Process for preparing glaze for electric porcelain using basket type sand mill as main body

A sand mill and basket type technology, applied in the field of preparing electric enamel, can solve the problems of fluctuation of glaze composition, difficult cleaning, long grinding time, etc., and achieve the effect of improving glaze quality, simple structure and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

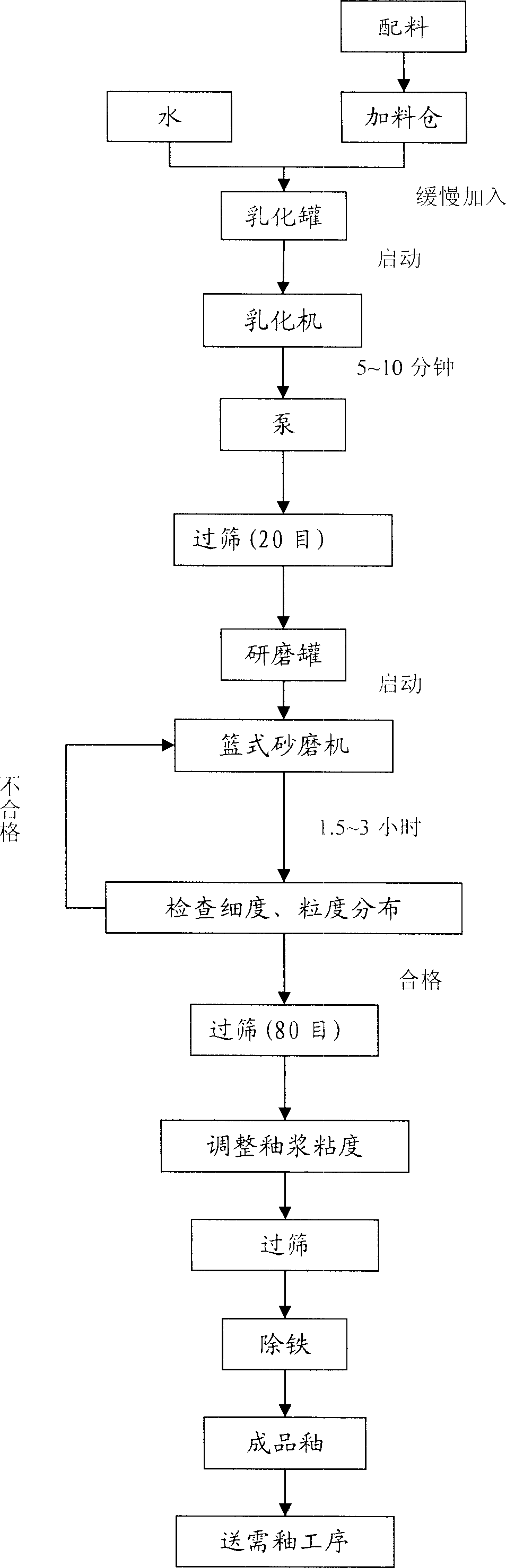

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of brown glaze slurry in an electric porcelain factory

[0018] The main raw materials of brown glaze for electric porcelain in this factory are feldspar powder, quartz powder, porcelain powder, field soil, calcite powder, cooked talc powder, MnO 2 、Cr 2 o 3 As well as some clay raw materials, the above-mentioned raw materials are all powder or clay that is easy to pulp. According to the recipe requirements, weigh several samples with a total weight of 2kg, put them in a 31-liter stainless steel container, add appropriate amount of water, first use SAI-3 emulsifier to melt the slurry, and then use SMA-0.75 basket sand mill to grind . The test process and results are listed in Table 1.

[0019] Table 1 The experimental process and results of brown glaze preparation in an electric porcelain factory

[0020]

[0021] Add appropriate amount of water to the above two kinds of glaze slurries respectively, adjust to the appropriate viscosi...

Embodiment 2

[0022] Example 2: Factors of Glazing Quality in an Electric Porcelain Factory

[0023] The electric porcelain factory mainly produces high-strength electric porcelain. Its electric porcelain brown glaze has defects such as obvious glaze flowers in several consecutive kilns, which are specifically manifested in the uneven color and luster of the glaze surface. Regarding this phenomenon, the factory has two opinions. One is that the raw material changes, resulting in unstable composition, and the other is that the composition of the glaze slurry changes due to the wear of the grinding body during grinding by the ball mill. It has not been possible to determine the cause of the glaze bloom defect.

[0024] Three glazes with a weight of 2 kg were prepared according to the production recipe that grinding the glaze with a ball mill produced obvious glaze defects. By the process method of implementation example 1, prepared glaze slip, its experimental result is shown in Table 2.

...

Embodiment 3

[0028] Embodiment 3: the preparation of the brown glaze of a certain electric porcelain factory

[0029] The factory mainly produces capacitor bushings, and the main components of its brown glaze are feldspar powder, quartz powder, porcelain powder, field soil, calcite powder, cooked talc powder, MnO 2 、Cr 2 o 3 As well as some clay raw materials, better quality can also be obtained by using a ball mill to make a glaze. In a 1001 stainless steel cylinder, add 80kg of glaze, first disperse with STAY-7.5 high-shear dispersing emulsifier, and then grind with SMA-7.5 basket sand mill. The results are shown in Table 3 below.

[0030]Table 3 Glazing process parameters and glaze slurry results of basket sand mill mechanism

[0031]

[0032] After adding appropriate amount of water to the glaze slurry to adjust the viscosity, the quality of the glaze surface after firing is better than that of the glaze slurry prepared by a ball mill, whether it is applied on a test stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com