Glazing device for jun porcelain

A Jun porcelain and glaze technology, applied in the field of Jun porcelain firing equipment, can solve problems such as unfavorable long-term operation of mass production workers, easy fatigue of workers, physical damage, etc., to ensure the quality of glazing, improve the quality of glazing, easy to use effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

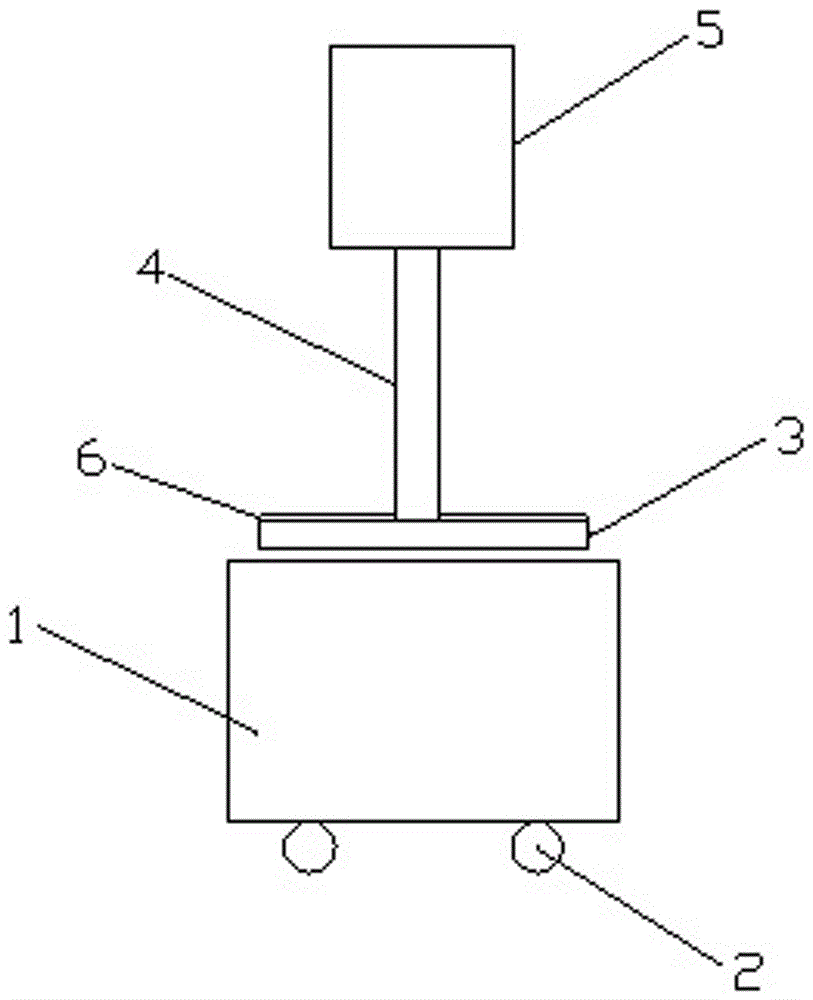

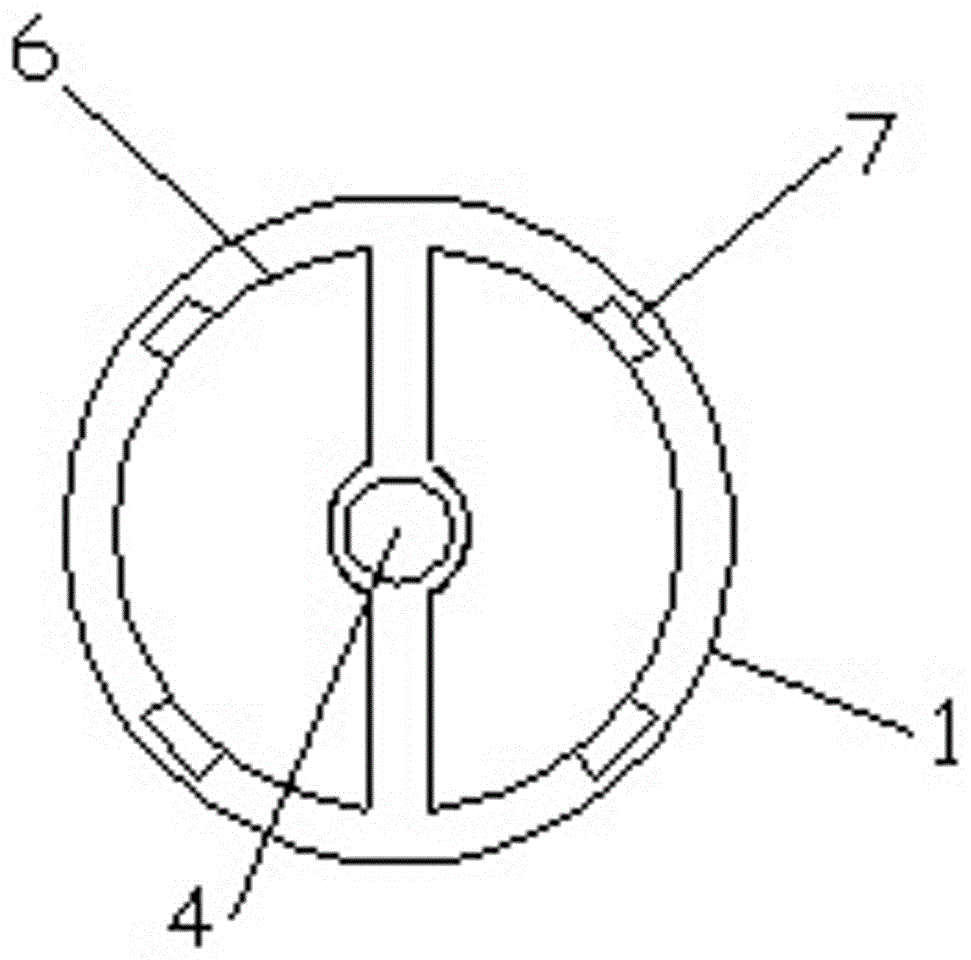

[0012] like figure 1 , 2 As shown, a Jun porcelain glazing device includes a glaze box 1, a hydraulic cylinder 5 is arranged above the glaze box 1, a hydraulic rod 4 is arranged on the hydraulic cylinder 5, and a tray is fixedly connected to the end of the hydraulic rod 4 3. The tray 3 is placed with a support 6 , and the maximum diameters of the tray 3 and the support 6 are both smaller than the inner diameter of the glaze box 1 . The quantity of described holder 6 is 2, and the shape of holder 6 is semicircle, and the center of holder 6 straight edges is provided with semicircle, and the diameter of semicircle is greater than the diameter of hydraulic rod 4, and the outside of holder 6 is provided with There is a handle 7, and the sum of the maximum diameter of the holder 6 and the maximum length of the handle 7 is smaller than the inner diameter of the glaze box 1. The bottom of the glaze box 1 is provided with a roller 2 .

[0013] When the present invention is used spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com