A kind of silica dispersant for rubber and preparation method thereof

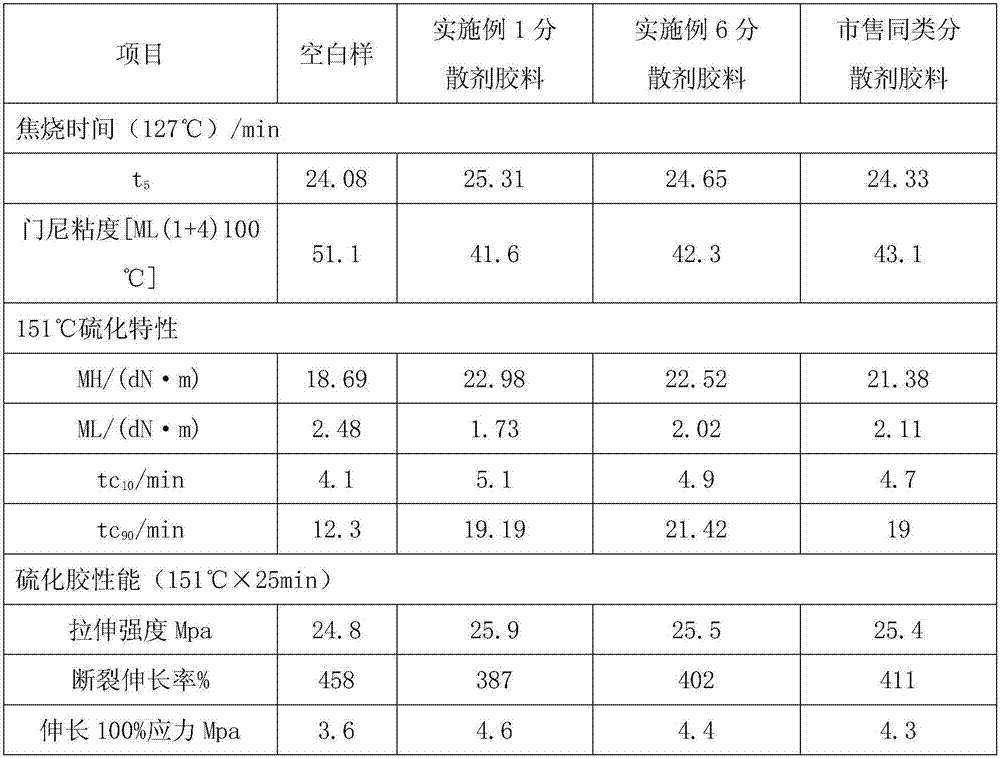

A technology of white carbon black and dispersant, which is applied in the field of new-type white carbon black dispersant for rubber and its preparation, can solve the problems of affecting the performance of rubber compound, limited improvement of white carbon black dispersibility, poor compatibility, etc. The effect of viscosity and processing energy consumption, improving processing safety performance, and improving wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The composition of the silica dispersant for rubber is polyethylene glycol 6000 stearate, which is prepared by heating reaction of polyethylene glycol 6000 and stearic acid.

[0055] The preparation method is: add 1mol of polyethylene glycol 6000 and 2.1mol of stearic acid into the reaction kettle, heat to melt completely, add 0.1mol of p-toluenesulfonic acid, and then pass inert gas N 2 , control the temperature at 130° C. for 5 h, stop the reaction, neutralize with triethanolamine to pH 7, and dry to obtain a solid product, that is, a silica dispersant for rubber.

Embodiment 2

[0057] The formulation of the white carbon black dispersant for rubber of the present invention is: 50 parts of polyethylene glycol 6000 stearate and 50 parts of polyethylene glycol 4000 stearate. Polyethylene glycol 6000 stearate is prepared by heating reaction of polyethylene glycol 6000 and stearic acid, and polyethylene glycol 4000 stearate is prepared by heating reaction of polyethylene glycol 4000 and stearic acid.

[0058] The preparation method of polyethylene glycol 6000 stearate and polyethylene glycol 4000 stearate is the same as example 1. After the reaction of the two products is completed, they can be discharged after heating, melting and mixing in the reaction vessel.

Embodiment 3

[0060] The formula of the white carbon black dispersant for rubber of the present invention is: 50 parts of polyethylene glycol 6000 stearate, 30 parts of polyethylene glycol 4000 stearate, and 20 parts of polyethylene glycol 2000 stearate.

[0061] Polyethylene glycol 6000 stearate, polyethylene glycol 4000 stearate, the preparation method of polyethylene glycol 2000 stearate is the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com