Automatic dipping machine of ceramic product for daily use

A ceramic product and glaze dipping machine technology, which is applied in the field of glazing machinery, can solve the problems of high waste rate and low degree of automation, and achieve the effect of high degree of automation, improving production efficiency and ensuring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

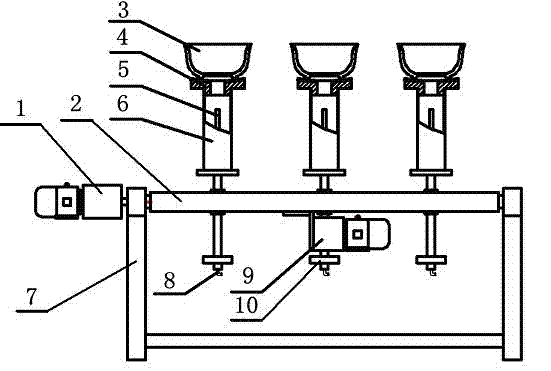

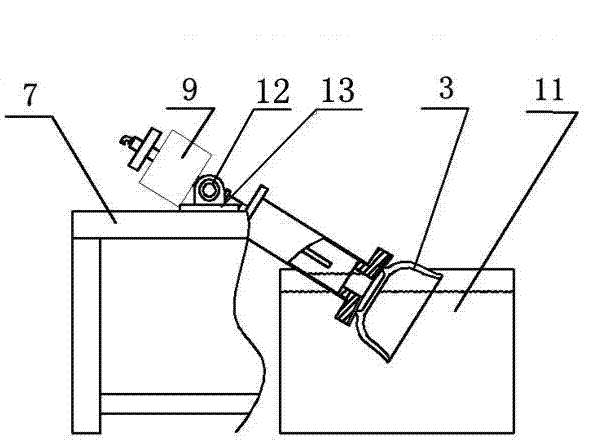

[0018] like figure 1 , 2 As shown, when the automatic glazing machine for daily-use ceramic products of the present invention is in a non-working state, the support 7 is placed next to the production line of the glazing process for ceramic products, and bearing blocks 13 and bearings 12 are fixedly installed at both ends of the upper surface of the support 7, and the overturning transmission mechanism 1 The power output end of the rotating shaft 2 is connected to the turning main shaft 2. When the turning transmission mechanism 1 has no power output, it is in a standby state. The three sets of rotating cylinders 6 fixed on the turning main shaft 2 are fixed in a vertical position, and the rotating cylinder 5 is not injected with glaze. The paddle, the support head 4 is tightly sleeved with the upper part of the drum 6, inside the bracket, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com