Patents

Literature

116results about How to "Good glazing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium temperature alabastrine galze and its pren process

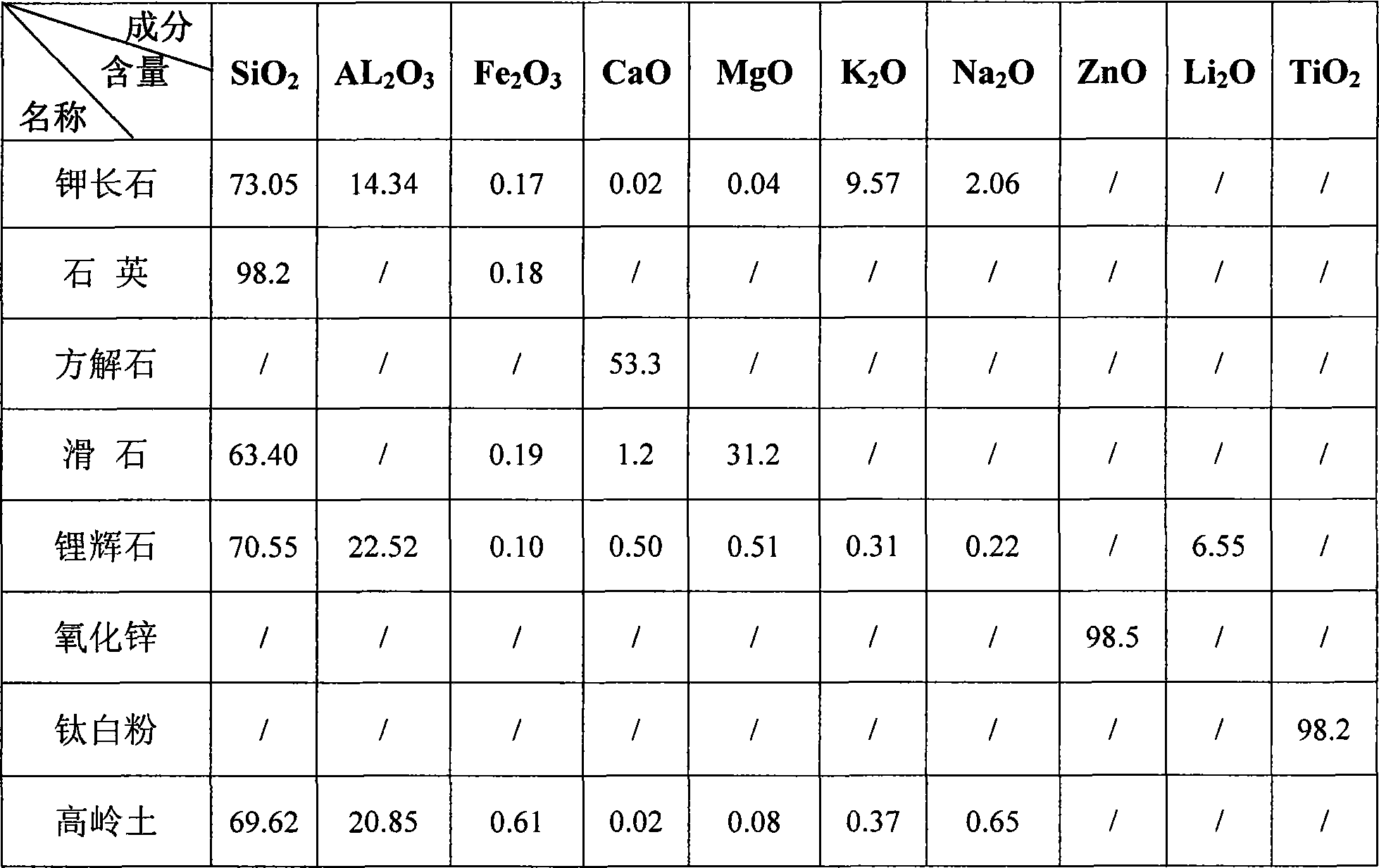

The present invention is one kind of medium temperature alabastrine glaze including priming glaze and overglaze and its preparation process. The medium temperature alabastrine glaze is prepared with crystallizing agent of TiO2 and ZnO, crystallizing assistant MgO, CaO, Li2O, etc, borax for regulating crystal shape and glaze viscosity. The preparation process includes the following steps: milling the material in a ball mill for 24 hr, 320 mesh sieving, diluting with water to 48-50 Be deg, 120 mesh sieving the glaze sluury, applying priming glaze and applying overglaze, and sintering at 1230- 1280 deg.c in a kiln to form the alabastrine glaze.

Owner:HUNAN HUALIAN YIBAILI CERAMIC IND

Method and device for coating and curing ultraviolet curing coating

InactiveCN101518774AHigh coating densitySimple compositionPretreated surfacesCoatingsUltravioletMaterials science

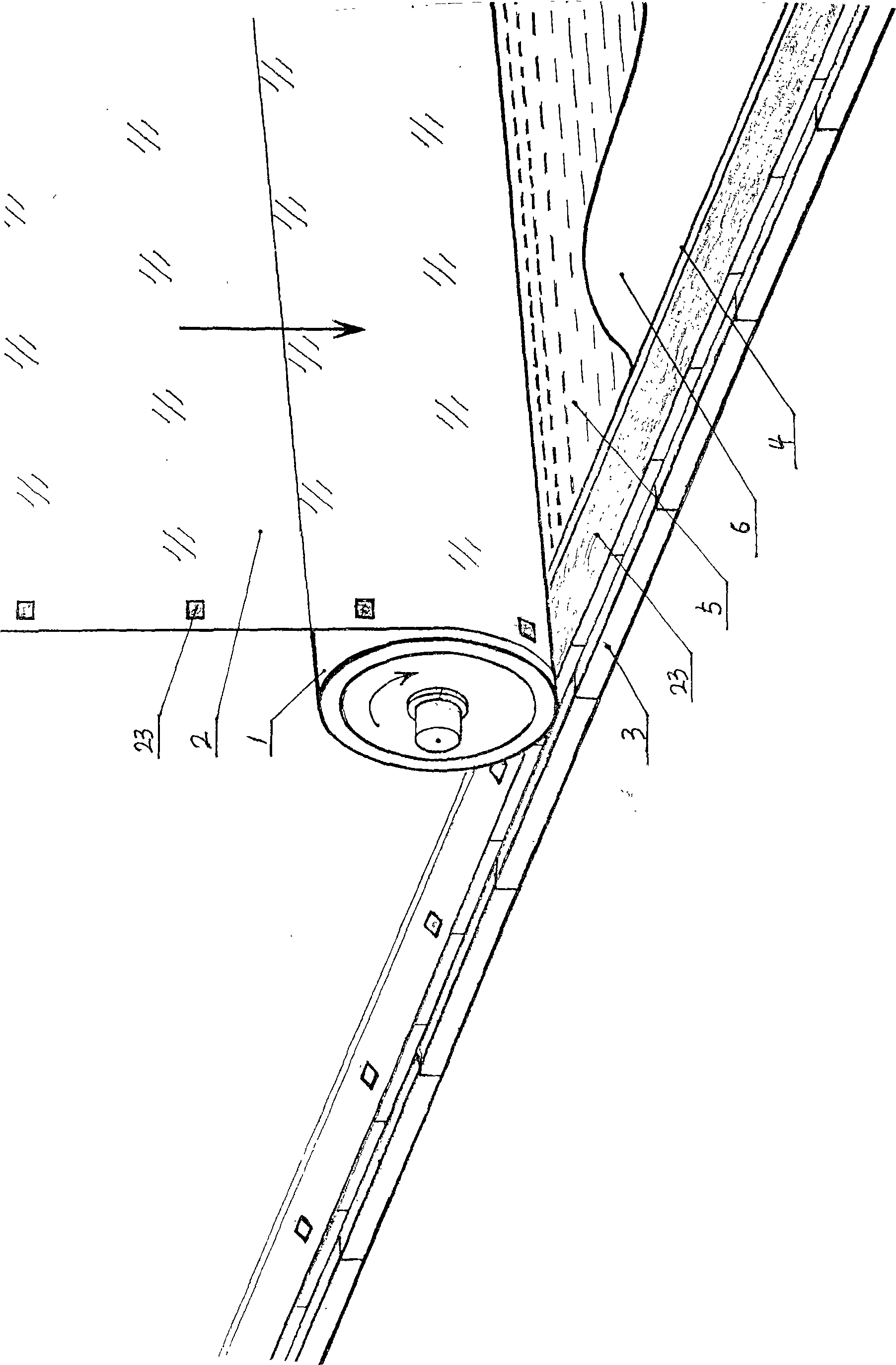

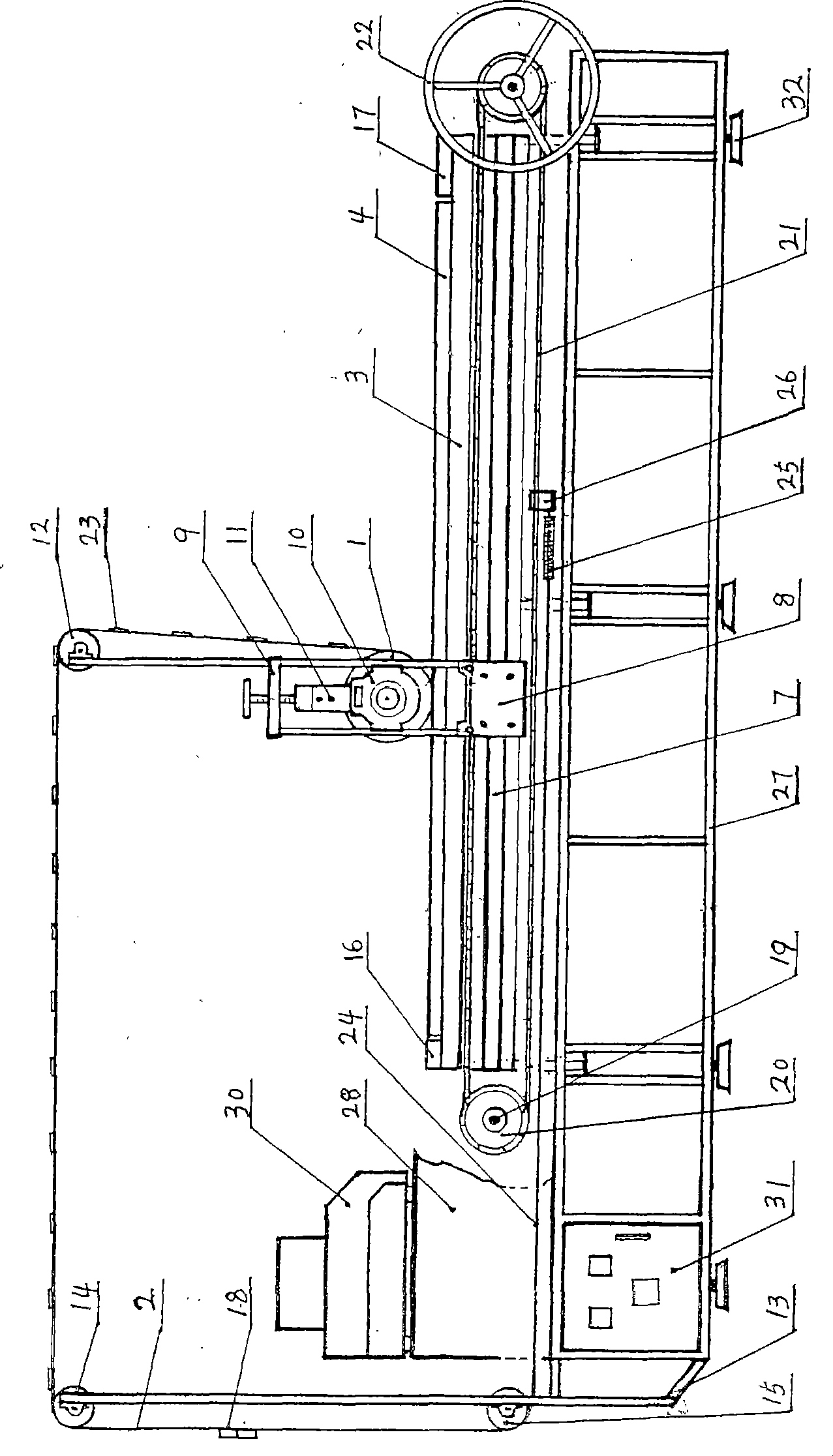

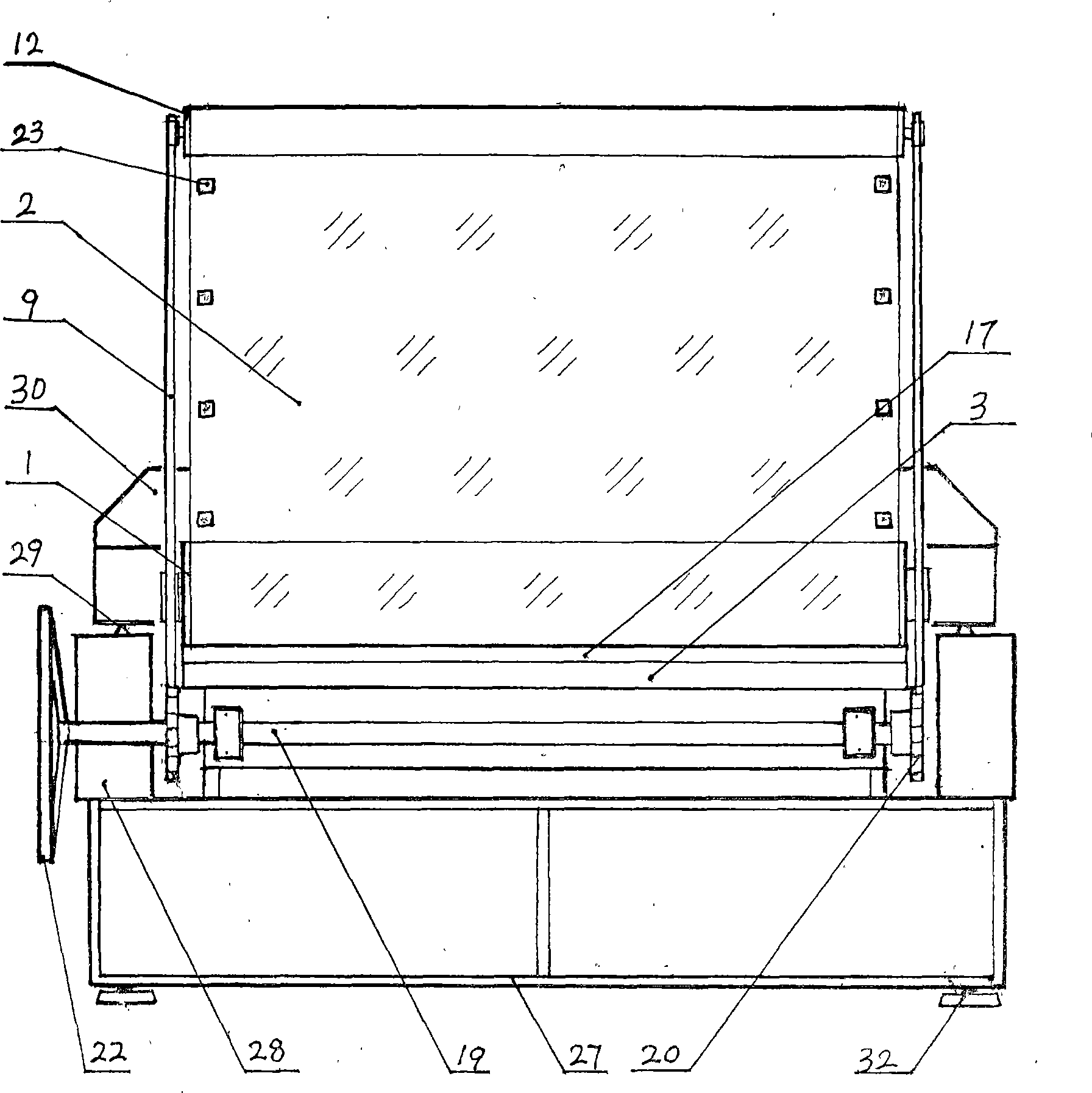

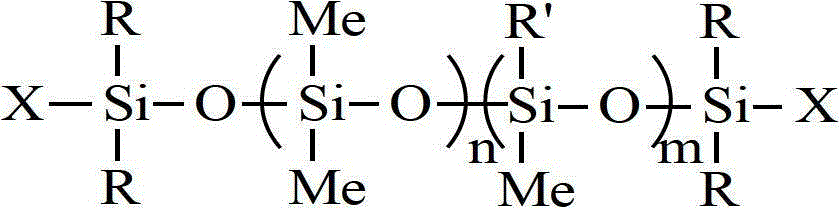

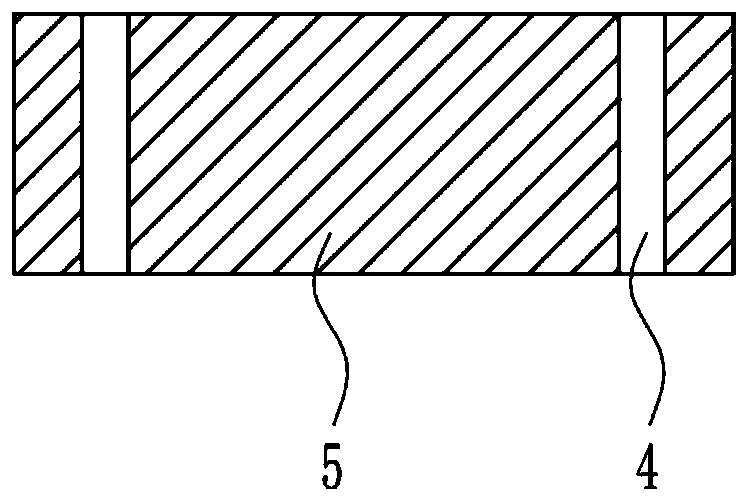

The invention relates to a method and a device for coating and curing ultraviolet cured coating, in particular to a method and a device for coating and curing coating on the surface of an object with ultraviolet. The method comprises the following steps: an objected to be coated with ultraviolet cured coating on the surface is placed flat; the ultraviolet cured coating is coated on the surface of the object; the surface of an press roll passes by a transparent coating, and the press roll is cooperatively arranged above the object; the press roll shifts relative to the object, rotationally rolls, presses, spreads and evenly coats the ultraviolet cured coating, and conveys and coats the transparent coating on the surface of the object; the ultraviolet cured coating under the transparent coating is cured under the irradiation of an ultraviolet lamp with ultraviolet rays penetrating the transparent coating; and the transparent film is uncovered, with the result that the ultraviolet cured coating is cured on the surface of the object. The invention has the advantages of low manufacturing cost, high degree of finish, good effect, reliable running, easy operation, and the like.

Owner:秦皇岛洛克维德新材料技术有限公司

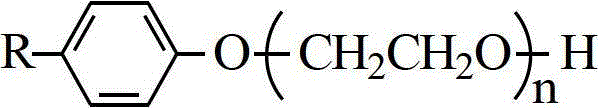

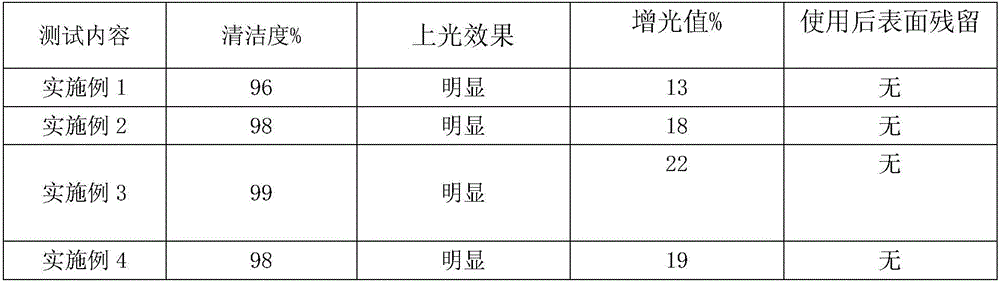

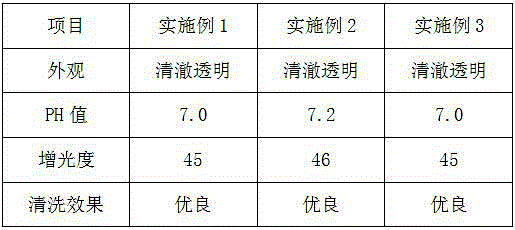

Concentrated solution for preparing leather polish and care products, and application

ActiveCN102942875AConvenient careGood glazing effectPolishing compositionsLeather surface finishingChemistryInorganic chemistry

Owner:BEIJING SUNPU BIOCHEM TECH

Moldproof softening and brightening agent for cleaning leather and preparation method thereof

The invention discloses a moldproof softening and brightening agent for cleaning leather and a preparation method thereof. The moldproof softening and brightening agent for cleaning leather is prepared from surfactant, brightener, oleic acid, animal fat leather greasing agent, fluorosilicon oil, triethanolamine, mold preventive, essence and deionized water in certain mass ratio. The preparation method comprises the following steps: preparing raw materials, mixing oil phases, mixing water phases, mixing oil and water, and filtering and filling. Due to the addition of the fluorosilicon oil and multiple assistants, the moldproof softening and brightening agent for cleaning leather has favorable effects on cleaning and nourishing leather, can endow the leather with the characteristics of smoothness, softness, water resistance, wear resistance, mold resistance and the like.

Owner:JIANGSU XUE BAO DAILY CHEM CO

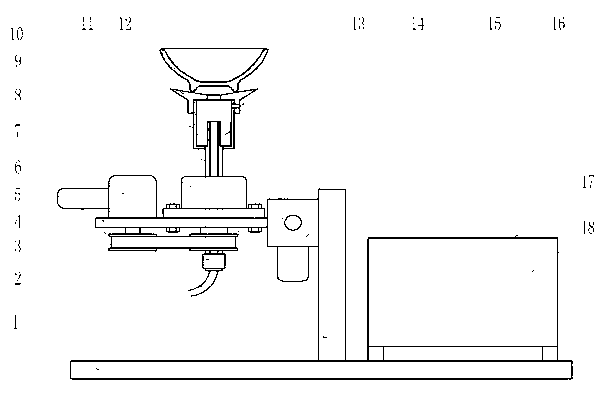

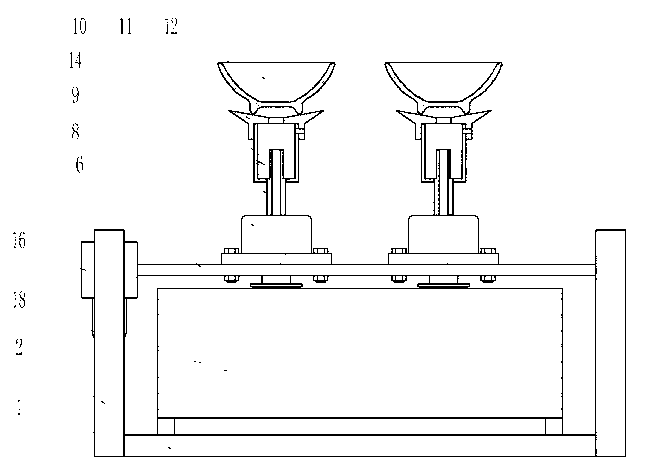

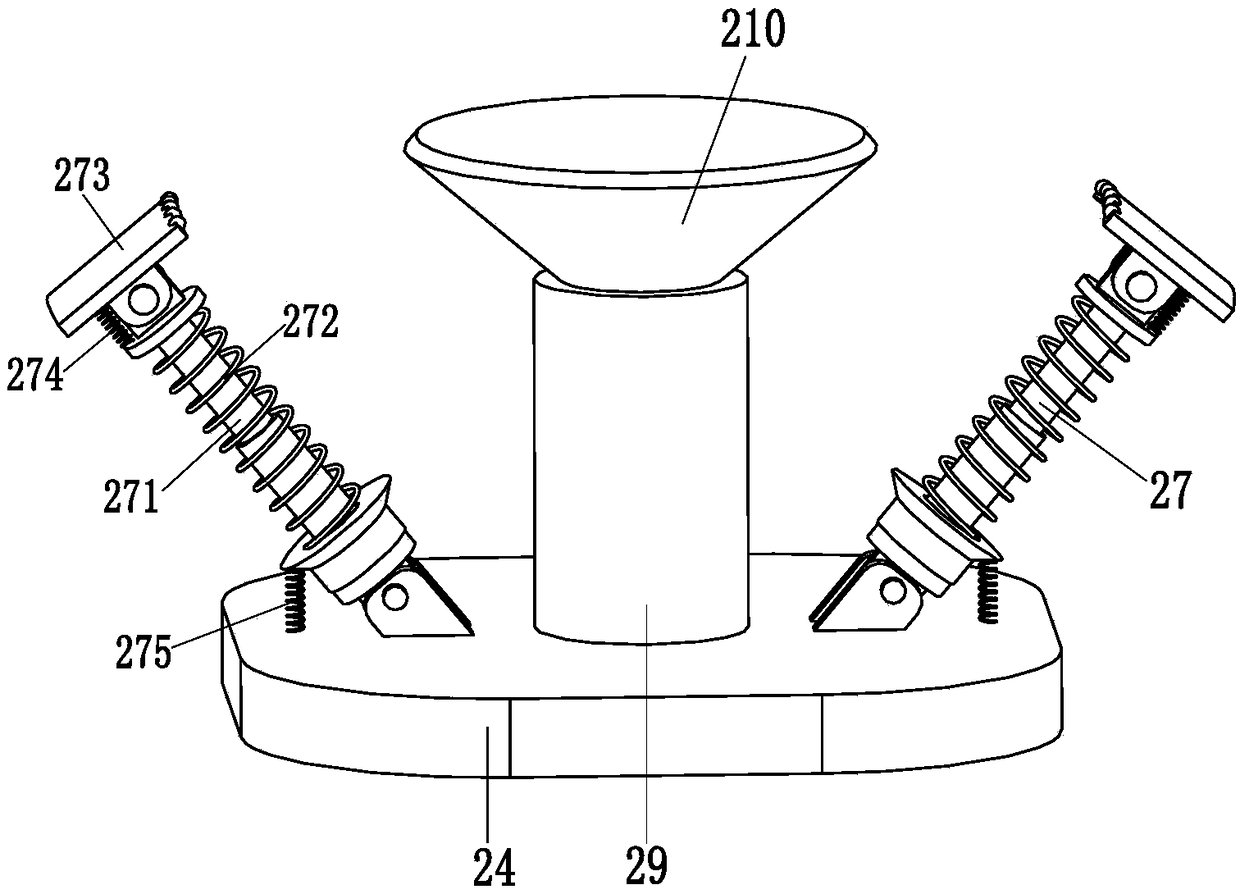

Automatic glazing device for domestic ceramics

The invention discloses an automatic glazing device for domestic ceramics. The automatic glazing device comprises a sucking disc device, a supporting plate and a rack upright post, wherein the sucking disc device is used for absorbing a bowl blank; the supporting plate is used for supporting the sucking disc device and sucking disc rotation speed reducers; the sucking disc device is connected with the supporting plate by a bearing; the bearing base of the bearing is fixed on the supporting plate by a bolt; a glaze sucking hole is formed on the side surface of the sucking disc device; and glaze water in a glaze sucking and storing barrel can be supplemented through the glaze sucking hole in a glaze soaking process. Two speed reducers are combined in different spaces and at different times, i.e., the sucking plate is driven by the sucking plate rotation speed reducers to rotate; and the whole sucking plate device and the supporting plate are driven by the supporting plate speed reducer to rotate, so that the automatic glazing process of the whole device is realized, thereby solving the problems that the existing glazing device is low in efficiency, poor in glazing quality and large in labor intensity; moreover, the automatic glazing device has the advantages of complete and uniform glazing effect, good glazing effect, high efficiency and high automation degree.

Owner:GUANGXI BEILIU CITY ZHICHENG CERAMIC AUTOMATION TECH

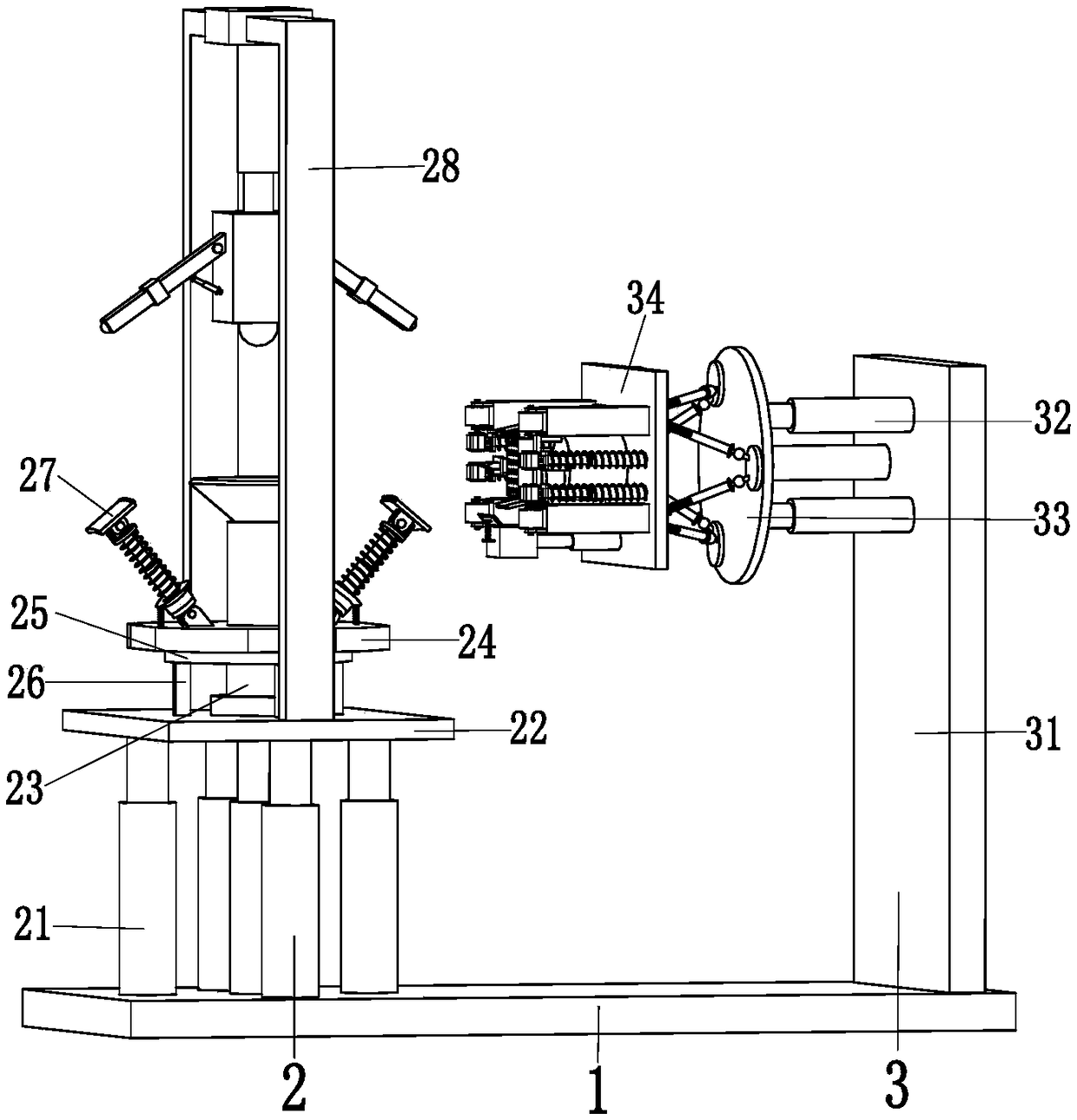

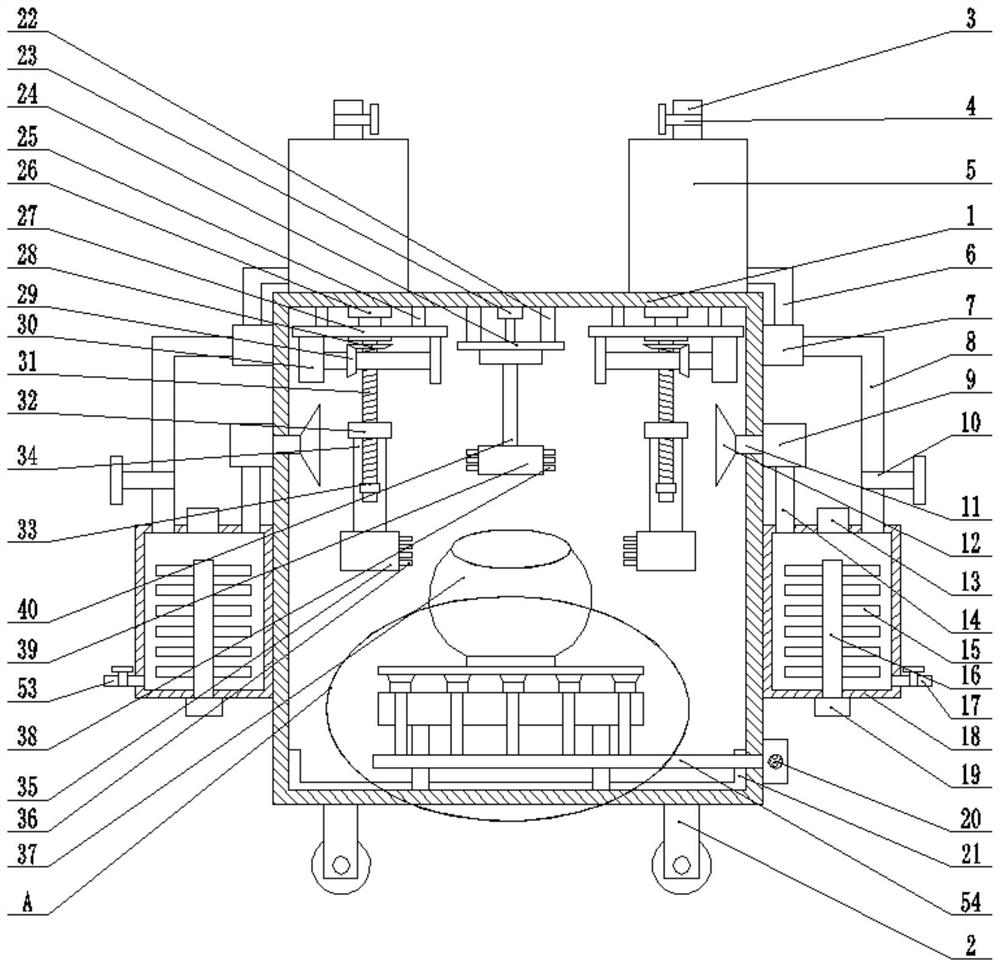

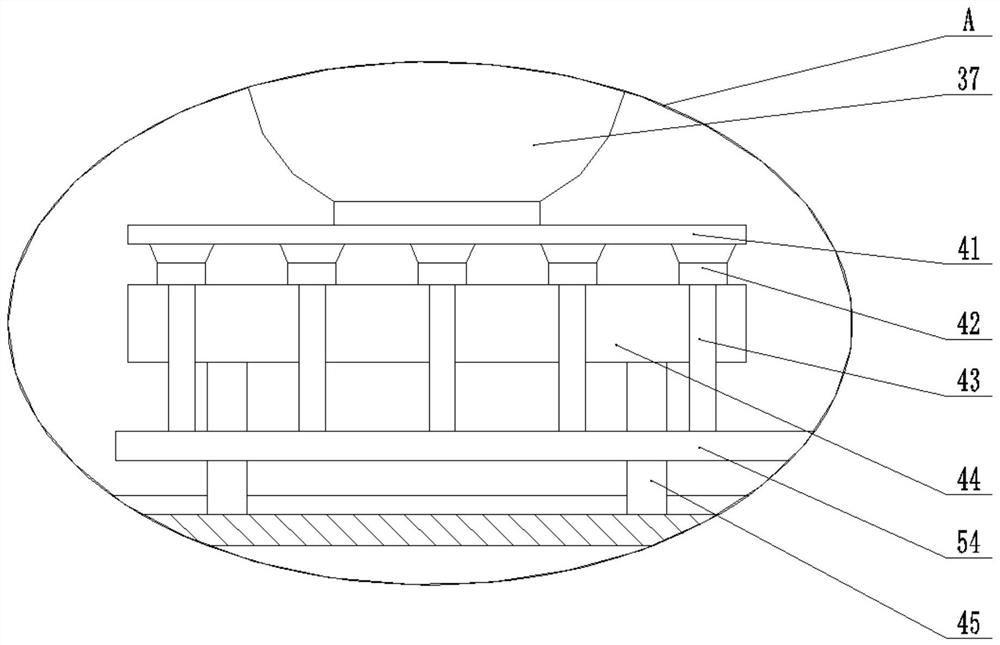

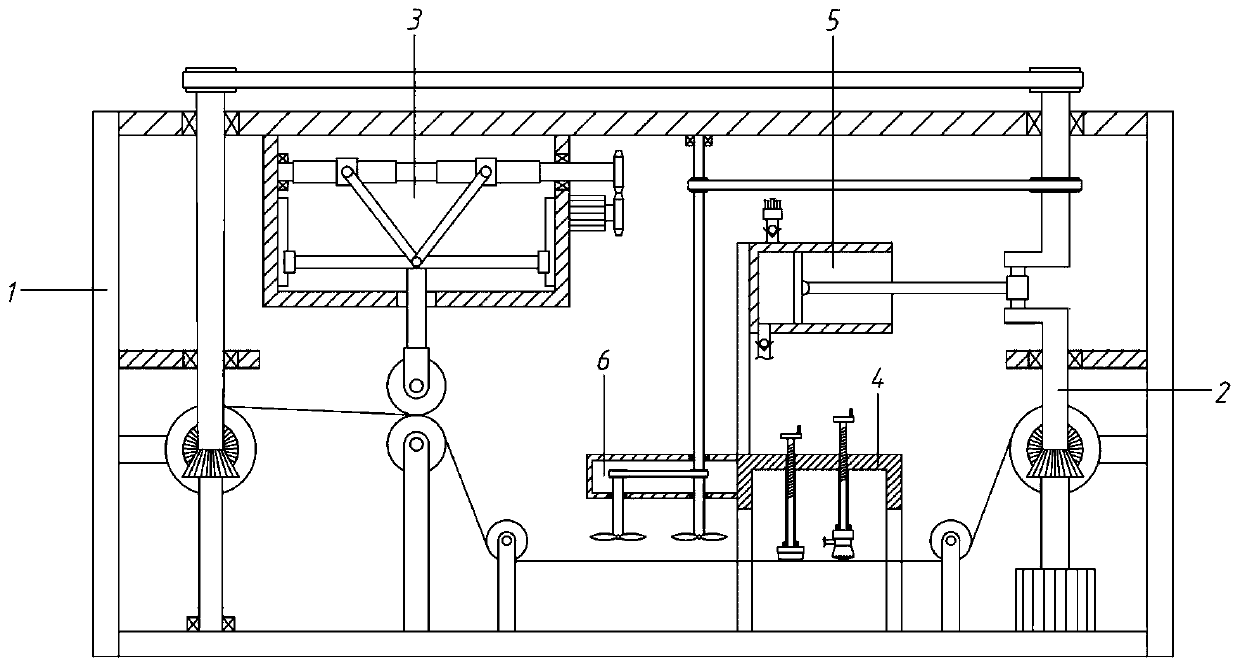

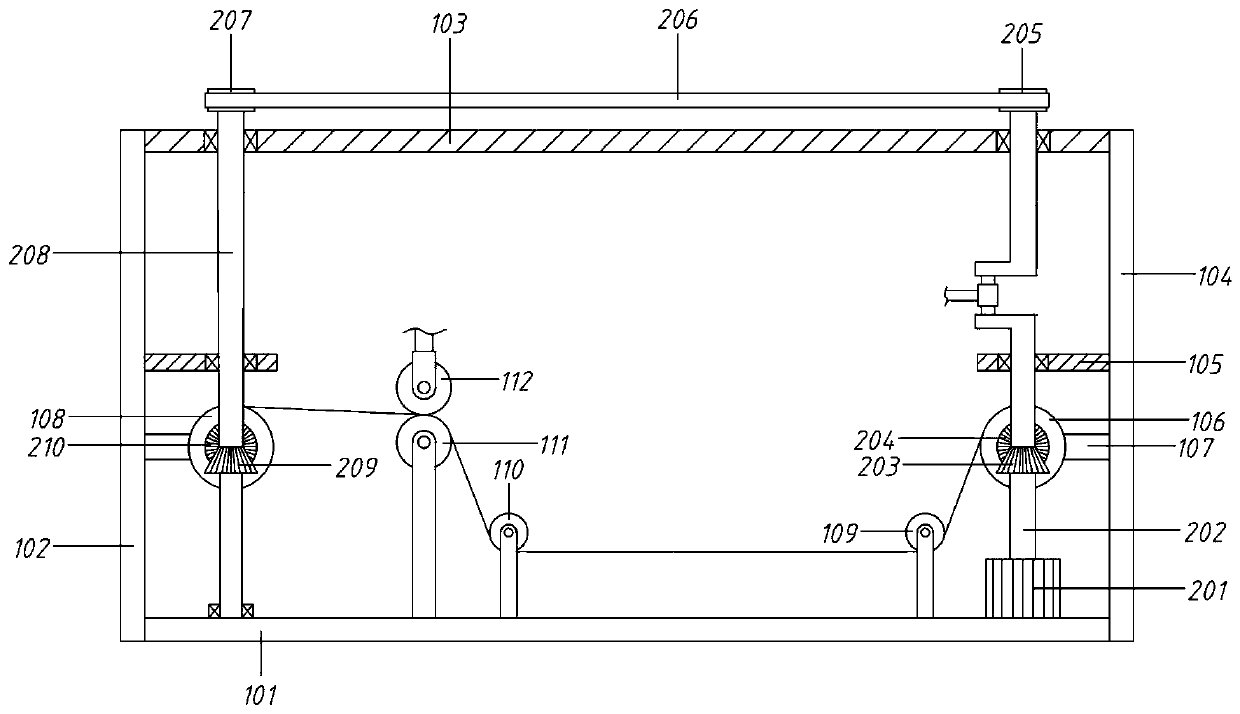

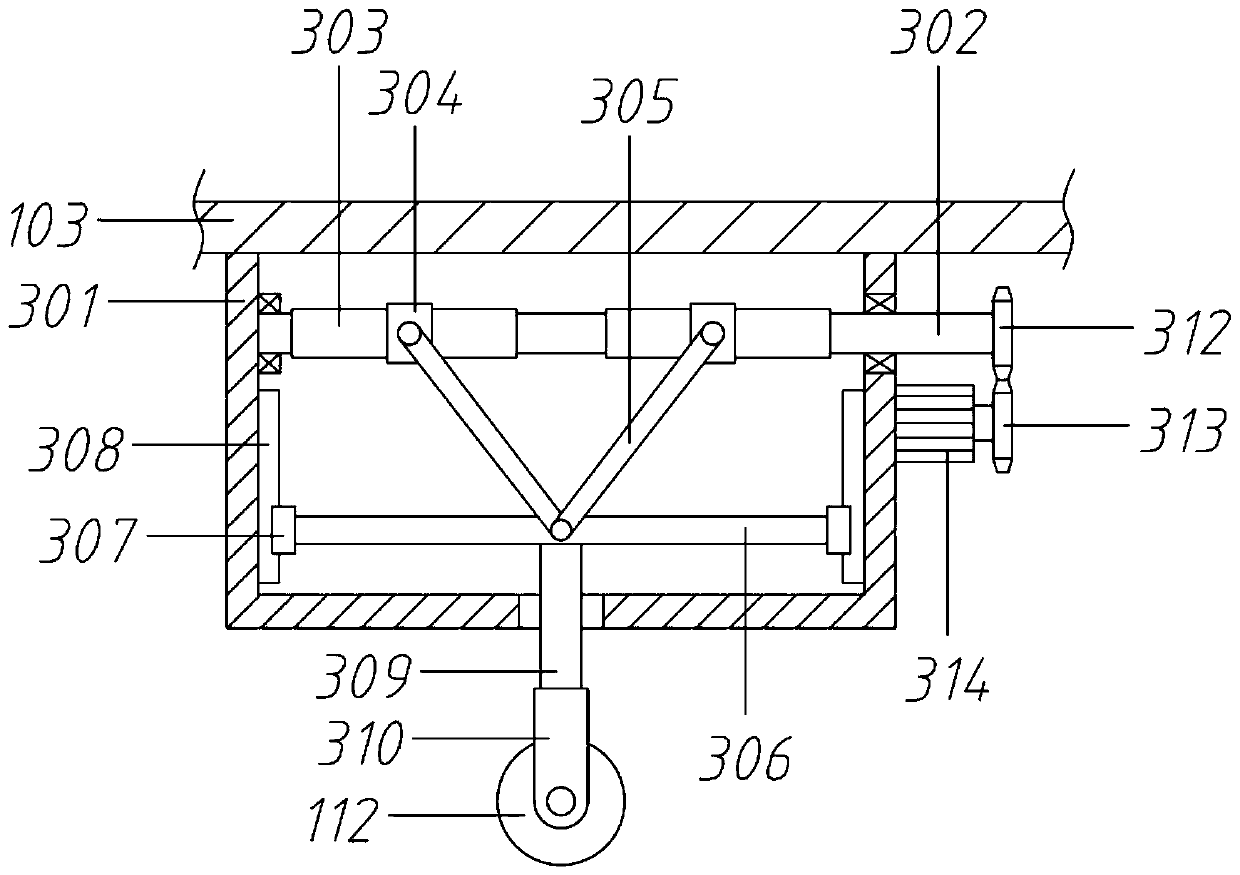

Multi-station automatic glaze spraying machine for ceramic

InactiveCN108858704AImplement suction lockSpray glaze smoothCeramic shaping apparatusEngineeringCeramic

The invention relates to a multi-station automatic glaze spraying machine for ceramic. The multi-station automatic glaze spraying machine comprises a supporting base plate, a fixing device and a glazespraying device; the fixing device is installed at the top of the left end of the supporting base plate; the glaze spraying device is installed at the top of the right end of the supporting base plate; the glaze spraying device comprises a glaze spraying side plate, a glaze spraying push rod, a parallel mechanism, a glaze spraying support plate, a positioning mechanism, a glaze spraying mechanismand a scraping and conveying mechanism. The multi-station automatic glaze spraying machine provided by the invention can solve the problems that in an existing ceramic glaze spraying process, different fixing tools are required if the ceramic is different in size, the position of the ceramic cannot be locked, the ceramic is easily changed in position in rotation; when the outer side surface of the ceramic is subjected to glaze spraying action manually, the manual glaze spraying effect is poor, the ceramic glaze spraying is out of flatness, the redundant glaze material cannot be recycled, thethickness of the glaze material on the surface of the ceramic cannot be regulated and the like; and the multi-station automatic glaze spraying machine can realize the functions of sucking and lockingthe ceramic, limiting the ceramic when the ceramic rotates and implementing overall uniform glaze spraying on the outer side surface of the ceramic.

Owner:ZHEJIANG NANSONG CERAMIC

Antique matte cracked glaze and preparation technology thereof

The invention discloses antique matte cracked glaze and a preparation technology thereof. The cracked glaze comprises the following raw materials in parts by weight: 25-30 parts of feldspar, 40-45 parts of limestone, 5-10 parts of kaolin, 5-10 parts of calcined kaolin, and 9-15 parts of quartz. The preparation technology of the antique matte cracked glaze comprises the following steps that: the raw materials are uniformly mixed to obtain a mixture; water is added into the mixture with the weight ratio of the mixture to the water being equal to 1:0.80, and ball-milling and sieving are performed on the mixture and the water to obtain a glaze material of the cracked glaze; and a red clay porcelain body coated with the glaze material is sintered, and then the sintered red clay porcelain body is colored, thus obtaining the finished product of the antique matte cracked glaze. The glazed effect of the antique matte cracked glaze is stable; the glaze color of the antique matte cracked glaze is slightly dim, so that the antique matte cracked glaze is more of an antique beauty; in addition, as the sintering time for a single batch of the antique matte cracked glaze can be 12 hours, the quick sintering adaptability of the antique matte cracked glaze is high, so that the antique matte cracked glaze is applicable to volume production; and as the sintering time is short, the efficient production is realized, the aims of energy conservation and environmental friendliness are achieved, the production cost of the antique matte cracked glaze is reduced, and the market competitiveness of theantique matte cracked glaze is improved, so that the antique matte cracked glaze has very high social and economic benefits.

Owner:FUJIAN JIAMEI GRP +1

Non-washing type automobile essence and preparation method thereof

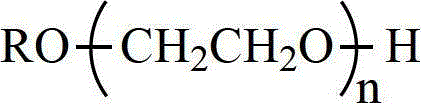

ActiveCN102586036AEffective maintenanceWon't scratchAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsGlycerolFatty alcohol

The invention relates to a non-washing type automobile essence and a preparation method thereof. The non-washing type automobile essence mainly comprises the following components in percentage by weight: 15 percent of sodium dodecyl benzene sulfonate, 5 percent of aqueous montan wax, 20 percent of dimethicone, 3 percent of oleic acid, 15 percent of glycerol, 5 percent of fatty alcohol-polyoxyethylene ether, 3 percent of emulsifier, 32.5 percent of ionic water, and 1.5 percent of waterproofing agent. The invention has the advantages that the non-washing type automobile essence quickly penetrates, ensures that a gap is generated between stains and an automobile paint, and forms a protective layer between sandy soil particles and the automobile paint, the generated wax water isolates the stains from the automobile paint at the periphery of the stains, a surfactant is used for removing the stains, a phenomenon that sand and stains slide and flow on the paint surface is generated, and the sand and the stains are lightly wiped by a towel and adhered to the towel; meanwhile, a polishing towel is used for drying and attaching a layer of protective film, so that the automobile film is bright; the harm of rain, snow, wind, sand and the like to an automobile body is effectively reduced, and the luster of the mirror surface of the automobile paint is protected against damage; and the invention has the greatest advantage of saving water resources.

Owner:孔国星

Matt glaze and fabrication process

The present invention discloses a matt glaze and a fabrication process. The matt glaze consists of transparent glaze material, high-expansion glaze material and Suzhou kaolin clay at mass ratio. Each of the transparent glaze material and the high-expansion glaze material consists of silica, alumina oxide, potassium feldspar, albite, calcium carbonate, borax and barium carbonate. The fabrication process comprises the following steps: uniformly mixing the raw materials in proportion, then mixing the mixture with water to stir, and putting the mixture into a ball mill for ball milling so as to prepare matt glaze material; spraying and coating the matt glaze material onto the surface of a ceramic body, feeding into a baking furnace for baking, and obtaining a calcined product with a matt glaze surface effect after cooling from the kiln. The matt glaze provided by the present invention is simple in composition and reasonable in formula, and the prepared matt glaze is stable in glaze surface effect, comfortable in gloss, free of glare, smooth and is high in strength. In the fabrication process, the calcining time is short, and the sintering temperature is low, so that the power consumption is reduced, the energy is saved, the environment is protected, and the production cost is reduced.

Owner:MYINGFA CERAMIC CO LTD DEHUA FUJIAN

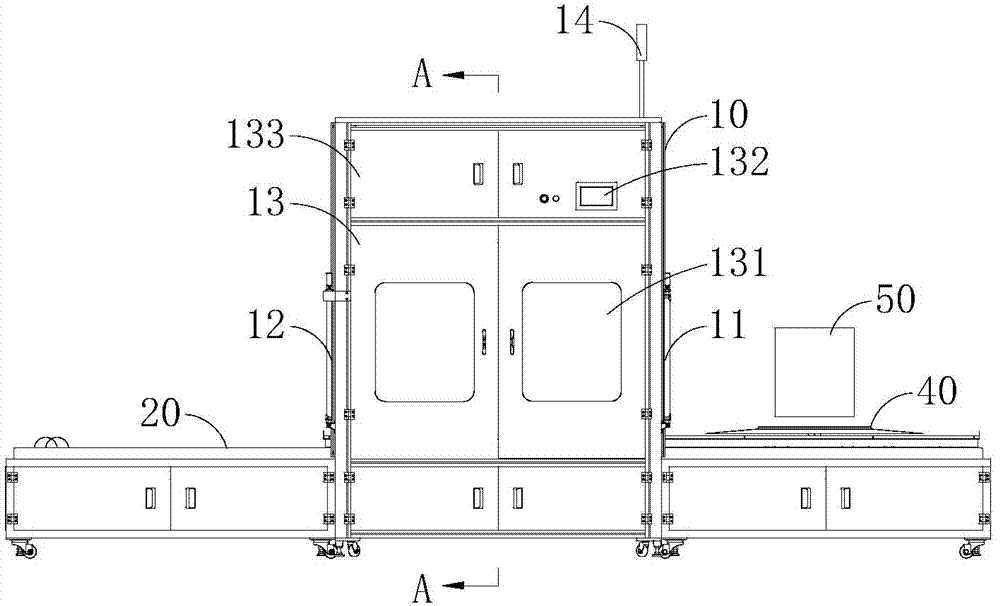

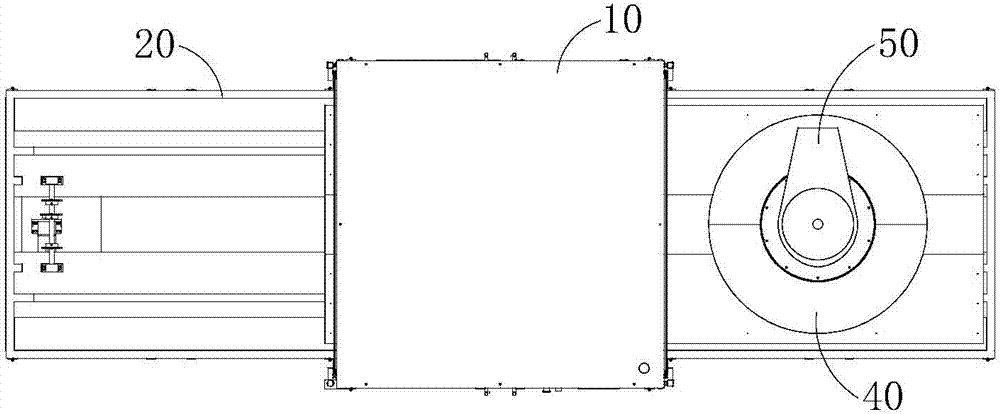

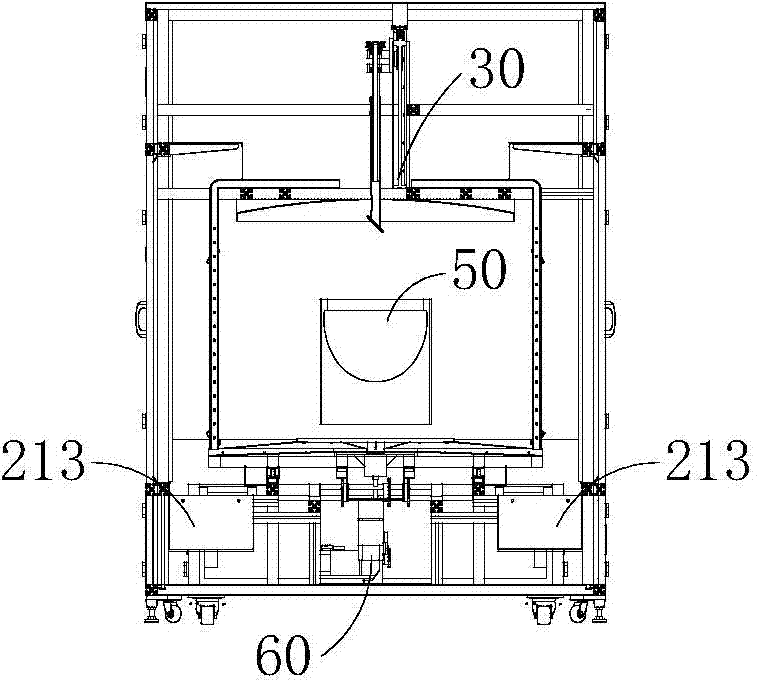

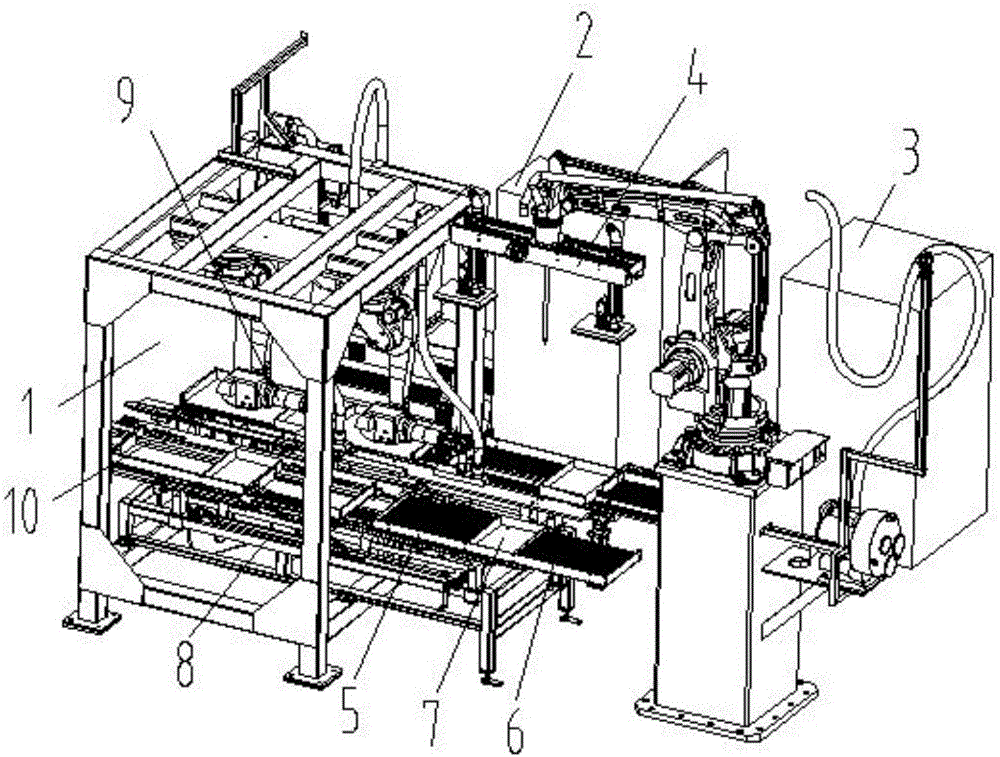

Automatic glaze spraying device

InactiveCN103936462AOvercoming the lack of regularity of manual hand-held spray gunsOvercome stabilityDrive motorEngineering

The invention relates to the technical field of ceramic production equipment and in particular relates to an automatic glaze spraying device. The automatic glaze spraying device comprises a spraying frame, a conveying assembly and a control assembly, wherein a spraying assembly which is electrically connected with the control assembly and a driving motor assembly which drives the conveying assembly are respectively arranged in the spraying frame; a rotating mechanism which is used for placing a spraying workpiece and is electrically connected with the driving motor assembly is arranged on the conveying assembly; a workpiece inlet and a workpiece outlet through which the rotating mechanism can pass are respectively formed in the left and right sides of the spraying frame; the spraying workpiece arranged on the conveying assembly is input from the workpiece inlet, is sprayed by the spraying assembly and is then output from the workpiece outlet. The device disclosed by the invention can automatically spray glaze inside and outside a ceramic product and is high in glazing quality and high in automation level.

Owner:邱松辉

Resin paint surface nursing emulsion and preparation method thereof

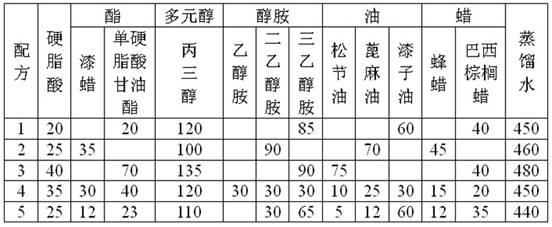

InactiveCN102174292AEasy to useNo excretionOrganic detergent compounding agentsWax coatingsWaxEmulsion

The invention discloses resin paint surface nursing emulsion, which consists of the following components in part by weight: 10 to 50 parts of stearic acid, 20 to 80 parts of ester, 90 to 150 parts of polyol, 80 to 100 parts of alcohol amine, 50 to 80 parts of solvent oil, 30 to 60 parts of wax and 400 to 500 parts of distilled water. A preparation method comprises the following steps of: uniformly mixing the polyol, the alcohol amine and the distilled water to obtain a component A; heating and stirring the stearic acid, the ester, the solvent oil and the wax at the temperature of between 85 and 95 DEG C, and mixing for 30 to 40 minutes to obtain a component B; and uniformly mixing the component A and the component B. The emulsion can completely remove oil dirt, glue stain and asphalt on the surface of a resin paint, has high varnishing performance, can nurse a glass steel die, and is convenient to use; and the three wastes (waste gas, waste water and waste residue) are not generated in the production process, and the method is environment-friendly.

Owner:NORTHWEST UNIV

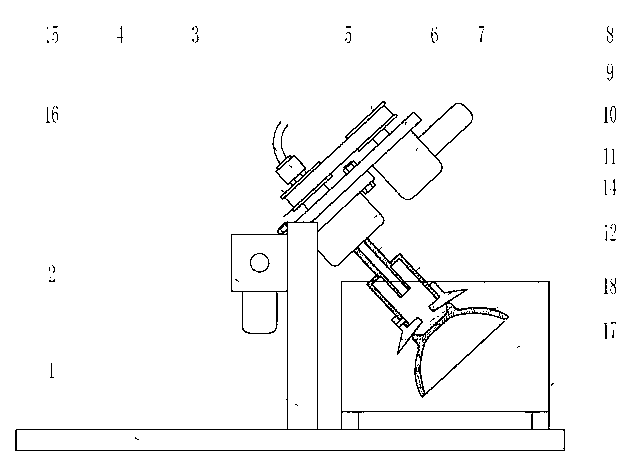

Ceramic glaze spraying device capable of adjusting angle

InactiveCN111660414ASimple structureEasy to operateSpraying apparatusAuxillary shaping apparatusCeramic glazeCeramic materials

The invention discloses a ceramic glaze spraying device capable of adjusting an angle. The device comprises a main body, a glaze spraying cavity with the right side communicating with the outside is formed in the main body, an outer side glaze spraying assembly is arranged in the glaze spraying cavity, a lifting cavity is formed in the lower side of the glaze spraying cavity, a hollow rotating platform extending downwards to the lifting cavity is rotationally installed on the lower end wall of the glaze spraying cavity, an inner side glaze spraying assembly matched with the hollow rotating platform is arranged in the lifting cavity, an adjusting cavity is formed in the left side of the lifting cavity through a lower side transmission cavity in a communicating mode. According to the ceramicglaze spraying device, ceramic is reversely buckled to the glaze spraying platform, when the glaze spraying platform rotates, the outer side glaze spraying assembly and the inner side glaze sprayingassembly gradually slide upwards to spray glaze; the angle of a nozzle of the outer glaze spraying assembly can be adjusted according to the appearance of ceramic, when the inner glaze spraying assembly slides to the uppermost side, the nozzle rotates to the vertical state to spray glaze to the bottom of the ceramic, meanwhile, glaze is stirred in the stirring cavity, and manual glaze spraying isnot needed.

Owner:XIAMEN ZHAISU CRAFTS CO LTD

Crackle glaze and manufacturing process

The invention discloses crackle glaze and a manufacturing process. The crackle glaze is composed of a transparent glaze material and a high-expansion glaze material according to a mass percentage. The transparent glaze material and the high-expansion glaze material are composed of silicon dioxide, aluminum oxide, potassium feldspar, albite, calcium carbonate, borax and barium carbonate of different mass percents. The raw materials are evenly mixed in proportion, the mixture and water are mixed in proportion, a crackle glaze material is obtained after ball milling and sieving, the surface of a ceramic green body is coated with the crackle glaze material and then the ceramic green body is sent into a heating-up furnace to be fired, a semi-finished product with a crackle cracked glaze effect is obtained after drawing and cooling, and cracks on the outer surface of the semi-finished product are colored. The crackle glaze is simple in composition and rational in formula, the glaze effect of the manufactured crackle glaze is stable, the crack effect is good, and the crackle glaze is more uniform and attractive. The firing time in the manufacturing process is short, the firing temperature is low, so that the energy consumption is reduced, the crackle glaze saves energy and is environmentally friendly, and the production cost is reduced.

Owner:MYINGFA CERAMIC CO LTD DEHUA FUJIAN

Antibacterial automobile detergent and preparation method thereof

InactiveCN103981035AEasy to useSimple processOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBacteriostatic agentActive agent

The invention relates to an antibacterial automobile detergent and a preparation method thereof. The existing automobile detergent has the defects of irrational raw material selection and single effect, can simultaneously remove the wax layer on the automobile surface, and has strong corrosion actions on the paint and metals on the automobile body due to strong alkalinity. The antibacterial automobile detergent is prepared by mixing a surfactant, a lustering agent, an antibacterial agent, a pH regulator and water, and has the effects of cleaning and lustering. The antibacterial automobile detergent has an antibacterial action, better cleaning effect and higher lustering performance; and the product is environment-friendly, pollution-free and convenient to use, and has the effects of no corrosion on the automobile rubber part and the like. The antibacterial automobile detergent has the characteristics of simple technique, long shelf life, ideal cost performance and the like, can easily implement mass production, and can be widely used in cleaning and lustering various high / medium-grade automobiles and other care processes.

Owner:于文 +1

Transparent glaze and manufacture technology

The invention discloses transparent glaze and a manufacture technology thereof. The transparent glaze is composed of potash feldspar, Longyan kaolin, quartz, zinc oxide and barium carbonate at a certain mass ratio. The manufacture technology comprises the following steps: uniformly mixing the above raw materials, adding water, fully stirring, ball-milling, sieving through a sieve, coating the surface of a sintered porcelain body with transparent glaze, sending the porcelain body into a heating-up furnace and carrying out three stagewise high-temperature firings, taking the product out of the furnace, and cooling. The formula of the transparent glaze is reasonable. The manufactured transparent glaze has stable glaze effect, presents a crystal and clear glaze effect, is flawless, has uniform and fine texture, has good quality and is beautiful and elegant.

Owner:福建省德化县腾艺陶瓷有限公司

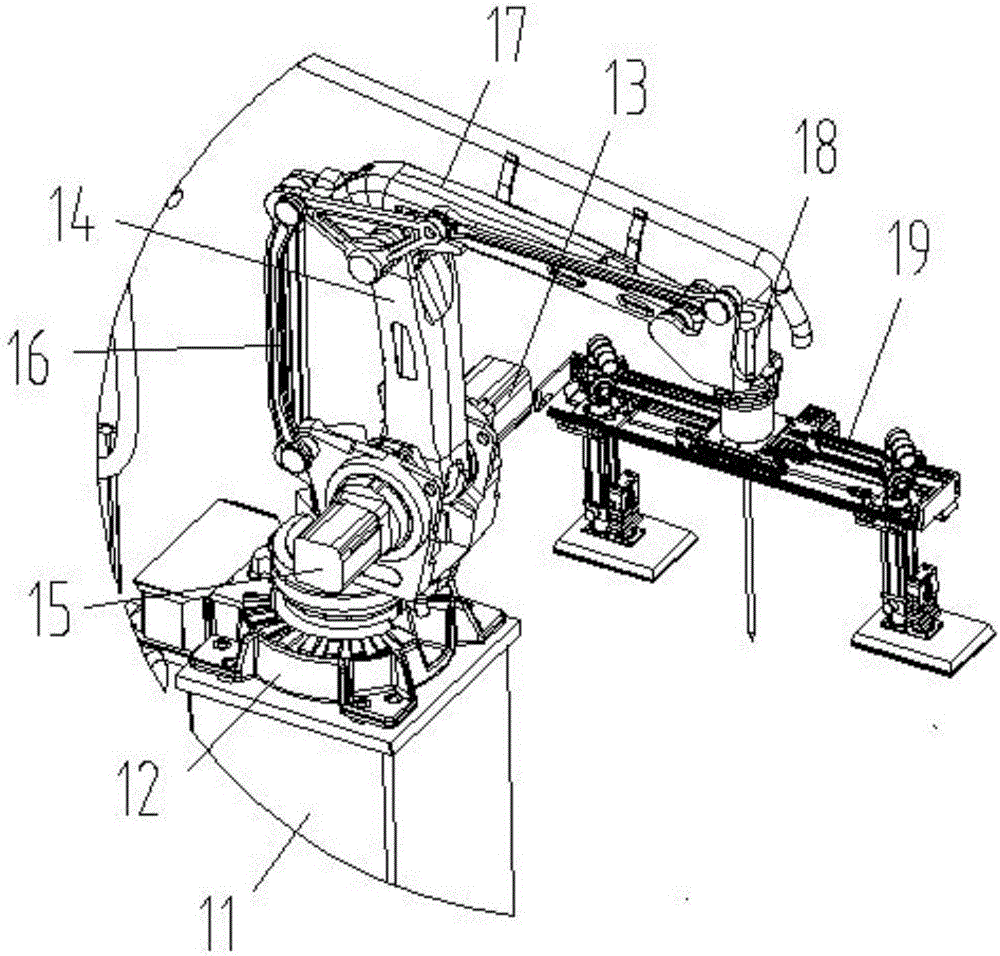

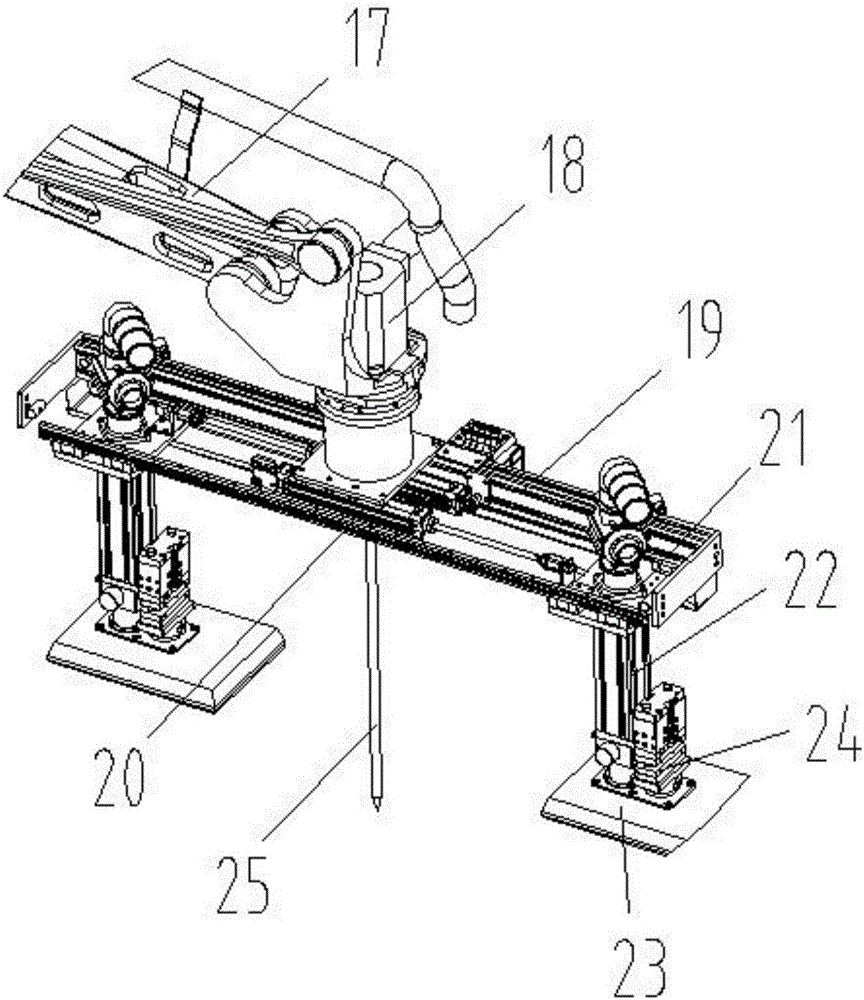

Uniform and automatic glaze spraying machine for ceramic

ActiveCN106827201ARealize all-round automatic glaze sprayingAutomatic even spraying glazeCeramic shaping apparatusConveyor partsDistribution controlElectric machinery

The invention relates to a uniform and automatic glaze spraying machine for ceramic. The uniform and automatic glaze spraying machine comprises a machine frame and a power distribution control cabinet. A glaze-spraying conveying device is arranged on the machine frame. A glaze-spraying carrier is arranged on the glaze-spraying conveying device. A glaze spraying device matched with the glaze-spraying carrier is further arranged on the machine frame. The glaze spraying device comprises a glaze-spraying mounting base which is arranged on the upper portion of the machine frame. Glaze-spraying rotating bases are mounted on the glaze-spraying mounting base. First glaze-spraying rotating arms are hinged to the glaze-spraying rotating bases and matched with first glaze-spraying rotating arm motors. Second glaze-spraying rotating arms are hinged to the other ends of the first glazes-spraying rotating arms and matched with second glaze-spraying rotating arms. The second glaze-spraying rotating arms are connected with square glaze-spraying screen plates. The glaze-spraying screen plates are connected with glaze-spraying pumps through glaze spraying pipes. According to the uniform and automatic glaze spraying machine, glaze-spraying rotating discs are matched with the two connected glaze-spraying rotating arms so that omnibearing automatic glaze spraying of ceramic can be achieved; and the square glaze-spraying screen plates are used as glaze spraying heads so that automatic and uniform glaze spraying can be achieved, manual work is reduced, and a good glaze spraying effect is ensured.

Owner:醴陵创智机械有限公司

Polishing abrasive disc for polished crystal tiles and preparation method therefor

InactiveCN106078540AThe problem of lack of sharpnessSupplement the problem of lack of sharpnessAbrasion apparatusGrinding devicesMelamine resinDiamond

The invention discloses a polishing abrasive disc for polished crystal tiles and a preparation method thereof. The polishing abrasive disc comprises the following materials in percentages by weight: 5-10% of main abrasive material diamond particles, 20-30% of phenolic resin, 10-15% of melamine resin, 25-35% of an auxiliary abrasive material and 25-40% of an auxiliary polishing material. The preparation method comprises the following steps: proportioning the materials to prepare a mixed powdery material; and then putting the material in a mould to be heated and sintered and moulded. According to the polishing abrasive disc for polished crystal tiles provided by the invention, two resins: phenolic resin and melamine resin which are mixed in a specific proportion are creatively adopted, so that an important breakthrough is obtained in the polishing aspect of the polished crystal tiles. The phenolic resin accounts for 20-30% and the polishing property of the phenolic resin is fully utilized; the melamine resin accounts for 10-15% and solves the problem that the sharpness of the phenolic resin is short. The two are reasonably matched in use according to the proportion, so that the polishing effect is extremely excellent. The brightness of the product in the market only reaches 15-30 degrees, but the brightness of the product disclosed by the invention can reach 30-50 degrees, and the polishing abrasive disc for polished crystal tiles is quite obvious in advantage.

Owner:QUANZHOU ZHONGZHI NEW MATERIAL TECH

Cracked glaze and making process thereof

The invention discloses a cracked glaze and a making process thereof. The cracked glaze is composed of albite, kaolin, quartz, zinc oxide, barium carbonate and frits, wherein the frits are composed of quartz, red lead, feldspar, dolomite and barium carbonate, and the feldspar is composed of potassium feldspar and albite according to the mass ratio. The making process comprises the steps of smashing quartz, red lead, potassium feldspar, albite, dolomite and barium carbonate, uniformly mixing, and smelting to prepare the frits; and respectively smashing all the raw materials and the frits, uniformly mixing according to a certain ratio, then, adding water to stir, sieving by using a mesh screen after ball milling, coating the prepared glaze on the surface of a ceramic blank, firing in a roasting kiln, and cooling after taking the glaze out of the kiln. The cracked glaze disclosed by the invention is simple in component and reasonable in formula, the glaze surface effect of the prepared cracked glaze is stable, glaze surfaces with different effects can be made through changing the contents of the components, and the crack is good in effect and more uniform and attractive; and the making process is short in firing time and low in firing temperature, so that the energy consumption is reduced, the energy is saved, the environment is protected, and the production cost is reduced.

Owner:DEHUA HENGHAN ARTS

Production process for heat preservation vessel inner cavity heat-resistant glass or enamel coating layer

ActiveCN105862039AChemically stableNo corrosionMolten spray coatingContainers with thermal insulationRough surfaceThermal expansion

The invention discloses a production process for a heat preservation vessel inner cavity heat-resistant glass or enamel coating layer; the production process comprises the following steps: step S1, selecting a heat preservation vessel blank made of a metal material, carrying out sandblasting operation on the surface of an inner cavity of the heat preservation vessel blank, and making the surface of the inner cavity of the heat preservation vessel blank form a rough surface; step S2, carrying out enamel spraying operation on the rough surface, to make glass or an enamel glaze sprayed on the rough surface of the heat preservation vessel; step S3, drying the glaze on the rough surface; step S4, placing the heat preservation vessel blank after drying on a bracket; step S5, carrying out sintering operation on the heat preservation vessel blank; and step S6, after completion of sintering, taking the heat preservation vessel blank down from the bracket to obtain the finished product. In the process, in the preparation process of a moisturizing vessel, after a glass layer or an enamel layer is formed on the surface of the inner cavity, the self chemical properties of the glass layer or the enamel layer are relatively stable, no corrosion condition is generated, at the same time, changes of thermal expansion and cold contraction are relatively small, and the finished product is suitable for use as a container such as a heat preservation cup.

Owner:SOHOME HOUSEWARE (NANJING) CO LTD

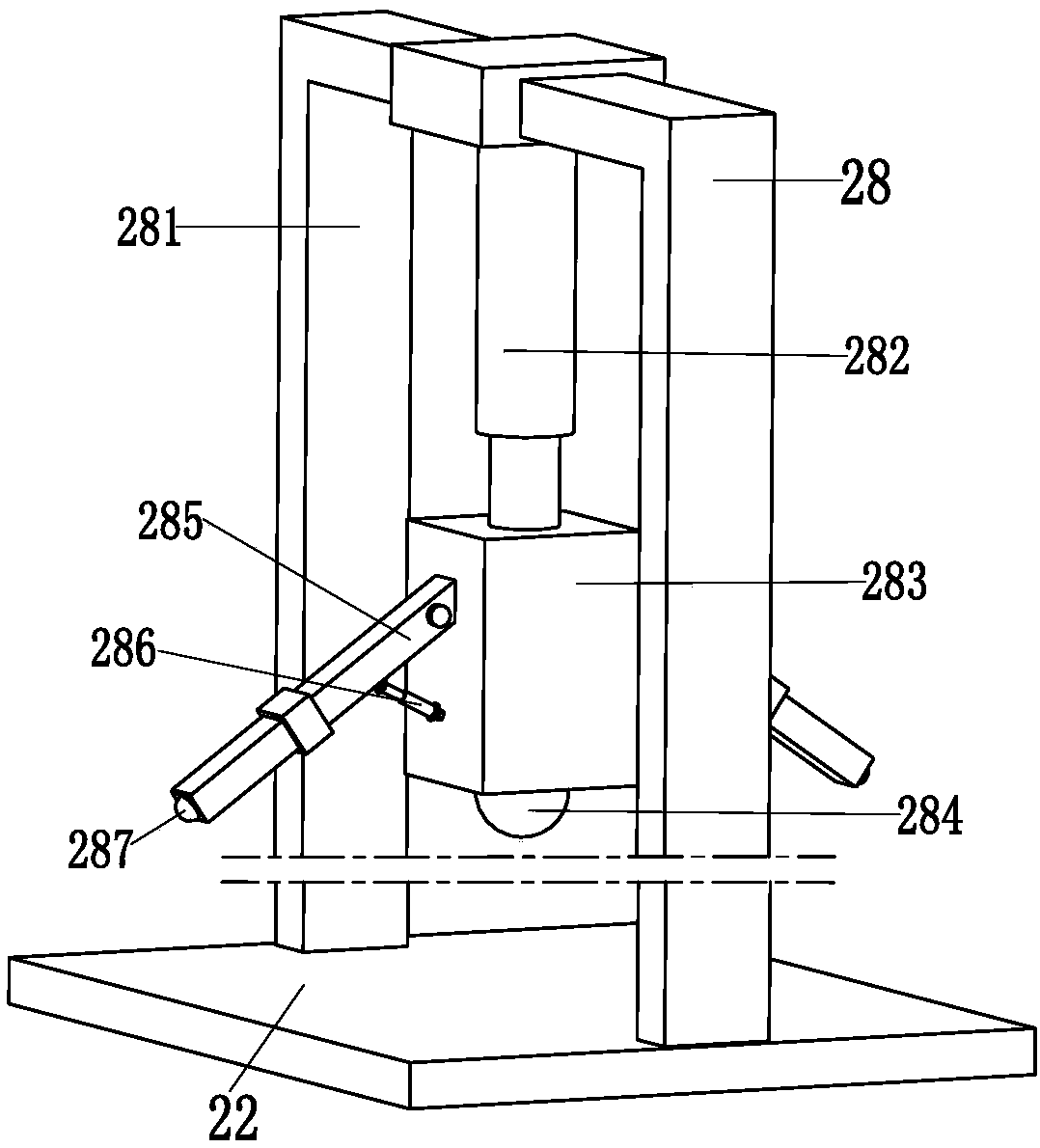

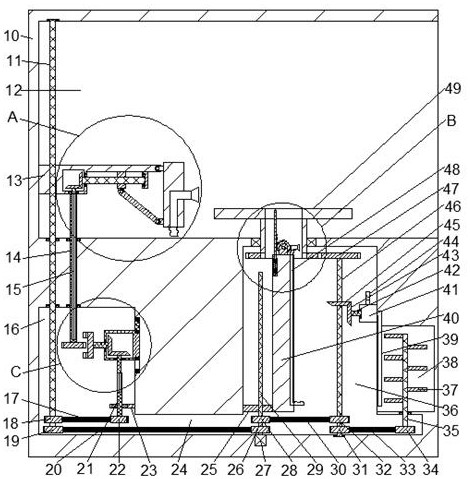

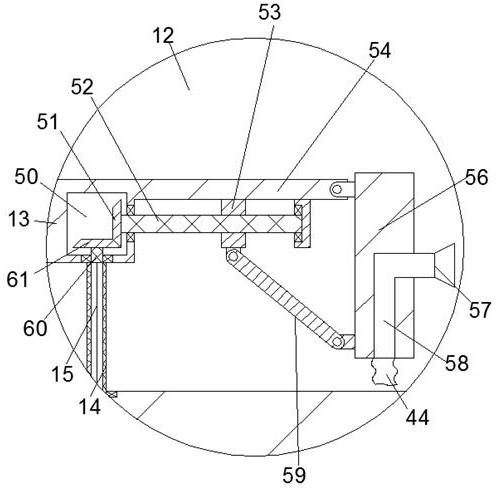

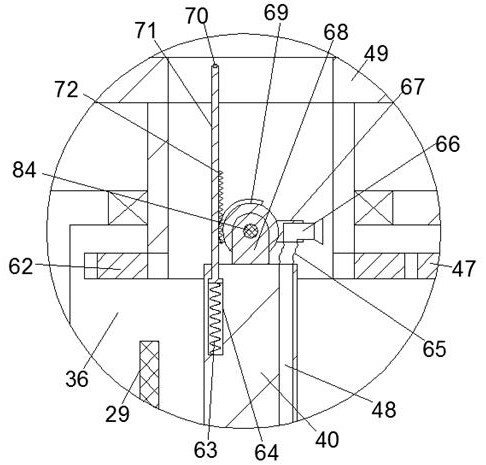

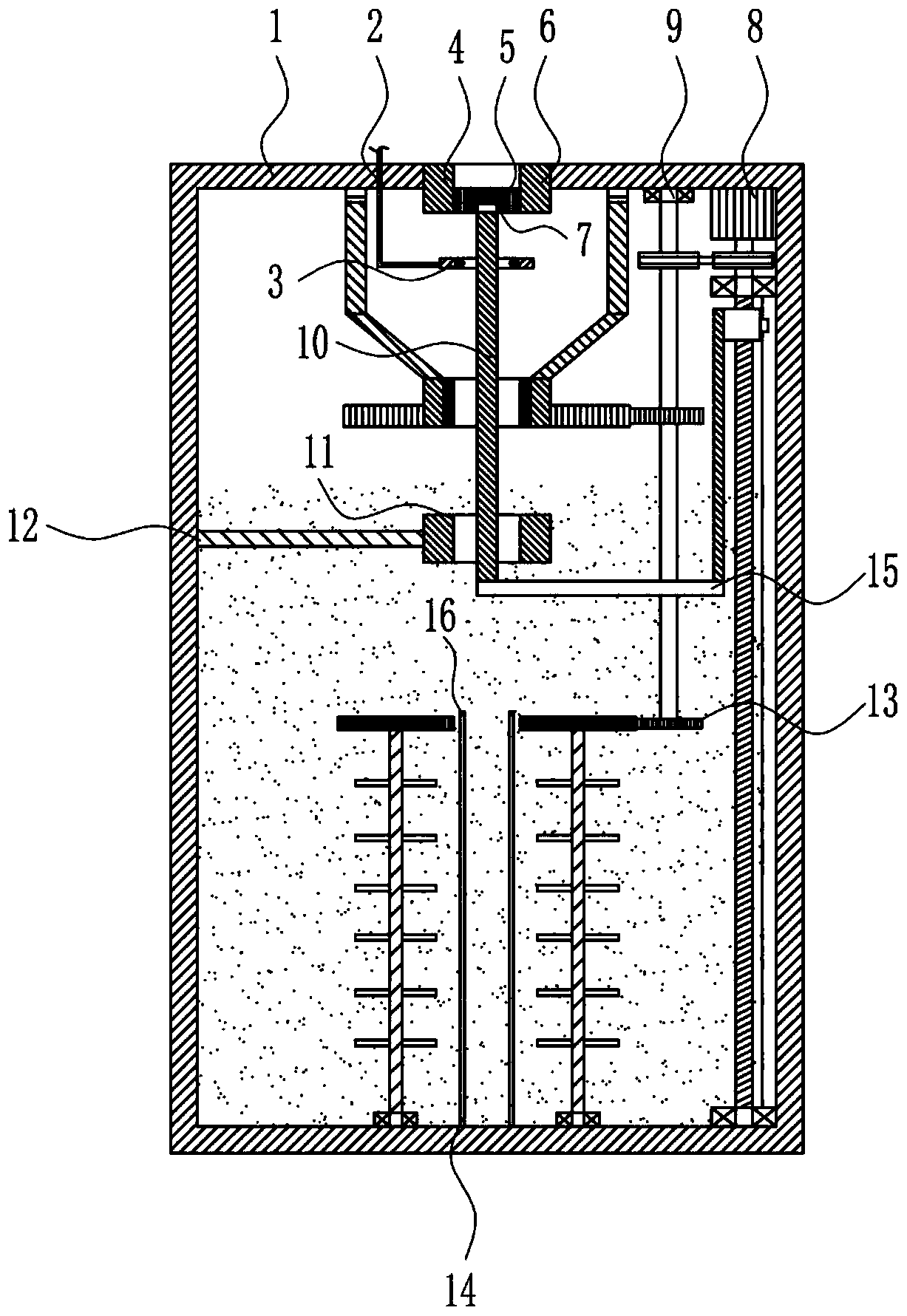

Structural ceramic glazing machine

InactiveCN109747034ANot easy to damageGood glazing effectAuxillary shaping apparatusGear wheelCeramic

The invention relates to the field of structural ceramics, in particular to a structural ceramic glazing machine. The structural ceramic glazing machine has a good glazing effect, good glazing quality, and high work efficiency. The structural ceramic glazing machine includes a machine body, a water inlet pipe, a ring-type spraying head, a first gear, a first sleeving body, a first bearing seat, alifting mechanism, a wiping mechanism, a second rotating shaft, a third sleeving body, a connecting rod, a stirring mechanism, a supporting rod and a frame body, wherein the water inlet pipe is installed on the top of the machine body, and the water inlet pipe extends inside the machine body and is fixedly connected with the ring-type spraying head; the first sleeving body is clamped on the top ofthe machine body and located over the ring-type spraying head; and the first gear is located in the first sleeving body, and through holes are formed in the vertical direction in the two sides of thefirst gear. The structural ceramic glazing machine has the beneficial effects that the glazing effect is good, the glazing quality and the work efficiency are high, and cylinder workblank is not prone to be spoiled.

Owner:夏敬品

Glaze spraying device for comprehensive and uniform spraying in ceramic production

InactiveCN112356244AGuarantee the quality of spray glazePrevent movementCombination devicesGas treatmentBall (bearing)Materials science

The invention relates to the technical field of ceramic production spraying, in particular to a glaze spraying device for comprehensive and uniform spraying in ceramic production. The glaze spraying device comprises a processing box, a collecting tank is arranged on the inner wall of the bottom end of the processing box, supporting legs are symmetrically arranged on the inner walls of the bottom ends of the left and right sides of the processing box, a processing table is arranged at the upper ends of the supporting legs, and a sucker is arranged at the top end of the processing table. The glaze spraying device is simple in structure, a first rotating motor, a first connecting plate, a second thrust ball bearing, a second rotating motor, a second connecting plate, a first gear, a second gear, an execution motor, an execution screw, a sleeve, a stop block, a lifting plate, a first spraying box, a first spray head, a second spray head and a second spraying box are arranged and used in cooperation, the glaze spraying device can comprehensively and uniformly spray glaze inside and outside a ceramic part, the glaze spraying effect is good, the glaze spraying quality of the ceramic partis guaranteed, and the working efficiency is improved.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

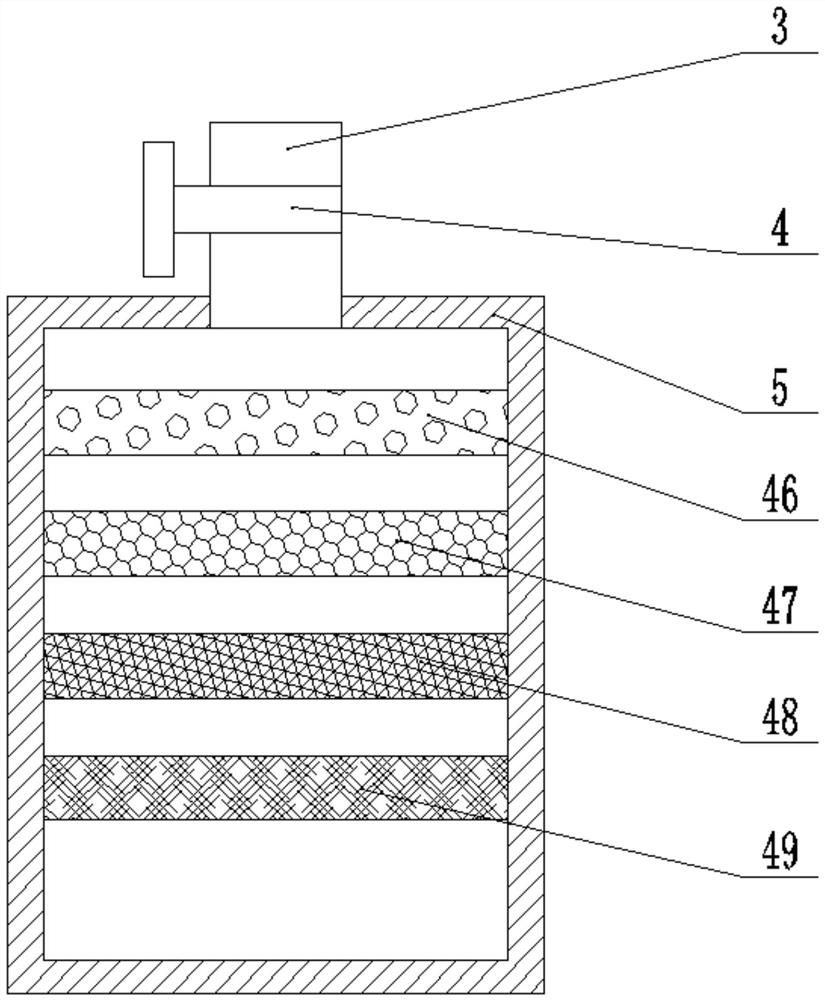

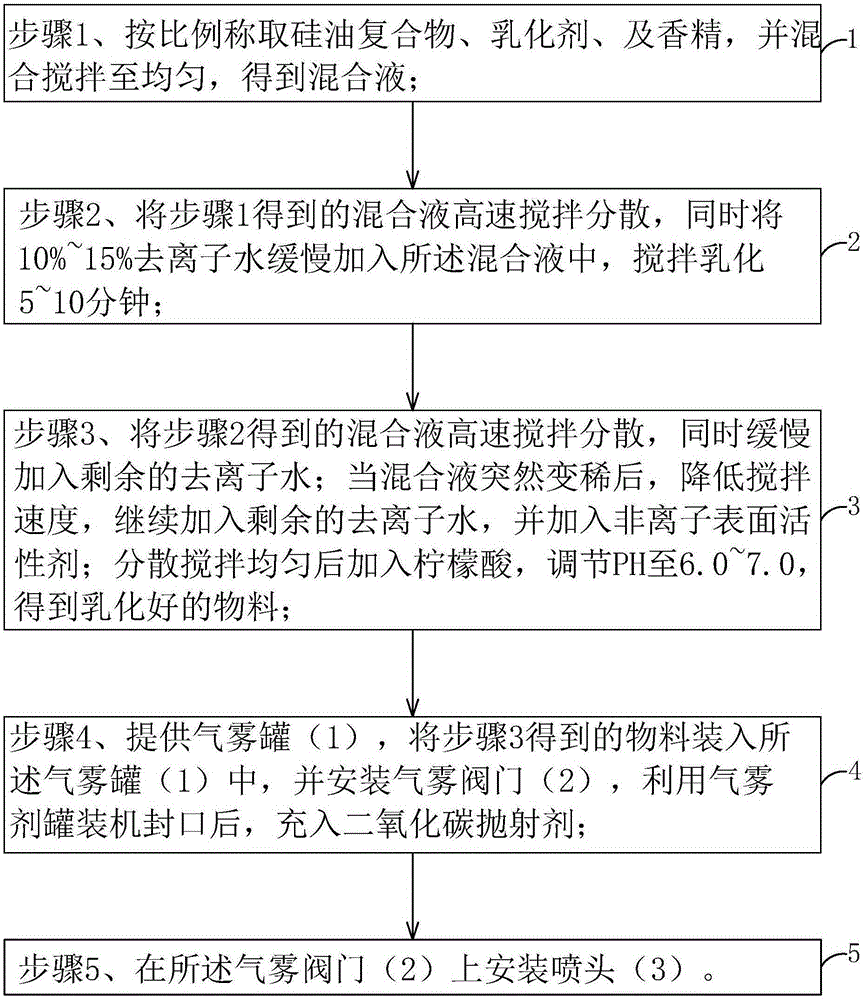

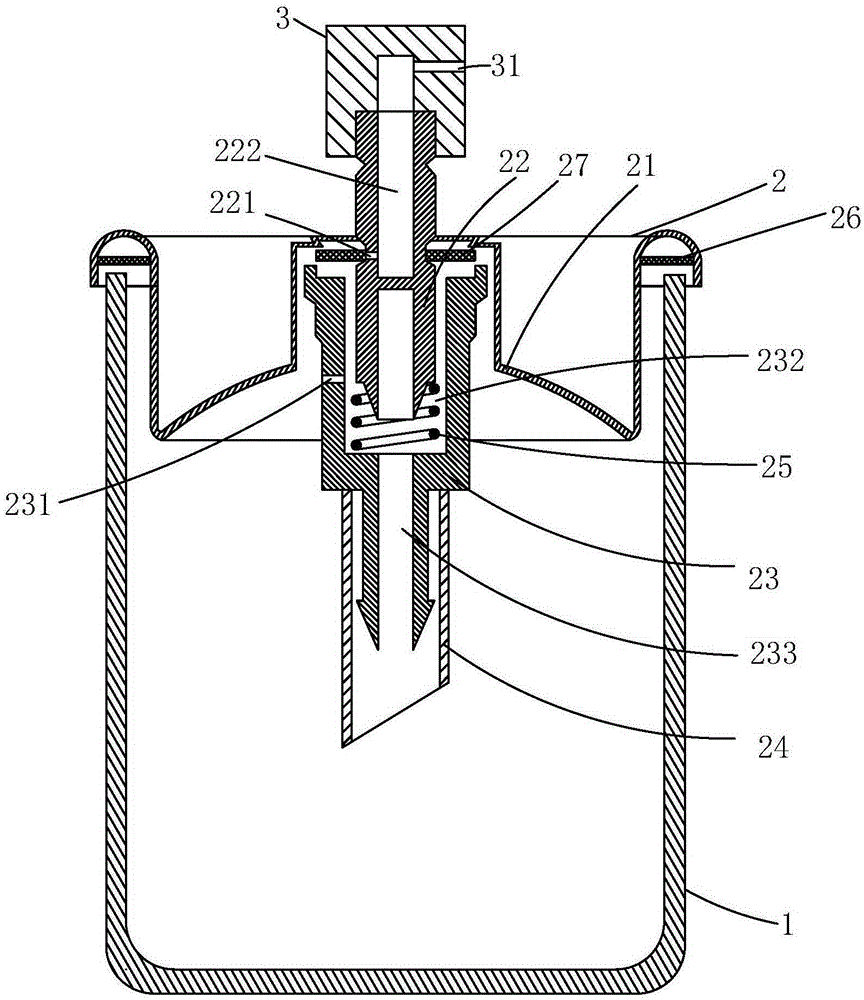

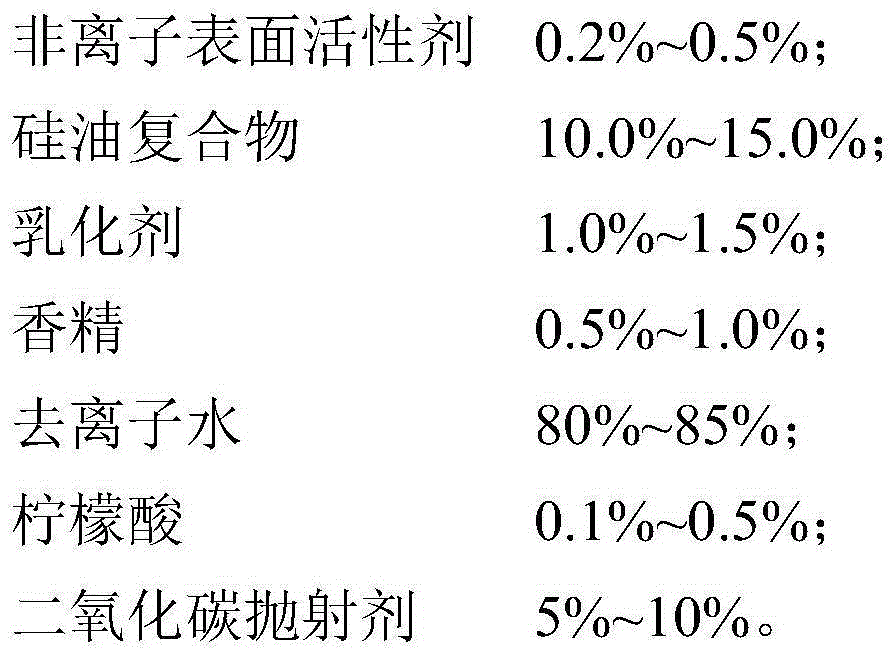

Aerosol-type polishing agent and manufacturing method thereof

InactiveCN105176408AGood glazing effectEasy to operateOther chemical processesSingle-unit apparatusSolventCarbon dioxide

The invention provides an aerosol-type polishing agent and a manufacturing method thereof. The aerosol-type polishing agent provided by the invention takes nonflammable carbon dioxide gas as a propellant, takes an oil-in-water emulsion which takes water as a solvent and has the functions of cleaning, polishing and protecting as a content material, is safe and environment-friendly and has a better polishing effect. The sprayed substance is kept in an aerosol state by taking the nonflammable carbon dioxide gas as the propellant, taking the oil-in-water emulsion which takes the water as the solvent and has the functions of cleaning, polishing and protecting as the content material, and adopting an aerosol valve and an aerosol nozzle with special structures and an atomizing effect during filling, so that the manufacturing method for the aerosol-type polishing agent provided by the invention is easy to operate, safe, environment-friendly and good in the atomizing effect.

Owner:SHENZHEN SUNRISE NEW ENERGY CO LTD

Fur coat glazing agent

InactiveCN104845534AGood glazing effectHigh glossPolishing compositionsLeather surface finishingBenzoic acidPolymer science

The invention relates to a fur coat glazing agent which is prepared from the following raw materials in parts by weight: 5-10 parts of liquid paraffin, 4-7 parts of triethyl citrate, 2-4 parts of benzoic acid, 6-9 parts of octadecyl trimethyl ammonium chloride, 5-7 parts of dimethyl silicone oil, 3-6 parts of SG-5 PVC (polyvinyl chloride) resin, 10-25 parts of carnauba wax, 1.5-2.4 parts of cationic surfactant, 2-6 parts of triethanolamine, 2-4 parts of cocoyl diethanolamine, 4-7 parts of white oil, 2.5-3 parts of liquid paraffin and 0.8-1.4 parts of polyethylene wax. The fur coat glazing agent has favorable glazing effect, effectively increases the glossiness, and can enable the fur coat to be clean, smooth and soft.

Owner:青岛千帆高新技术有限公司

Glaze for Jun porcelain plate and preparation method of glaze

The invention discloses glaze for a Jun porcelain plate and a preparation method of the glaze. The glaze is prepared from ground glaze and cover glaze, wherein the ground glaze is prepared from 4-5 parts of copper oxide, 10-16 parts of potash feldspar, 8-12 parts of kaolinite, 1-2 parts of tin dioxide, 8-12 parts of talc, 10-16 parts of Changbai stone and 10-20 parts of glass powder; the cover glaze is prepared from 4-5 parts of copper oxide, 10-16 parts of talc, 4-5 parts of tin dioxide, 2-6 parts of zinc oxide, 8-12 parts of potash feldspar, 5-10 parts of Changbai stone, 10-16 parts of kaolinite and 10-20 parts of glass powder. Uniform particles of the glaze are guaranteed by optimizing the formula of the cover glaze and the ground glaze for the Jun porcelain plate and performing fine adjustment on the preparation process of the cover glaze and the ground glaze, and the glazing effect is better.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Method for preparing artificial stone grinding sheet

ActiveCN108544384AImprove yield rateHigh chemical activityNon-macromolecular adhesive additivesAbrasion apparatusMelamine formaldehyde resinArtificial stone

The invention discloses a method for preparing an artificial stone grinding sheet. The method comprises the steps that (1) melamino-formaldehyde resin and filler are dosed according to the weight ratio of (40%-60%):(25%-40%); (2) carborundum and white corundum are added according to the weight ratio of (0-15%):(0-5%), mixing is carried out, and a matrix binding agent is prepared; (3) then diamondparticles are added into the matrix binding agent according to the weight ratio of 5%-15%, full stirring is carried out for more than 10 hours, and evenly mixed powder is prepared; and (4) the evenlymixed powder is put in a steel mold, leveling is carried out, nylon hook cloth is put in the steel mold, finally a pressing head is put in, the steel mold and the pressing head are put on an oil pressto be heated, sinter molding is carried out. The use sharpness of the grinding sheet special for artificial stone polishing is greatly improved, the service life of the grinding sheet is greatly prolonged, and the sharpness and the service life are more than two times those of a traditional grinding sheet, and the traditional grinding sheet can be replaced well; and the beneficial effects that dyeing and burning are avoided, the polishing effect is good, the yield is high, and the machining efficiency is remarkably improved are achieved.

Owner:QUANZHOU ZHONGZHI NEW MATERIAL TECH

Compound-wax type automobile polish and preparing method thereof

The invention discloses a compound-wax type automobile polish and a preparing method thereof. The compound-wax type automobile polish is prepared from 5 parts to 20 parts of compound wax, 2 parts to 6 parts of polyvinyl alcohol, 0.6 part to 1.4 parts of triethanolamine oleate, 0.03 part to 0.1 part of carboxyethyl cellulose, 2.1 parts to 3.6 parts of amino silicon oil, 0.3 part to 0.8 part of ethoxy dodecyl alcohol, 0.12 part to 0.54 part of nitrous acid diisopropylamine, 0.25 part to 0.55 part of dimethylaniline, 0.07 part to 0.12 part of N-methyl pyrrolidone, 0.13 part to 0.25 part of trihydroxyethyl methyI ammonium methosulfate, 0.45 part to 1.25 parts of glyceryl tristearate, 0.5 part to 1.8 parts of oil-based amino acid sodium, 0.01 part to 0.08 part of sodium dodecyl benzene sulfonate, 0.06 part to 0.15 part of potassium sorbate, 0.1 part to 0.4 part of simethicone and 15 parts to 30 parts of water. The polishing effect is good in stability, finishing paint is not corroded, and present imported products can be replaced.

Owner:李康

Leather flattening treatment equipment based on transmission

InactiveCN110923367AImprove efficiencyAdjust flattening tightnessLeather pressing/rollingSkins/hides/leather/fur manufacturing apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of leather flattening equipment, in particular to leather flattening treatment equipment based on transmission. A winding roller and an unwinding roller which are connected through a transmission assembly are arranged, and leather is led out of the unwinding roller from right to left and sequentially passes through the part among a first guide roller shaft, a second guide roller shaft, an upper pressing roller and a lower pressing roller and is wound on the winding roller. The unwinding roller performs unwinding, the winding roller synchronously performs winding, the leather is driven to move and flattened when passing through the upper pressing roller and the lower pressing roller, and the convenience and the efficiency are achieved. A liftingassembly is further arranged for adjusting the position of the upper pressing roller, changing a gap between the upper pressing roller and the lower pressing roller, being adapted to the leather withdifferent thicknesses, and adjusting the flattening compactness. A glazing box is further arranged, a spraying assembly is arranged in the glazing box, and a glazing agent is sprayed on the leather below the glazing box for glazing and maintaining the leather.

Owner:安徽粒粒信数据科技有限公司

Craft porcelain with raised particle effect on glaze surface and preparation method thereof

The invention discloses a craft porcelain with a raised particle effect on a glaze surface and a preparation method thereof. The craft porcelain with a raised particle effect on a glaze surface comprises a green body and overglaze arranged on the green body, the overglaze comprises a glaze slurry and frit dry particles, the glaze slurry comprises the following raw materials: Dehua quartz, halloysite, Dehua feldspar, montmorillonite, sepiolite, dickite, pyroxene, aluminum oxide and lanthanum oxide, during preparation of the craft porcelain, the overglaze is uniformly applied to the surface of the green body, then the green body is sent into a kiln for firing, the surface of the fired craft porcelain has the decoration effect of naturally fused convex bumped artistic patterns, and bump points are clear, vivid, full and rich in layering sense, thus further improving the aesthetic sense of the craft porcelain.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Cleaning and glazing agent for furniture and preparation method thereof

InactiveCN106753934AGood plot performanceGood glazing effectSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsSodium polyacrylateChemistry

The invention discloses a cleaning and glazing agent for furniture and a preparation method thereof. The cleaning and glazing agent is prepared from the following components: sodium dodecyl benzene sulfonate, magnesium stearate, sodium tripolyphosphate, sodium polyacrylate, polyacrylamide, silica, ethylenediamine, citric acid and ethanol aqueous solution. The preparation method comprises the following steps of adding the sodium dodecyl benzene sulfonate, magnesium stearate, the sodium tripolyphosphate, the sodium polyacrylate, the polyacrylamide and the silica into the ethanol aqueous solution, and agitating and mixing uniformly an obtained first mixture, so as to obtain a mixture I; afterwards, heating the mixture I, keeping the mixture I boiling, adding the ethylenediamine into the mixture I, agitating an obtained second mixture for 5 to 10 minutes, afterwards, adding the citric acid into the second mixture, mixing uniformly an obtained third mixture, and cooling the third mixture to a room temperature, so as to obtain the cleaning and glazing agent for the furniture. The cleaning and glazing agent provided by the invention has favorable cleaning and glazing effects, and is wide to apply.

Owner:ZHENJIANG HUAYU ENVIRONMENTAL PROTECTION EQUIP MFG

Automobile decontaminating and glazing agent

InactiveCN104531381AGood glazing effectGood decontamination effectOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsWaxBetaine

The invention discloses an automobile decontaminating and glazing agent, and belongs to the technical field of automobile care articles. The automobile decontaminating and glazing agent is prepared from the following components, by weight, 20-30 parts of dodecyl betaine, 10-12 parts of coconut oil alkanolamide, 15-20 parts of triethanolamine, 25-30 parts of methyl silicone oil, 5-8 parts of paraffin, 8-12 parts of palm wax, 15-20 parts of oleic acid and 50-55 parts of water. The automobile decontaminating and glazing agent has better glazing and decontaminating effects than present automobile decontaminating and glazing agents sold in the market.

Owner:韦良富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com