Concentrated solution for preparing leather polish and care products, and application

A technology of care products and concentrates, which is applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc. The light effect is not very ideal, heat loss and other problems, to achieve the effect of good environmental protection production technology, excellent care and glazing, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

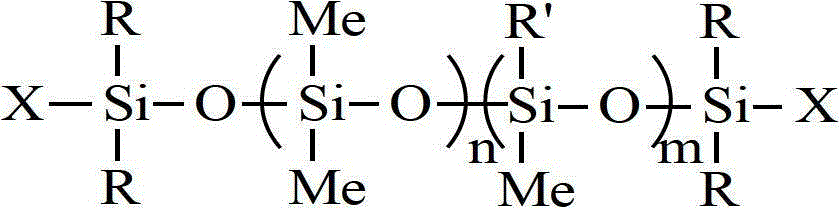

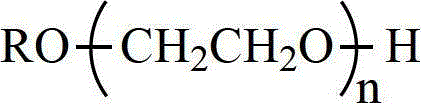

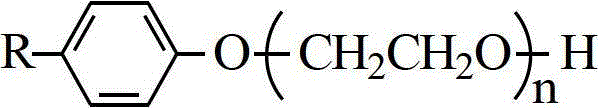

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of No. 1 to No. 12 concentrated solution is: ① Mix A) and B) components and heat to a molten state, keep it warm for 20-60 minutes, and use it as an oil phase; ② Heat C) to 80-90°C, Keep warm for 20-60 minutes and use it as the water phase; ③After the emulsification tank is heated to 80°C, add the oil phase to the emulsification tank, then slowly add 1 / 3 of the water phase into the emulsification tank, and then pump the remaining water phase into the emulsification tank. Stir at high speed, homogenize for 10-40 minutes, emulsify completely, keep warm for half an hour, cool down to 40°C, add component D) and continue stirring for 5-10 minutes.

[0056] Table 1. Feeding amount of each formula

[0057]

[0058]

[0059] Note:

[0060] AEO-n, n=10, 15, 20 are fatty alcohol polyoxyethylene ethers, S-40 is Span-40, S-60 Span-60, S-80 Span-80, T-60 is Tween -60, T-40 is Tween-40, EL-10 is the condensation product of ethylene oxide and castor oil,...

Embodiment 2

[0062] The stability of the diluent, after diluting the No. 1 to No. 12 concentrated solution in Example 1 with cold water (11°C) 5 to 30 times, observe whether there is stratification in 24 hours, the results are shown in Table 2, and it can be seen that the diluent of the concentrated solution of the present invention There is no delamination phenomenon, and it has good stability.

[0063] Table 2. Stability of Diluents

[0064]

Embodiment 3

[0065] Embodiment 3 glazing nursing evaluation

[0066] The evaluation adopts the sensory evaluation method. After diluting the concentrated solution No. 1 to No. 12 in Example 1 by 5, 10 and 20 times, impregnated with a spunlace non-woven fabric (60% cotton content), the water content is controlled at the level of the non-woven fabric. 300%-400% of the weight, spare.

[0067] Use this wet towel to wipe the designated area on the leather sofa, the area is 10cm×10cm, and the evaluation scores are 25, 50, 75 and 100, which in turn indicate that the glazing care effect is very poor, average, good, and very good. The number of evaluations is 5 people, and the average value is taken after the test, and the results are shown in Table 3.

[0068] Table 3. Evaluation results of glazing care

[0069]

[0070] As can be seen from Table 3, the concentrated solution of the present invention, after being diluted 20 times, has an evaluation score of more than 50, still has a certain gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com