Lifting oil disc device

A technology for oil pans and oil pans, which is applied in printing, printing machines, general parts of printing machinery, etc. It can solve the problems of easy volatilization and drying of oil, too much oil in the oil pan, and difficult cleaning of the oil pan. Not easy to volatilize and dry, prolong the use time and maintain the effect of glazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

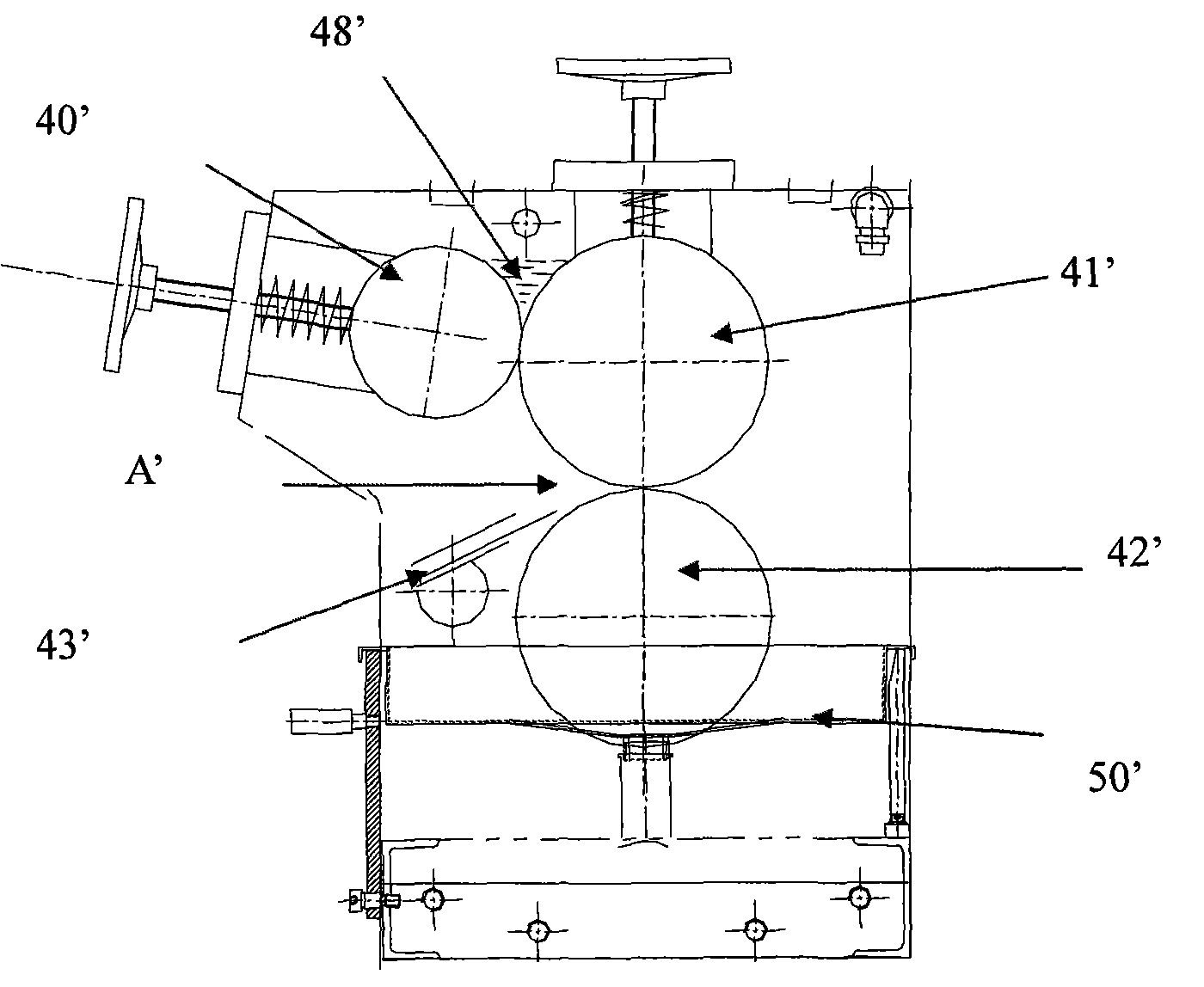

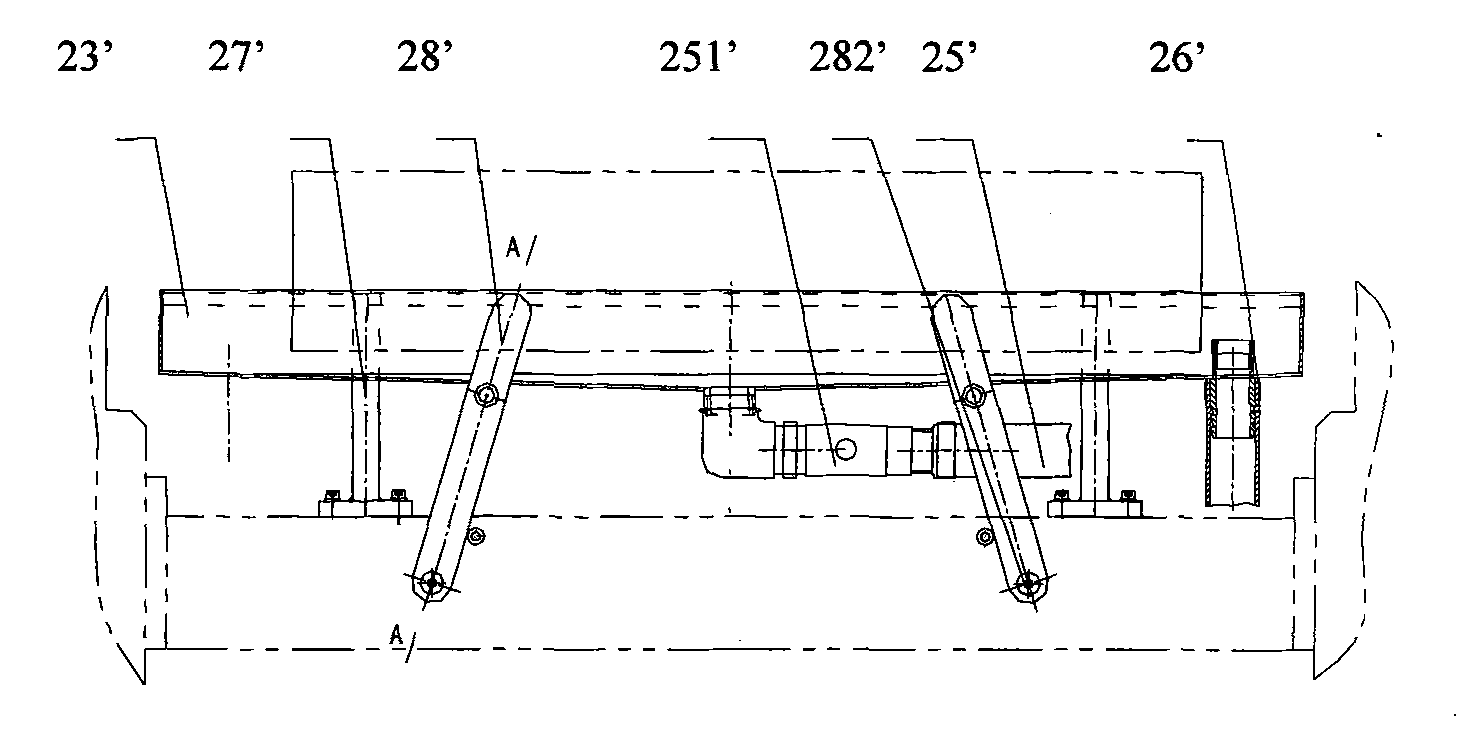

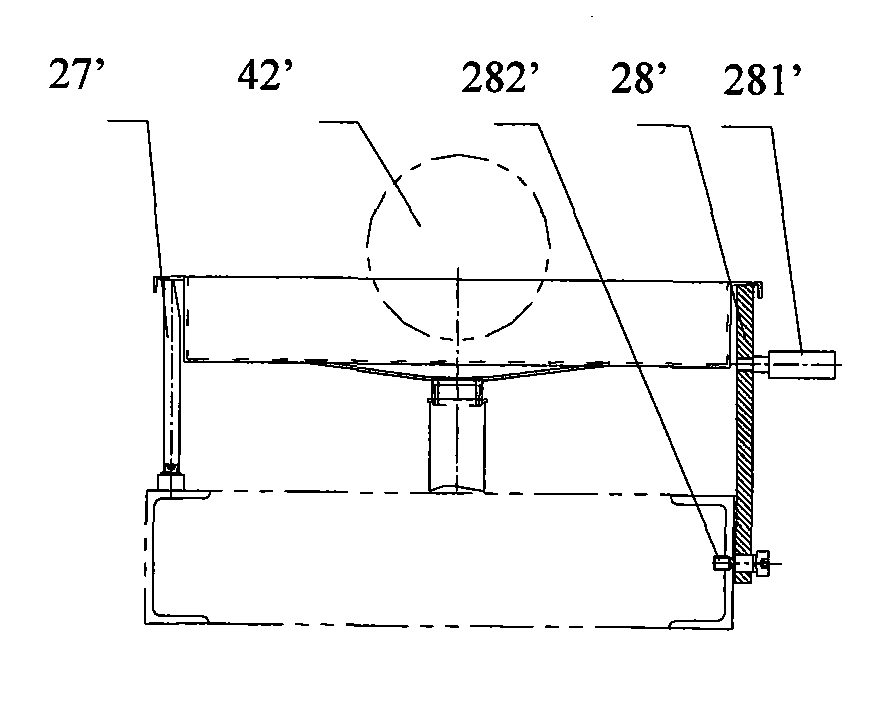

[0045] Such as Figure 4 As shown, it is a front view of a liftable oil pan device of the present invention, Figure 5It is a sectional view of a liftable oil pan device of the present invention. The liftable oil pan comprises an automatic control device, a lifting oil pan device, a mobile oil pan device and a lifting and moving control device connected with the automatic control device and controlling the lifting and moving of the oil pan. The automatic control device includes a control button and an electromagnetic reversing valve, the control button is installed on the outer surface of the automatic glazing machine, the electromagnetic reversing valve is electrically connected to the control button, and is triggered by the signal of the control button , to control the lifting oil pan control device, so that the user can conveniently perform the required operations. The mobile oil pan device includes an oil pan slide rail 24 and a movable oil receiving pan 23 arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com