Structural ceramic glazing machine

A ceramic and glaze machine technology, applied in the field of structural ceramics, can solve the problems of poor glazing effect, low work efficiency, low glazing quality, etc., and achieve the effects of uniform glazing, improving work efficiency and improving glazing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

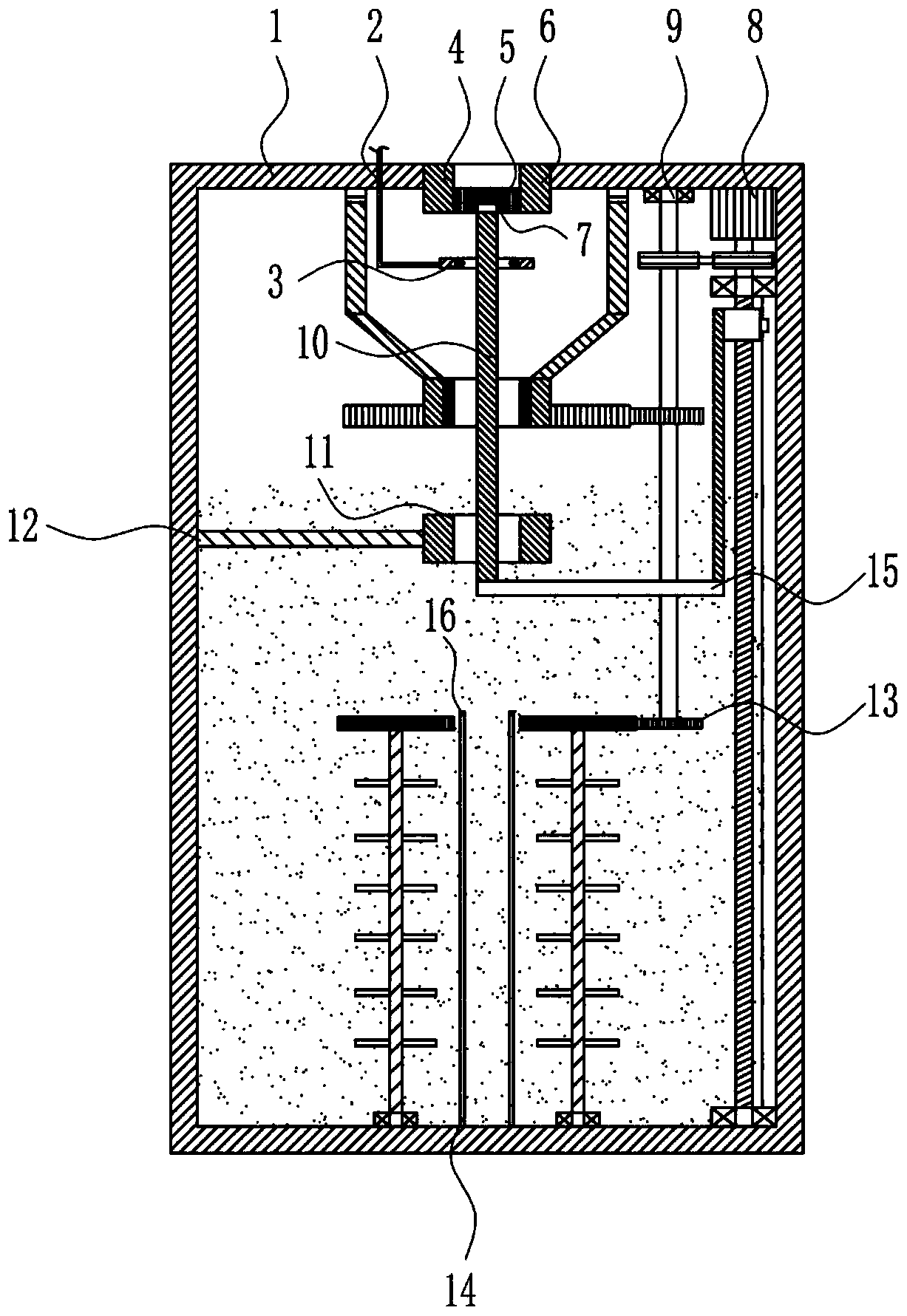

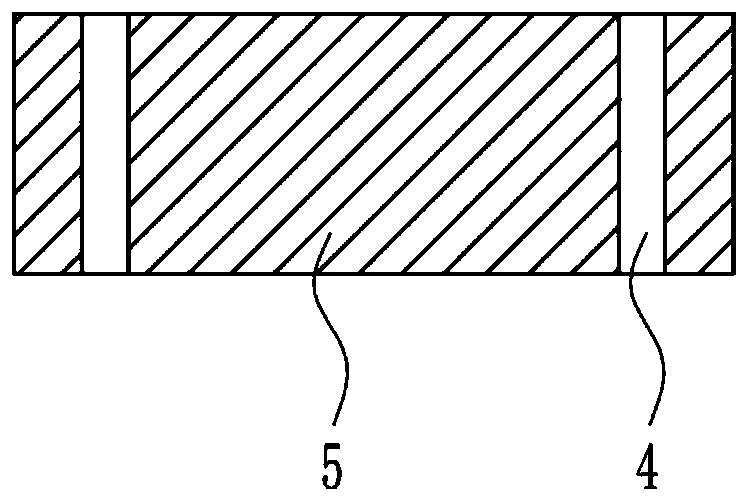

[0033] A structural ceramic glazing machine, such as Figure 1-10 As shown, it includes an organism 1, a water inlet pipe 2, an annular nozzle 3, a first gear 5, a first casing 6, a first bearing seat 7, a lifting mechanism 8, a wiping mechanism 9, a second rotating shaft 10, and a third casing 11 , connecting rod 12, stirring mechanism 13, support rod 14 and frame body 15; body 1 top is equipped with water inlet pipe 2, and water inlet pipe 2 stretches into body 1 and is fixedly connected with annular nozzle 3; body 1 top is clamped with first cover body 6. The first sleeve body 6 is located directly above the annular nozzle 3; the first gear 5 is located in the first sleeve body 6, and there are through holes 4 on both sides of the first gear 5 along the vertical direction, and the bottom of the first gear 5 The first bearing seat 7 is clamped, and the second rotating shaft 10 is pivotally connected to the first bearing seat 7; a wiping mechanism 9 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com