Ceramic glaze and ceramic

A ceramic glaze and ceramic technology, applied in the field of ceramic glaze and ceramics, can solve the problems of high equipment investment cost, low production efficiency, high technical cost, etc., and achieve the effect of improving glaze quality, reducing adsorption time, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

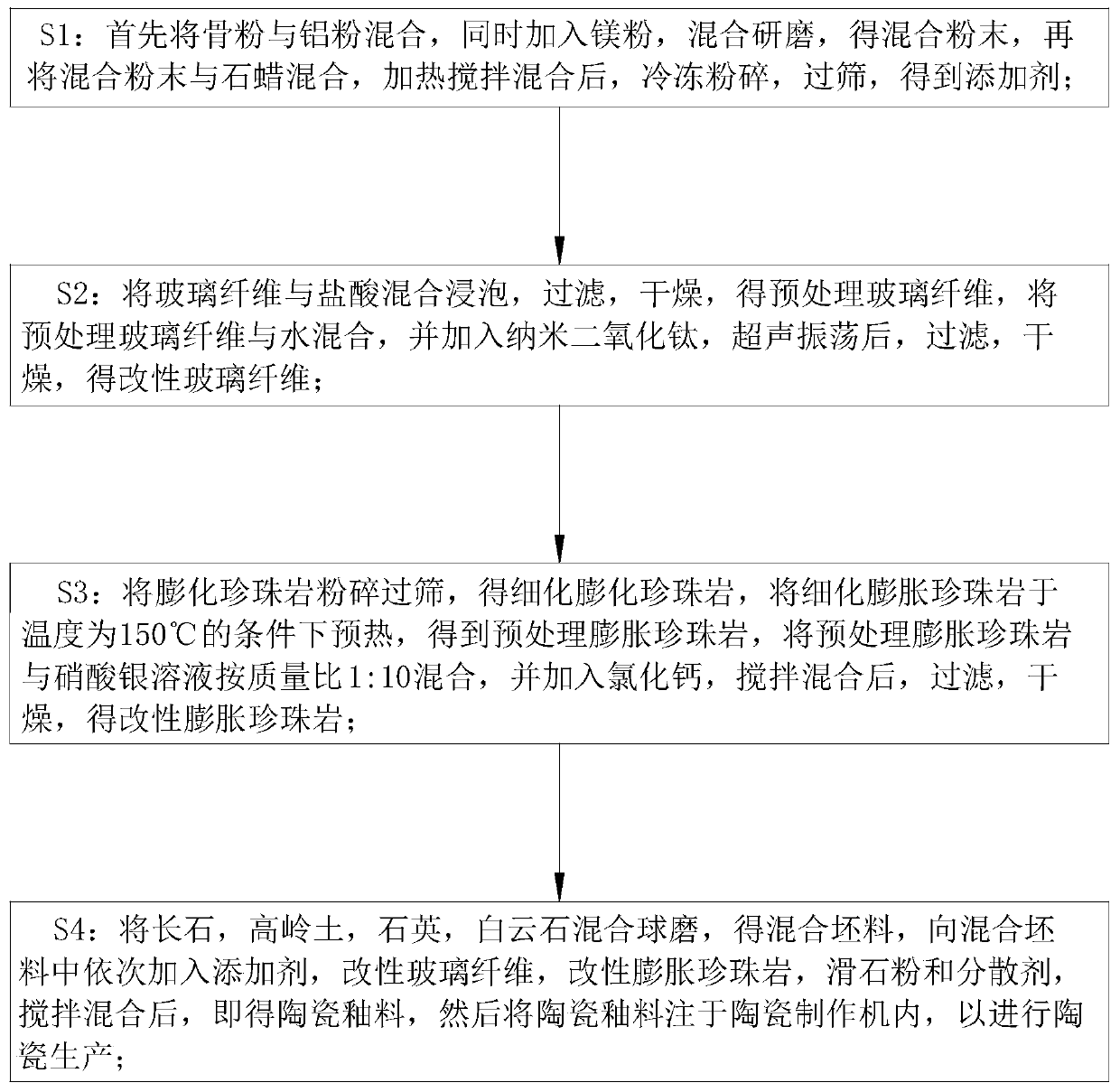

Method used

Image

Examples

Embodiment approach

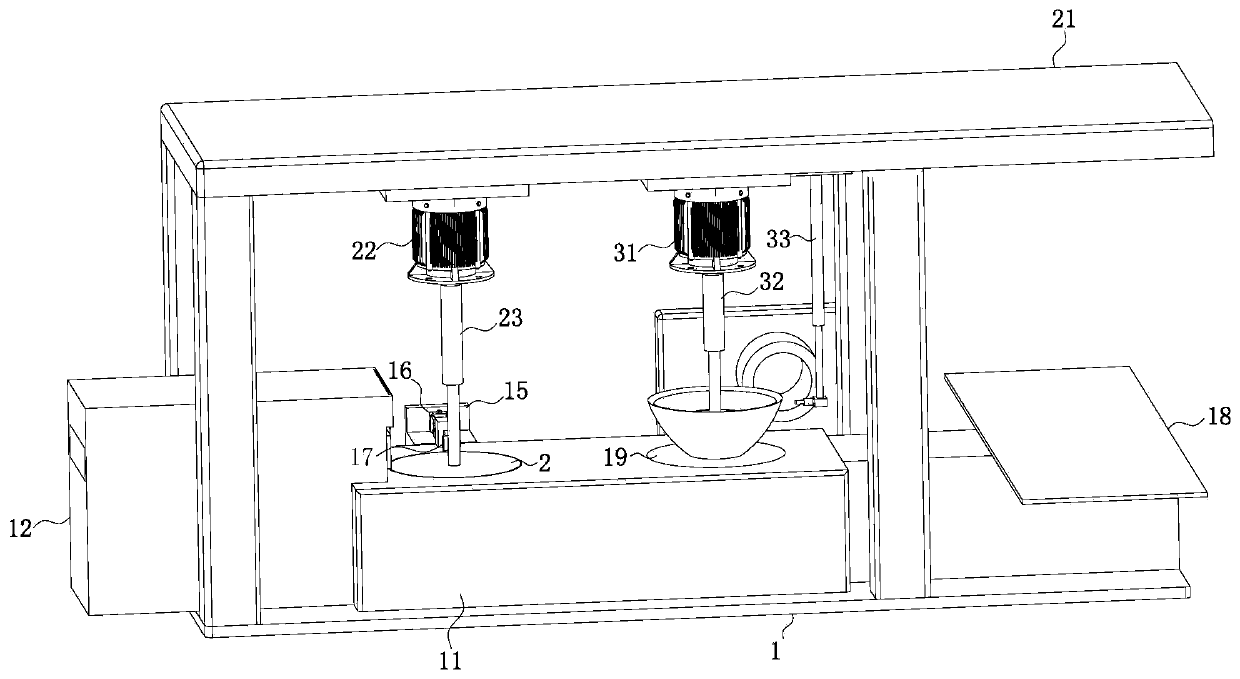

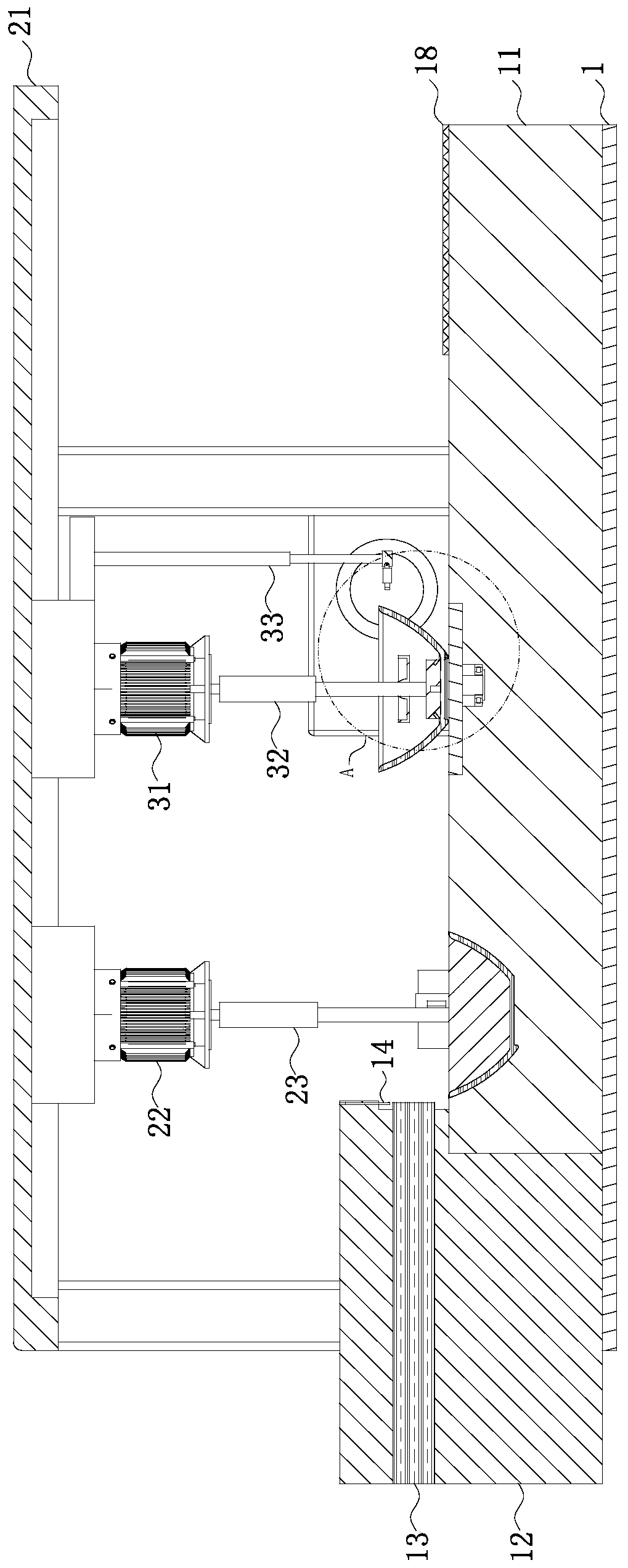

[0033]As an embodiment of the present invention, the lower surface of the third telescopic rod 33 is fixedly connected with a second fixed block; the left side of the second fixed block is hinged with a fourth telescopic rod 35, and the fourth telescopic rod The left side of 35 is fixedly connected with the atomizing nozzle 34; during work, in order to meet the glaze coating requirements of ceramic products of different shapes, and the distance between the nozzle and the ceramic product during the glaze coating process will seriously affect the quality of glaze coating on the ceramic surface, Therefore, the second fixed block is set so that the left side of the second fixed block is hinged to the fourth telescopic rod 35, and by the expansion and contraction of the fourth telescopic rod 35, the control of the distance between the atomizing nozzle 34 and the surface of the ceramic product can be realized, ensuring that the atomizing nozzle 34 During the process of glazing cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com