Method and device for coating and curing ultraviolet curing coating

A coating device, ultraviolet technology, applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., to achieve the effect of less equipment investment, high coating density, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

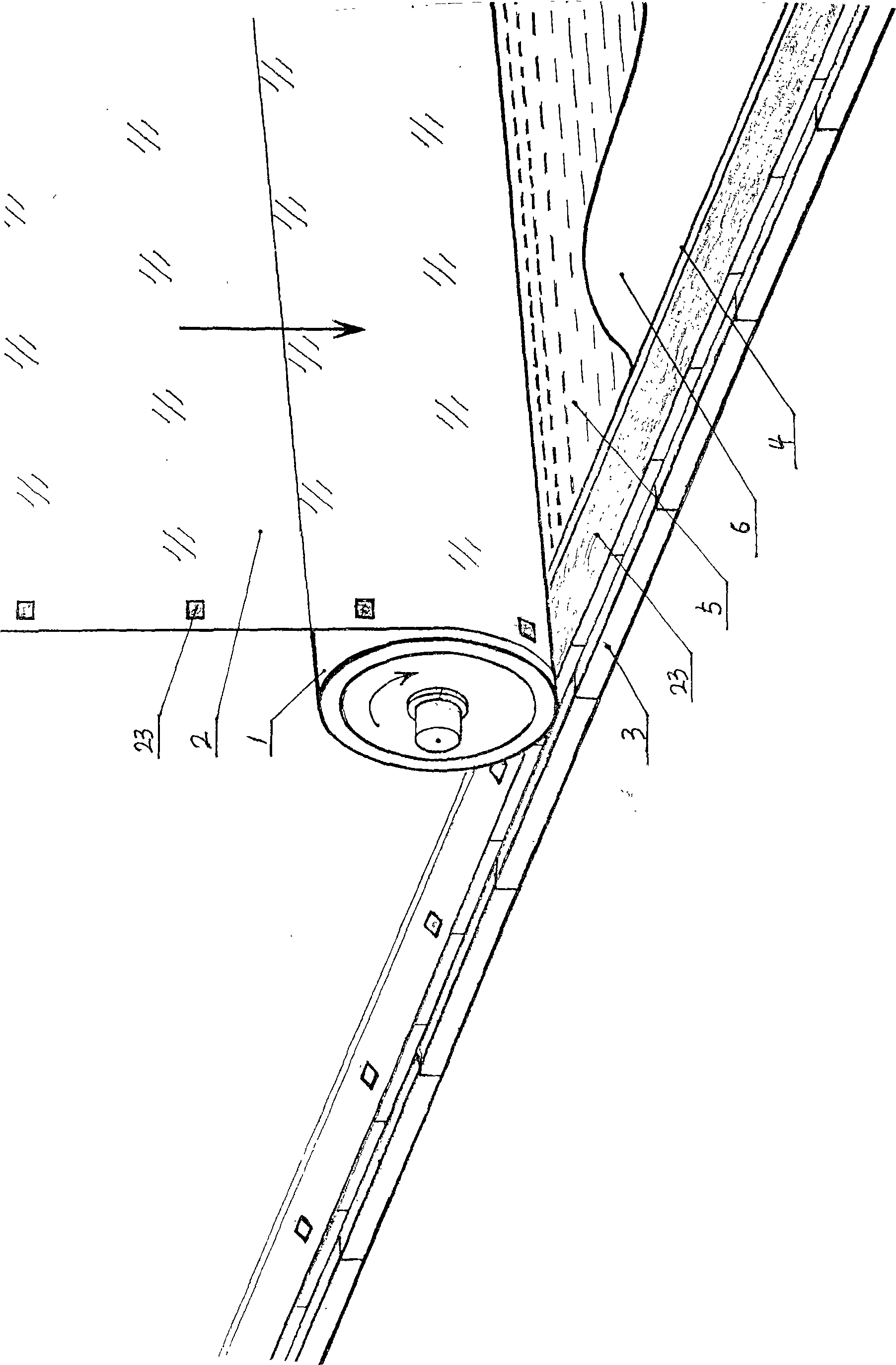

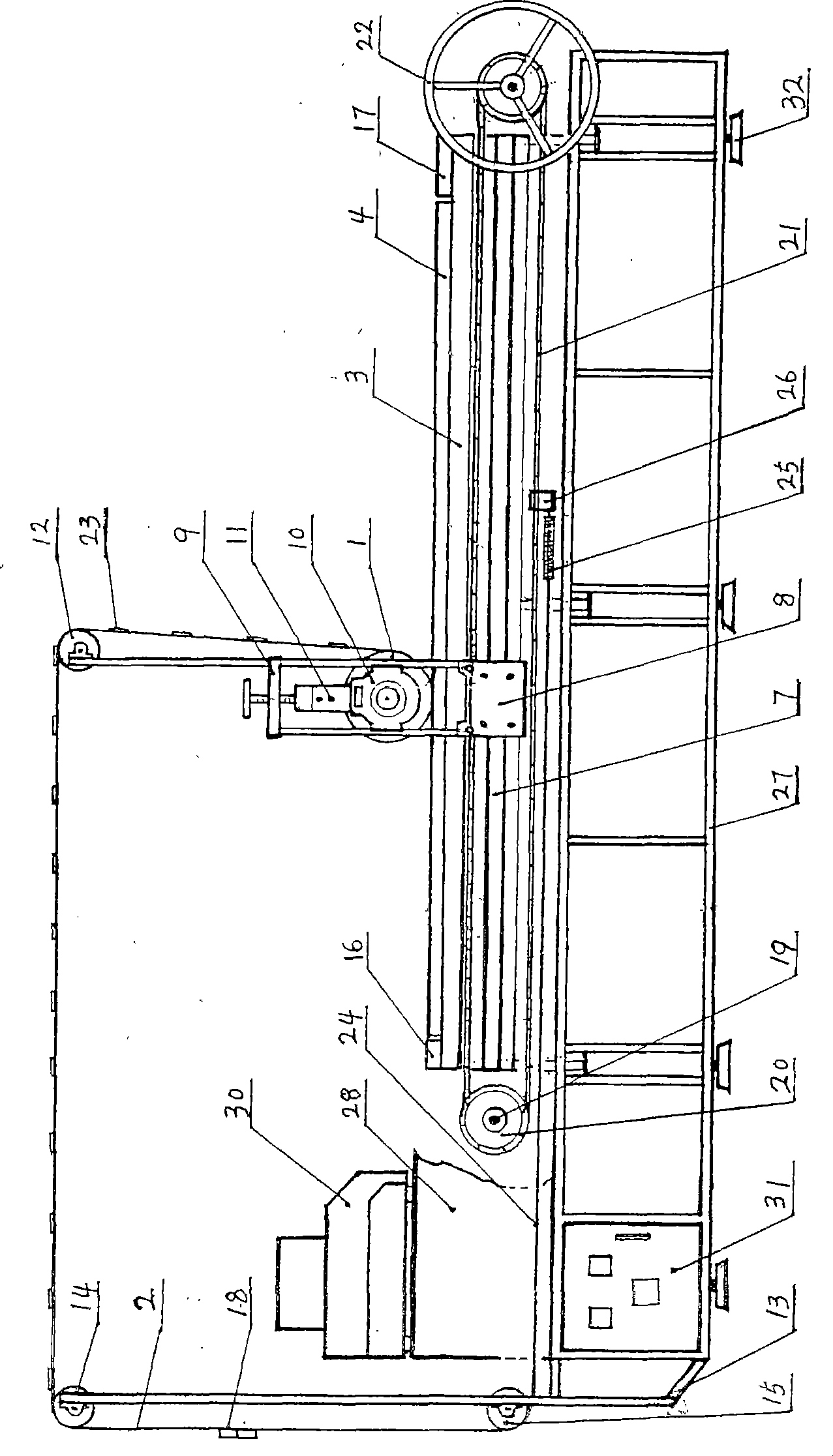

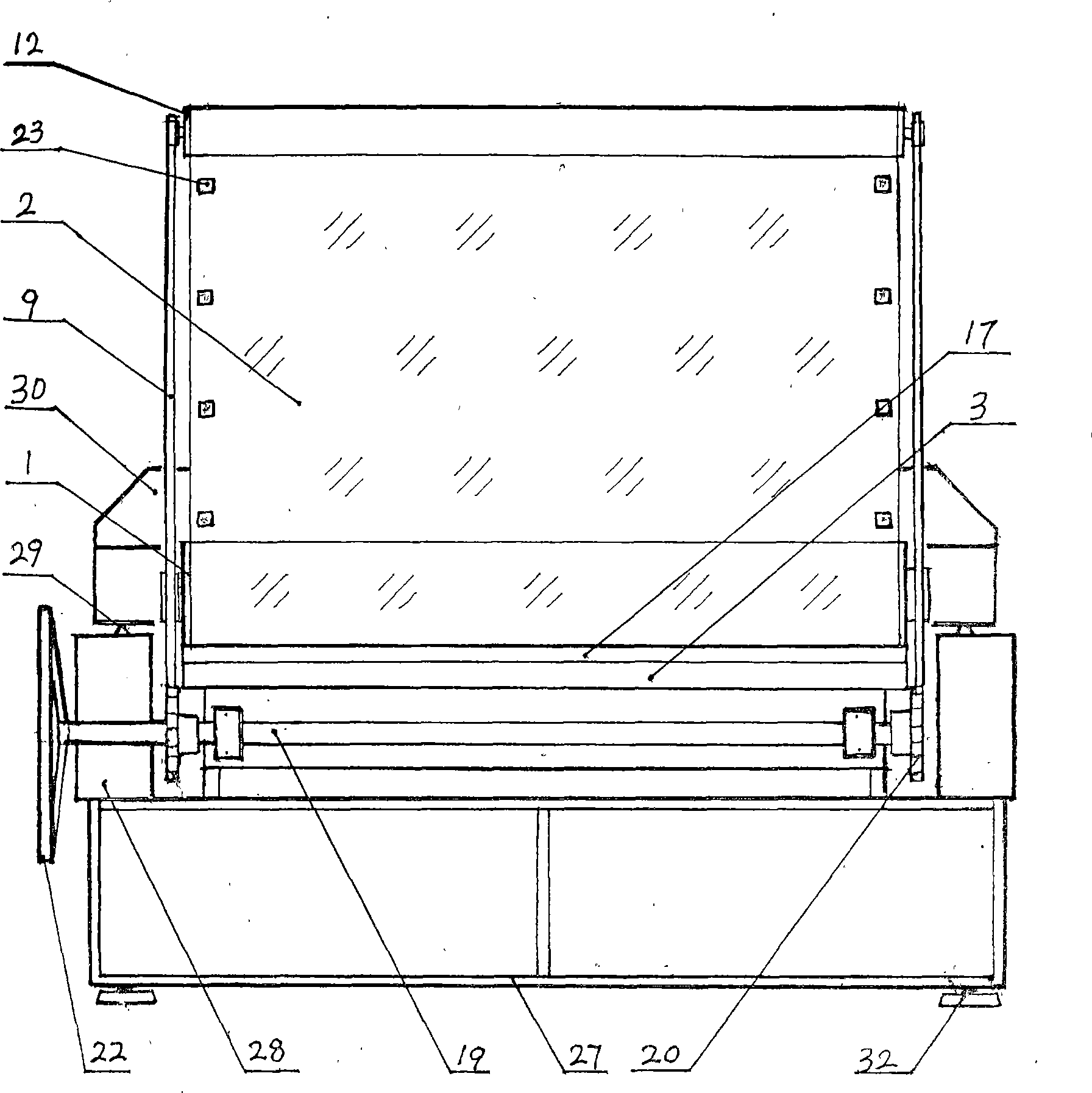

[0049] Refer to attached figure 1 , figure 2 , image 3 , the adjustable anchor plate 32 is installed under the frame 27, the platform 3 is installed on the frame 27, the level of the platform 3 is adjusted with the adjustable anchor plate 32, and one is installed respectively with the vertical surfaces on both sides of the platform length 3 direction, mutually Parallel linear optical axes 7, two linear optical axes 7 are parallel to the upper surface of the platform 27, respectively matching and installing linear bearings 8, and the two linear bearings 8 are formed parallel to each other. Install the pressure roller 1, the two ends of the pressure roller 1 shaft are respectively matched and installed with the same pressure roller bearing 10, and the pressure roller 1 is installed on the two pressure roller bearings 10 respectively. The pressure and lifting device 11 is combined with the pressure roller frame 9 to form the pressure roller 1 The arc of the lower roller surfa...

Embodiment 2

[0061] Refer to attached figure 1 , Figure 4 , Figure 5 , the present embodiment is to use: platform, linear motion conveyor belt, pressure roller, guide roller, front guide roller, rear guide roller, endless belt type transparent film, spring, roller frame, frame, nylon velcro, torque distribution gear box , sprockets, chains, scrapers, etc. The structure is that a power distribution box 31 and an electrical operation box 33 are installed in the frame 27 . Adjustable base plate 32 is installed under the frame 27, and platform 3 is installed on the frame 27, adjusts the level of platform 3 with adjustable base plate 32. The vertical surfaces on both sides of the platform 3 length direction are equipped with a conveyor belt frame 34, and the two ends of the conveyor belt frame 34 are also the two ends of the vertical surface of the platform 3. A conveyor belt roller 36 is installed respectively, and two conveyor belt rollers 36 shafts Both ends, respective matching bearin...

Embodiment 3

[0077] Refer to attached figure 1 , Figure 6 , Figure 7, the present embodiment is to use: platform, linear motion conveyor belt, pressure roller, guide roller, endless belt type transparent film, spring, roller frame, frame, nylon velcro, torque distribution gear box, sprocket wheel, chain scraper And so on. The structure is that a power distribution box 31 and an electrical operation box 33 are installed in the frame 27 . Adjustable base plate 32 is installed under the frame 27, and platform 3 is installed on the frame 27, adjusts the level of platform 3 with adjustable base plate 32. Both sides vertical surfaces of platform 3 length direction, conveyor belt frame 34 is installed, conveyor belt frame 34 two ends, also are the two ends vertical surfaces of platform 3, respectively install a conveyor belt roller 36, two conveyor belt rollers 36 axles respectively Matching bearings at both ends are installed in combination with the conveyor belt frame 34. One of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com