Nanometer aluminum oxide/paraffin compound phase change heat storage material, preparation thereof and application thereof

A composite phase change material and nano-alumina technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as wear or blockage, density difference, etc., to improve dispersibility, increase thermal conductivity, and improve thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

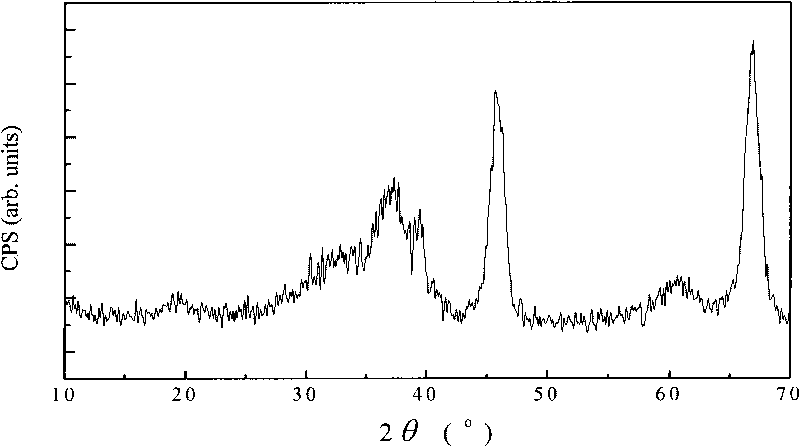

Method used

Image

Examples

Embodiment 1

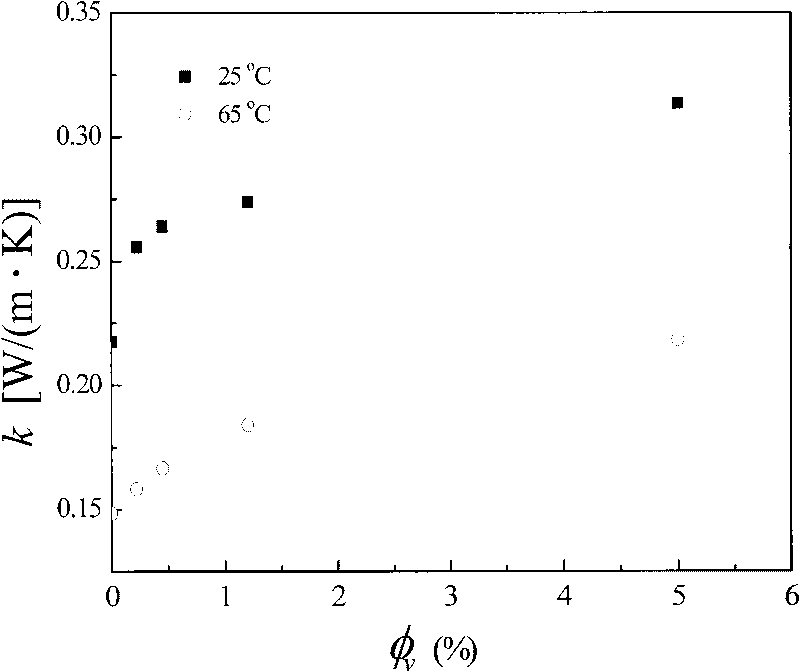

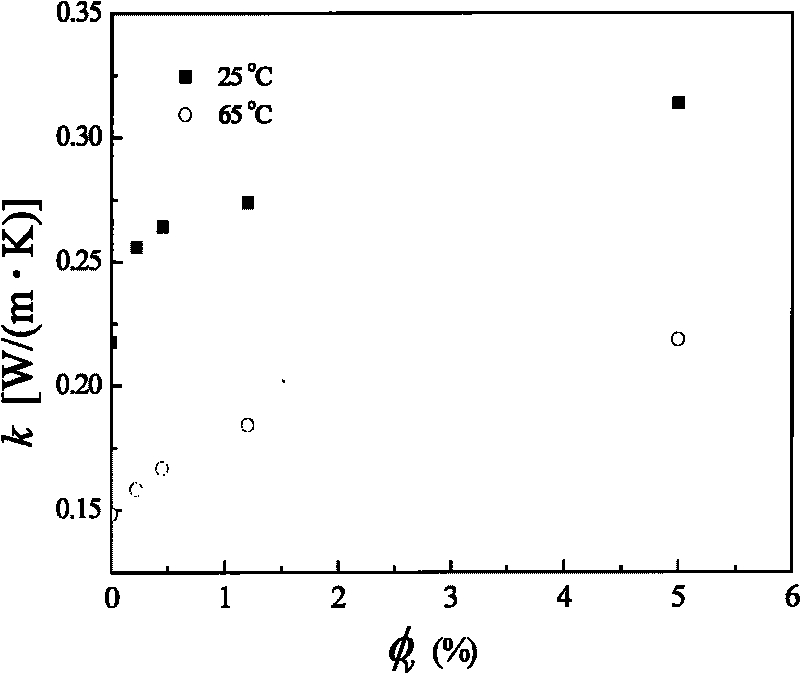

[0025] A composite phase change thermal storage material containing 0.2% volume fraction of alumina was prepared. Prepare alumina powder (average particle size 100 nm, gamma type) and paraffin wax at a volume ratio of 0.2:99.8, mix alumina and oleylamine (volume ratio of alumina to oleylamine is 2:1), and ball mill for 5 minutes before use. The treated alumina and paraffin were blended and melted in a volume ratio, magnetically stirred for 10 minutes, and ultrasonically vibrated for 40 minutes. The obtained nano-alumina / paraffin composite phase change material had a latent heat of phase change of 169.7J / g and a melting temperature of 48.3°C. , and its thermal conductivity at 25°C is 16% higher than that of palmitic acid. The molten mixture was stable for 24 hours without precipitation.

Embodiment 2

[0027] A composite phase change thermal storage material containing 0.2% volume fraction of alumina was prepared. Prepare alumina powder (average particle size 10 nanometers, gamma type) and paraffin wax at a volume ratio of 0.2:99.8, prepare oleylamine at a volume ratio of alumina to oleylamine of 1:2, add oleylamine to molten paraffin and sonicate for 10 minutes . The molten paraffin mixed with oleylamine was magnetically stirred. Add alumina powder while stirring, and then stir for 10 minutes after the alumina is completely added, then take out the magnet, and ultrasonicate at a constant temperature for 10 minutes, the obtained nano-alumina / paraffin composite phase change material has a latent heat of phase change of 165.7J / g, melts The temperature is 47.8°C, and its thermal conductivity at 25°C is 16.8% higher than that of palmitic acid. After 48 hours the molten mixture did not precipitate out.

Embodiment 3

[0029] A composite phase change heat storage material containing 5.0% volume fraction of alumina was prepared. Prepare alumina powder (average particle size: 20 nm, gamma type) and paraffin wax at a volume ratio of 5:95, mix alumina and oleylamine (volume ratio of alumina to oleylamine is 2:1), and ball mill for 25 minutes before use. The treated alumina and paraffin were blended and melted, magnetically stirred for 120 minutes, and held for 120 minutes with ultrasonic waves. The obtained nano-alumina / paraffin composite phase change material had a latent heat of phase change of 151.6J / g and a melting temperature of 45.3°C. At 25°C, the thermal conductivity is 32% higher than that of the matrix material. The molten mixture was free of precipitation for 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com