Self-cleaning antibacterial glaze used for sanitary ceramic ware

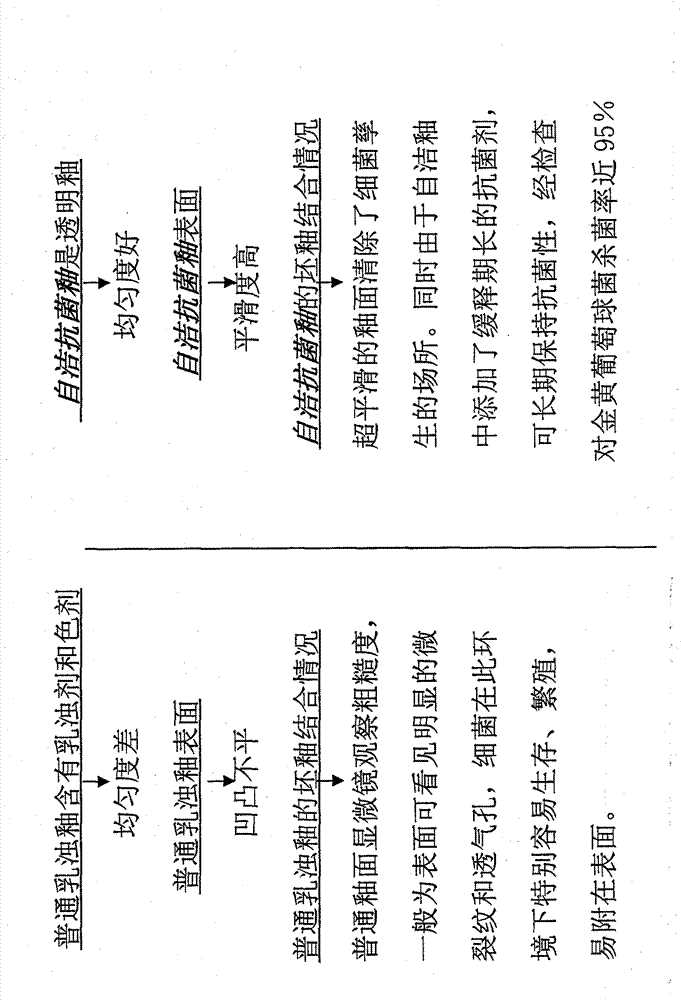

A technology of sanitary ceramics and antibacterial glaze, applied in the field of antibacterial glaze, can solve the problems of dirt adhesion, difficult to clean, human body harm, etc., and achieve the effects of easy cleaning, fine and smooth surface, and fewer pinholes on the glaze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

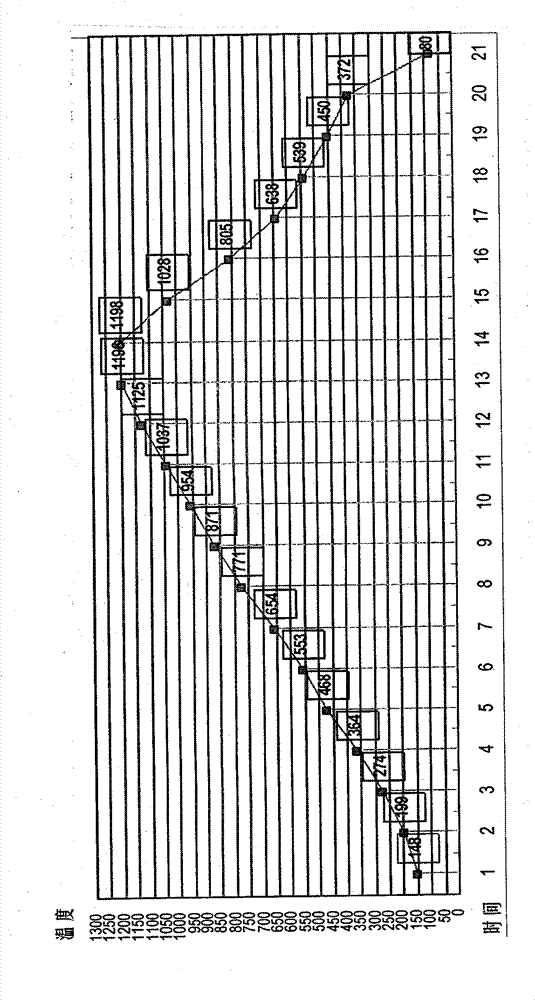

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

[0012] In this embodiment, the self-cleaning and antibacterial glaze for sanitary ceramic sanitary ware includes bottom glaze and surface glaze, wherein:

[0013] a. Containing components and specific gravity: The components and parts by weight of the bottom glaze are: 32.75 parts of superfine quartz powder, 20.05 parts of feldspar, 10 parts of wollastonite, 5.5 parts of calcite, and 4 parts of dolomite , 3.5 parts of Balin soil, 6.5 parts of calcined alumina micropowder, 2 parts of calcined zinc oxide, 4.5 parts of frit, 12.75 parts of zirconium silicate superfine powder; 38 parts of fine quartz powder, 23.75 parts of feldspar, 12.75 parts of wollastonite, 4 parts of calcite, 3 parts of dolomite, 4.5 parts of Balin soil, 7 parts of calcined alumina micropowder, 1.5 parts of calcined zinc oxide, 4.5 parts of frit, antibacterial 0.8 part of agent one, 0.2 part of antiba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com