Patents

Literature

38results about How to "Improve glazing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

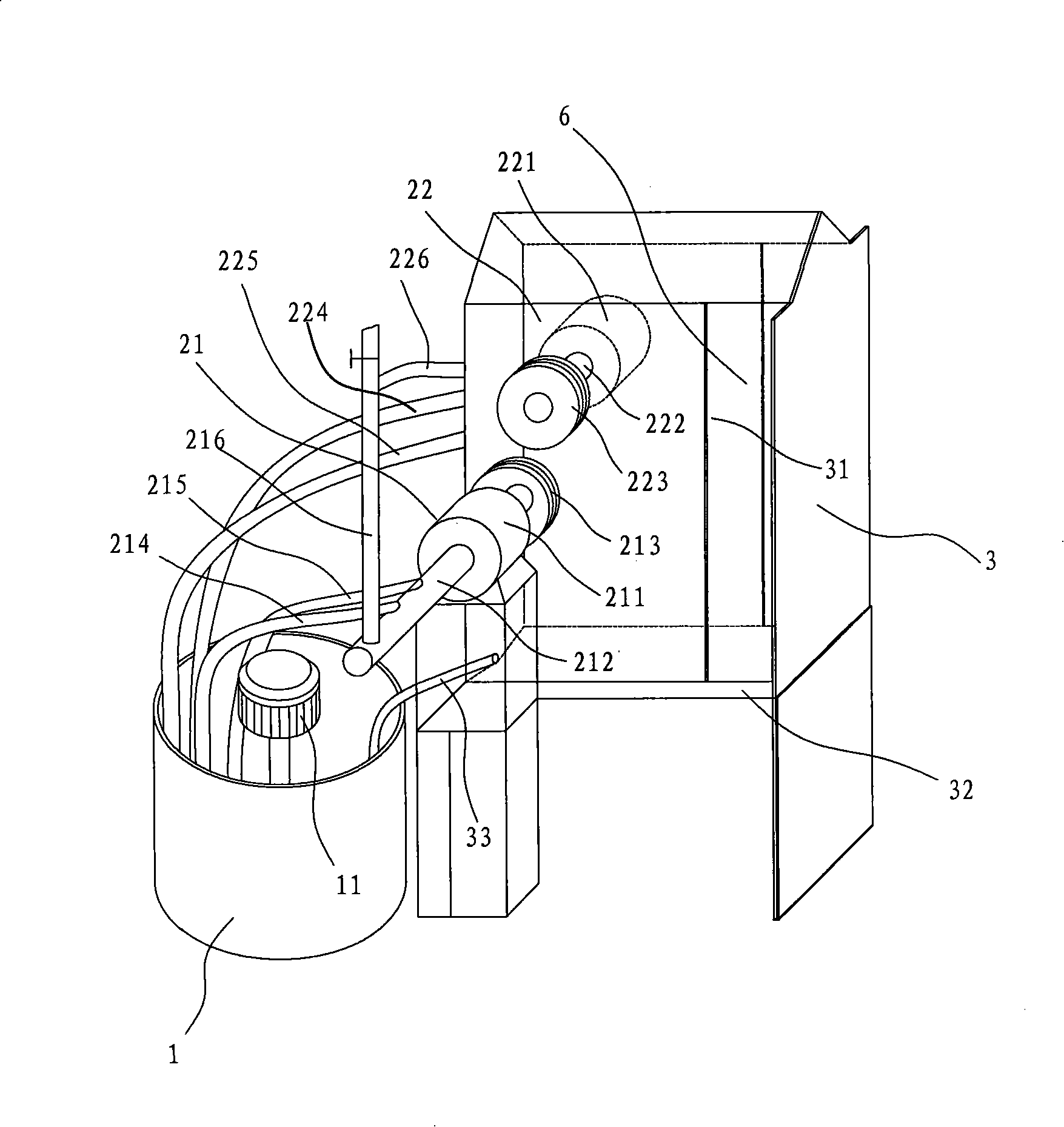

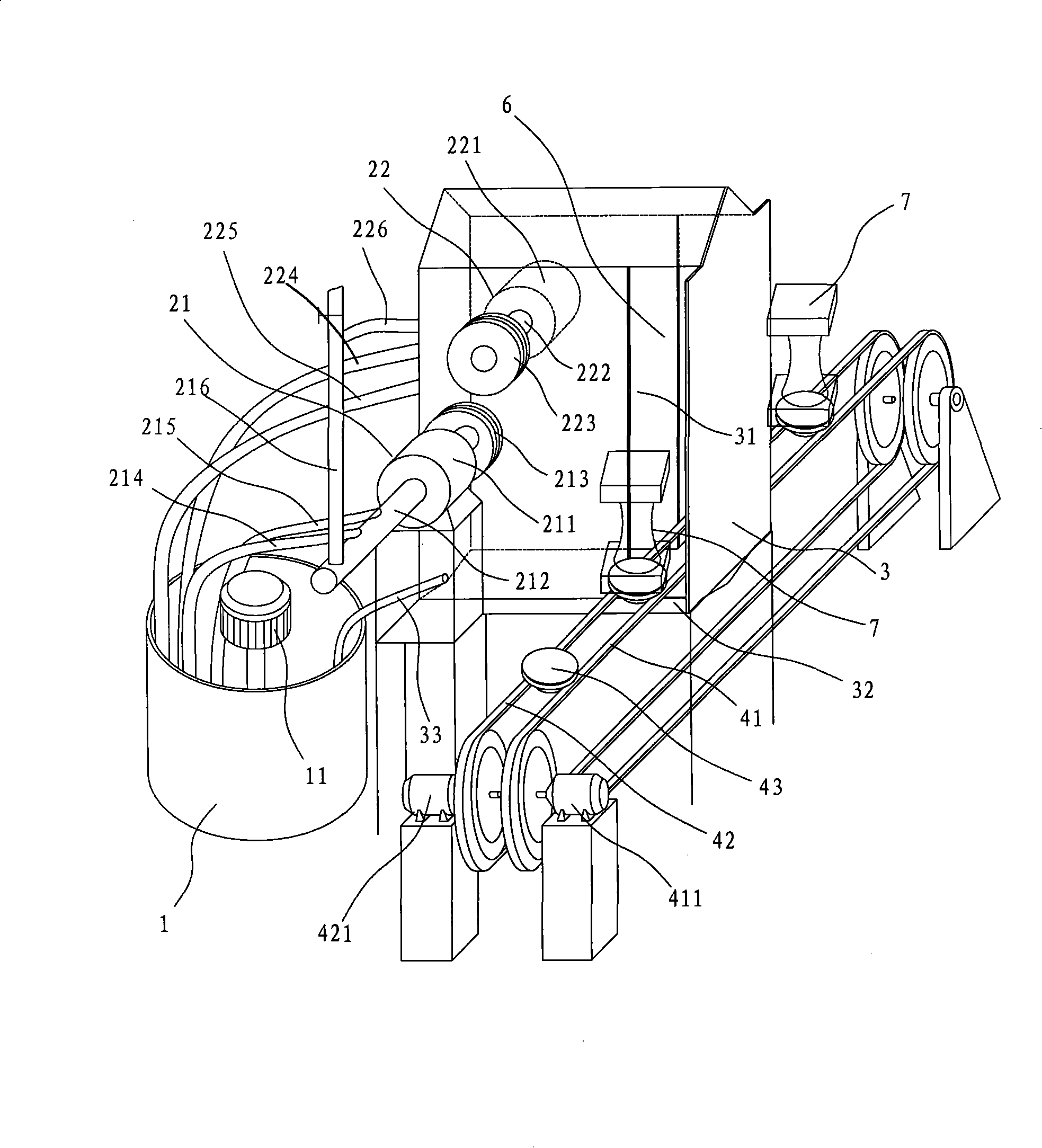

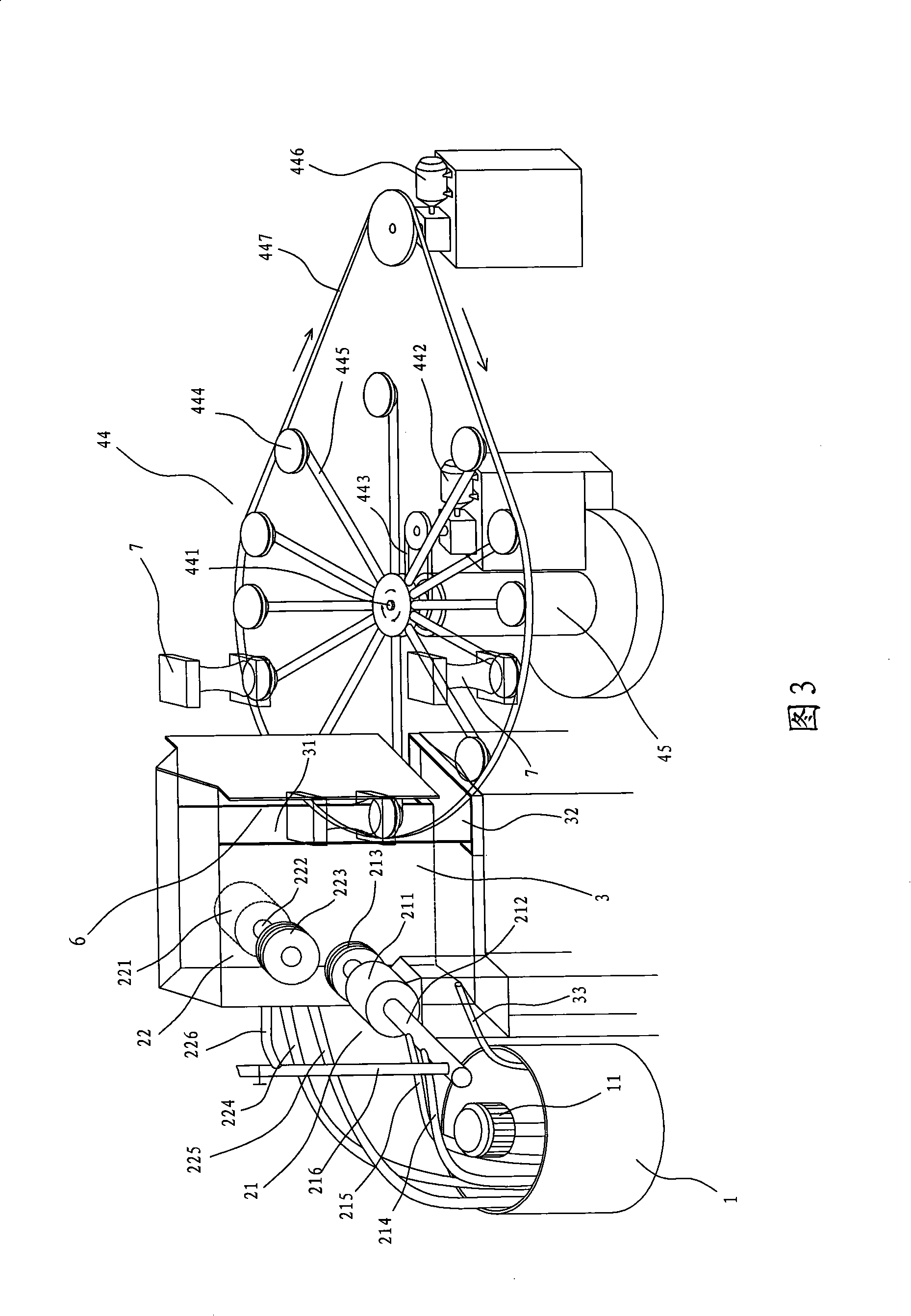

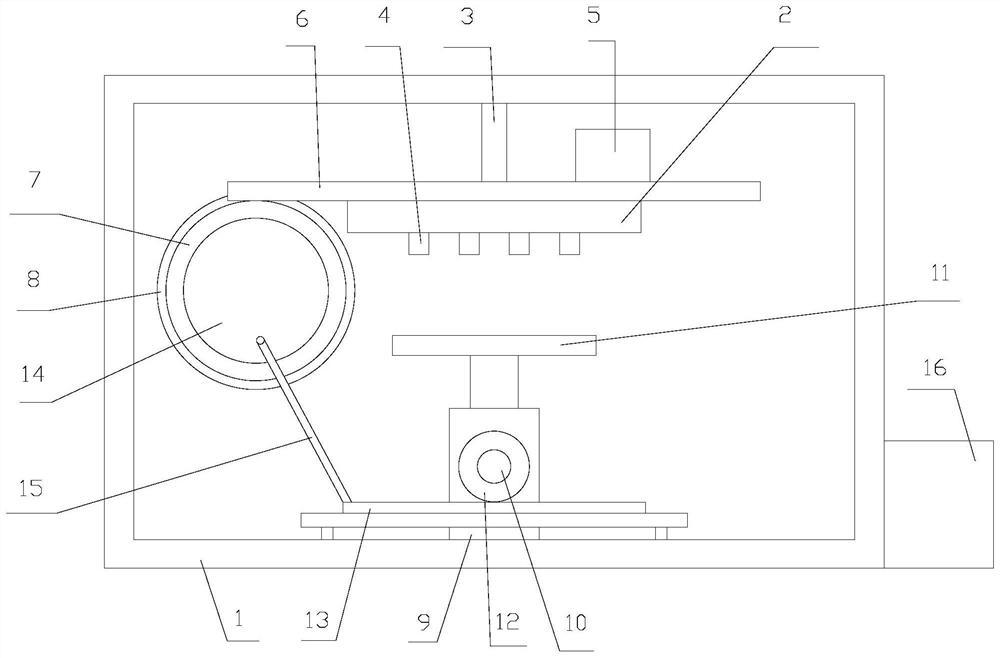

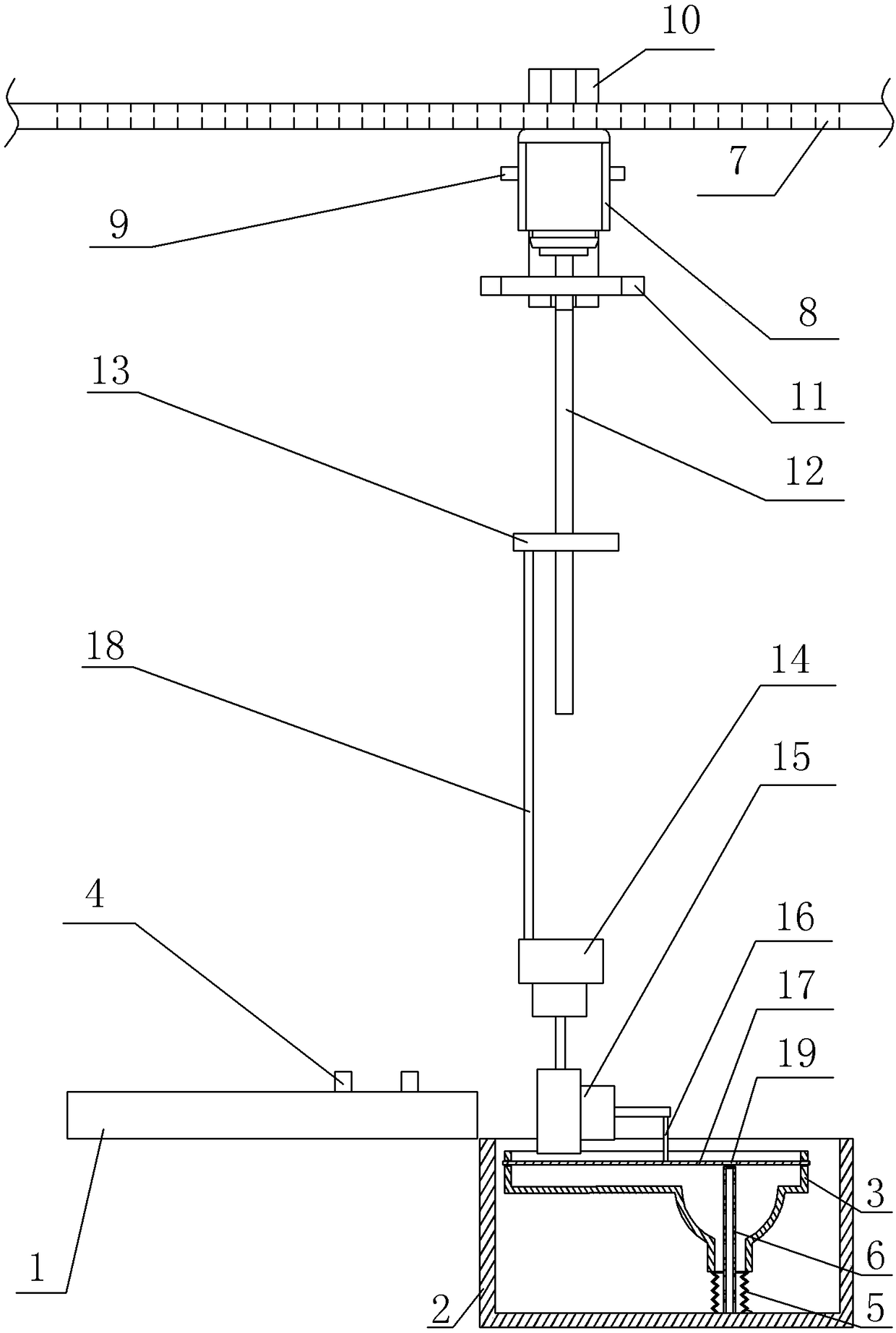

Glazing method and special equipment therefor

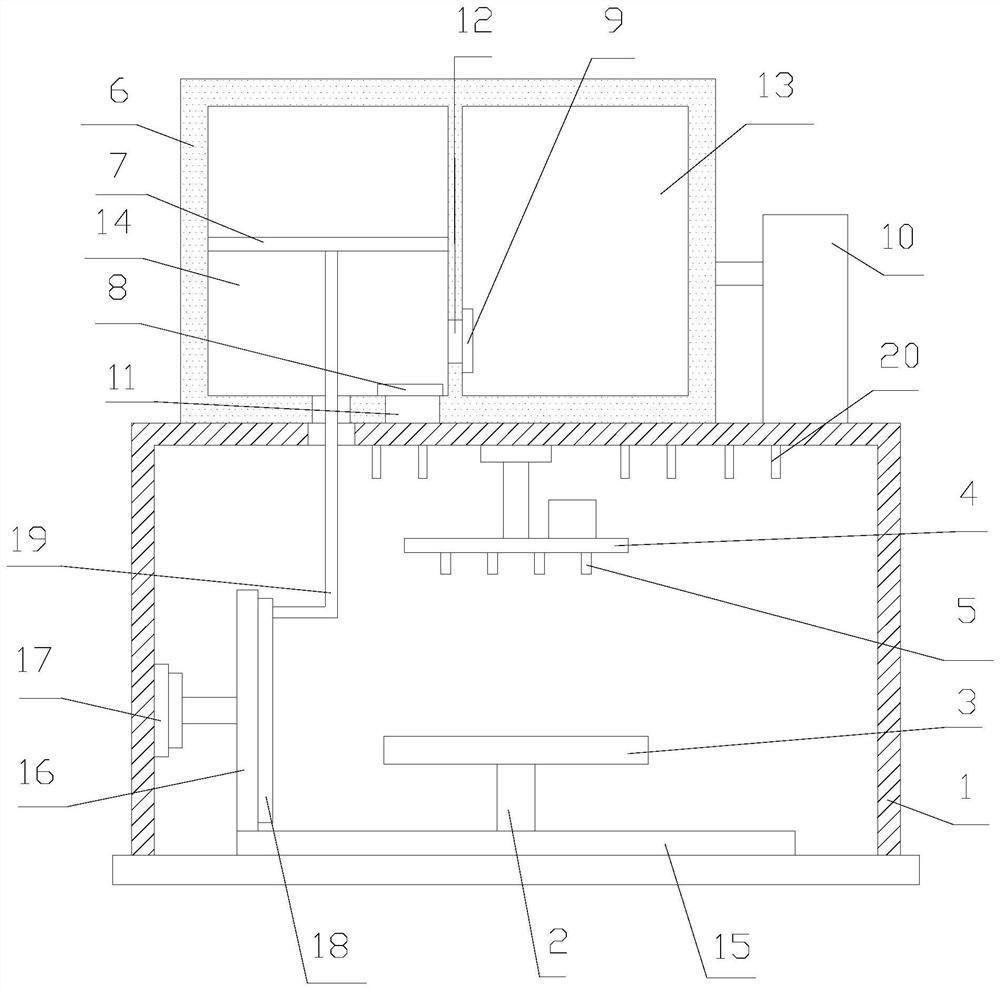

The invention discloses a glazing method and the specialized equipment, which transfers the solid ceramic product into the glazing die cavity of the glazing box of the automatic glazing equipment through a transmission device, drives the rotation of the ceramic product inside the glazing die cavity through a driving device, enabling the glazing of the whole peripheral surface by the glaze extractor of the glazing equipment, and transfers the glazed ceramic product outside the glazing equipment through the transmission equipment. The glazing specialized equipment comprises an automatic glazing equipment and the transmission device; wherein, the transmission device comprises a transmission apparatus and a plurality of movable workpiece supporting disks which are arranged on the transmission apparatus and connected with the driving device driving the rotation of the disks. Compared with the prior art, the glazing method and the specialized equipment has the advantages of high degree of automation, simple operation, high glazing quality, greatly improved production efficiency, available smooth glaze layer or alabaster glaze layer coated, various satisfied clients, and improved market competition of the products.

Owner:李劲松

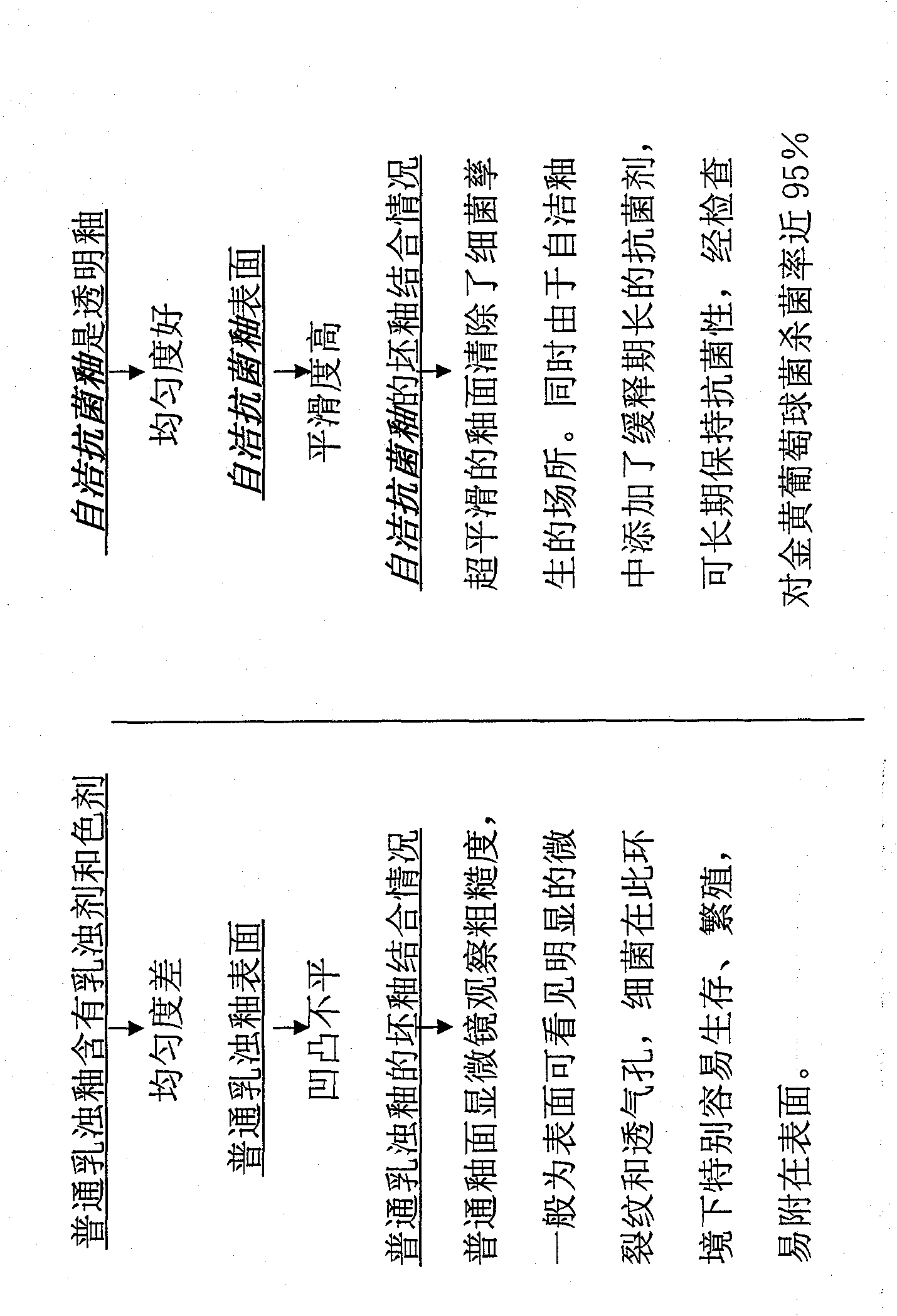

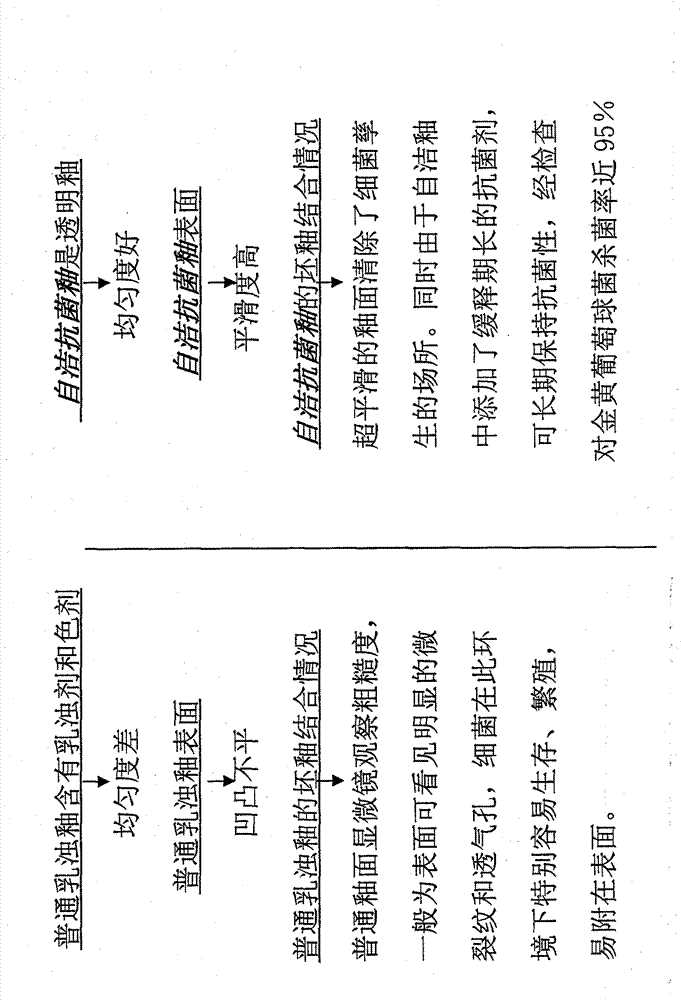

Self-cleaning antibacterial glaze used for sanitary ceramic ware

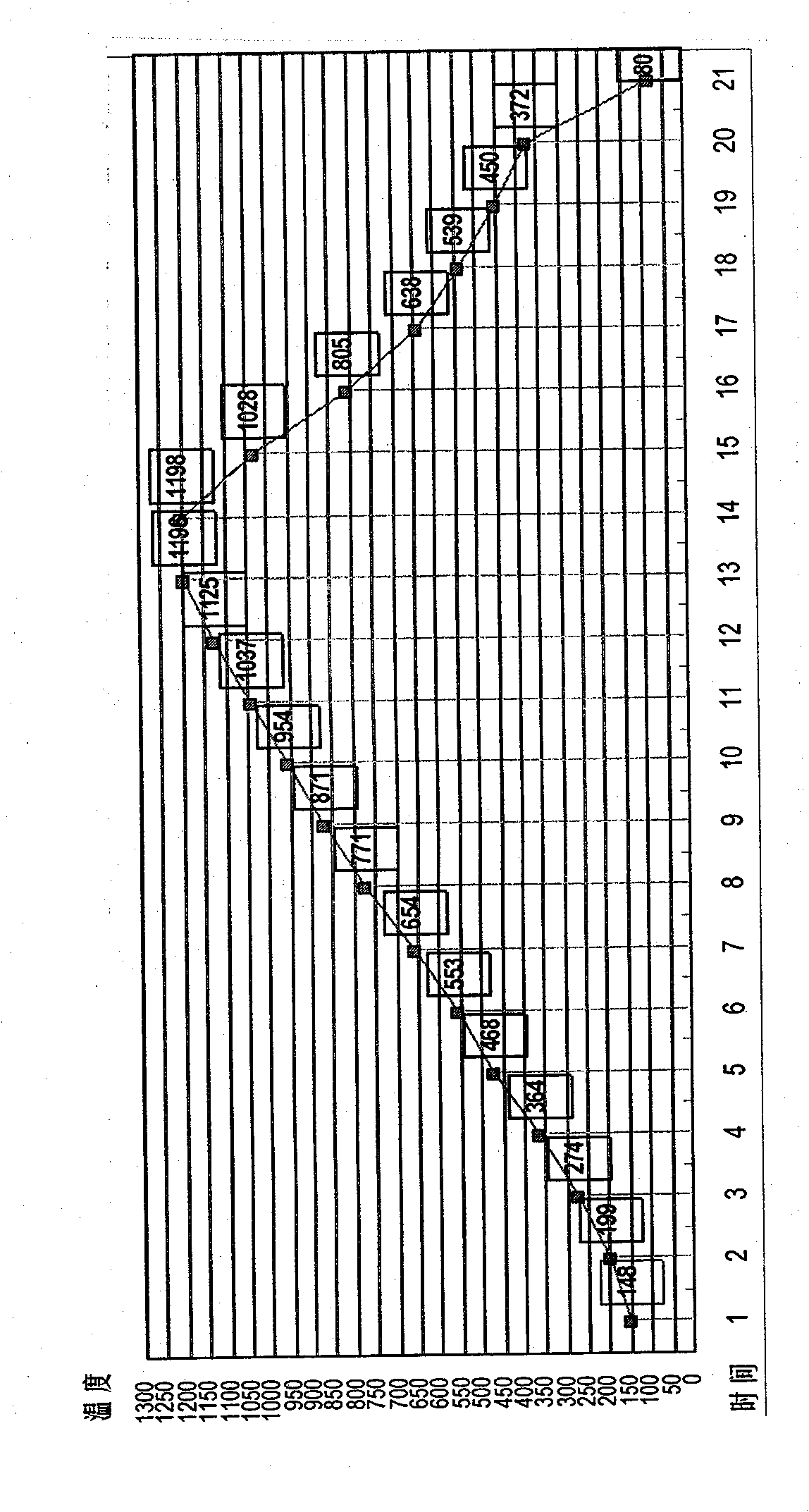

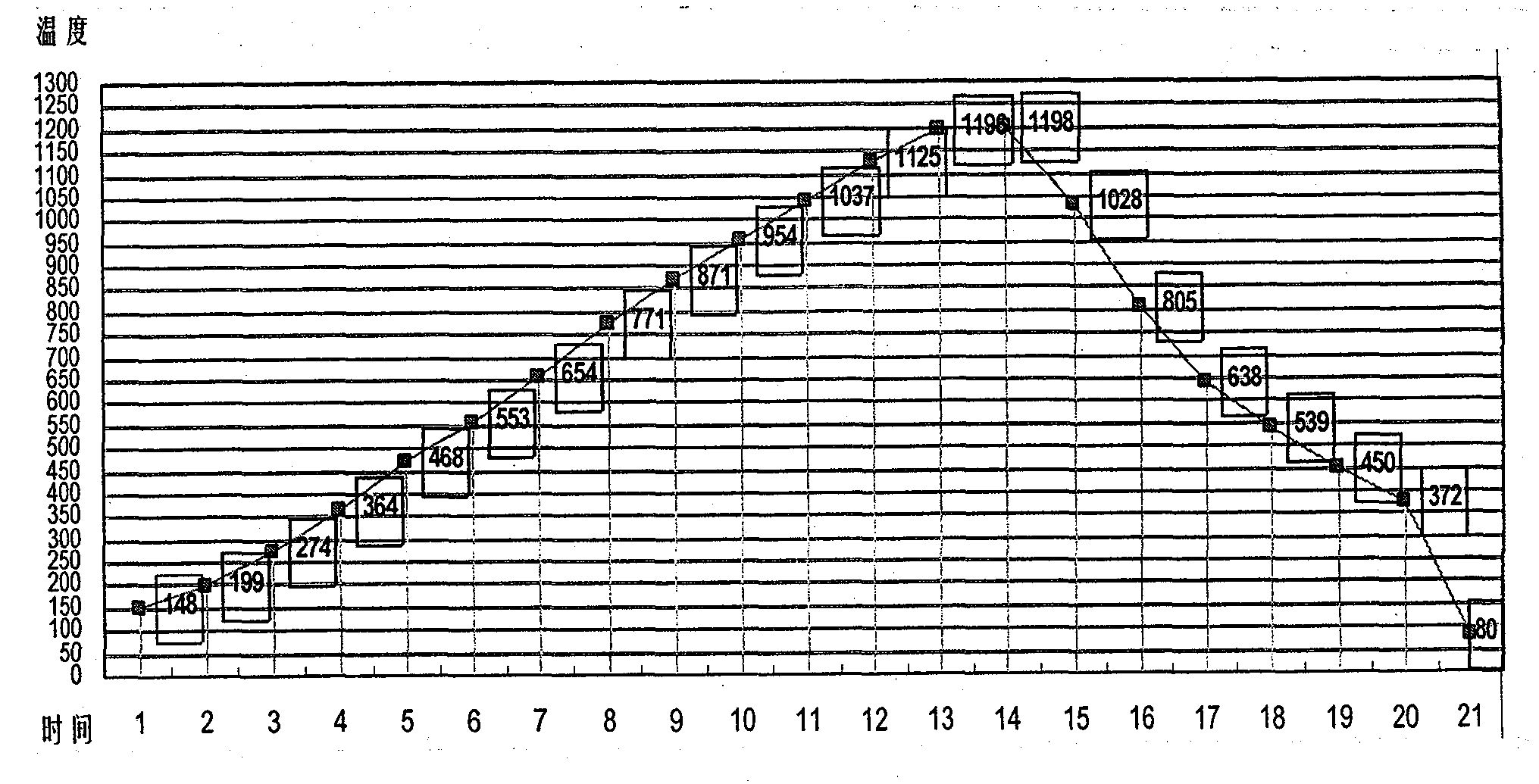

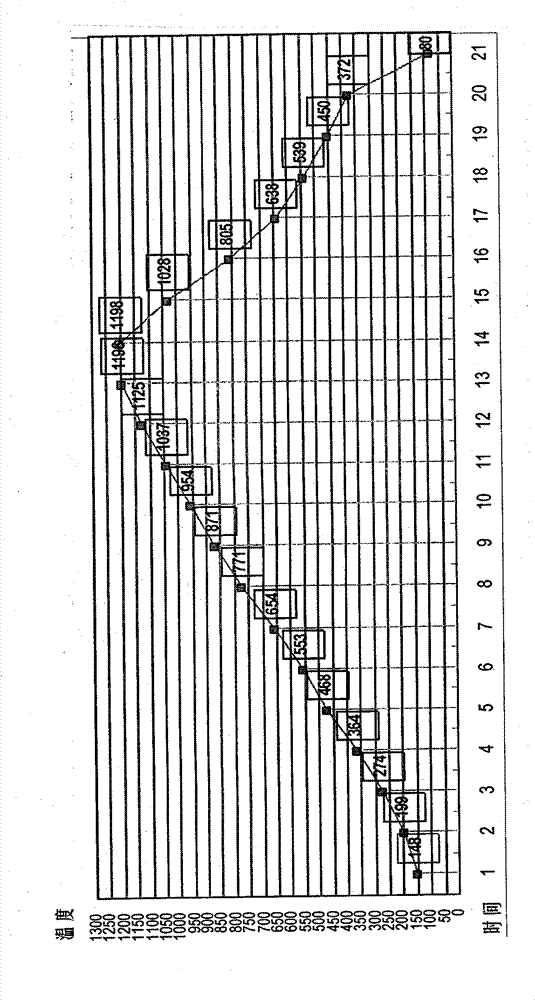

The invention discloses a self-cleaning antibacterial glaze. A bottom glaze comprises the following components: 32.75 parts of quartz powder, 20.05 parts of feldspar, 10 parts of wollastonite, 5.5 parts of calcite, 4 parts of dolomite, 3.5 parts of Balin soil, 6.5 parts of alumina powder, 2 parts of zinc oxide, 4.5 parts of frit, and 12.75 parts of zirconium silicate powder; a cover glaze comprises the following components: 38 parts of quartz powder, 23.75 parts of feldspar, 12.75 parts of wollastonite, 4 parts of calcite, 3 parts of dolomite, 4.5 parts of Balin soil, 7 parts of alumina powder, 1.5 parts of zinc oxide, 4.5 parts of frit, 0.8 part of antibacterial agent A, and 0.2 part of antibacterial agent B; the bottom glaze has the grain size of between 1 and 10 micrometers and the thickness of between 0.8 and 1.0mm; the cover glaze has the grain size of between 1 and 10 micrometers and the thickness of between 0.2 and 0.3mm; and the bottom glaze and the cover glaze are separately fired, the initial temperature is 148DEG C, the highest temperature is 1,198DEG C, the cooling temperature is 80DEG C, and the firing time is 12 to 21 hours. The glaze layer of the bottom glaze has less pinholes and cracks, and the prepared product has the advantages of homogenized texture, smooth and bright surface and difficult dirt attachment.

Owner:TANGSHAN MONOPY CERAMIC

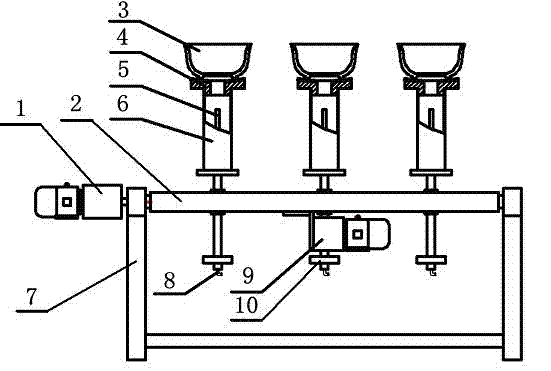

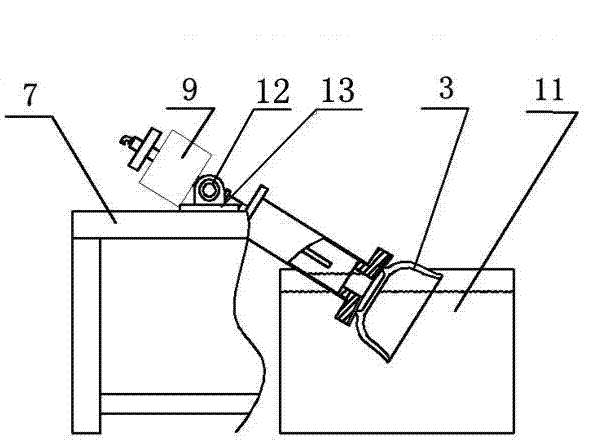

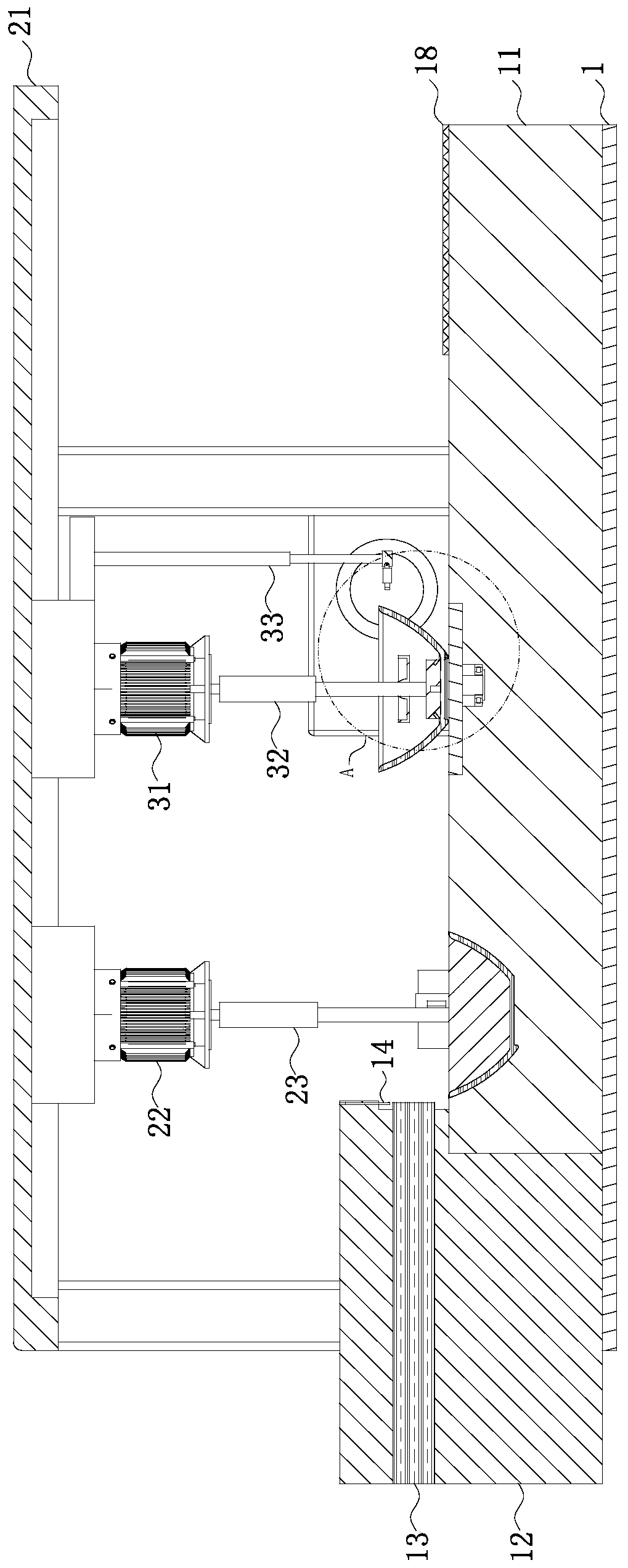

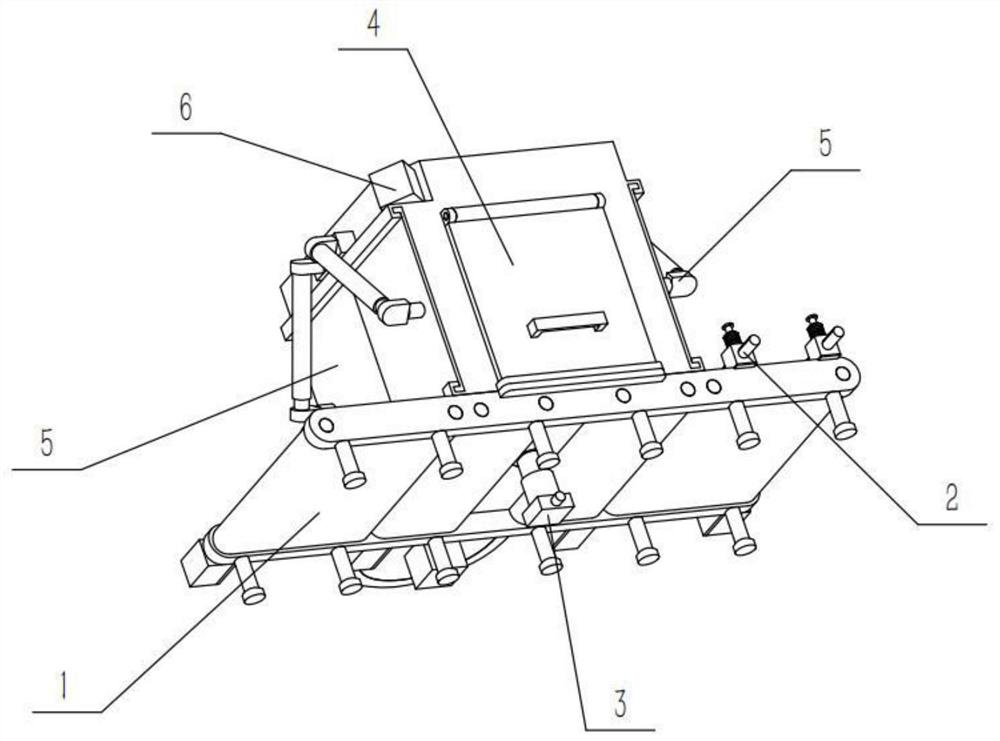

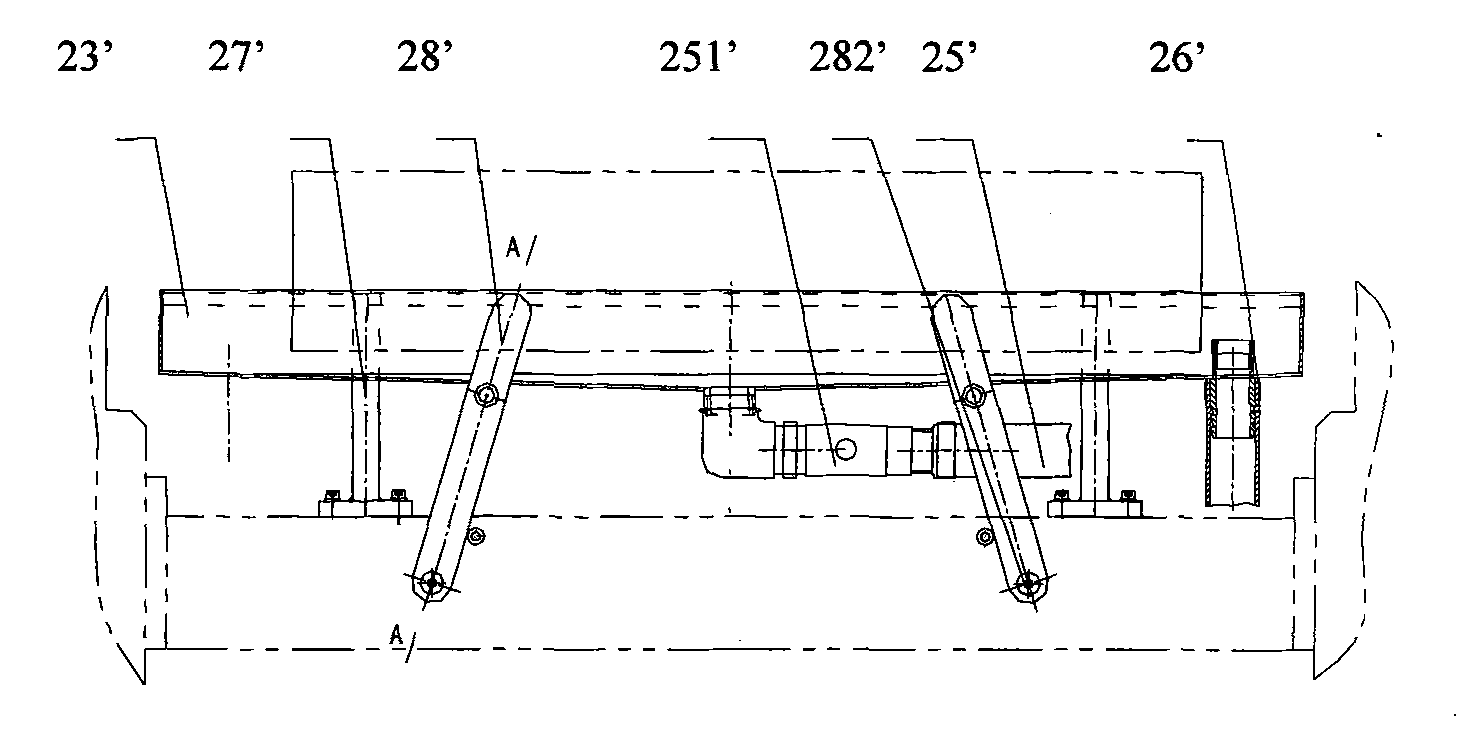

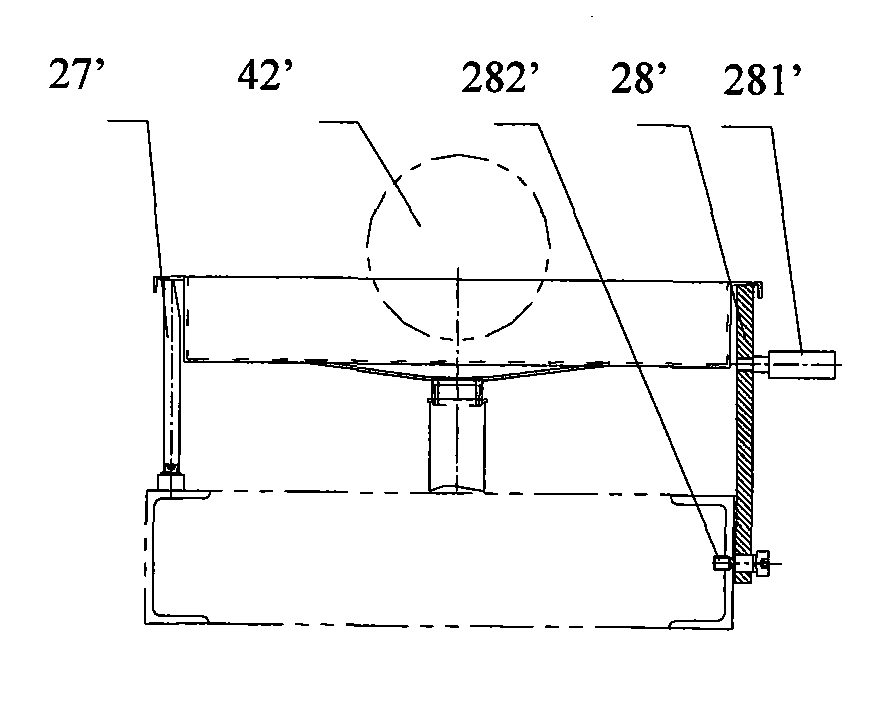

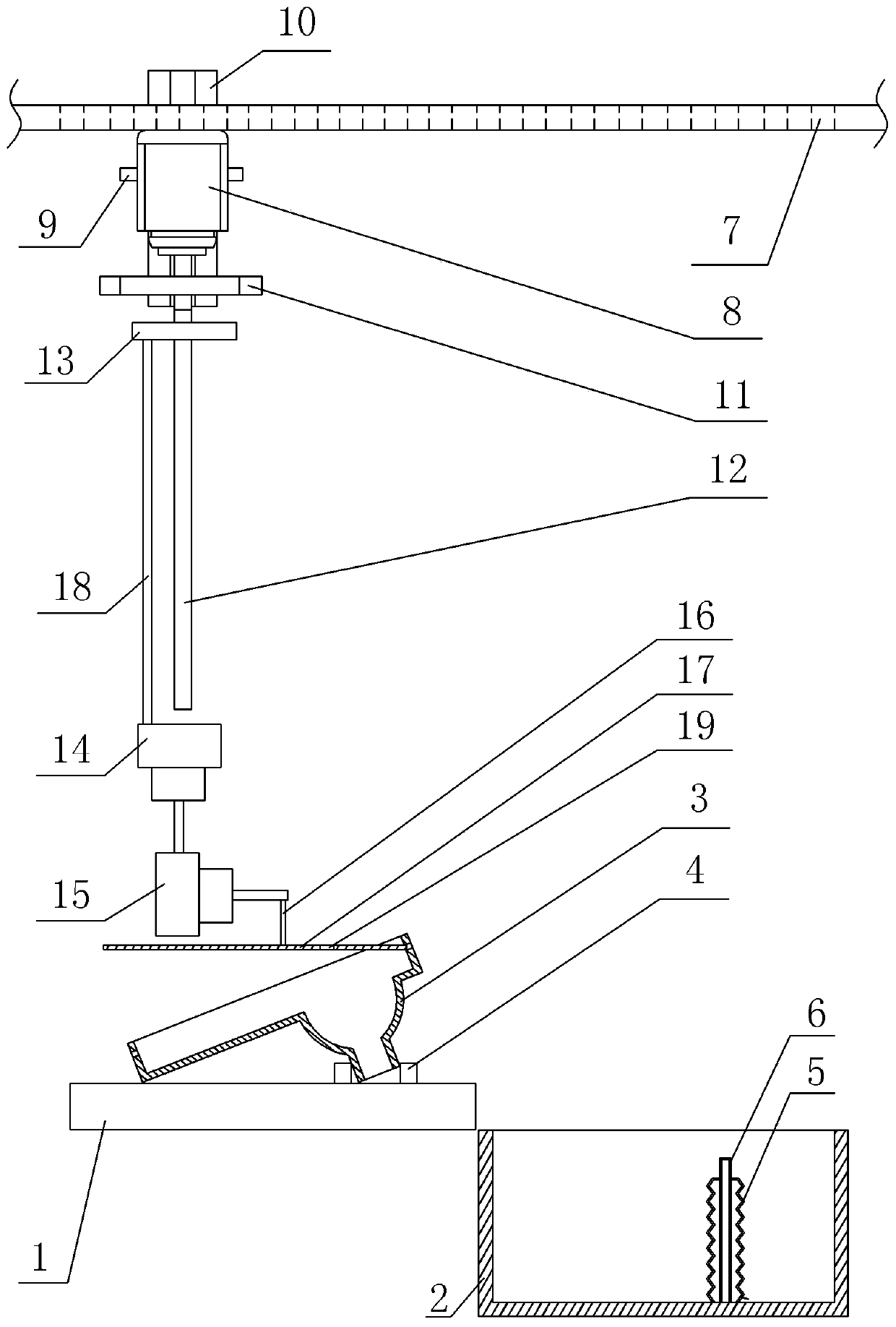

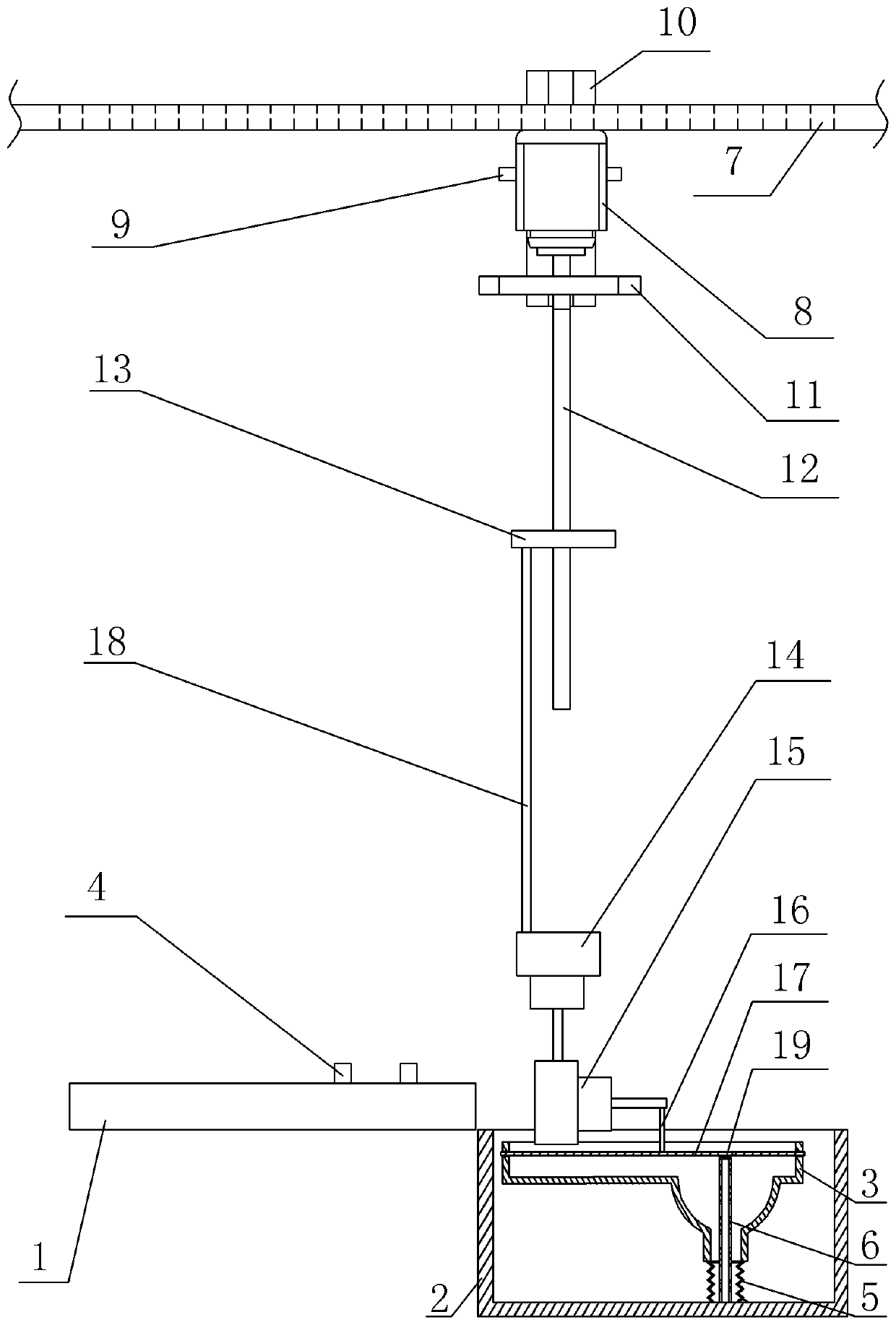

Automatic dipping machine of ceramic product for daily use

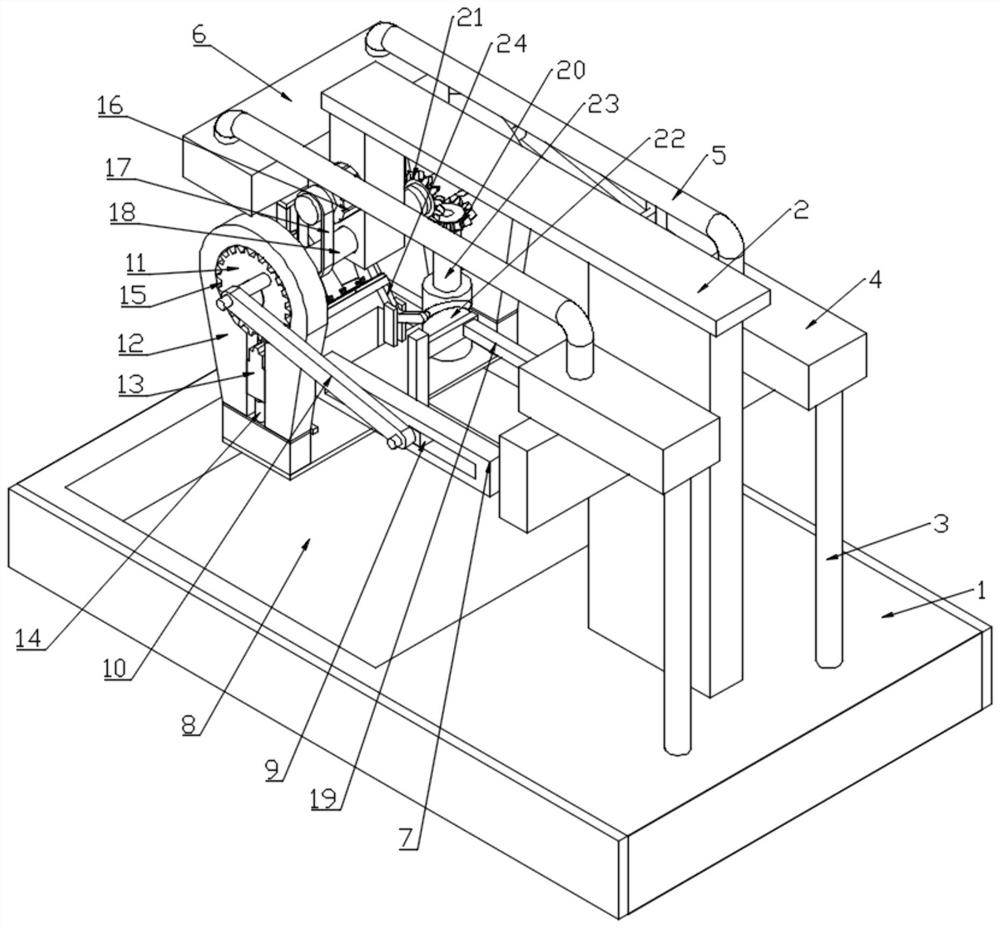

The invention discloses an automatic dipping machine of a ceramic product for daily use for an automatic dipping procedure in a process of producing the ceramic product. A bearing block and a bearing are fixedly arranged at two ends of the upper surface of a bracket; a turnover spindle passes through the bearing; the turnover spindle passes through the overall bracket; the part of the turnover spindle extending out of the bracket is connected with a turnover drive mechanism; a center pipe is arranged inside a drum; the vacuum degree inside the drum can be controlled through a rotary joint and a vacuum generator, so that the bottom part of the ceramic product can be dipped when the ceramic product is sucked; the rotary drive mechanism is fixed opposite to the turnover spindle and alternatively works orderly at a certain beat; the work smoothness is ensured; and the production rate is also ensured. Therefore, the problems of low automatic degree and high waste defective rate in the process of producing the ceramic product are solved by the invention; the automatic dipping machine has the characteristics of high automatic degree, simple operation, high dipping quality and even enamel layer; and the production cost is reduced when the production efficiency is improved.

Owner:GUANGXI BEILIU ZHIYU CERAMIC AUTOMATION EQUIPCO

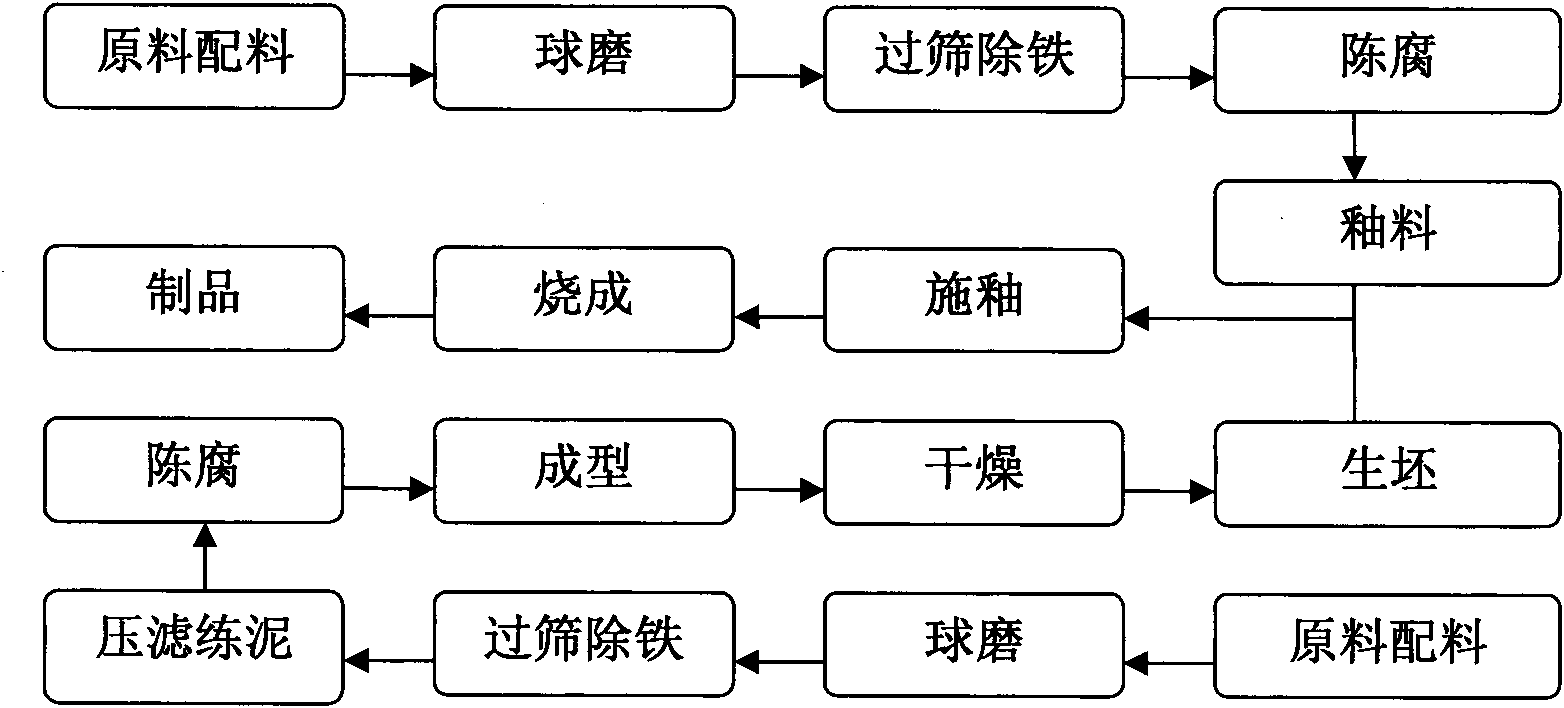

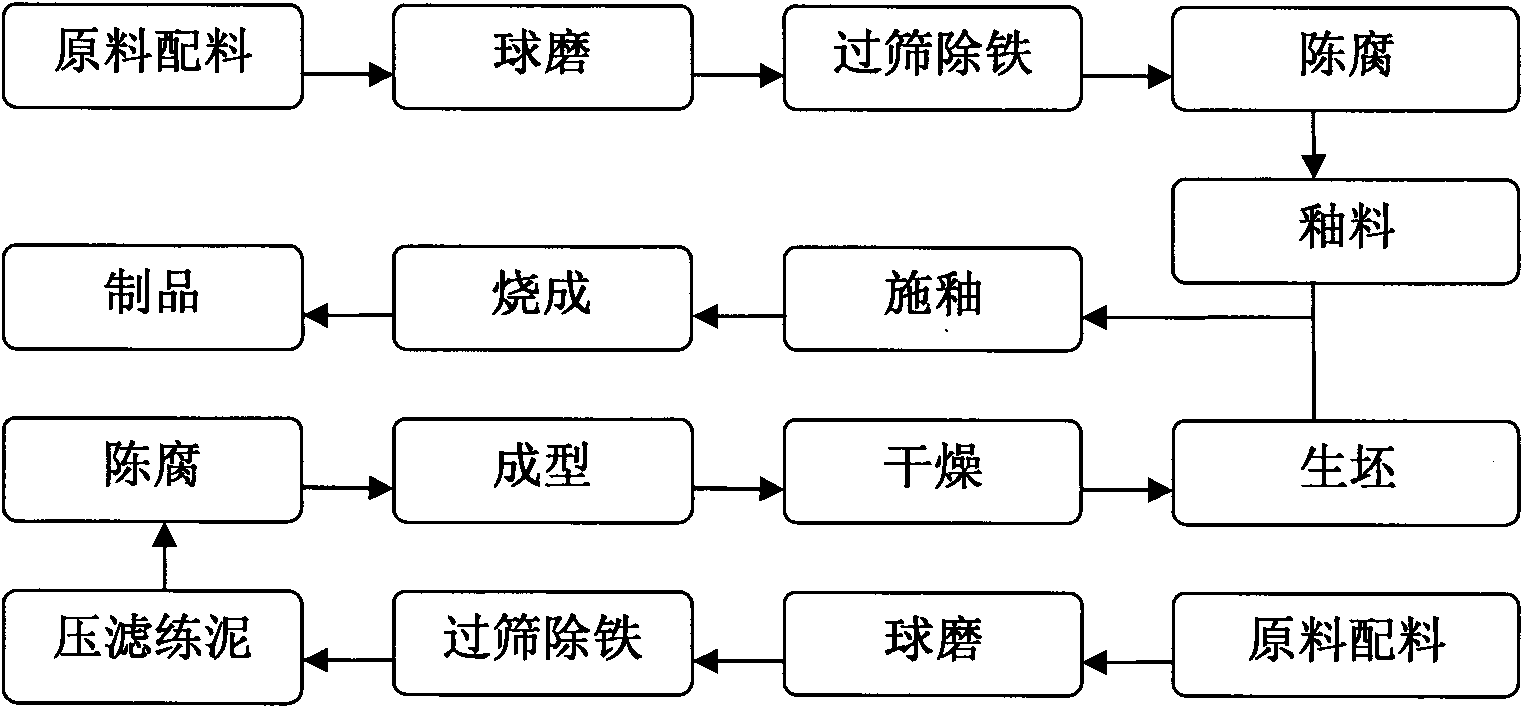

Preparation method of emerald ceramic

The invention discloses a preparation method of emerald ceramic, which comprises the steps of: (1) weighing raw materials according to a formula, mixing quartz, Guangxi Kaolinite and calcite for carrying wet-method ball-grinding, adding high-plasticity clay and low-plasticity clay for carrying out wet-method ball-grinding; (2) sieving and dewatering, ageing mud for 4-6 days, drying at a temperature of 80-110 DEG C after carrying out plastic forming; and (3) glazing, insulating the temperature at a temperature of 1240-1280 DEG C for 1-1.5h in an oxidizing atmosphere, and then cooling. The prepared emerald ceramic has the advantages of better permeability, light green color, emerald texture, high strength, good heat stability, lower production cost and better application value.

Owner:SOUTH CHINA UNIV OF TECH

Ceramic product with self-cleaning glaze and making method thereof

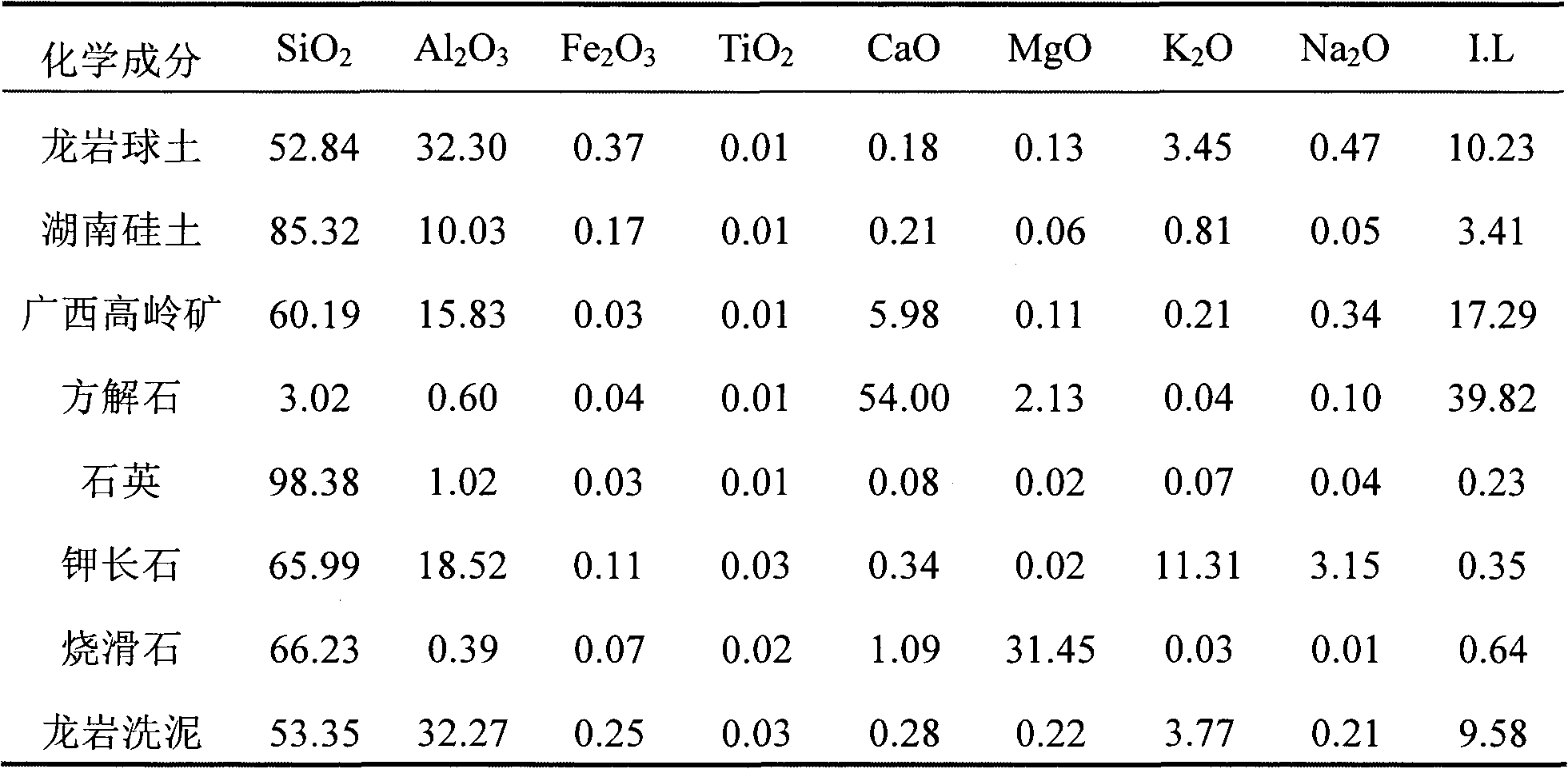

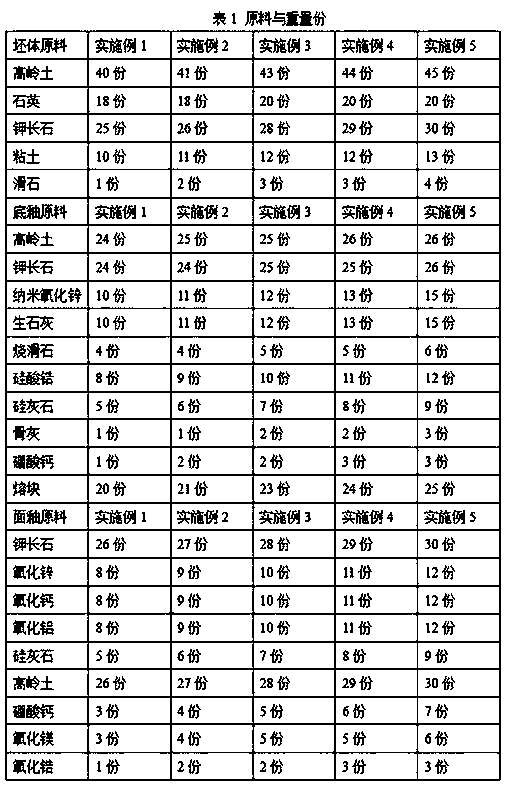

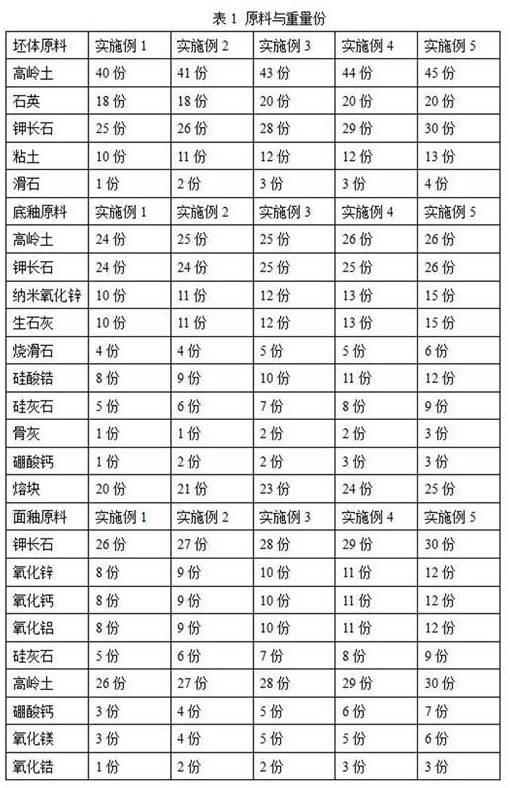

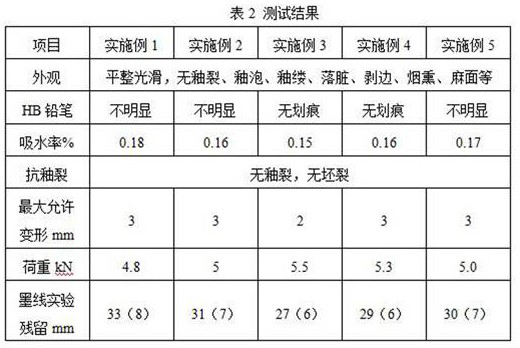

The invention provides a ceramic product with self-cleaning glaze. The ceramic product comprises a tire material and the glaze, wherein the tire material comprises kaolin, quartz, potassium feldspar,clay and talc; the glaze comprises ground glaze and cover glaze, wherein the ground glaze comprises the following raw materials: potassium feldspar, nano zinc oxide, calcium oxide, burning talc, zirconium silicate, wollastonite, kaolin, bone ash, calcium borate and frit; the cover glaze comprises the following raw materials: potassium feldspar, kaolin, wollastonite, zinc oxide, calcium oxide, aluminum oxide, magnesium oxide, zirconium oxide and calcium borate. A making method of the ceramic product with the self-cleaning glaze comprises the following steps: (1) respectively mixing the tire material and the glaze, adding water, wet-milling with a ball mill and sieving to obtain tire material slurry and glaze slurry; (2) making a green body with the tire material slurry for biscuit firing; (3) applying the ground glaze; (4) applying the cover glaze; (4) firing. The ceramic product made of the making method provided by the invention is fine and bright in glazed surface and can effectivelyprevent the accumulation of dirt and the formation of black spots.

Owner:福建省德化龙辉陶瓷有限公司

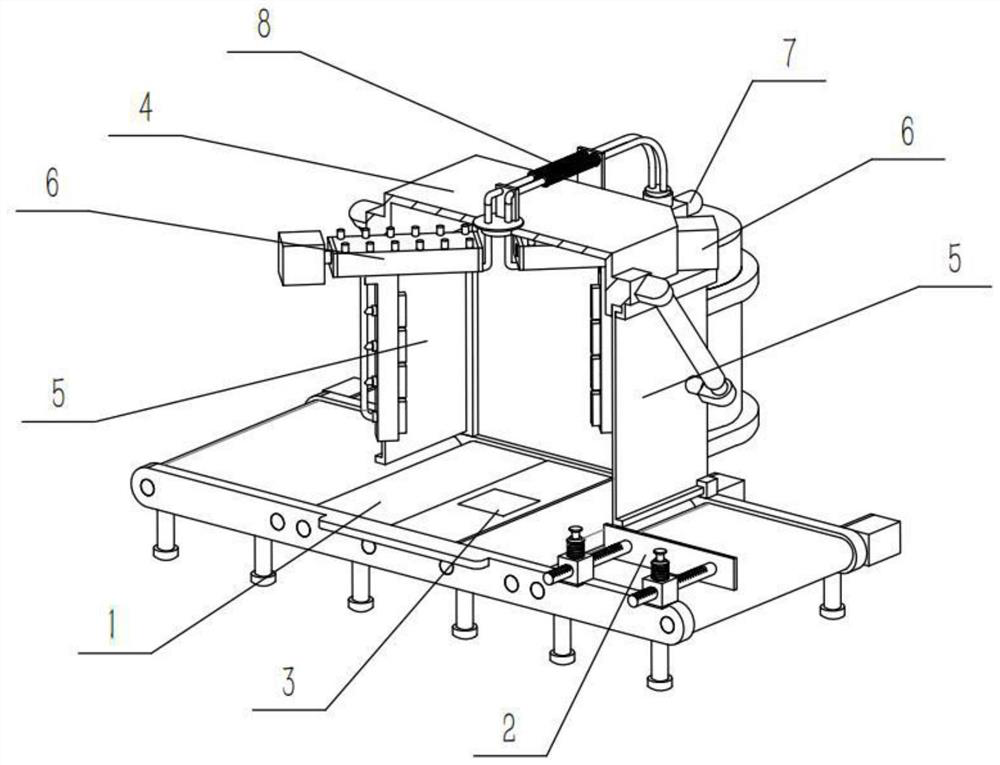

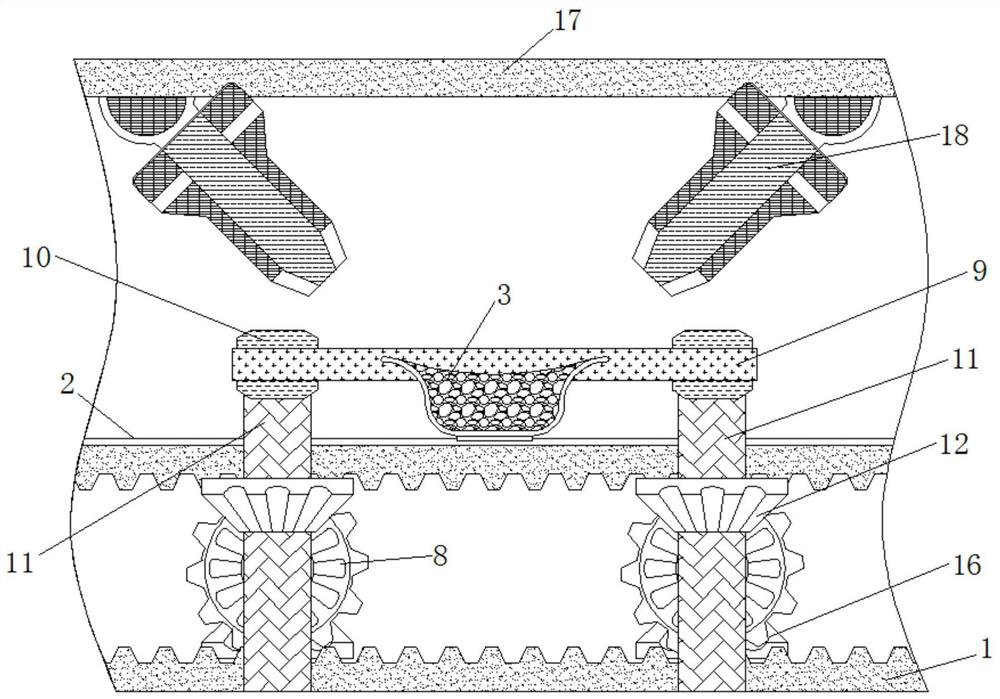

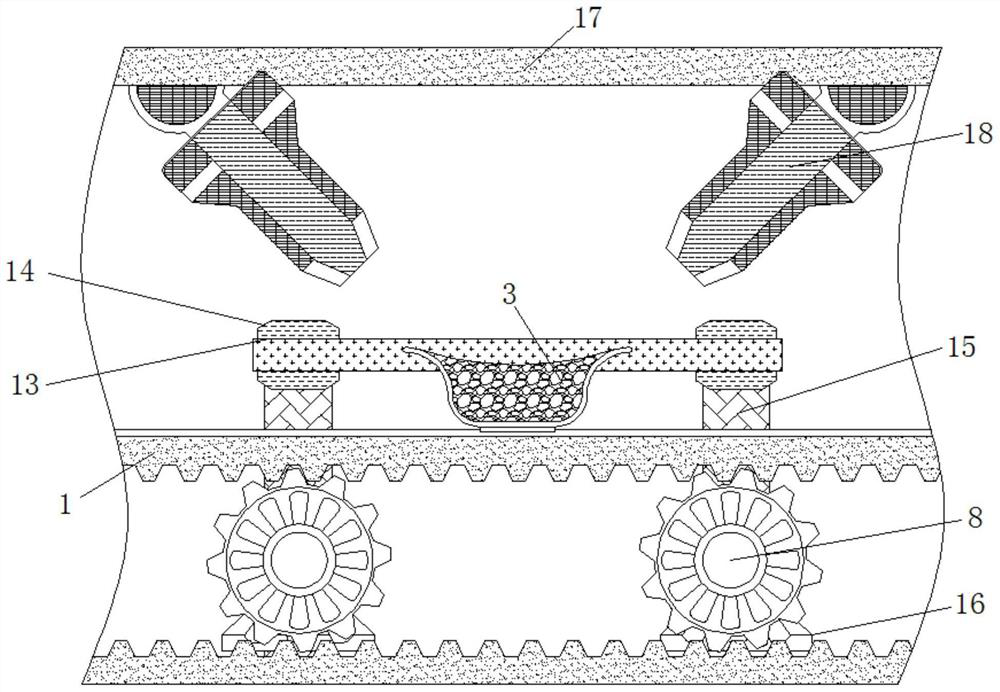

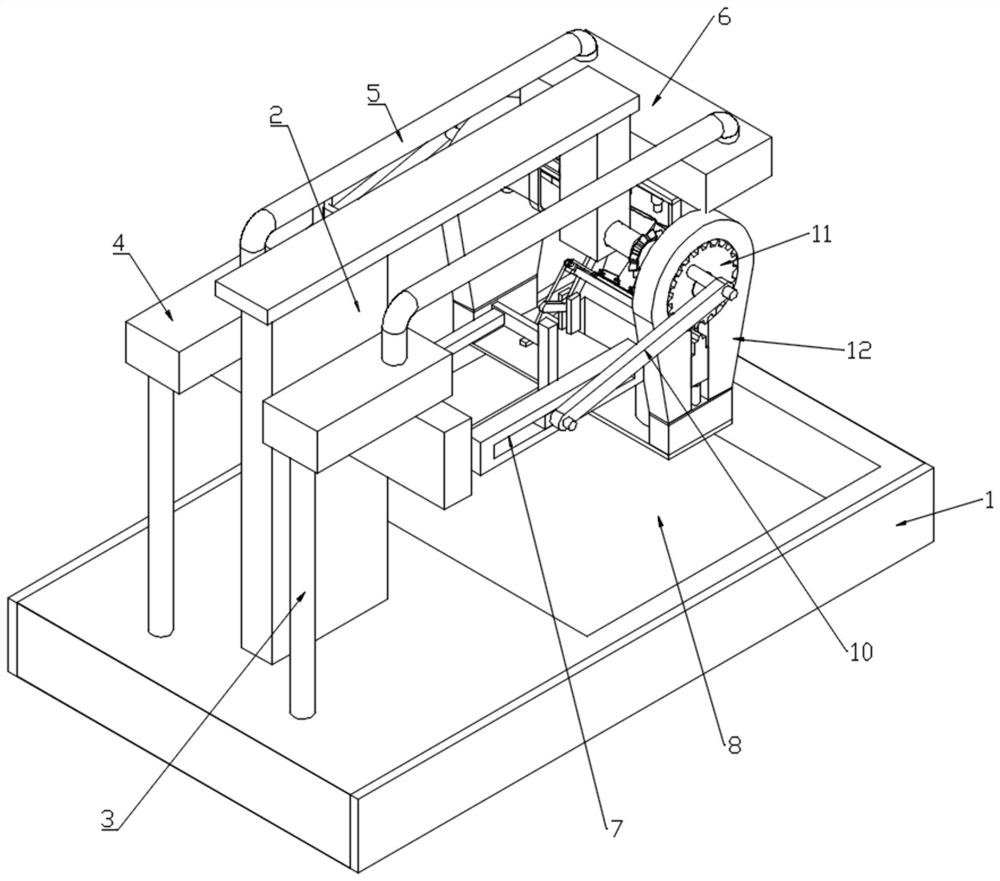

Structural ceramic glazing machine

InactiveCN109747034ANot easy to damageGood glazing effectAuxillary shaping apparatusGear wheelCeramic

The invention relates to the field of structural ceramics, in particular to a structural ceramic glazing machine. The structural ceramic glazing machine has a good glazing effect, good glazing quality, and high work efficiency. The structural ceramic glazing machine includes a machine body, a water inlet pipe, a ring-type spraying head, a first gear, a first sleeving body, a first bearing seat, alifting mechanism, a wiping mechanism, a second rotating shaft, a third sleeving body, a connecting rod, a stirring mechanism, a supporting rod and a frame body, wherein the water inlet pipe is installed on the top of the machine body, and the water inlet pipe extends inside the machine body and is fixedly connected with the ring-type spraying head; the first sleeving body is clamped on the top ofthe machine body and located over the ring-type spraying head; and the first gear is located in the first sleeving body, and through holes are formed in the vertical direction in the two sides of thefirst gear. The structural ceramic glazing machine has the beneficial effects that the glazing effect is good, the glazing quality and the work efficiency are high, and cylinder workblank is not prone to be spoiled.

Owner:夏敬品

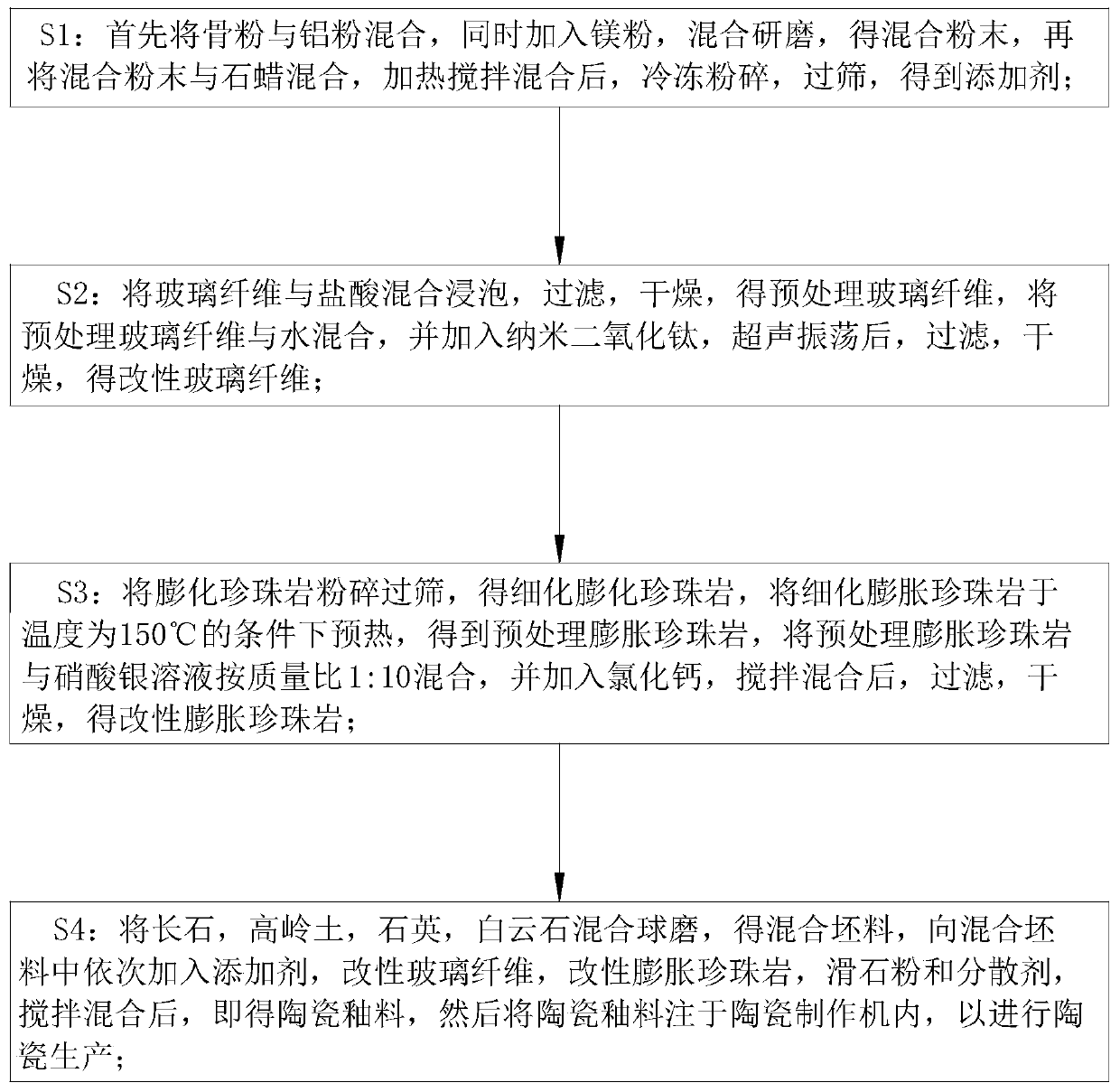

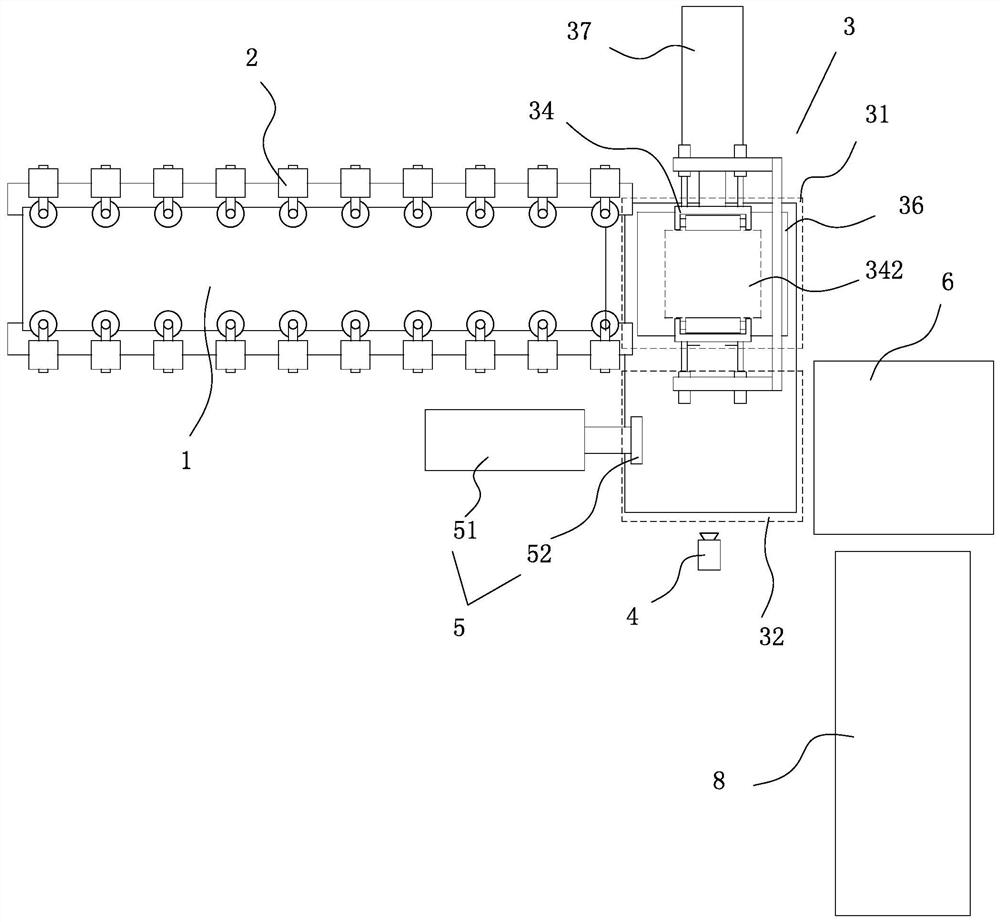

Production process of domestic ceramic

ActiveCN111775288AEasy to spray glaze treatmentImprove stabilityAuxillary shaping apparatusClay mixing apparatusCeramicCeramic materials

The invention discloses a production process of domestic ceramic. In the process, a plain blank is glazed by a glazing device, and the glazing device comprises a circulating feeding device, a ceramicgrabbing device, a glaze spraying device and a ceramic transferring device, wherein the glaze spraying device and the ceramic transferring device are arranged on one side of the circulating feeding device. According to the production process, the plain blank is fixed by the ceramic grabbing device, so that the surface of the plain blank is conveniently subjected to glaze spraying treatment; specifically, the glazed part and the non-glazed part of the plain blank are separated by a limiting separation ring, the ceramic grabbing device clamping the domestic ceramic plain blank is transferred into a working area of the glaze spraying device, and a glaze spray head in the glaze spraying device moves around the circumferential direction of the ceramic, so that the glaze spraying work on the surface of the plain blank is completed, the rotation of the plain blank is avoided, the fixing stability of the plain blank in the glaze spraying work is improved, the influence of the centrifugal forceof the rotation of the plain blank on the distribution uniformity of the glaze is reduced, and the regularity of the joint of the glazed surface and the non-glazed surface of the plain blank and theglazing quality of the glazed surface are improved.

Owner:广东盘古陶瓷原料有限公司

Ceramic self-cleaning glaze

The invention discloses a ceramic self-cleaning glaze. A ground glaze consists of 33 parts of an ultrafine quartz powder, 20 parts of feldspar, 10 parts of wollastonite, 5.5 parts of calcite, 4 parts of dolomite, 3.5 parts of bahrain soil, 6.5 parts of a calcined alumina powder, 2 parts of calcined zinc oxide, 4.5 parts of frit and 13 parts of an ultrafine zirconium silicate powder; an overglaze consists of the components in parts by weight; 38 parts of the ultrafine quartz powder, 24 parts of feldspar, 13 parts of wollastonite, 4 parts of calcite, 3 parts of dolomite, 4.5 parts of bahrain soil, 7 parts of a calcined alumina powder, 1.5 parts of calcined zinc oxide and 4.5 parts of frit; the particle size of the ground glaze is 1-10 microns, and the ground glaze is 0.8-1.2mm in thickness; the particle size of the overglaze is not greater than 10 microns, and the overglaze is 0.2-0.3mm thick; the ground glaze and the overglaze are calcined independently; the start temperature is 145 DEG C, the highest temperature is 1,298 DEG C, and the glazes are cooled to 70-80 DEG C; the calcining time is 12-22 hours. The number of needle holes and the number of cracks on the surface of the ground glaze are small, so that a product is uniform in texture, the surface is fine and bright, and dirt is unlikely to attach.

Owner:南安市荣兴专利技术转移中心有限公司

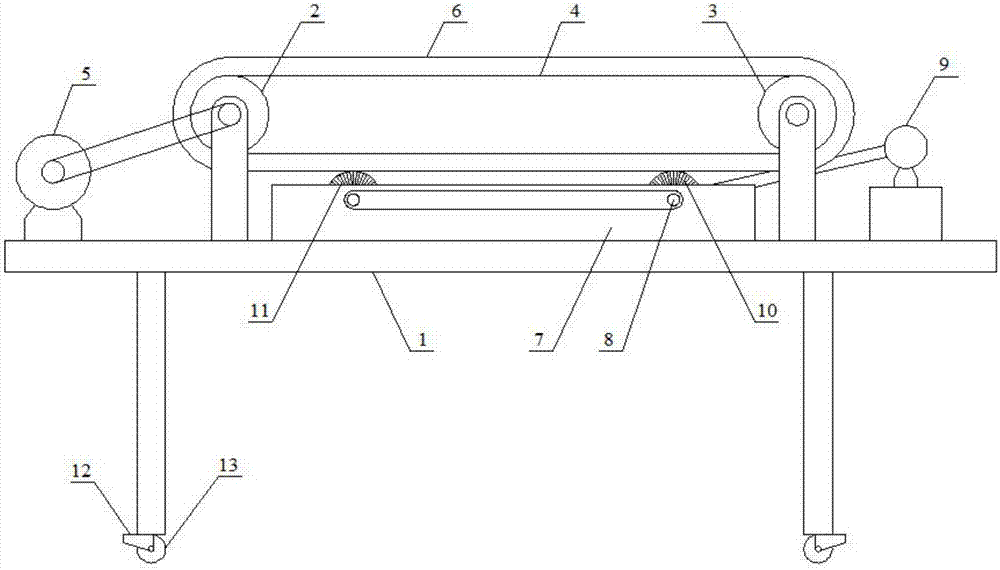

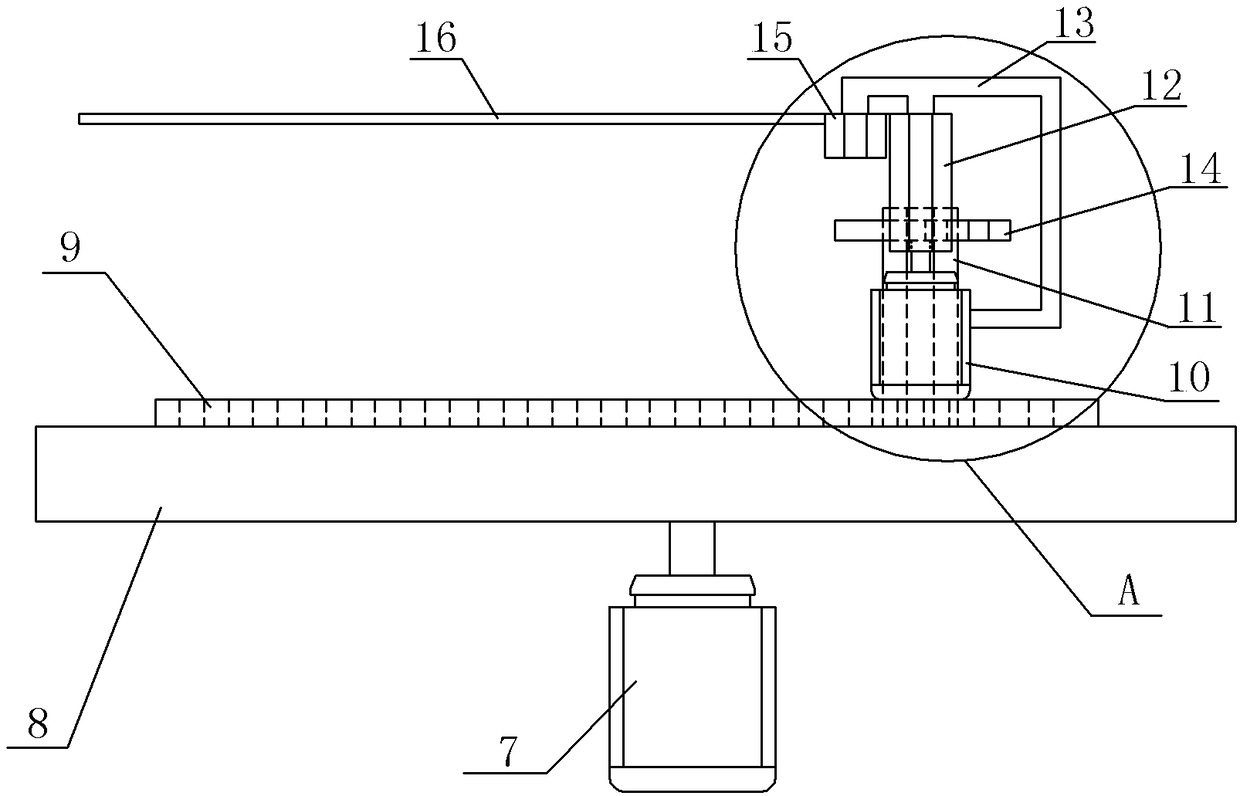

Wiping device for glaze solution on bottom of domestic ceramic glazed blank

InactiveCN107511915AExtended service lifeEasy to replaceCeramic shaping apparatusOrganic non-surface-active detergent compositionsCeramic glazeDrive motor

The invention discloses a wiping device for a glaze solution on the bottom of domestic ceramic glazed blank, and relates to the technical field of domestic ceramic. The wiping device comprises a rack, a wiping mechanism and a cleaning mechanism, wherein the wiping mechanism consists of a first rotary wheel, a second rotary wheel, a conveyor belt which surrounds the first rotary wheel and the second rotary wheel and a first motor for driving the first rotary wheel to rotate; glaze wiping cloth tightly sleeves the conveyor belt; the cleaning mechanism consists of a cleaning slot with a cleaning liquid, a sponge cleaning roller mounted inside the cleaning slot through a roller and a second drive motor for driving the sponge cleaning roller to rotate; the liquid surface of the cleaning liquid in the cleaning slot submerges the roller; when the sponge cleaning roller rotates, the sponge outer wall is in interference contact with the glaze wiping cloth; and a rotation direction of the sponge cleaning roller is reverse to that of the first rotary wheel. According to the wiping device disclosed by the invention, the wiping mechanism is matched with the cleaning mechanism, and bottom wiping work is guaranteed to be orderly performed after the ceramic blank is applied with glaze, so that glaze applying quality of the ceramic blank is improved.

Owner:安徽省德邦瓷业有限公司

Fluorescent glaze, ceramic product prepared from same and method for preparing ceramic product

The invention belongs to the technical field of ceramic decoration and discloses fluorescent glaze, a fluorescent ceramic product prepared from the same and a method for preparing the product. The fluorescent glaze is prepared from fluorescent powder, borax and a proper amount of glass powder and zinc oxide, wherein the glass powder is obtained by grinding waste colorless ordinary glass. On the one hand, the recycling value of the waste glass is improved, the production cost is reduced, and the economic benefit is increased. On the other hand, the glass has quite stable chemical properties andthermal stability by one-time high-temperature solid phase treatment and is not prone to reaction with other components in the raw materials. Besides, borax can also reduce erosion of other components to the fluorescent powder in a high temperature environment and improves stability of fluorescent glaze.

Owner:彭远焜

Method for carrying out local UV varnishing on printed product

InactiveCN109895498AImprove stabilityIncreased durabilityPolyurea/polyurethane coatingsEpoxy resin coatingsElectrical and Electronics engineeringLight curing

The invention discloses a method for carrying out local UV varnishing on a printed product, and belongs to the technical field of printing. The method comprises the following steps that firstly, a diecutting plate is manufactured according to the range, needing local varnishing, of the printed product, and then is installed on the die-cutting machine, the pressure of the die-cutting machine is adjusted to perform die-cutting on varnishing rubber cloth composed of five-layer structure so as to cut off the area corresponding to the non-varnishing part in the printed product, only the varnishingarea is left, during die cutting, only top three layers of the rubber cloth are die-cut, and the bottom two layers are kept complete; then, the cut varnishing rubber cloth is installed on a printingplate roller of a local varnishing machine; then the local varnishing machine is started, the varnishing rubber cloth is used for coating the area, where needs to be locally varnished, of the printedproduct with UV varnishing oil; and finally, a UV light curing instrument is used for curing the varnished printed product. The method is simple, and the varnishing quality of the printed product canbe improved.

Owner:SHANGHAI PUDONG HUANGGONG PRINTING

Ceramic glaze and ceramic

InactiveCN111196677AAvoid flowShort adsorption timeCeramic shaping apparatusElectric machineryMaterials science

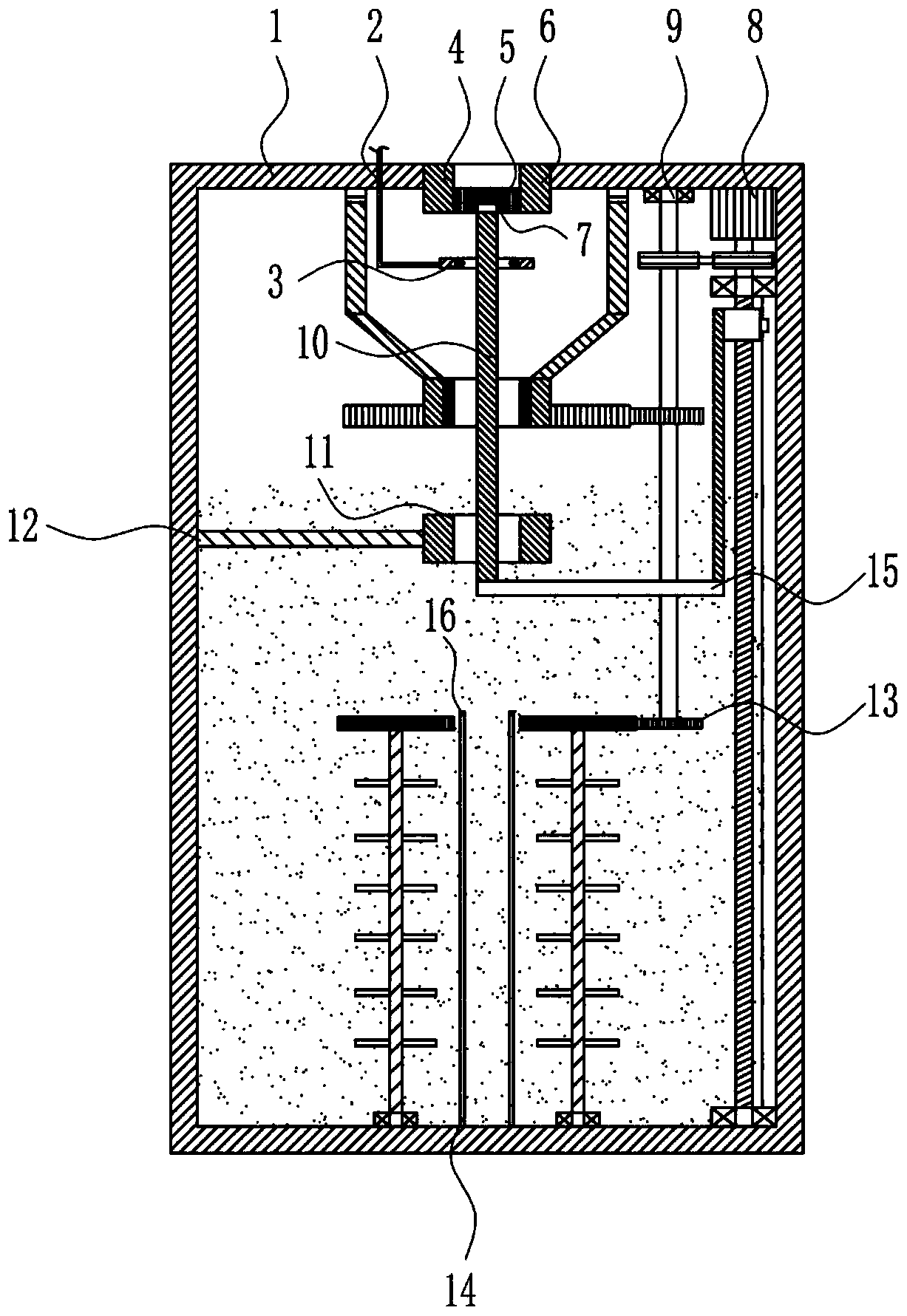

The invention belongs to the technical field of ceramic manufacturing, and particularly relates to a ceramic glaze and ceramic. A bottom plate, an upper die and a suction plate are arranged. The uppersurface of the bottom plate is fixedly connected with a lower die; a top plate is arranged above the bottom plate; the lower surface of the top plate is in left-right sliding connection with a firstsliding block; the lower surface of the first sliding block is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a first telescopic rod; the lower surface of the first telescopic rod is fixedly connected with the upper die; a second sliding block is fixedly connected to the position, on the right side of the first sliding block, in the sliding groove; the lower surface of the second sliding block is fixedly connected with a second motor; an output shaft of the second motor is fixedly connected with a second telescopic rod; and the suction plateis fixedly connected to the lower surface of the second telescopic rod. By means of the ceramic glaze and the ceramic making machine used in the ceramic glaze processing process, integrated productionof ceramic forming and glazing is achieved, the structure is simple, the production efficiency and the automation degree are high, and the equipment investment cost can be effectively reduced.

Owner:杨宁东

Ceramic processing device

ActiveCN111688005ASmooth glazeImprove glazing qualitySpraying apparatusCeramic shaping apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of ceramic processing equipment, in particular to a ceramic processing device. The device comprises a conveying mechanism, a limiting mechanism, a liftingmechanism, a protection mechanism, closing mechanisms, spraying mechanisms, a liquid supply mechanism and a telescopic tube mechanism, the limiting mechanism is fixedly connected to the right side ofthe upper end of the conveying mechanism, the lifting mechanism is arranged in the middle of the conveying mechanism, the protection mechanism is fixedly connected to the middle of the upper end of the conveying mechanism, two closing mechanisms are slidably connected to the front and rear ends of the protection mechanism respectively, two spraying mechanisms are diagonally fixedly connected to the top end inside the protection mechanism, the liquid supply mechanism is fixedly connected to the left end of the protection mechanism, the telescopic tube mechanism is fixedly connected to the upperend of the protection mechanism, and the two ends of the telescopic tube mechanism are fixedly connected with the two spraying mechanisms and the liquid supply mechanism respectively, so that glazingof ceramics is more uniform, and glazing quality of the ceramics is improved, at the same time, the concentration of glaze liquid during processing is maintained, the quality of ceramic products is improved, and processing efficiency of ceramic glazing is further improved.

Owner:扬州科丰高新产业投资开发集团有限公司

Self-cleaning antibacterial glaze used for sanitary ceramic ware

The invention discloses a self-cleaning antibacterial glaze. A bottom glaze comprises the following components: 32.75 parts of quartz powder, 20.05 parts of feldspar, 10 parts of wollastonite, 5.5 parts of calcite, 4 parts of dolomite, 3.5 parts of Balin soil, 6.5 parts of alumina powder, 2 parts of zinc oxide, 4.5 parts of frit, and 12.75 parts of zirconium silicate powder; a cover glaze comprises the following components: 38 parts of quartz powder, 23.75 parts of feldspar, 12.75 parts of wollastonite, 4 parts of calcite, 3 parts of dolomite, 4.5 parts of Balin soil, 7 parts of alumina powder, 1.5 parts of zinc oxide, 4.5 parts of frit, 0.8 part of antibacterial agent A, and 0.2 part of antibacterial agent B; the bottom glaze has the grain size of between 1 and 10 micrometers and the thickness of between 0.8 and 1.0mm; the cover glaze has the grain size of between 1 and 10 micrometers and the thickness of between 0.2 and 0.3mm; and the bottom glaze and the cover glaze are separately fired, the initial temperature is 148DEG C, the highest temperature is 1,198DEG C, the cooling temperature is 80DEG C, and the firing time is 12 to 21 hours. The glaze layer of the bottom glaze has less pinholes and cracks, and the prepared product has the advantages of homogenized texture, smooth and bright surface and difficult dirt attachment.

Owner:TANGSHAN MONOPY CERAMIC

A kind of production technology of daily-use ceramics

ActiveCN111775288BEasy to spray glaze treatmentImprove stabilityAuxillary shaping apparatusClay mixing apparatusCentrifugal forceCeramic glaze

The invention discloses a production process of daily-use ceramics. In the process, a glazing device is used to perform glazing treatment on a plain embryo. The glazing device includes a circulation feeding device, a ceramic grasping device, a glaze spraying device installed on one side of the circulation feeding device, and a ceramic Transfer device; the present invention fixes the plain embryo through a ceramic grasping device, so as to facilitate the glaze spraying treatment on the surface of the plain embryo. Specifically, the glazed part and the non-glazed part of the plain embryo are separated by a limit separation ring , transfer the ceramic grasping device holding the daily-use ceramic blank to the working area of the glaze spraying device, and the glaze nozzle in the glaze spraying device moves around the ceramic to complete the glaze spraying work on the surface of the blank. Avoid the rotation of the blank, improve the stability of the blank during the glaze spraying work, and also reduce the influence of the centrifugal force of the blank rotation on the uniformity of the glaze distribution, and improve the regularity of the junction of the glazed surface and the unglazed surface on the surface of the blank And the glaze quality of the glazed surface.

Owner:广东盘古陶瓷原料有限公司

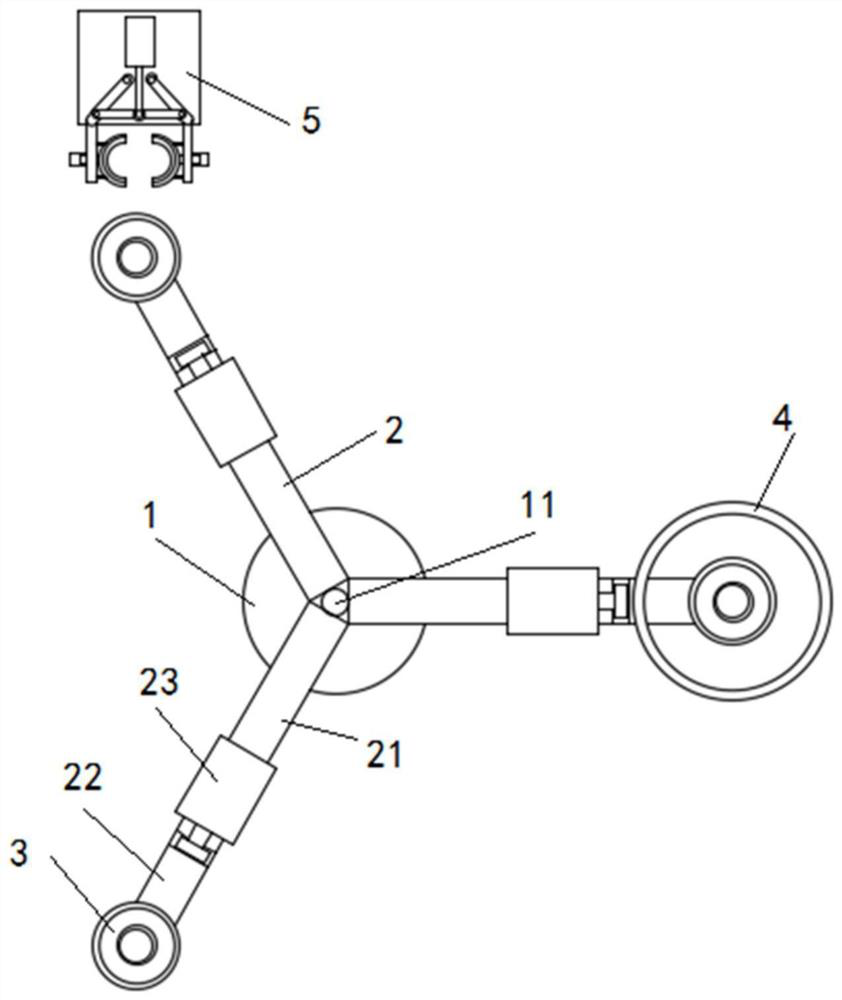

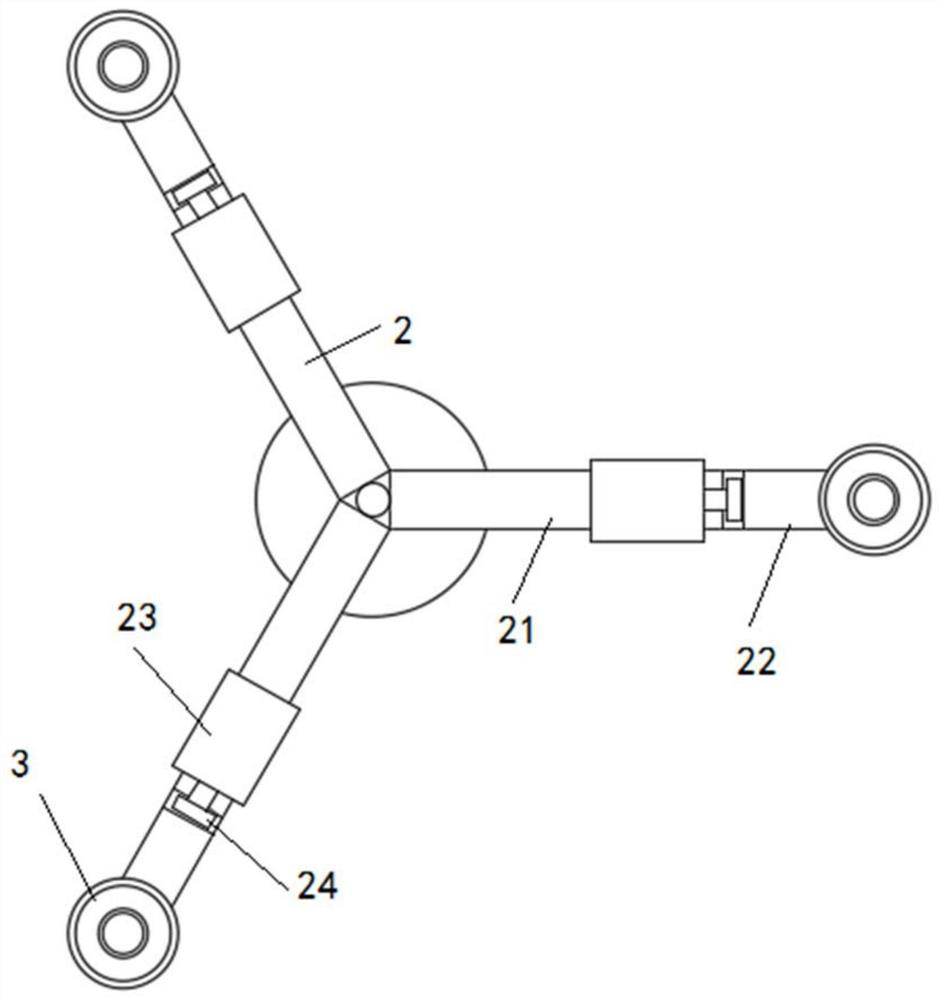

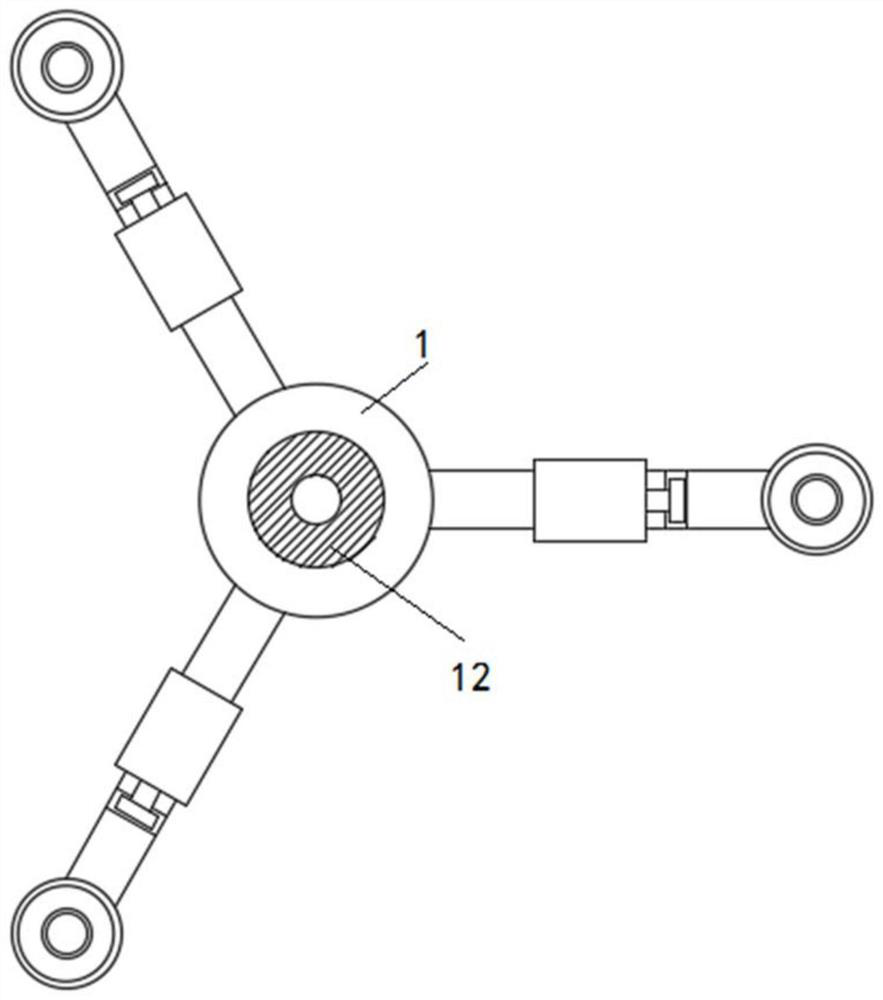

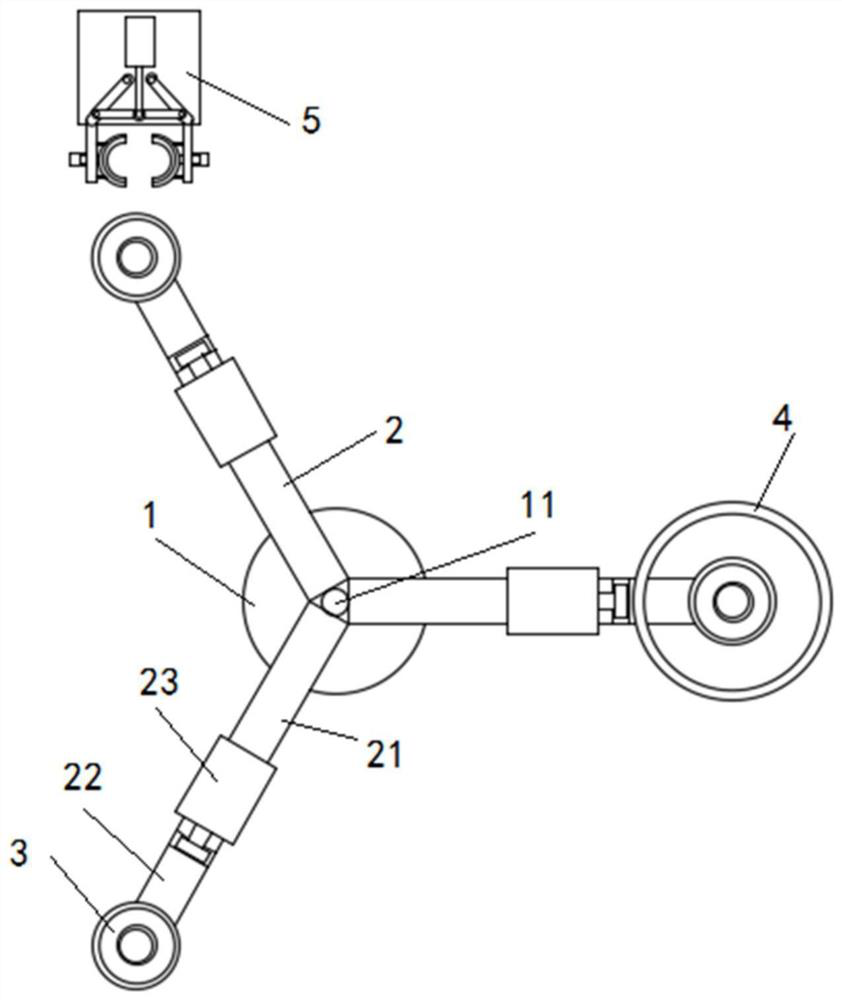

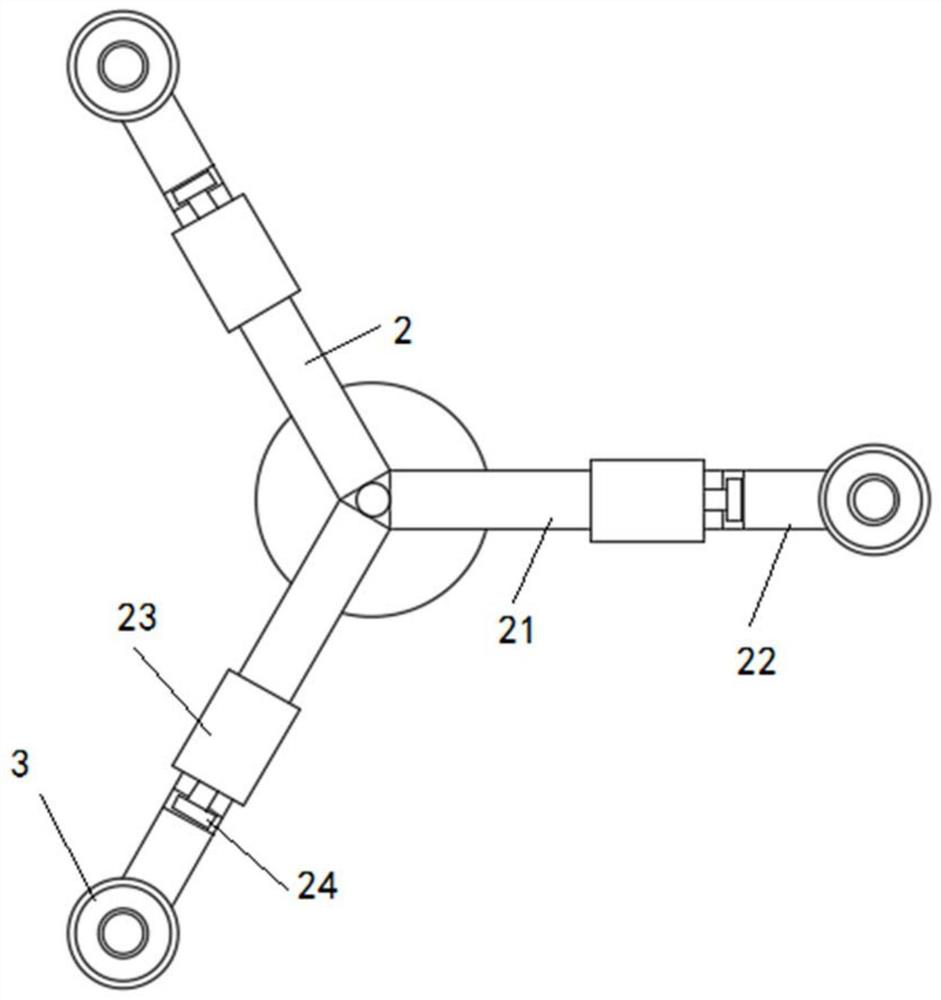

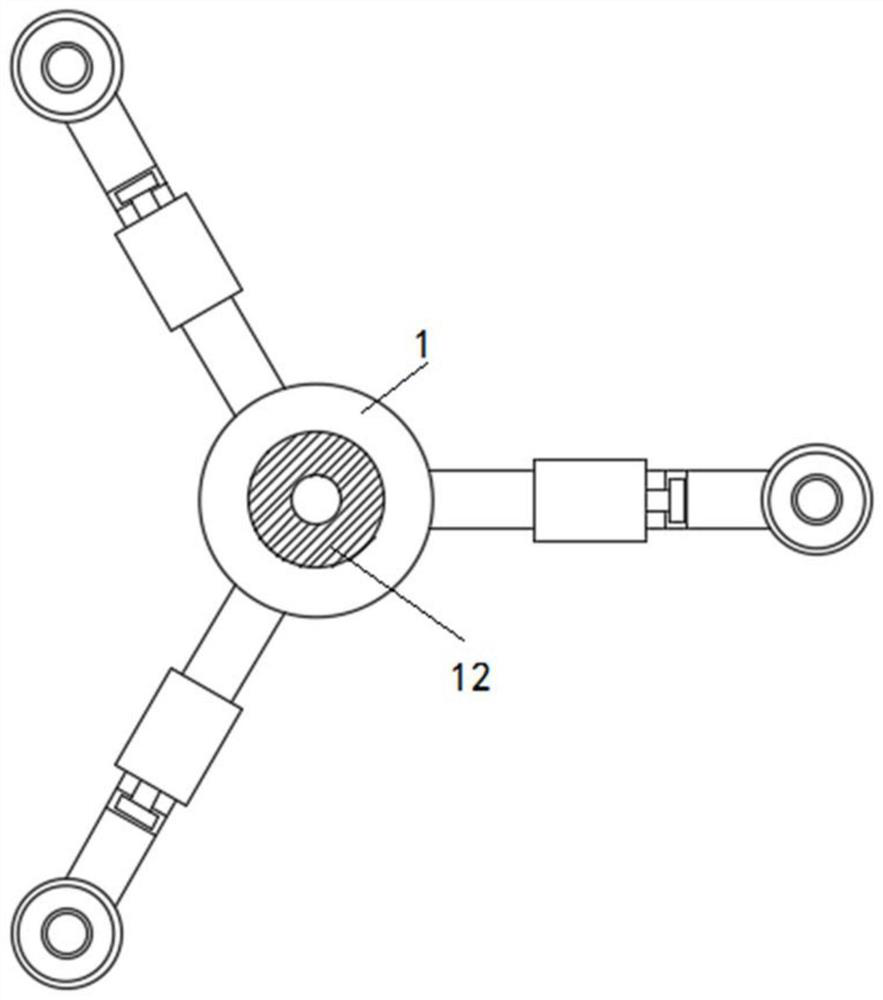

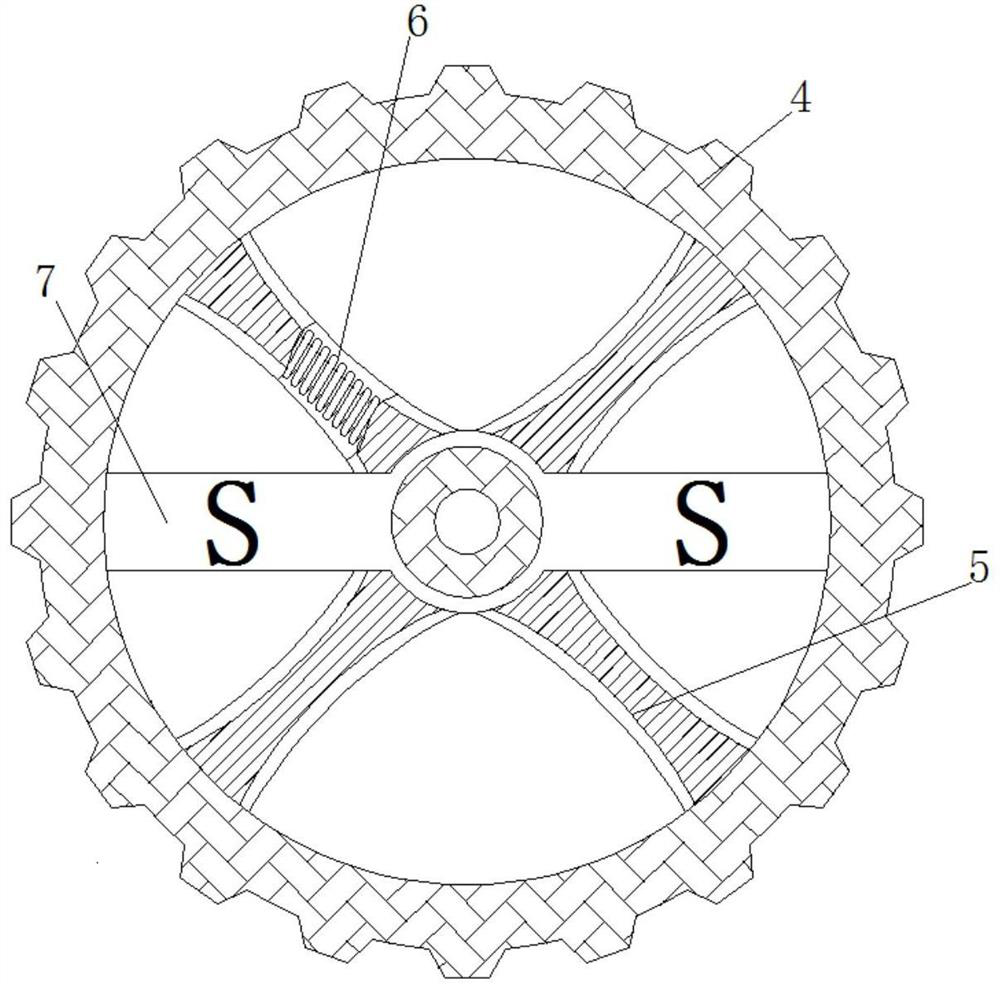

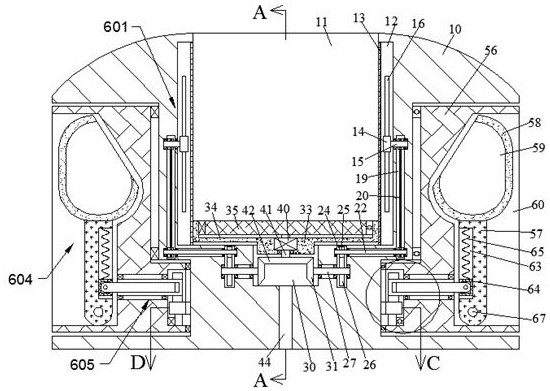

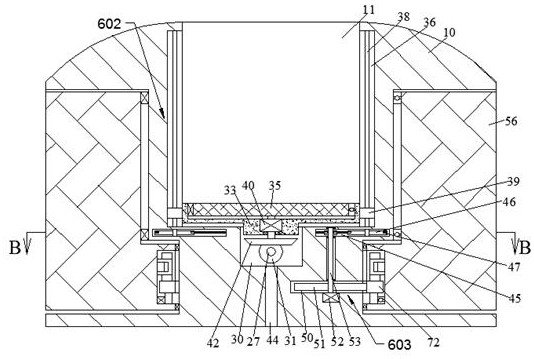

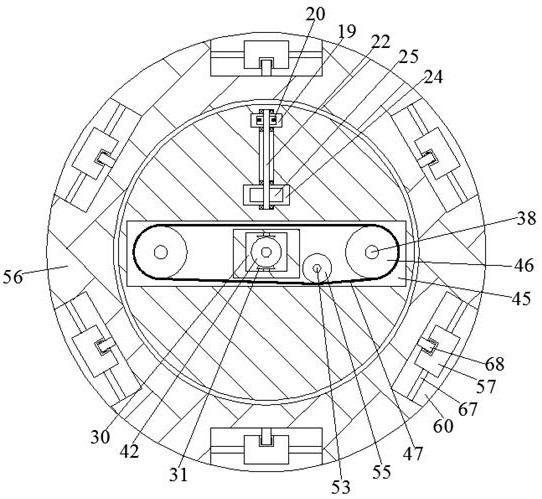

A Uniformly Glazed Ceramic Structure Using Lenz's Law

ActiveCN112318689BEvenly glazed structureSmooth glazeAuxillary shaping apparatusTransmission beltStructural engineering

Owner:安徽磐盛新型材料科技有限公司

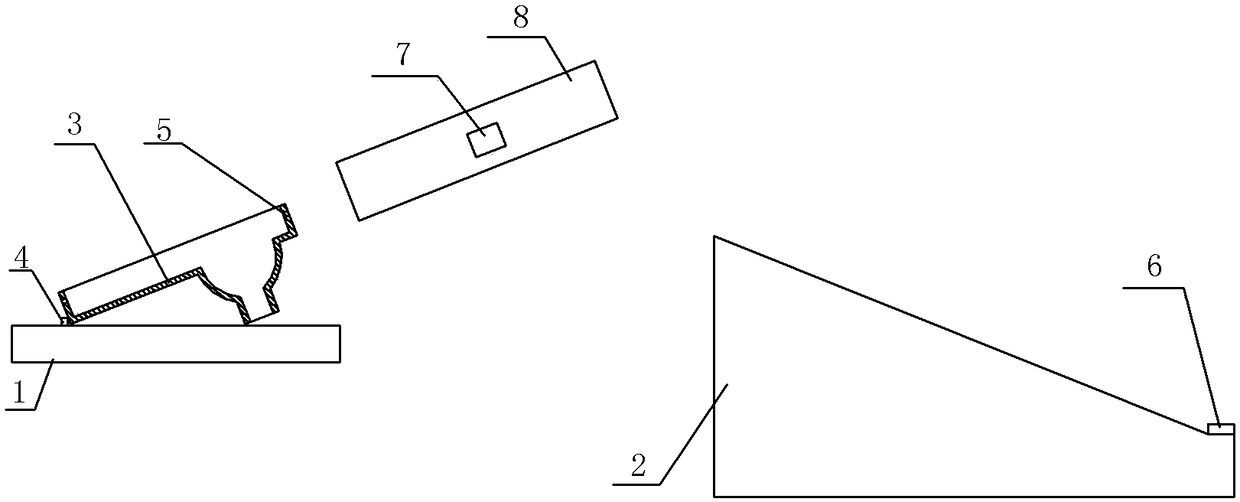

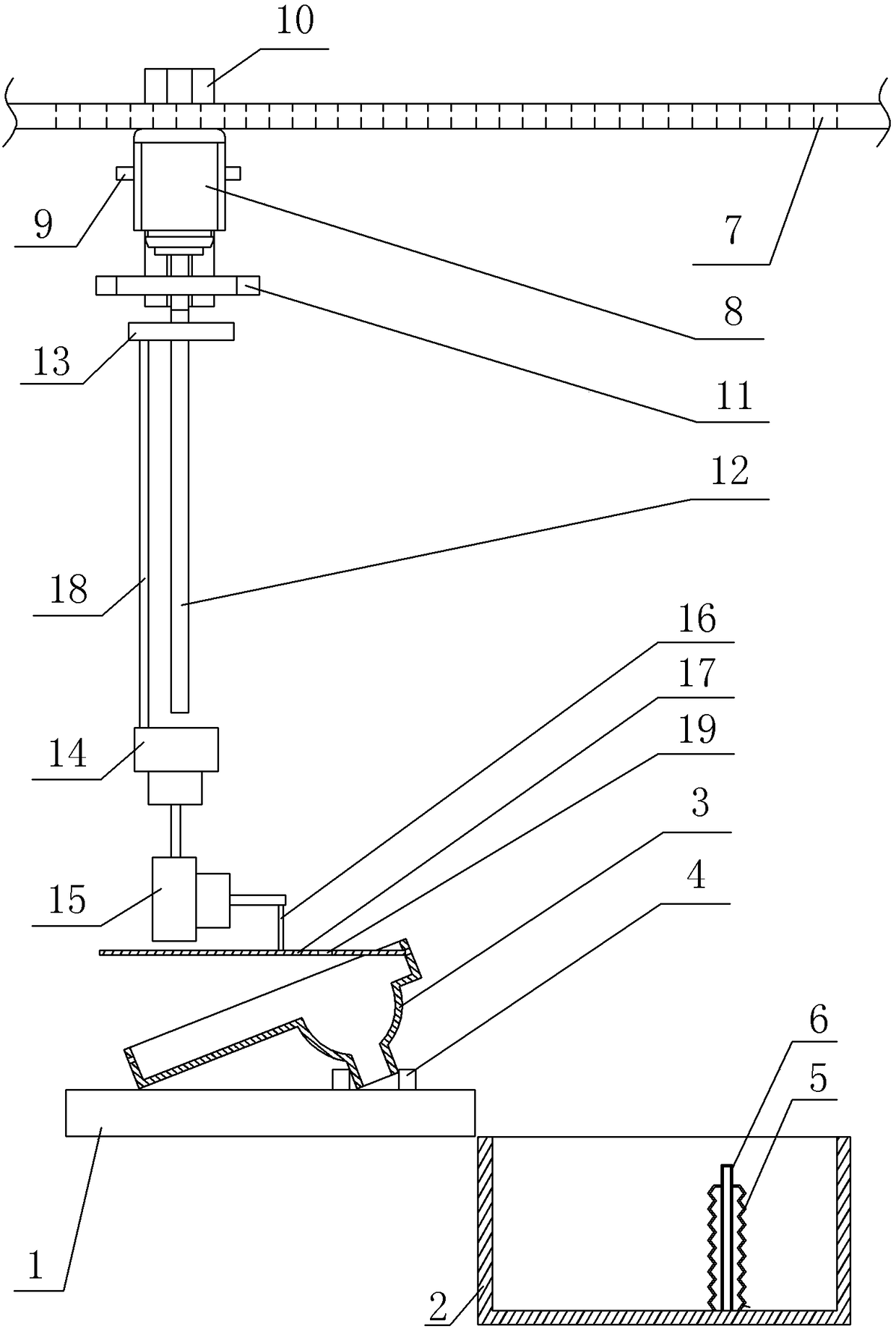

Sanitary ware glazing process

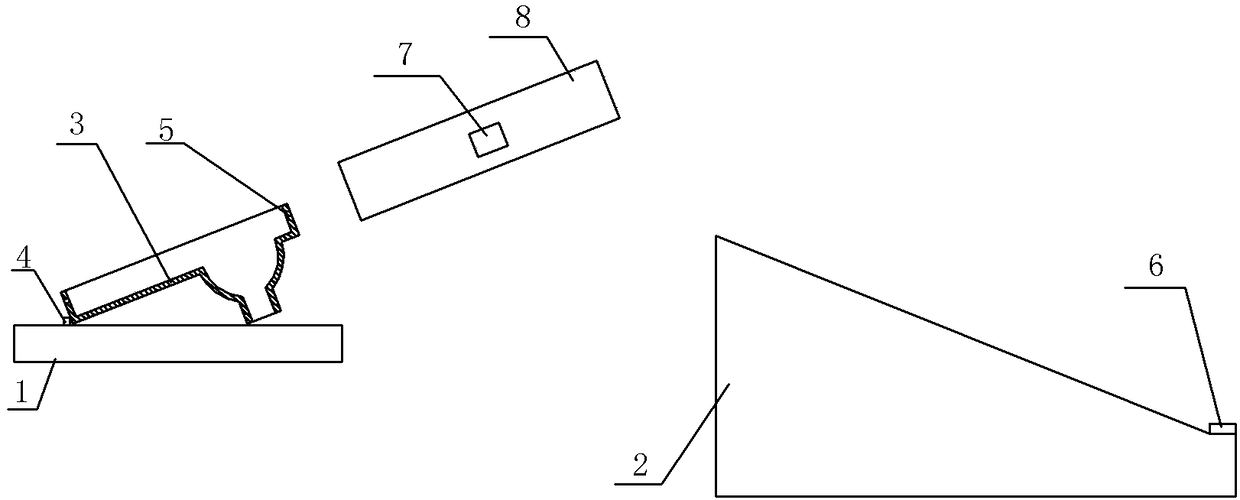

ActiveCN108383547AImprove glazing qualityTroubleshooting Damaged Glaze LayersEngineeringTransfer mechanism

The invention relates to the field of ceramic processing, in particular to a sanitary ware glazing process. The process comprises the following steps: 1, preparing a sanitary ware glazing device comprising a conveyor belt, a spray gun, a transfer mechanism, a dryer and a support table; 2, enabling a squatting pan to be contacted with the transfer mechanism when the squatting pan is transmitted onthe conveyor belt; 3, spraying glaze onto the outer side of the squatting pan by using the spray gun in a process of the transfer mechanism driving the squatting pan to leave from the conveyor belt; 4, drying the squatting pan by using dryer in a process of the transfer mechanism driving the squatting pan to rotate; 5, transferring the squatting pan onto the support table, and then collecting. After the technical scheme is adopted, the all-directional glazing of the squatting pan can be realized at one time.

Owner:CHONGQING CONCAST SANITARY WARE

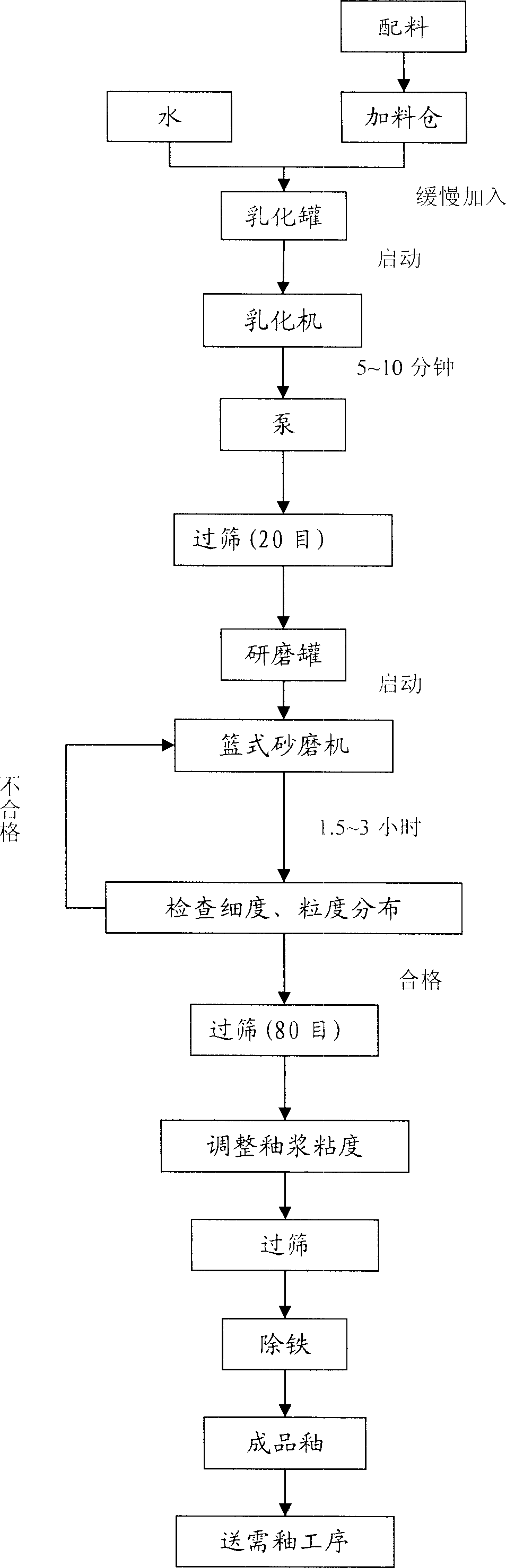

Process for preparing glaze for electric porcelain using basket type sand mill as main body

The invention relates to a method for preparing electric ceramic glaze, especially a method for using basket grinder as main device. Wherein, the inventive method comprises that using shearing emulsifier to emulsify for 5-10min, making slurry, grinding with basket grinder for 1.5-3h, when reaches demands, adding water to adjust the viscosity and density, screening, removing iron, to obtain the final glaze. The invention replaces ball grinder with basket grinder, to reduce the energy consumption (only 40% of ball grinder), and improve efficiency more than 6-10 times, with stable components and high quality.

Owner:HUNAN UNIV

Ceramic automatic mechanical equipment based on vector control

PendingCN114789503ABuild a three-dimensional structureAchieve orientationAuxillary shaping apparatusControl vectorControl system

The invention relates to the field of ceramic production equipment, in particular to ceramic automatic mechanical equipment based on vector control, and mainly solves the problems that in the prior art, ceramic glaze spraying efficiency is low, and the surface is prone to overflow. Comprising a rack, a control system arranged on the rack, an input conveying belt, guide assemblies, a transfer assembly, a surface pretreatment assembly, a material pushing assembly, a glaze spraying box, a glaze spraying assembly and an output conveying belt, the guide assemblies are arranged on the two transverse sides of the input conveying belt, and the transfer assembly is arranged at the output end of the input conveying belt 1; the transferring assembly is provided with a temporary storage station and an identification station, the pushing assembly is arranged at the output end of the transferring assembly, the glaze spraying box is arranged at the output end of the pushing assembly, a second supporting platform and a third driving motor connected with the second supporting platform are arranged in the glaze spraying box, and the glaze spraying assembly is arranged in the glaze spraying box and located on the upper side of the second supporting platform; the output conveying belt is arranged at the output end of the glaze spraying box.

Owner:晋江捷兴机械有限公司

Lead- and zinc-free transparent fritted glaze

A fritted glaze without Pb and Zn for ceramics contains SiO2, Al2O3, CaO, MgO, K2O, Na2O, SrO, Li2O, B2O3, Fe2O3, Bi2O3 and Y2O3 proportionally. Its advantages are high adhesion, smooth and bright surface, and gay color.

Owner:JIANGSU BAIFU TECH CO LTD

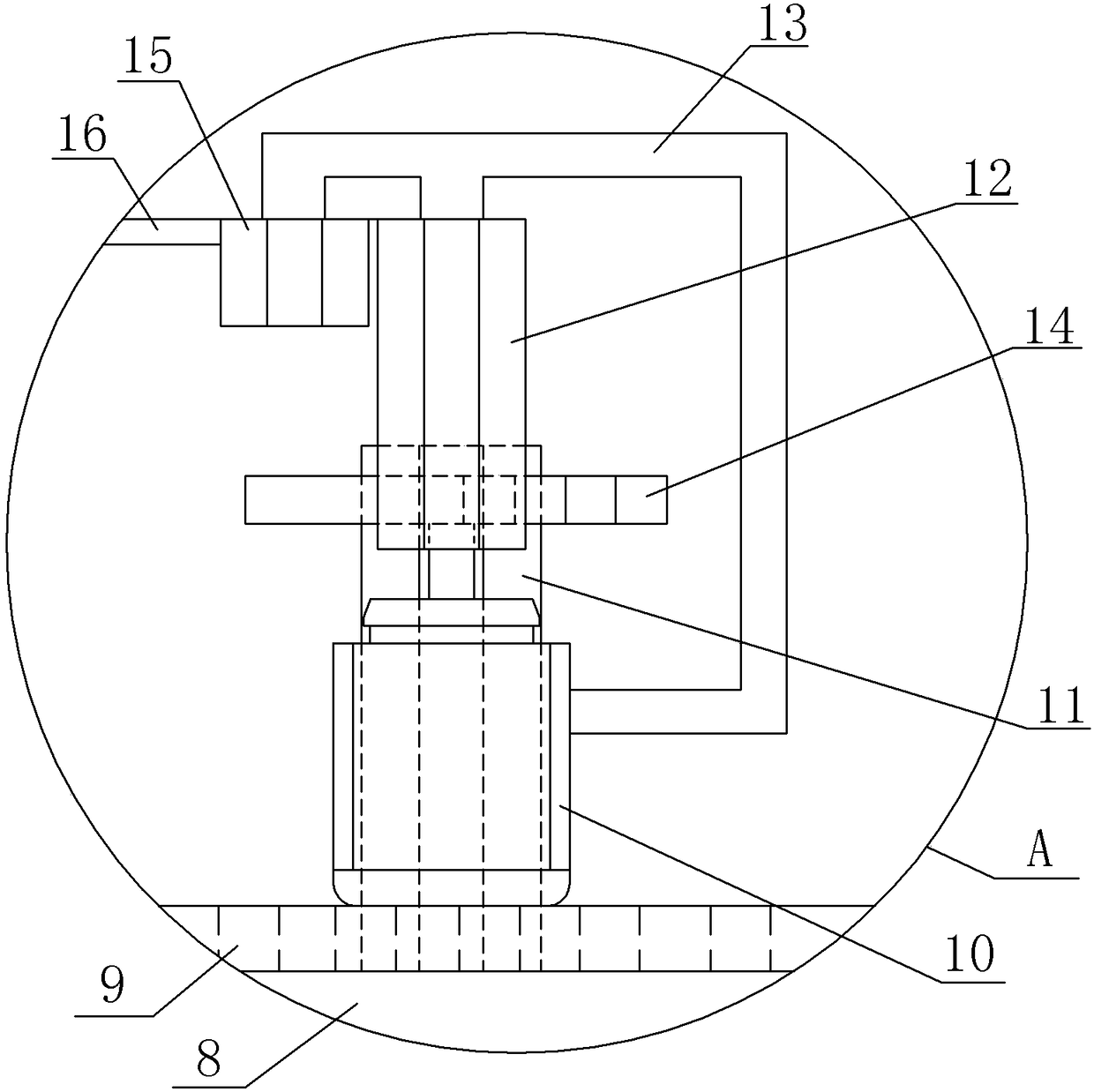

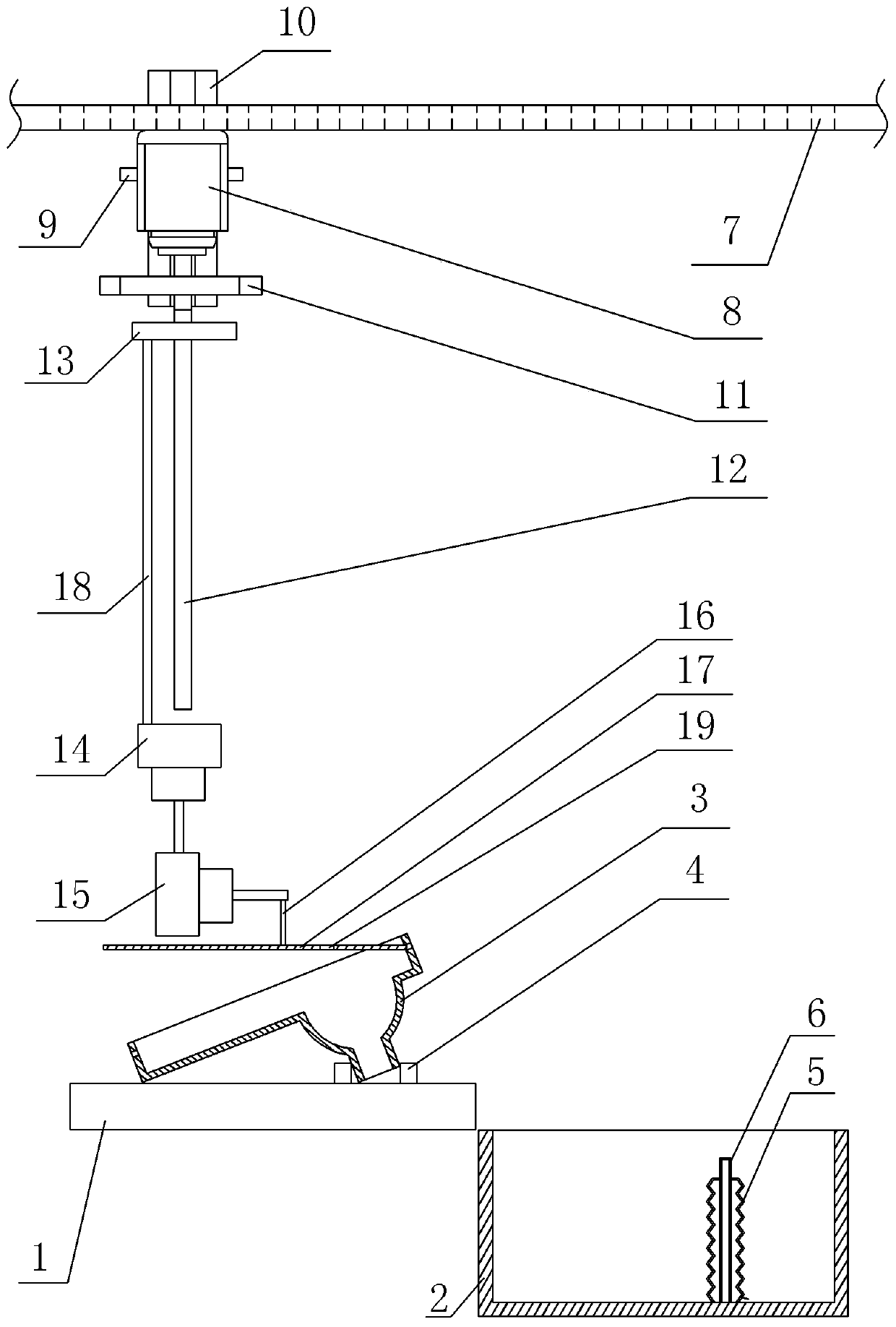

Lifting oil disc device

ActiveCN101537730BEasy to operateFully automatedPrinting press partsAutomatic controlMovement control

The invention discloses a lifting oil disc device. The lifting oil disc device is connected with a fully automatic glazing machine and comprises an automatic control device, a lifting and movement control device connected with the automatic control device, an oil disc lifting device controlled by the lifting and movement control device, and an oil disc moving device controlled by the lifting and movement control device. The lifting oil disc device has the advantages of convenient operation and convenient outward movement of the lifting oil disc, and can periodically clean the lifting oil disc, ensure the cleanness of the liftable oil disc, improve the glazing quality and prolong the service life of an oiling rubber roll of the full automatic glazing machine.

Owner:SHANGHAI DRAGON PRINTING MACHINERY

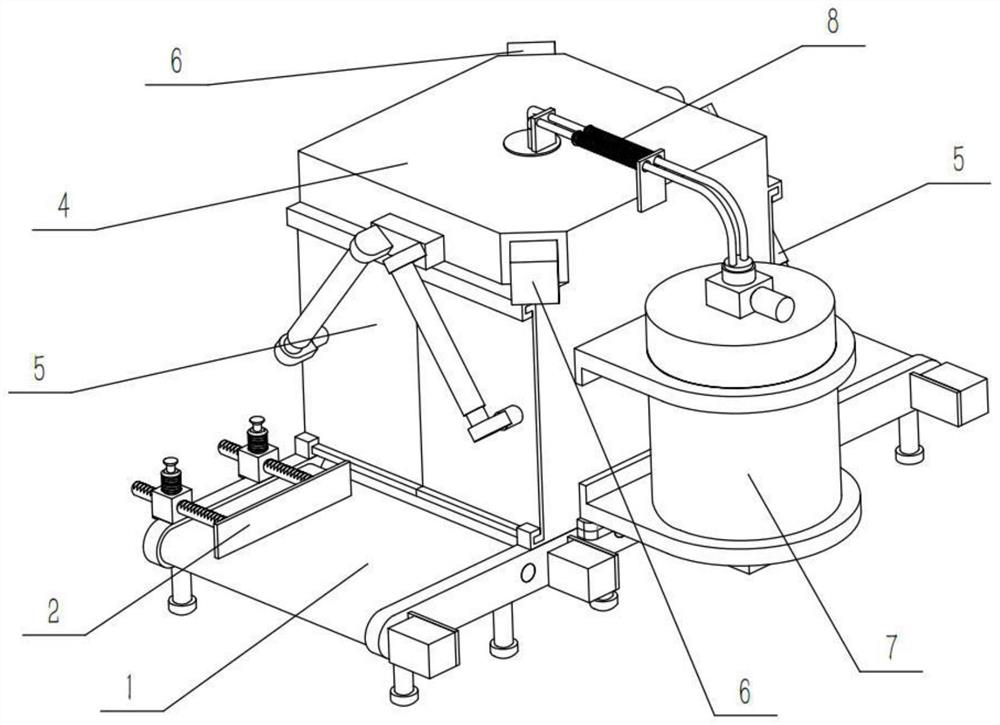

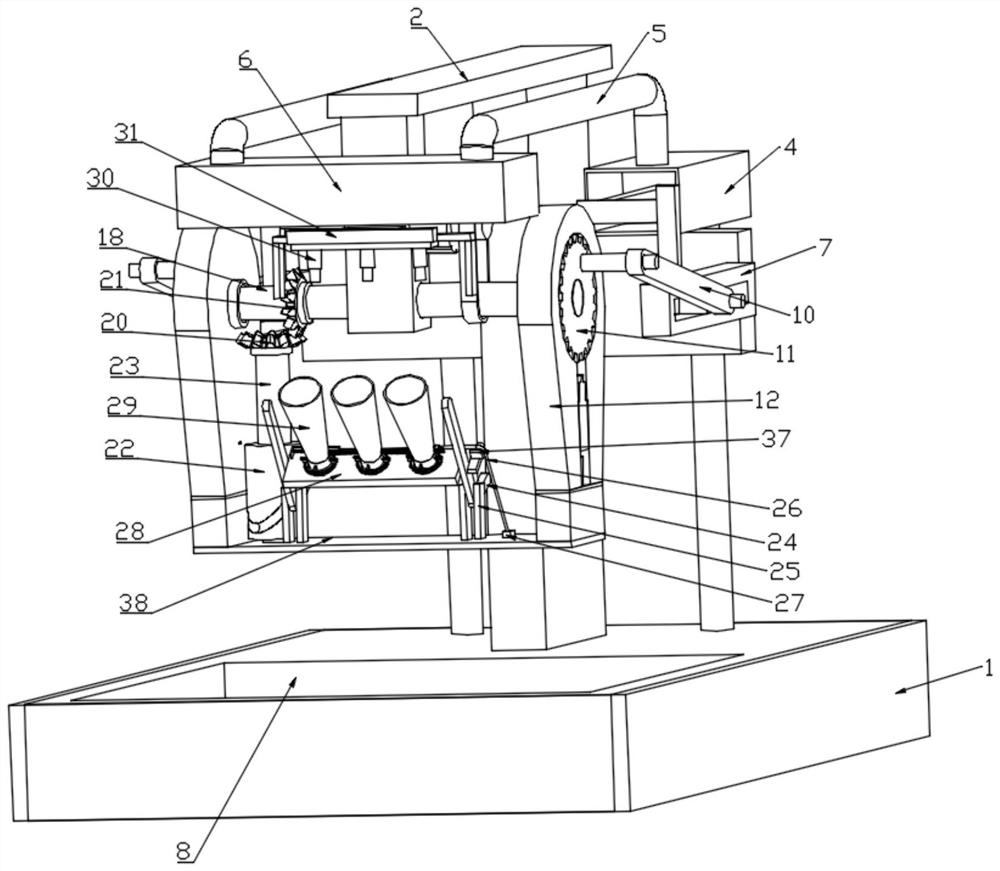

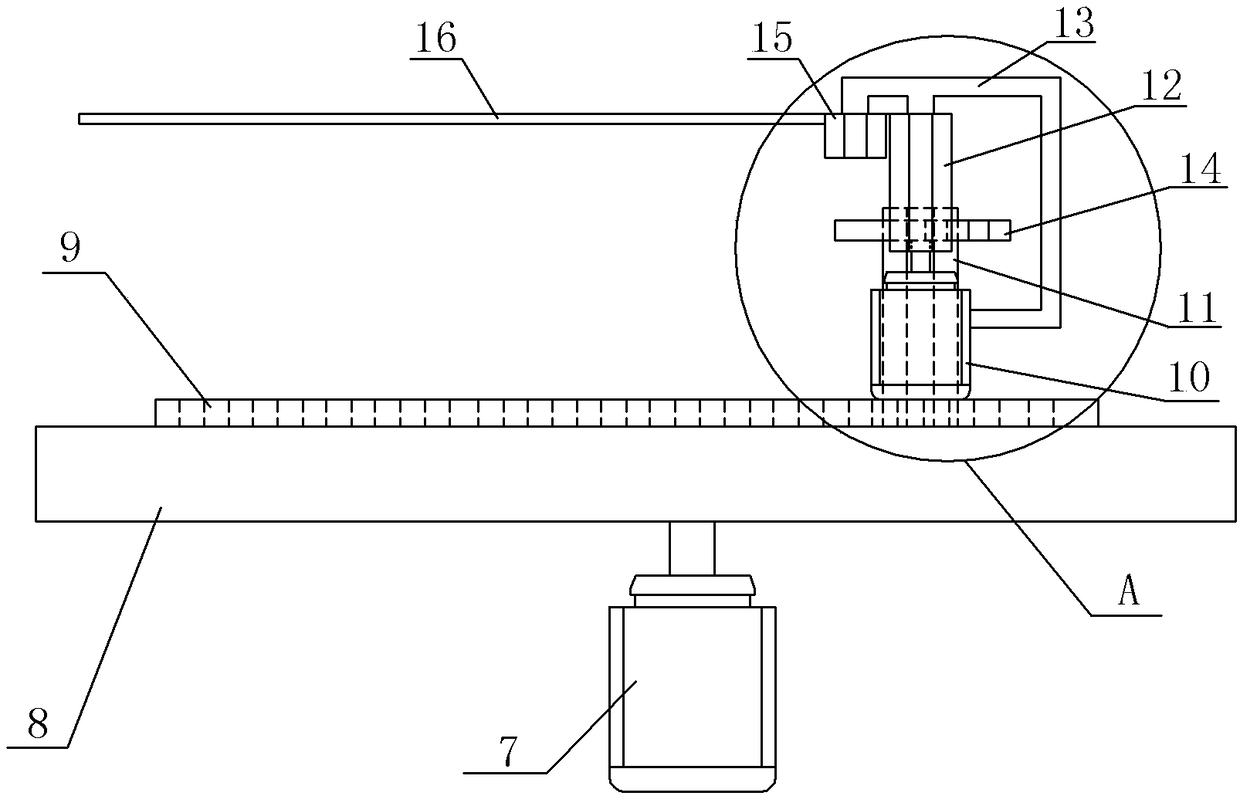

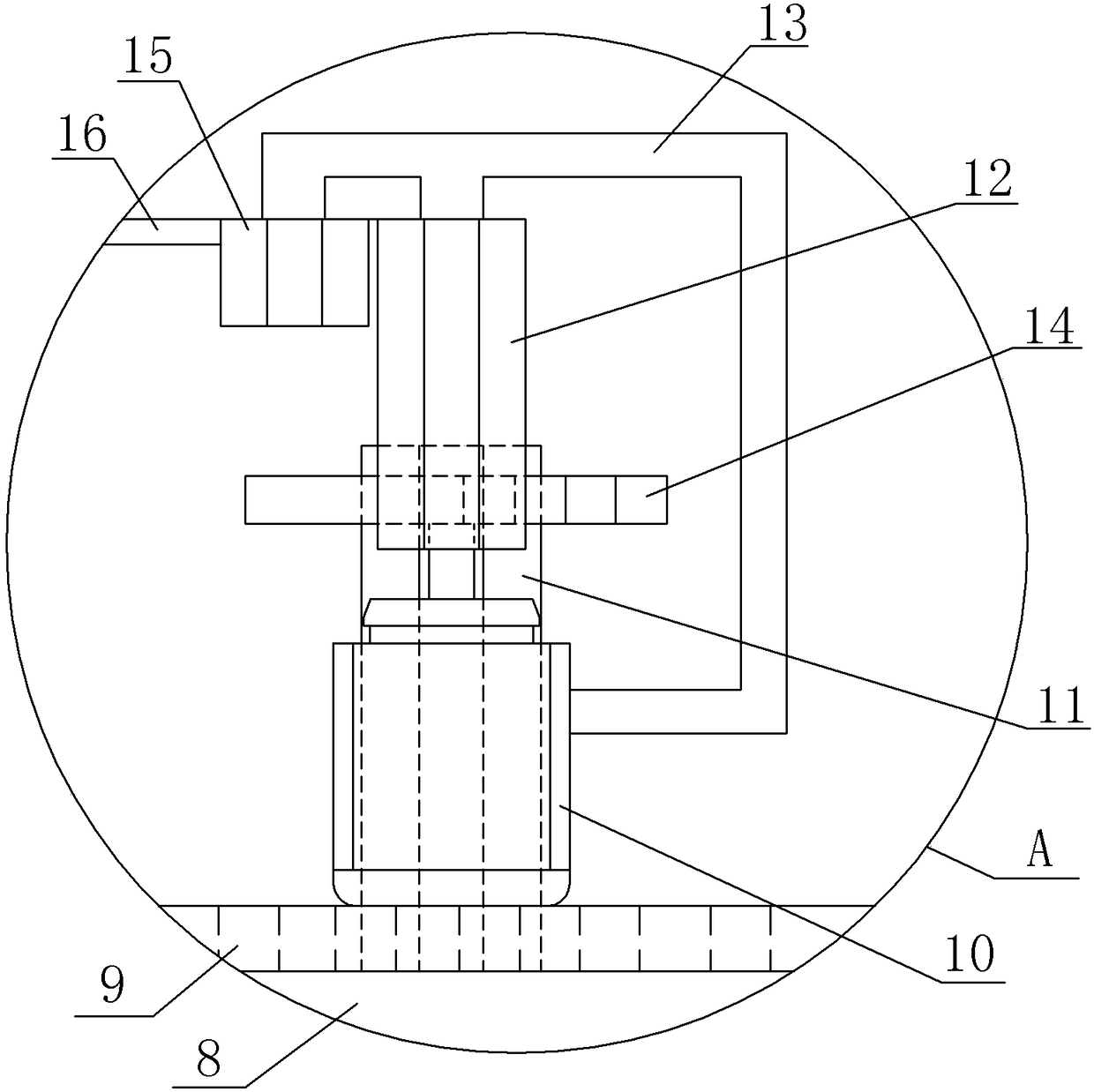

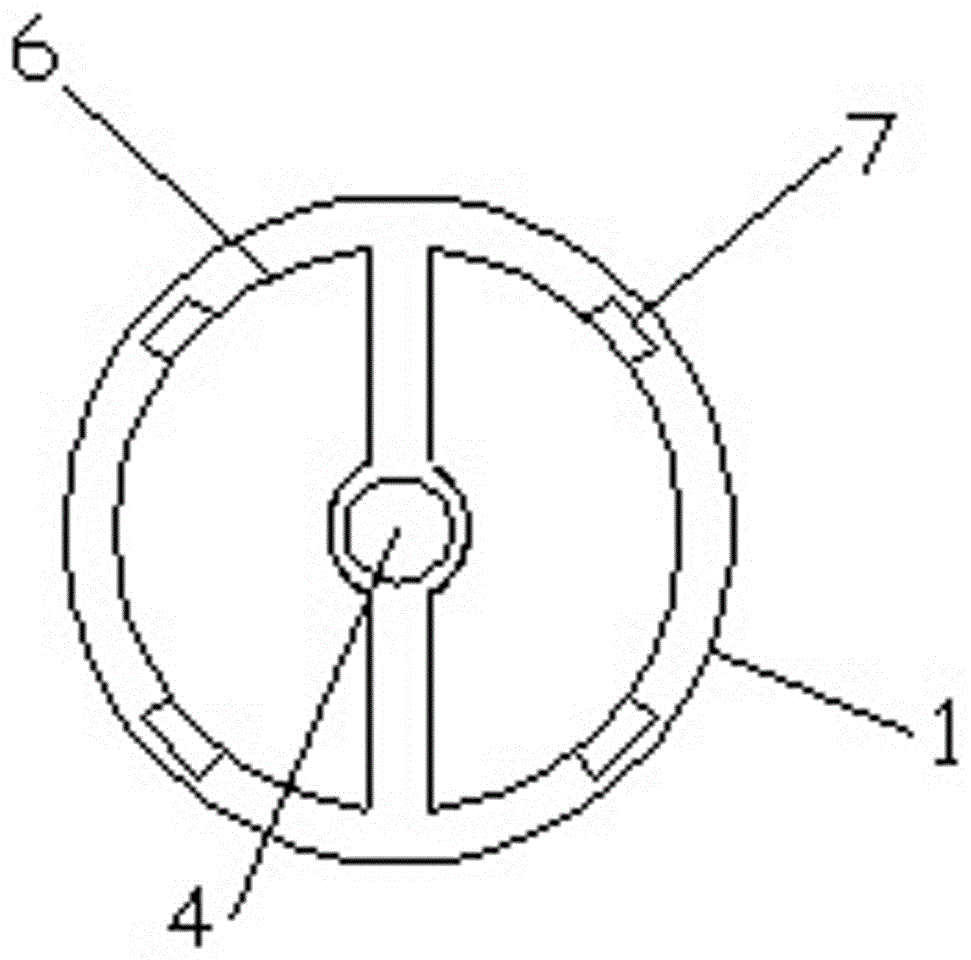

A device for spraying glaze powder

ActiveCN108858708BImprove glazing qualityImprove spraying effectCeramic shaping apparatusPowder SprayPhysics

The invention discloses a device for spraying glaze powder, which comprises a casing, a supporting shaft, a clamping assembly, a power mechanism, a supporting tube, a plurality of spray heads, and a feeding mechanism. The supporting shaft is located in the casing and connected to the casing in rotation; The component is located in the housing and installed on the support shaft; the power mechanism is used to drive the support shaft to rotate; the support tube is located in the housing and above the clamping assembly, the support tube is connected to the housing, and the support tube is connected to the feeding mechanism; multiple The nozzles are all located in the casing and installed on the support pipe, and a plurality of nozzles are distributed sequentially.

Owner:芜湖固高自动化技术有限公司

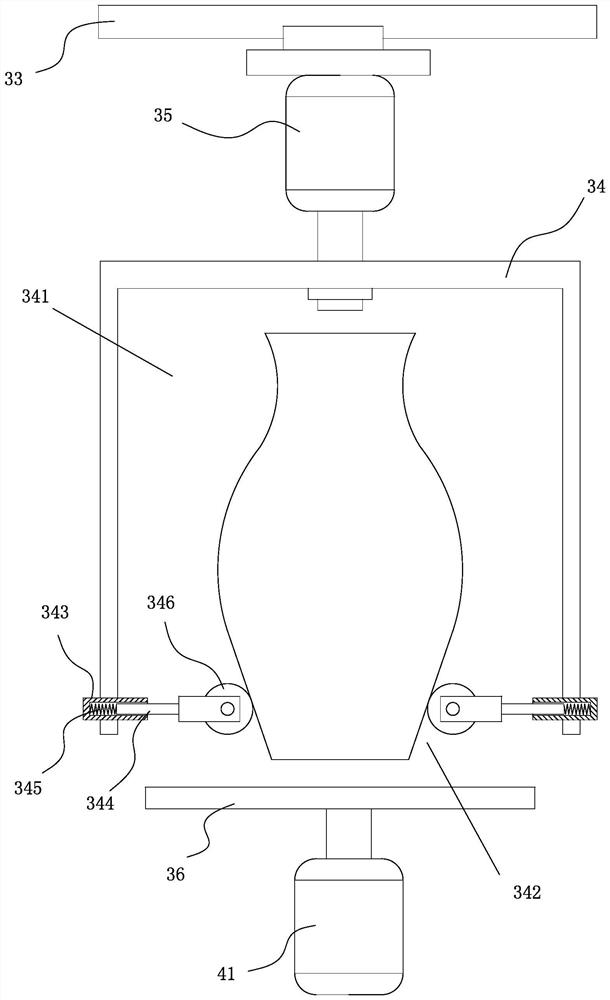

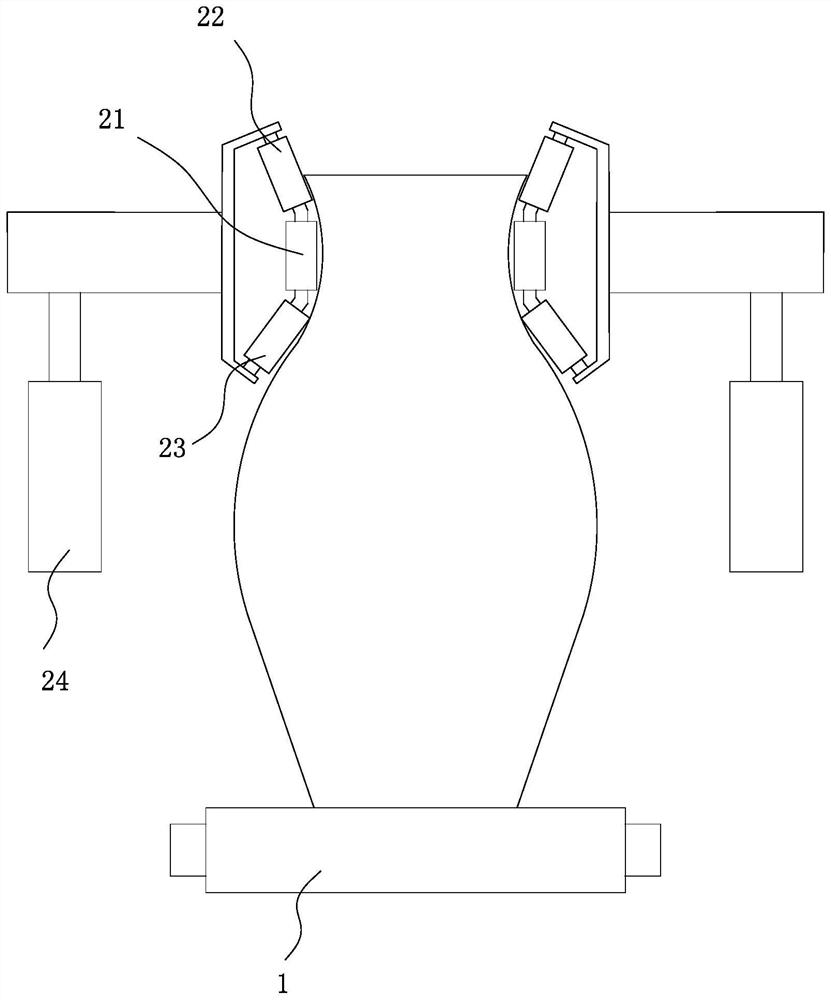

Glazing equipment based on ceramic bottle manufacturing

The invention discloses ceramic bottle manufacturing-based glaze shaking equipment which comprises a bottom plate, a supporting frame is fixedly mounted on the bottom plate, a rotating shaft is rotatably mounted on the supporting frame, mounting plates are arranged at the two ends of the rotating shaft through damping rings respectively, and a supporting table is fixedly connected to the bottoms of the two mounting plates; and a glaze shaking mechanism for shaking the ceramic bottle body is arranged on the upper surface of the supporting table. According to the ceramic bottle glazing device, through the cooperation of the glaze oscillating mechanism and the cam driving mechanism, when a cam column rotates, an oscillating rod can be driven to deflect back and forth, and a ceramic bottle body on the workbench can be driven to oscillate back and forth, so that the ceramic bottle body is uniformly glazed up, down, left and right, and the glazing quality is greatly improved.

Owner:陈新孟

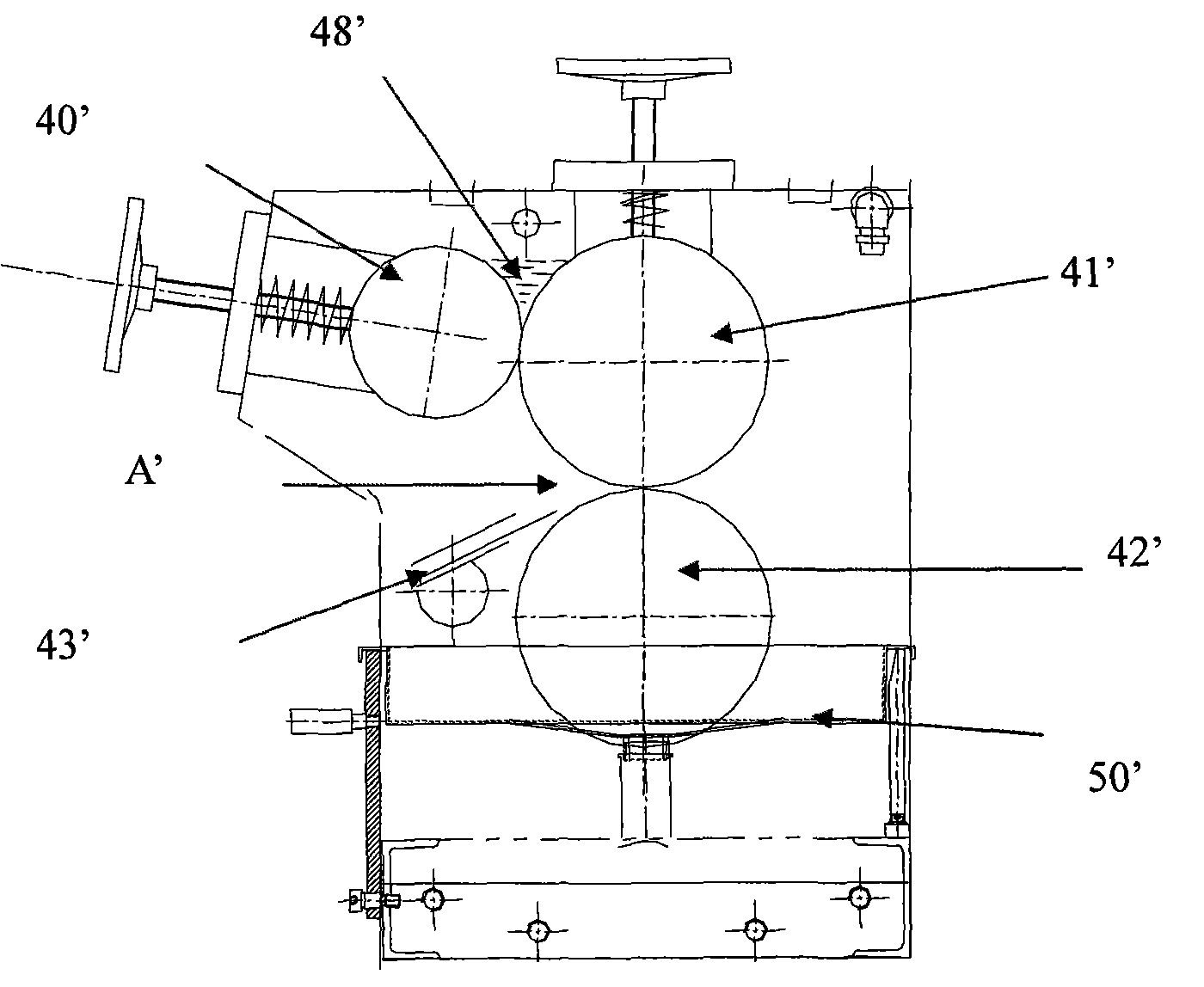

A device for spraying glaze powder

ActiveCN108908668BImprove glazing qualityImprove spraying effectCeramic shaping apparatusEngineeringMaterial supply

The invention discloses equipment used for spraying glaze powder. The equipment comprises a box body, a clamp part, a connecting pipe, a support rod, a power mechanism, multiple nozzles and a materialsupply mechanism. The clamp part is located in the box body. The connecting pipe is disposed in the box body. The connecting pipe is rotatably connected with the box body through the support rod. Thepower mechanism is used for driving the support rod to rotate. The multiple nozzles are all located in the box body and uniformly installed on the connecting pipe. The multiple nozzles are all disposed above the clamp part and connected with the material supply mechanism.

Owner:芜湖固高自动化技术有限公司

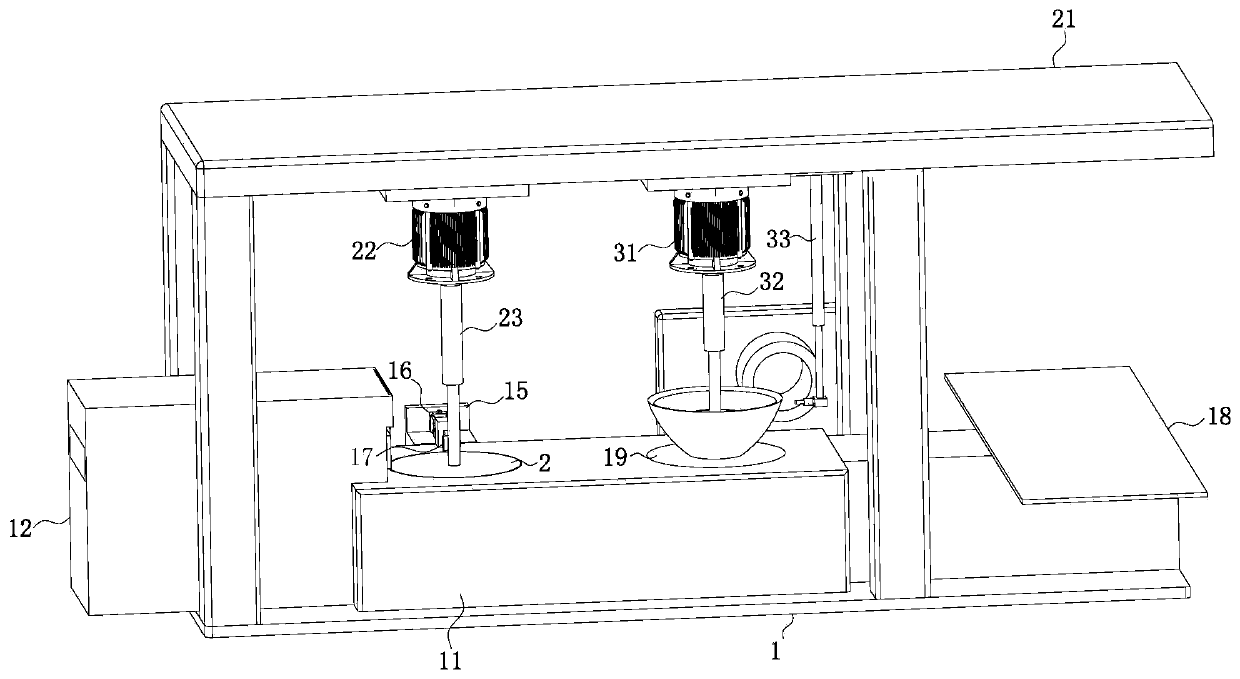

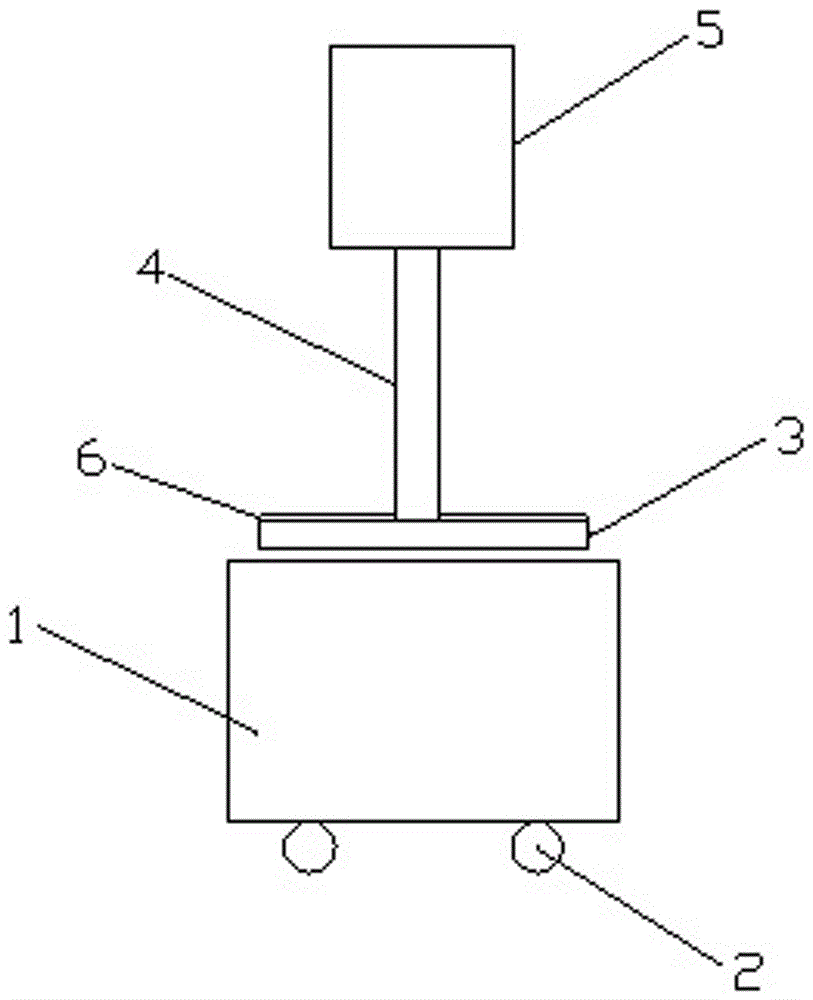

Daily-use glazing equipment for ceramic handicrafts

ActiveCN110193880BEasy to useImprove glazing qualityCeramic shaping apparatusGlazeElectric machinery

The invention discloses a daily glazing device for ceramic artworks. The daily glazing device comprises a machine body. A lifting cavity is formed in the machine body. A containing plate is arranged in the lifting cavity in a rotating manner. A rotation motor is installed in the containing plate. The lower end of the rotation motor is in power connection with a motor shaft. A driving bevel gear isfixedly arranged at the lower end of the motor shaft. A rotation cavity is formed in the containing plate. A rotation plate is arranged in the rotation cavity in a rotating manner. The rotation plateis used for containing the to-be-glazed ceramic artworks. A glaze containing device is arranged in the glazing device, all colors of glazes are managed in a unified and orderly manner, and the glazescan be conveniently replaced and used in the glazing process; the glaze containing device can be drawn back in the machine body and is convenient to store and contain; and secondly, after glazing isfinished, the ceramic artworks can be evenly dried through a drying device, and the glazing quality of the ceramic artworks is improved.

Owner:大埔县顺兴陶瓷有限公司

Processing device of ceramic product

InactiveCN108381740AImprove glazing qualityTroubleshooting Damaged Glaze LayersCeramic shaping apparatusEngineeringTransfer mechanism

The invention relates to the field of ceramic processing, particularly to a processing device of a ceramic product. The processing device comprises a rack, a conveyer belt, a transfer mechanism and asupporting table, wherein the transfer mechanism comprises a No.1 servo motor, a supporting plate, a gear rack, a No.2 servo motor, a No.1 gear rod and a No.2 gear rod; the gear rack is arranged on the supporting plate in a sliding manner; the No.2 servo motor is fixedly connected to the gear rack; the No.1 gear rod and the No.2 gear rod are relatively rotatably arranged on the two sides of the No.2 servo motor; the No.1 gear rod meshes with the gear rack; an incomplete gear which can intermittently mesh with the No.1 gear rod and the No.2 gear rod is fixed to an output shaft of the No.2 servomotor; a gear which meshes with the No.2 gear rod is rotatably arranged on a support frame; a supporting rod is fixedly connected to the gear; a spray gun capable of spraying glaze to a squatting panis mounted in the position, above the conveyer belt, of the rack; and a drying machine capable of drying the squatting pan is mounted in the position, above the supporting table, of the rack. Throughadoption of the technical scheme, comprehensive glazing can be carried out on the squatting pan.

Owner:CHONGQING CONCAST SANITARY WARE

Glazing technology for sanitary appliances

The invention relates to the field of production of sanitary appliances and in particular relates to a glazing technology for the sanitary appliances. The glazing technology comprises the following steps: step 1: preparing sanitary appliance glazing equipment comprising a conveyor belt, a glaze immersing tank, a transferring mechanism and a lifting mechanism, wherein a glaze spraying mechanism isarranged in the glaze immersing tank; step 2: placing a squatting pan on the conveyor belt; when conveying the squatting pan to the lifting mechanism, driving the squatting pan to move upward throughthe lifting mechanism; step 3: driving the squatting pan to move in the direction toward the glaze immersing tank through the transferring mechanism; step 4: when moving the squatting pan to the upperside of the glaze spraying mechanism, driving the squatting pan to move downward through the transferring mechanism; step 5: when the glaze spraying mechanism is in contact with the squatting pan, spraying glaze to an inner side of the squatting pan by the glaze spraying mechanism; meanwhile, glazing an outer side of the squatting pan in a process of downward moving the squatting pan in the glazeimmersing tank. By adopting the glazing technology provided by the invention, the glazing speed and quality can be both considered; meanwhile, a water inlet of the squatting pan also can be preventedfrom being blocked and a glaze layer is prevented from being damaged.

Owner:CHONGQING CONCAST SANITARY WARE

A kind of ceramic product with self-cleaning glaze and preparation method thereof

The invention provides a ceramic product with a self-cleaning glaze, including a base material and a glaze material, the base material includes kaolin, quartz, potassium feldspar, clay and talc; the glaze material includes a bottom glaze and a top glaze, wherein the bottom glaze includes the following weight Parts of raw materials: potassium feldspar, nano zinc oxide, calcium oxide, burnt talc, zirconium silicate, wollastonite, kaolin, bone ash, calcium borate and frit; the surface glaze includes the following raw materials in parts by weight: potassium feldspar, kaolin, Wollastonite, zinc oxide, calcium oxide, aluminum oxide, magnesium oxide, zirconium oxide, calcium borate. The method for making ceramic products with self-cleaning glaze includes the following steps: (1) mixing the above-mentioned tire material and glaze material respectively, adding water, wet grinding with a ball mill, and sieving to obtain the tire material slurry and glaze slurry; (2) the tire material (3) Applying bottom glaze; (4) Applying top glaze; (4) Firing. The glaze surface of the ceramic product produced by the invention is delicate and bright, which can effectively prevent the accumulation of dirt and the formation of black spots.

Owner:福建省德化龙辉陶瓷有限公司

Glazing process for sanitary ware

Owner:CHONGQING CONCAST SANITARY WARE

Glazing device for jun porcelain

The invention relates to the technical field of firing equipment of jun porcelain, in particular to a glazing device for the jun porcelain. The glazing device comprises a glaze box, wherein a hydraulic cylinder is arranged above the glaze box; a hydraulic rod is arranged on the hydraulic cylinder; a tray is fixedly connected to the end part of the hydraulic rod; supporting utensils are putted on the tray; the maximum diameter of the tray and the maximum diameters of the supporting utensils are respectively smaller than the inside diameter of the glaze box. By using the glazing device, workers feels easy and do not easily feel fatigue; a plurality of jun porcelain green bodies can be glazed at one time; the glazing device is suitable for large-batch production and is high in production efficiency; the glazing quality is improved; the operation of workers holding with hands is eliminated, so that touching marks generated by holding with the hands is avoided, and the glazing quality is guaranteed.

Owner:温书强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com