Glaze spraying device for comprehensive and uniform spraying in ceramic production

A comprehensive and uniform technology, applied in the field of glaze spraying devices with comprehensive and uniform spraying in ceramic production, can solve the problems of reducing work efficiency, reducing device practicability, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

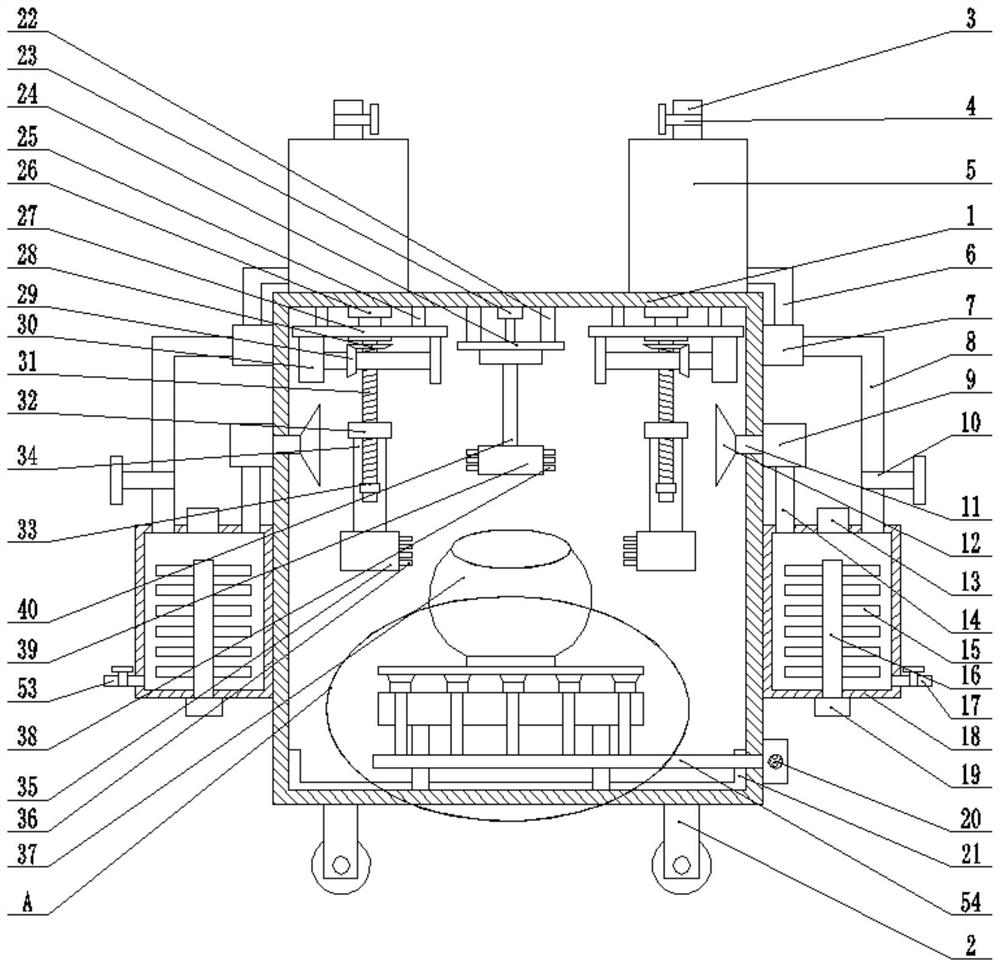

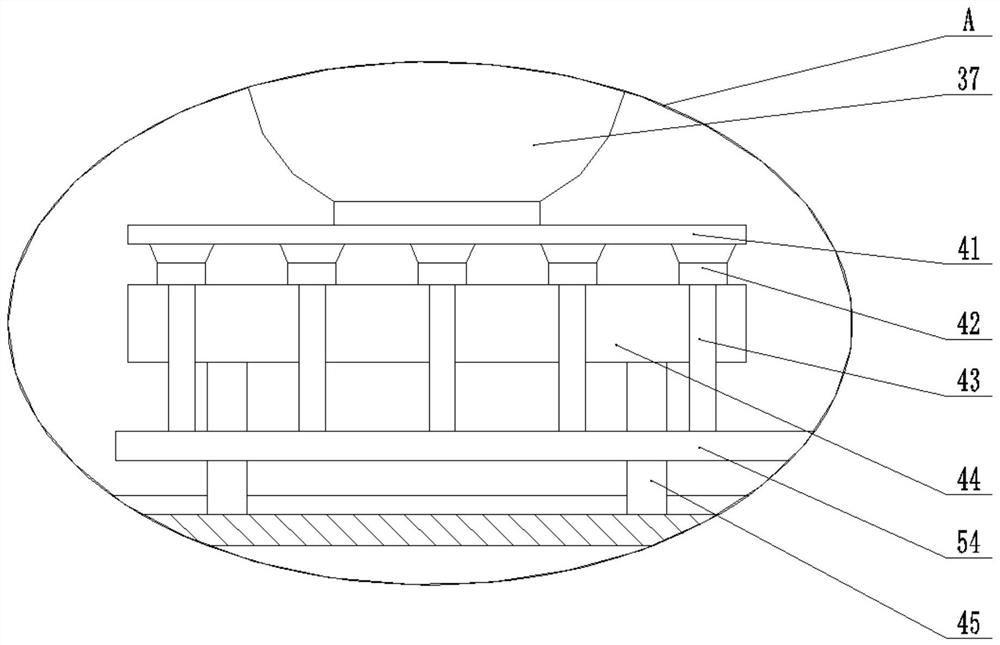

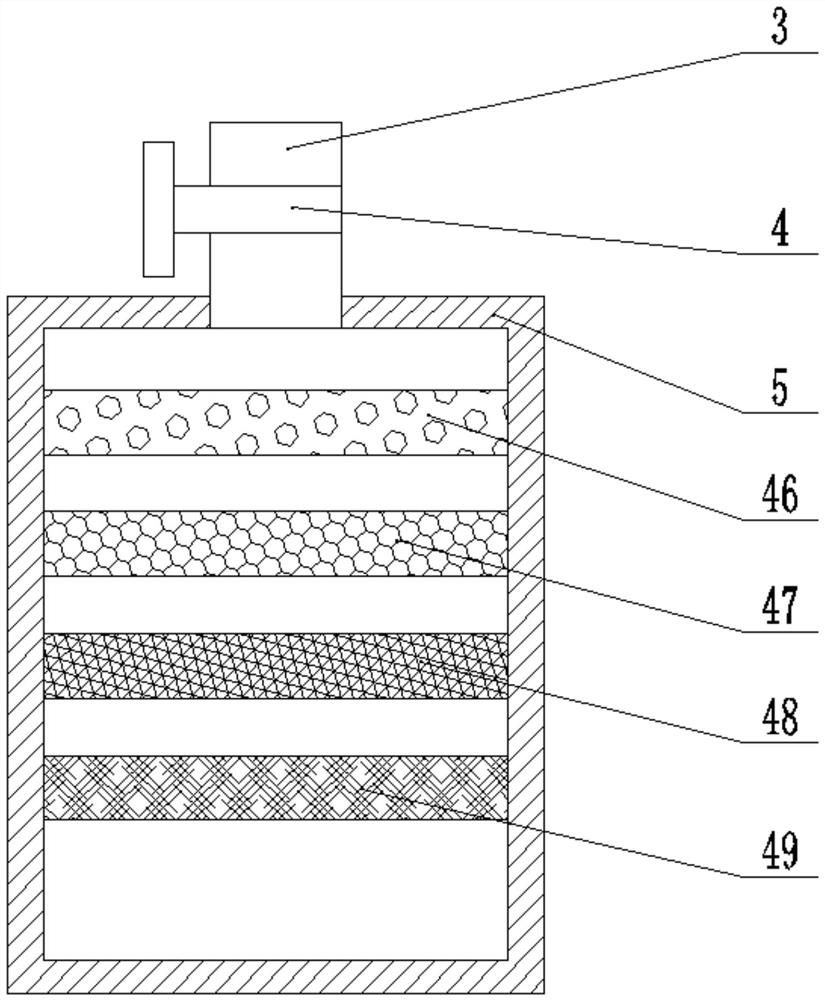

[0023] see Figure 1~Figure 4As shown, a glaze spraying device used for ceramic production and spraying is comprehensive and uniform, including a processing box 1, a collecting tank 21 is arranged on the inner wall of the bottom end of the processing box 1, and a collection tank 21 is arranged symmetrically on the inner wall of the bottom end of the left and right sides of the processing box 1. Support leg 45, the upper end of support leg 45 is provided with processing table 44, and the top of processing table 44 is provided with suction cup 42, and the suction cup 42 is provided with base 41, and the top of base 41 is placed with ceramic part 37, and suction cup 42 lower end is provided with connecting pipe 54, and The connecting pipe 54 runs through the processing table 44 and extends to the lower end of the processing table 44. A vacuum pump 20 is arranged on the outer wall of the bottom end of the right side of the processing box 1. The left end of the vacuum pump 20 is pro...

Embodiment 2

[0030] On the basis of embodiment one, refer to Figure 4 , a control panel 50 is provided on the front top outer wall of the processing box 1, a warehouse door 51 is arranged on the front bottom outer wall of the processing box 1, and a transparent glass window 52 is inlaid on the front side outer wall of the warehouse door 51; by setting the control panel 50 can realize intelligent control, reduce manpower operation, improve work efficiency, be convenient to take ceramic part 37 by arranging warehouse door 51, be convenient to observe the working situation inside processing box 1 by arranging transparent glass window 52.

[0031] Working principle: In the process of use, by setting the first rotating motor 23, the first connecting plate 24, the second thrust ball bearing 25, the second rotating motor 26, the second connecting plate 27, the first gear 28, and the second gear 29. The combination of executive motor 30, executive screw 31, sleeve 32, stopper 33, lifting plate 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com