Novel carbon black dispersing agent for rubber and preparation method thereof

A dispersant and rubber technology, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. It can solve the problems of poor self-adhesiveness, poor wear resistance, and poor wear resistance of mixed rubber problems, to achieve the effect of improving anti-vulcanization reversion and heat resistance, improving fluidity and extrusion rate, and making the preparation process simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of carbon black dispersion agent for novel rubber, is made up of the raw material of following weight part:

[0028] Polyethylene wax (WAX-420P) 10 parts Zinc stearate 15 parts Stearic acid (1801) 20 parts Polyethylene glycol 400 10 parts Pentaerythritol tetrastearate 45 parts.

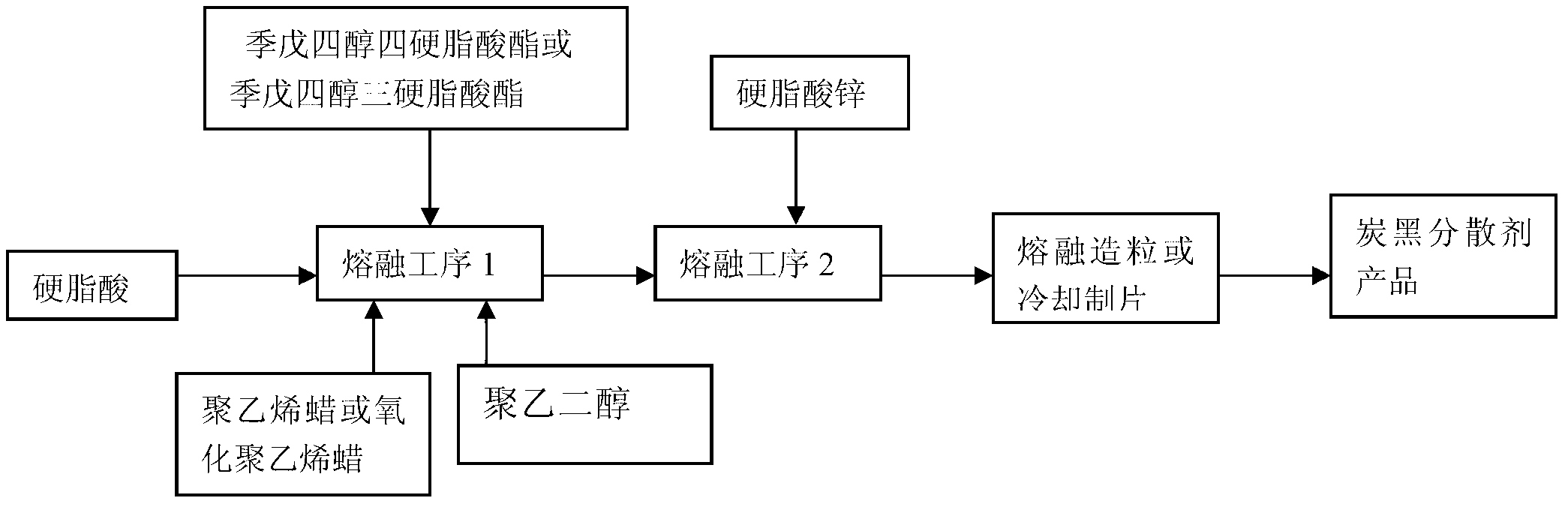

[0029] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 100°C, then add stearic acid at a temperature of 130°C Zinc is stirred and melted, added once every ten minutes, three additions are completed, poured out and cooled for tableting or melted and granulated to obtain a new type of carbon black dispersant for rubber. The preparation process flow chart is shown in figure 1 .

Embodiment 2

[0031] A kind of carbon black dispersion agent for novel rubber, is made up of the raw material of following weight part:

[0032] Polyethylene wax (WAX-420P) 15 parts Zinc stearate 20 parts Stearic acid (1801) 25 parts Polyethylene glycol 400 10 parts Pentaerythritol tetrastearate 30 parts.

[0033] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 110°C, then add stearin at 140°C Acid zinc is stirred and melted, added once every ten minutes, three additions are completed, melted and granulated or poured out and cooled to make tablets to obtain a new type of carbon black dispersant for rubber.

Embodiment 3

[0035] A kind of carbon black dispersion agent for novel rubber, is made up of the raw material of following weight part:

[0036] Polyethylene wax (WAX-420P) 30 parts Zinc stearate 20 parts Stearic acid (1801) 10 parts Polyethylene glycol 400 10 parts Pentaerythritol tetrastearate 30 parts.

[0037] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 105°C, and then add stearin at a temperature of 130°C Stir and melt the acid zinc, add once every ten minutes, add three times, and finally pour it out and cool it to make tablets or granulate to obtain a new type of carbon black dispersant for rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com