Mold-drawing method and special device for v-casting manhole cover

A mold and casting technology, which is applied in the field of the V method casting well block manhole cover and its special device field, can solve the problems of EVA film breaking, film damage, reducing production efficiency, etc. It is convenient to take out the mold and reduce the effect of being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

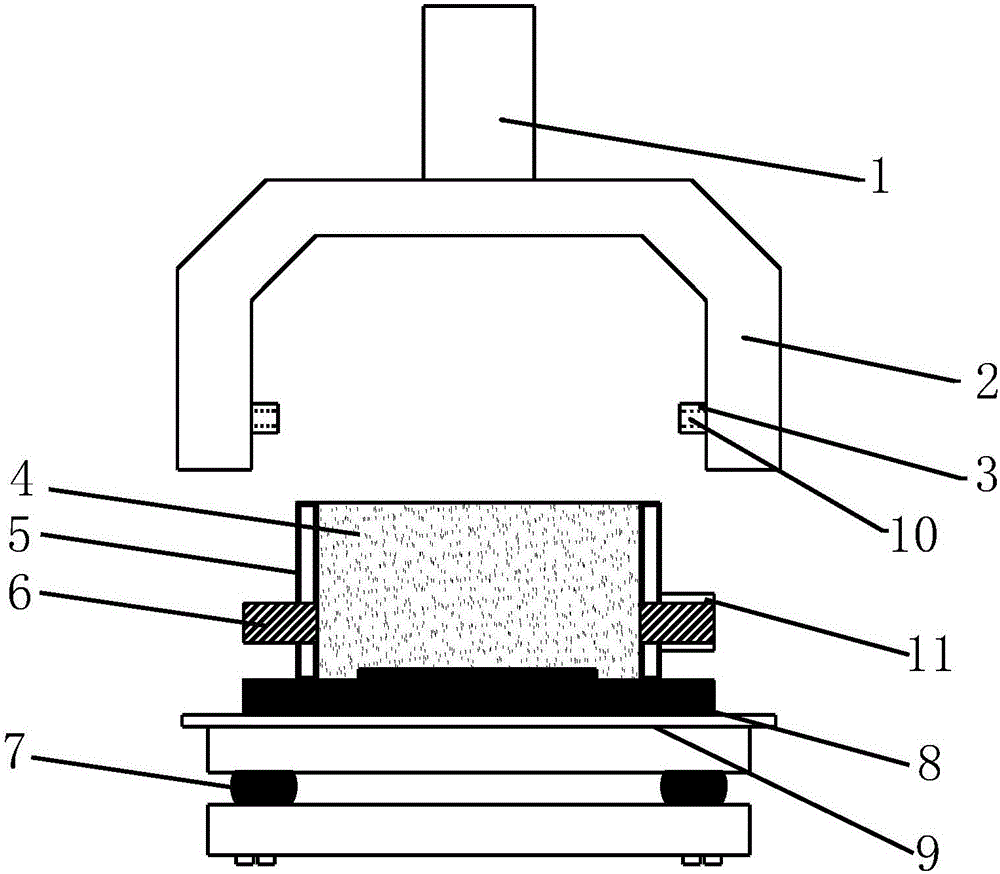

[0027] image 3 It is a special device for the mold drawing method of the present invention, and the device includes a manipulator 1, a sand box 5 with sand 4, a mold 8 and a mobile shaking table. The manipulator 1 is provided with a manipulator arm 2, and the manipulator arm 2 is provided with a manipulator box mechanism 3. The manipulator box mechanism 3 is a semi-circular structure with an inner ring diameter of 120 mm, an outer ring diameter of 150 mm, and a length of 180 mm. There are two supporting box mechanisms on each mechanical arm, and the distance between the centers of two manipulator supporting box mechanisms 3 is 900mm. When the manipulators clamped, their inner rings just cooperated with the supporting box mechanisms 6 on the sand box. The manipulator holding box mechanism 3 is provided with a manipulator holding box vacuum interface 10 .

[0028] Manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com