Rolling type precision seeding device for small and medium-sized seeds

A small-seed, rolling technology, applied in the field of hand-push rolling seeders, can solve the problems of difficult germination, increased manpower and working hours, and low sowing efficiency, so as to ensure the emergence rate and yield, save manpower and time, and save weeding The effect of the seedling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

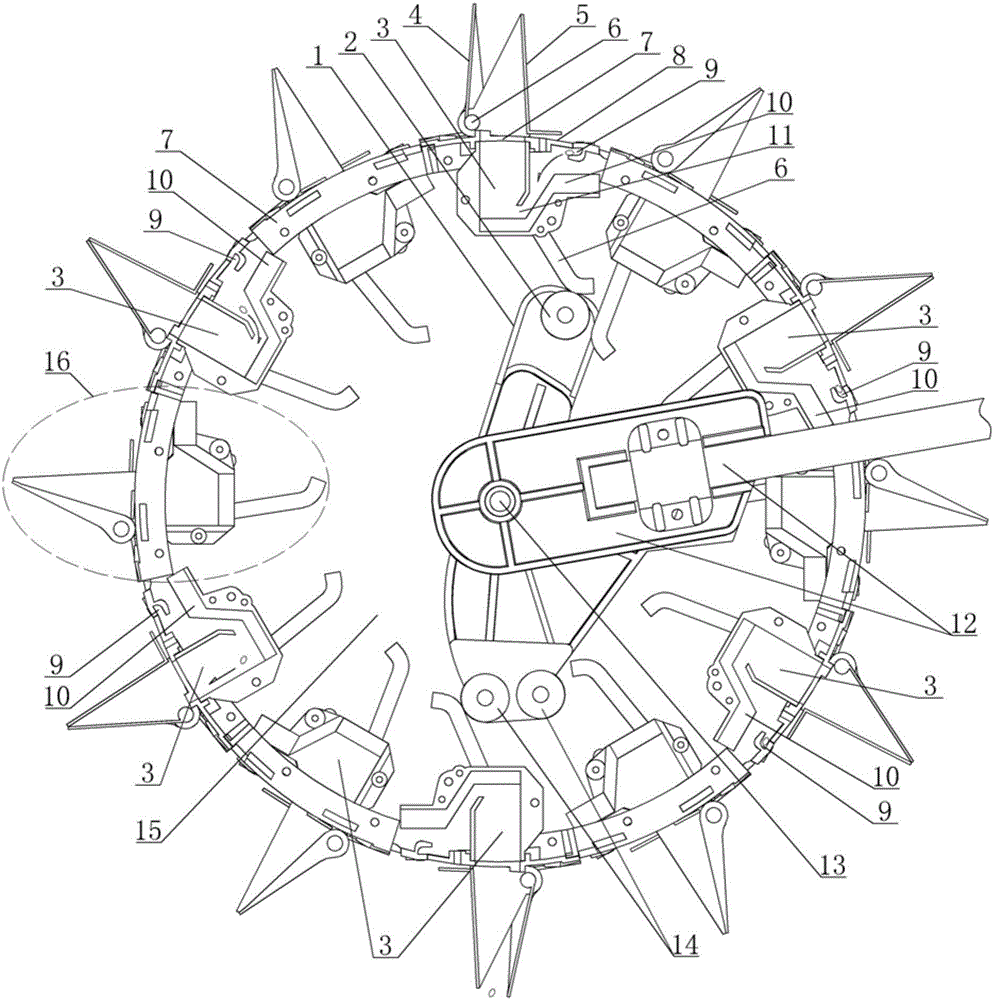

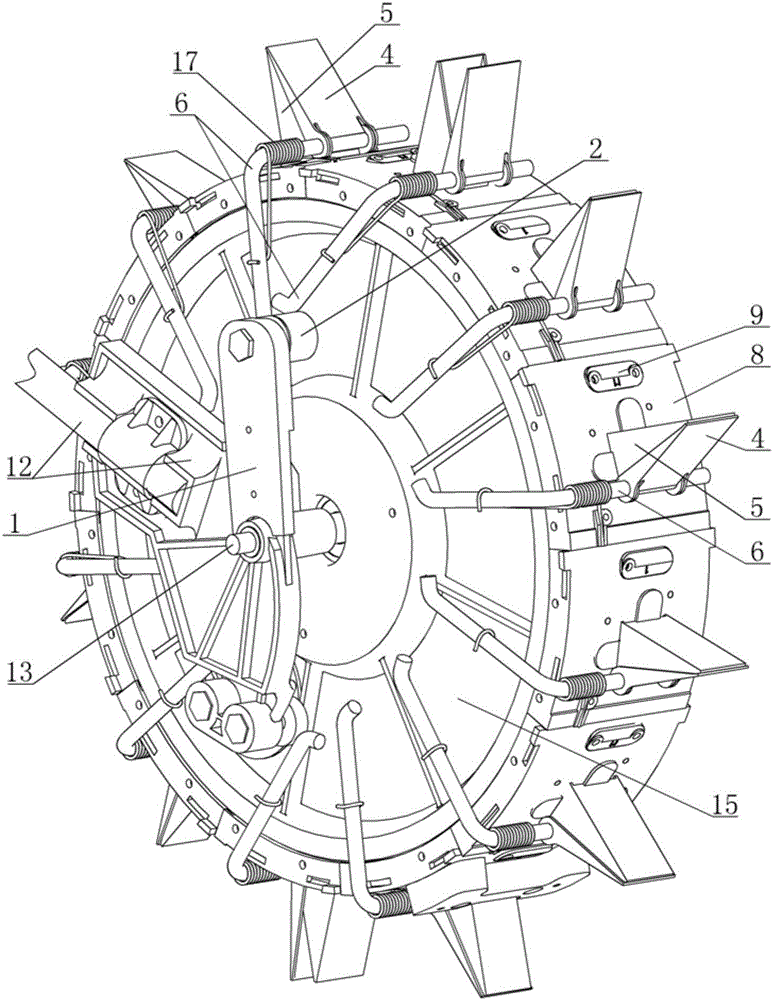

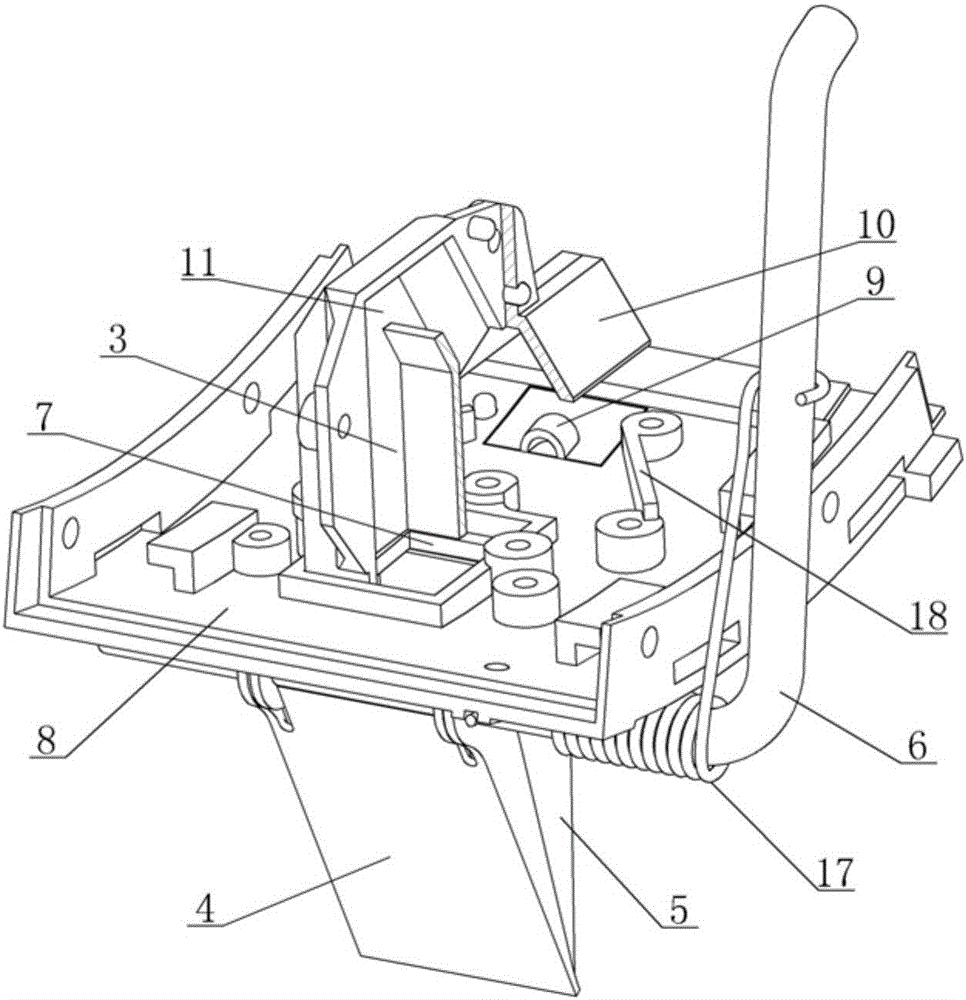

[0019] The rolling type small and medium-sized seed sowing device comprises a push rod 12 and a seed box 15. The side of the seed box is provided with a seed drop port, and the front end of the push rod is equipped with a main shaft 13. A plurality of planting devices 16 are housed on the circumference of the case, each planting device comprises arc plate 8, seed bin 3, inoculation tank 10 and duckbill, arc plate is movably connected with the seed box, and the inner arc surface of arc plate A seed-taking spoon 9 is housed on the top, and the seed-taking spoon is movably connected with the arc-shaped plate. The arc-shaped plate is provided with a through hole 7, and one end of the through hole positioned at the outer arc surface of the arc-shaped plate communicates with the inside of the duckbill, and the fixed piece in the duckbill It is fixedly connected with the arc-shaped plate, and the other end of the through hole is connected with the seed outlet at one end of the seed bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com