remove oil dirt, glue stain and asphalt on the surface of a resin paint, has high varnishing performance, can nurse a glass steel die, and is convenient to use; and the three wastes (waste gas, waste water and waste residue) are not generated in the production process, and the method is environment-friendly.

Owner:NORTHWEST UNIV

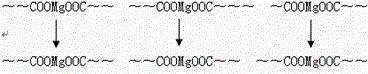

Application of zinc isoocatanoate in reduction on agglomeration of white carbon black, white carbon black dispersing agent containing zinc isoocatanoate and preparation method thereof

The invention provides application of zinc isoocatanoate in reduction on agglomeration of white carbon black. According to research, the inventor discovers that the polarity of a silanol group on the surface of white carbon black can be reduced by zinc isoocatanoate so as to play a role in dispersing white carbon black. Under the support of the function, zinc isoocatanoate can be used in the application field of multiple white carbon blacks. The invention also provides a white carbon black dispersing agent containing zinc isoocatanoate and a preparation method thereof. The method is simple, free of pollution, energy-saving and environment-friendly; the obtained dispersing agent has functions of physical dispersion and chemical dispersion, and is suitable for dispersing sizing materials with high filling amount of white carbon black, so that the dispersibility of the white carbon black can be improved, the processing performance of the sizing material also can be improved, the mixing time is shortened, the smoothness and dispersion uniformity of the sizing material is increased, the flowability of the sizing material in the processing and mixing stage is increased, and the Mooney viscosity is reduced; moreover, the white carbon black dispersing agent has a strengthening effect, and the mechanical property of vulcanized rubber is improved.

Owner:SHANDONG YANGGU HUATAI CHEM

Preparation technology of fair-faced concrete and preparation method of special admixture

The invention relates to a preparation technology of fair-faced concrete and a preparation method of a special admixture. The fair-faced concrete is prepared from the following components: water, cement, fly ash, mineral powder, medium sand, gravels, a dispersing agent, a defoaming agent, an air entraining agent and a water reducing agent. The fair-faced concrete has good apparent effects; by utilizing molding effects of the concrete, a decorative effect can be realized, and secondary finishing and decorating of partial molded concrete are eliminated; the fair-faced concrete is often used as decorative concrete and has the characteristics of small color difference and the like; the cured and molded concrete has the advantages of no obvious color difference in surface color and unique texture; the fair-faced concrete has the advantages of flat and smooth surface, uniform color, angular property, no damage or pollution, good environmental affinity and close to nature when being used forengineering construction.

Owner:成都精准混凝土有限公司

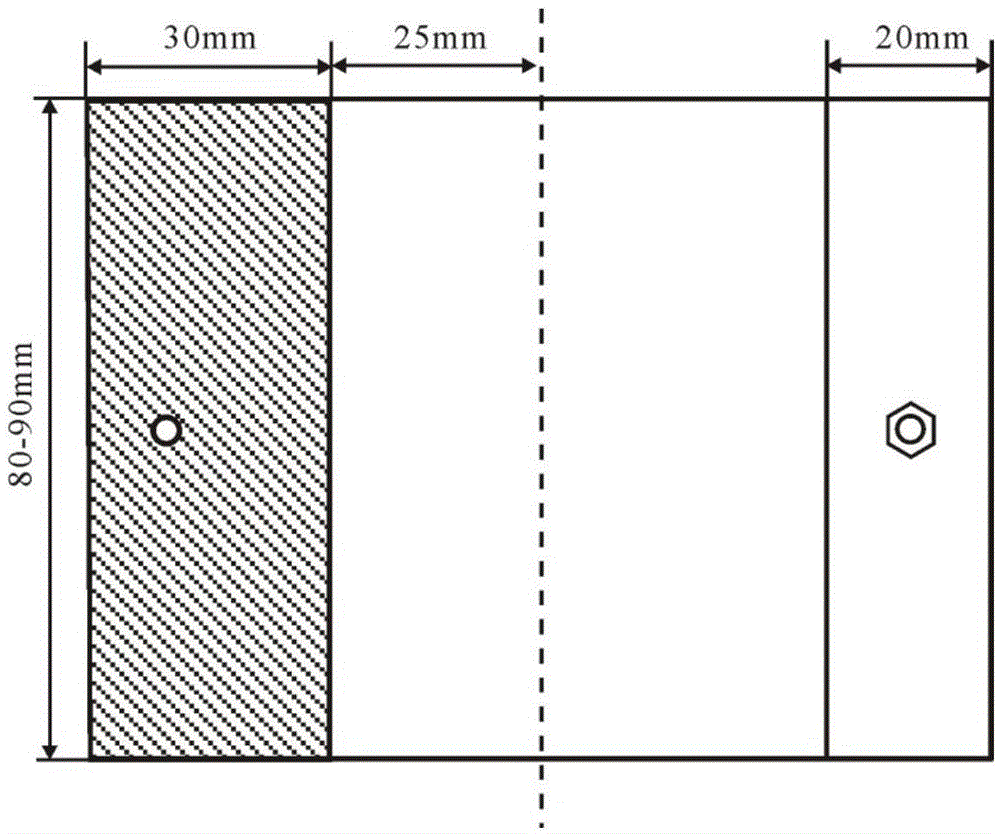

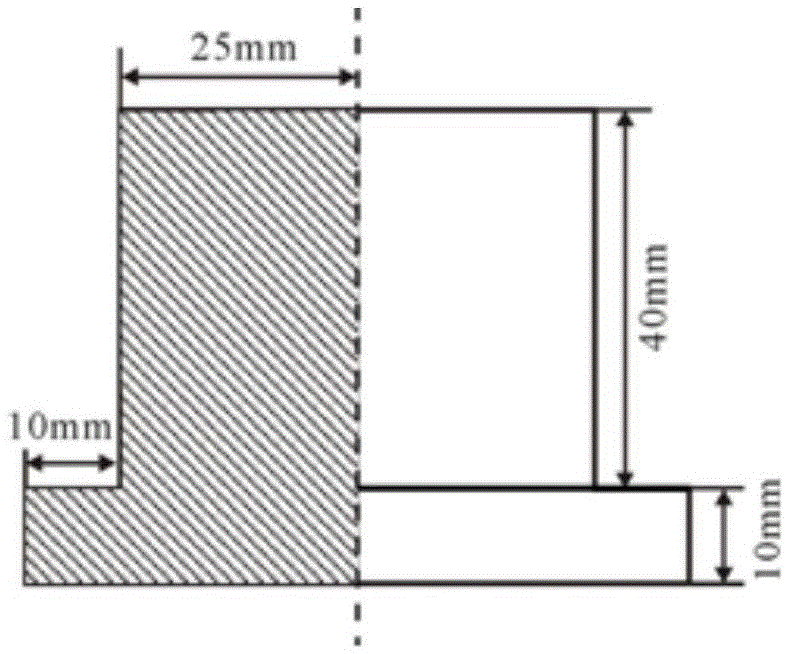

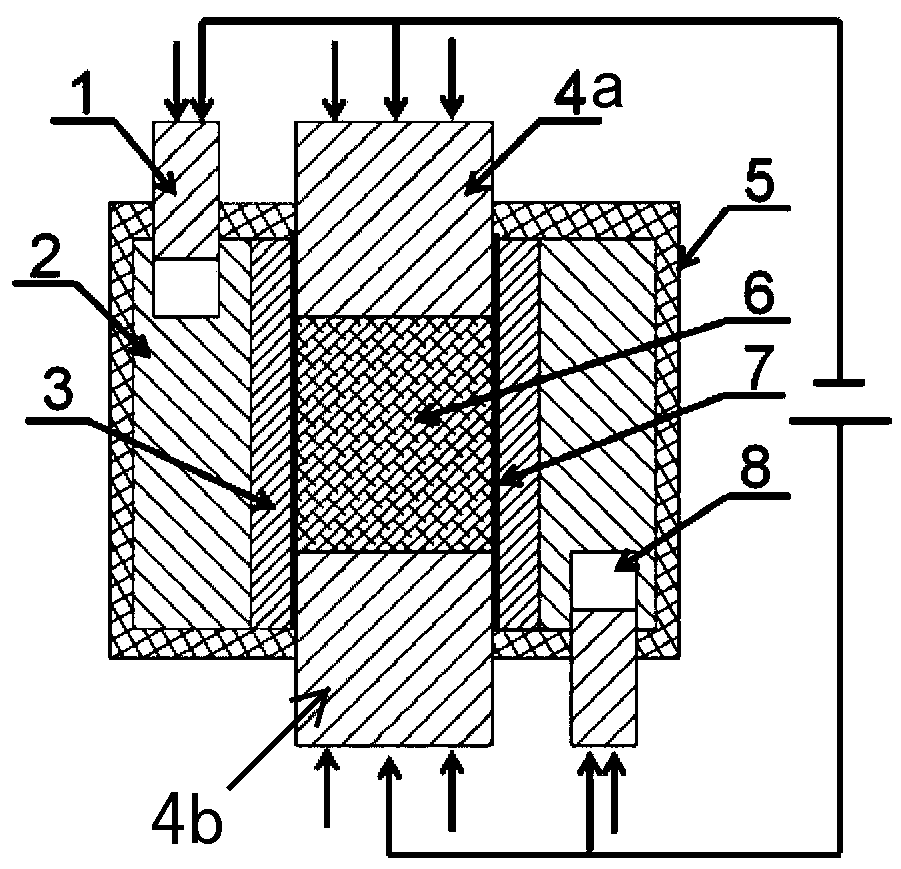

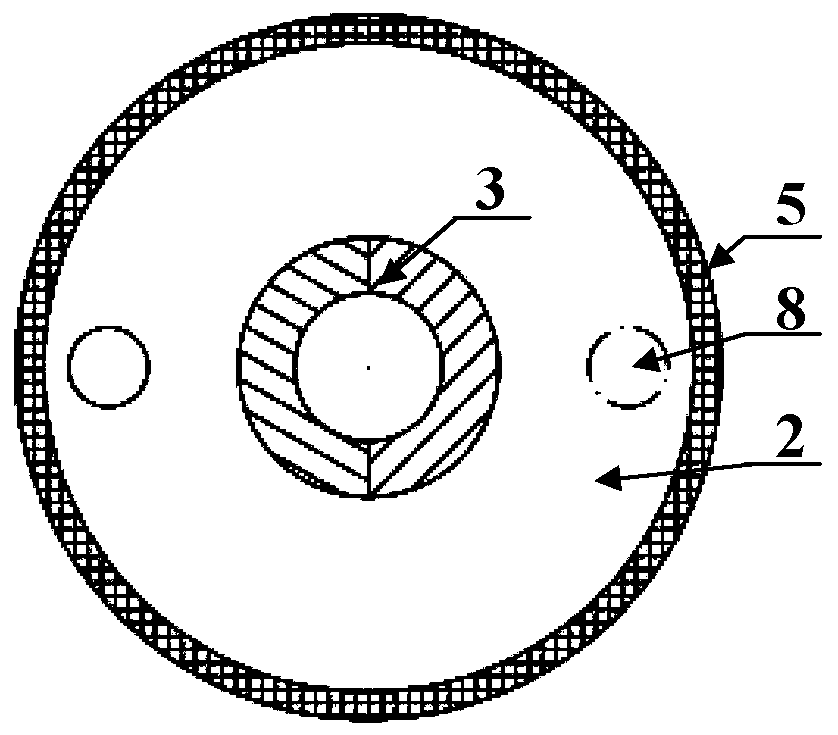

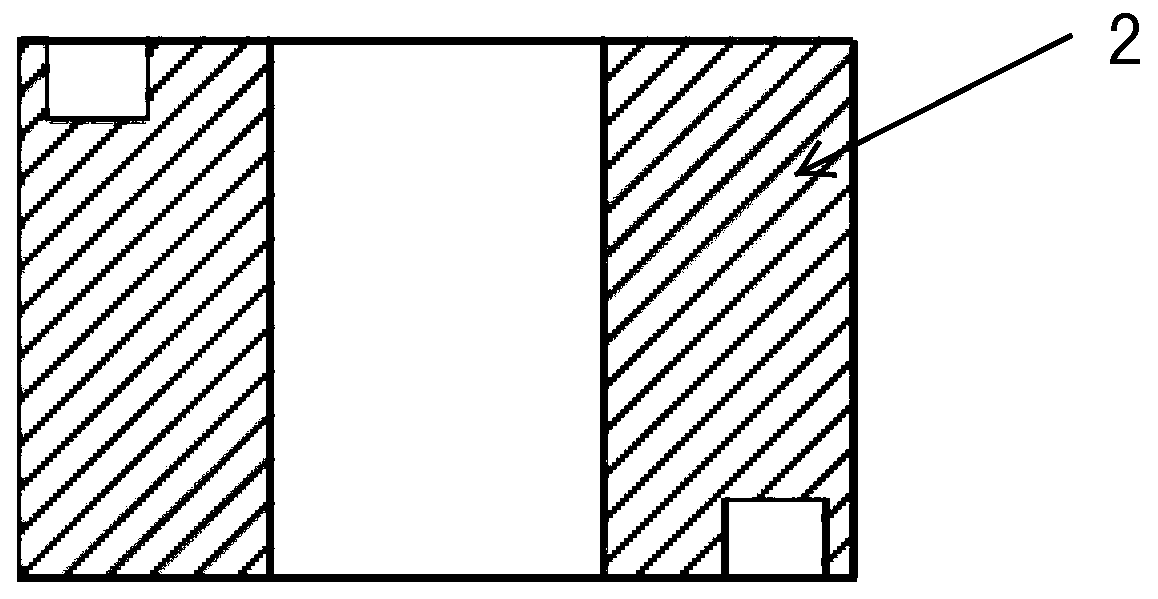

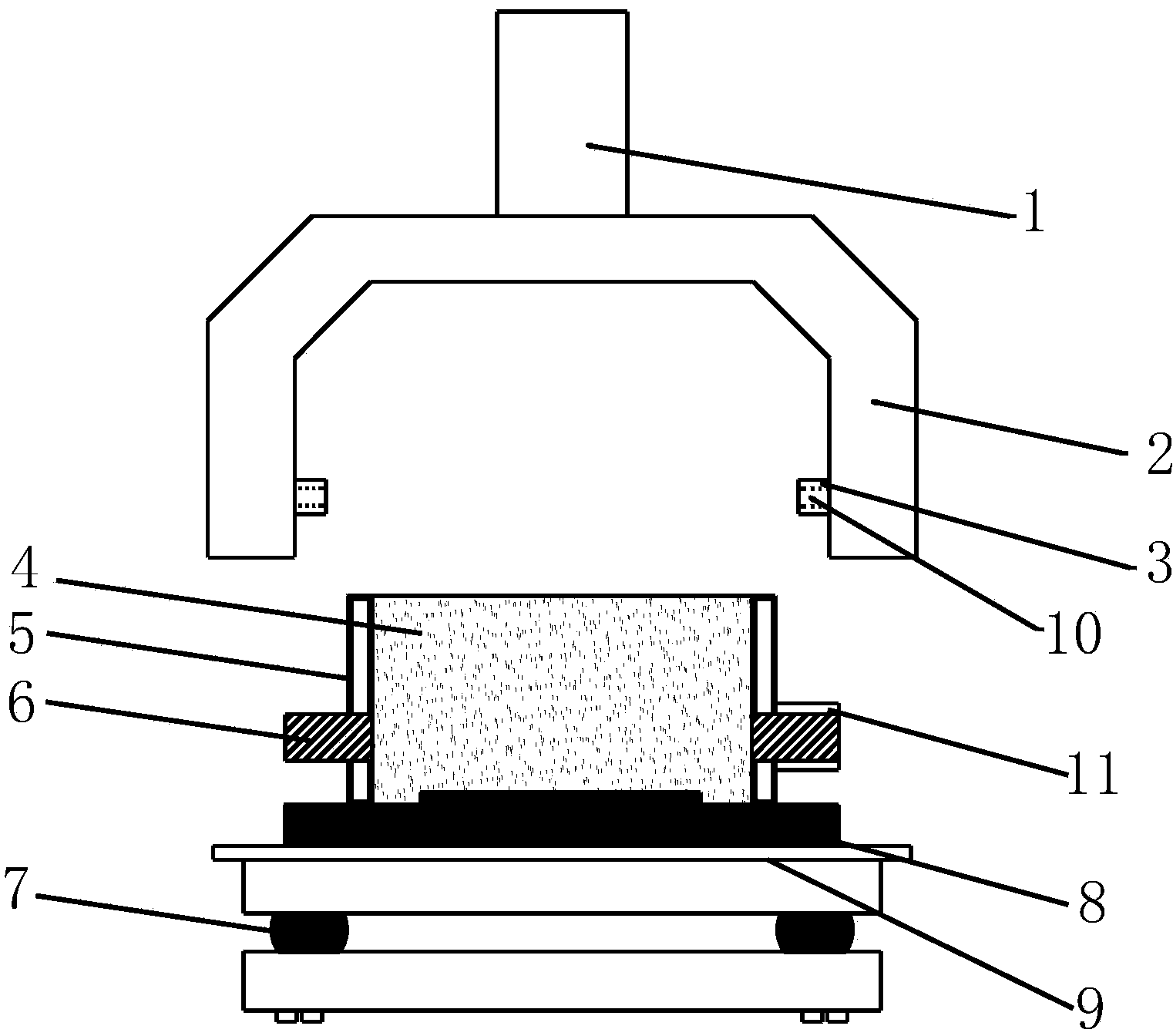

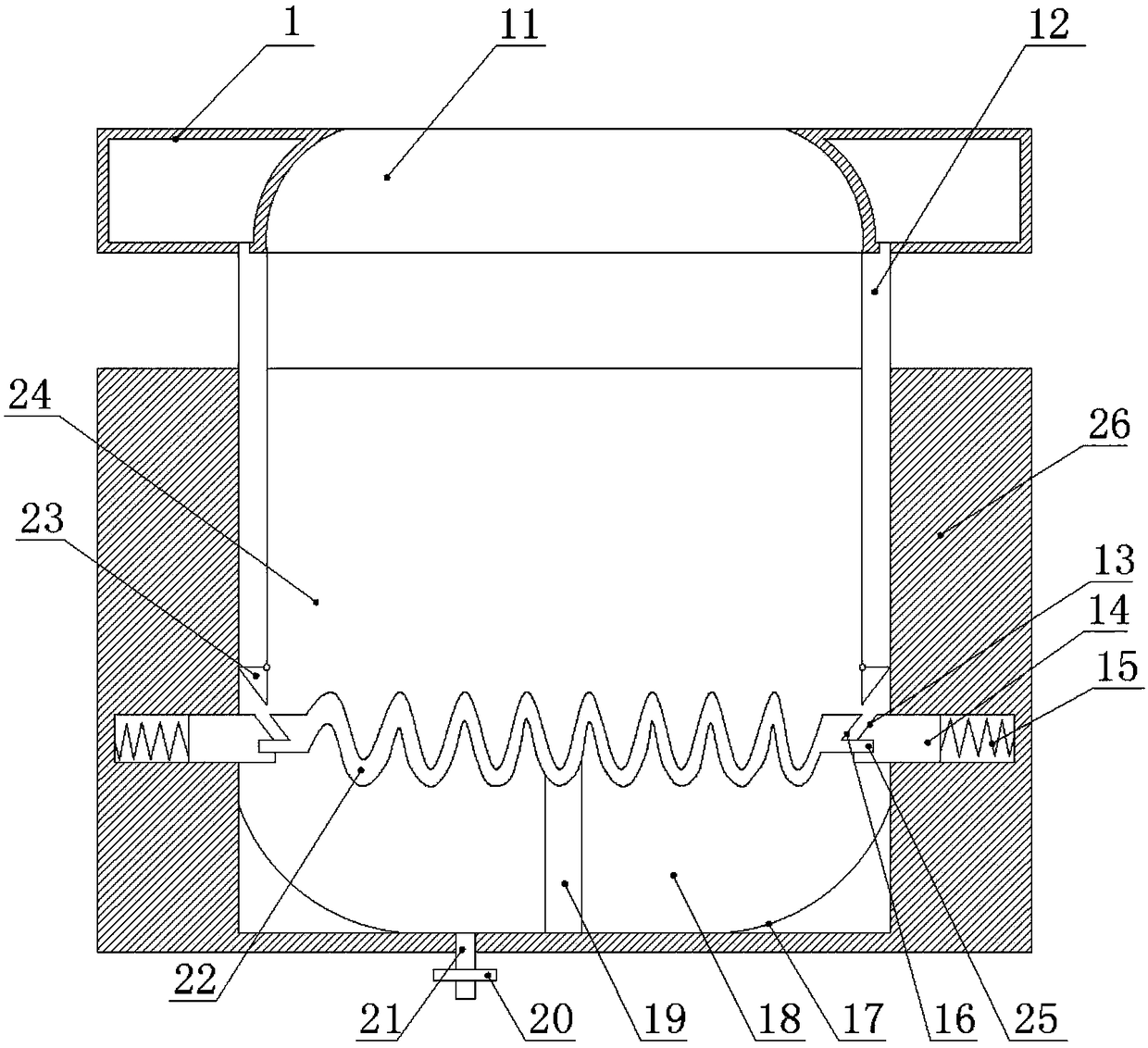

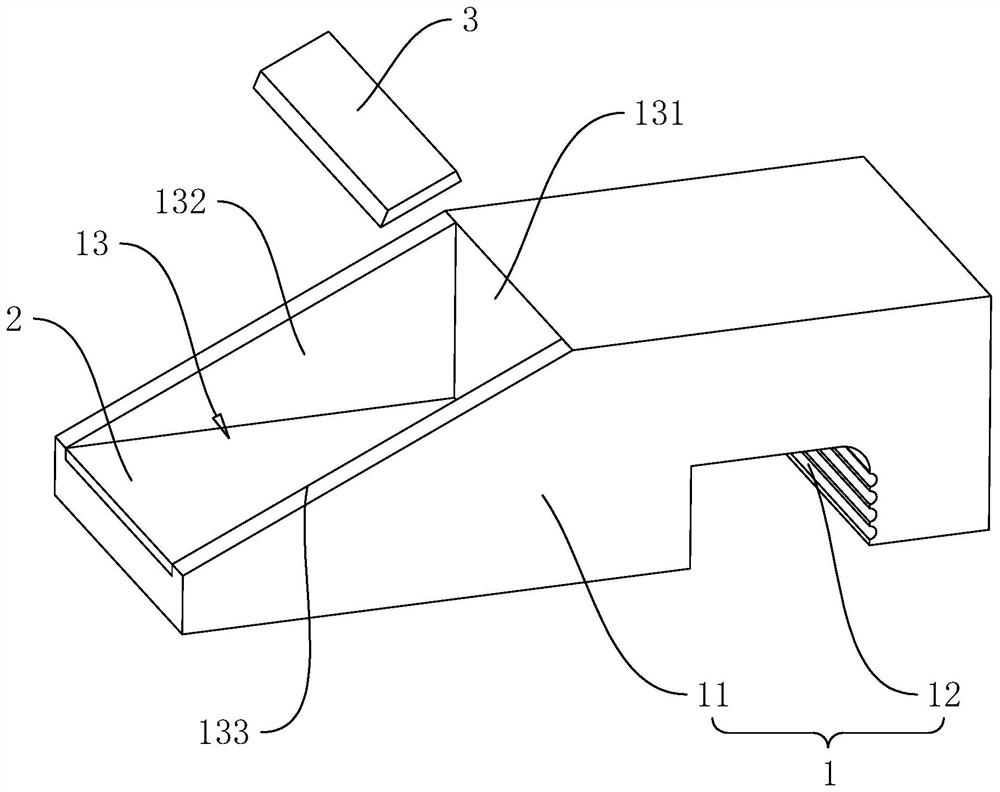

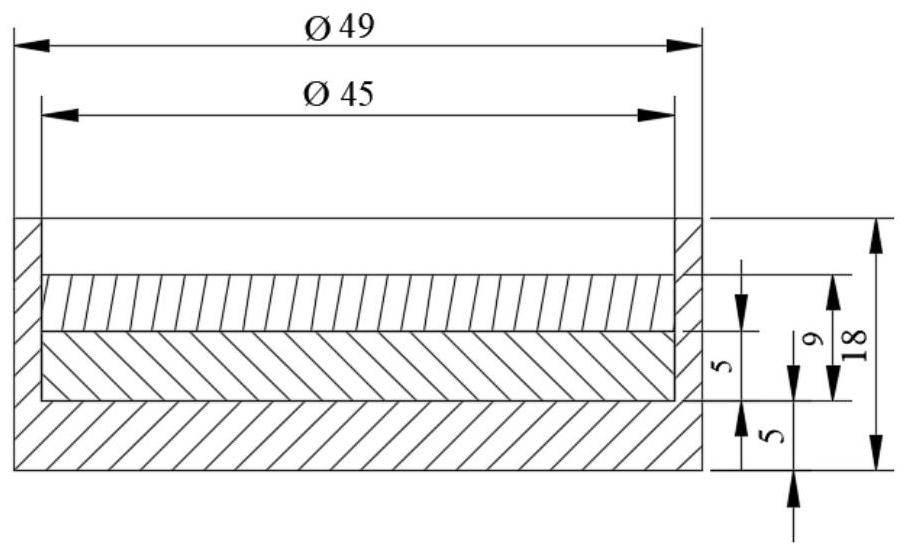

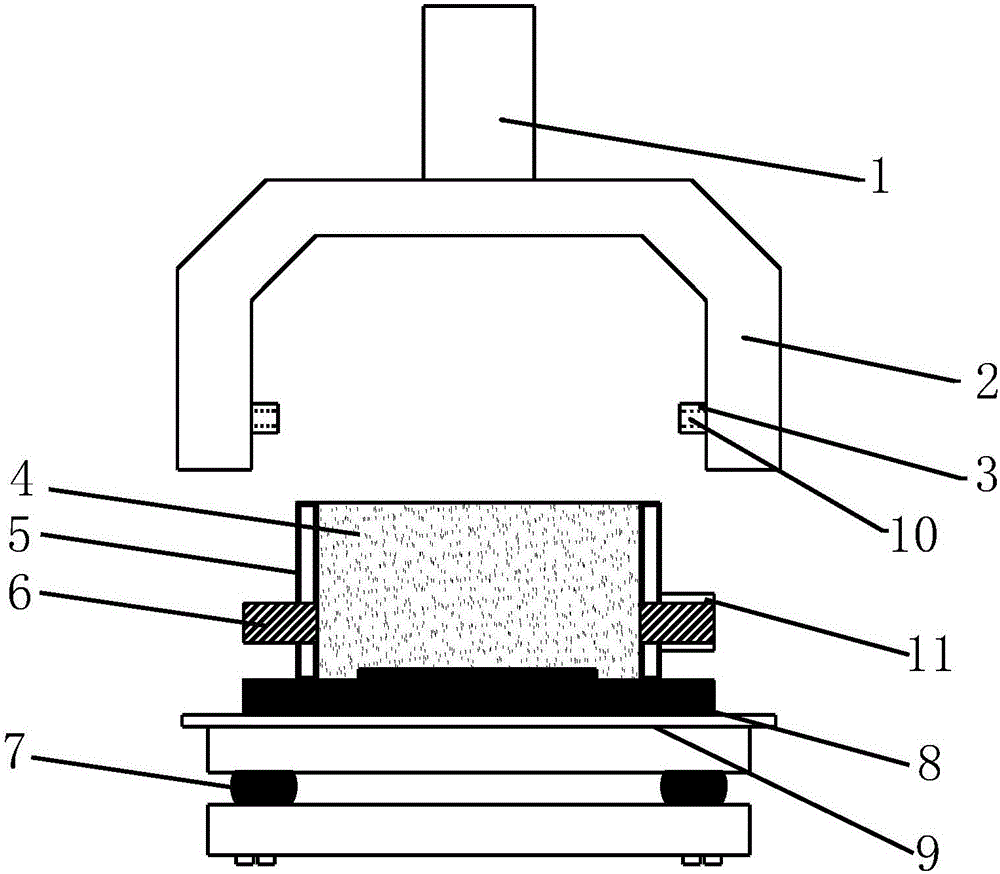

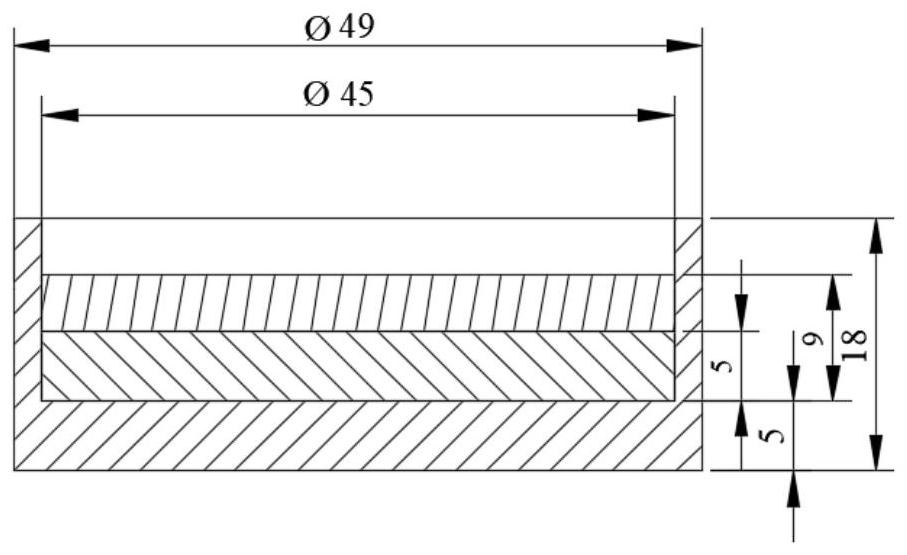

Electrified sintering die

ActiveCN108748620AImprove uniformityImprove integrityMouldsCeramic shaping mandrelsEngineeringCounterbore

The invention provides an electrified sintering die which comprises an internal movable block forming die and an outer die sleeve arranged from inside to outside and further comprises an upper pressure head and a lower pressure head arranged in the internal movable block forming die, wherein a counterbore hole is formed in the outer die sleeve; a shunting flow deflector is arranged in the counterbore hole; and the inner wall of the outer die sleeve or the outer wall of the internal movable block forming die is coated with a release agent. The electrified sintering die can improve the uniformity of a sintering temperature field and reduces the demoulding difficulty of a sintered sample to improve the sintering uniformity of the sample and the integrity of the sintered sample.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

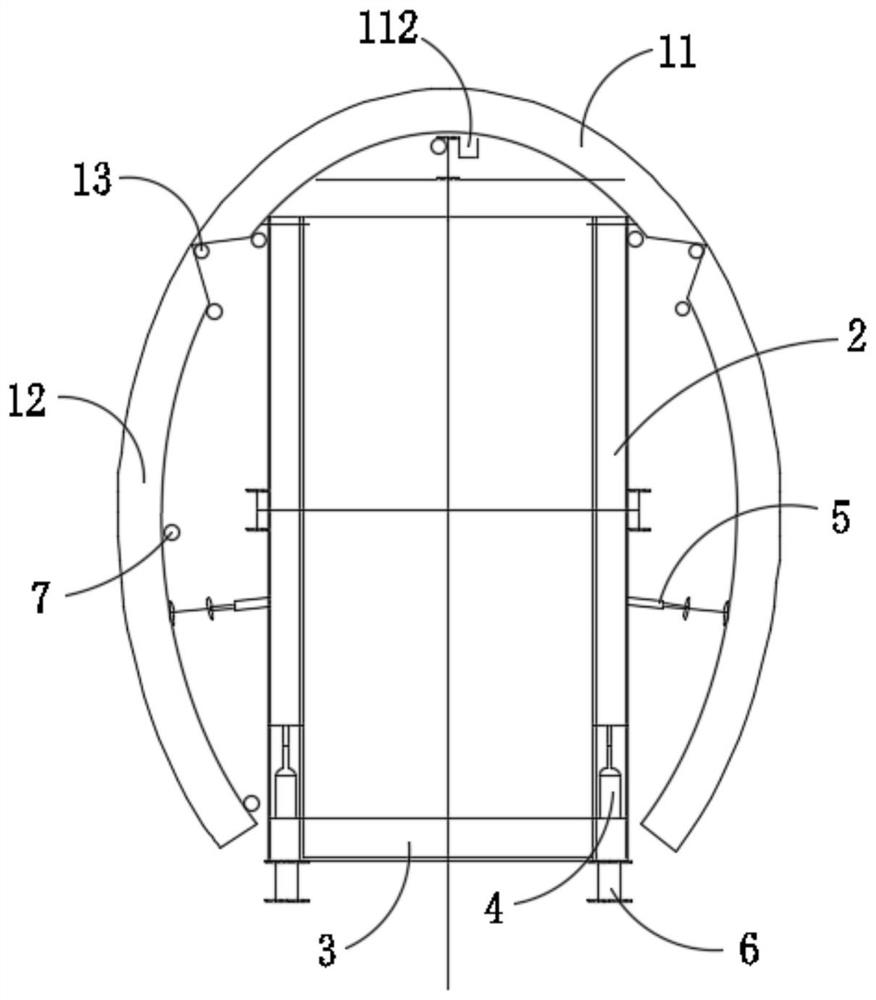

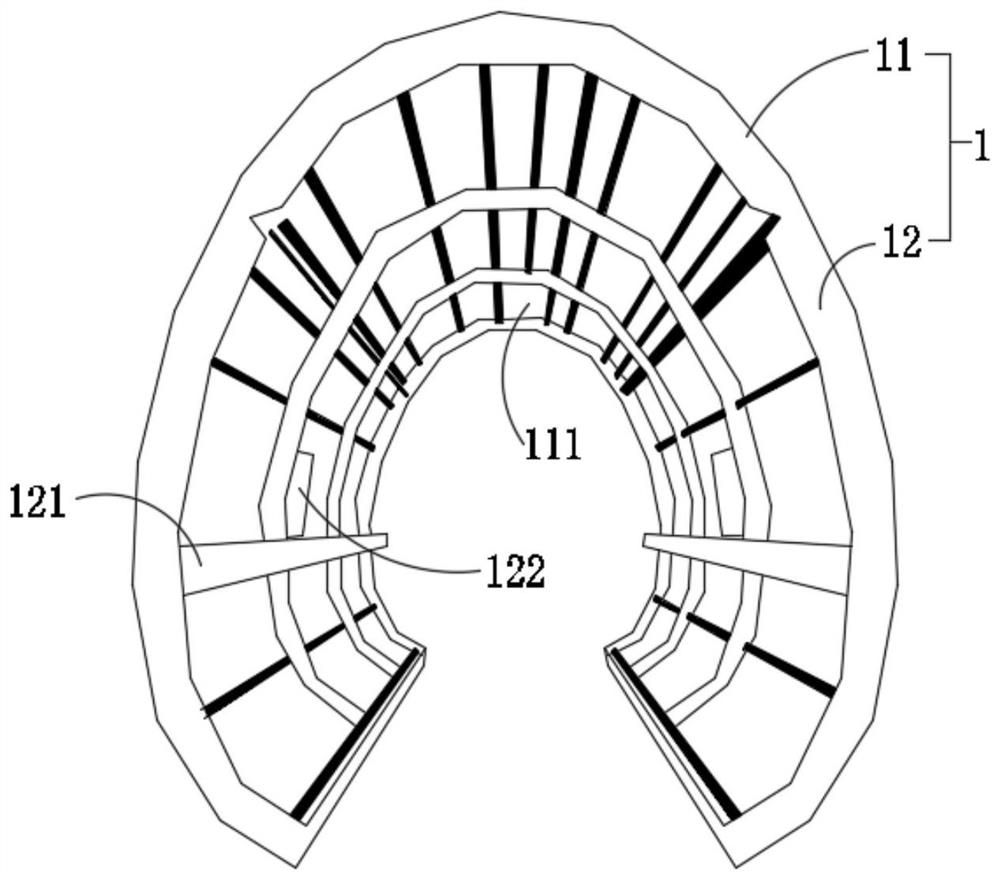

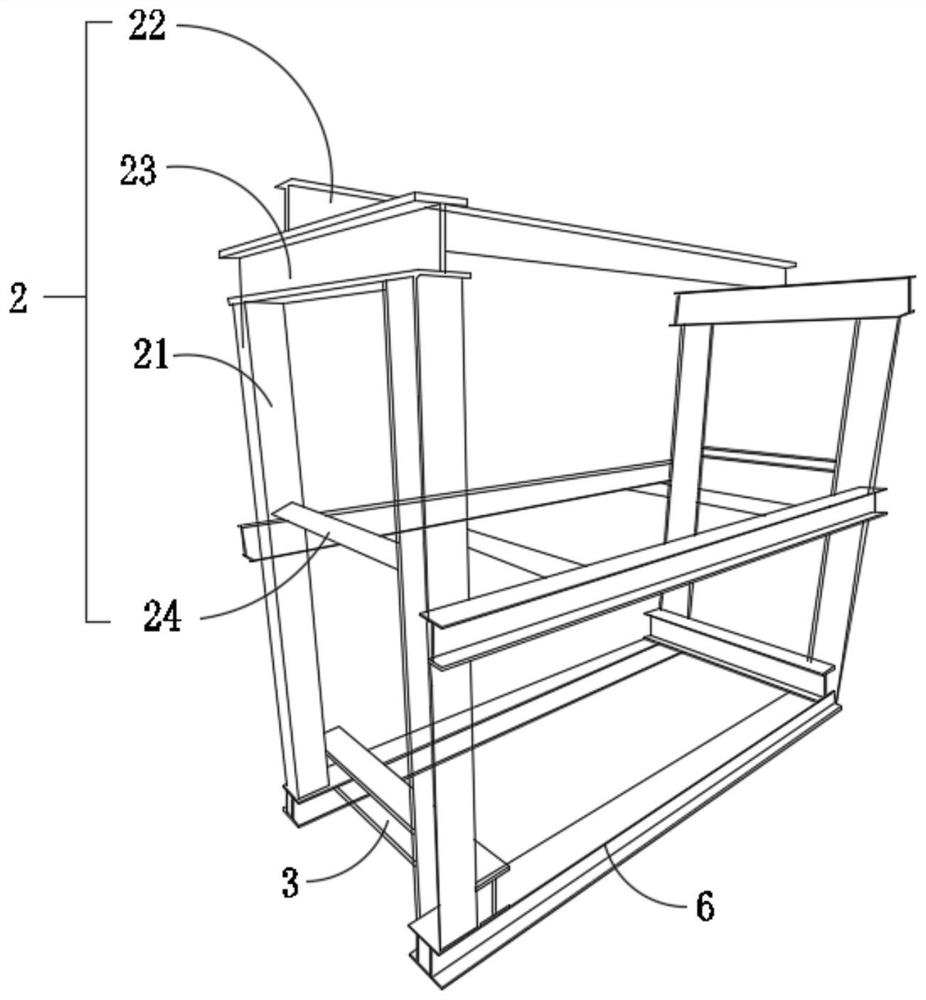

Small-section chamber lining hydraulic formwork trolley and construction method

PendingCN113266397AEasy to adjust connection angleLow costUnderground chambersTunnel liningArchitectural engineeringHydraulic pressure

The invention relates to the technical field of tunnel construction, in particular to a small-section chamber lining hydraulic formwork trolley and a construction method. The small-section chamber lining hydraulic formwork trolley comprises formworks, a supporting frame and a translation component, the formworks comprise the first formwork and the second formwork, and the first formwork is used for making contact with the top of a tunnel. The second formworks are used for making contact with the side wall of the tunnel, the second formworks are connected to the two sides of the first formwork and hinged to the first formwork, the connecting angle of the second formworks and the first formwork can be adjusted conveniently, and the tunnel formwork is suitable for tunnels with different sections. The supporting frame is connected with the first formwork and used for supporting the first formwork. The translation component is located at the bottom of the supporting frame, the lifting component is arranged between the translation component and the supporting frame, longitudinal positioning of the trolley can be adjusted through lifting of the lifting component, after concrete on the inner wall of a tunnel is solidified, demolding can be facilitated by lowering the lifting component, and one set of trolley can be suitable for various tunnels with different sections and different gradients. The construction cost is reduced.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD +1

A kind of silica dispersant for rubber and preparation method thereof

ActiveCN104830045BIncreased process safetyImprove mechanical propertiesSilica particlePolymer science

Owner:SHANDONG YANGGU HUATAI CHEM

White carbon black dispersant for rubber and preparation method of white carbon black dispersant

Owner:SHANDONG YANGGU HUATAI CHEM

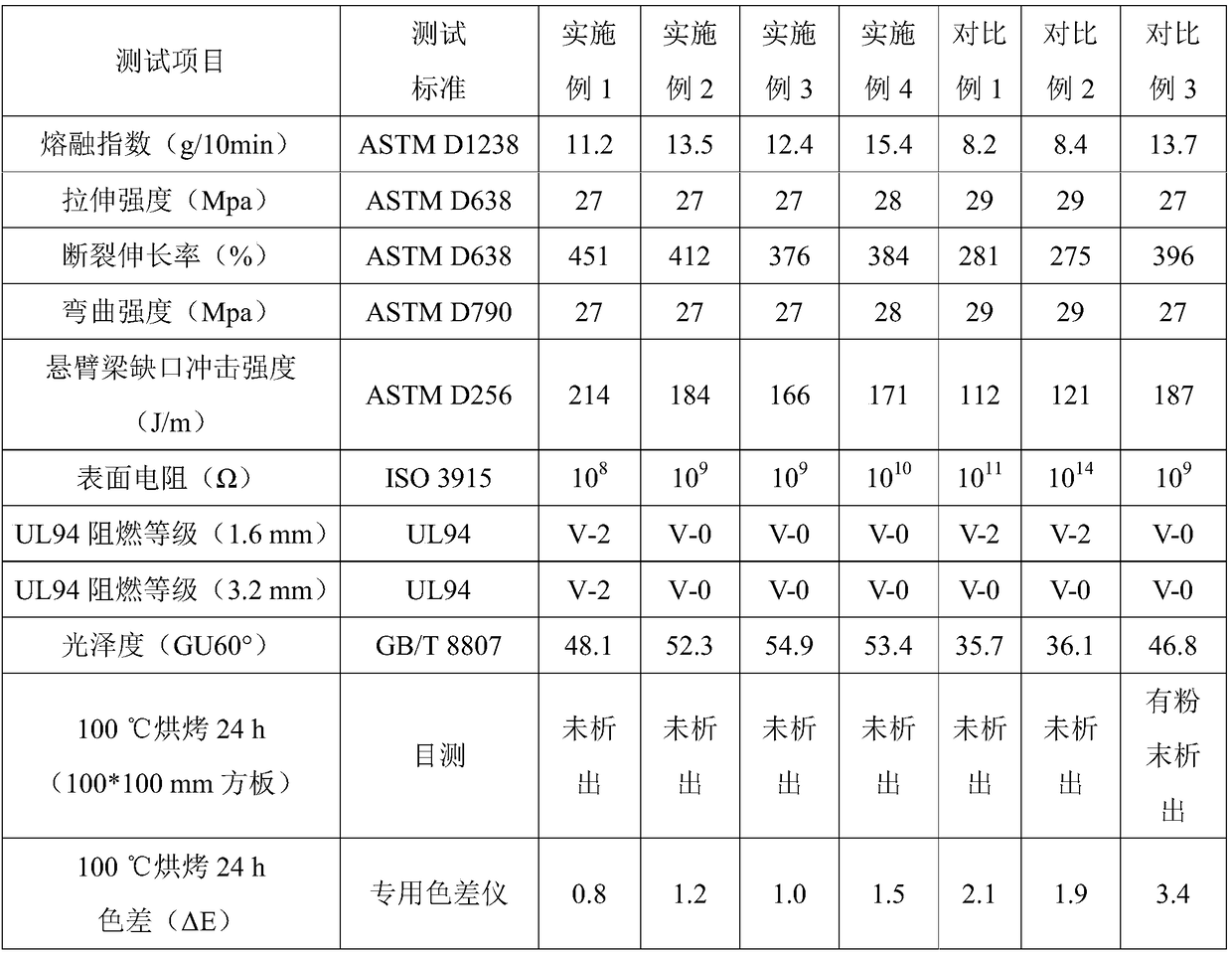

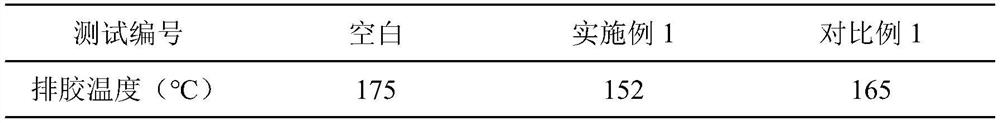

Flame-retardant polypropylene material as well as preparation method and application thereof

The invention discloses a flame-retardant polypropylene material as well as a preparation method and application thereof. The flame-retardant polypropylene material is prepared from the following rawmaterials in terms of 100 parts by mass: 72-85 parts of copolymerization polypropylene resin, 8-15 parts of brominated flame retardant-antioxidant 1010 compound, 3-6 parts of antimonic flame retardant, 1-3 parts of titanium dioxide, 0.5-1.2 parts of lubricant, 1-2 parts of antistatic agent, 0.5-1.2 parts of antioxidant and 0.3-1 part of antibacterial agent. The flame-retardant polypropylene has agood antistatic effect, has a surface resistance of 108-109 omegas, is high in glossiness, does not produce flame retardant precipitate, has a flame retardant rating of UL94V-0, and has the advantagesof being capable of inhibiting bacterial growth for a long time, being good in antibacterial effect and the like. The preparation method is simple and efficient, easily guarantees flame retardance and high-brightness white color of the material, and is high in production efficiency.

Owner:GUANGDONG JUSHI CHEM CO LTD

Alloy-processing tool and coating agent thereof

InactiveCN101462148AGood anti-corrosion performanceGood lubricityFoundry mouldsFoundry coresAdhesiveFluoride calcium

The invention relates to a coating agent, which comprises the following components by weight portion: 100 portions of calcium fluoride, 0.7 to 3.3 portions of boric acid, and 5.5 to 11 portions of adhesive. The coating agent is used for protecting a processing tool during production of low-melting point alloys, and has the advantages of low cost and good protecting effect.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of novel rubber additive

The invention discloses a preparation method of a novel rubber additive. The novel rubber additive is prepared from the following components in parts by weight: 20-30 parts of vinyl resin, 18-25 parts of unsaturated polyester resin, 12-16 parts of unsaturated fatty acid, 1.5-2 parts of zinc oxide and 6-9 parts of trifluoropropyl methyl dichlorosilane. The preparation method comprises the steps of adding unsaturated fatty acid into a container, heating to the temperature of 80-90 DEG C for melting, stirring, then adding zinc oxide, raising the temperature to 120-130 DEG C, and reacting for 2-3 hours to obtain viscous liquid; and adding the viscous liquid obtained in the step S1 into vinyl resin, unsaturated polyester resin and trifluoropropyl methyl dichlorosilane, raising the temperature to 110-115 DEG C, and carrying out melt blending for 3-5 hours to obtain the additive.

Owner:赣州晶鑫新材料有限公司

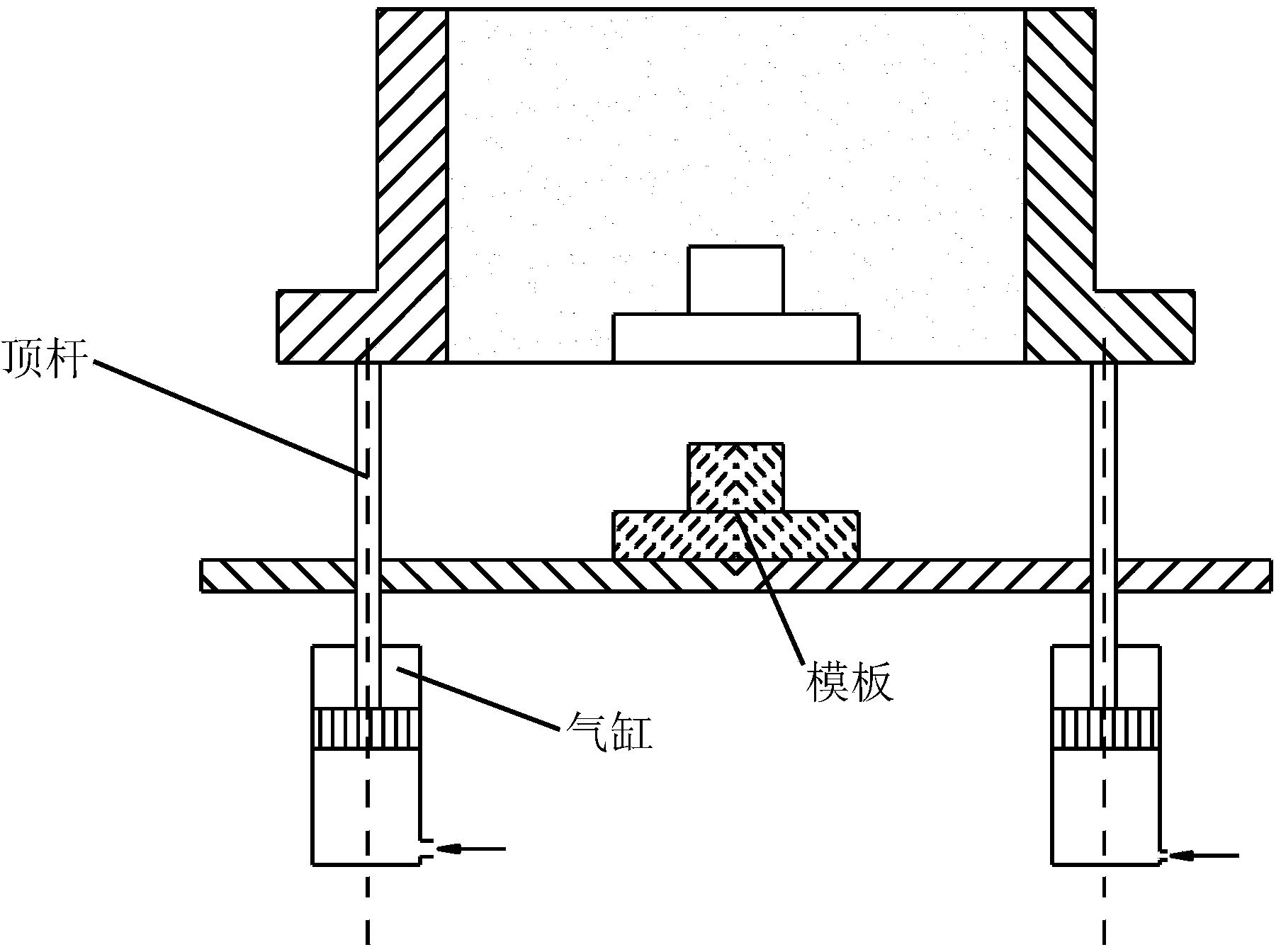

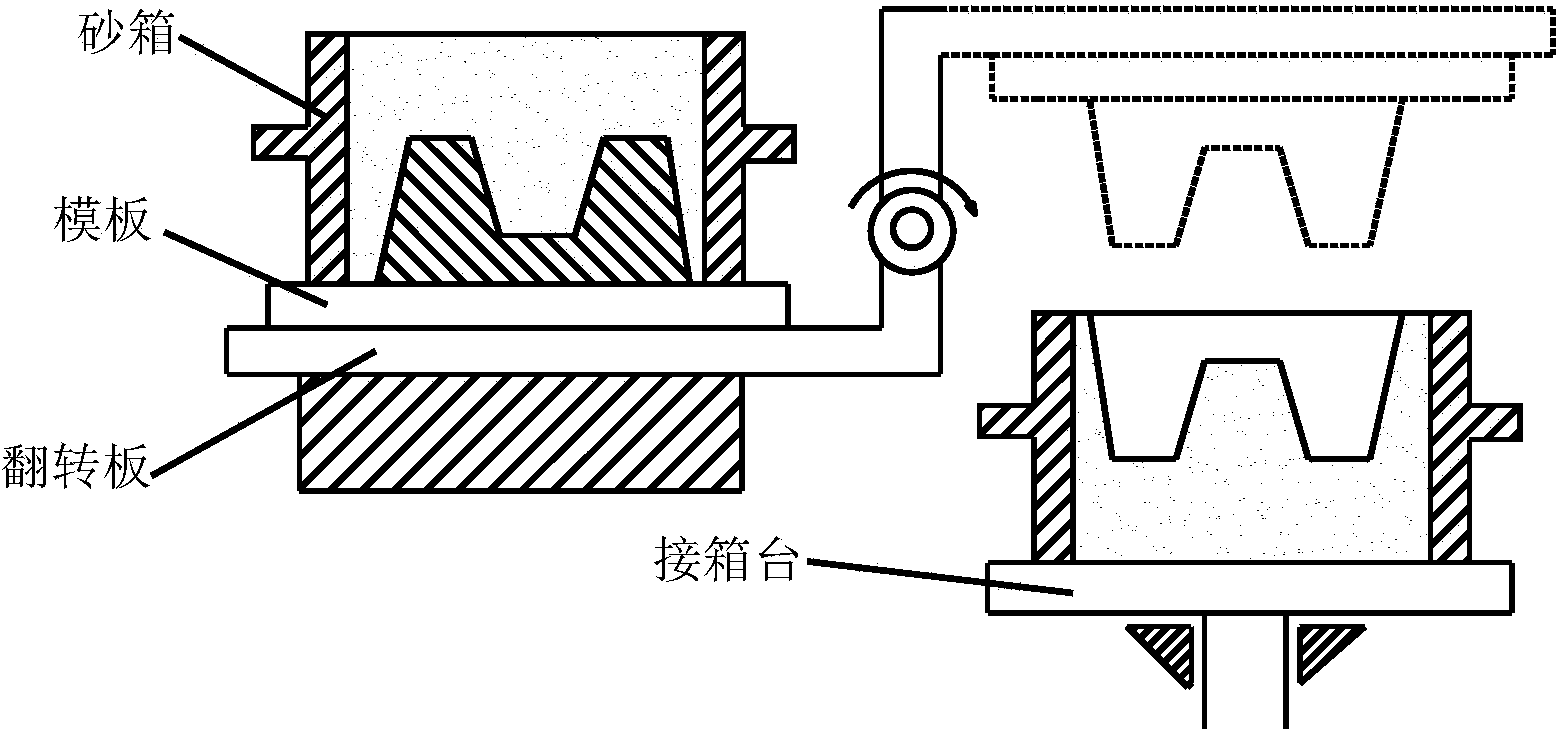

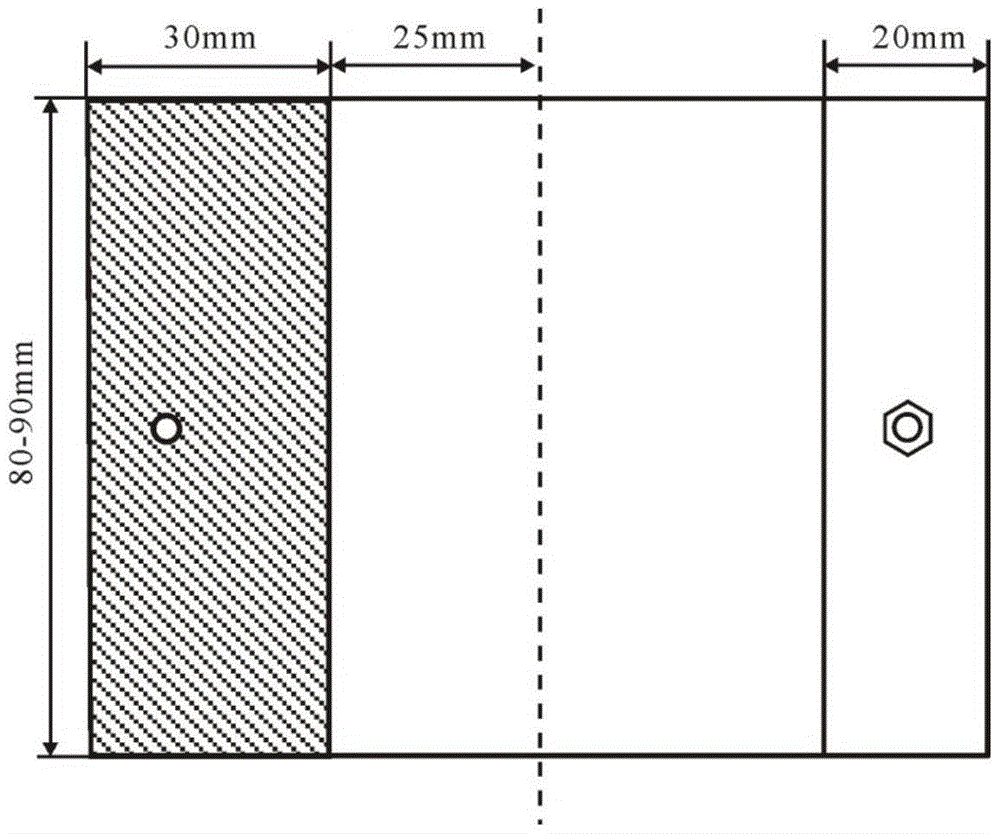

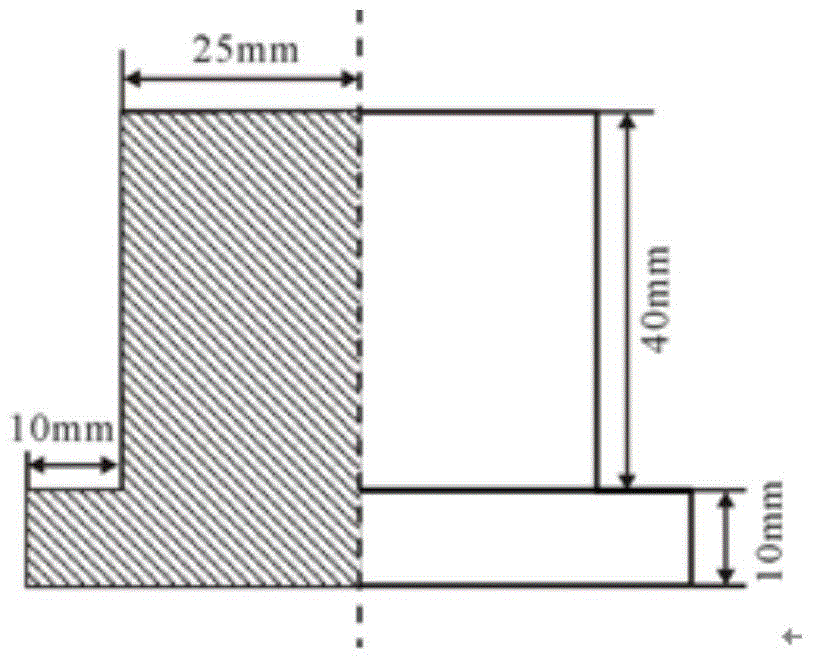

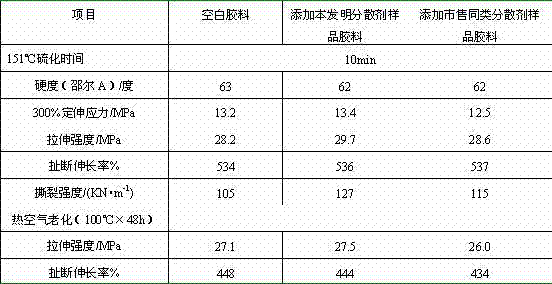

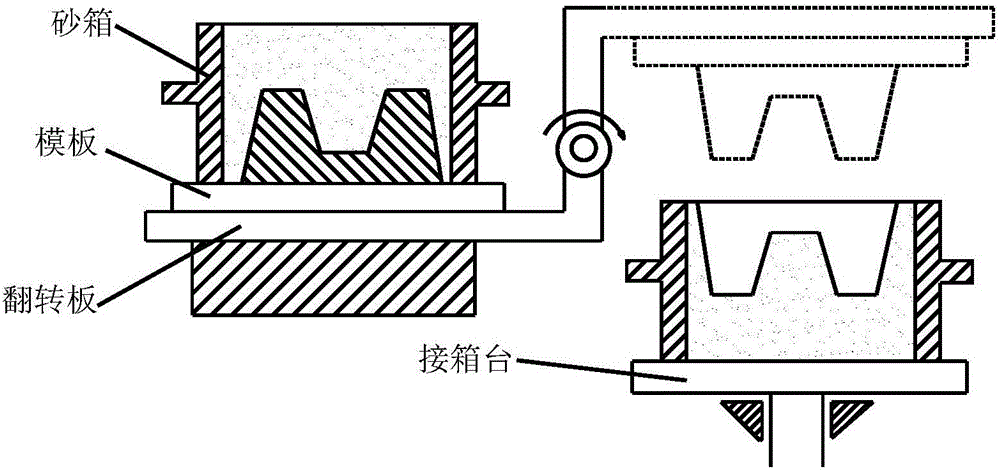

Method for rapping of V method casting well base well cover and special device

ActiveCN104096808AImprove protectionReduce damageFoundry mouldsMoulding machinesAir springEngineering

The invention discloses a method for rapping of a V method casting well base well cover and a special device. The method comprises a first step of moving a casting mold to the working position of a mechanical hand; a second step of descending the mechanical hand to enable a mechanical hand box supporting mechanism to be matched with a sand box lifting mechanism; a third step of keeping the mechanical hand fixed in situ, disconnecting an air spring with compressed air, retracting the air spring, enabling the working plane of a moving plain jolter to descend along with the air spring, driving a die to descend together; a fourth step of separating the die and a sand box; a fifth step of utilizing the mechanical hand to lift the casting mold to enter a next process after the rapping is finished, enabling the moving plain jolter to return to a laminating station, and entering a next process. Compared with the prior art, the rapping method enables rapping to be more convenient; and due to the fact of original tiny deviation of the air spring in each direction horizontally, the rapping method not only is favorable for demolding, but also is favorable for protecting an EVA film of the casting mold and greatly reduces the damage to a facial film.

Owner:CHENGDU XINTONG HIGH COMPOSITE EQUIP

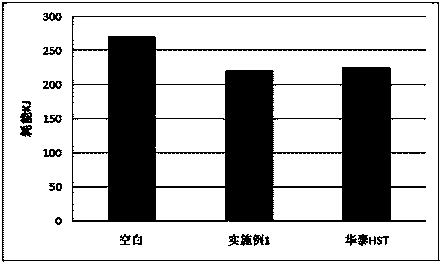

Coupling dispersant for rubber

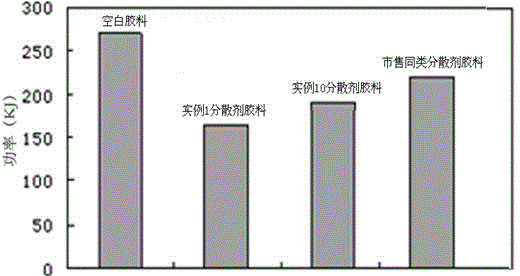

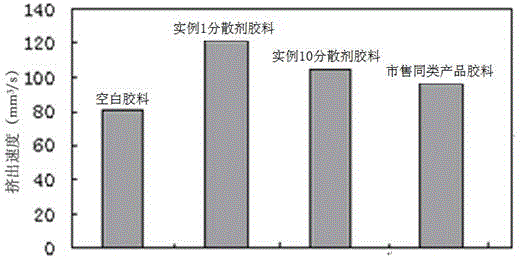

The invention discloses a coupling dispersant for rubber. The coupling dispersant consists of the following raw materials in parts by weight: 10-20 parts of polyethylene glycol borate, 10-20 parts of stearic acid, 25-35 parts of monostearin, 15-25 parts of light calcium and 15-25 parts of zinc stearate. The coupling dispersant has the characteristics of small dosage, wide application range and the like, is applied to the mixing process of natural rubber and synthetic rubber and can improve the dispersity of filler and other powder aids in a sizing material, reduce the viscosity of the sizing material and increase the fluidity and extrusion rate of the sizing material so as to reduce the energy consumption of tire or product processing and increase the mixing efficiency; moreover, the demoulding of vulcanized products is promoted, the mould is kept clean, and the processing safety, physical and mechanical properties and vulcanization speed of the rubber sizing material can be improved; and through the application test comparison, the sizing material prepared by adding the coupling dispersant for rubber, disclosed by the invention, is superior to the same kind of products on the market in terms of processing safety, physical and mechanical properties and vulcanization speed.

Owner:沂水祥腾化工有限公司

Die stock and warm compaction process thereof

InactiveCN103231129AReduce alloy composition segregationRemove bulkyThread cutting machinesHardnessMaterials science

The invention discloses a die stock which comprises a stock body used for accommodating and fixing screw dies, wherein symmetrical outward extending handlebars are arranged on the stock body. According to weight percentage, the stock body is composed of components as follows: 1-4% of Cu, 0.6-0.9% of C, 0.1-0.3% of S, other impurities occupying smaller than or equal to 2%, and the balance Fe. The invention further discloses a warm compaction process of the die stock. The warm compaction process is characterized in that in the sintering procedure, a heating part is divided into three heating zones in a gradual warming heating mode, and therefore volatilizing of super lubricants added in a material mixing procedure is benefited, cracking and surface bulging of laminates in the forging process are effectively avoided, the quality of warm compaction products is improved, and inside-to-outside hardness and use intensity of the warm compaction products are improved due to the gradual warming mode.

Owner:LAIZHOU TIANRUN MACHINERY CO LTD

Sponge processing device

The invention relates to the technical field of sponge processing, in particular to a sponge processing device. The sponge processing device comprises a foaming box which is internally provided with awavy floating plate, the foaming box is divided by the floating plate into an upper foaming cavity and a lower cavity, connecting mechanisms are arranged at the side walls of the floating plate, andsliding plates are arranged in a sliding mode on the side walls of the foaming box. A clamping portion, which is able to be connected to the corresponding connecting mechanism, is arranged at one endof each sliding plate, the other end of each sliding plate is connected to the foaming box by a spring, a water storage box is arranged in a sliding mode above the foaming box, a hollow rectangular frame is arranged at the bottom of the water storage box. The rectangular frame opens upwards and the top end of the of the rectangular frame communicates with the water storage box, water outlet holesare formed in the bottom end of the rectangular frame, and cutting knifes are hinged to the bottom end of the rectangular frame, wherein the hinged joints are in the rectangular frame and the cuttingknifes abut against the clamping portions. An arc guiding groove is formed in the cavity, the arc center of the guiding groove is positioned in the foaming cavity and the guiding groove abut against the cutting knifes. The sponge processing device solves the problems of inconvenient sponge demoulding and the sponge being liable to be damaged in the prior art.

Owner:重庆致昌塑胶制品有限公司

a ti 3 sic 2 Preparation method of /sic functionally graded material

ActiveCN105541331BUniform and dense structureModerate combinationGradient materialOxidation resistant

The invention discloses a preparation method of a Ti3SiC2 / SiC functionally gradient material, comprising the steps of mixing Ti3SiC2 powder and SiC powder in a die layer by layer in a gradient way, then preparing a blank, performing vacuum hot-pressing sintering on the blank to obtain a green body, and sequentially performing dipping densification and pyrolysis treatment on the green body; the SiC powder comprises micron beta-SiC powder and nanometer beta-SiC powder; the vacuum hot-pressing sintering temperature is 1600-1700 DEG C, and is kept for 3-5h, and the maximum pressure is 25MPa; the dipping densification comprises performing dipping densification on gradient layers containing 60-100 vol. percent of SiC in the green body subjected to the hot-pressing sintering in polycarbosilane liquid. The Ti3SiC2 / SiC functionally gradient material prepared by the method is high in compactness, contains multiple gradient layers along the thickness direction from Ti3SiC2 to SiC (designing can be performed as required), the structure is uniform and compact in each gradient layer, interfaces among the gradient layers are moderately combined, the mechanical strength is high, the breaking tenacity is good, under high temperature, the oxidation resistance and the thermal shock resistance are good, and the Ti3SiC2 / SiC functionally gradient material having 11 gradient layers and the thickness of 8-15mm can be prepared.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

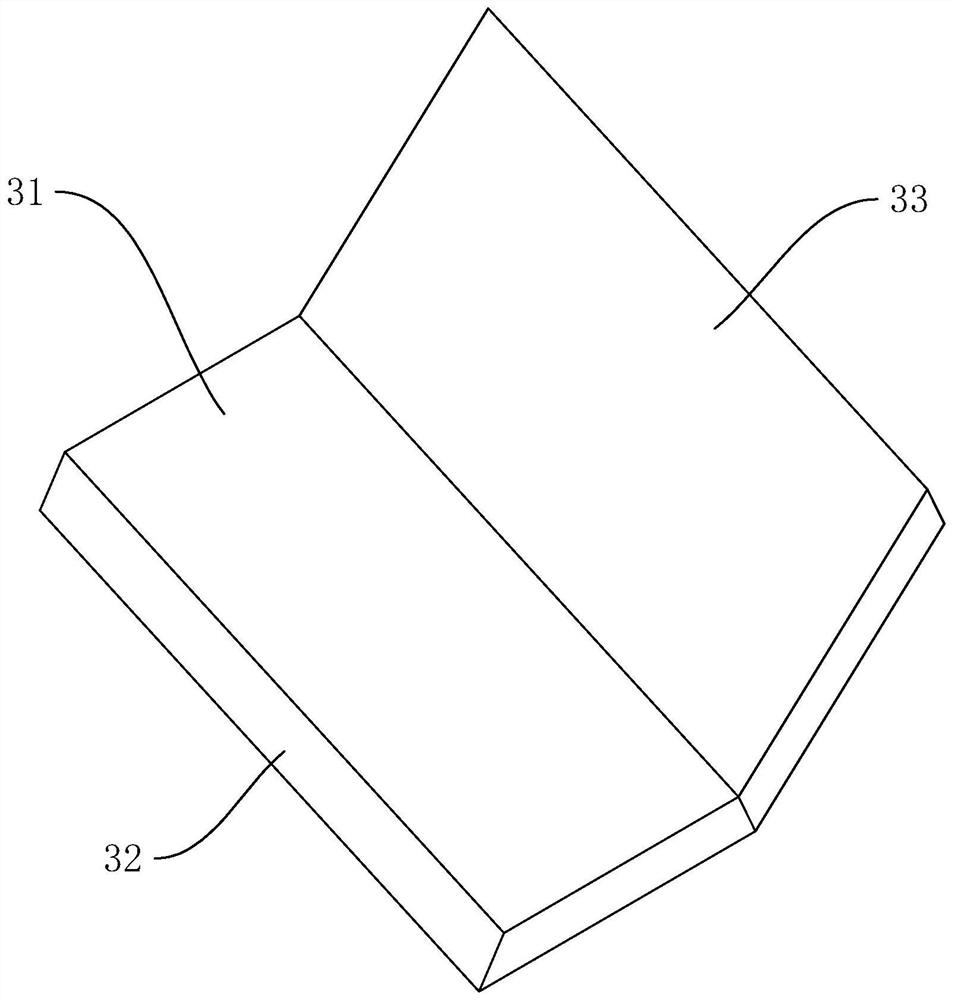

False tooth colorimetric mold forming mold

ActiveCN113229972AImprove colorimetric accuracyEnsure colorimetric accuracyArtificial teethEngineeringDentistry

Owner:厦门市仿真美义齿科技有限公司

Application method of a composite phase change material in copper-steel bimetal casting process

ActiveCN113214799BImprove insulation effectImprove feeding effectHeat-exchange elementsMolten saltStearic acid

Owner:HEFEI UNIV OF TECH

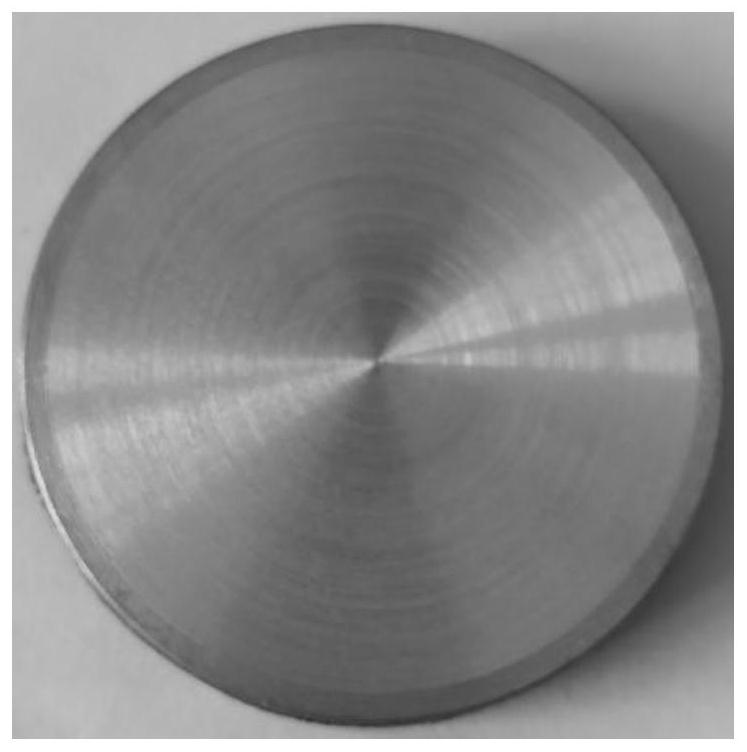

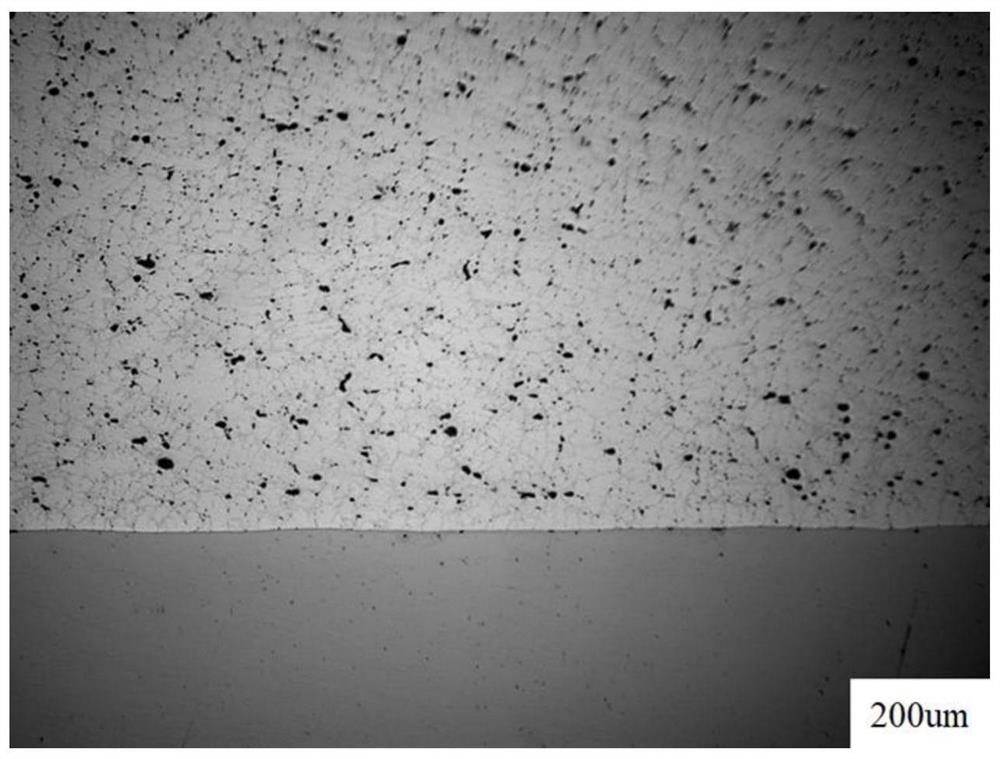

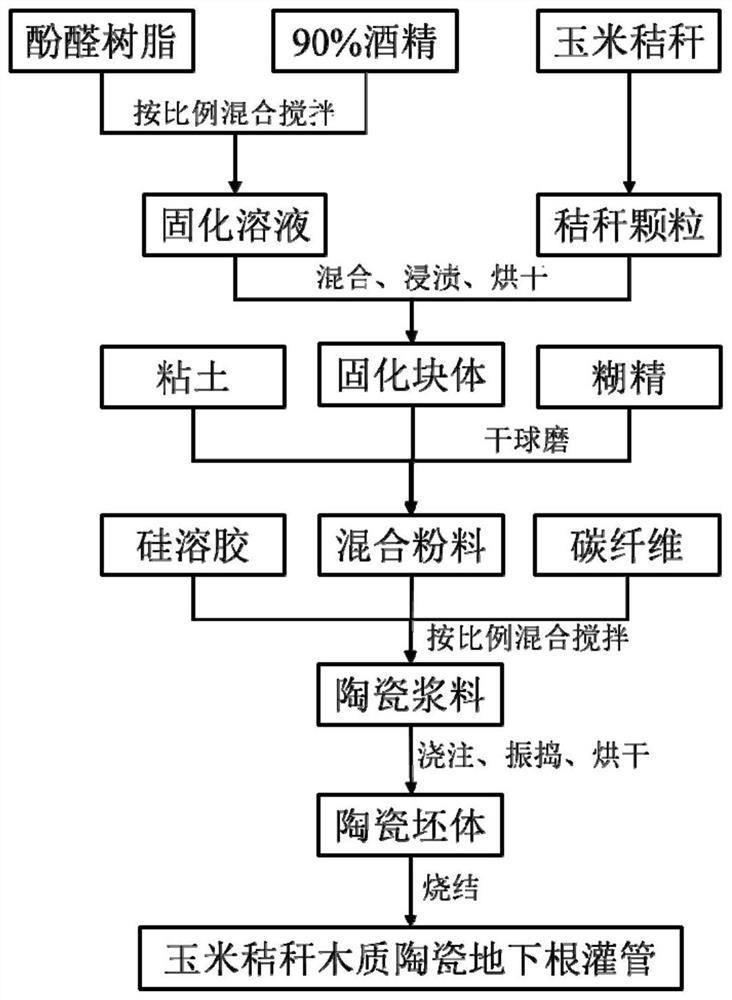

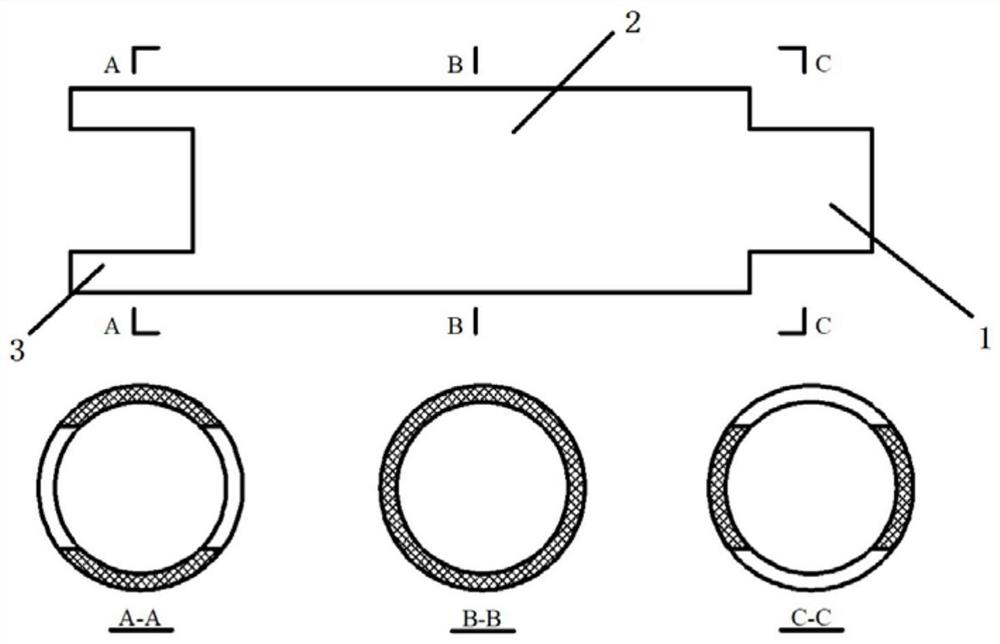

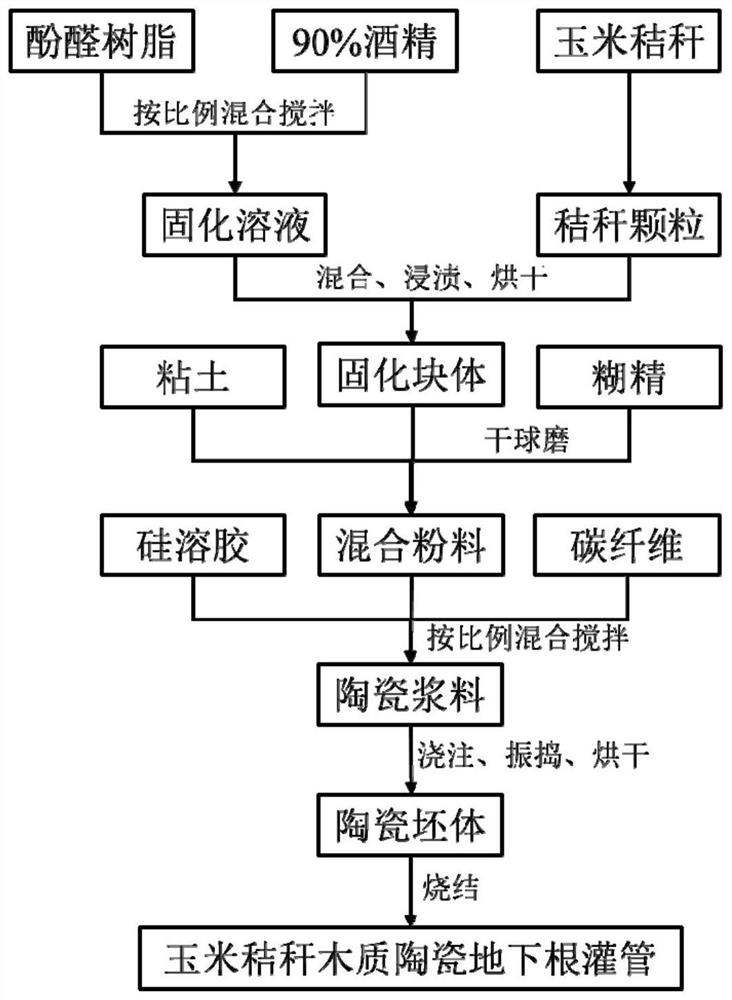

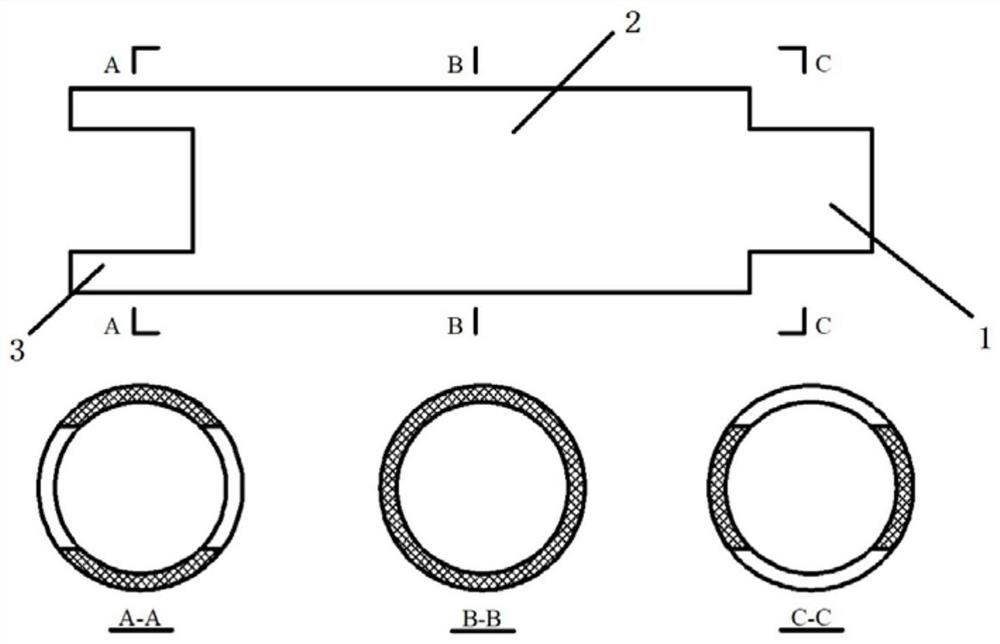

Straw wood ceramic root irrigation pipe as well as preparation method and application thereof

ActiveCN111978101ARealize the function of no recyclingSimple structureWatering devicesSpray nozzlesFiberCarbon fibers

The invention discloses a straw wood ceramic root irrigation pipe and a preparation method and application thereof. The root irrigation pipe is prepared from the following raw materials: phenolic resin, alcohol, straw, clay, dextrin, silica sol and carbon fibers. A blank of a specific structure is prepared through casting molding, and the underground root irrigation pipe is prepared through nitrogen protection sintering. According to the method, underground root irrigation pipes with required shapes can be prepared according to actual requirements, the underground irrigation pipelines can be rapidly connected, and the preparation and installation cost is greatly reduced. Meanwhile, the root irrigation pipe has good environmental coordination, does not need to be recycled after reaching thedesigned service life, and can be directly crushed and returned to the field, so that the recycling cost is saved, and the soil structure can be effectively improved.

Owner:NORTHWEST A & F UNIV

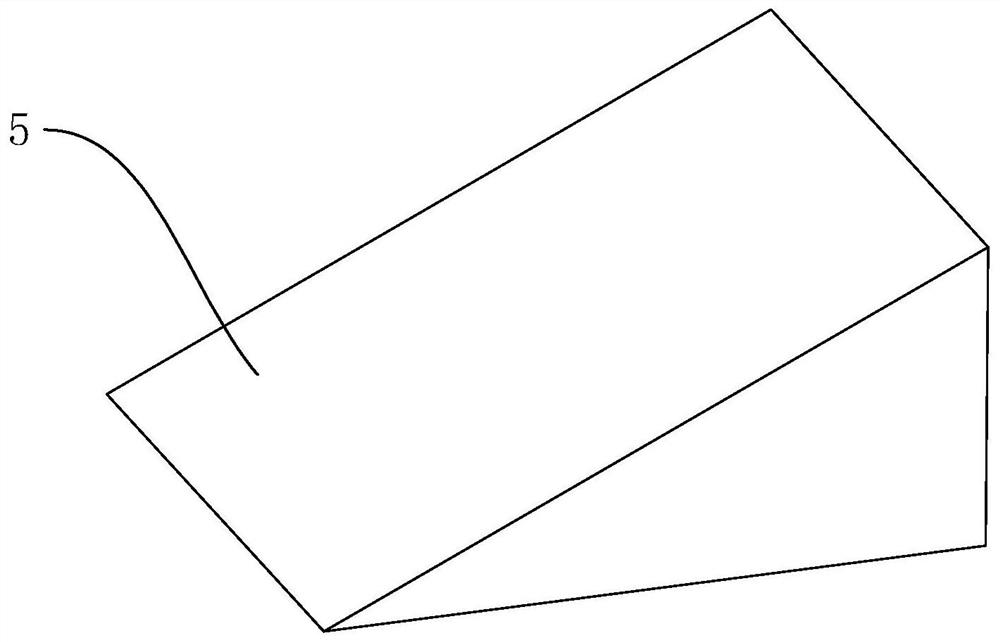

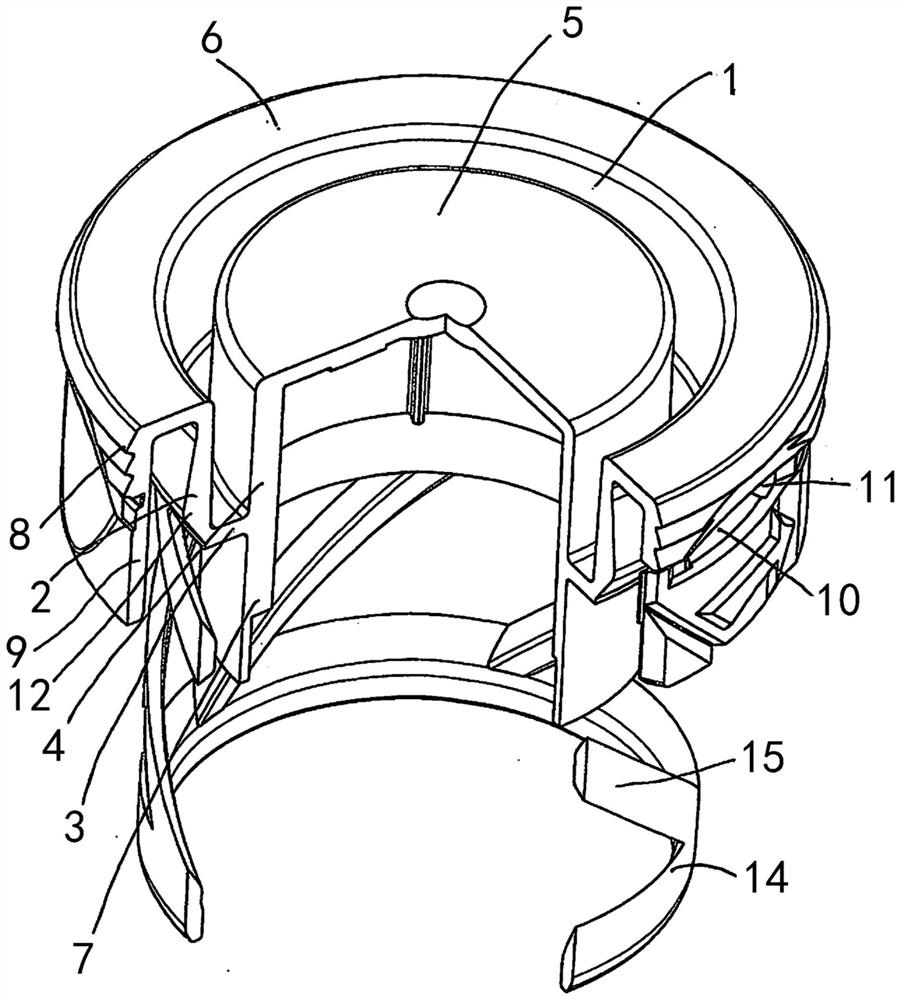

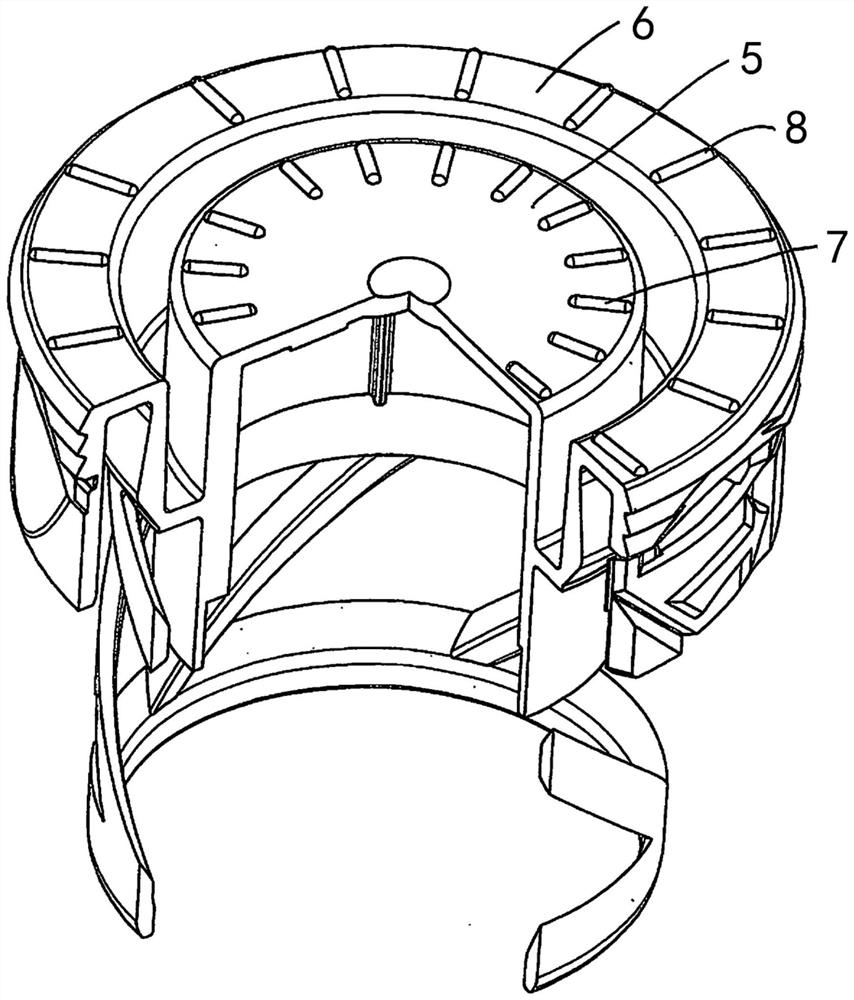

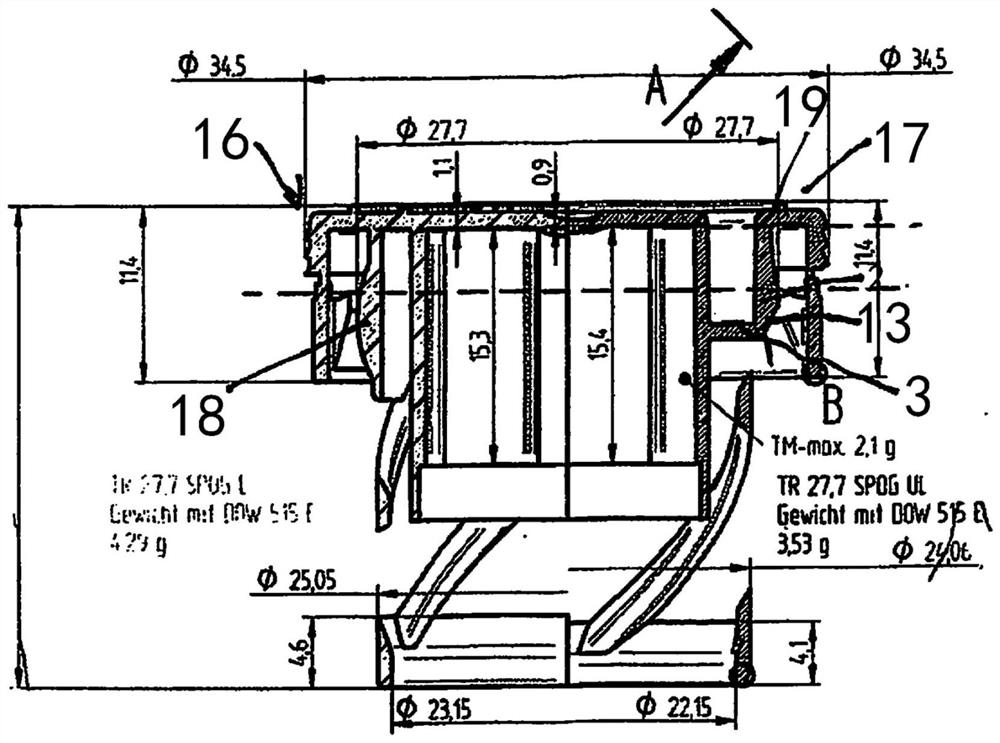

Container stopper

PendingCN114476354AAids in demouldingHelp to pry offClosure using stoppersClosure capsClassical mechanicsStructural engineering

A container stopper having a cap with a peripheral wall engaged around a neck of the container and integrally formed at a lower edge with a tearable peripheral safety ring for anti-unsealing security of the contents of the container with an inwardly oriented locking feature, the stopper has an inward locking structure that engages in the fastened position of the stopper in the lower portion of the outwardly oriented annular projection of the container, the stopper having an olivary member provided with a peripheral annular flange for engaging with the opening of the container, a circular concentric recess formed in the cap, the safety ring has a recess having a radially outer annular wall and a radially inner annular wall connected together by a bottom wall, the radially outer annular wall defining an olivary member, an opening being formed directly above the locking structure, the opening passing through the safety ring and extending on both sides beyond the locking structure.

Owner:盖普拉斯特股份有限公司

Novel carbon black dispersing agent for rubber and preparation method thereof

ActiveCN103304881BIncreased process safetyImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsRubber materialPolymer science

The invention relates to a preparation method of a novel carbon black dispersing agent for rubber. The novel carbon black dispersing agent comprises the following raw materials in parts by weight: 10-30 parts of polyethylene waxes or oxidized polyethlene waxes, 10-20 parts of zinc stearate, 10-30 parts of stearic acid, 10-30 parts of polyethylene glycol and 30-80 parts of pentaerythritol stearate. The novel carbon black dispersing agent disclosed by the invention can enhance the processing safety property, physical and mechanical property and vulcanizing rate of a rubber material, has multiple functions of dispersion, lubrication and physical plasticizing, is used for the mixing process of natural rubber and synthetic rubber, and can enhance the dispersibility of a filler and other powdery auxiliary agents in the rubber material, reduce the viscosity of the rubber material and enhance the flowability and extrusion rate of the rubber material, thereby reducing the energy consumption of tire or product processing, increasing the mixing efficiency, facilitating the demoulding of a vulcanized product and keeping the mould clean; and the novel carbon black dispersing agent disclosed by the invention can enhance the vulcanization reversion resistance and heat resistance of vulcanized rubber after being applied to the natural rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

Mold-drawing method and special device for v-casting manhole cover

ActiveCN104096808BImprove protectionReduce damageFoundry mouldsMoulding machinesAir springCasting mold

The invention discloses a mold-drawing method and a special device for V-method casting manhole covers. The method includes the following steps: ①Move the casting mold to the working position of the manipulator; The mechanisms are matched together; ③The manipulator remains in the original position. At this time, the connection between the air spring and the compressed air is disconnected. Box separation. ⑤ After the mold is removed, the manipulator lifts the mold to proceed to the next step, and the mobile vibrating table also returns to the laminating station to proceed to the next step. Compared with the existing ones, the ejection method of the present invention makes the ejection more convenient, and this ejection method is not only helpful for demoulding, but also beneficial for protecting the The molded EVA film greatly reduces the damage of the mask.

Owner:CHENGDU XINTONG HIGH COMPOSITE EQUIP

A kind of straw wood ceramic root irrigation pipe and its preparation method and application

ActiveCN111978101BRealize the function of no recyclingSimple structureWatering devicesSpray nozzlesFiberCarbon fibers

The invention discloses a straw wood ceramic root irrigation pipe and its preparation method and application. The raw materials of the root irrigation pipe include phenolic resin, alcohol, straw, clay, dextrin, silica sol and carbon fiber, and are prepared by pouring molding with a specific structure. The green body is sintered under the protection of nitrogen to make the underground root irrigation pipe. The method can prepare underground root irrigation pipes with required shapes according to actual needs, can realize fast connection of underground irrigation pipes, and greatly reduces preparation and installation costs. At the same time, the root irrigation pipe has good environmental coordination. After reaching the design life, it can be directly crushed and returned to the field without recycling, which not only saves recycling costs, but also effectively improves the soil structure.

Owner:NORTHWEST A & F UNIV

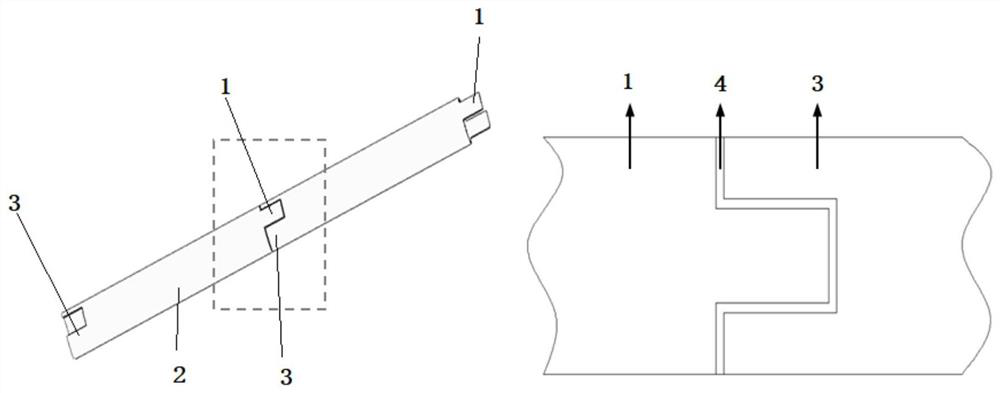

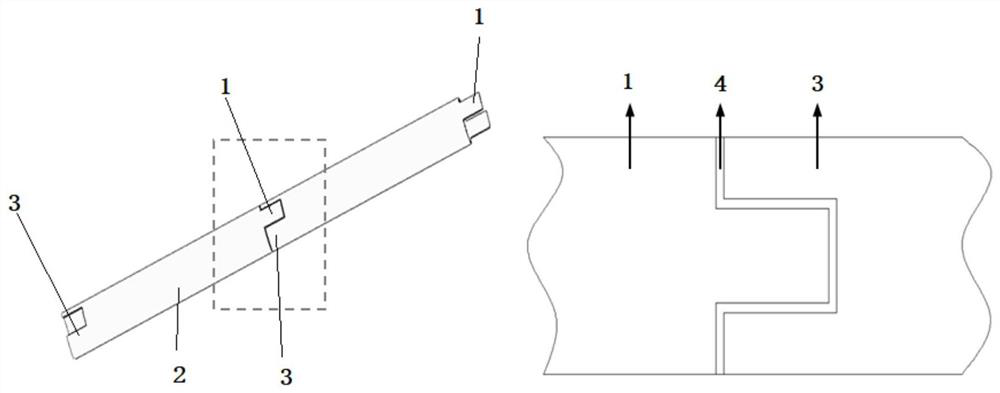

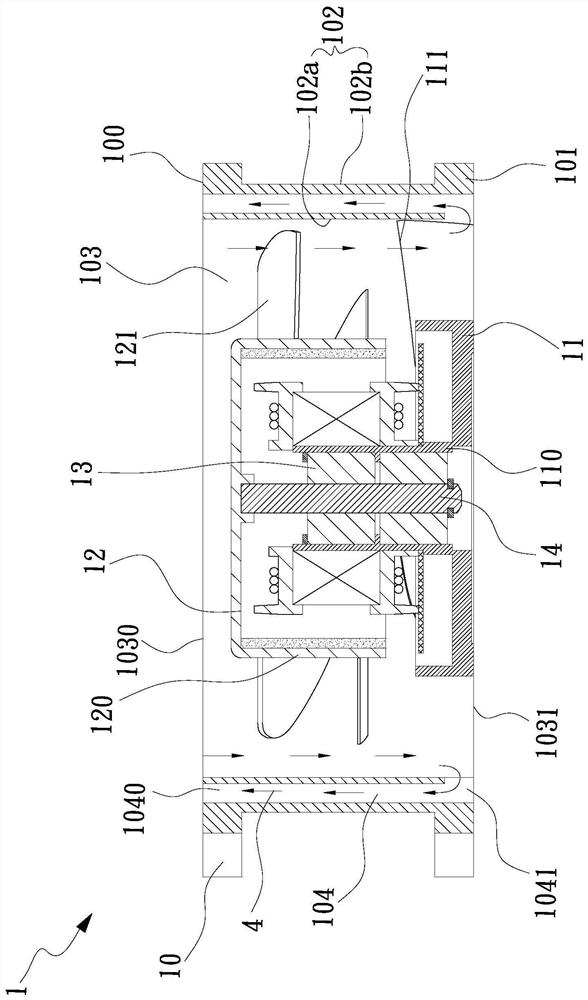

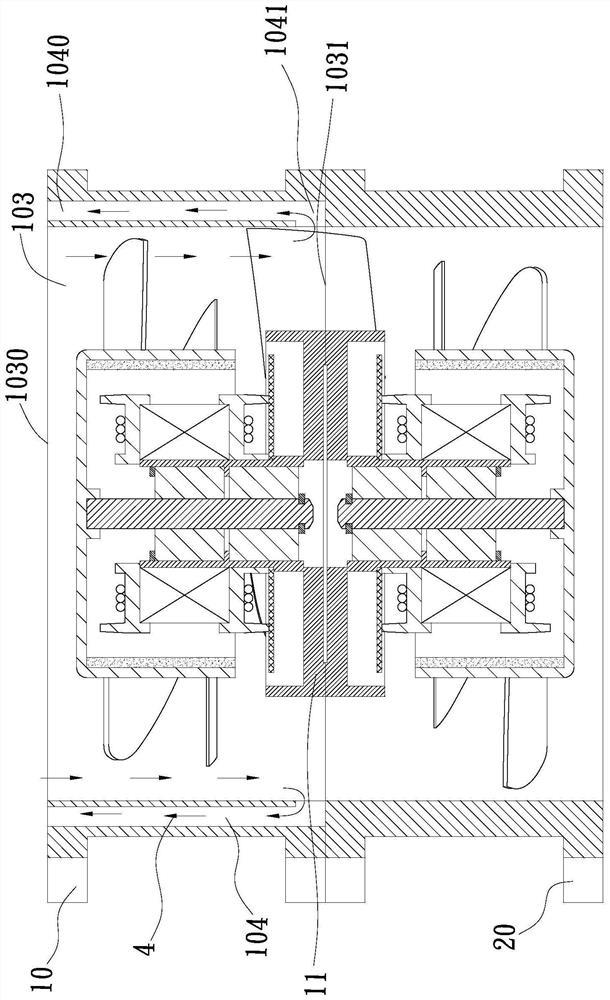

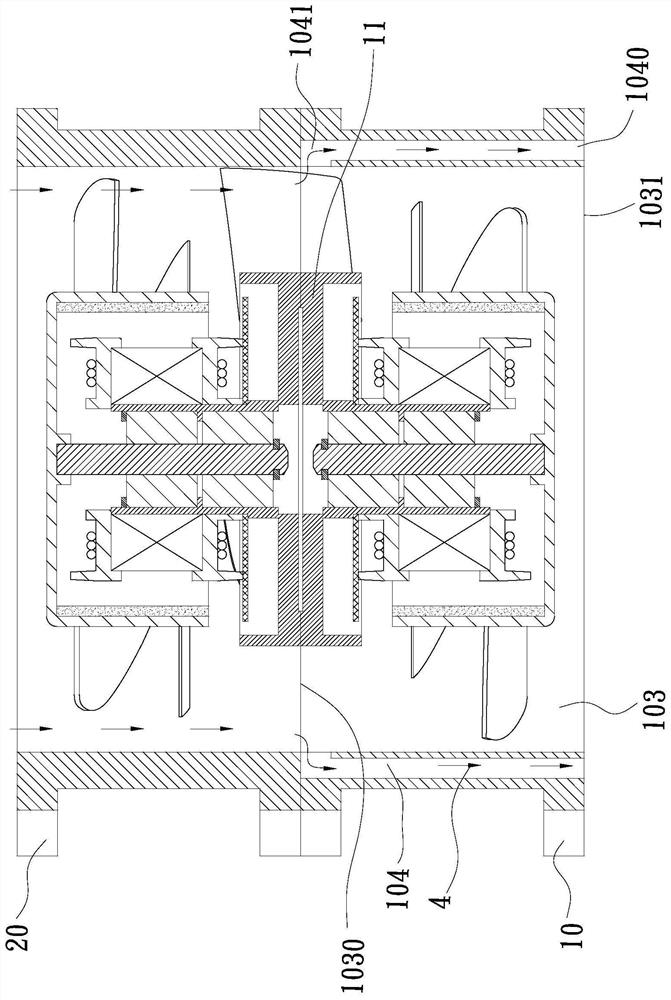

Fan frame structure

PendingCN111779712AImprove noiseHigh trafficPump componentsPump installationsStructural engineeringMechanical engineering

The invention provides a fan frame structure which comprises a first frame. The first frame is provided with a first upper end, a first lower end, a first frame wall and a first main runner, the firstmain runner penetrates through the first frame and forms a first main inlet and a first main outlet at the first upper end and the first lower end correspondingly, a first auxiliary runner parallel to the first main runner is arranged in the first frame wall, the first auxiliary runner is located on the outer side of the first main runner and is provided with a first auxiliary outlet and a firstauxiliary inlet, the first auxiliary outlet is located in the first upper end of the first frame and is parallel to and adjacent to the first main inlet, the first auxiliary inlet is adjacent to the first lower end of the first frame and communicated with the first main runner, airflow can be guided to be jetted towards the first main inlet through the arrangement of the first auxiliary runner, and then the effects of noise reduction and airflow increase are achieved.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Use method of composite phase change material in copper-steel double-metal casting process

ActiveCN113214799AImprove insulation effectImprove feeding effectHeat-exchange elementsLiquid stateMolten salt

The invention discloses a use method of a composite phase change material in a copper-steel double-metal casting process, which comprises the following steps: mixing fused salt, SiO2, stearic acid and borax, uniformly ball-milling, pressing, forming and sintering to obtain the composite phase change material used in the copper-steel double-metal casting process, and the fused salt is formed by mixing KF and MgF2. According to the method, the composite phase change material is placed on the upper layer of the copper alloy, the composite phase change material is converted from a solid state to a liquid state during casting so as to absorb and store heat, the composite phase change material is converted from the liquid state to the solid state during cooling so as to release the stored heat, and a good heat preservation effect on the copper alloy is achieved; therefore, a larger temperature difference exists between the lower layer and the upper layer of the copper alloy during cooling, a good feeding effect can be achieved between the upper layer and the lower layer, and the problems of shrinkage porosity and shrinkage cavities are avoided.

Owner:HEFEI UNIV OF TECH

A kind of fair-faced concrete preparation technology and special admixture preparation

ActiveCN108129086BImprove structural strengthReduce dispersalLubricant compositionArchitectural engineeringStructural engineering

The invention relates to a preparation technology of fair-faced concrete and a preparation method of a special admixture. The fair-faced concrete is prepared from the following components: water, cement, fly ash, mineral powder, medium sand, gravels, a dispersing agent, a defoaming agent, an air entraining agent and a water reducing agent. The fair-faced concrete has good apparent effects; by utilizing molding effects of the concrete, a decorative effect can be realized, and secondary finishing and decorating of partial molded concrete are eliminated; the fair-faced concrete is often used as decorative concrete and has the characteristics of small color difference and the like; the cured and molded concrete has the advantages of no obvious color difference in surface color and unique texture; the fair-faced concrete has the advantages of flat and smooth surface, uniform color, angular property, no damage or pollution, good environmental affinity and close to nature when being used forengineering construction.

Owner:成都精准混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com