Application method of a composite phase change material in copper-steel bimetal casting process

A composite phase change material, bimetal technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of not meeting the requirements of copper-steel bimetal casting process, no relevant reports, specific heat capacity and phase change latent heat, low thermal conductivity coefficient and other issues, to achieve the effect of good thermal insulation, avoid shrinkage porosity, and good feeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

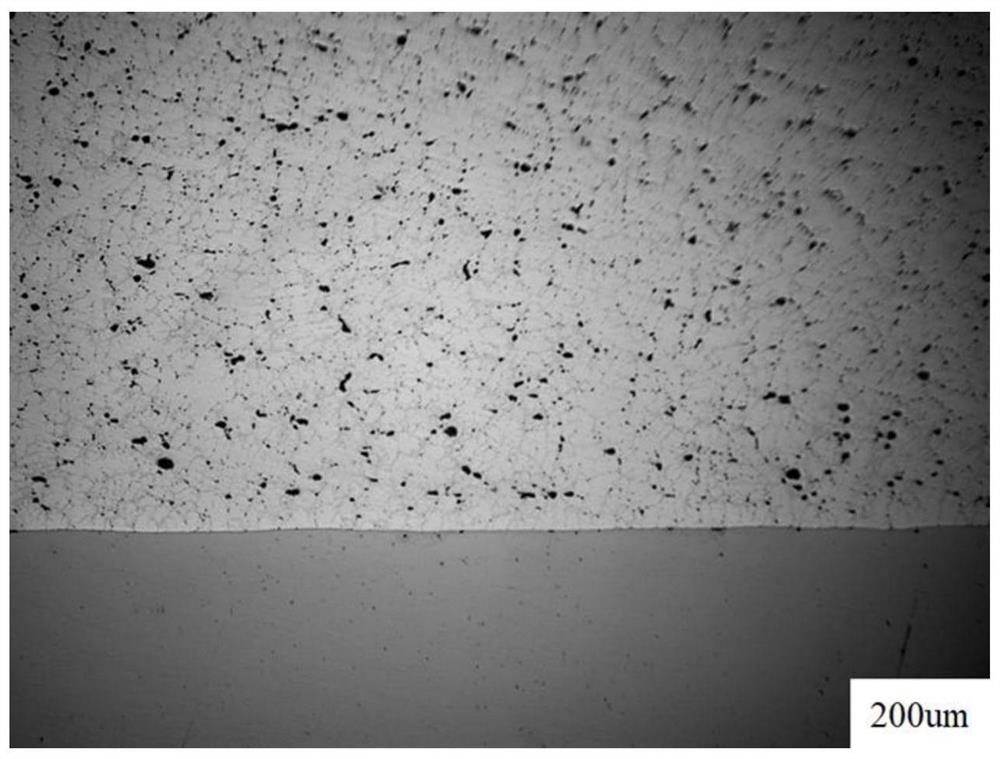

[0026] A method for using a composite phase change material in a copper-steel bimetal casting process, comprising the steps of:

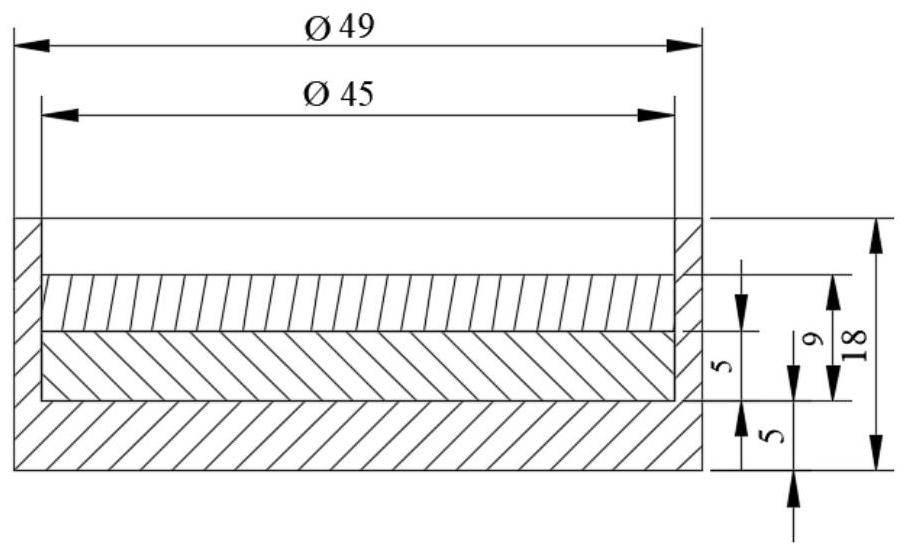

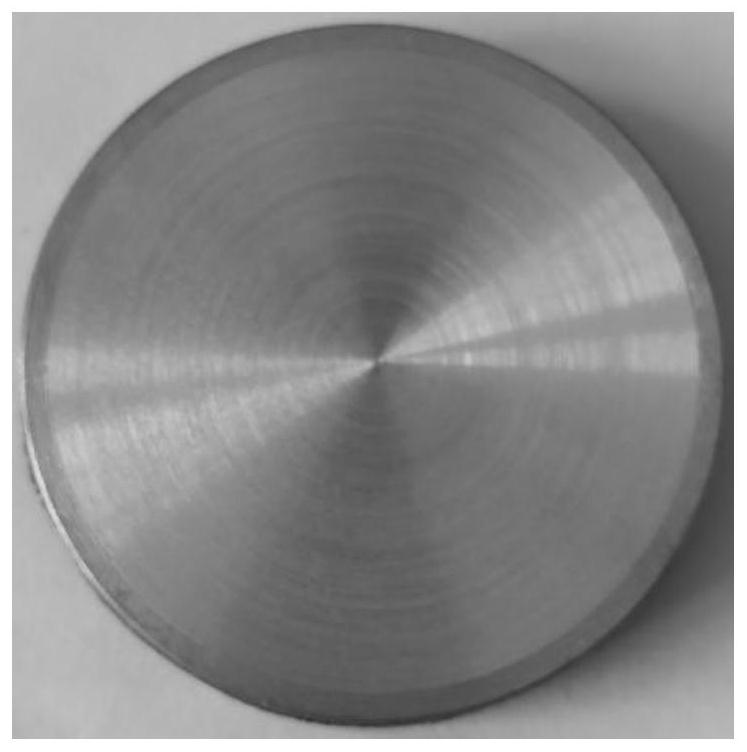

[0027] Step 1, preparation of composite phase change material

[0028] Combine KF with MgF 2 According to the molar ratio of 30%: 70% mixed to form a molten salt; the molten salt, SiO 2 , stearic acid and borax are mixed and ball milled (the rotating speed of ball milling is 200r / min, and the ball milling time is 1.5h) evenly, and then pressed into a disc with a diameter of 45mm and a thickness of 4mm, the pressing pressure is 30MPa, and the holding time is 10min; The wafer was put into the sintering furnace, and under the protection of the ammonia gas decomposition atmosphere, the temperature was first raised from room temperature to 200°C at a rate of 3°C / min and kept for 60 minutes, and then raised to 1050°C at a rate of 5°C / min. Insulate for 1 hour to obtain a composite phase change material. Wherein, the mass percent of each raw material is:...

Embodiment 2

[0035] A method for using a composite phase change material in a copper-steel bimetal casting process, comprising the steps of:

[0036] Step 1, preparation of composite phase change material

[0037] Combine KF with MgF 2 According to the molar ratio of 35%: 65% mixed to form a molten salt; the molten salt, SiO 2 , stearic acid and borax are mixed and ball milled (the rotating speed of ball milling is 200r / min, and the ball milling time is 1.5h) evenly, and then pressed into a disc with a diameter of 45mm and a thickness of 4mm, the pressing pressure is 30MPa, and the holding time is 10min; The wafer was put into the sintering furnace, and under the protection of the ammonia gas decomposition atmosphere, the temperature was first raised from room temperature to 200°C at a rate of 3°C / min and kept for 60 minutes, and then raised to 1050°C at a rate of 5°C / min. Insulate for 1 hour to obtain a composite phase change material. Wherein, the mass percent of each raw material is: m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com