Glazing method and special equipment therefor

A technology of special equipment and equipment, applied in other home appliances, applications, home appliances, etc., can solve the problem that automatic glazing equipment cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

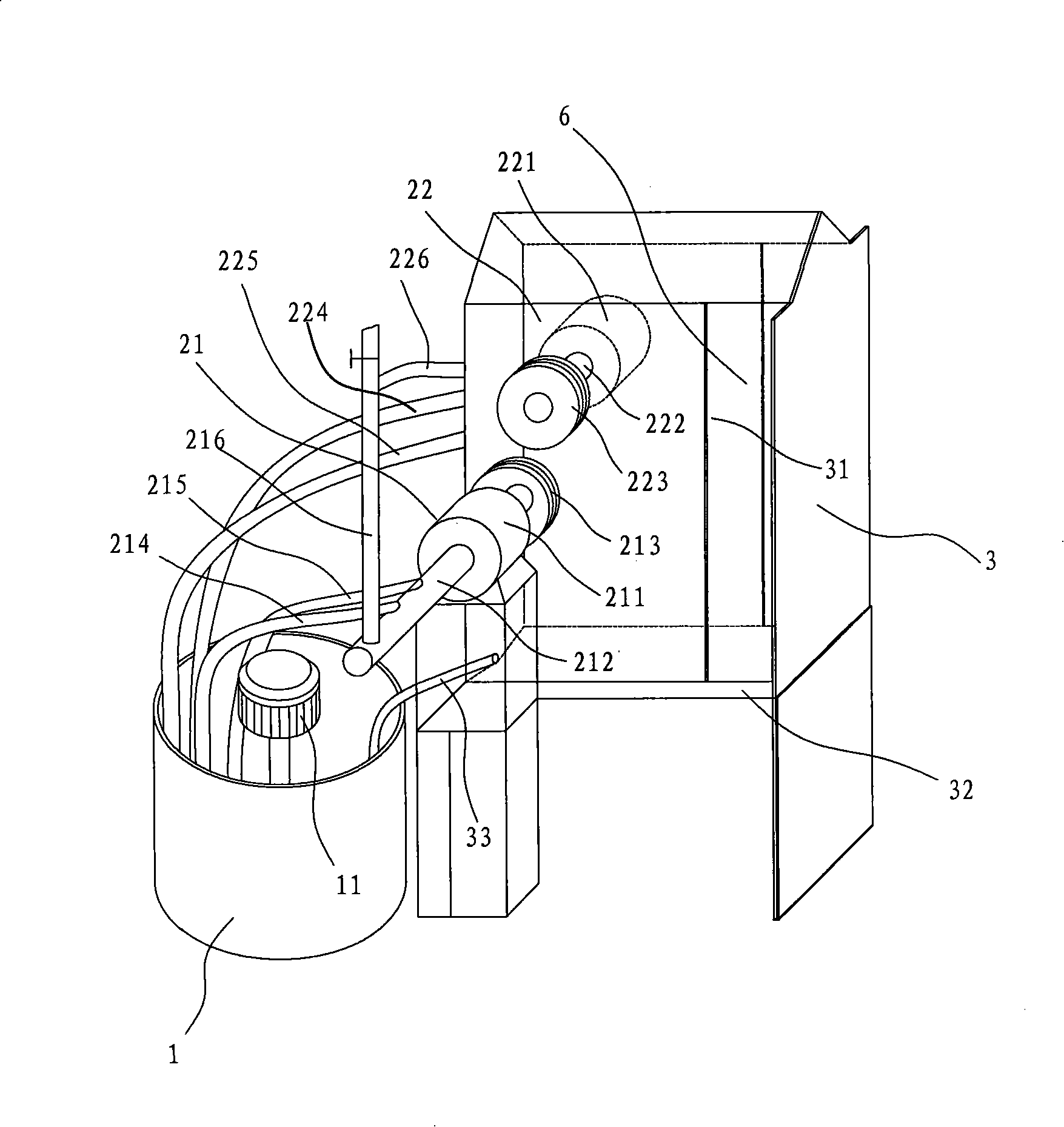

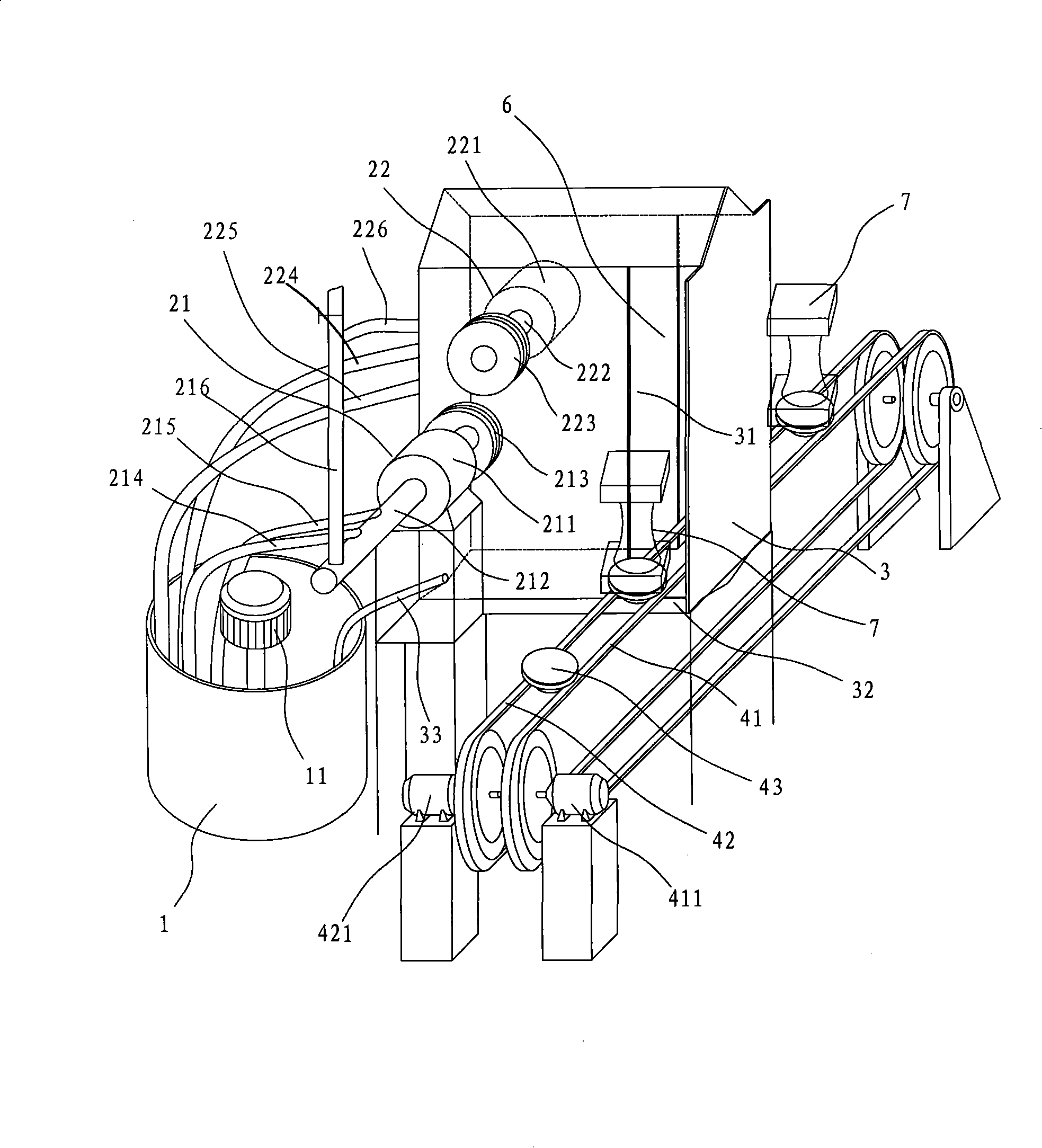

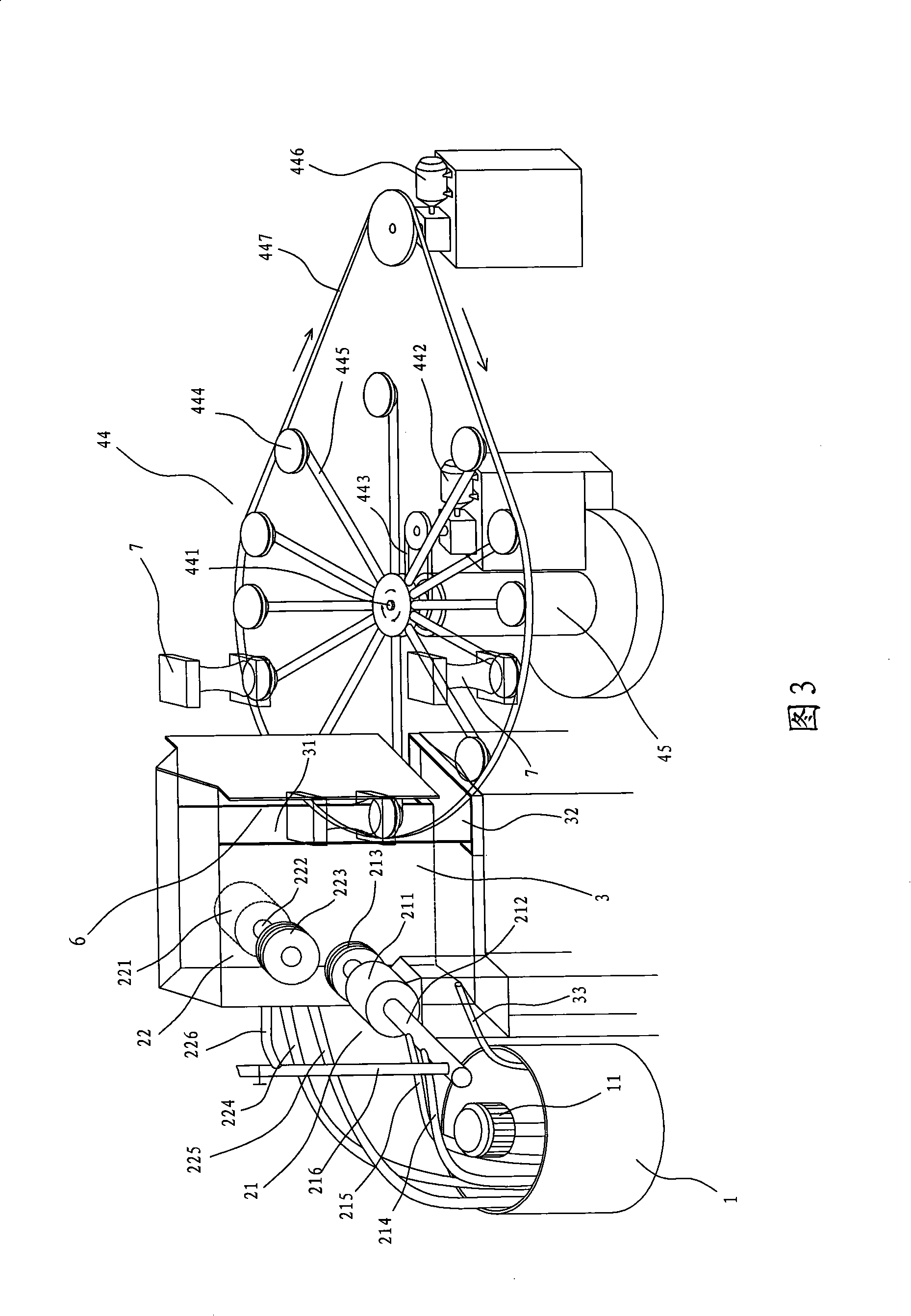

[0019] A glazing method of the present invention is realized by the following scheme: the three-dimensional ceramic product is transported into the glazing cavity of the glazing box of the automatic glazing equipment through a transmission device, and the ceramic product is rotated in the glazing cavity through the driving device, Therefore, the glaze throwing machine of the glazing equipment can glaze the entire surface, and finally the glazed ceramic products can be sent out of the automatic glazing equipment through this transmission device. Adjust the relationship between the motor speed of the glaze throwing machine of the automatic glazing equipment, the transmission speed of the transmission device, and the rotation speed of the workpiece support plate. At this time, the misty glaze thrown out by the glaze throwing pan head evenly glazes the entire peripheral surface of the ceramic product to form a smooth and flat glaze; The point-shaped glaze thrown out by the pan hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com