Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

A technology of chemical fibers and blended fabrics, which is applied in the processing of textile materials, continuous processing of textile materials, and weaving. It can solve the problems of wool fiber damage, low dyeing fastness, and large color difference, and achieve good moisture absorption and excellent wearing comfort. Excellent performance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

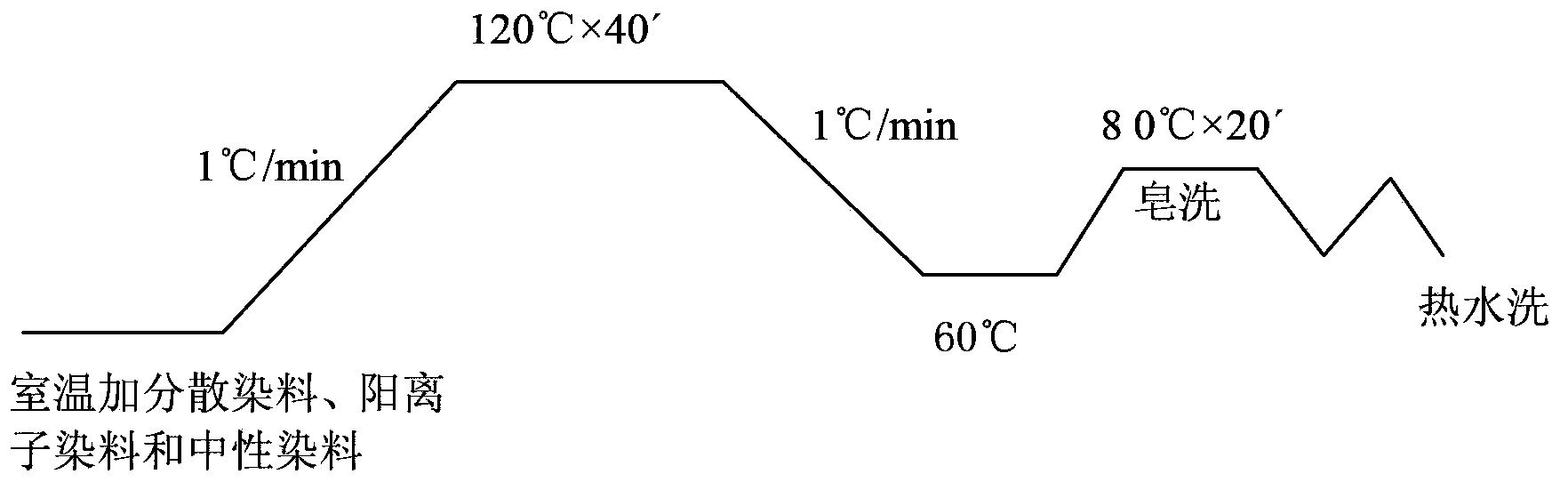

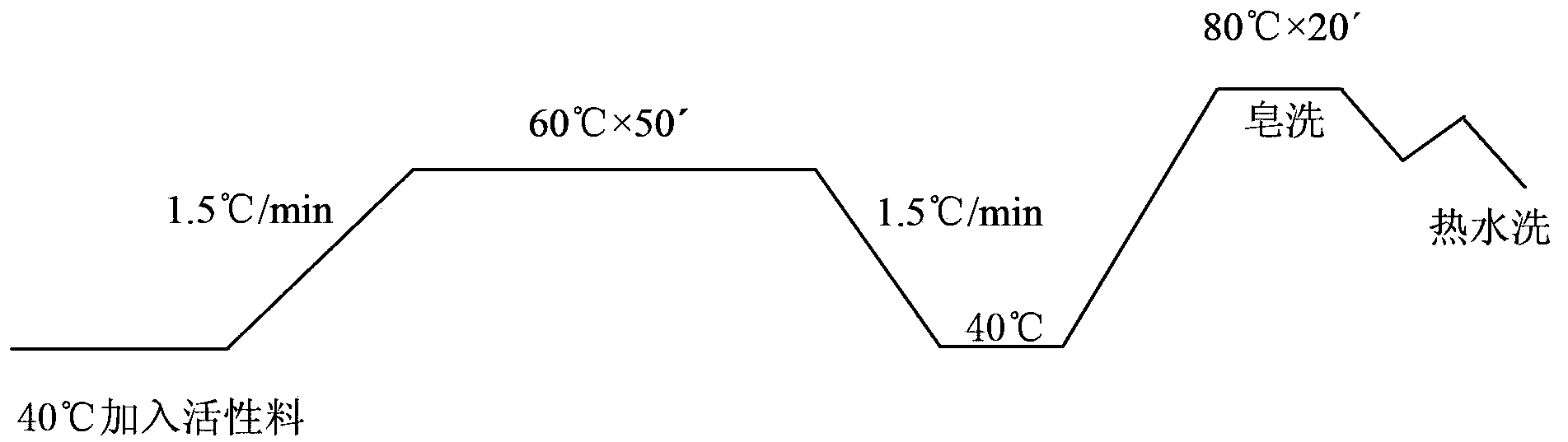

Embodiment 1

[0058] "Polyester / cationic polyester / viscose / tencel / wool / conductive fiber" serge fabric production technology:

[0059] 1. Spinning raw material ratio and yarn specifications

[0060] (1) Weight percentage of spinning material:

[0061] Polyester staple fiber 39.4﹪;

[0062] Cationic polyester 30%;

[0063] 10% viscose;

[0064] Tencel 10%;

[0065] 10% wool;

[0066] Carbon composite conductive fiber 0.6%.

[0067] 2. Yarn specifications:

[0068] ①Yarn 1: 50S / 1, twisting direction S, used as warp yarn;

[0069] ②Yarn 2: 36S / 1, twist direction Z twist, as weft yarn.

[0070] 2. Weaving process

[0071] 1. Preparation process before weaving:

[0072] ①Banding and twisting:

[0073] Warp yarn: use a twisted doubling machine to combine two 50S / 1 single yarns to form a ply yarn 50S / 2; use a two-for-one twister to twist, with a twist of 1050T / m, an S twist, and a spindle speed of 9000rpm.

[0074] ②Warp yarn steaming: the temperature of the yarn is 85℃, and the time is 90 minutes.

[0075] ③Split warpi...

Embodiment 2

[0124] Spinning raw material weight percentage:

[0125] Polyester staple fiber 30%;

[0126] Cationic polyester 24.9%;

[0127] 10% viscose;

[0128] Tencel 5﹪;

[0129] 30% wool;

[0130] 0.1% carbon composite conductive fiber.

[0131] The weaving process is as follows:

[0132] 1. Yarn specifications:

[0133] ①Yarn 1: 48S / 1, twisting direction S, used as warp yarn;

[0134] ②Yarn 2: 40S / 1, twist direction Z twist, as weft yarn.

[0135] 2. Weaving process

[0136] 1. Preparation process before weaving:

[0137] ①Banding and twisting:

[0138] Warp yarn: Two 48S / 1 single yarns are combined with a twisted doubling machine to form a ply yarn 48S / 2; twisted with a two-for-one twister, with a twist of 1000T / m, an S twist, and a spindle speed of 8000rpm.

[0139] ②Warp yarn steaming: the temperature of the yarn is 85℃, and the time is 85 minutes.

[0140] ③Split warping process

[0141] The total warp number is 5900, the twist number is 15 twists, the warping tension is 18dN, and the back shaft tens...

Embodiment 3

[0185] The weight percentage of spinning material is:

[0186] 38% polyester staple fiber;

[0187] Cationic polyester 20.5%;

[0188] Viscose 18%;

[0189] Tencel 15%;

[0190] Wool 8%;

[0191] Carbon composite conductive fiber 0.5%.

[0192] The process is as follows:

[0193] 1. Yarn specifications:

[0194] ①Yarn 1: 55S / 1, twisting direction S, as warp yarn;

[0195] ②Yarn 2:30S / 1, twist direction Z twist, as weft yarn.

[0196] 2. Weaving process

[0197] 1. Preparation process before weaving:

[0198] ①Banding and twisting:

[0199] Warp yarn: Two 55S / 1 single yarns are combined with a twisted doubling machine to form a ply yarn 55S / 2; twisted with a two-for-one twister, twist 1050T / m, S twist, spindle speed 9000rpm.

[0200] ②Warp yarn steaming: the temperature of steaming is 90℃, and the time is 90 minutes.

[0201] ③Split warping process

[0202] The total number of warp roots is 6000, the number of twists is 18, the warping tension is 20dN, and the back shaft tension is 0.3MPa.

[0203] ④...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com