Patents

Literature

392results about How to "Act as a lubricant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified polyvinyl chloride power cable protection material

The invention discloses a modified polyvinyl chloride power cable protection material which comprises the following raw materials in parts by weight: 70-80 parts of polyvinyl chloride, 5-10 parts of ethylene propylene diene rubber, 10-15 parts of chlorinated polyethylene, 10-15 parts of chlorinated polypropylene, 5-8 parts of calcium stearate, 2-3 parts of novel rare-earth stabilizing agents, 0.5-1.5 parts of pentaerythritol, 1.5-3 parts of lanthanum stearate, 3-5 parts of methyl tin mercaptide, 11-13.5 parts of ASA, 2-5 parts of polymethyl methacrylate, 0.8-1.3 parts of dioctyl phthalate, 10-15 parts of coupling agent modified wood flour, 2-3 parts of montmorillonite, 10-15 parts of modified nanometer calcium carbonate, 4-9 parts of ethylenedioxy chloroethyl disilicate, 1-3 parts of red phosphorus, 0.4-1.5 parts of lubricating agents, 1-3 parts of coupling agents and 1-1.8 parts of processing auxiliary agents. The modified polyvinyl chloride power cable protection material disclosed by the invention has the advantages of good ageing resistant property, good impact resistance and long service life.

Owner:无为县华祥电缆材料有限公司

Polycarboxylate water reducer

The invention discloses a polycarboxylate water reducer. The modified polycarboxylate water reducer is prepared by mixing a pulp of a white clay of a papermaking waste, heating, evenly mixing with a corn straw, then adding lauryl sodium sulfate, stirring, drying, and extruding into blocks to obtain a block material for later use; hydrolyzing, and adjusting the pH value of a straw hydrolysate to 6.0-7.0 with CaO to obtain a hydrolysate for later use; drying, oxidizing and sulfonating the hydrolysate, adding into a polycarboxylate-type water reducer, stirring evenly, and treating through ultrasonic waves for 1-2 hours. The papermaking waste is used to manufacture the water reducer, the waste is well turned into the wealth, the strong base in the papermaking waste pretreats the corn straw, so that the corn straw is better pickled for hydrolysis; the substances like cellulose produced after the hydrolysis of the corn straw improve the water reducing effect of the water reducer after being oxidized and sulfonated, meanwhile, the polycarboxylate water reducer also plays a role in lubricating the concrete.

Owner:安徽贯华新材料科技有限公司

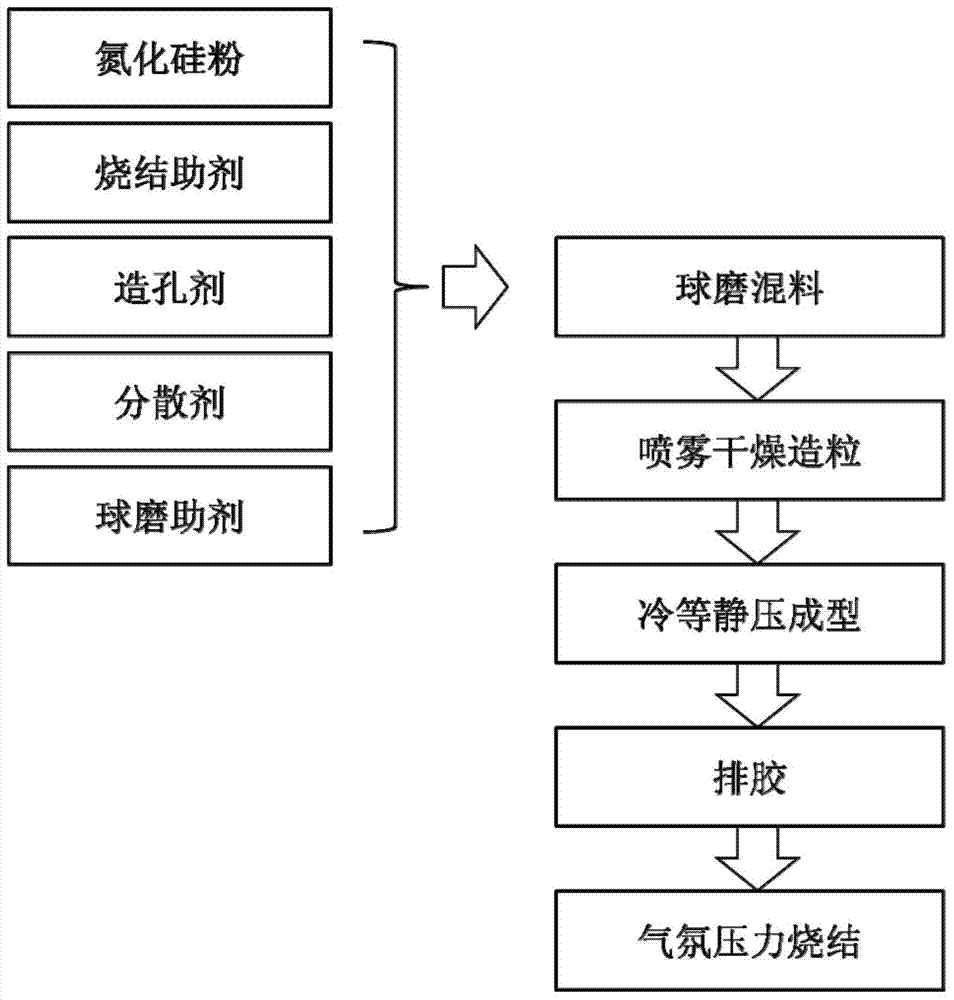

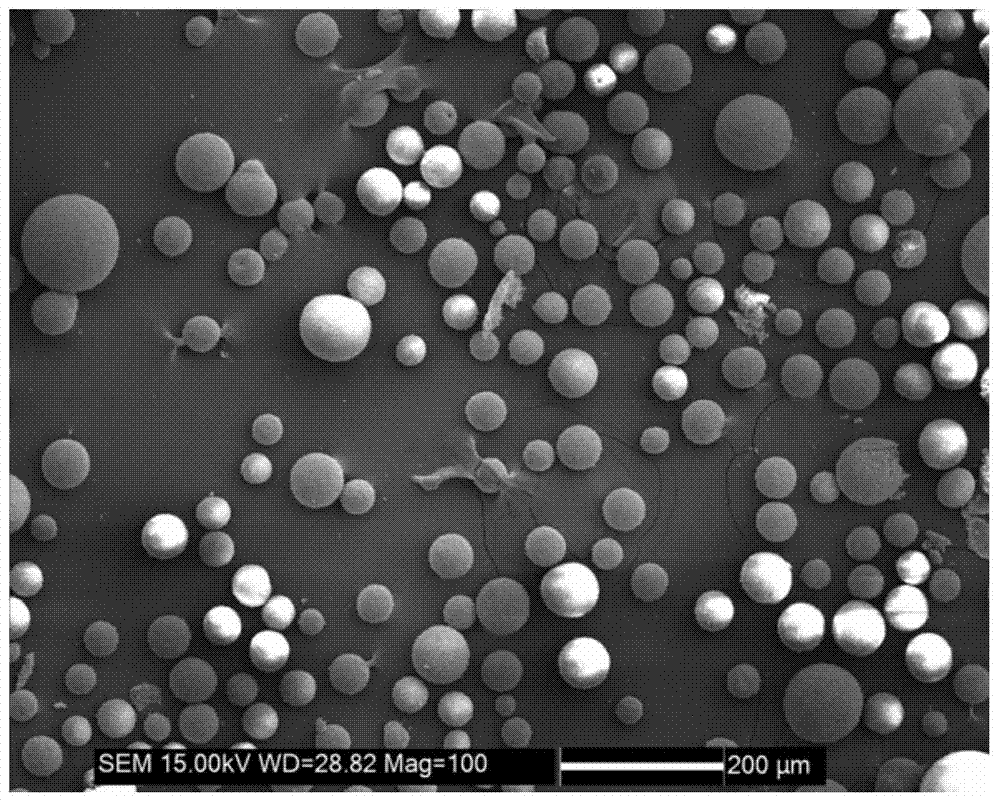

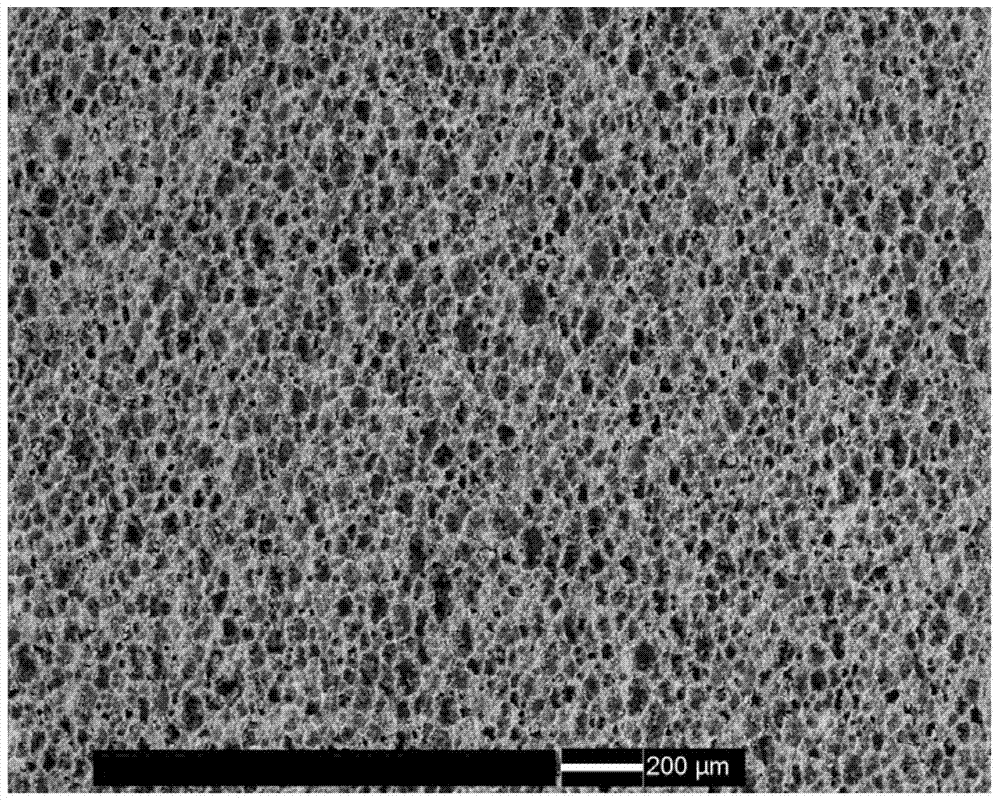

Preparation method of porous silicon nitride ceramic material with spherical pore structure

The invention relates to a preparation method of a porous silicon nitride ceramic material with a spherical pore structure. The method comprises the following steps: uniformly mixing silicon nitride powder with a mono-dispersed polymethyl methacrylate (PMMA) spherical pore forming agent to prepare a stable slurry, preparing microsphere powder (the silicon nitride powder and / the spherical pore forming agent are uniformly dispersed in the above microspheres) with good fluidity and regular shape through a spray drying process, carrying out a direct cold isostatic pressing technology on the microsphere powder to prepare a blank with uniform density, carrying out an optimized batching technology to completely remove the pore forming agent and other organic matters, and sintering in nitrogen pressure atmosphere to obtain the complete non-crack porous silicon nitride ceramic material. The porous silicon nitride ceramic material prepared through the method has the advantages of uniform space distribution, uniform size spherical pores, high bending strength and small discreteness.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

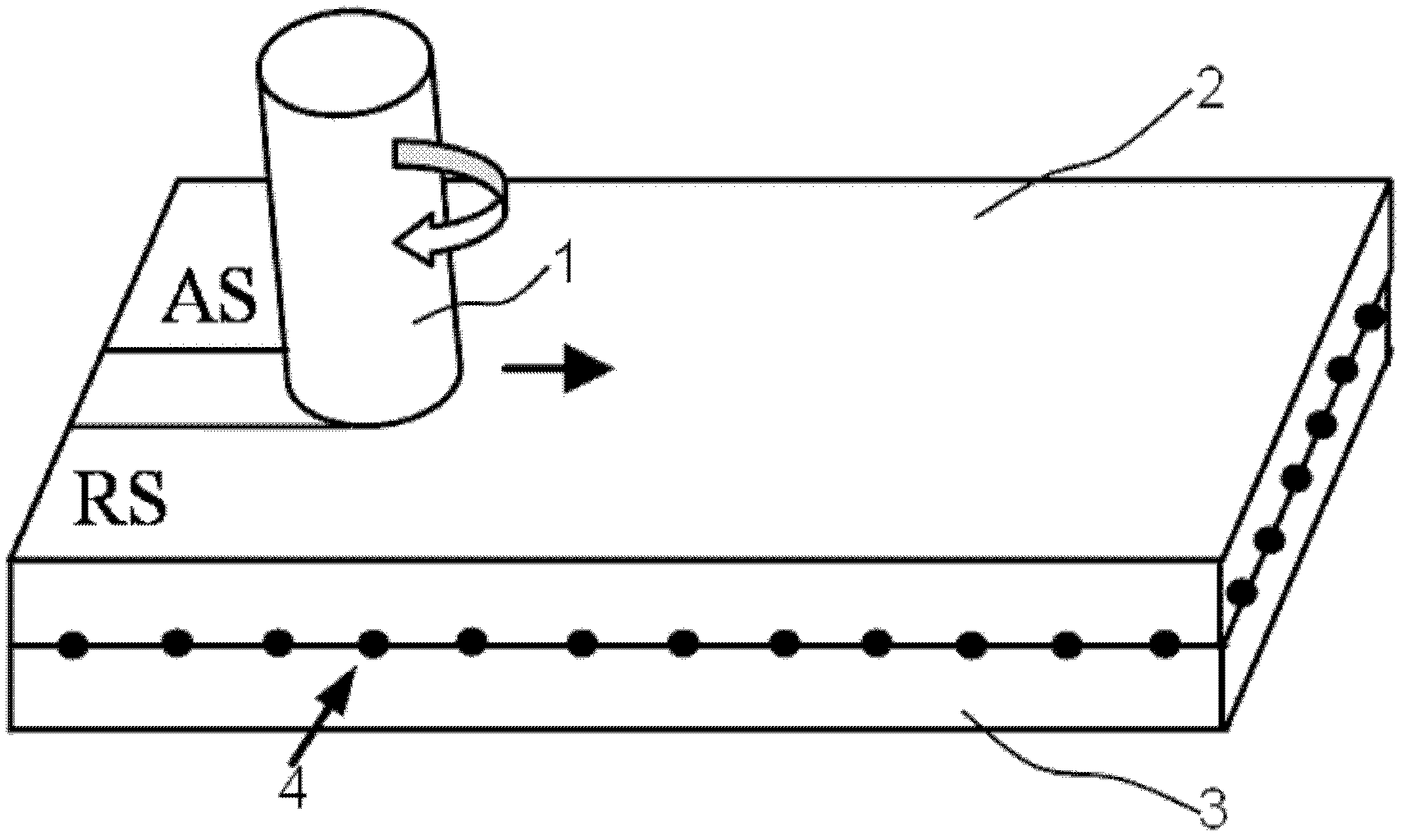

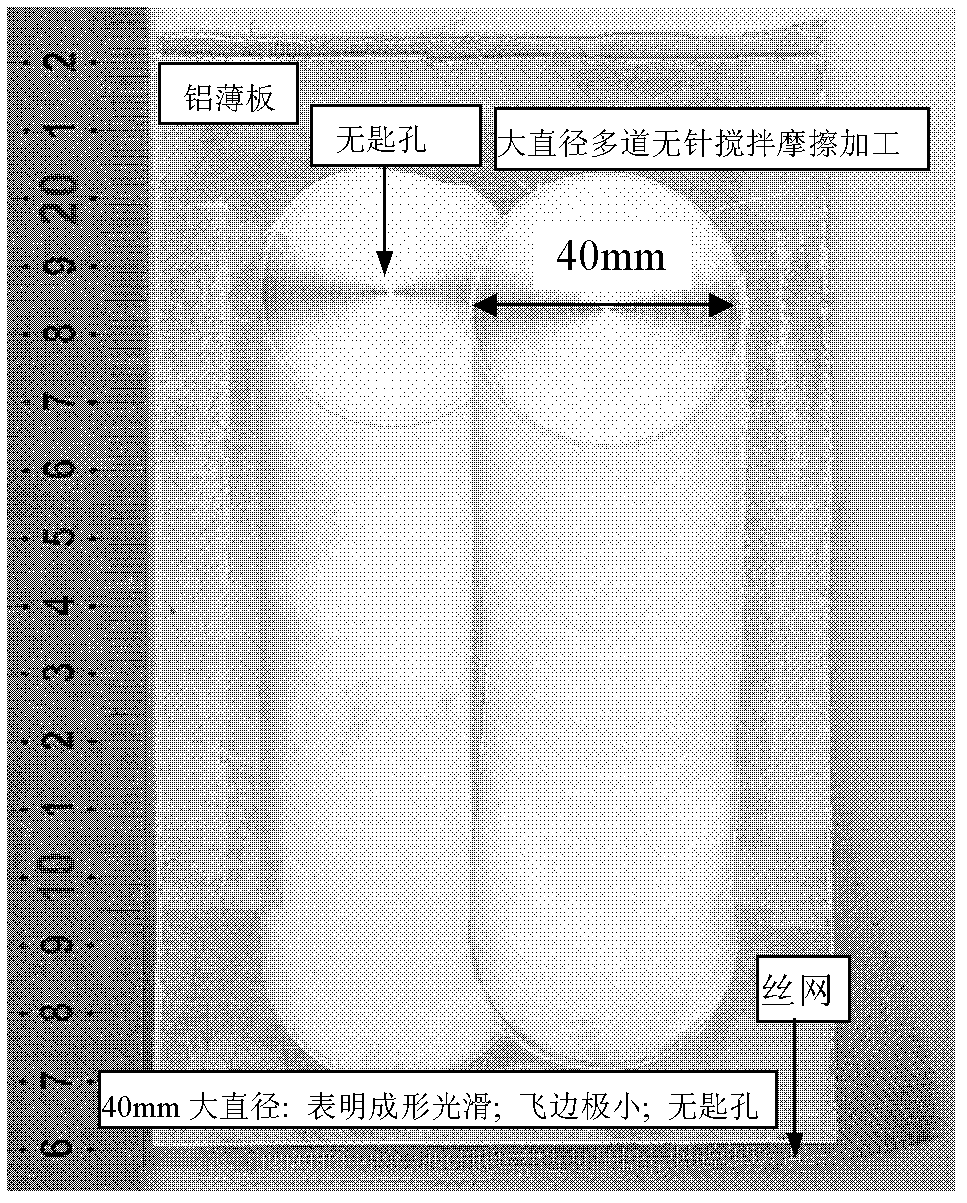

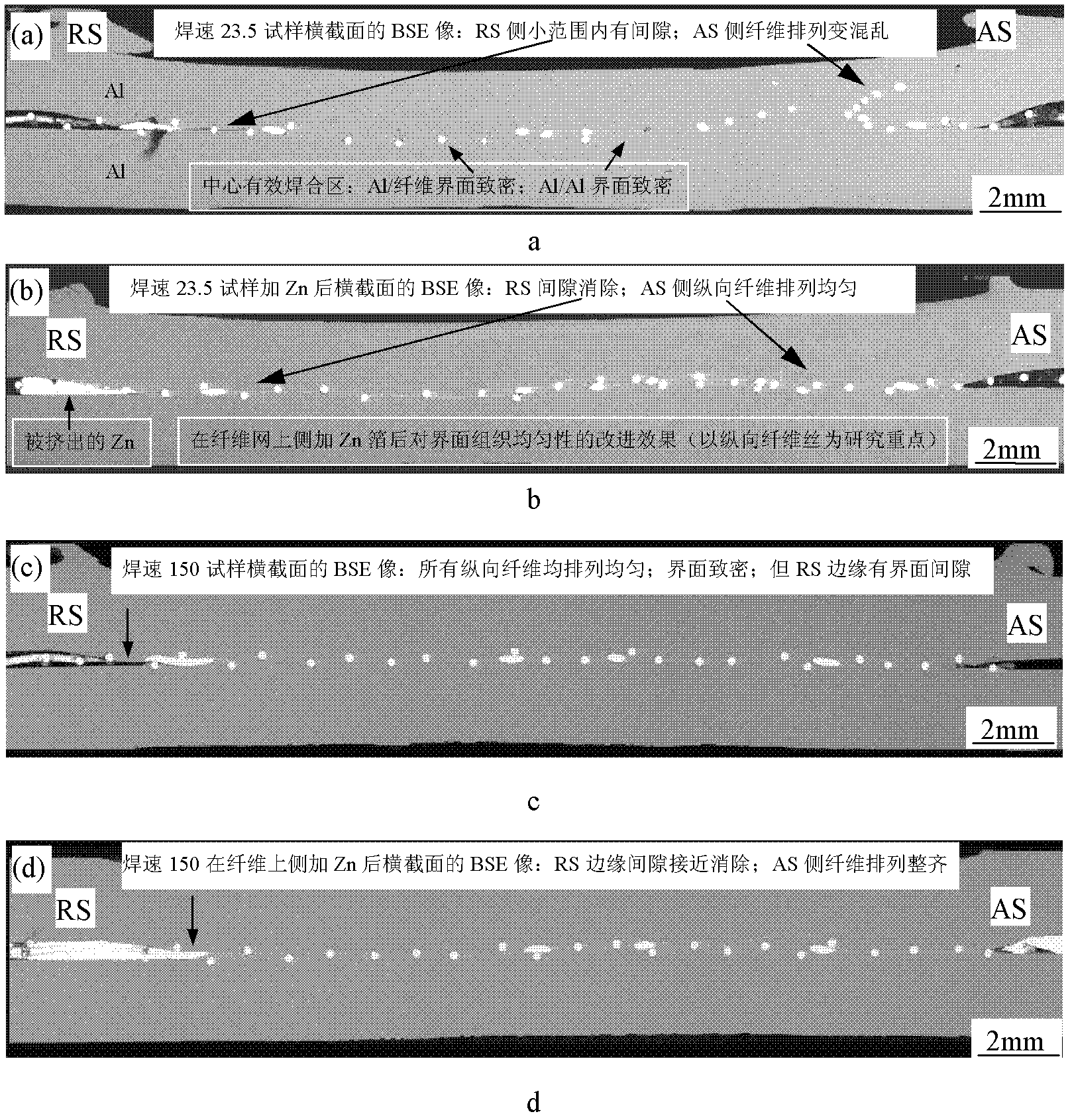

Large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites

InactiveCN102319954AImprove plastic fluidityClose contactNon-electric welding apparatusFiber bundleMetal matrix composite

The invention discloses a large-diameter multi-pass pin-less friction stir processing method for fabricating fiber-reinforced metal matrix composites. Firstly, metal matrix sheets are ground and cleaned in advance; secondly, a preprocessed fiber net or unidirectional fiber bundle is clamped between the two metal matrix sheets in a prearranging manner, and needs to be completely covered and sufficiently protected by the covering sheets; meanwhile, a pin-less friction stir tool is slightly inclined and mounted; the pin-less stool is started to rotate to rub the surface of the covering sheet and move, a plastic deformation gradient field generated by the forging and torsional effects of the shoulder is utilized, consequently, not only can the oxide skin of the metal matrix interface be broken, but also the metal matrix which heats to be softened can plastically flow around the fibers to wrap the fibers, and thereby the fiber / matrix and the matrix / matrix interfaces can be compactly combined. A pin-less stir head with a large diameter more than 40mm to 50mm is adopted to carry out multi-pass multi-layer friction stir processing, and thereby a large, thick fiber-reinforced metal matrix composite plate can be produced. The addition of brazing filler metal can solve the contradiction between fiber injury and interface bonding improvement.

Owner:XI AN JIAOTONG UNIV

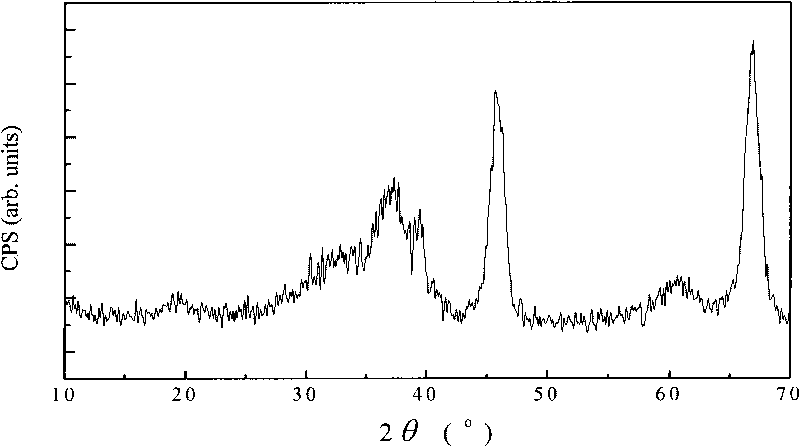

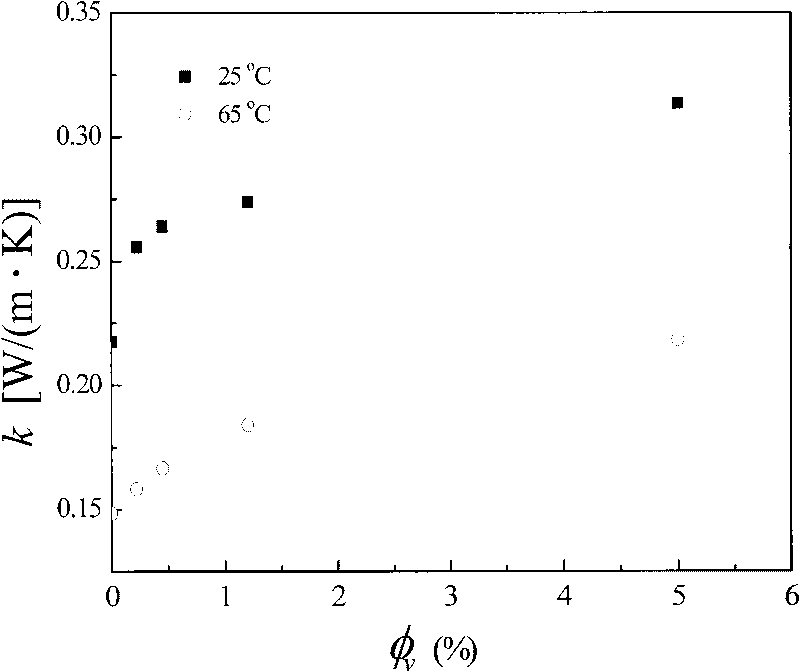

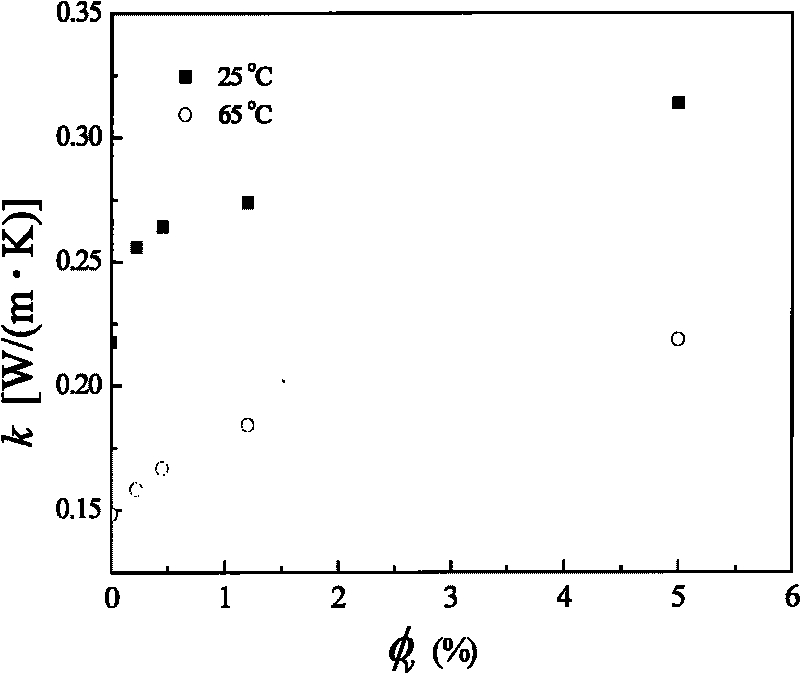

Nanometer aluminum oxide/paraffin compound phase change heat storage material, preparation thereof and application thereof

InactiveCN101724380AGood dispersionImprove thermal conductivityHeat-exchange elementsNano al2o3Air conditioning

The invention relates to a nanometer aluminum oxide / paraffin compound phase change heat storage material, preparation thereof and application thereof. The compound phase change heat storage material is the evenly stabilized compound formed by compounding nanometer aluminum oxide and paraffin. The phase change temperature of the compound phase change heat storage material is adjusted to near the 48 DEG C; thermal analysis tests show that the enthalpy of phase change is big, that the enthalpies of the solid-solid phase change and the solid-liquid total phase change are over 150J / g and that the coefficient of thermal conductivity of the compound phase change heat storage material is greatly increased than that of the mother substance. Thus, the compound phase change heat storage material is widely applied in civilian and military areas such as solar energy utilization, waste heat recovery, intelligent automatic air-conditioning buildings, glass greenhouses, phase change energy storage type air conditioners and constant temperature of electrical appliances.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

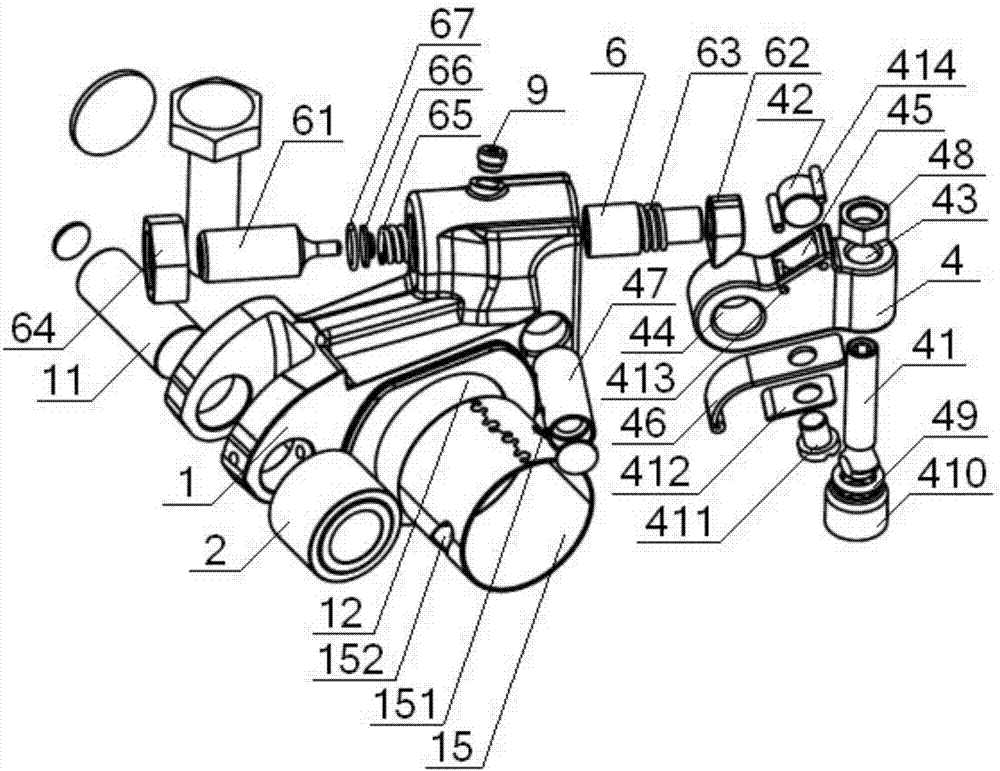

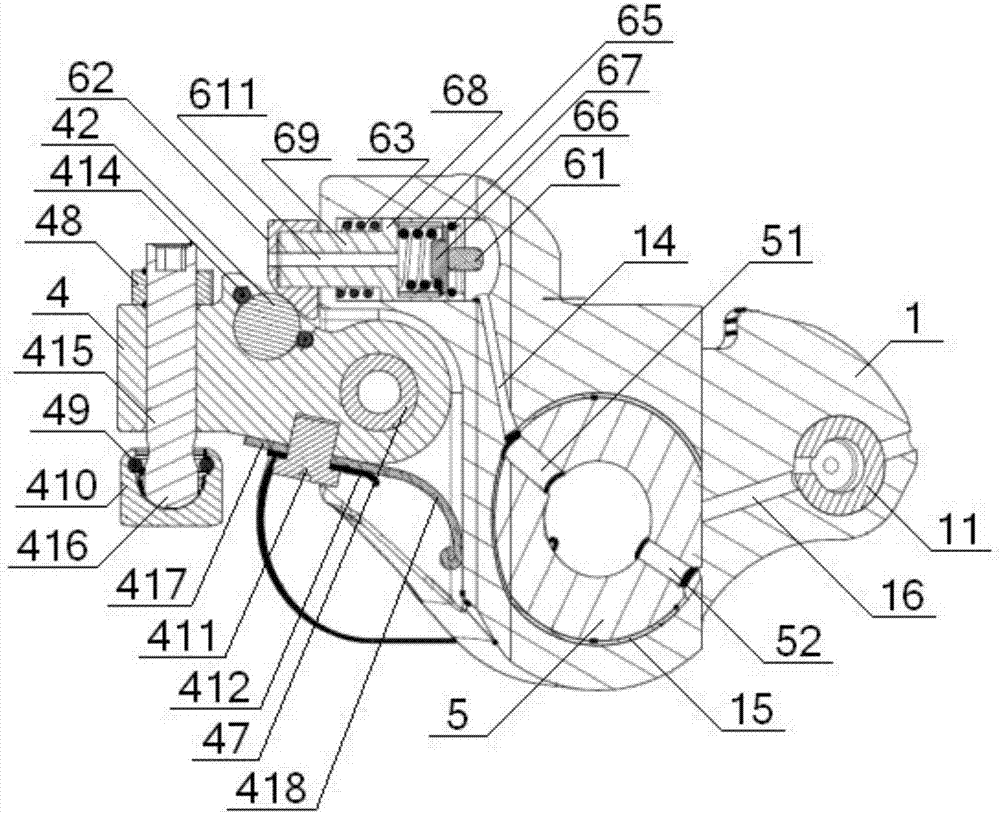

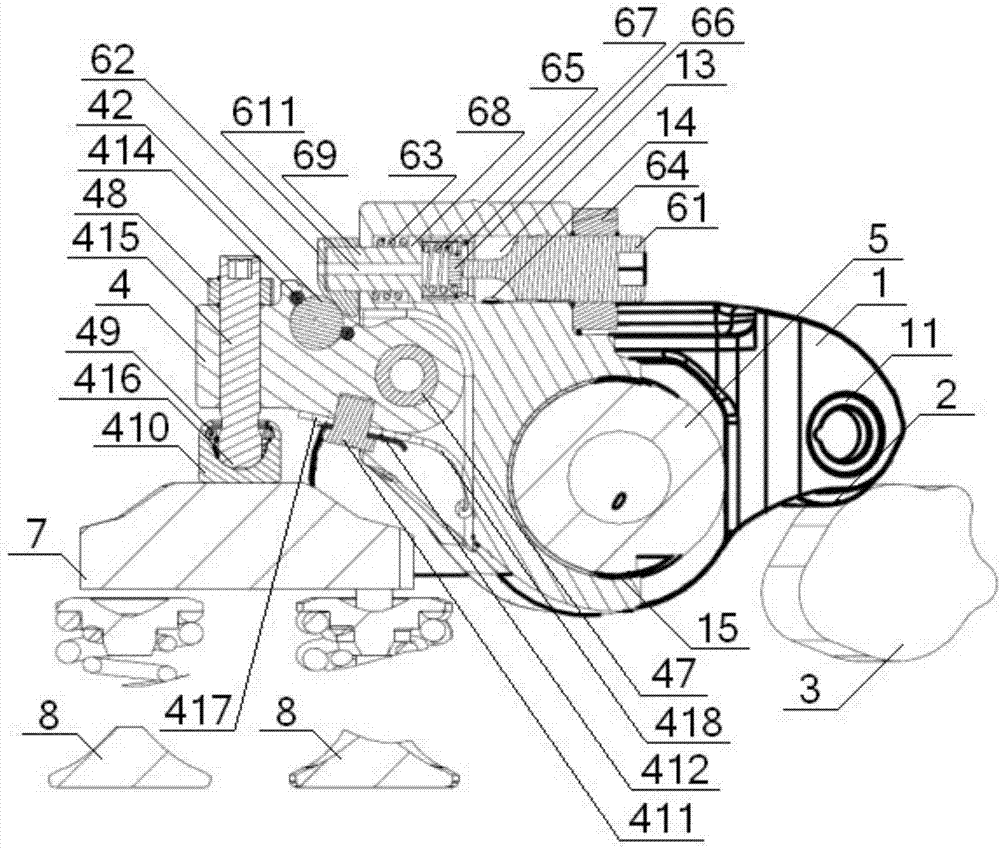

Heavy-duty diesel engine split type rocker arm brake mechanism for commercial vehicle

ActiveCN107143394AReduced processing performanceShorten the lengthValve arrangementsLubrication of auxillariesDieselingCam

A heavy-duty diesel engine split type rocker arm brake mechanism for a commercial vehicle comprises a rocker arm body, a swing mechanism and a hydraulic drive system; the rocker arm body is mounted on a rocker arm shaft through a main mounting hole, the swing mechanism comprises a swing head, a first adjusting bolt and a rolling column, the swing head is mounted on the rocker arm body, a sheet-shaped spring is arranged at the bottom of the swing head, and is pressed on the bottom of the rocker arm body, a ball head of the first adjusting bolt is mounted in a ball socket in an elephant foot shape, the hydraulic drive system comprises a hydraulic plunger with a return spring sleeved, a second adjusting bolt in contact with the hydraulic plunger and a rocker arm cam in threaded connection with the hydraulic plunger, the hydraulic plunger is mounted in a drive cavity of the rocker arm body, the rocker arm cam makes contact with the rolling column, a brake hydraulic oil way communicated with the main mounting hole, the drive cavity and a swing arm shaft hydraulic oil hole is arranged in the rocker arm body, and the heavy-duty diesel engine split type rocker arm brake mechanism is high in reliability, low in cost, high in lightweight degree, simple in structure, convenient to assemble and maintain and good in brake effect.

Owner:DONGFENG COMML VEHICLE CO LTD

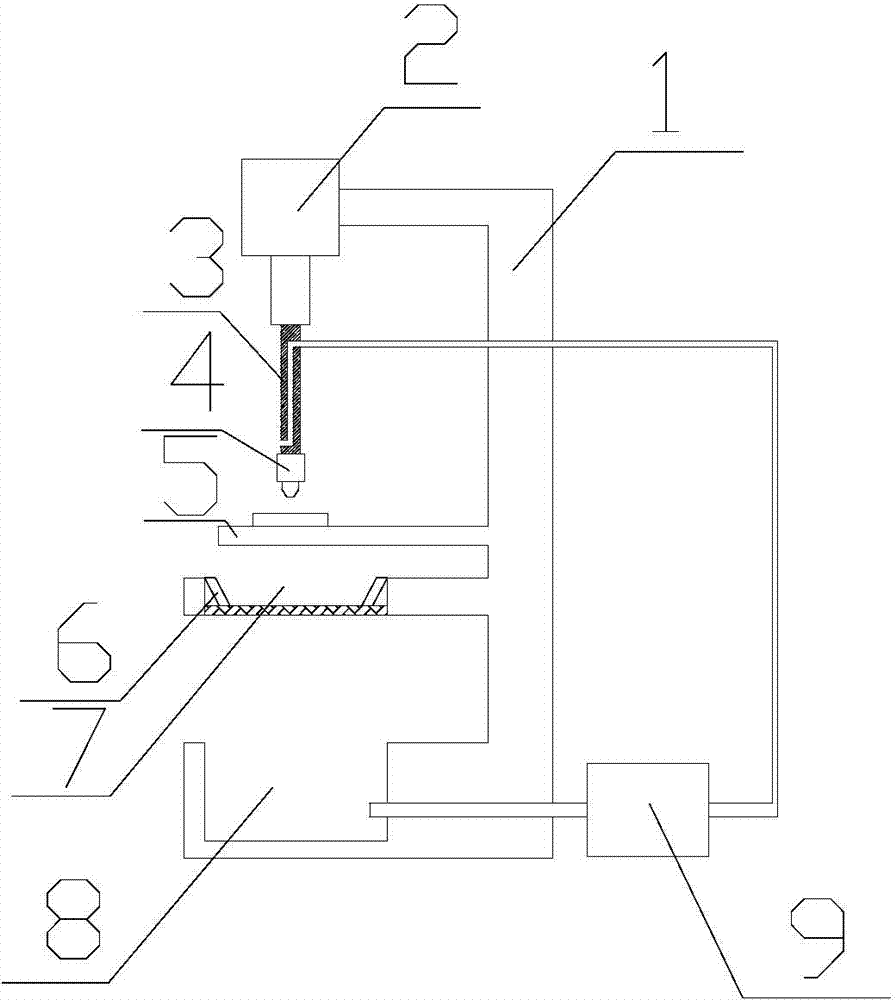

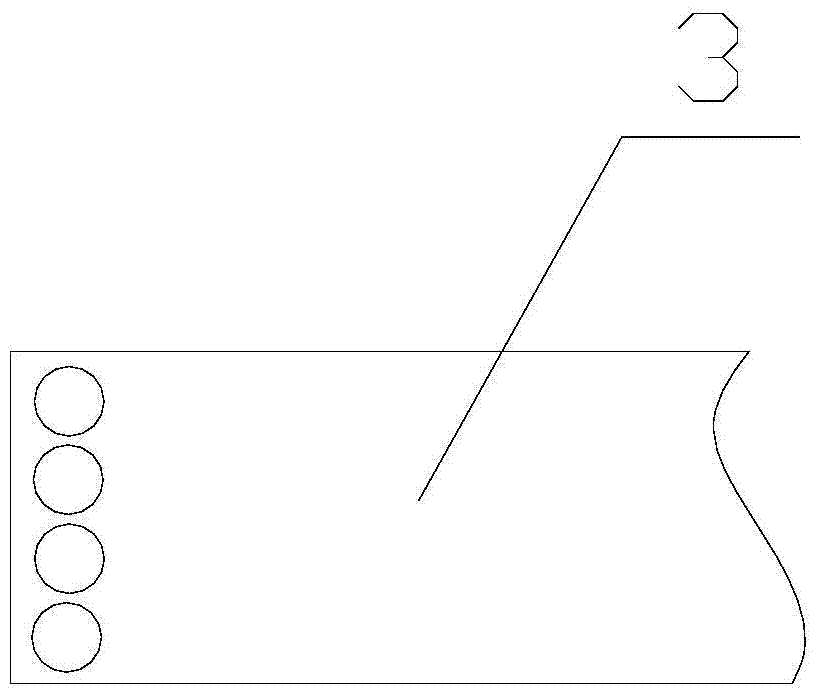

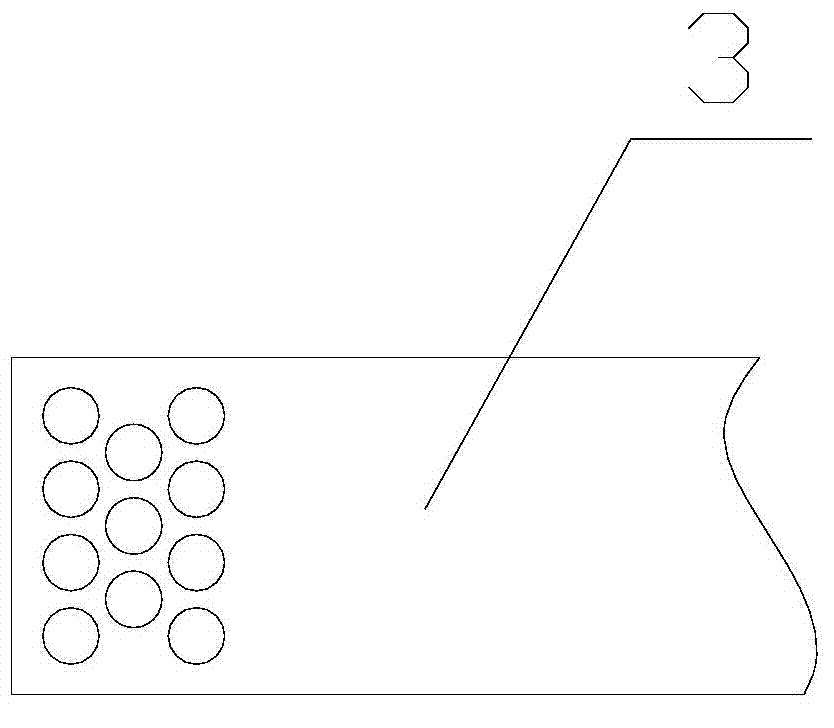

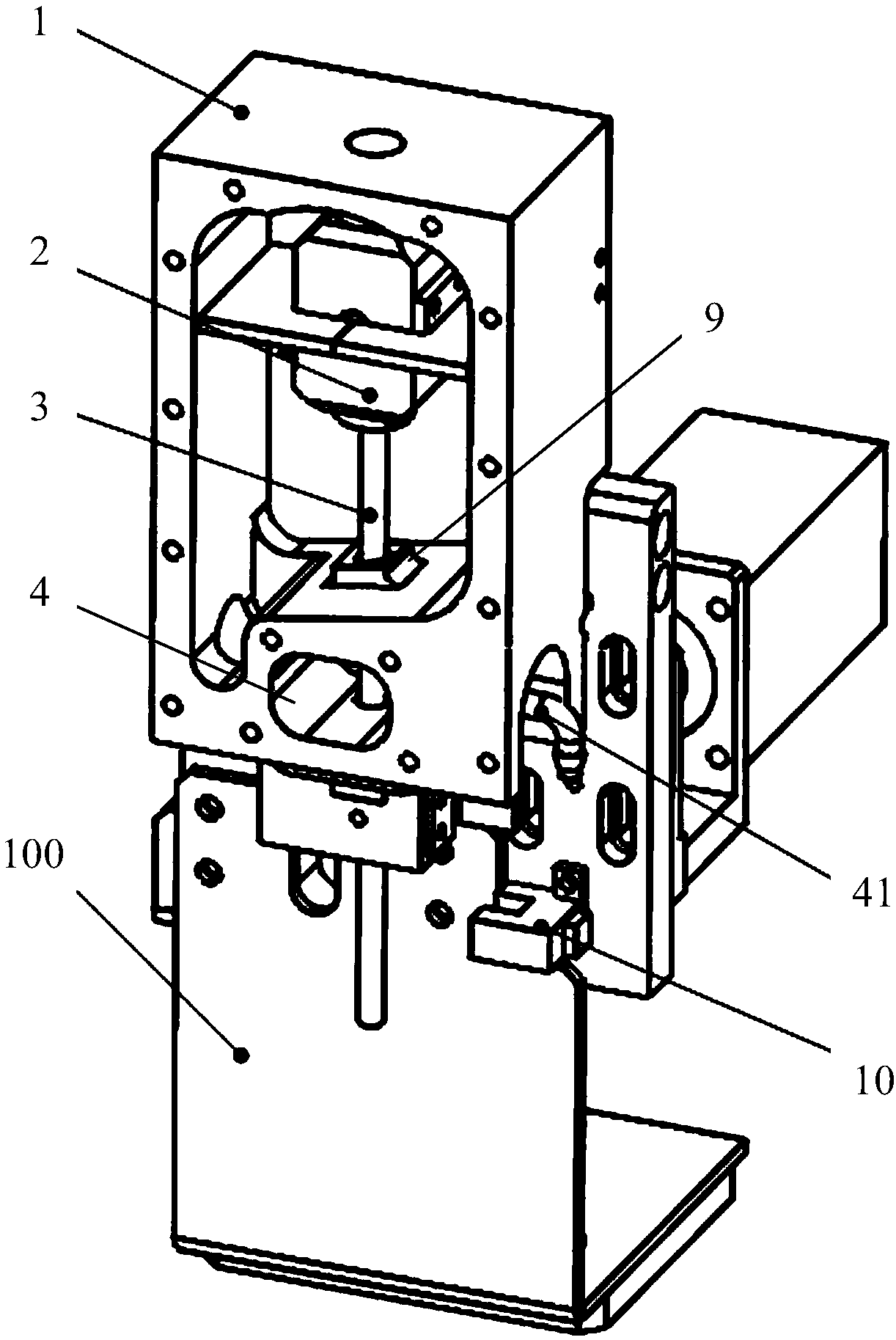

Machine tool

InactiveCN103567489AEasy to cleanProtection bitBoring/drilling componentsMaintainance and safety accessoriesScrapDrill bit

The invention discloses a machine tool, comprising a machine tool body, a drive device, a clamp mechanism and a processing mechanism, wherein the drive device, the clamp mechanism and the processing mechanism are mounted on the machine tool body; the processing mechanism comprises a drill rod; one end of the drill rod is provided with a first connecting structure capable of mounting a drill bit; the output shaft of the drive device is in drive connection with one end, far away from the first connecting structure, of the drill rod and drives the drill rod to rotate; the drill rod is of a hollow structure; a water inlet is formed in the rod wall of one end, far away from the first connecting structure, of the drill rod; at least one water outlet is formed in the rod wall of one end, close to the first connecting structure, of the drill rod; a scrap placing disk is connected to the machine tool body and is located below the clamp mechanism; the bottom of the scrap placing disk is a filter screen; a liquid collecting groove is arranged below the scrap placing disk; a water pump is arranged at one end of the liquid collecting groove; the water inlet pipe of the water pump is communicated with a pipeline in a liquid collecting groove body; the water outlet pipe of the water pump is connected with a water inlet hose of the drill rod.

Owner:ANHUI PROVINCE JIEYONGDA INTELLIGENT MACHINE

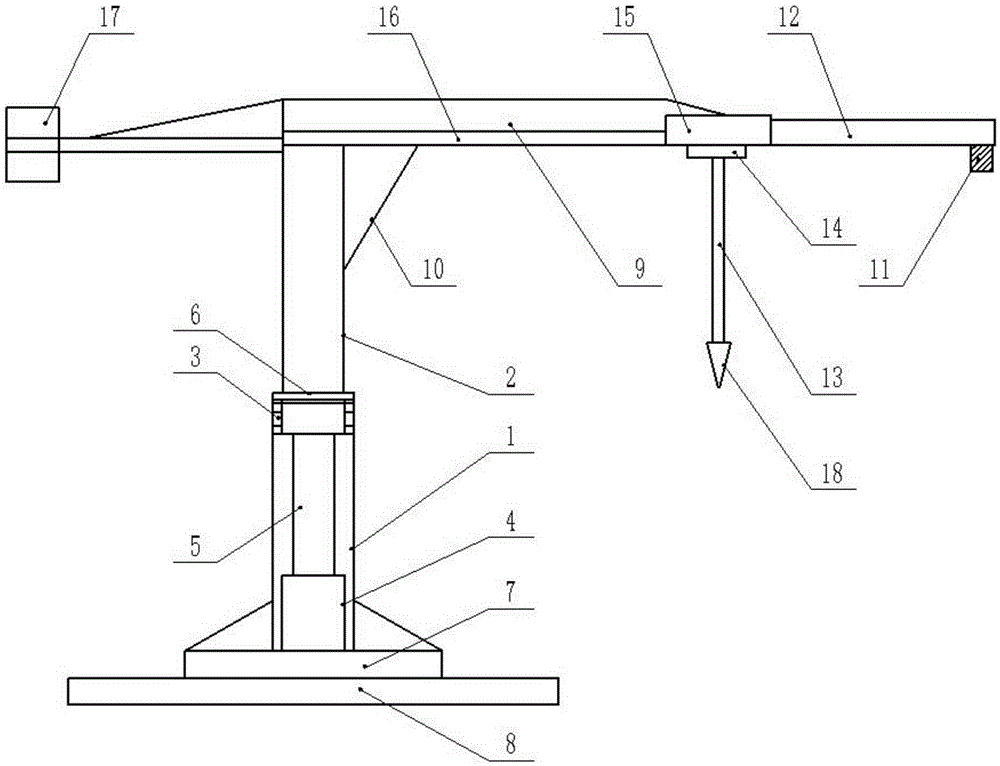

Crane

The invention discloses a crane, comprising an outer barrel, an inner barrel and a cantilever; the inner barrel is sleeved in the outer barrel, the cantilever is arranged at the top end of the inner barrel, a rubber washer is sleeved on the inner barrel; a hydraulic driving system is arranged at the bottom of the outer barrel, a shock pad is arranged below the hydraulic driving system; a lubricating oil storage tank is connected to the top end of the outer barrel; a fixed base is arranged at the bottom of the shock pad and is fixedly connected with the ground by bolts; a triangular reinforcing rib is arranged above the inner barrel, the upper parts of the inner barrel and the triangular reinforcing rib are connected with the cantilever; the cantilever comprises a stop pin, a telescopic boom, a wire cable, a sliding mechanism, a telescopic motor, a reset spring and a weight box; and the stop pin is arranged at the right front end of the telescopic boom, the left end of the telescopic boom is connected to the inside of the cantilever in a sliding way, and the left end of the cantilever is provided with the weight box. The crane can prevent dust and abrasion, is good in sealing and lubricating effect, conforms to engineering mechanics, and can save energy.

Owner:ANHUI CHAOSHENG HOISTING MACHINERY CO LTD

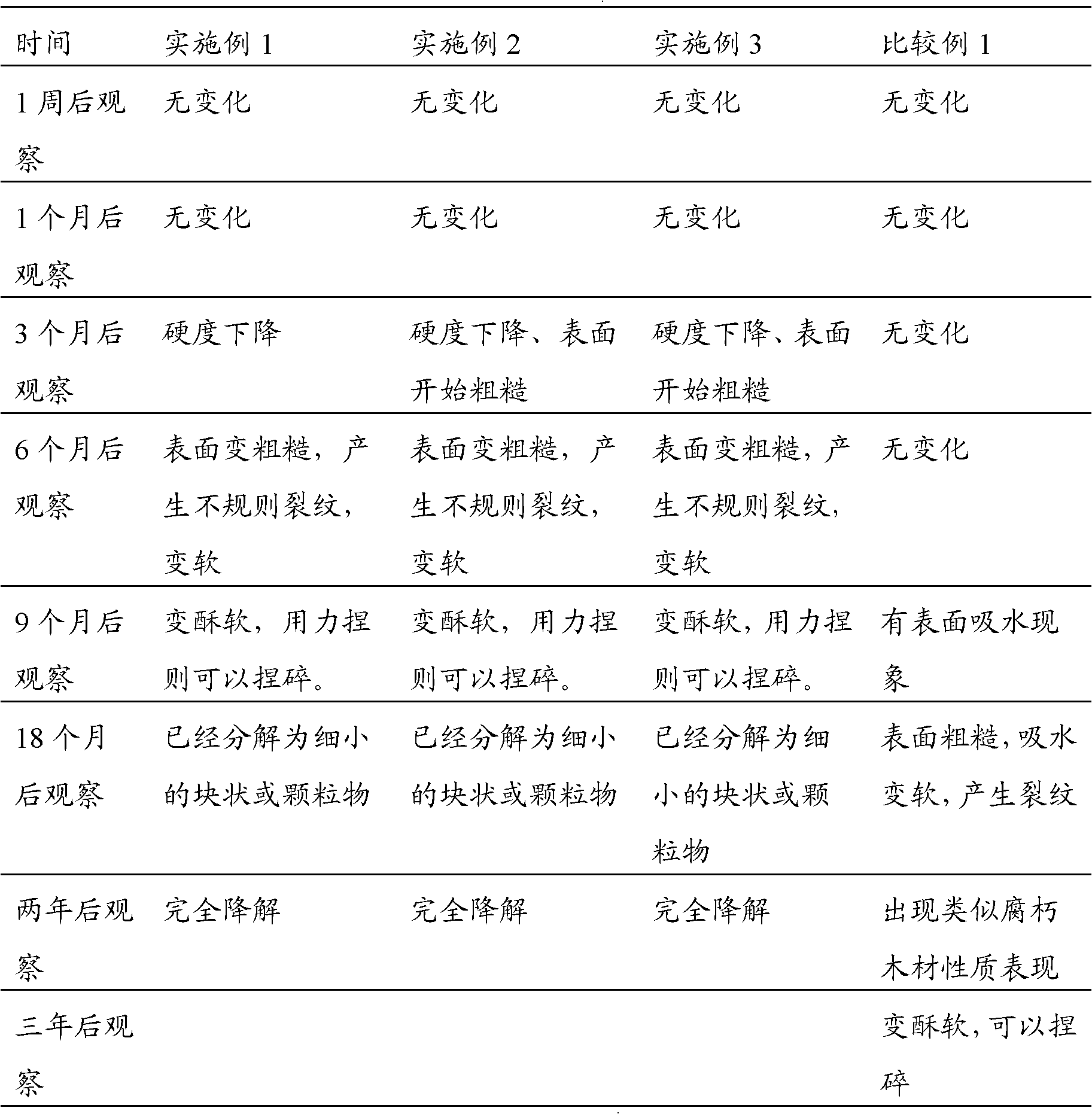

Plant fiber material composite and preparation method of plant fiber product

The embodiment of the invention discloses a plant fiber material composite and a preparation method of a plant fiber product. The method comprises: 40wt% to 50wt% of plane fiber powder, 30wt% to 40wt% of soy protein adhesive, 5wt% to 10wt% of corn starch, 5wt% to 10wt% of glycerol, 4wt% to 7wt% of cavings and 3wt% to 8wt% of water are mixed and molded through heating and mould pressing to prepare the plant fiber product. The soy protein adhesive has the action of adhesion, and the protein component in the soy protein adhesive can supply rich nutrition components for microorganisms, and accelerates the decomposition of the plant fiber product by utilizing the microorganisms and the degradation of the plant fiber product in the degradation course of the plant fiber product. The experiment result indicates that the prepared plant fiber product has quicker degradation rate, starts to be degraded in 2 to 6 months, can be completely degraded in two years and has the advantages of no pollution and environmental friendliness.

Owner:宁波木林森纤维科技有限公司

Rubber and metal framework bonding method

The invention discloses a rubber and metal framework bonding method, which is characterized by comprising six steps including preparation of rubber, cleaning of a metal framework, drying of the metalframework, covering of primer, covering of surface glue and vulcanization. Through the above method, bonding strength between rubber and the metal framework can be remarkably enhanced, and it is ensured that rubber has good processability.

Owner:NINGBO TUOPU GROUP CO LTD

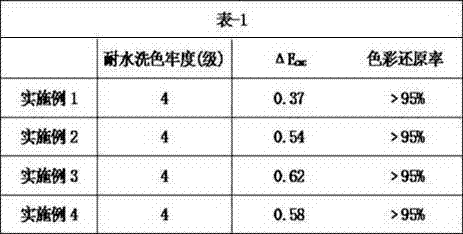

Water-based nano pigment ink for textile printing

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

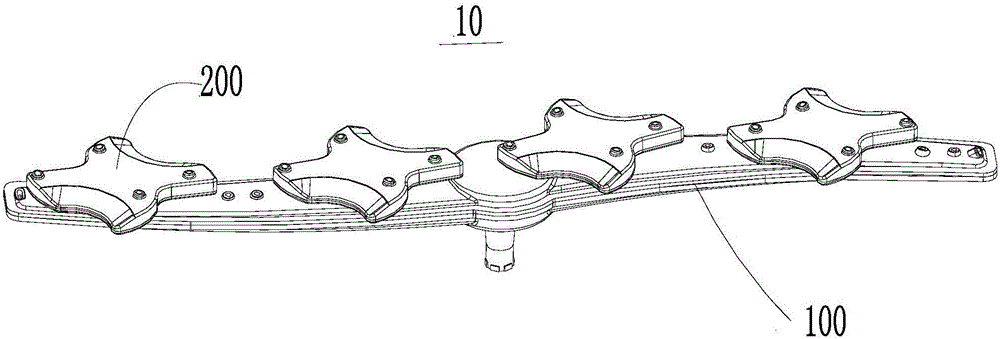

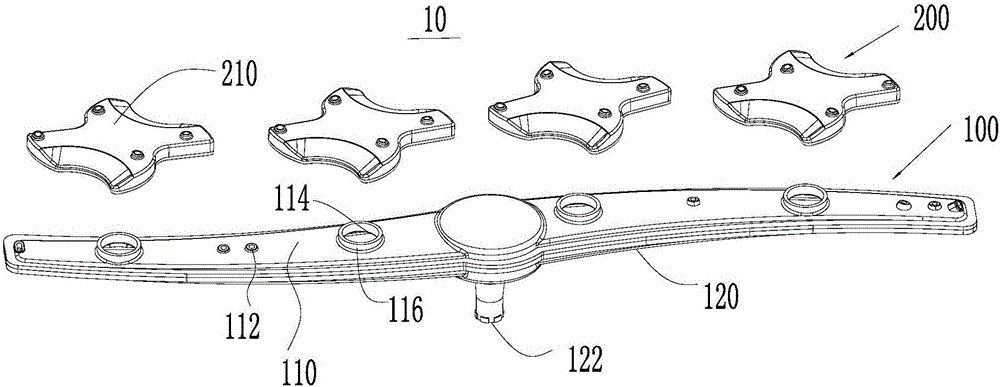

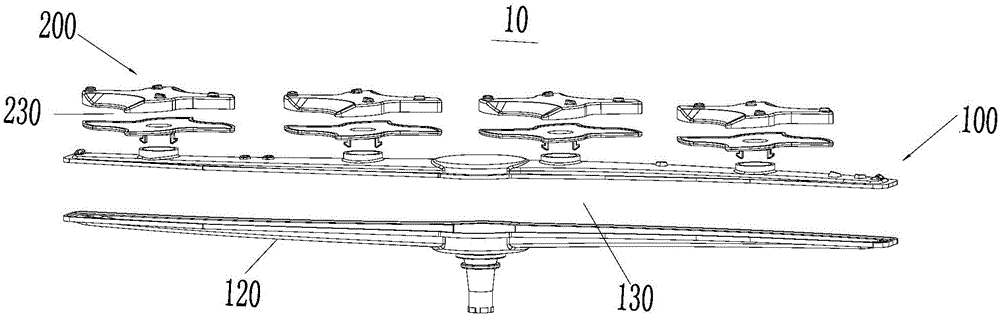

Spraying device of dish washing machine and dish washing machine

ActiveCN105919529AHigh efficiency washing effectEven distribution of water flowTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention provides a spraying device of a dish washing machine. The spraying device comprises a first sprayer and a second sprayer, wherein the first sprayer comprises a first water storage cavity and a first spraying surface; the second sprayer is rotationally arranged on the first spraying surface; the second sprayer is a quadrilateral sprayer, and comprises a second water storage cavity, a second spraying surface and a plurality of second spraying holes; the second spraying holes are formed in the second spraying surface, and are communicated with the second water storage cavity; the first water storage cavity is communicated with the second water storage cavity. The spraying device has the advantage that the second sprayer is the quadrilateral sprayer, so that the distribution of sprayed water flow is more uniform, the blind area of washing is reduced, the effective washing area is increased, and the washing efficiency of the spraying device of the dish washing machine is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

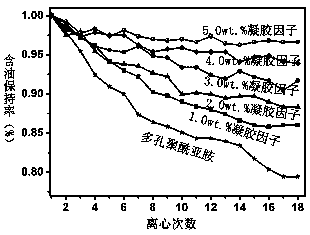

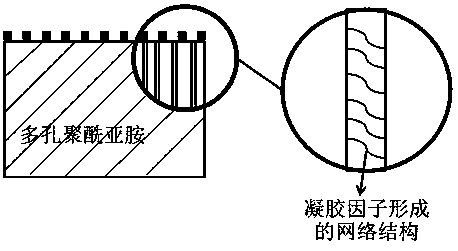

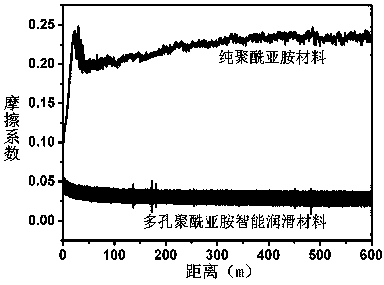

Preparation method for porous polyimide intelligent lubricating material

The invention relates to a preparation method for a porous polyimide intelligent lubricating material. The method comprises the following steps: (1) preparing a leucine gelator: adding leucine, hexadecanol and a p-toluene sulfonic acid monohydrate to a methylbenzene solvent, after performing an esterification reaction, to obtain an oily substance; firstly dissolving the oily substance, and adjusting a pH value, to obtain leucine hexadecyl ester; after enabling the leucine hexadecyl ester to be dissolved in absolute ethyl alcohol, adding glucolactone, after performing a reflux reaction, enabling a residue to be dissolved in hot 1,4-dioxane, filtering while hot, and recrystallizing, to obtain the leucine gelator; and (2) preparing the porous polyimide intelligent lubricating material: aftersieving polyimide powder, cold-pressing, covering die in a normal pressure, sintering, and slicing, preparing a massive porous polyimide material; adding the leucine gelator to lubricating oil, afterheating and adequately dissolving, enabling the massive porous polyimide material to be immerged, cooling in a room temperature, to obtain the porous polyimide intelligent lubricating material. The porous polyimide intelligent lubricating material is capable of effectively improving an oiliness retention rate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

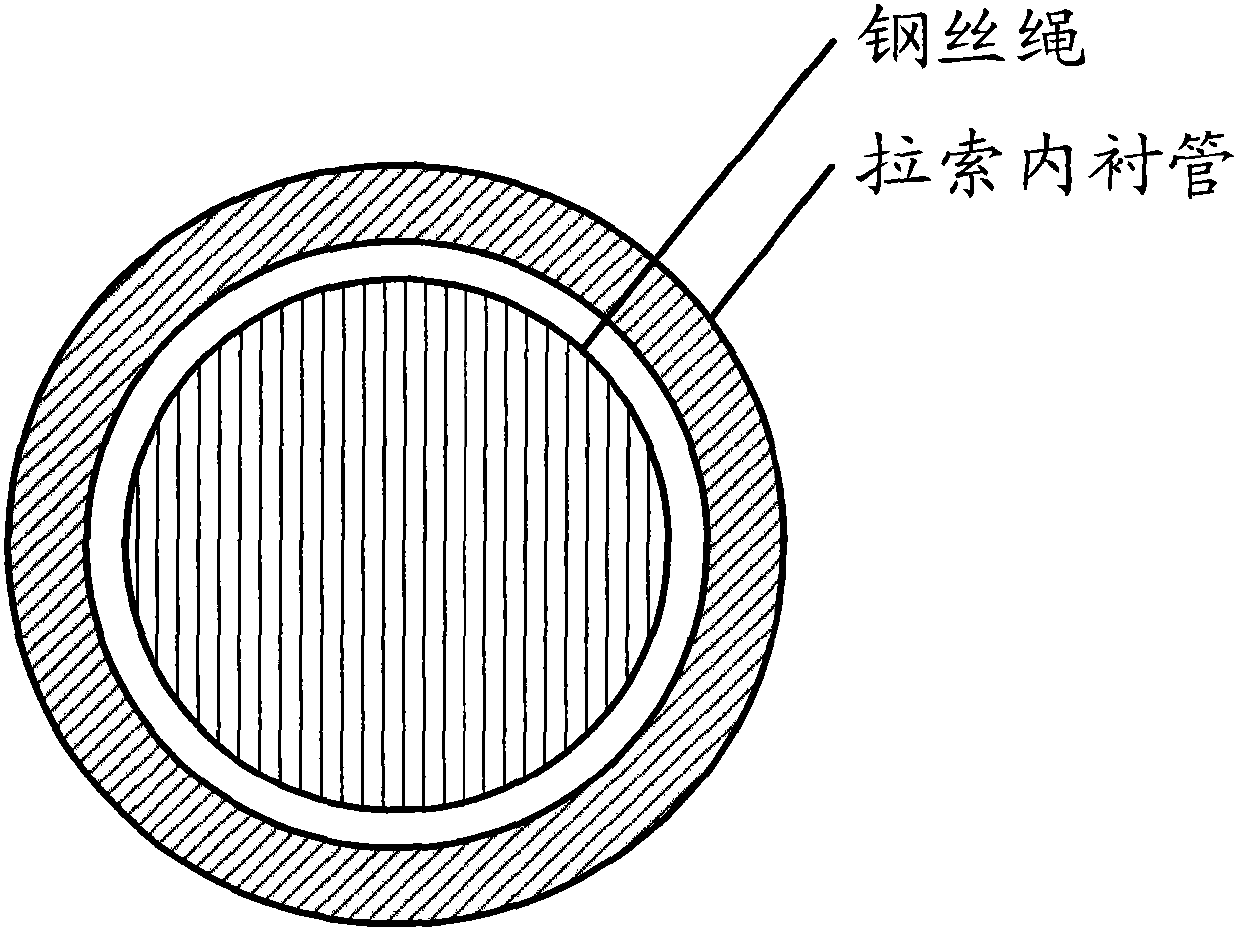

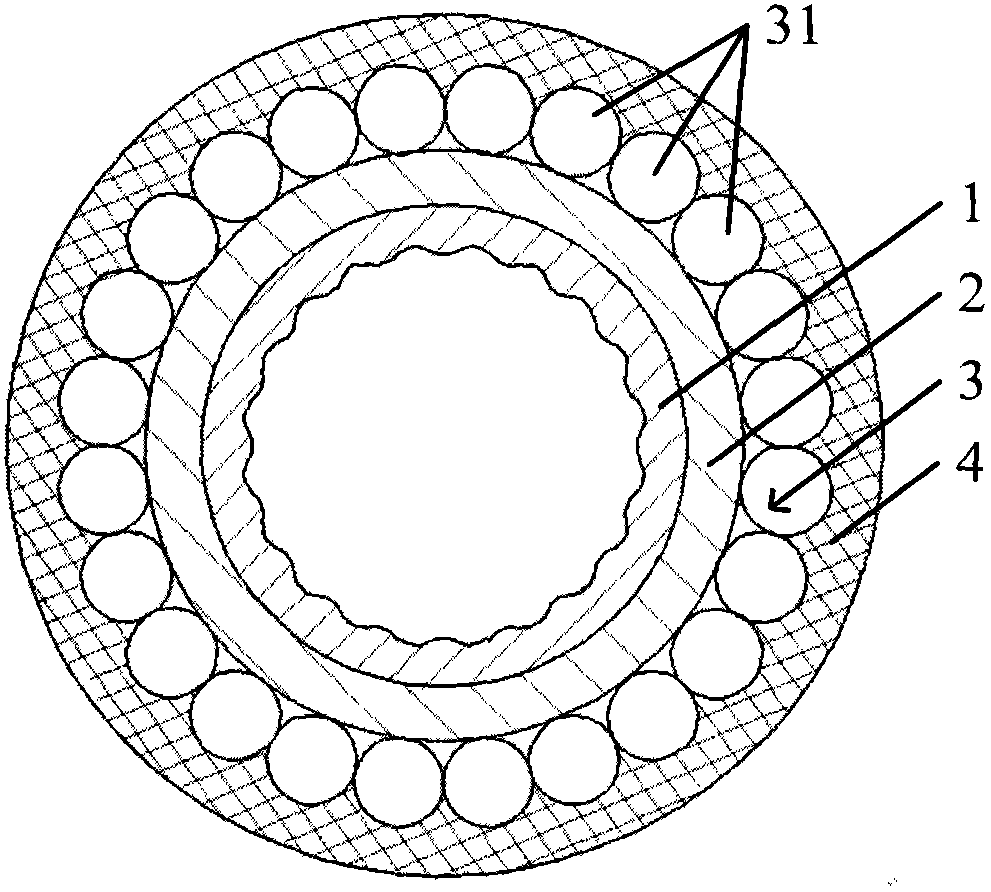

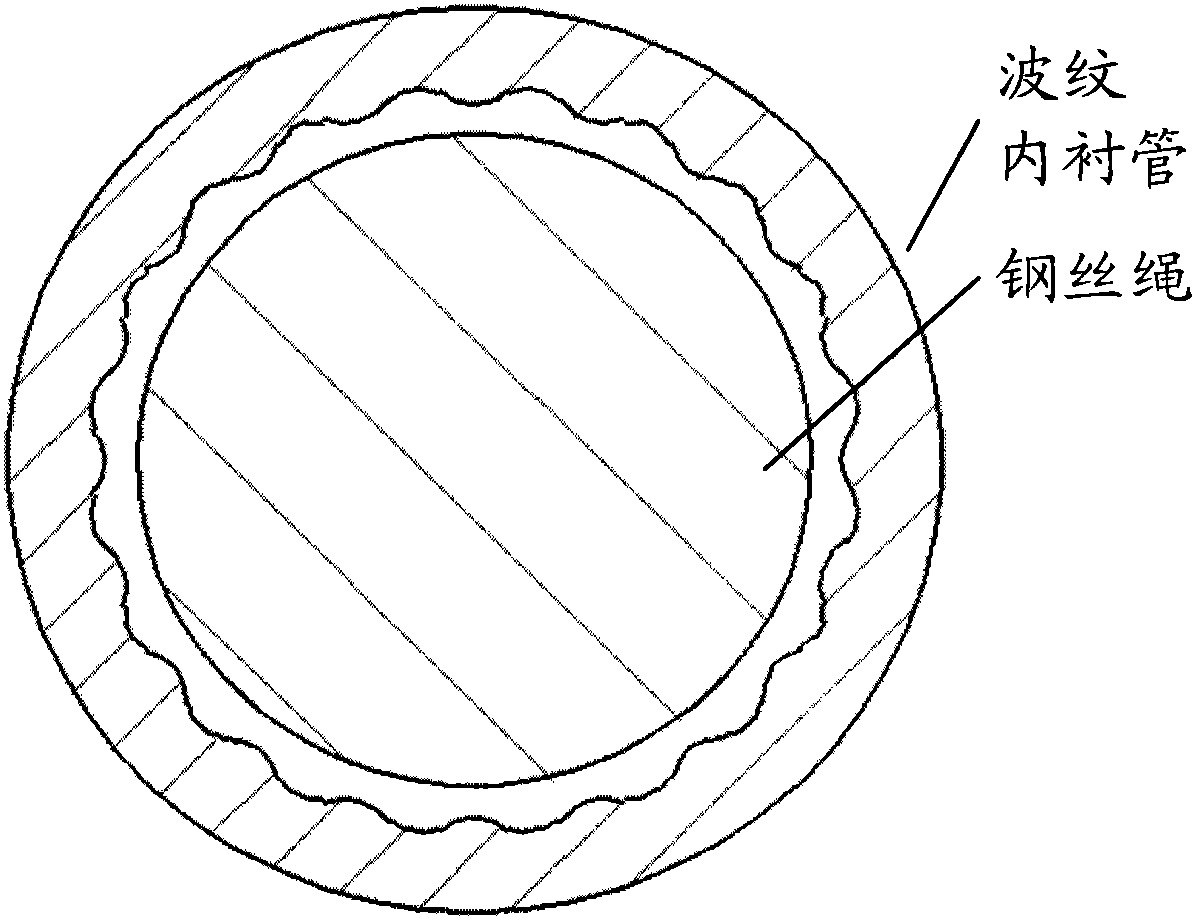

Inhaul cable sleeve for automobile

The embodiment of the invention discloses an inhaul cable sleeve for an automobile. The inhaul cable sleeve comprises a corrugated lining tube, a flat steel belt, a steel wire layer and a plastic coating layer in turn from inside to outside, wherein the corrugated lining tube has a hollow tubular structure; the inner surface of the corrugated lining tube is the surface with continuous corrugated bulges; the flat steel belt has a flat banded structure; the flat steel belt is spirally wound on the outer surface of the corrugated lining tube; a bare tube of the inhaul cable sleeve for the automobile is formed by the flat steel belt and the corrugated lining tube; the steel wire layer is composed of a plurality of steel wires; the steel wires in the steel wire layer are uniformly distributed on the outer surface of the bare tube; and the plastic coating layer covers the outermost layer of the tubular structure formed by the corrugated lining tube, the flat steel belt and the steel wire layer. By adopting the inhaul cable sleeve for the automobile provided by the invention, a contact area of a lining tube and a steel wire rope is reduced, and a frictional force caused by the relative motion of the lining tube and the steel wire rope, namely, an operating force during the working process of an inhaul cable of the automobile, is reduced, so that the force-transferring efficiency of the inhaul cable of the automobile is increased and the noise caused by the vibration of the steel wire rope and the lining tube is reduced.

Owner:SHANGHAI WR CONTROLS CO LTD

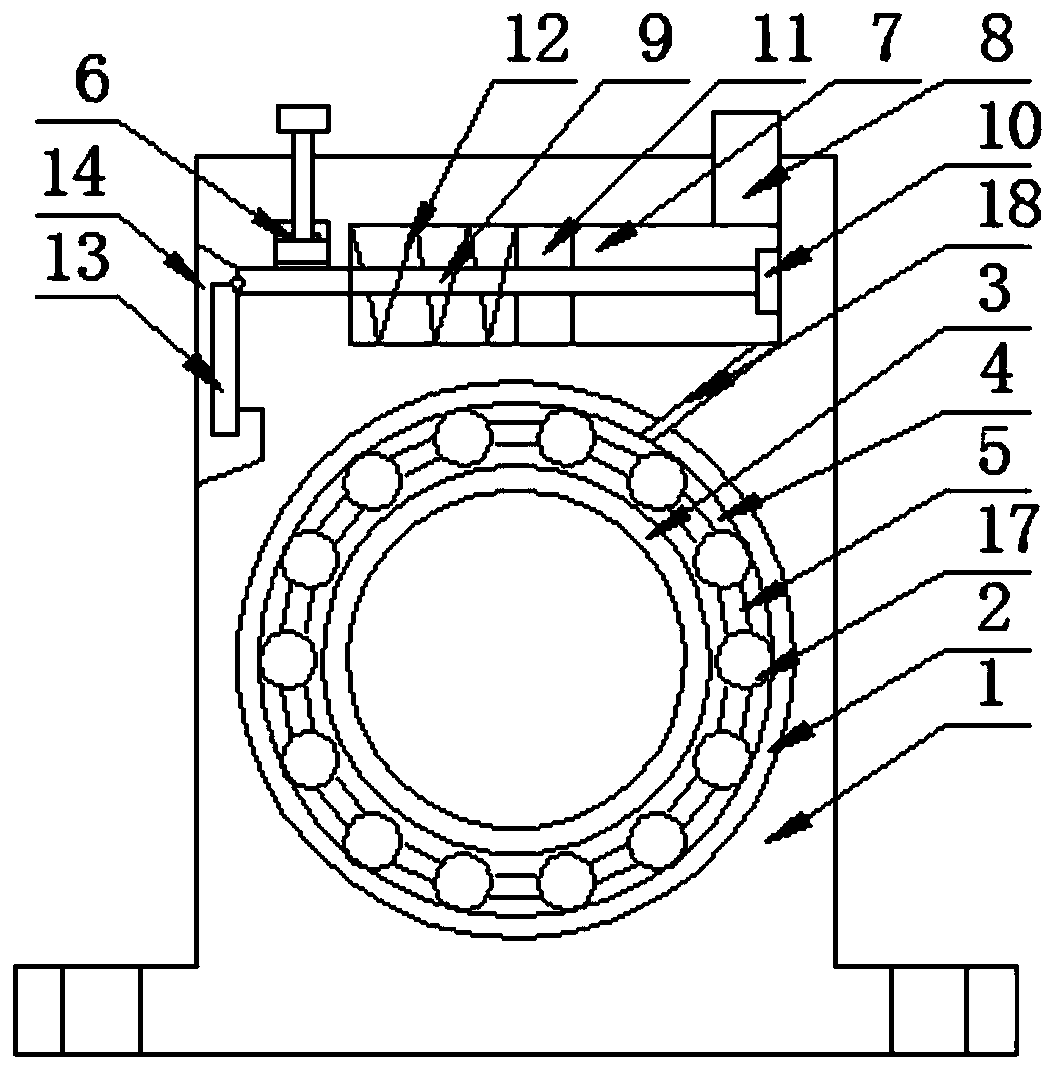

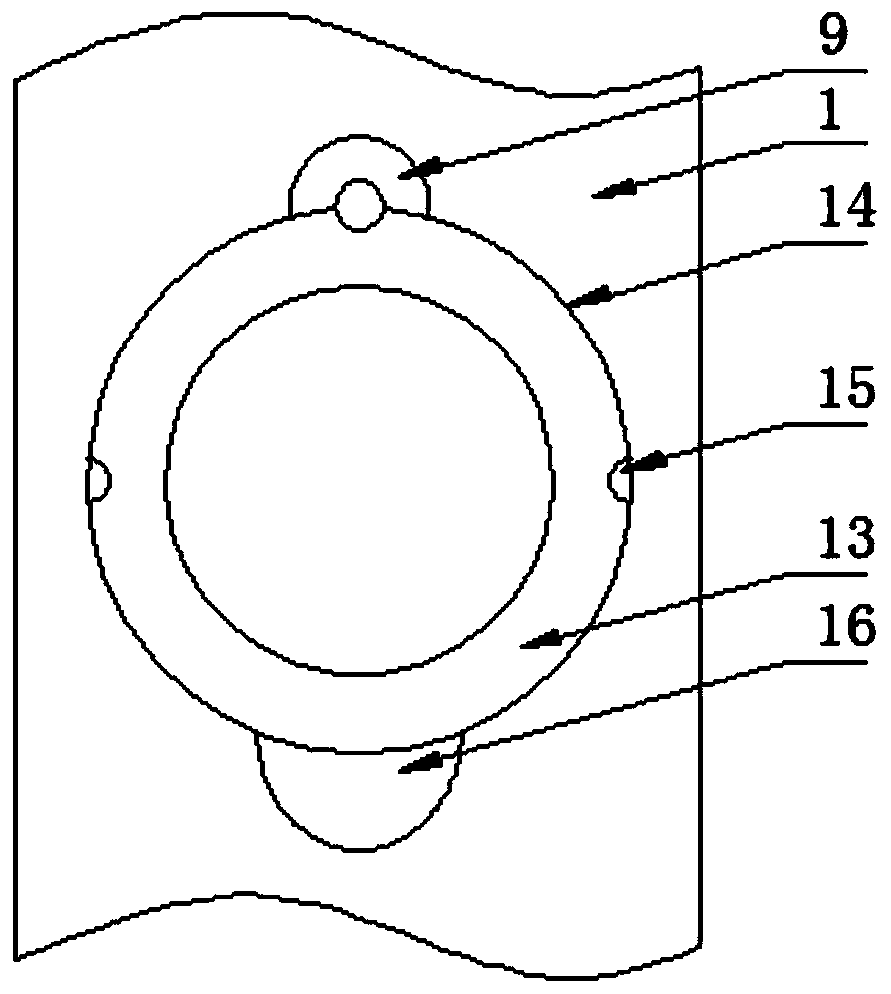

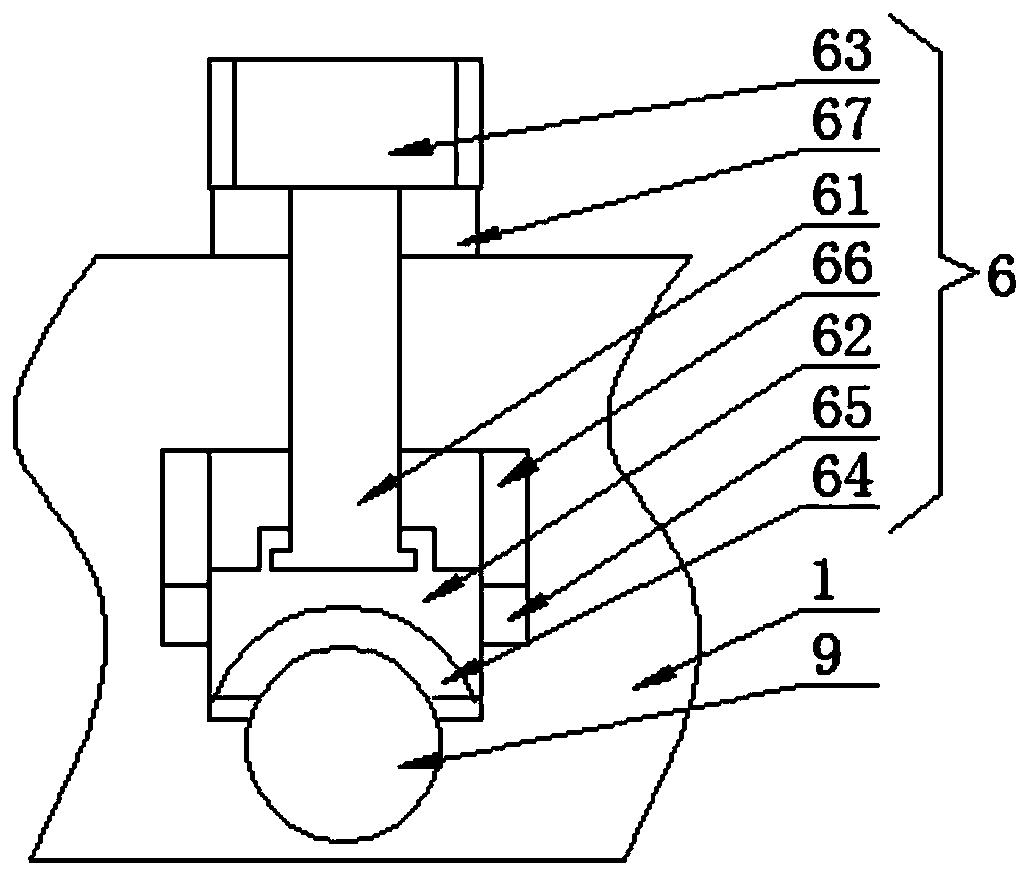

Bearing seat capable of achieving automatic lubricating oil adding

InactiveCN109973797ALarge thrustAvoid cloggingEngine lubricationBearing unit rigid supportEngineeringPiston

The invention discloses a bearing seat capable of achieving automatic lubricating oil adding applied in the technical field of bearings. The bearing seat comprises a base. An outer ring is arranged inthe middle of an inner chamber of the base. An inner ring is arranged in an inner chamber of the outer ring. The top of the base is provided with an oil storage chamber. A piston block is arranged inthe middle of an inner chamber of the oil storage chamber. A reset spring is arranged on the left side wall of the piston block. A pull rod is connected to the piston block in a penetrating and inserted manner. A stop block is arranged at the right end of the pull rod. An oil nozzle is arranged at the right side of the top side wall of the oil storage chamber. An oil conveying channel is formed in the right side of the bottom side wall of the oil storage chamber. An oil inlet matched with the oil conveying channel is formed in the right side of the top side wall of the outer ring. A fixing device matched with the pull rod is arranged at the left side of the top side wall of the base. According to the bearing seat, the reset spring expands, the piston block moves rightwards and pushes, andthe pushing force applied to lubricating oil is increased; the lubricating oil in the oil storage chamber is pushed into an inner chamber of an annular cavity through the oil conveying channel and the oil inlet, and thus, the lubricating effect is achieved; the oil inlet can be effectively prevented from being blocked; and normal work of the bearing seat is guaranteed.

Owner:RUGAO NONSTANDARD BEARING

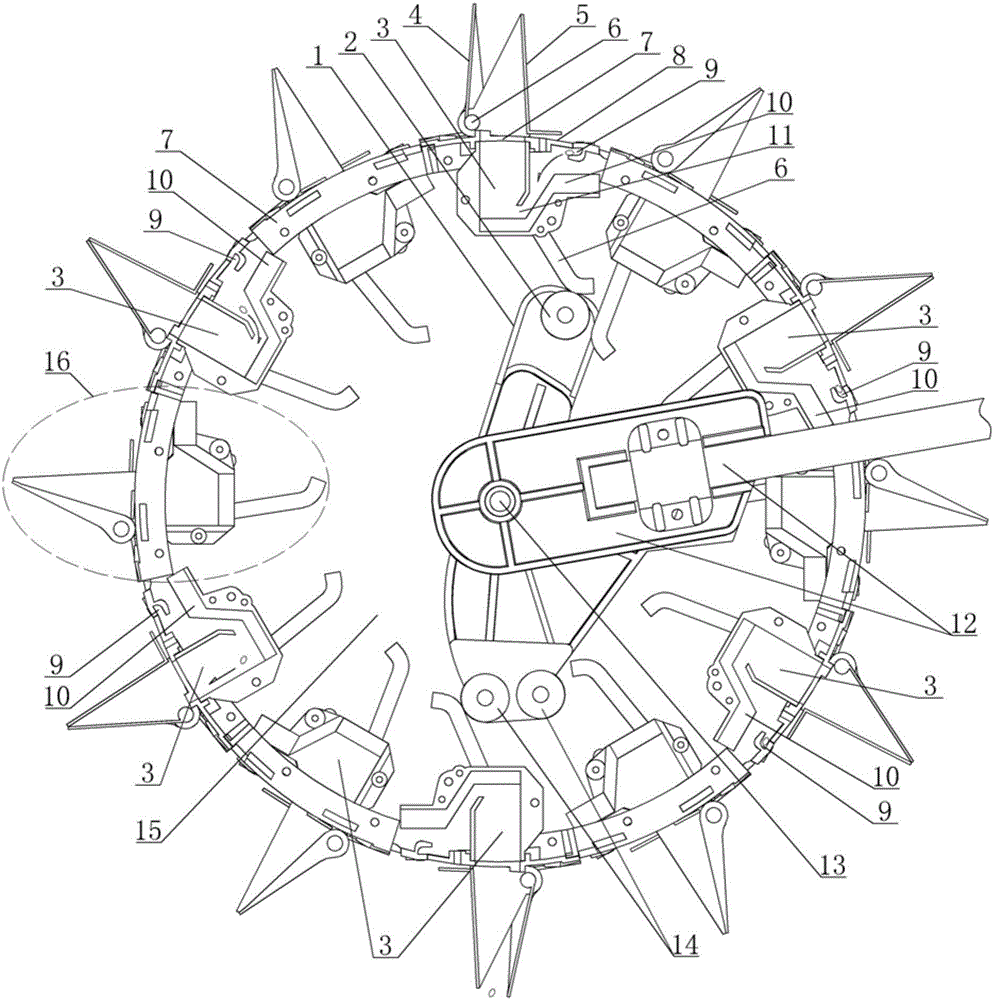

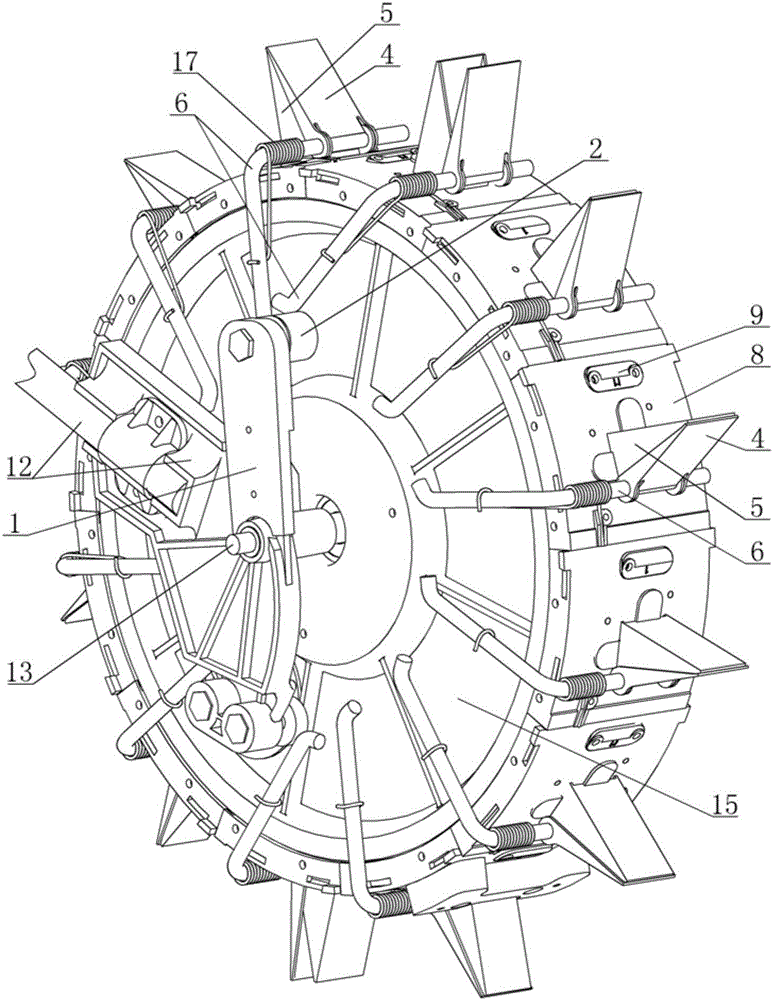

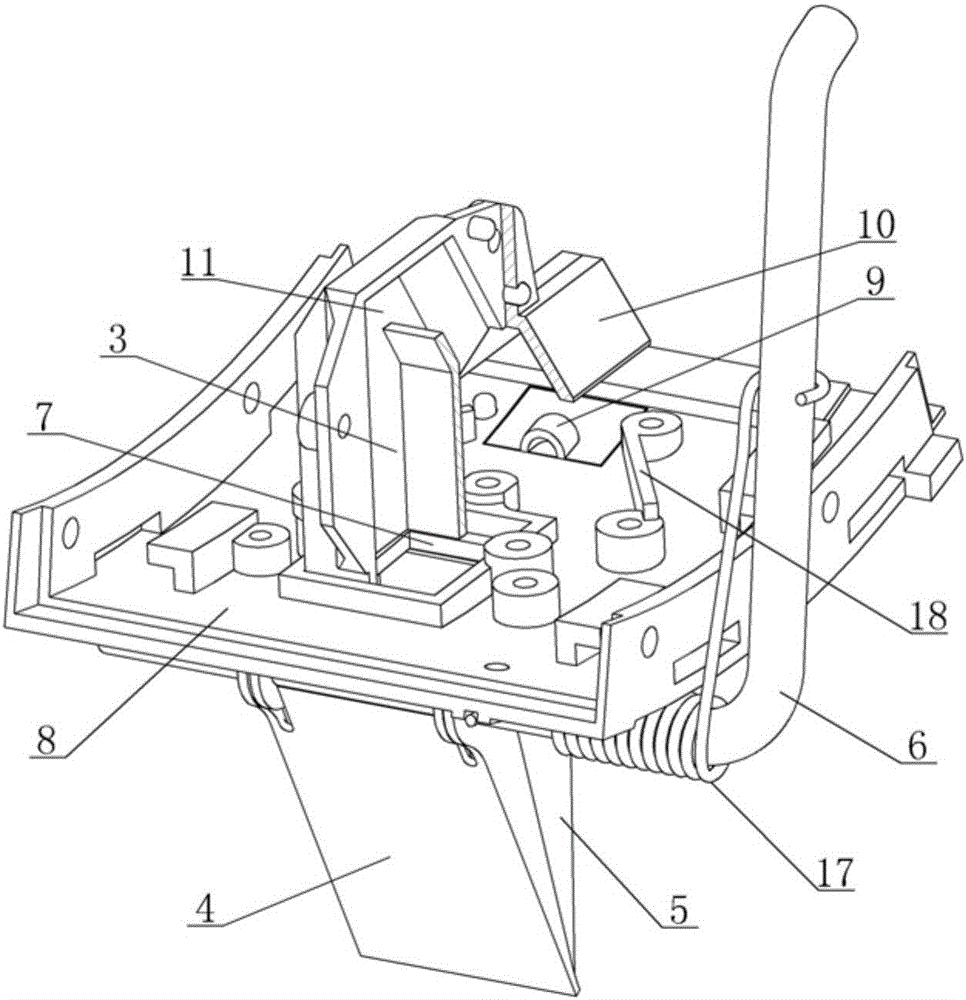

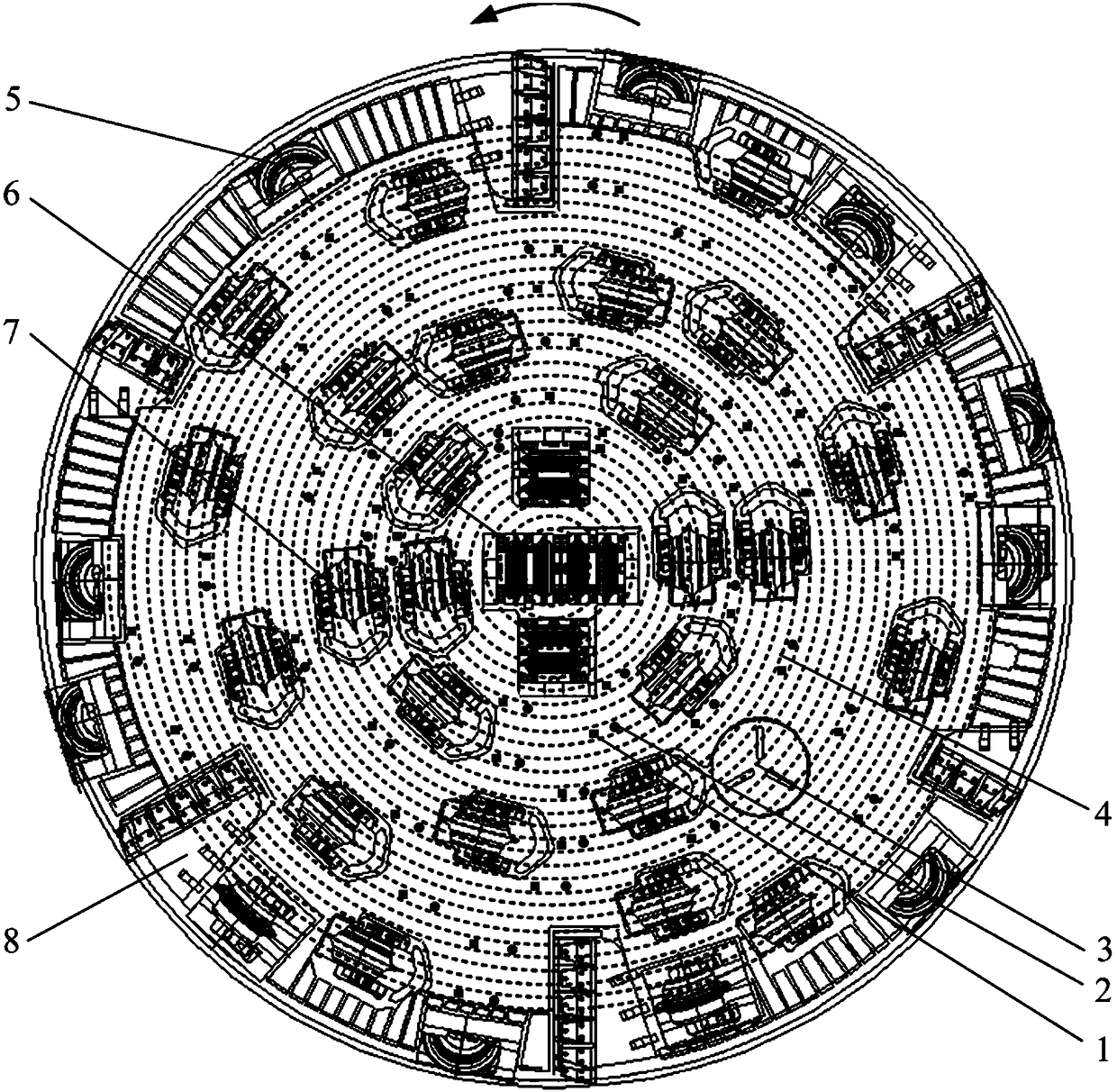

Full cross-section rock tunnel heading machine knife flywheel for assisting to break rock with burning and water-shocking

PendingCN108222958AIncrease the heating areaImprove work efficiencyTunnelsPetrologyTunnel boring machine

The invention discloses a full cross-section rock tunnel heading machine knife flywheel for assisting to break rock with burning and water-shocking. The full cross-section rock tunnel heading machineknife flywheel for assisting to break the rock with the burning and water-shocking comprises a rock tunnel heading machine knife flywheel body, and the rock tunnel heading machine knife flywheel bodyis provided with side hobs, center blades, positive hobs, ballast outlets and ballast scraping buckets. Multiple high-temperature flame nozzles and low-temperature water nozzles are evenly arranged onthe end face of the knife flywheel body, and the arrangement height of the high-temperature flame nozzles and the low-temperature water nozzles is lower than the height of the envelope surfaces of the positive hobs; and the high-temperature flame nozzles communicate with a combustible gas pipeline and an oxygen pipeline, and the low-temperature water nozzles communicate with a water supply pipeline. The problems of low rock-breaking and tunnelling efficiency and serious hob wear in the process of breaking hard rock by rock tunnel heading machine in the prior art is solved, the initiation andthe extension of cracks in the rock is promoted based on the principle of thermal expansion and thermal contraction the thermal splitting, so that rocks are easy to break, the rock breaking efficiencyof hobs is improved, the wear of hobs is reduced, and the construction cost is reduced.

Owner:CHANGAN UNIV

High-performance concrete organic-inorganic composite additive

InactiveCN102643041AReduce permeabilityProtects against weathering and deteriorationSodium silicateSurface-active agents

The invention discloses a high-performance concrete organic-inorganic composite additive. The composite additive comprises the following components by weight percent: 30-90% of active powder, 0-10% of sodium silicate and 5-70% of surface active agent. The additive disclosed by the invention is suitable for long-distance transportation; by using the additive, the compaction is increased, the durability is improved, and concrete can obtain high early strength. The additive is especially suitable for steaming and improvement of early strength.

Owner:SHANGHAI ZHONGJI PILE IND

Double-cavity diluting apparatus

PendingCN108458915APrevent inflowAvoid wear and tearPreparing sample for investigationHollow article cleaningPhosphateEngineering

The invention relates to a double-cavity diluting apparatus. The double-cavity diluting apparatus comprises a washing cavity, a diluting container, a washing pipe and a liquid injection cavity; the top side wall and the bottom side wall of the washing cavity are respectively provided with a liquid inlet and a liquid outlet; the diluting container is rotatably arranged in the washing cavity, the diluting container is symmetrically provided with two diluting cavities with one end being opened, and the diluting container can be driven by a driving device to rotate; the liquid injection cavity isarranged below the washing cavity, and the liquid injection cavity is connected with a liquid injection pipe; and the washing pipe penetrates through the liquid injection cavity and a communication hole between the liquid injection cavity and the washing cavity to enter the washing cavity and is driven by the driving device to move up and down. By adopting the double-cavity diluting apparatus, phosphate in the washing cavity is prevented from flowing into the liquid injection cavity, the washing pipe is flushed, the part, contacting the phosphate, of the washing pipe is always immersed in thepurified water and does not contact a friction sealing ring, and the crystallization of the liquid injection pipe is effectively prevented from damaging a sealing member.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

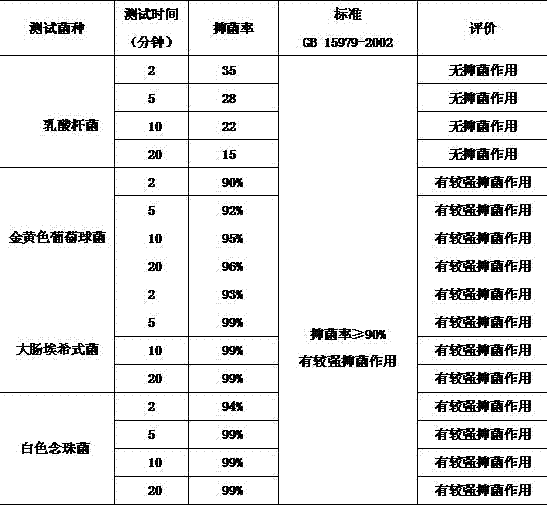

Aqueous human body lubricating liquid containing compound antibacterial agent

The invention relates to a water-based human body lubricating liquid containing a compound antibacterial agent, which adopts water-soluble chlorhexidine, nano-silver complex antibacterial liquid, Cnidium chinensis extract, propolis extract, honeysuckle extract, and aloe extract , purslane extract, glycerol, propylene glycol, preservatives, macromolecular mucopolysaccharide, carbomer, 2-sodium acrylate homopolymer, hydroxyl ethyl cellulose, pH regulator and sterilized deionized water made. The water-based human body lubricant not only has the functions of lubricating, nourishing and caring, but also is mild in nature, has no adverse reaction to the human body, is healthy and environmentally friendly, and is easy to clean afterwards, not greasy, and has good anti-inflammatory and antibacterial functions, and its antibacterial function does not affect Beneficial bacteria. This water-based body lubricant can be used in couples during sex to help with vaginal dryness or over condoms.

Owner:深圳市宜丽健康科技发展有限公司

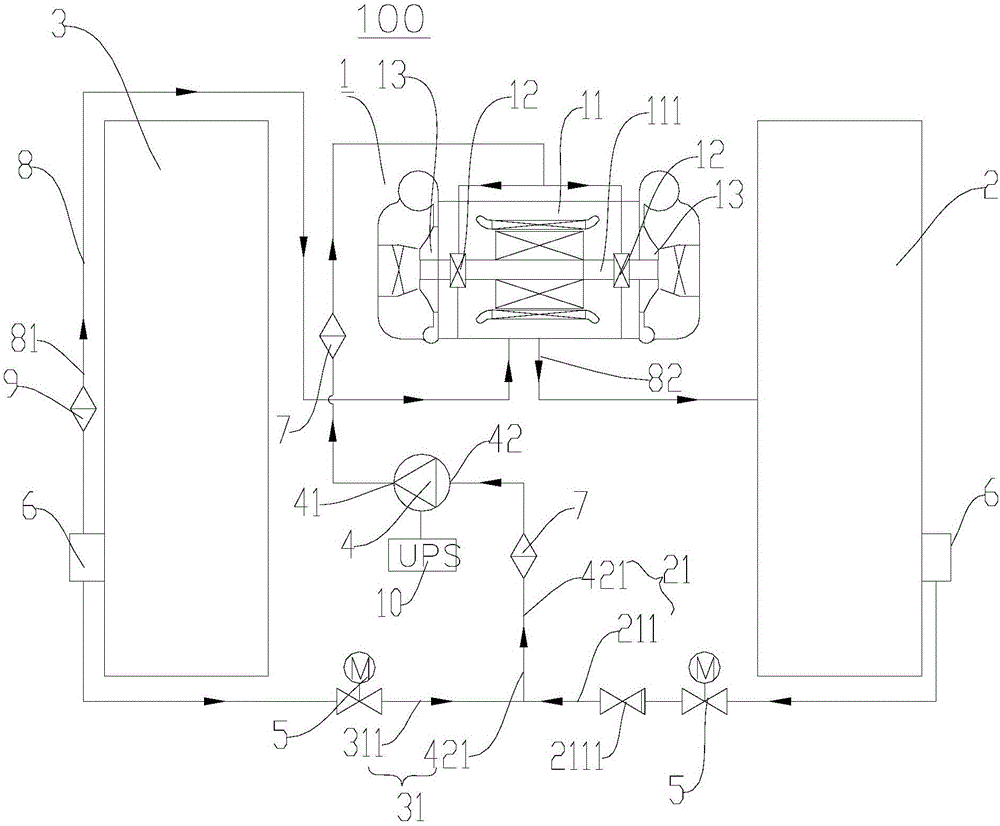

Refrigerating unit

InactiveCN106091188AExtended service lifeSimple structureCompressorFluid circulation arrangementRefrigerantCentrifugal compressor

The invention discloses a refrigerating unit which comprises an oilless centrifugal compressor, an evaporator and a condenser, wherein a refrigerant circulating flow path is composed of the oilless centrifugal compressor, the evaporator and the condenser. The oilless centrifugal compressor comprises a motor, a plurality of sets of bearings and impellers. A rotor shaft of the motor is sleeved with the bearings. The impellers are arranged on the rotor shaft and driven by the rotor shaft to rotate. The refrigerating unit further comprises a refrigerant pump and a control device. The refrigerant pump is used for conveying a refrigerant. An outlet of the refrigerant pump corresponds to each bearing so as to supply the refrigerant serving as lubricating liquid to each bearing. An inlet of the refrigerant pump is connected with at least one of the evaporator and the condenser. The control device is connected with the refrigerant pump and the oilless centrifugal compressor. According to the refrigerating unit, a function of lubricating the bearings can be achieved, so that the service life of the bearings is prolonged; and in addition, the structure is simple, and a control system of the refrigerating unit is simplified, so that the failure rate of the control system is decreased, and the cost the oilless centrifugal compressor is reduced.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

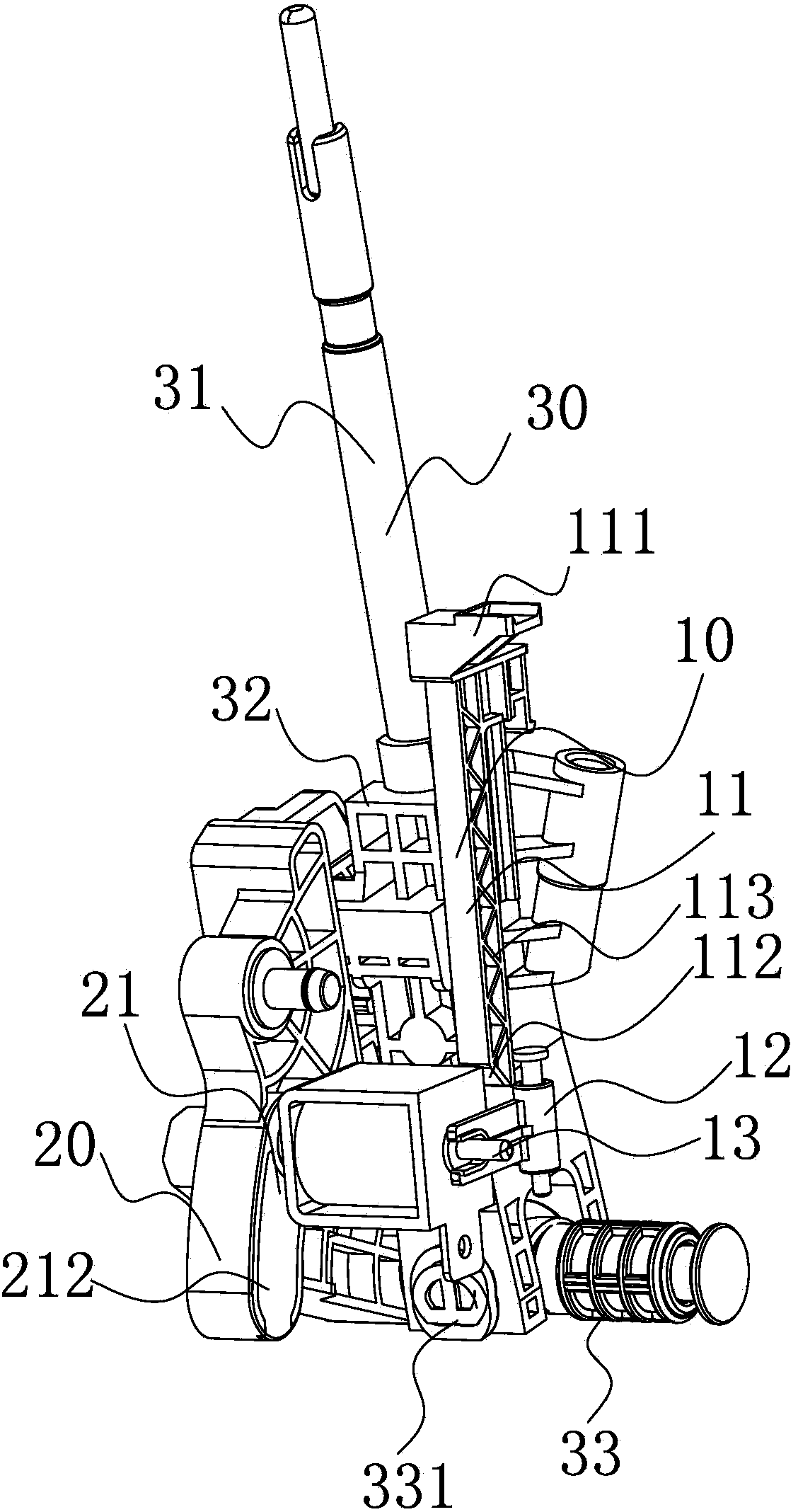

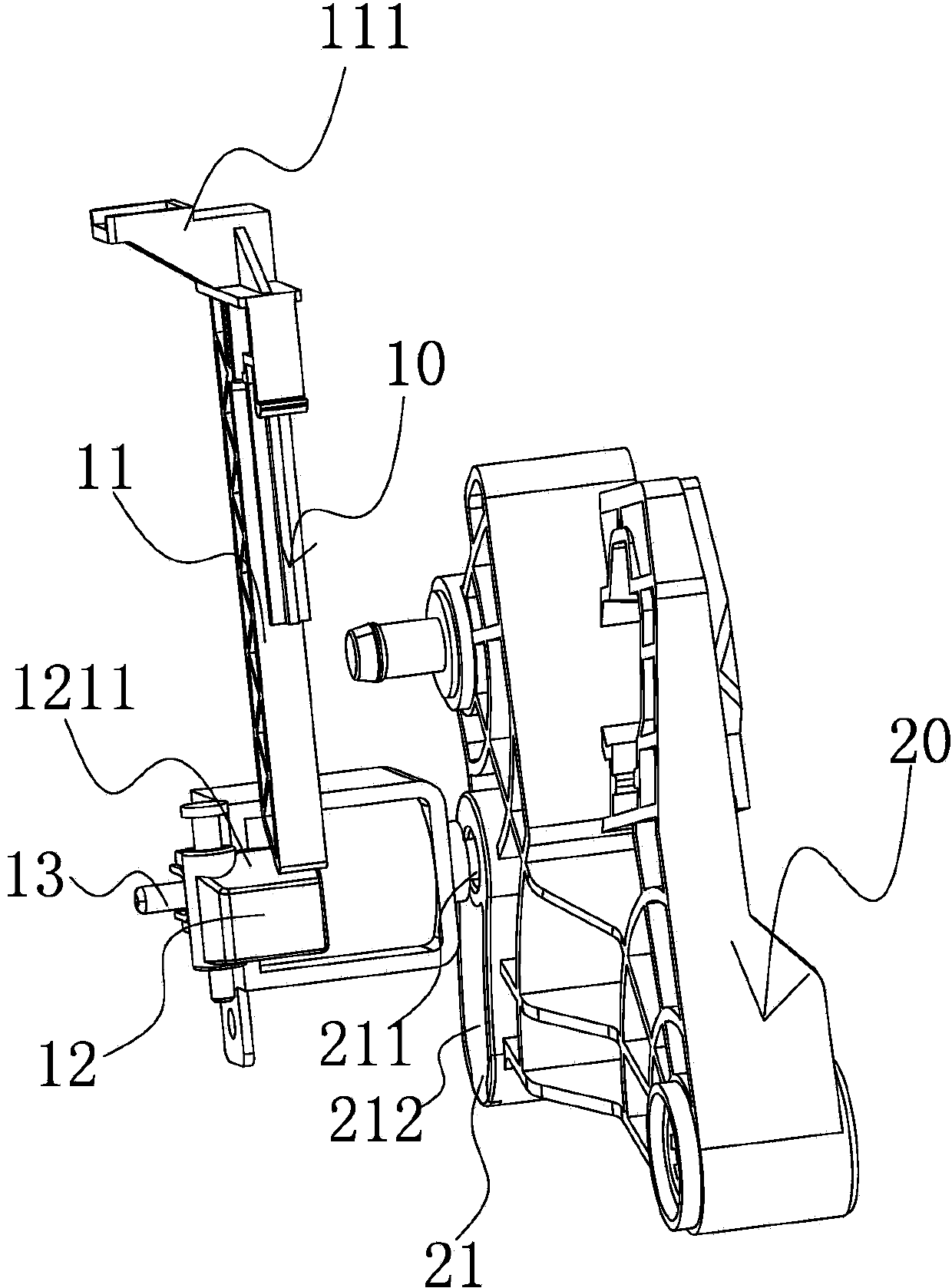

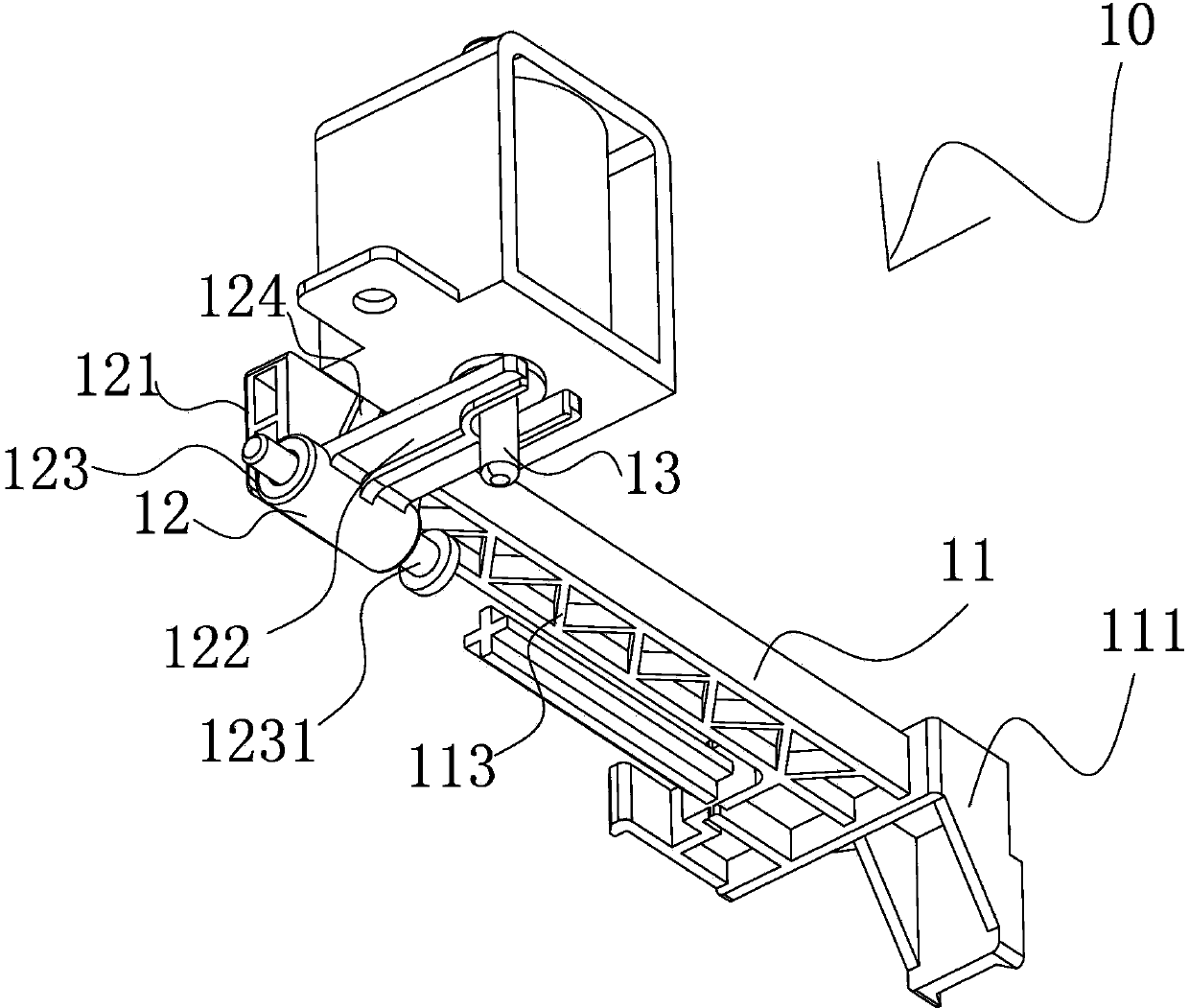

Automatic automobile gear shifter

ActiveCN104196992ASimple structureReduce contact surfaceGearing controlGearing detailsLow noiseLocking mechanism

The invention provides an automatic automobile gear shifter, and belongs to the technical field of automobiles. The automatic automobile gear shifter comprises a locking mechanism and a gear shifting arm, wherein a lug part is arranged on the gear shifting arm, and comprises a locking hole and an unlocking part; the locking mechanism comprises a transfer rod, an unlocking rod and a bar-shaped lock rod; a pressing part is arranged at the upper end of the lock rod; the lower end of the lock rod is a lock rod inclined surface; the transfer rod comprises a pressure rod, and a pull rod integrated with the pressure rod; the side surface of the pressure rod is a pressure rod inclined surface corresponding to the lock rod inclined surface; a rotating shaft hole with a shaft pin is formed in the connected position of the pressure rod and the pull rod; the transfer rod can rotate surrounding the shaft pin; one end of the unlocking rod is in hinged connection with the pull rod, and the other end of the unlocking rod is an outwards projected circular arc surface capable of being clamped and embedded in the locking hole; and when the lock rod downwards moves, the pressure rod is driven to approach the unlocking rod, the pull rod drives the unlocking rod to move, and the unlocking rod is deviated from the locking hole. The automatic automobile gear shifter has the advantages of simple structure, low noise and high safety performance.

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

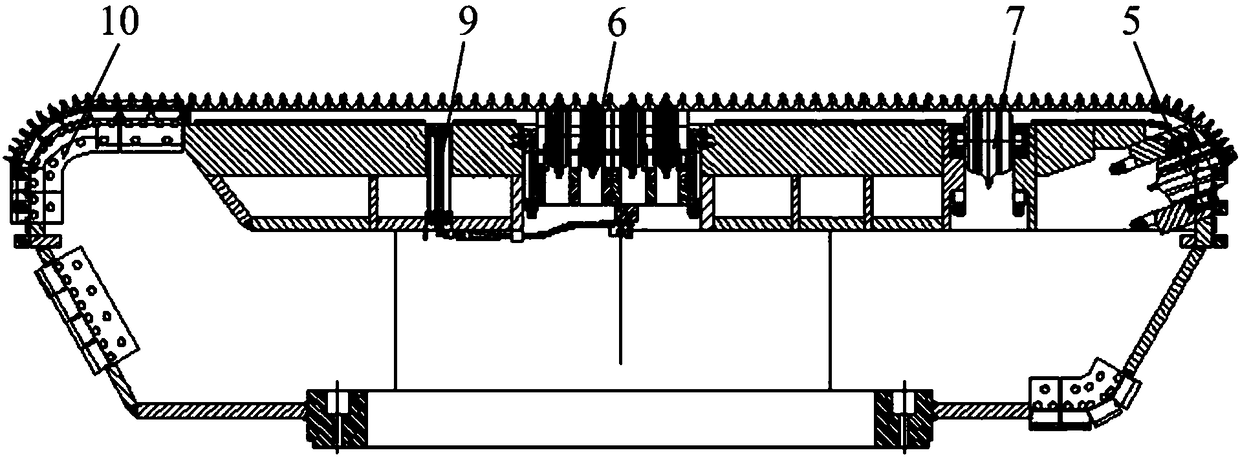

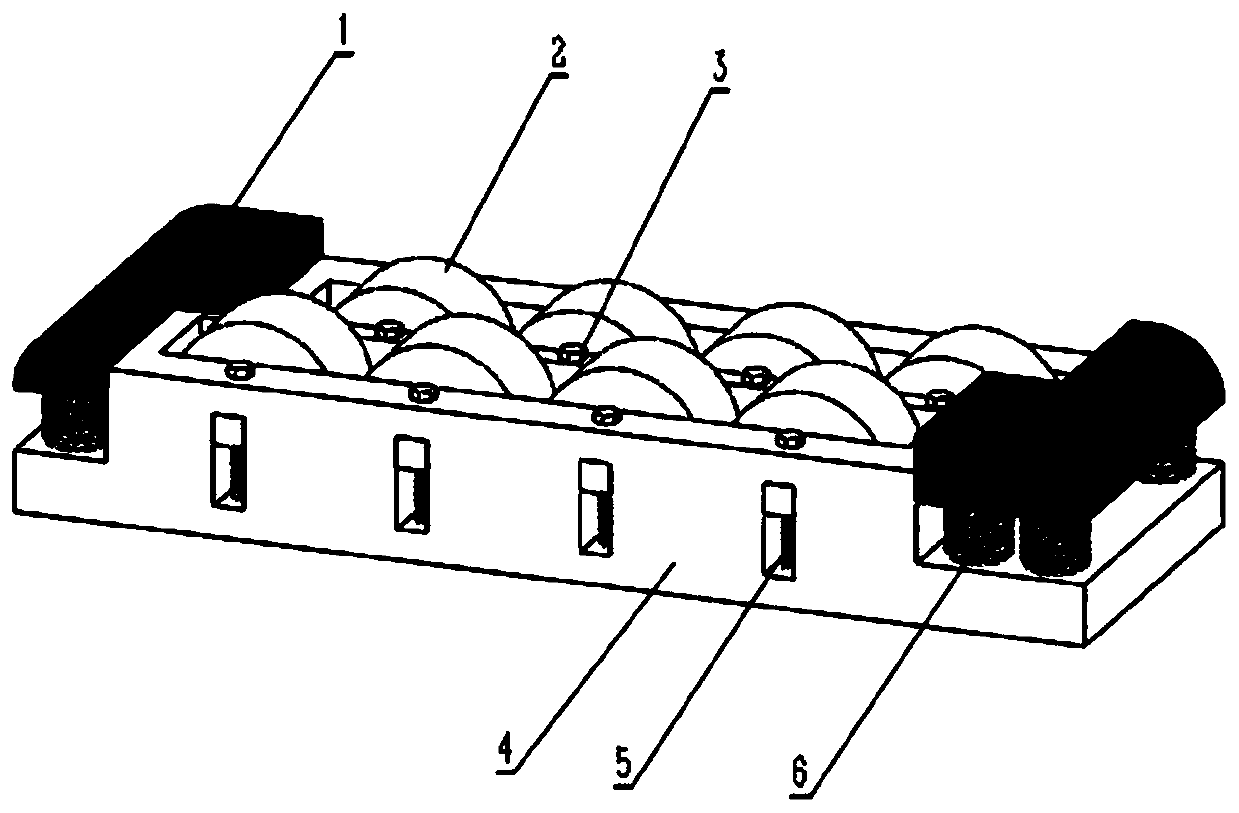

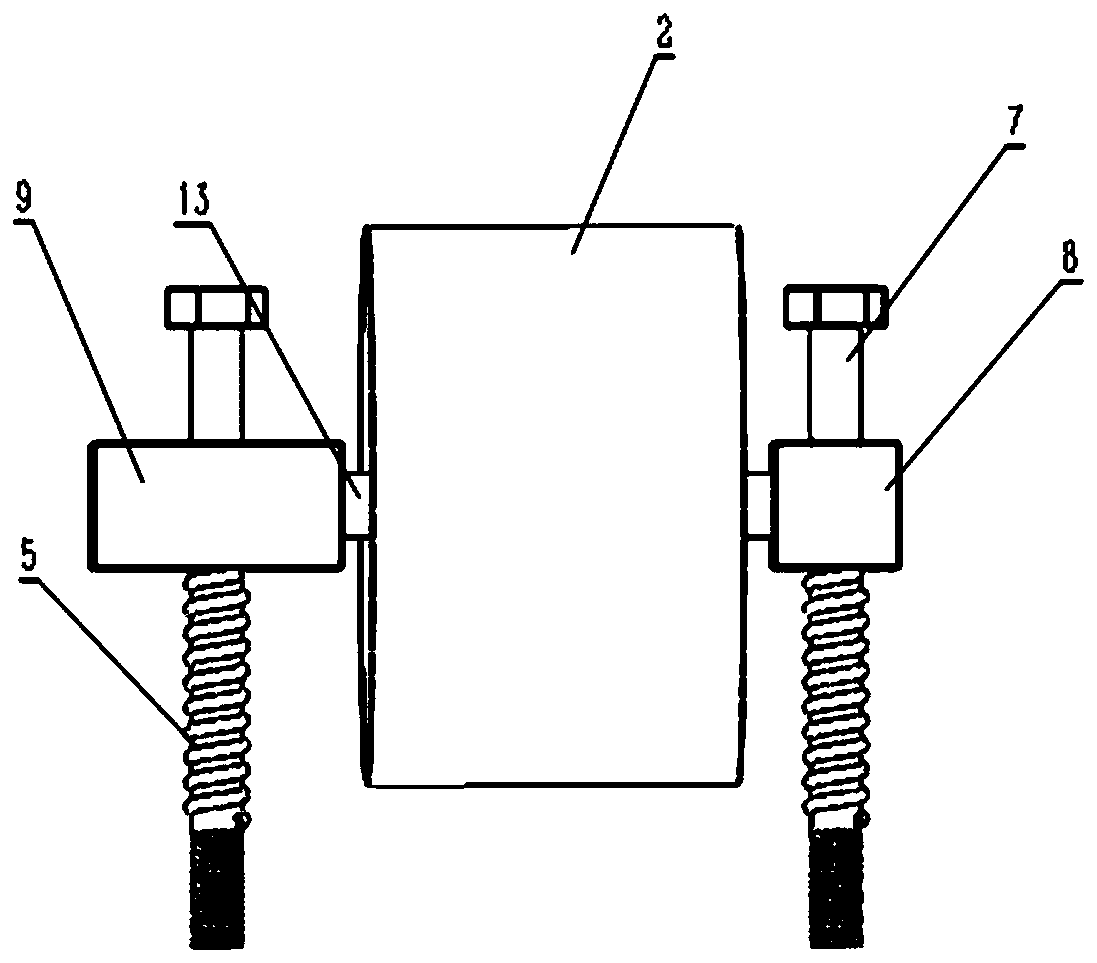

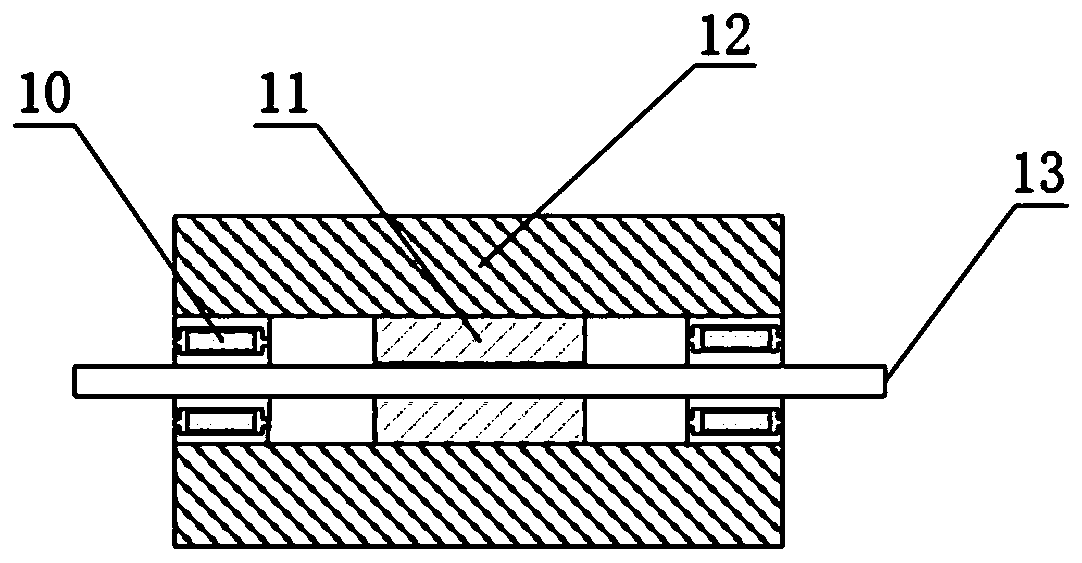

Double-row multi-roller type modular current-receiving device for electric locomotive

PendingCN110370936AReduce wearReduced service lifeRotary current collectorPower current collectorsModularitySlide plate

Disclosed is a double-row multi-roller type modular current-receiving device for an electric locomotive. According to the double-row multi-roller type modular current-receiving device for the electriclocomotive, two rows of metal rollers are annularly arranged on an insulating base; each rolling wheel is arranged in the manner that two insulating stand columns are fixed to the insulating base, compression springs sleeve the two insulating stand columns correspondingly, insulating blocks sleeve the insulating stand columns and are located above the compression springs, metal shells of the rollers are installed on metal shafts through two insulating bearings, the metal shafts are fixed to the two insulating blocks, the outer surface of an annular current receiving electric brush makes contact with the roller metal shells to receive current, the inner surface of the annular current receiving electric brush is fixed to the metal shafts, all the metal shafts are connected through cables and are then used for supplying power to vehicle-mounted power consuming equipment, and two pure carbon sliding plates are fixed to the insulating base through more than four springs. The friction forceand the friction noise of the current-receiving device and a rigid contact rail can be effectively reduced, and the double-row multi-roller type modular current-receiving device can adapt to the changes of locomotive traction power requirements and has good buffering performance, heat dissipation performance and rail attaching performance.

Owner:SOUTHWEST JIAOTONG UNIV

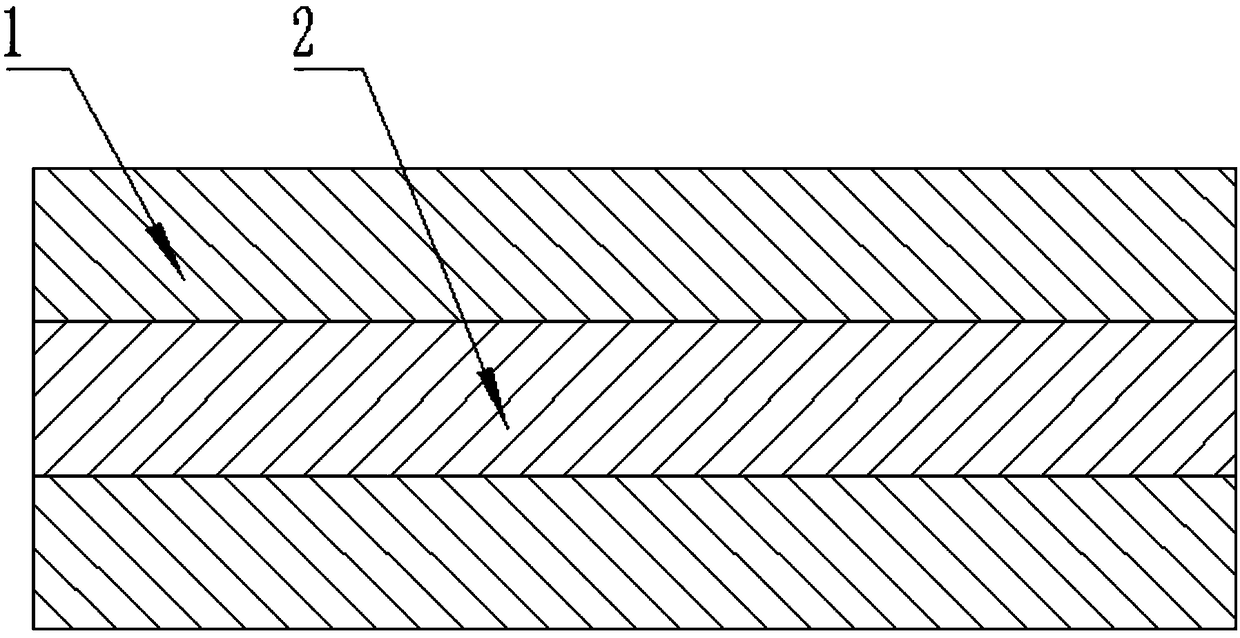

PVC composite plate and preparation method thereof

InactiveCN108239356ALow densityHigh compressive strengthSynthetic resin layered productsAgricultural engineeringComposite plate

The invention discloses a PVC composite plate. The PVC composite plate is of a composite layer structure and comprises outer panel layers and an inner panel layer arranged between the outer panel layers, wherein the outer panel layers contain the following components in parts by weight: 47-58 parts of PVC resin, 32-38 parts of nano-light calcium carbonate, 5-7 parts of a calcium-zinc stabilizer, 0.98-1.42 parts of an inner lubricant, 1-1.5 parts of a PVC foaming modifier, 0.18-0.22 part of ACR-401 and 1-1.5 parts of titanium dioxide. The invention further discloses a preparation method of thePVC composite plate. According to the PVC composite plate provided by the invention, the density of the PVC composite plate is reduced, the integral strength of a product is enhanced, and light and pressure-proof effects are achieved.

Owner:湖南五祥新材料科技有限公司

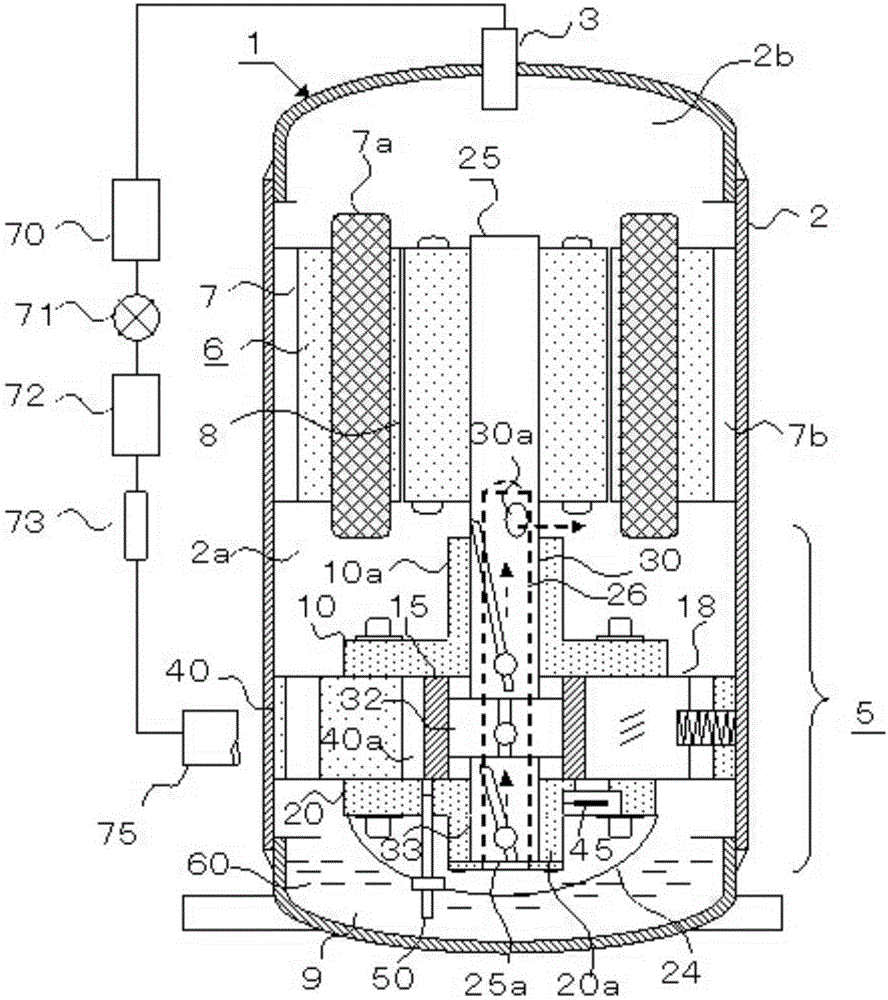

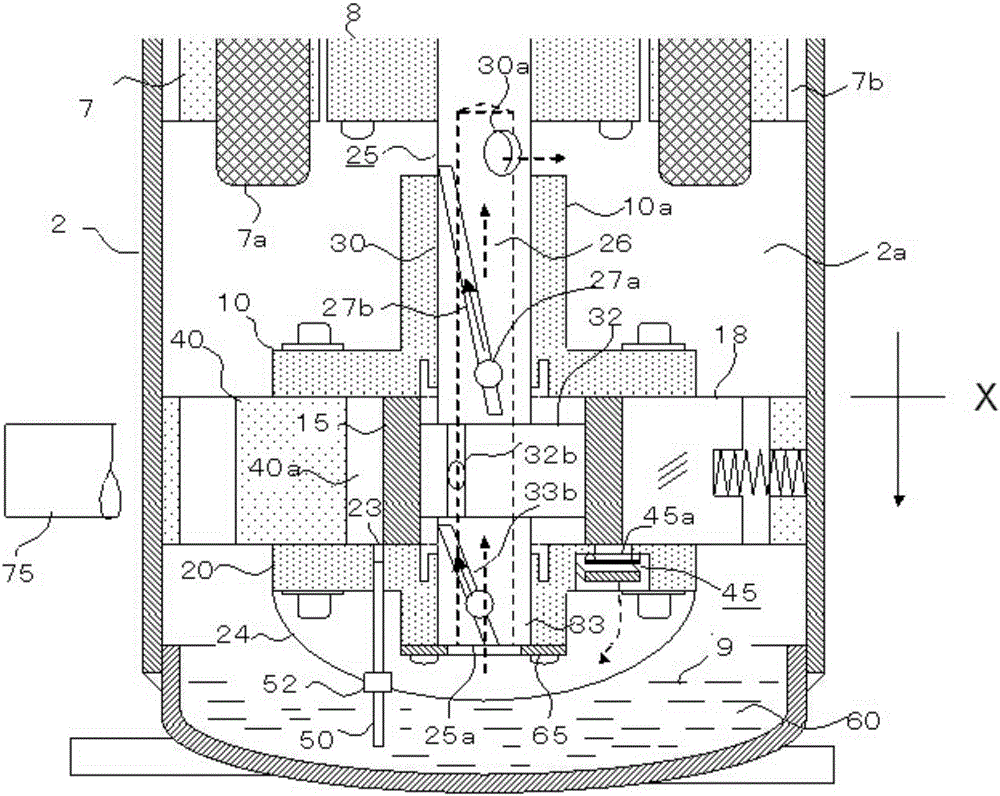

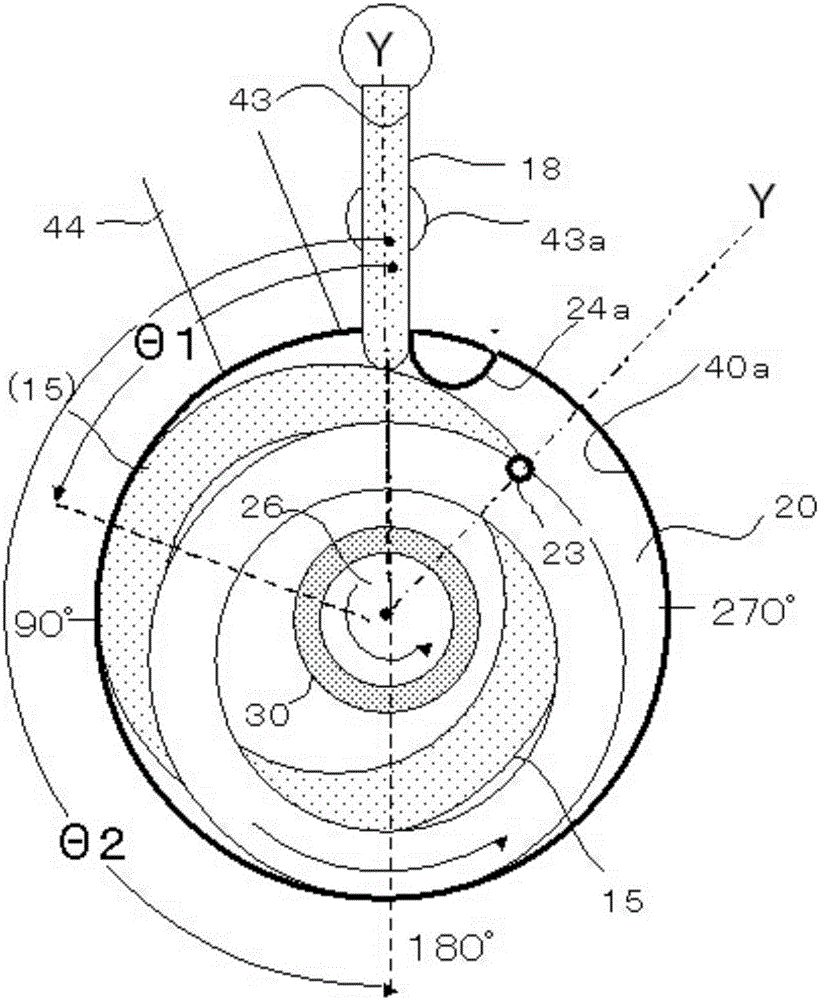

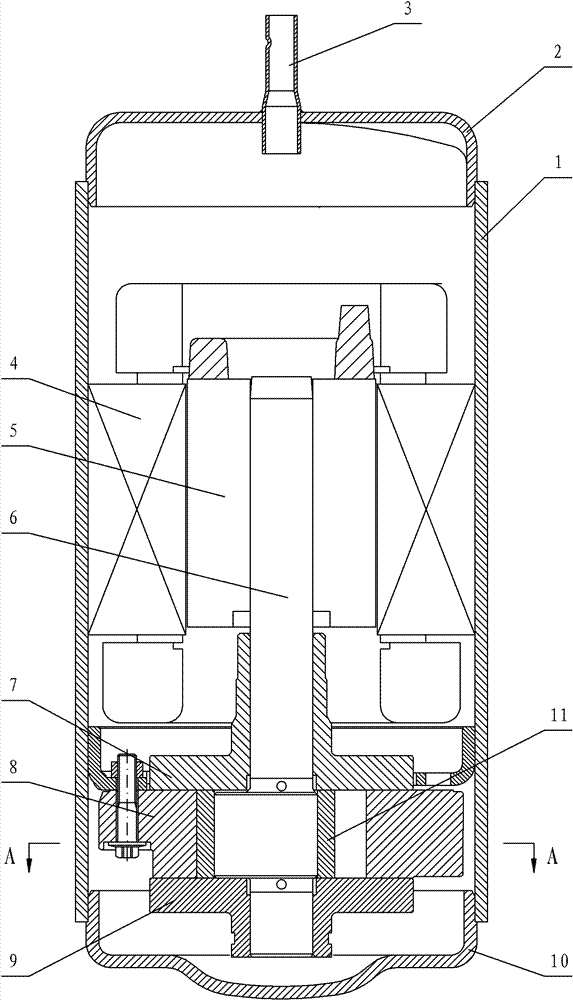

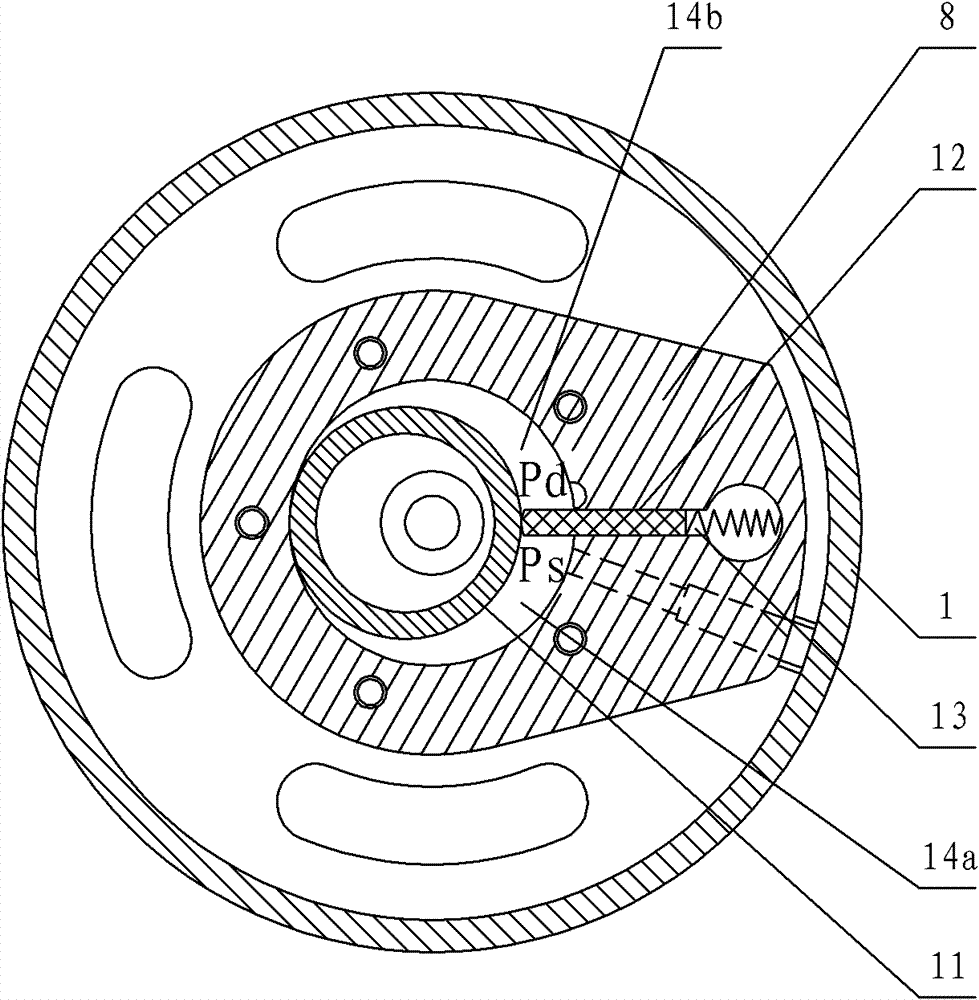

Rotation compressor and refrigerating cycle device with same

ActiveCN106089710AReduce oil dischargeNo need to increase oil seal volumeCompressorCompression machines with non-reversible cycleCrankshaftPiston

The invention discloses a rotation compressor and a refrigerating cycle device with the rotation compressor. An electric motor and a compression mechanism portion are contained in a sealed shell of the rotation compressor. A suction pipe is arranged on the shell. An oil storage tank storing lubricating oil is arranged at the bottom of the shell. The compression mechanism portion comprises an air cylinder, a piston, a slide sheet, a crankshaft and bearings. The air cylinder is provided with a compression cavity. Refrigerant gas, containing oil, discharged from the compression cavity at least flows through a gas passageway arranged between the crankshaft and the bearings to be discharged into the shell. According to the rotation compressor, the oil discharge amount of the compressor is lowered, and on the basis that oil supply to the compression mechanism portion is sufficient, the seal oil amount of the compressor does not need to be increased.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

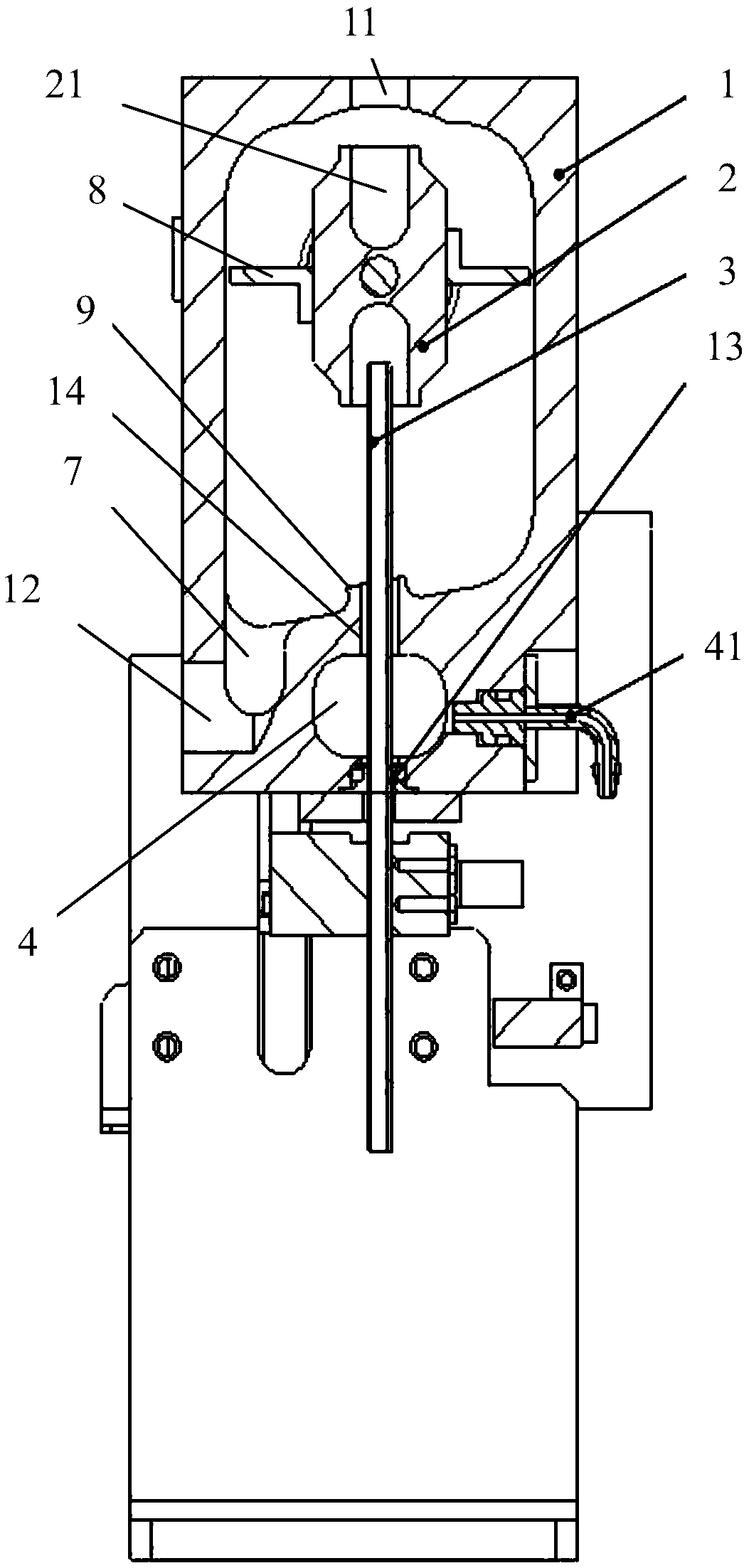

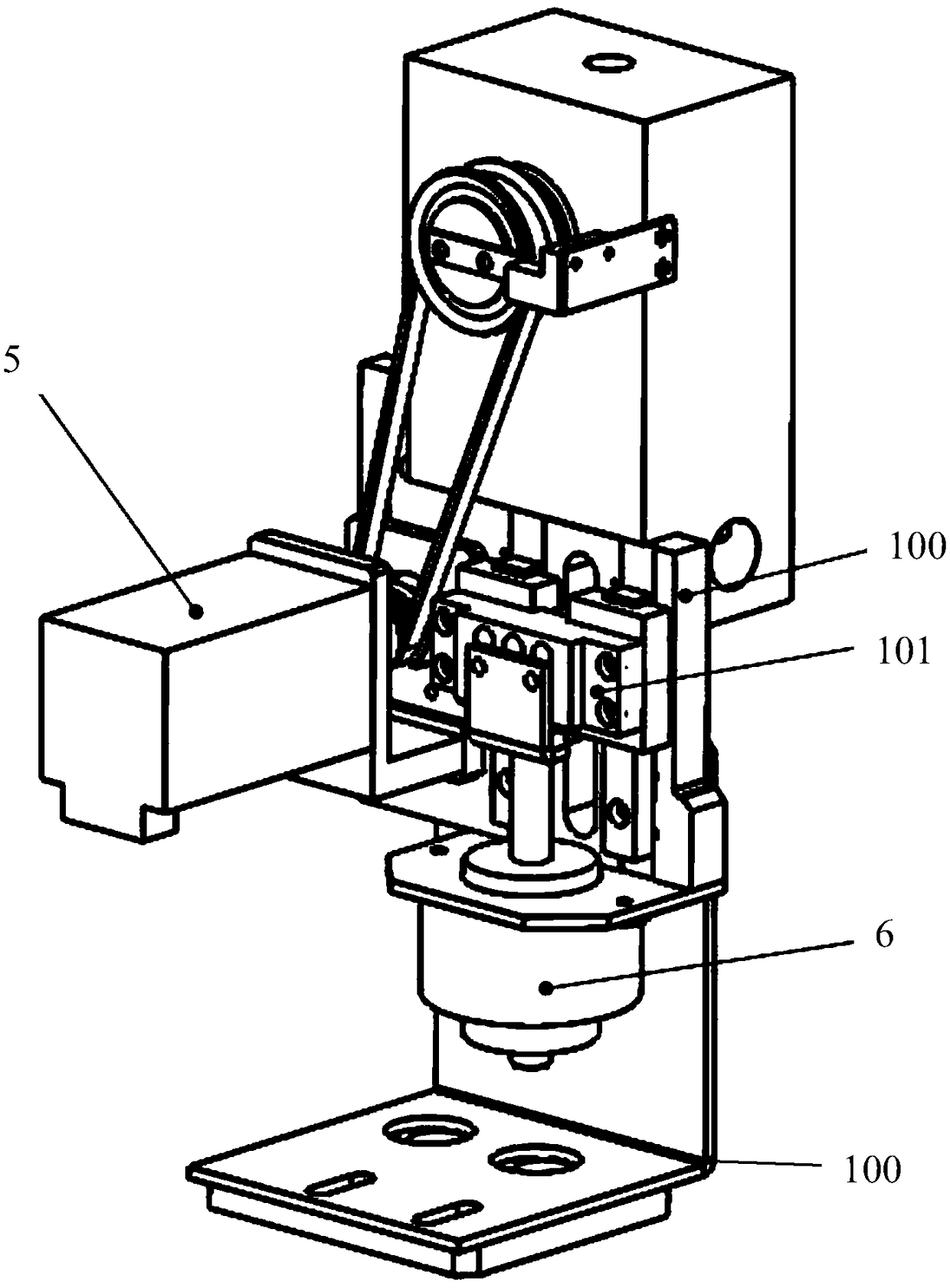

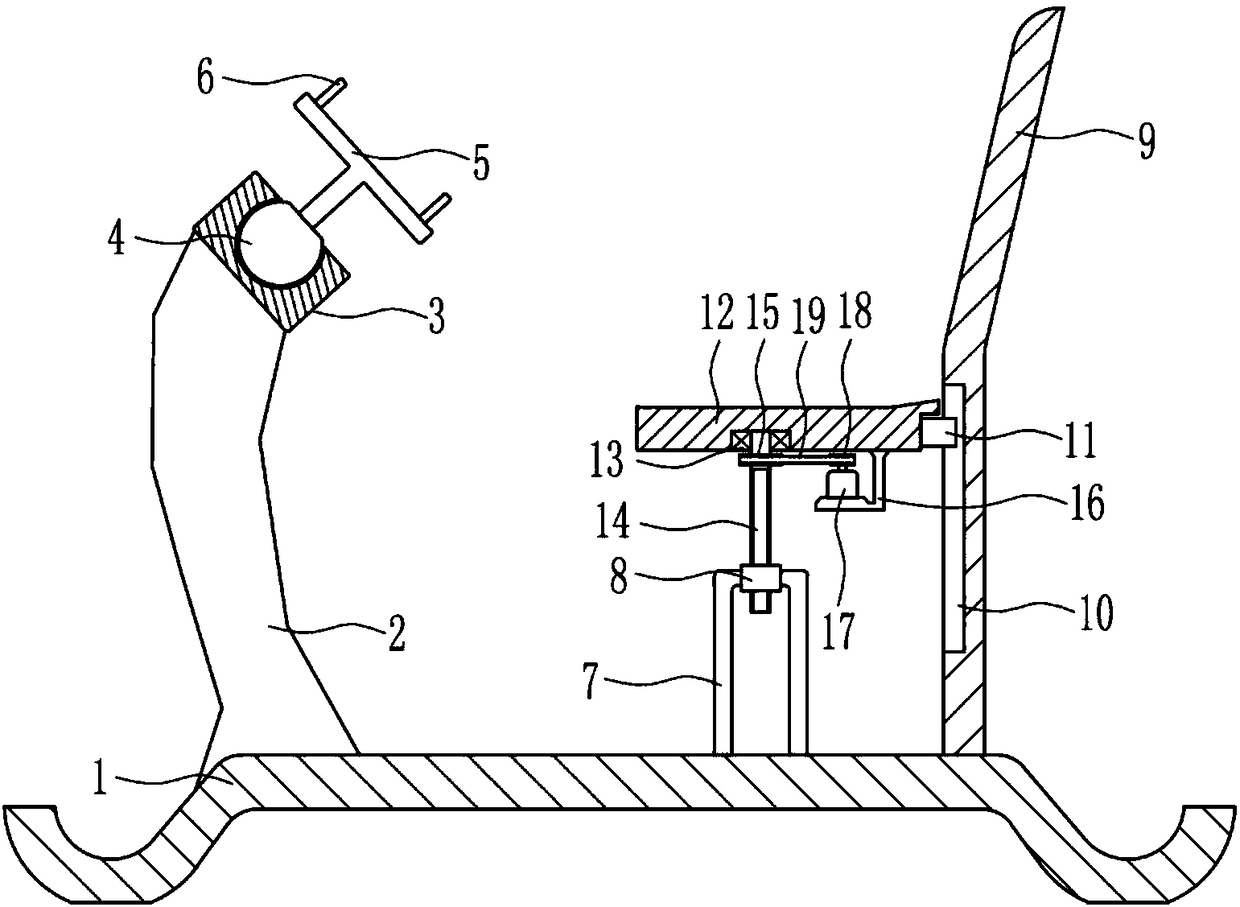

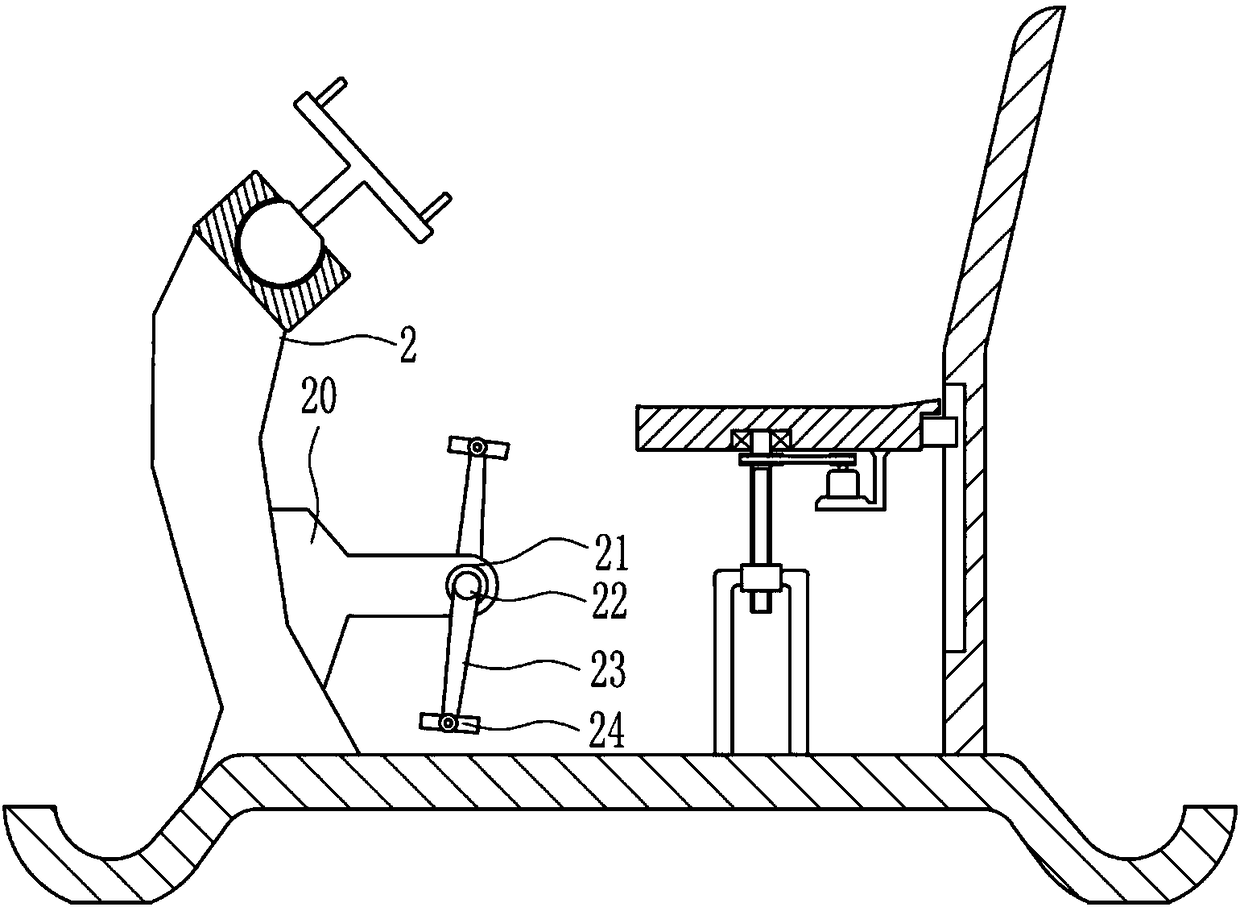

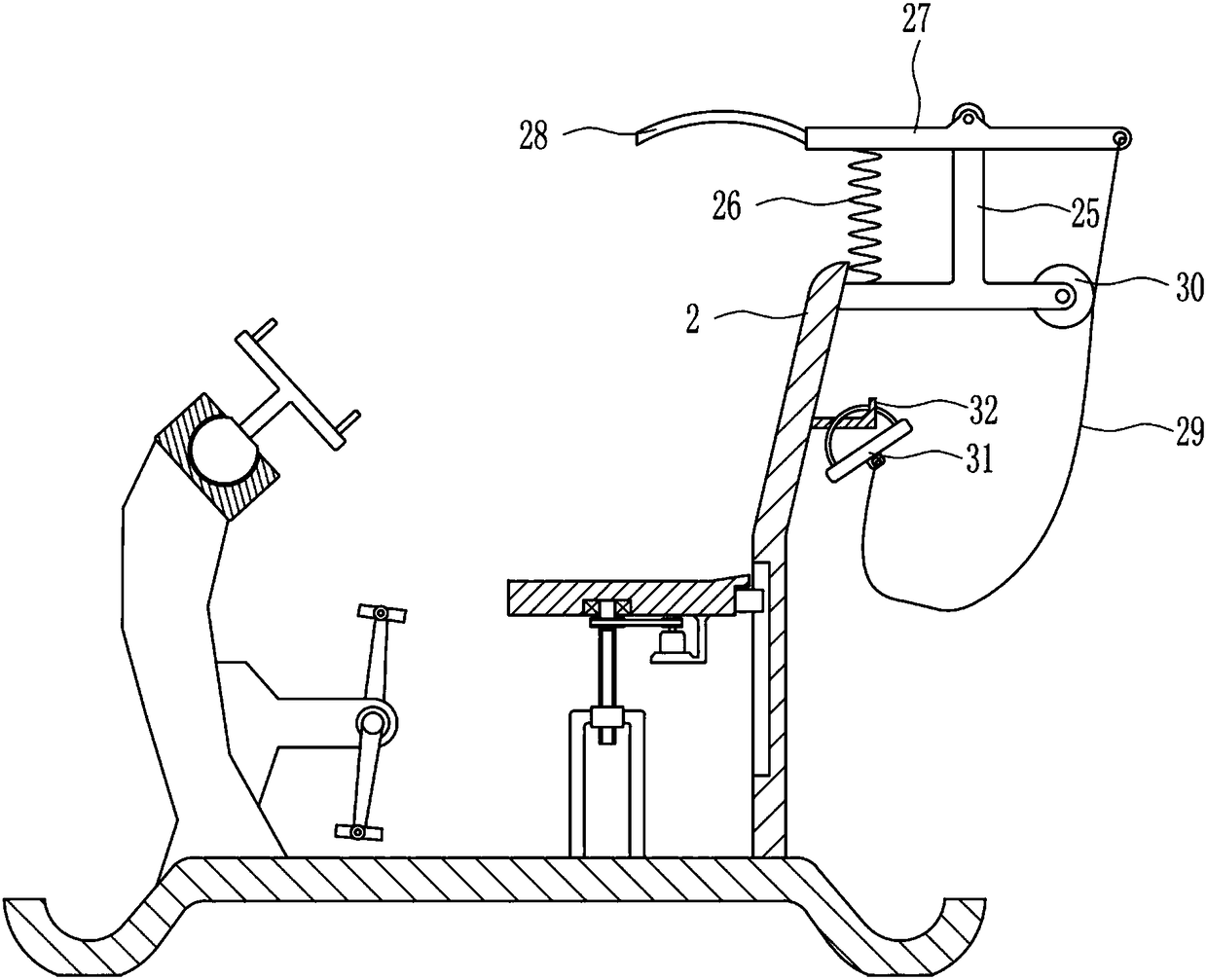

Foot step type double-arm coordination exercise recovery device for medical treatment

InactiveCN108578994AAchieve exerciseAct as a lubricantMovement coordination devicesCardiovascular exercising devicesCushionPhysical exercise

The invention relates to an exercise device, in particular to a foot step type double-arm coordination exercise recovery device for medical treatment. The foot step type double-arm coordination exercise recovery device for the medical treatment is more in exercise pattern and high in exercise enjoyment. According to the technical scheme, the foot step type double-arm coordination exercise recoverydevice for the medical treatment comprises a base, a first machine frame, a universal seat, a universal ball, a rotating disc, handles, a first supporting rod, a nut, a backup plate, a sliding rail,a sliding block, a cushion, a first bearing seat and the like. The first machine frame is arranged on the left side of the top of the base, the universal seat is arranged at the top of the first machine frame, the universal ball is arranged in the universal seat in a matched mode, the rotating disc is arranged on the universal ball, and two handles are arranged on the rotating disc. The foot steptype double-arm coordination exercise recovery device for the medical treatment enables a user to place feet on a pedal and rotates the rotating disc while performing arm exercise, thereby performingleg exercise by stepping on the pedal, and thus enables the user to perform leg exercise while performing the arm exercise.

Owner:沈义琪

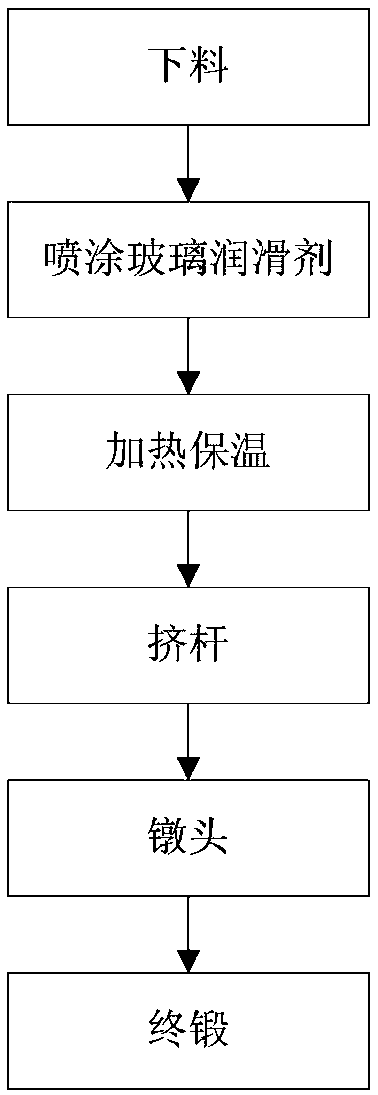

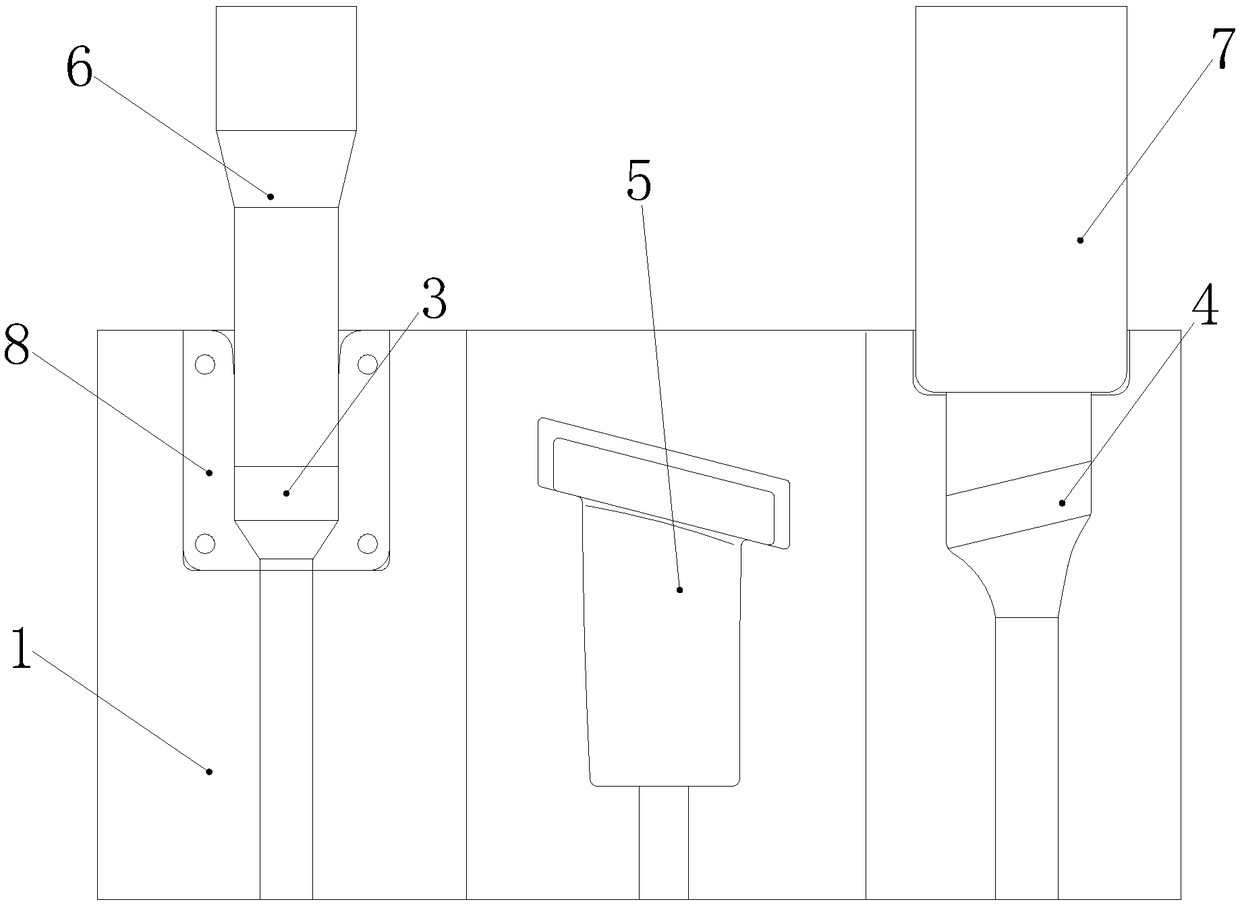

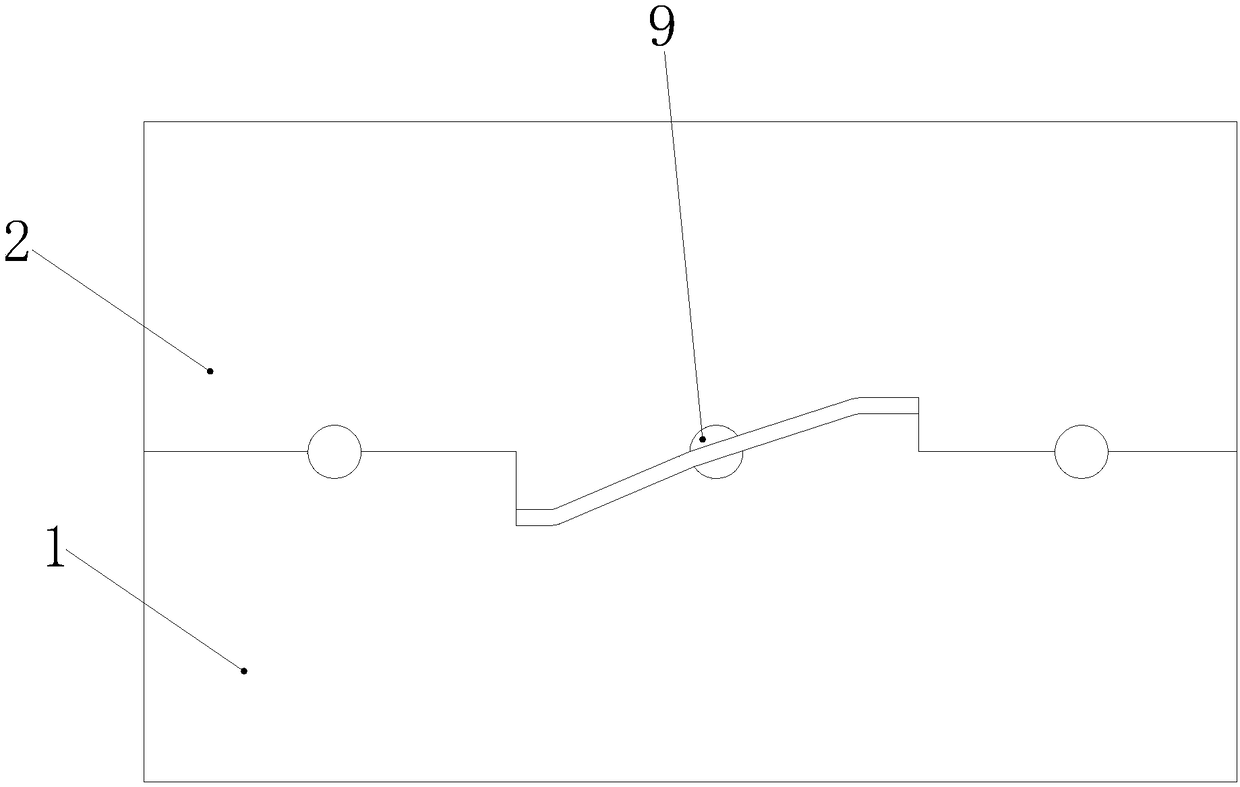

Aviation engine blade forging method and die

ActiveCN109317588AReduce the temperaturePrevent oxidationForging/hammering/pressing machinesEngine componentsAviationEngineering

The invention provides an aviation engine blade forging method and a die. The aviation engine blade forging method comprises the following steps that firstly, a blank is discharged; secondly, a glasslubricant is sprayed to the surface of the blank; thirdly, the blank is heated to the recrystallization temperature or above, and the temperature is kept; fourthly, the blank is put into a preheated extrusion cavity of the die, rod extruding is carried out, and an extrusion rod piece is obtained; fifthly, after rod extruding is completed, the extrusion rod piece is put into a heading cavity of thedie within 4 s-6 s, heading is carried out, and a heading piece is obtained; sixthly, after heading is completed, the heading piece is put into a finish forging cavity of the die within 4 s-6 s, final forging is carried out, and a blade is obtained. Due to the fact that the extrusion cavity, the heading cavity and the finish forging cavity are formed in the same die, the time interval between rodextruding and heading and the time interval between the heading and the finish forging are extremely short, the temperature of the extrusion rod piece and the temperature of the heading piece are reduced limitedly, and in the whole forging process, only one time of heating is needed for the blank.

Owner:CHINA HANGFA SOUTH IND CO LTD

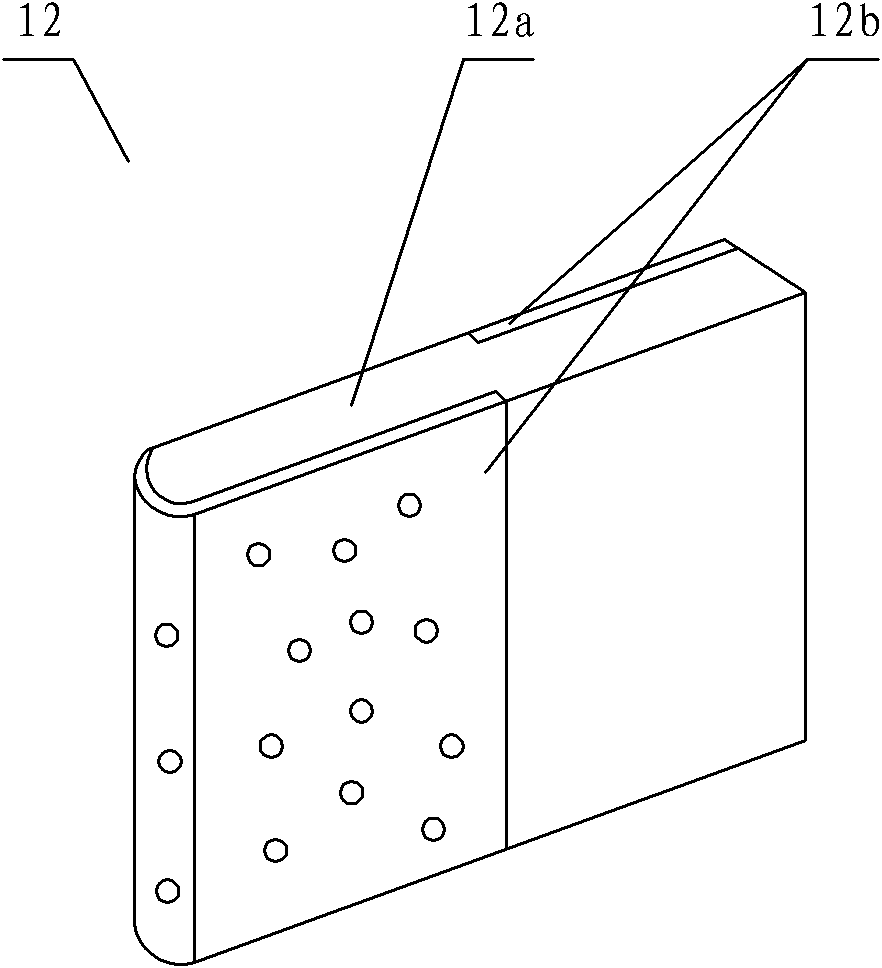

Rotary compressor and its manufacturing method

InactiveCN102767520AHigh surface hardnessImprove wear resistanceRotary piston pumpsRotary piston liquid enginesCeramic compositeSlide plate

Disclosed are a rotary compressor and its manufacturing method. The rotary compressor comprises a motor and a compressing mechanism which are arranged inside a housing. The compressing mechanism comprises a cylinder with a compression chamber and a piston which rotates eccentrically inside the compression cavity. The cylinder is also provided with a sliding plate groove for holding a slide plate. One end of the slide plate is propped to the periphery of the piston. The slide plate comprises a slide plate metal matrix and a slide plate ceramic composite layer arranged on the slide plate metal matrix. The slide plate ceramic composite layer is arranged at one side, two sides or distal end of the slide plate metal matrix. The slide plate metal matrix is a cast iron matrix or steel matrix. The slide plate ceramic composite layer comprises a porous slide plate ceramic layer and metal embedded in the slide plate ceramic layer. The slide plate ceramic layer is an alumina layer, oxygen ambient silica layer or zirconia layer. The rotary compressor provided by the invention has characteristics of simple and reasonable structure, flexible operation, low manufacturing cost, high surface hardness, good wear resistance, good impact toughness and long service life.

Owner:GUANGDONG MEIZHI COMPRESSOR

High performance polyamide 6 based friction material and preparation method thereof

InactiveCN105385151AImprove thermal conductivityImprove mechanical propertiesManufacturing technologyPolymer science

The invention discloses a high performance polyamide 6 based friction material and a preparation method thereof. The friction material comprises the following components in percentage by weight: 55 to 65% of polyamide 6, 10 to 15% of chopped glass fiber, 10 to 15% of composite solid lubricant, 2 to 5% of compatibilizer, 10 to 15% of flame retardant, 0.5 to 2% of antistatic agent, 0.05 to 0.5% of anti-aging agent, and 0.5 to 1% of silane coupling agent. The friction material is prepared by the following steps: mixing all materials together according to the ratio mentioned above, and making the mixture into a high performance polyamide 6 based friction material through a fusion method. The friction material has the advantages of simple manufacturing technology, low wear rate, low friction coefficient, high strength, flame resistance, electrostatic resistance, high / low temperature resistance, corrosion resistance, aging resistance, and low cost.

Owner:CENT SOUTH UNIV

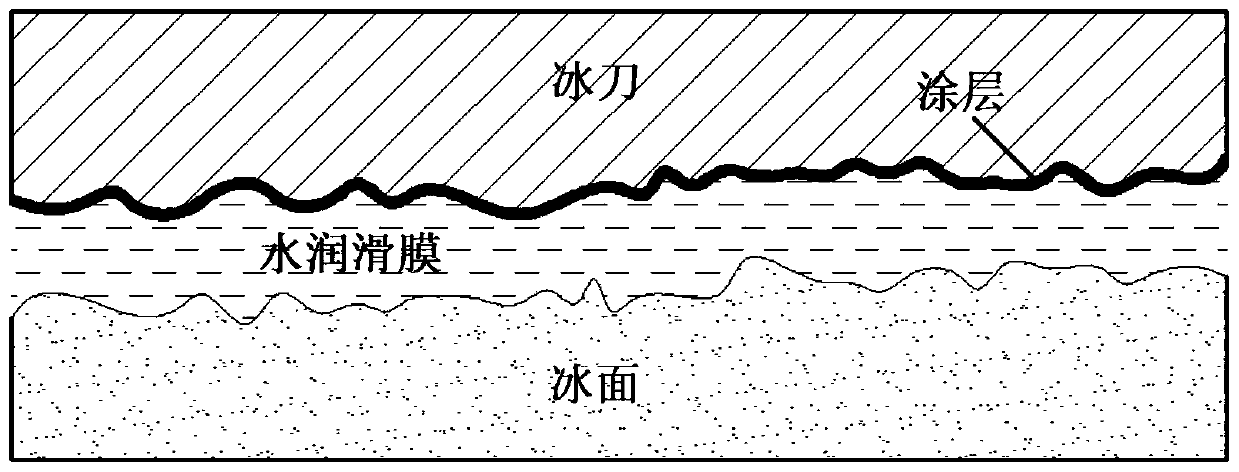

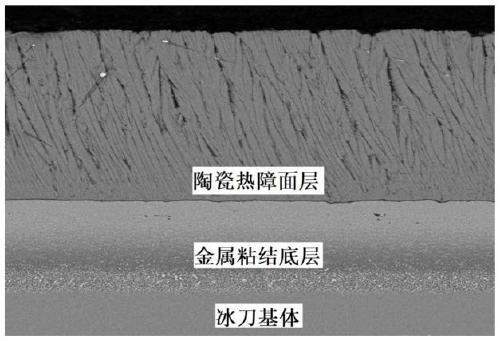

Novel ice skate blade drag reduction technology and implementation method thereof

InactiveCN109972097AAchieve drag reductionNovel technical principleVacuum evaporation coatingSputtering coatingWater basedHeat flow

The invention provides a novel ice skate blade drag reduction technology and an implementation method thereof, aiming at the dynamic characteristics and technical status of skating sports equipment. According to the novel ice skate blade drag reduction technology and the implementation method, through surface modification treatment on an ice skate blade substrate, the heat conductivity coefficientof an ice skate blade and heat loss caused by friction heat conduction to the ice skate blade substrate are obviously reduced, the heat flow distribution coefficient of the friction heat conduction to the ice surface is increased, and more friction heat is used for melting the ice surface to increase the thickness of a water lubricating film, so that water-based lubrication drag reduction is realized, the friction coefficient of the ice surface is greatly reduced, and the tribological performance of the ice skate blade is improved. The novel ice skate blade drag reduction technology and the implementation method have the outstanding characteristics of novel technical principle, remarkable drag reduction effect, easiness in engineering realization and the like.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com