Automatic glazing device for domestic ceramics

An automatic glazing device and ceramic technology, which is applied in the field of daily-use ceramic production, can solve problems such as complex structure, high labor intensity, and poor glazing quality, and achieve high automation, comprehensive and uniform glazing, and good glazing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

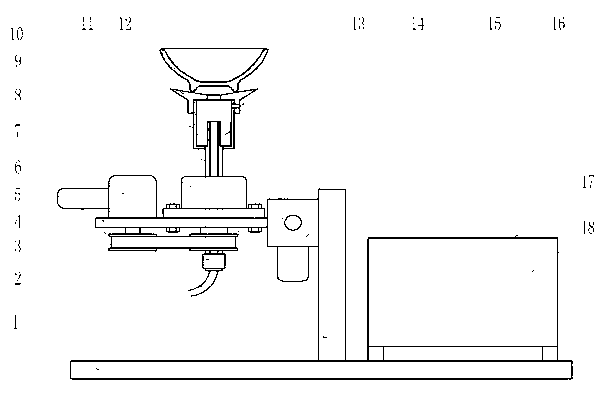

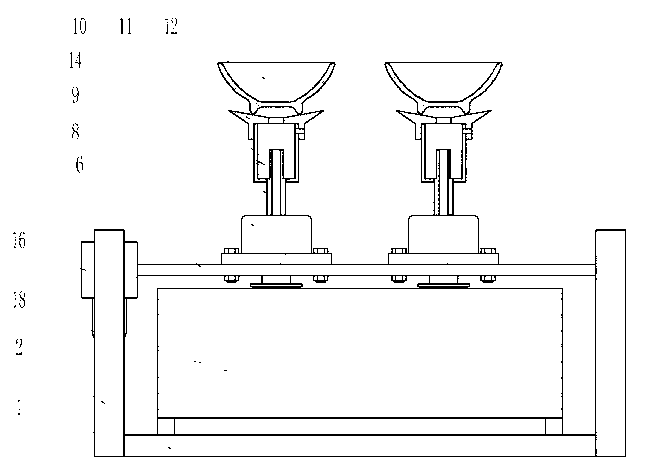

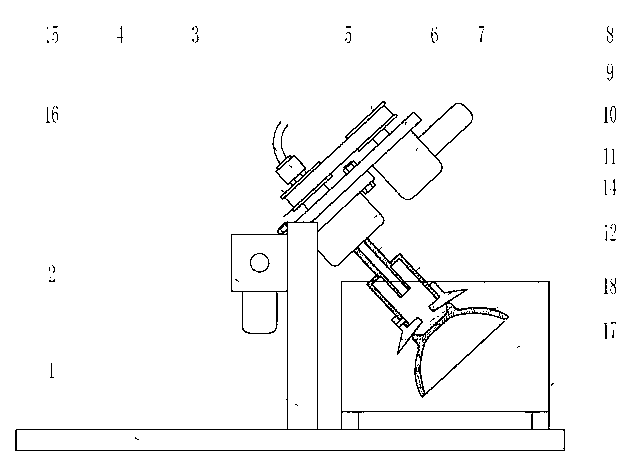

[0025] Such as figure 1 Shown, a kind of daily ceramic automatic glazing device, comprises the sucker device for absorbing bowl base, is used to support the support plate 6 of sucker device and sucker rotation speed reducer 7, frame column 2 etc., and described sucker device passes through The bearing is connected with the support plate 6, and the bearing seat 8 of the bearing is fixedly connected on the support plate 6 by bolts, and the support plate 6 is provided with a sucker rotation speed reducer 7 for driving the sucker device to rotate.

[0026] The frame column 2 is located between the support plate 6 and the glaze pool 17 for storing glaze water 18, the lower end of the frame column 2 is connected with the frame bottom plate 1, the upper end is connected with the support plate 6, and the frame column 2 is close to the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com