Cleaning and glazing agent for furniture and preparation method thereof

A cleaning and furniture technology, applied in the field of cleaners, can solve the problems of not being able to reach the furniture, use affects the appearance, and not strong pertinence, etc., and achieve good plot performance, good glazing effect, and obvious glazing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

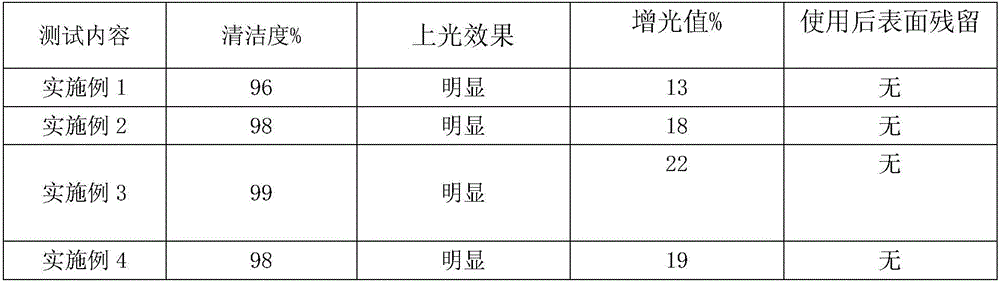

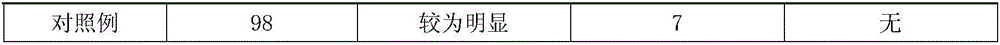

Examples

Embodiment 1

[0016] A cleaning and polishing agent for furniture, comprising the following components in parts by weight: 2 parts of sodium dodecylbenzenesulfonate, 1 part of magnesium stearate, 0.5 part of sodium tripolyphosphate, 1 part of sodium polyacrylate, poly 0.5 parts of acrylamide, 0.2 parts of silicon dioxide, 0.1 parts of ethylenediamine, 0.2 parts of citric acid, and 100 parts of ethanol aqueous solution.

[0017] The preparation method of described furniture cleaning polish, comprises the following steps:

[0018] Step 1, add sodium dodecylbenzenesulfonate, magnesium stearate, sodium tripolyphosphate, sodium polyacrylate, polyacrylamide and silicon dioxide into the ethanol aqueous solution, stir and mix evenly, wherein the stirring speed is 150 rpm / minute, time 30 minutes, stirring temperature 30 ℃, obtain mixture 1;

[0019] Step 2: Once the mixture is heated and kept boiling, ethylenediamine is added and stirred for 5 minutes, then citric acid is added, mixed evenly, and...

Embodiment 2

[0021] A cleaning and polishing agent for furniture, comprising the following components in parts by weight: 2 parts of sodium dodecylbenzenesulfonate, 2 parts of magnesium stearate, 0.6 parts of sodium tripolyphosphate, 2 parts of sodium polyacrylate, poly 0.7 parts of acrylamide, 0.3 parts of silicon dioxide, 0.2 parts of ethylenediamine, 0.2 parts of citric acid, and 106 parts of ethanol aqueous solution.

[0022] The preparation method of described furniture cleaning polish, comprises the following steps:

[0023] Step 1, add sodium dodecylbenzenesulfonate, magnesium stearate, sodium tripolyphosphate, sodium polyacrylate, polyacrylamide and silicon dioxide into the aqueous ethanol solution, stir and mix evenly, wherein the stirring speed is 160 rpm / minute, time 32 minutes, stirring temperature 35 ℃, obtain mixture 1;

[0024] Step 2: Heat mixture 1 to boiling at a heating rate of 5-8°C / min, add ethylenediamine, stir for 7 minutes, then add citric acid, mix evenly, cool ...

Embodiment 3

[0026] A cleaning and polishing agent for furniture, comprising the following components in parts by weight: 3 parts of sodium dodecylbenzenesulfonate, 2 parts of magnesium stearate, 0.7 parts of sodium tripolyphosphate, 2 parts of sodium polyacrylate, poly 0.8 parts of acrylamide, 0.5 parts of silicon dioxide, 0.2 parts of ethylenediamine, 0.3 parts of citric acid, and 110 parts of ethanol aqueous solution.

[0027] The preparation method of described furniture cleaning polish, comprises the following steps:

[0028] Step 1, add sodium dodecylbenzenesulfonate, magnesium stearate, sodium tripolyphosphate, sodium polyacrylate, polyacrylamide and silicon dioxide into the aqueous ethanol solution, stir and mix evenly, wherein the stirring speed is 180 rpm / minute, time 36 minutes, stirring temperature 37 ℃, obtain mixture 1;

[0029] Step 2: Heat the mixture 1 to boiling at a heating rate of 5-8°C / min, add ethylenediamine, stir for 10 minutes, then add citric acid, mix evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com