Resin paint surface nursing emulsion and preparation method thereof

A resin paint and emulsion technology, applied in chemical instruments and methods, anionic surface active compounds, polishing compositions, etc., can solve the problems of operator health hazards, poor product glazing performance, affecting human health, etc., and achieve environmental friendliness, The effect of good glazing effect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the resin paint surface care emulsion formula of the present invention that table 1, 2 provides, the preparation method of the resin paint surface care emulsion of the present invention may further comprise the steps:

[0030] (1) Mix polyol, alcohol amine and distilled water evenly to obtain component A; or dissolve emulsifier in distilled water, then add polyol and alcohol amine to obtain component A;

[0031] (2) Heat stearic acid, fat, solvent oil and wax at 85°C to 95°C, stir, and knead for 30 to 40 minutes to obtain component B;

[0032] (3) Mix components A and B evenly.

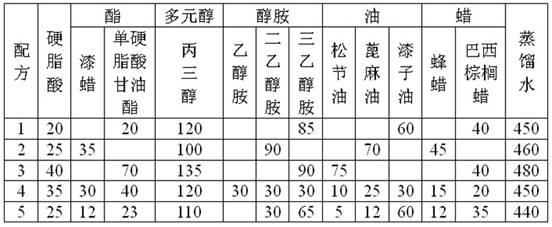

[0033] Table 1 Resin paint surface care emulsion formula table 1 of the present invention

[0034]

[0035] In the preparation of formula 2, 30 parts of Pingpingjia O were added;

[0036] Added 40 parts of fatty alcohol polyoxyethylene ether in the preparation of formula 5;

[0037] Table 2 Resin paint surface care emulsion formula table 2 of the present invention

[0038] ...

Embodiment 2

[0041] Embodiment 2 furniture, floor

[0042] Apply the prepared formula 1 on cotton yarn or soft cloth, distribute evenly, repeatedly wipe the painted surface of furniture and floor, the effect is bright and clean.

Embodiment 3

[0043] Example 3 Leather

[0044] Mix the prepared formula 3 with water at a volume ratio of 1:1, spray evenly on the leather surface with a spray device, dry it, and wipe the leather surface with cotton yarn or soft cloth, and the effect is as bright as ever.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com