Patents

Literature

94results about How to "Shedding evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

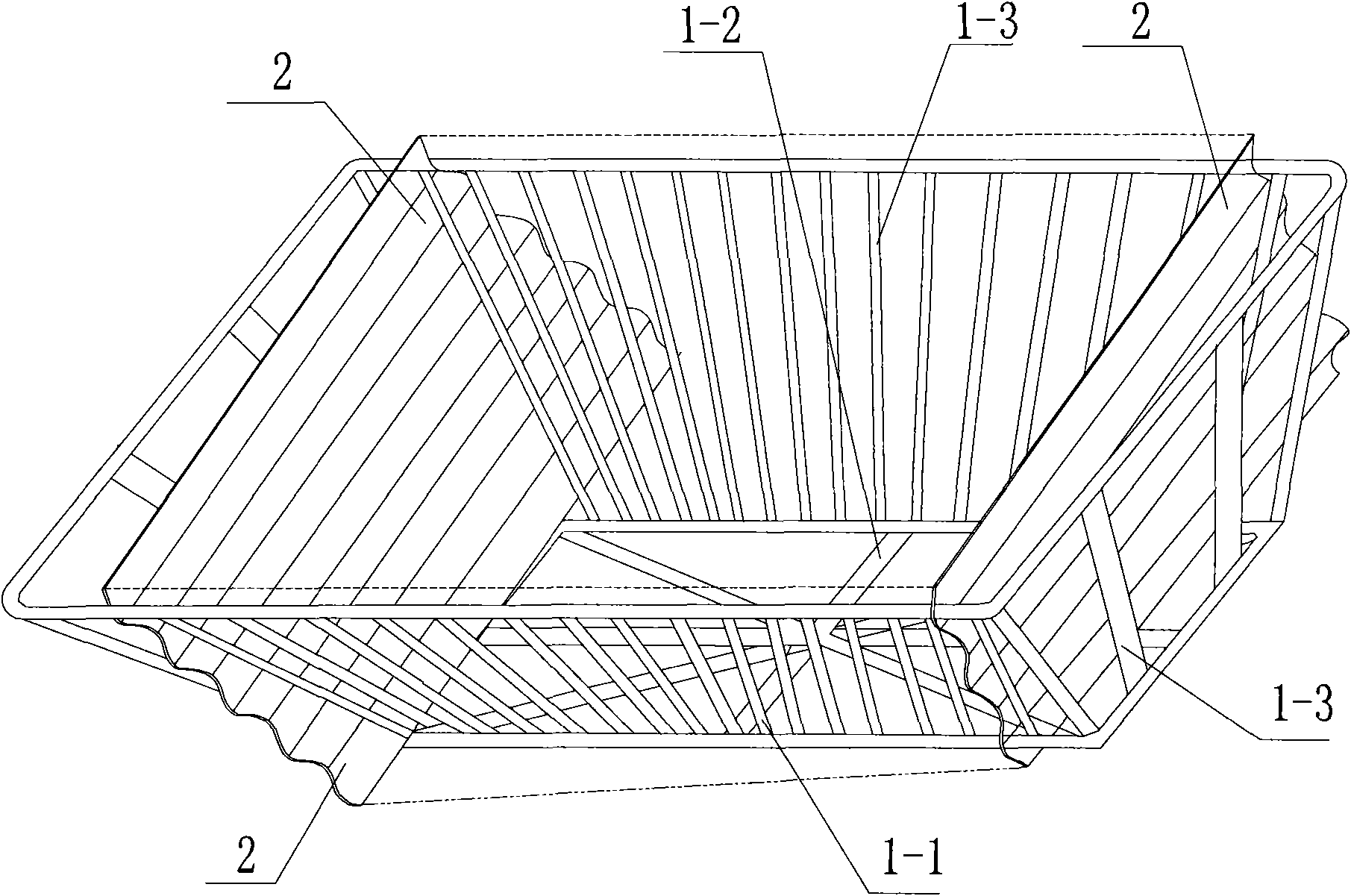

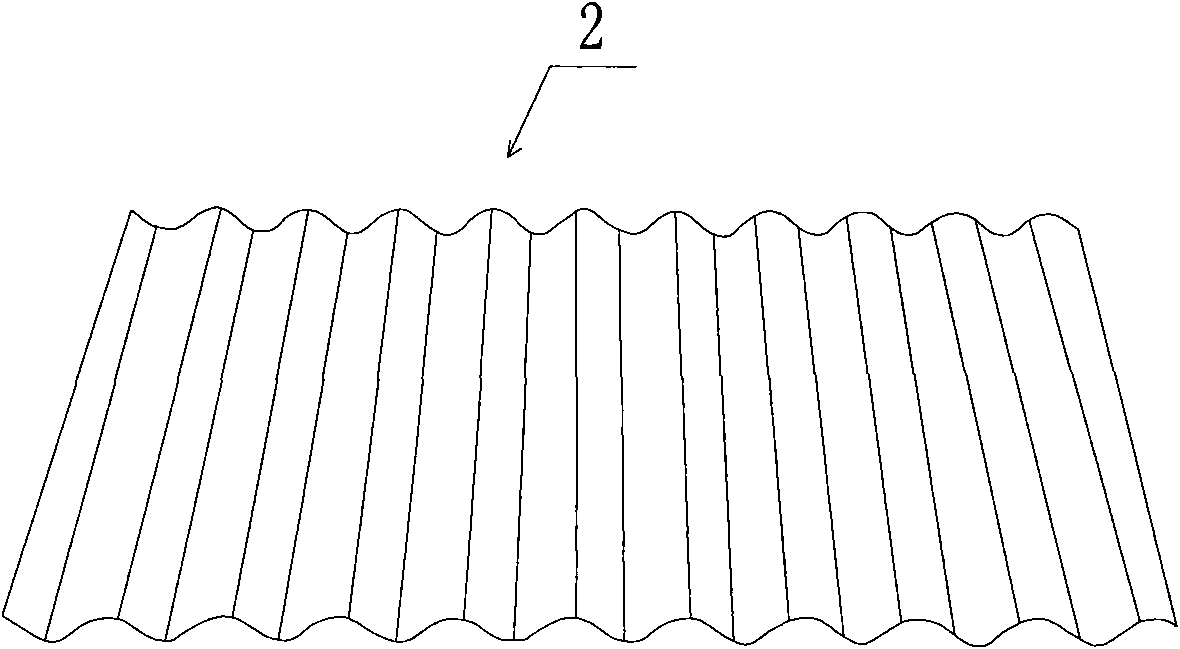

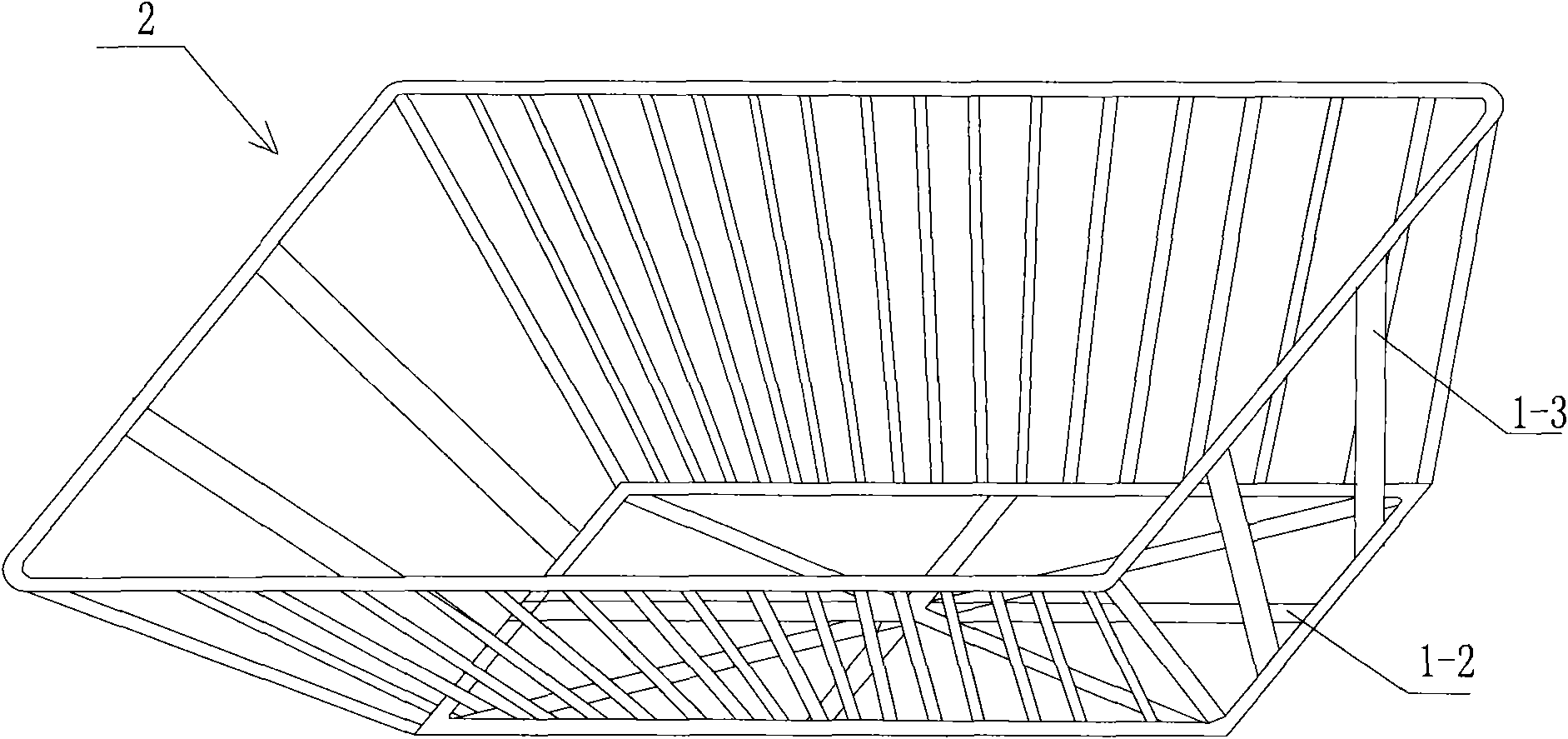

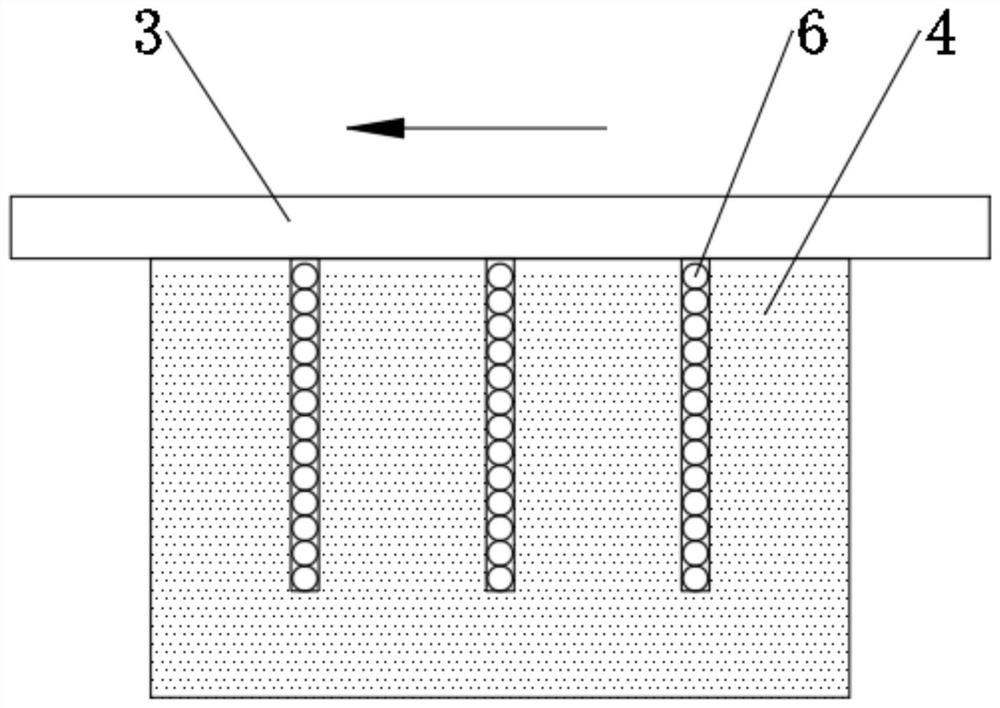

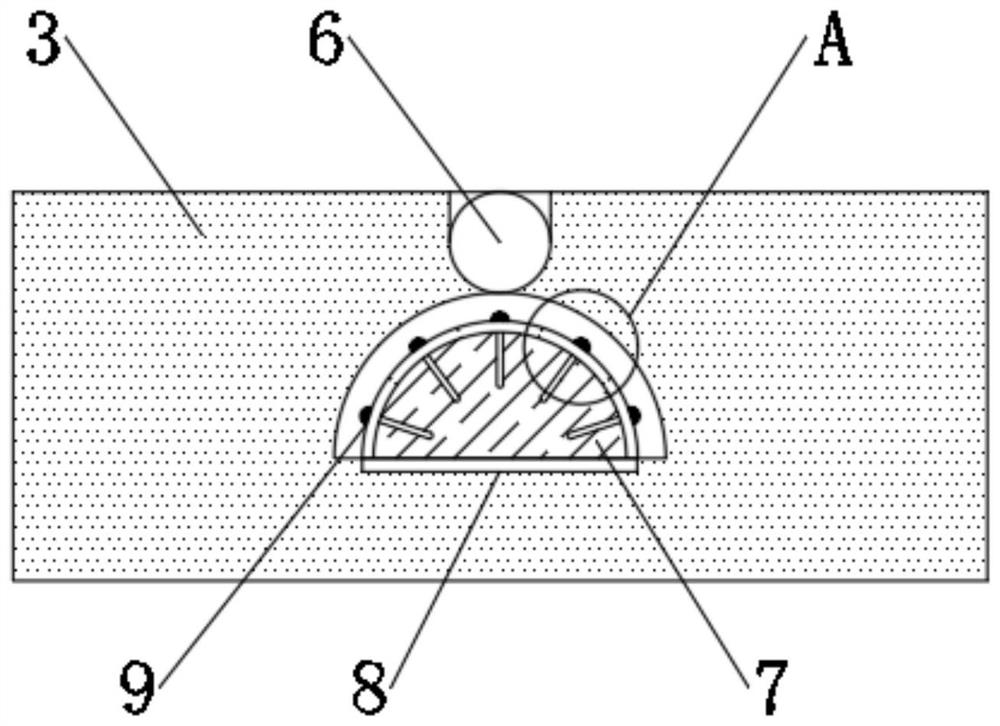

Method for culturing monomeric oyster seeds and seed collector

InactiveCN101773079AEasy to useExcellent adhesionClimate change adaptationPisciculture and aquariaOysterMonomer

The invention provides a method for culturing monomeric oyster seeds and a seed collector. The problems such as poor seed fixation effect, difficult substrate removal and the like in the prior art can be solved. By using a plastic corrugated plate as the fixation substrate of the monomeric oyster seeds in the invention, the problems such as unsatisfactory seed collection effect, difficult substrate removal, easy breakage of the oyster seeds, mutual conglomeration and attachment of oysters and the like in the prior art are solved.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

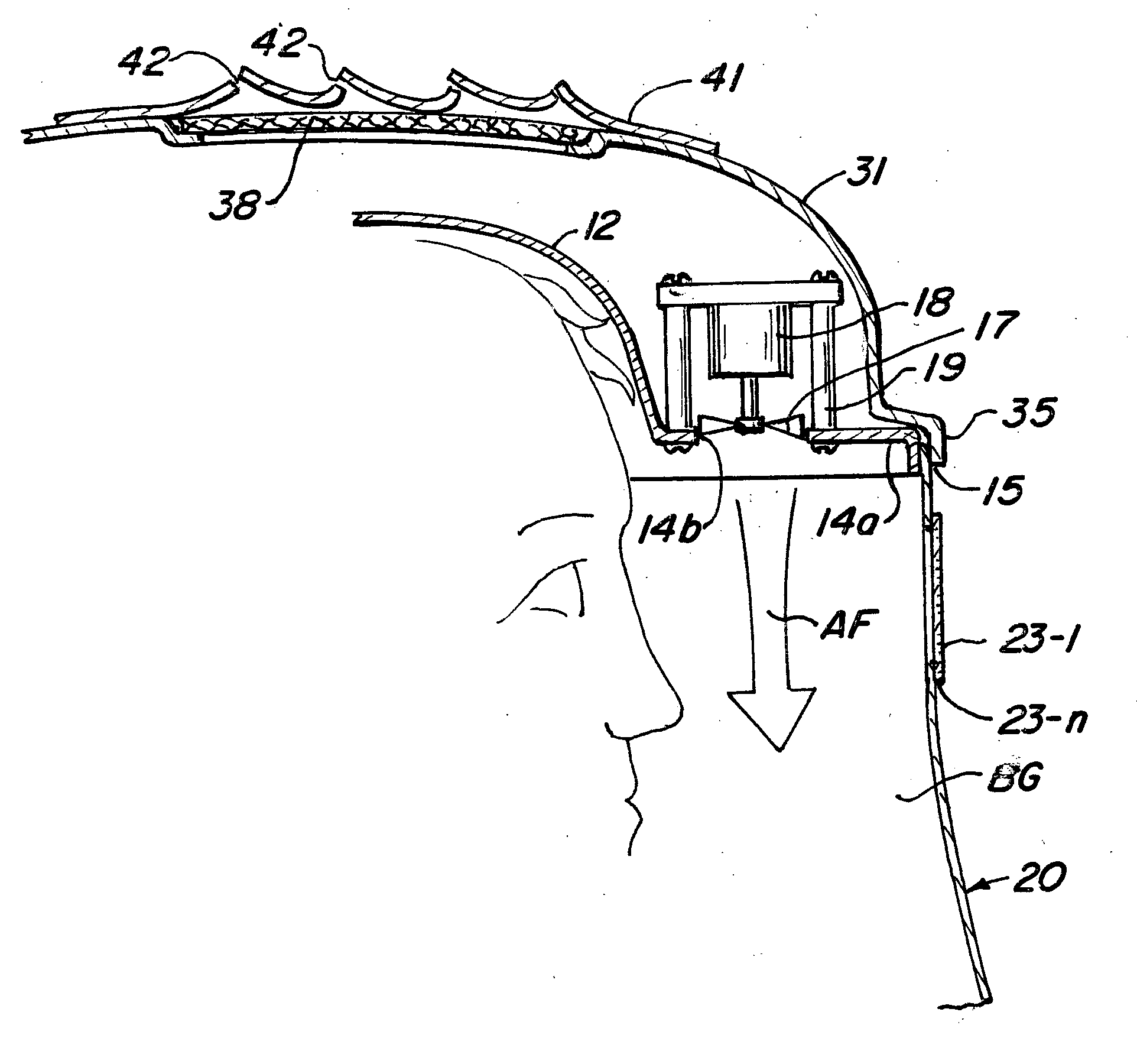

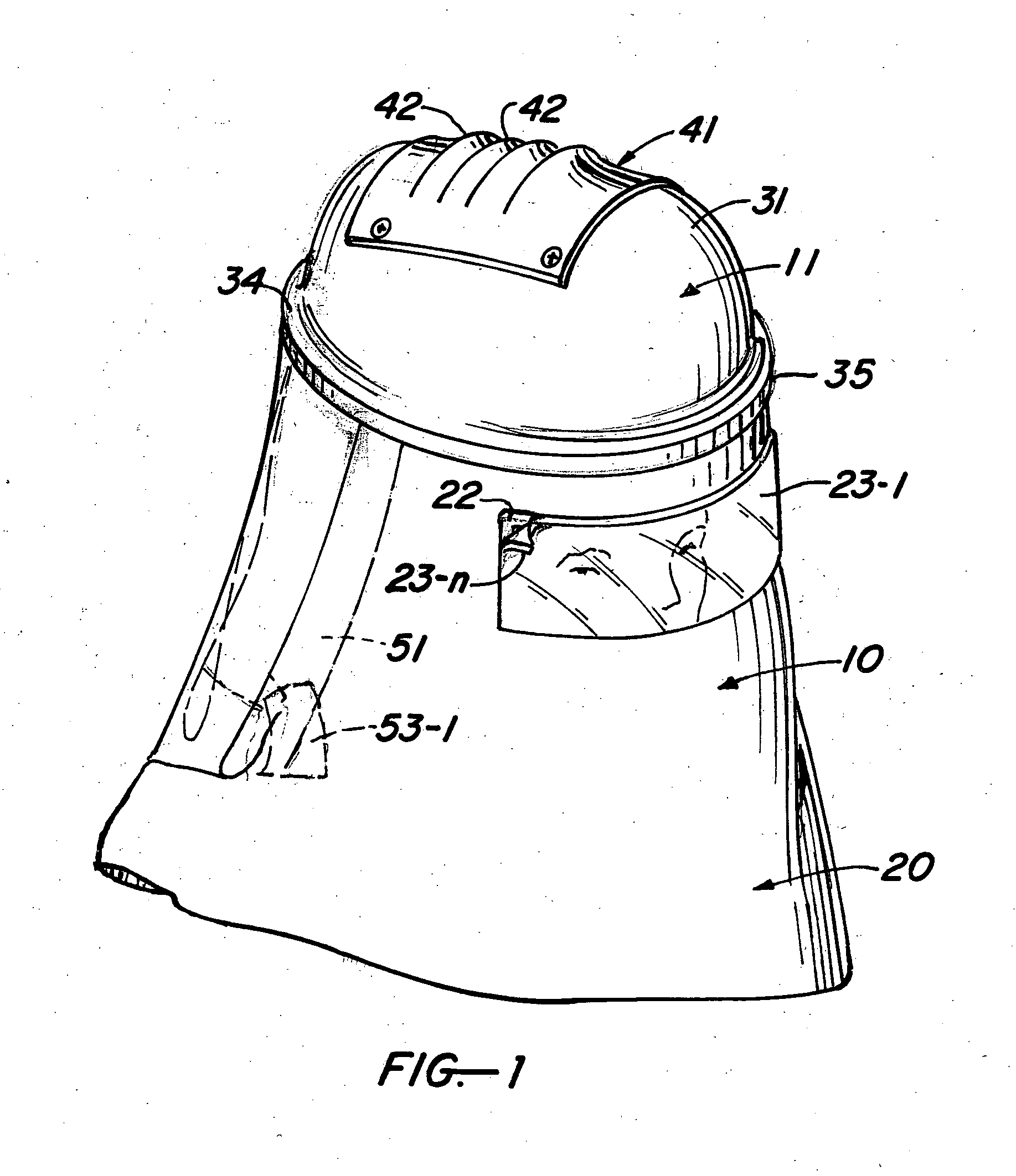

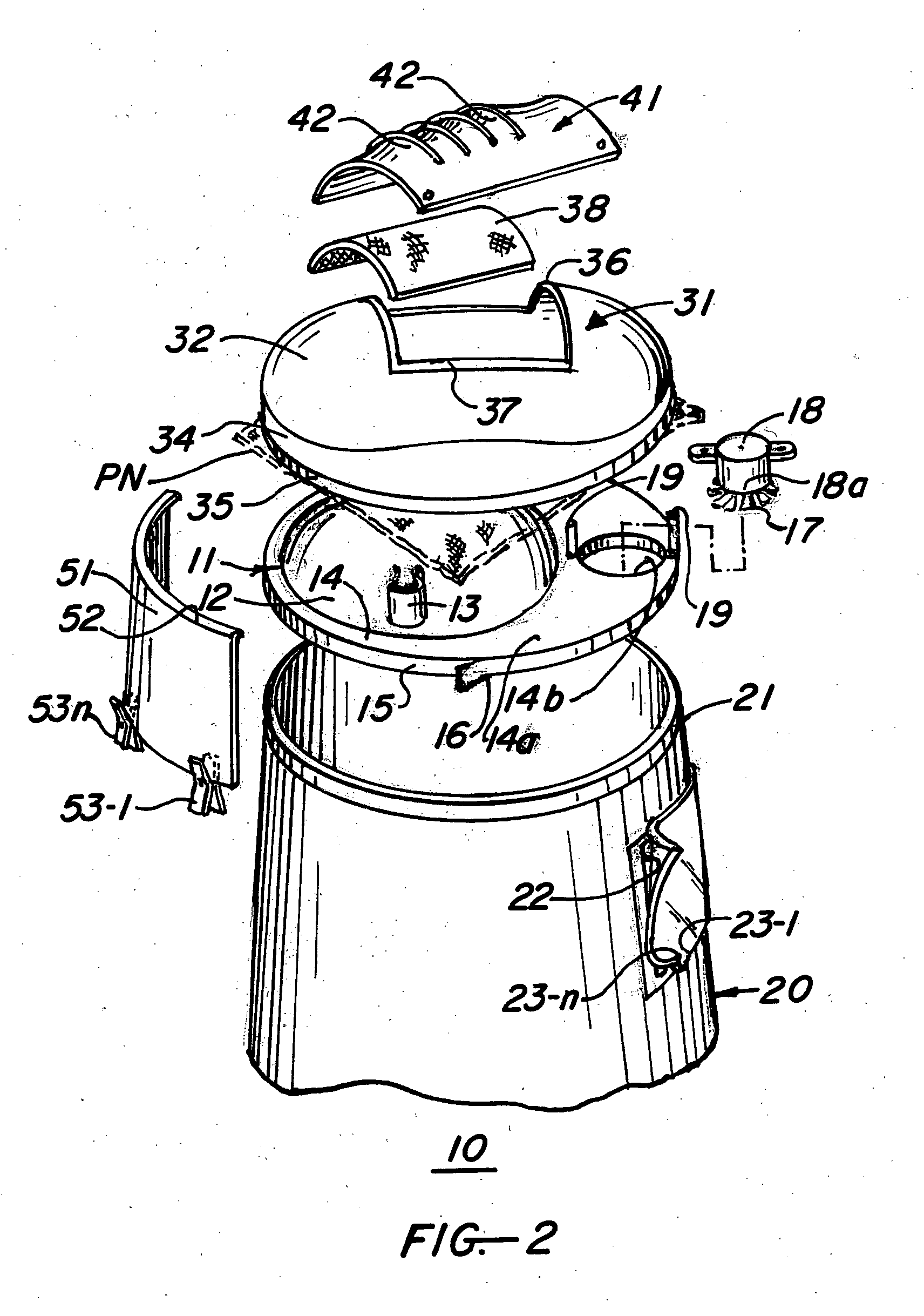

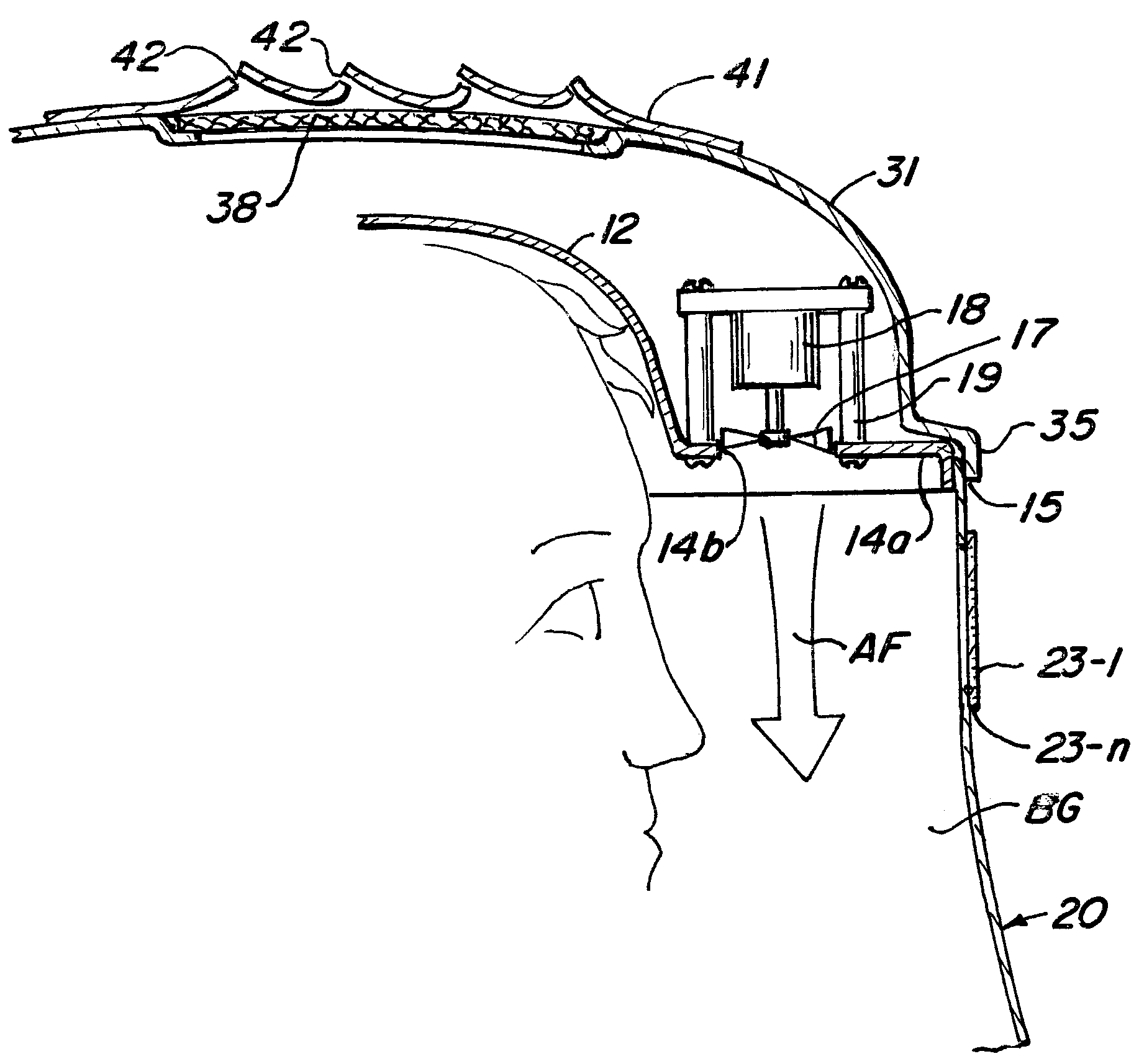

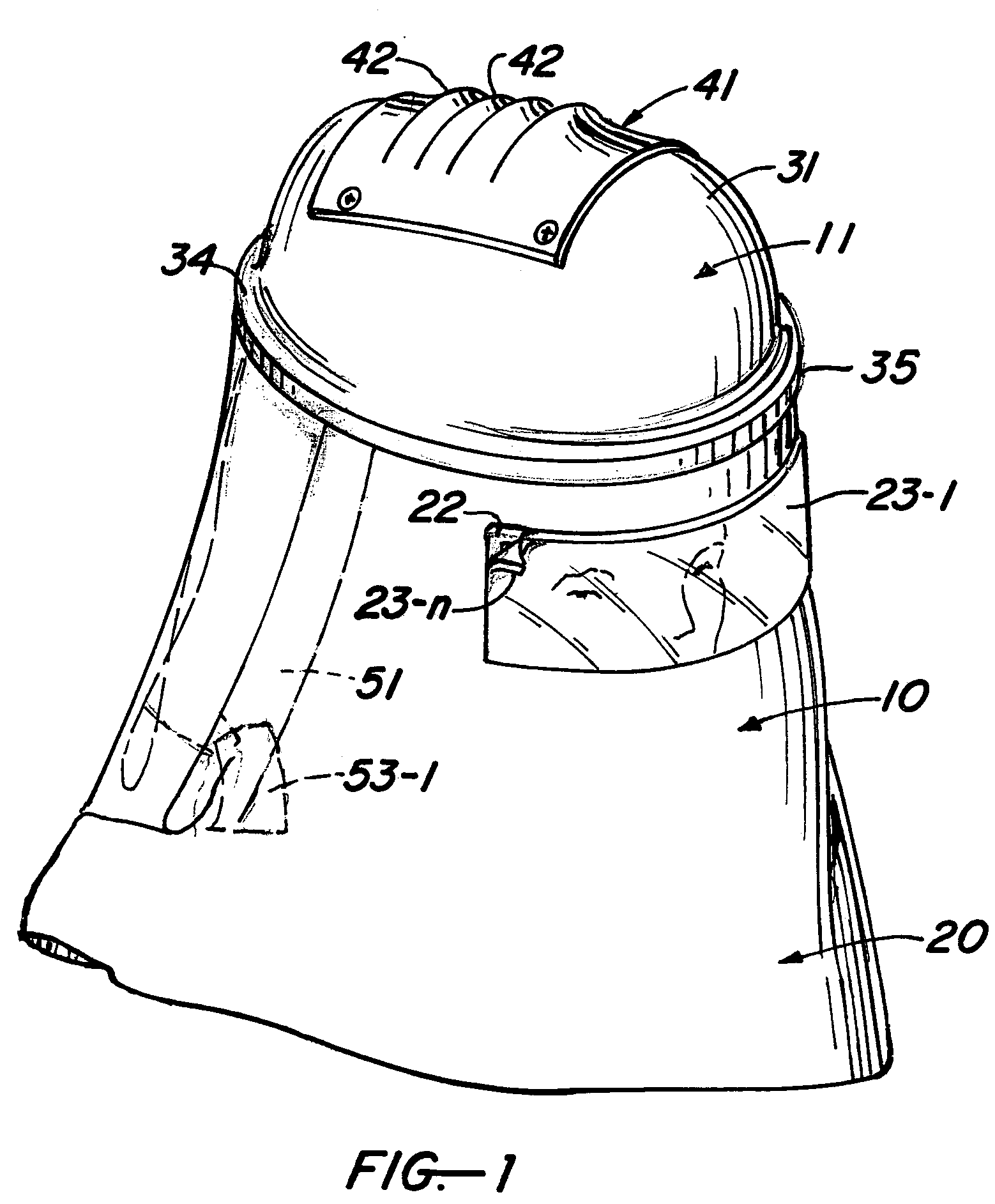

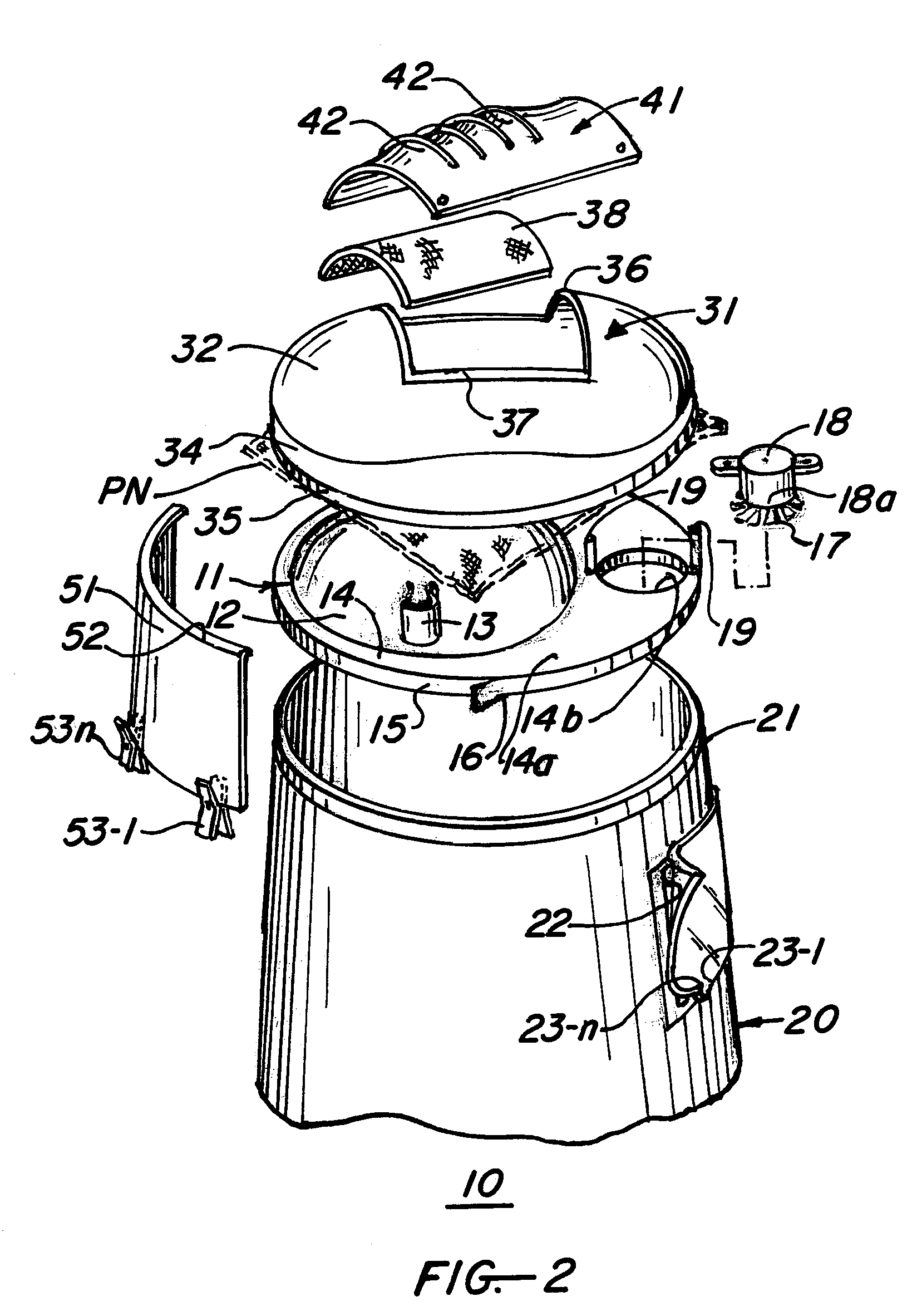

Respiration hood useful in biological, radiological and chemical emergencies

InactiveUS20070221214A1Function increaseUse polarizedChemical protectionHeat protectionElectricityHOOD assembly

A respiration hood assembly is effected from a thin-walled headpiece nested within the periphery of a mating exterior housing that includes a filtered aperture. The nested engagement between the headpiece and the housing is also useful in capturing one edge of a plastic membrane skirt that is thus suspended to drape over the person wearing the headpiece. A battery powered electric fan is deployed within the housing to draw ambient air through the vent aperture into the space shrouded by the skirt. The nested headpiece arrangement is useful in retaining other fibrous towels or tissue to extend the usefulness of the assembly and a parallel connection is provided to a motor vehicle battery to extend the period of electrical excitation.

Owner:BROCKMAN ROBERT

Respiration hood useful in biological, radiological and chemical emergencies

InactiveUS7275535B1Easy to wearInexpensive to fabricateChemical protectionHeat protectionFiberMobile vehicle

A respiration hood assembly is effected from a thin-walled headpiece nested within the periphery of a mating exterior housing that includes a filtered aperture. The nested engagement between the headpiece and the housing is also useful in capturing one edge of a plastic membrane skirt that is thus suspended to drape over the person wearing the headpiece. A battery powered electric fan is deployed within the housing to draw ambient air through the vent aperture into the space shrouded by the skirt. The nested headpiece arrangement is useful in retaining other fibrous towels or tissue to extend the usefulness of the assembly and a parallel connection is provided to a motor vehicle battery to extend the period of electrical excitation.

Owner:BROCKMAN ROBERT

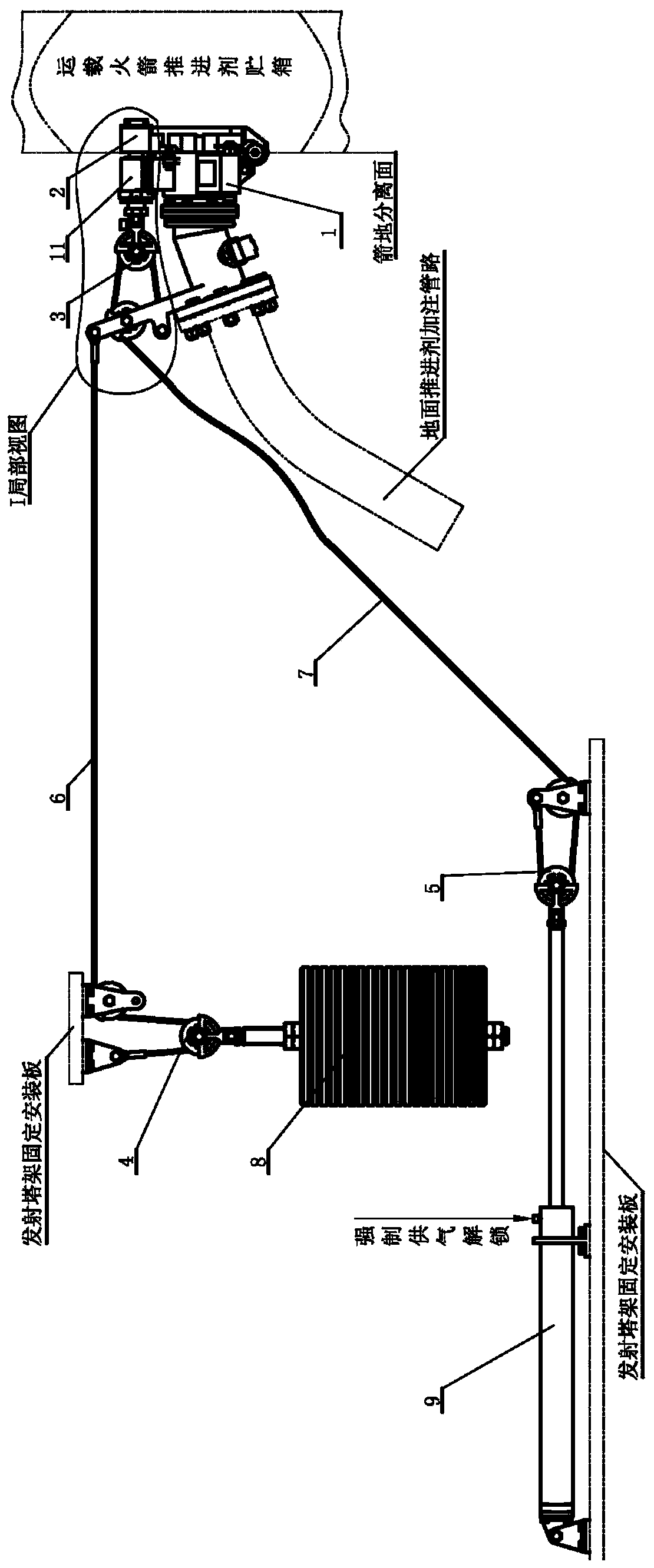

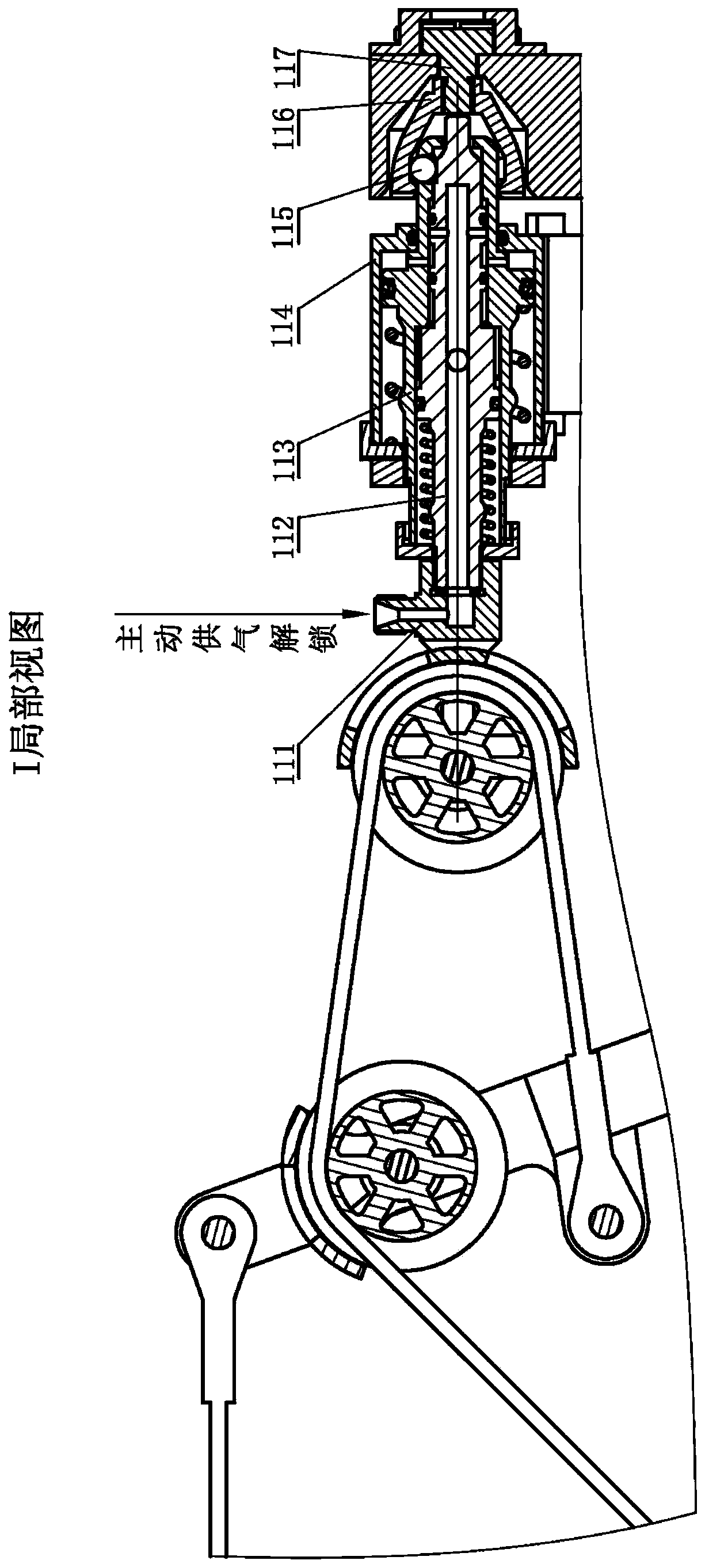

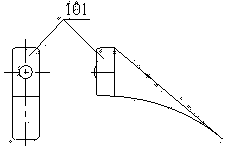

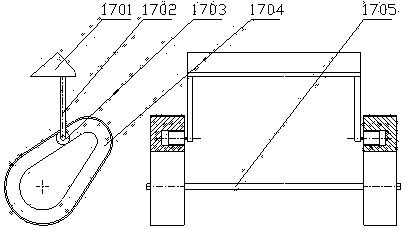

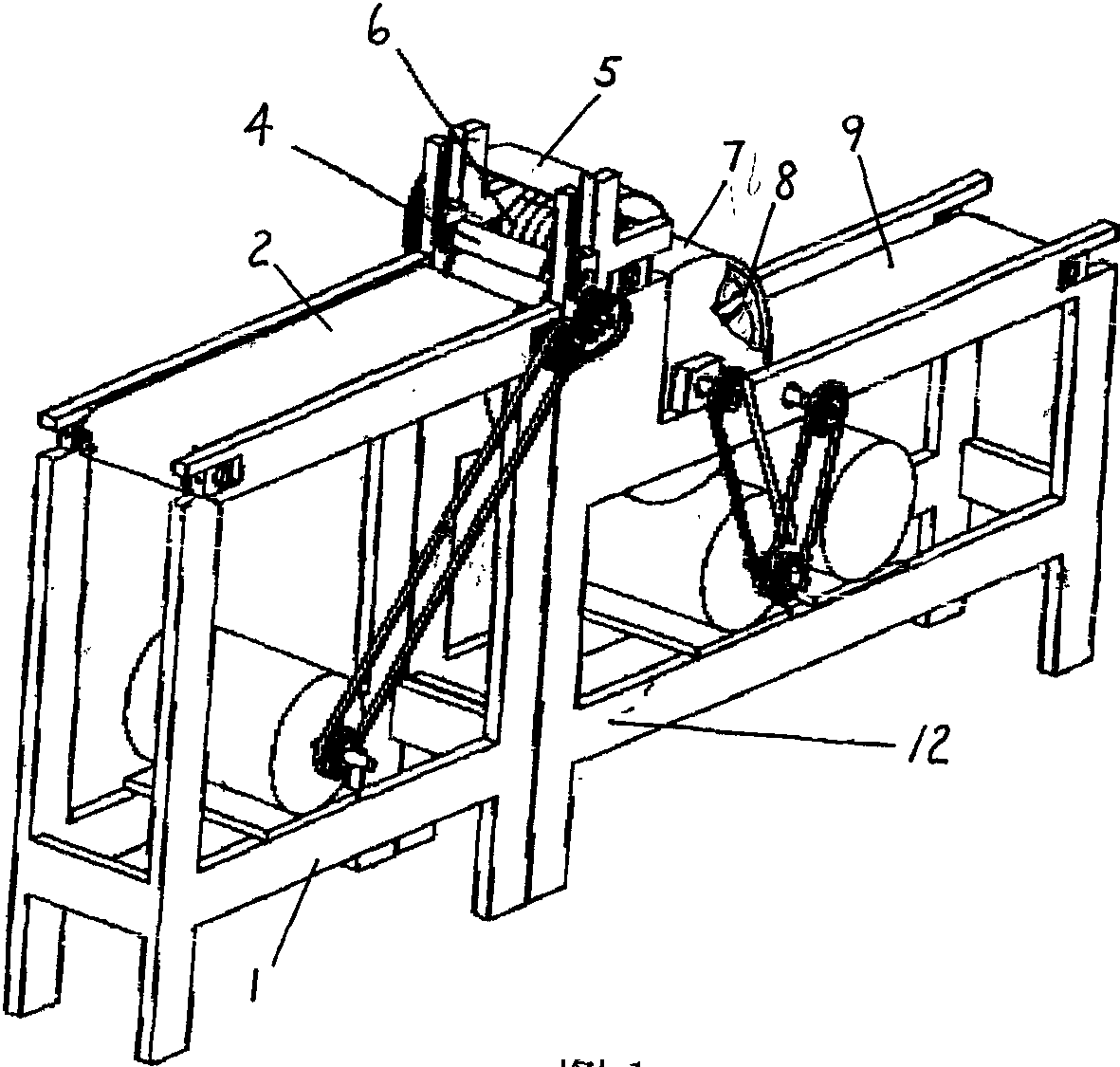

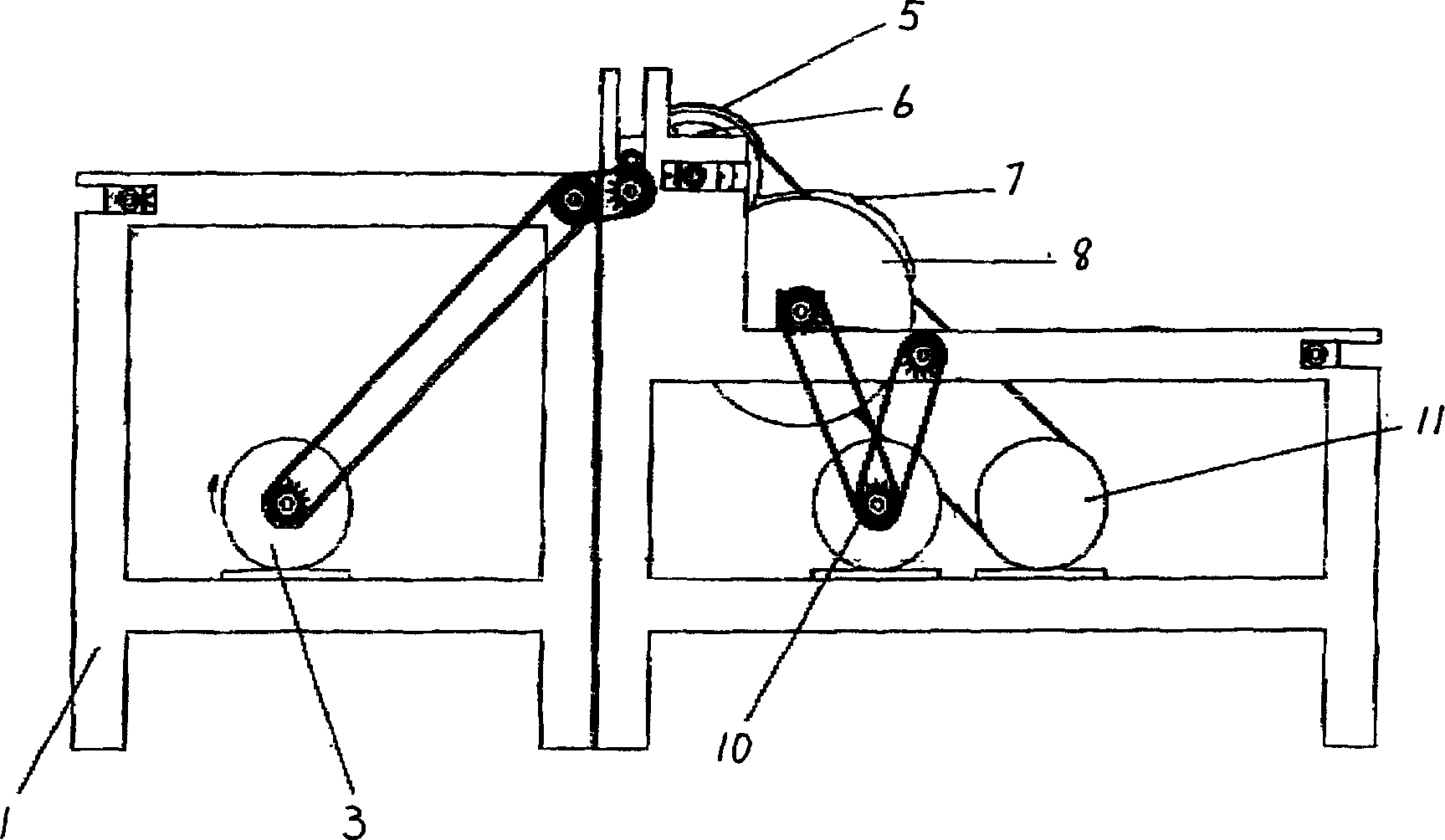

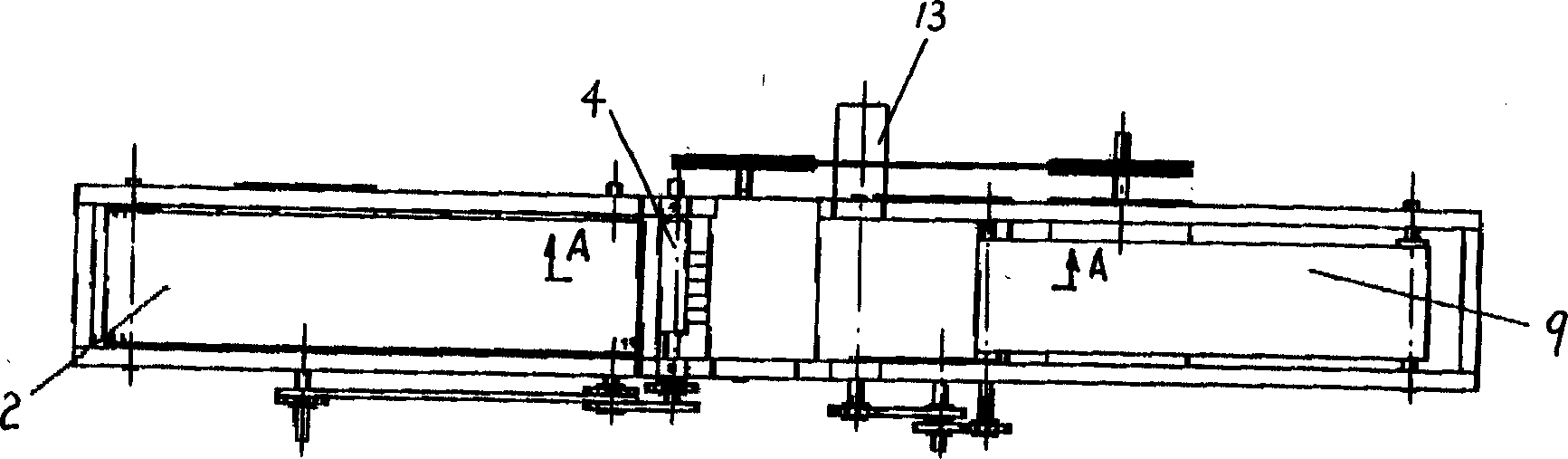

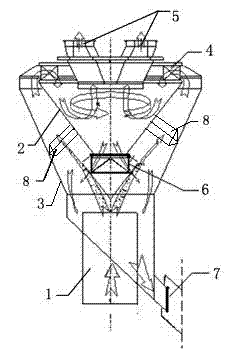

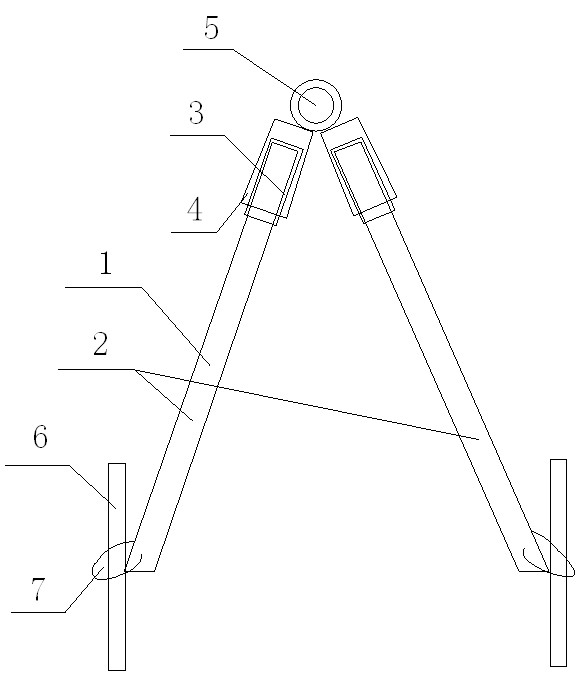

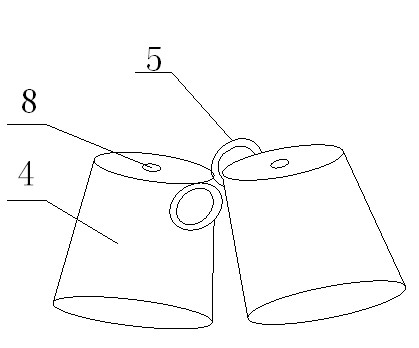

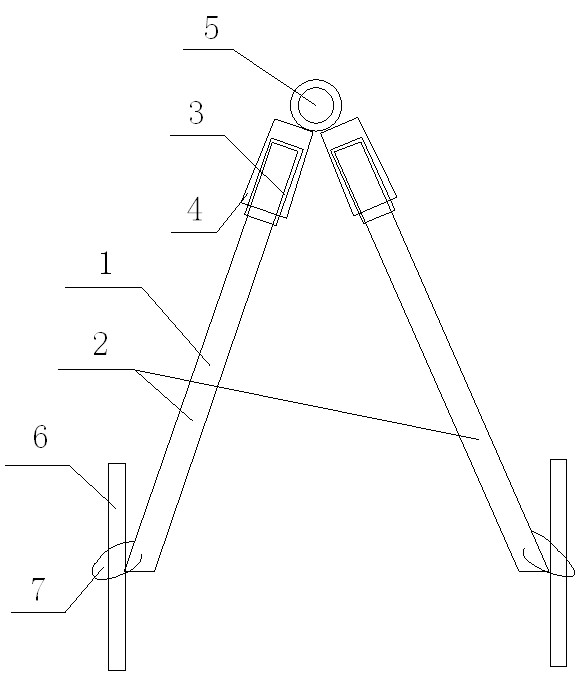

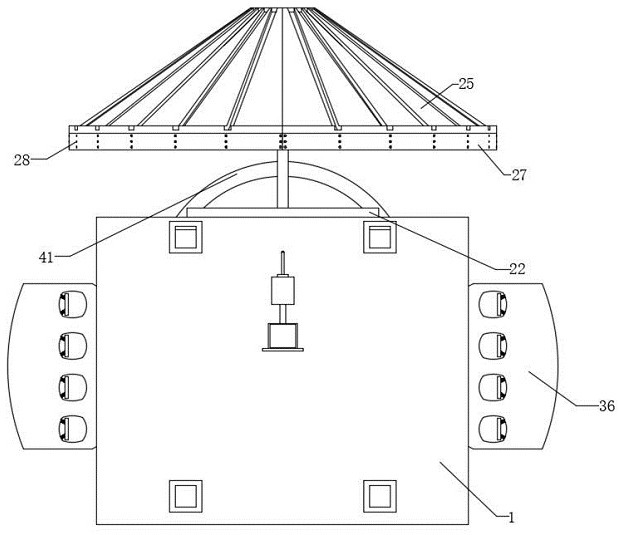

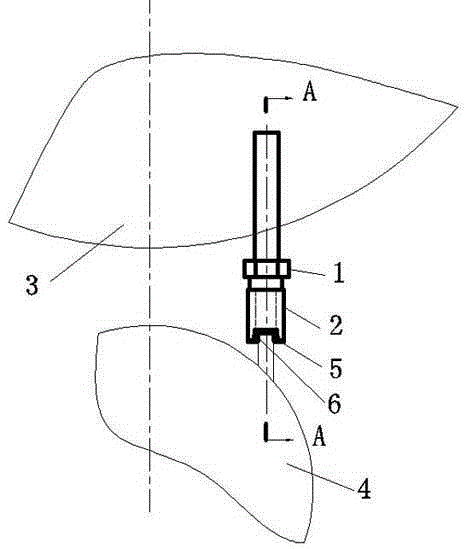

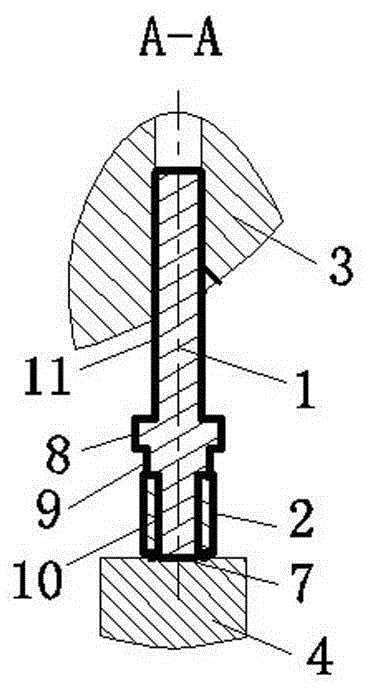

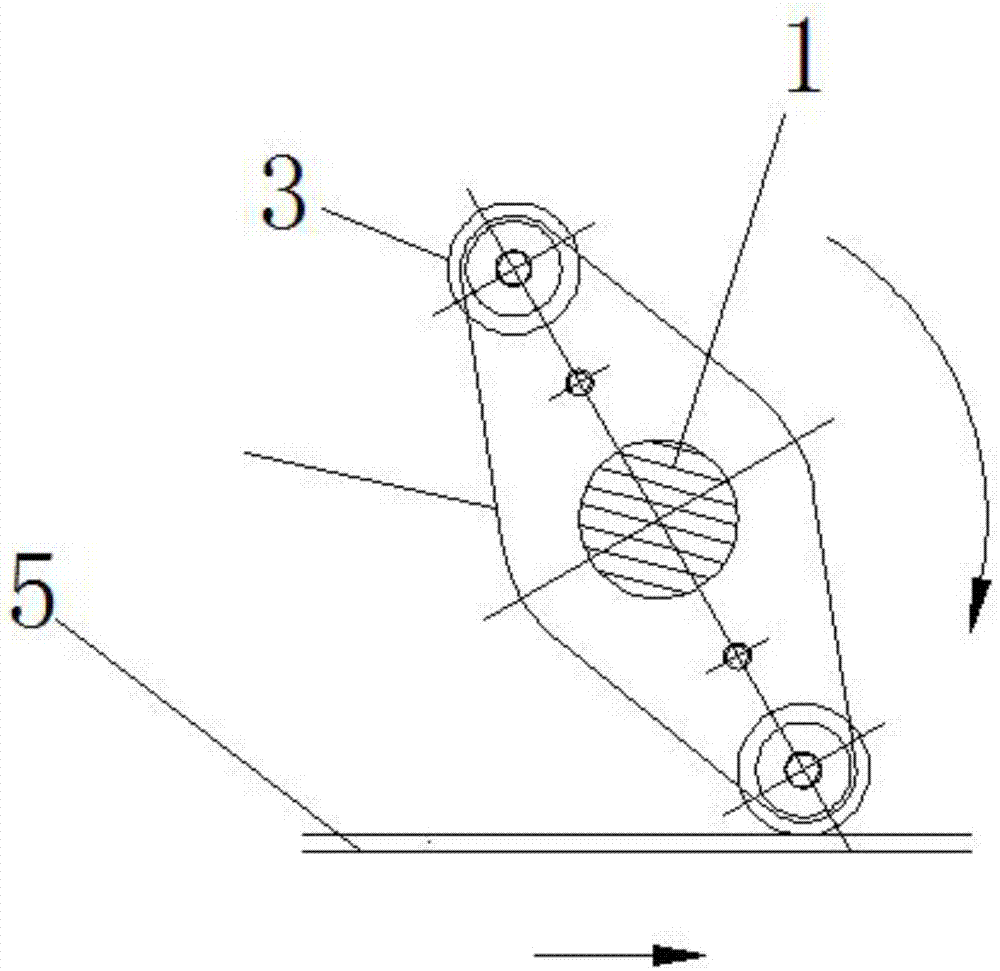

Zero-second dropping-off normal-temperature propellant adding and discharging connector for carrier rocket and method

ActiveCN110002015AShedding evenlyEnsure safe takeoffCosmonautic ground equipmentsBlock and tackleTower

The invention relates to a zero-second dropping-off normal-temperature propellant adding and discharging connector for a carrier rocket and a method. The zero-second dropping-off normal-temperature propellant adding and discharging connector for the carrier rocket comprises a connector ground part, a connector on-rocket part, a first pulley set, a second pulley set, a third pulley set, a recoveryrope, a traction rope, a counterweight, an air cylinder and a ball lock; the connector on-rocket part is mounted on a propellant storage tank of the carrier rocket, the second pulley set and the air cylinder are mounted on a launching tower, the connector ground part is connected with the connector on-rocket part through the ball lock, the counterweight is connected with the connector ground partthrough the second pulley set and the recovery rope, and the air cylinder is connected with the ball lock through the third pulley set, the traction rope and the first pulley set. The connector between a ground normal-temperature propellant filling pipeline and the on-rocket propellant storage tank can drop off reliably after zero-second ignition for taking off of the carrier rocket.

Owner:SHANGHAI AEROSPACE SYST ENG INST

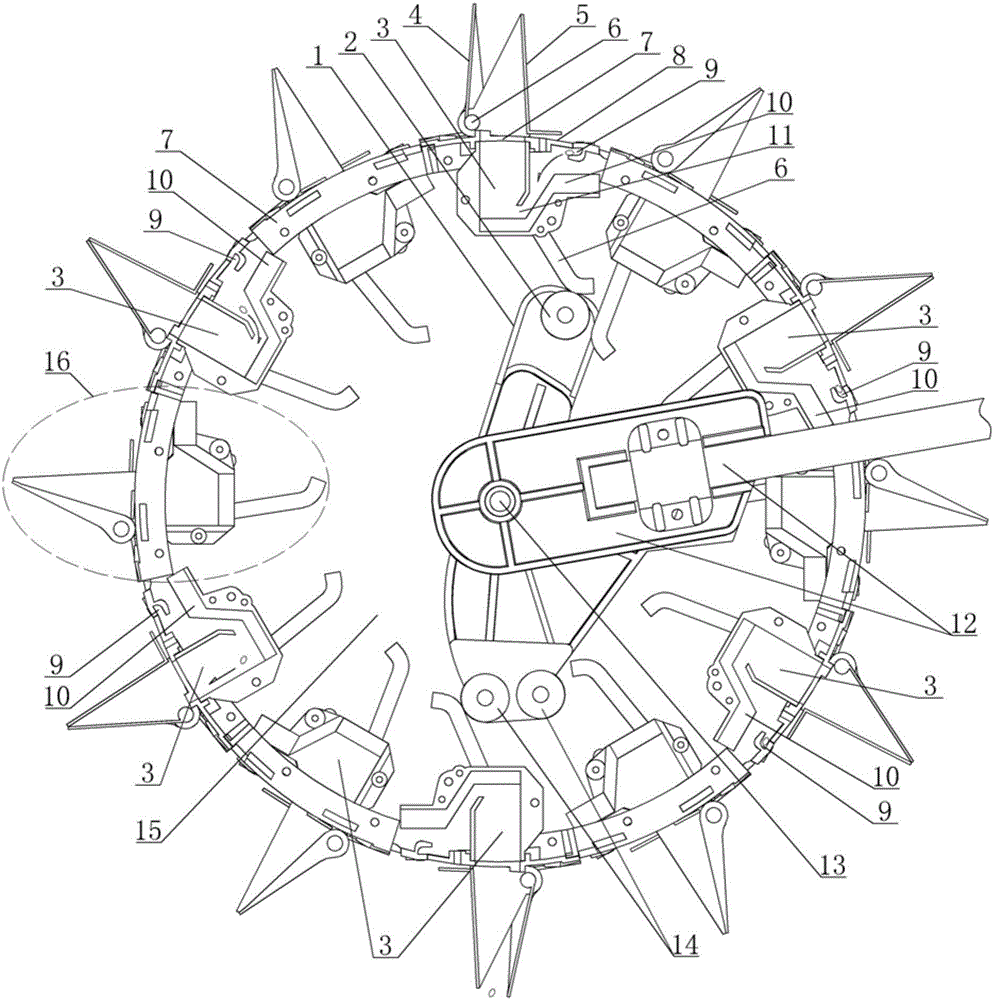

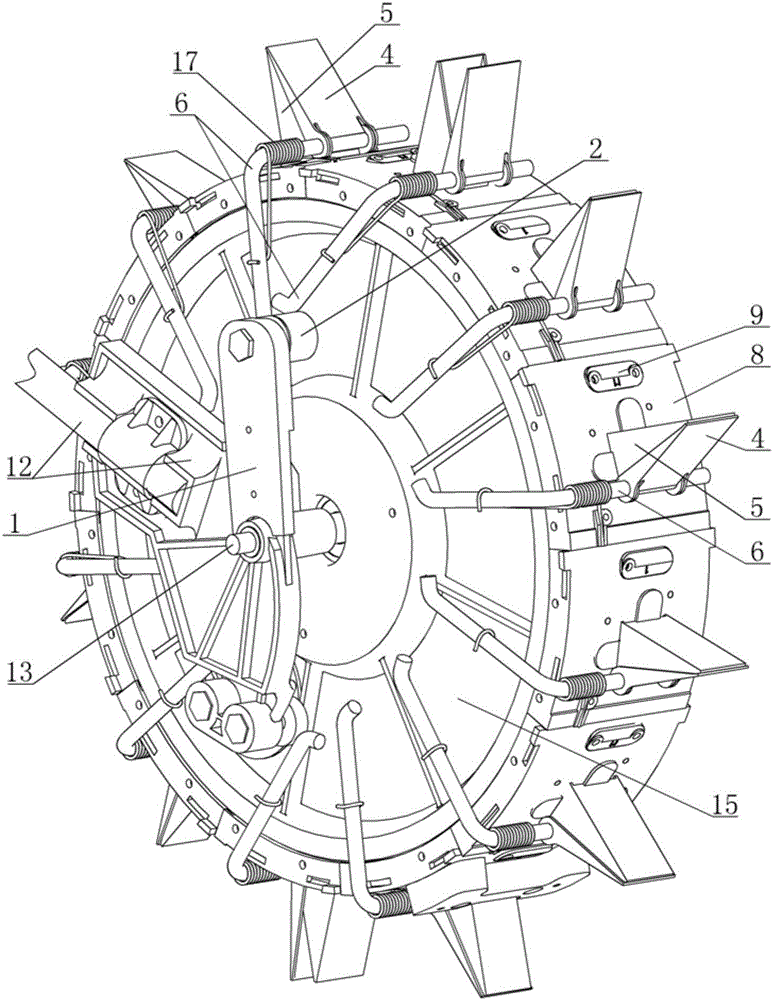

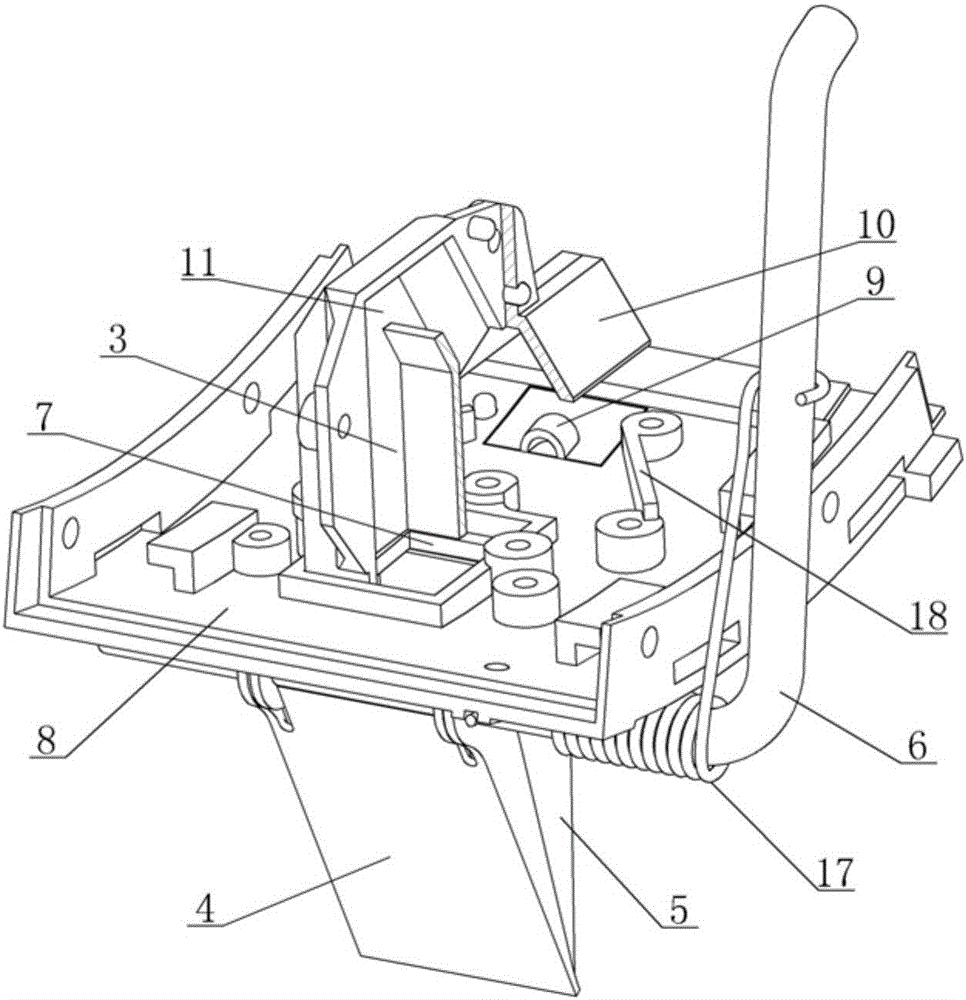

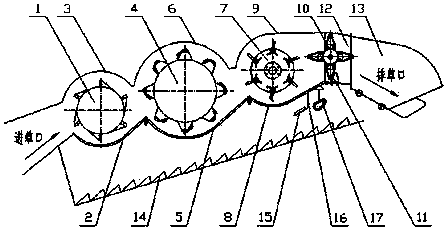

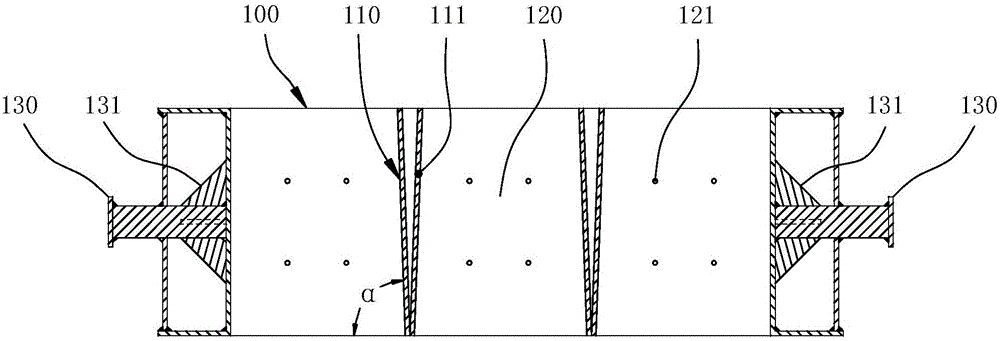

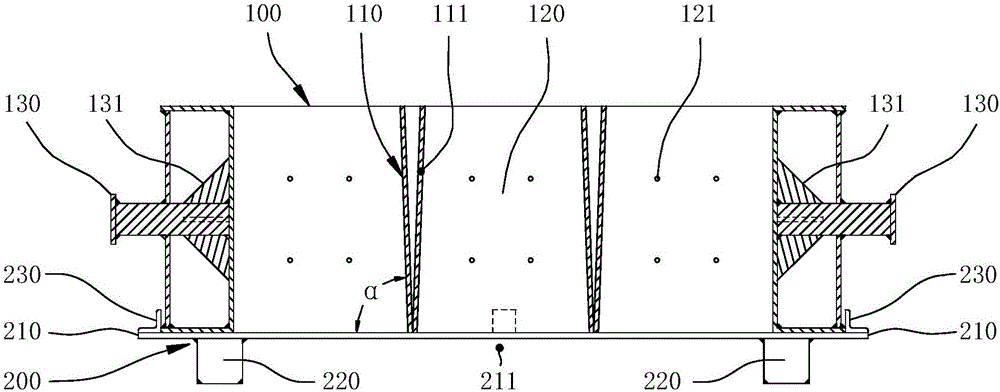

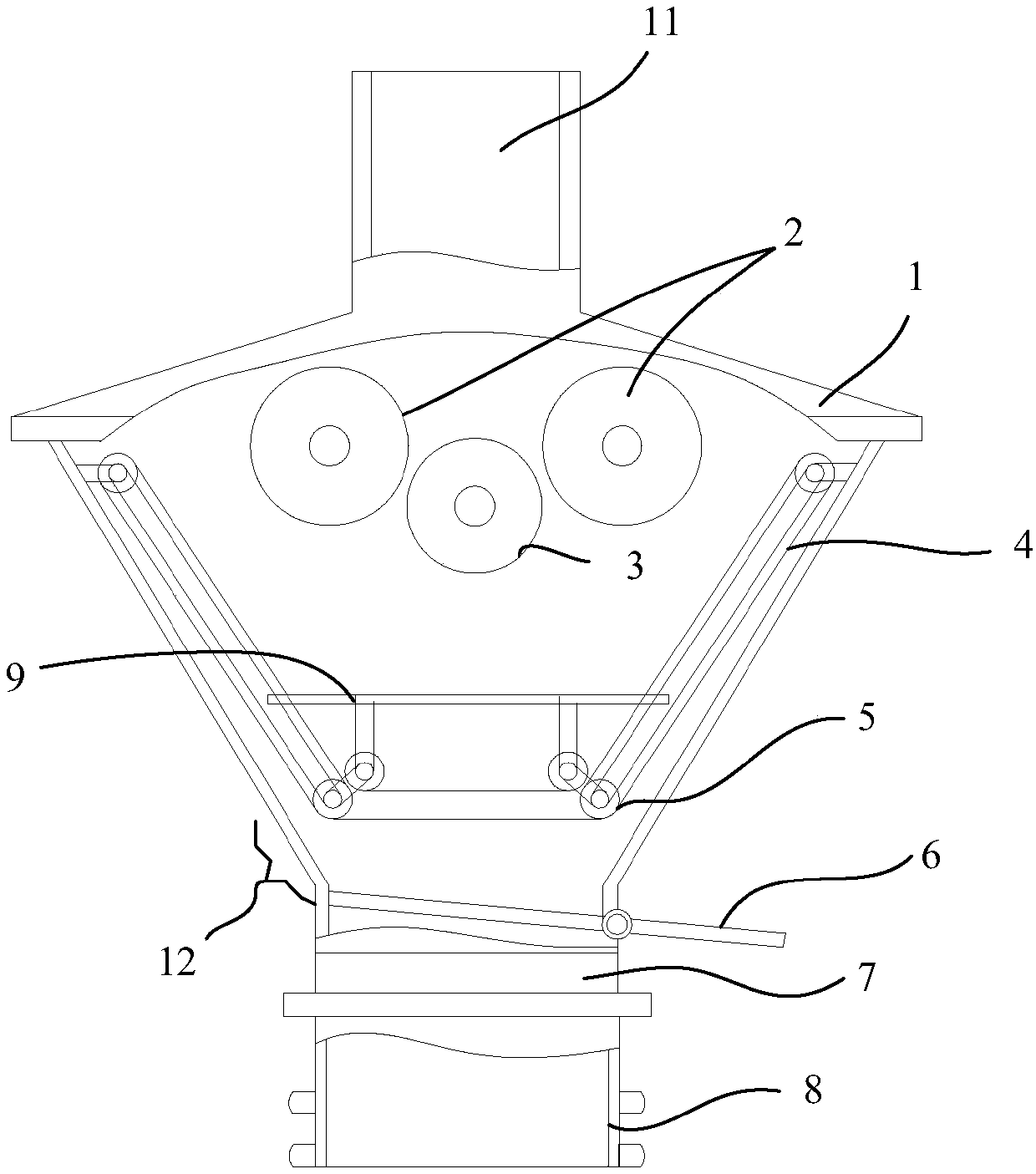

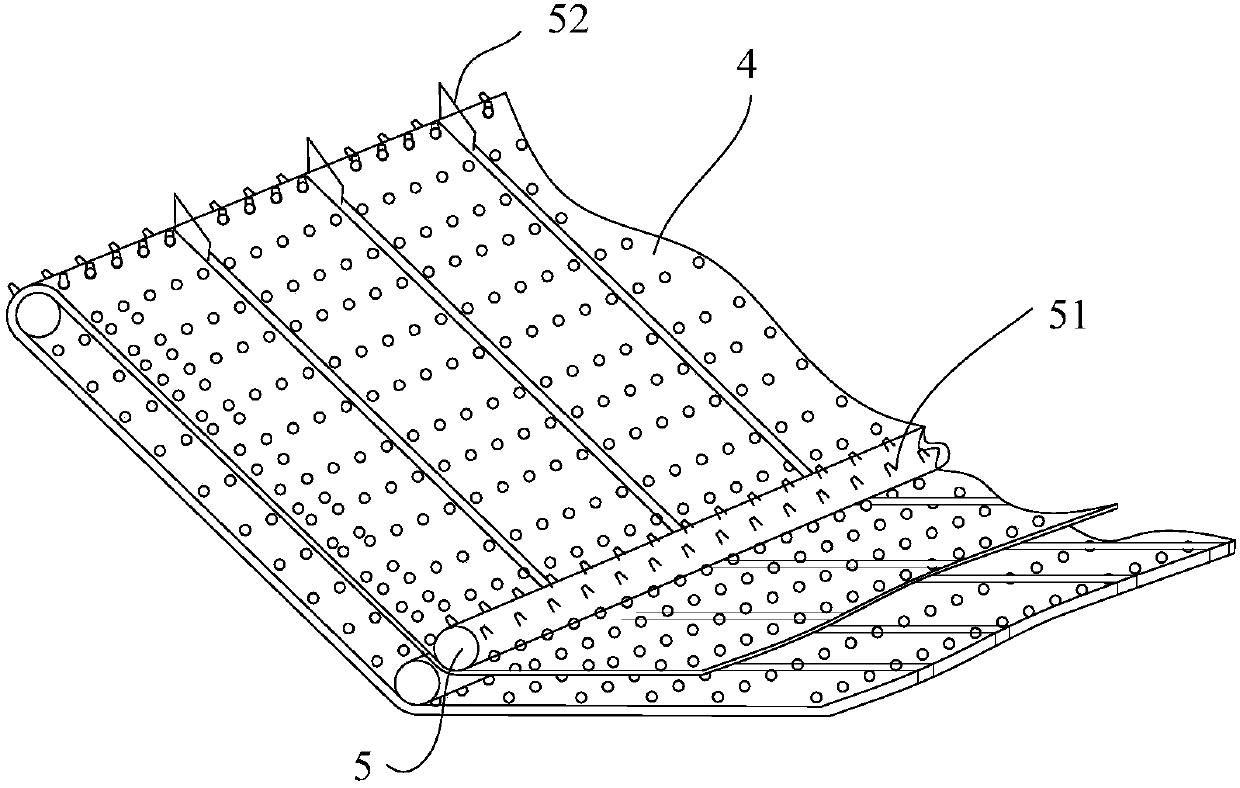

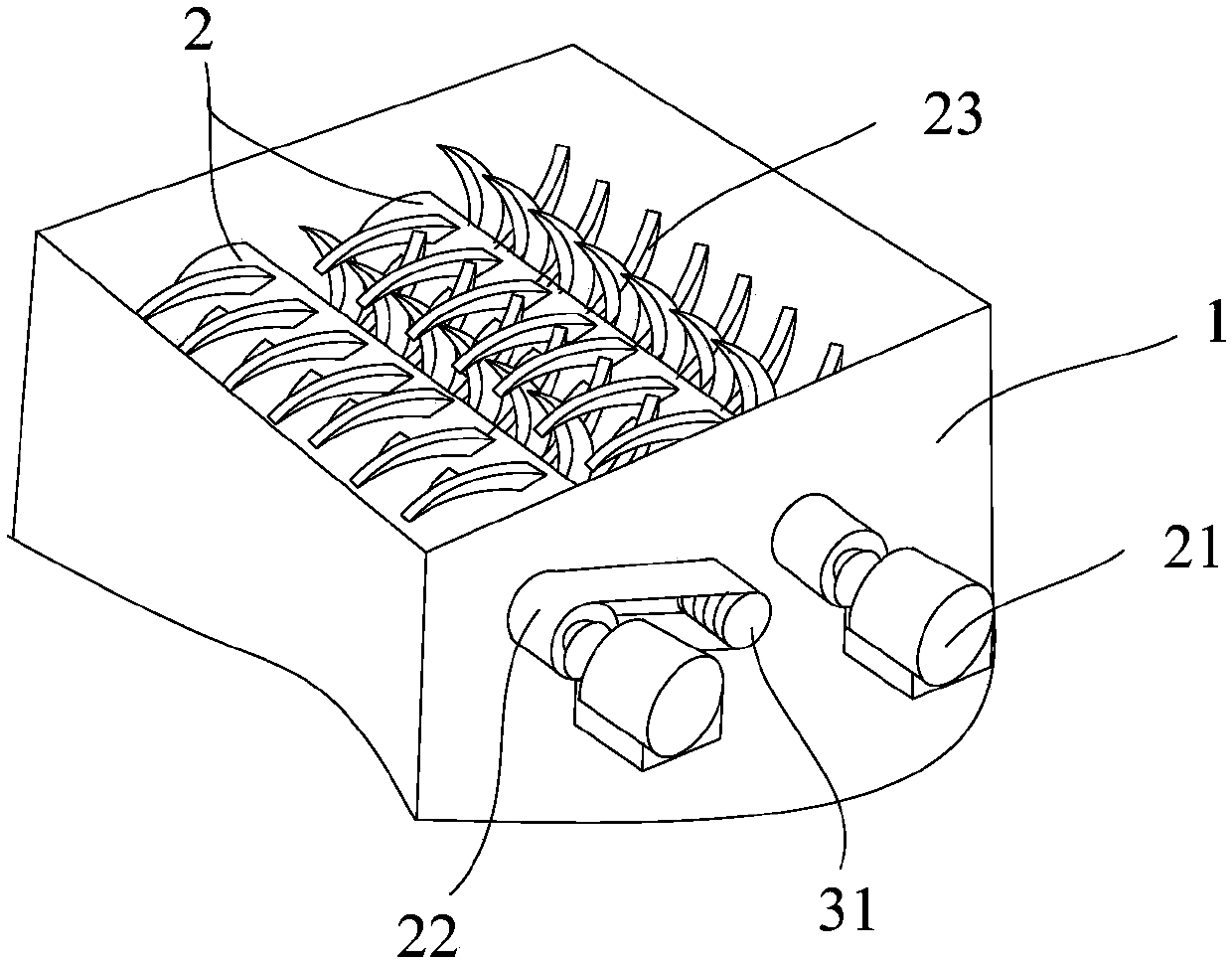

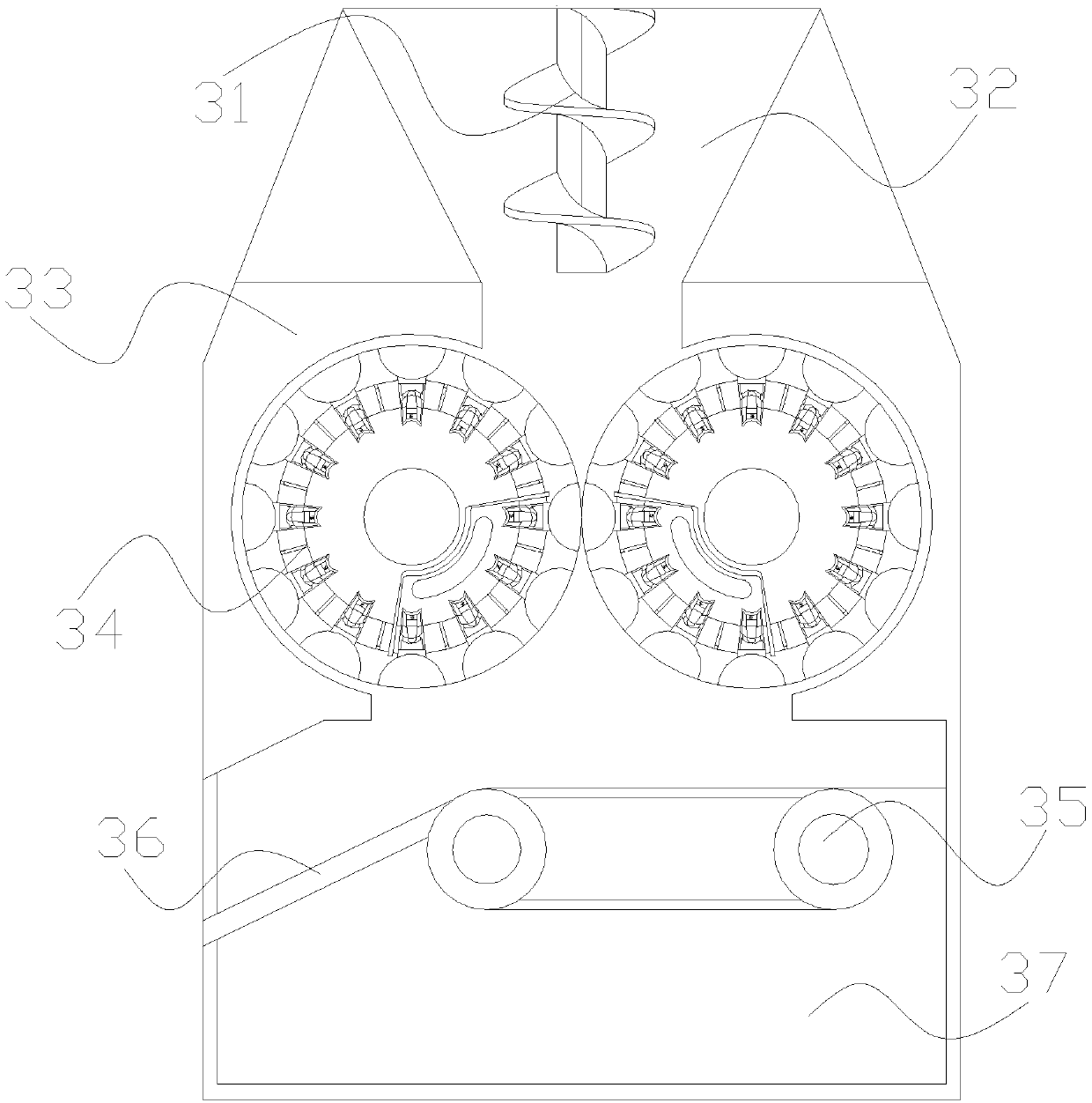

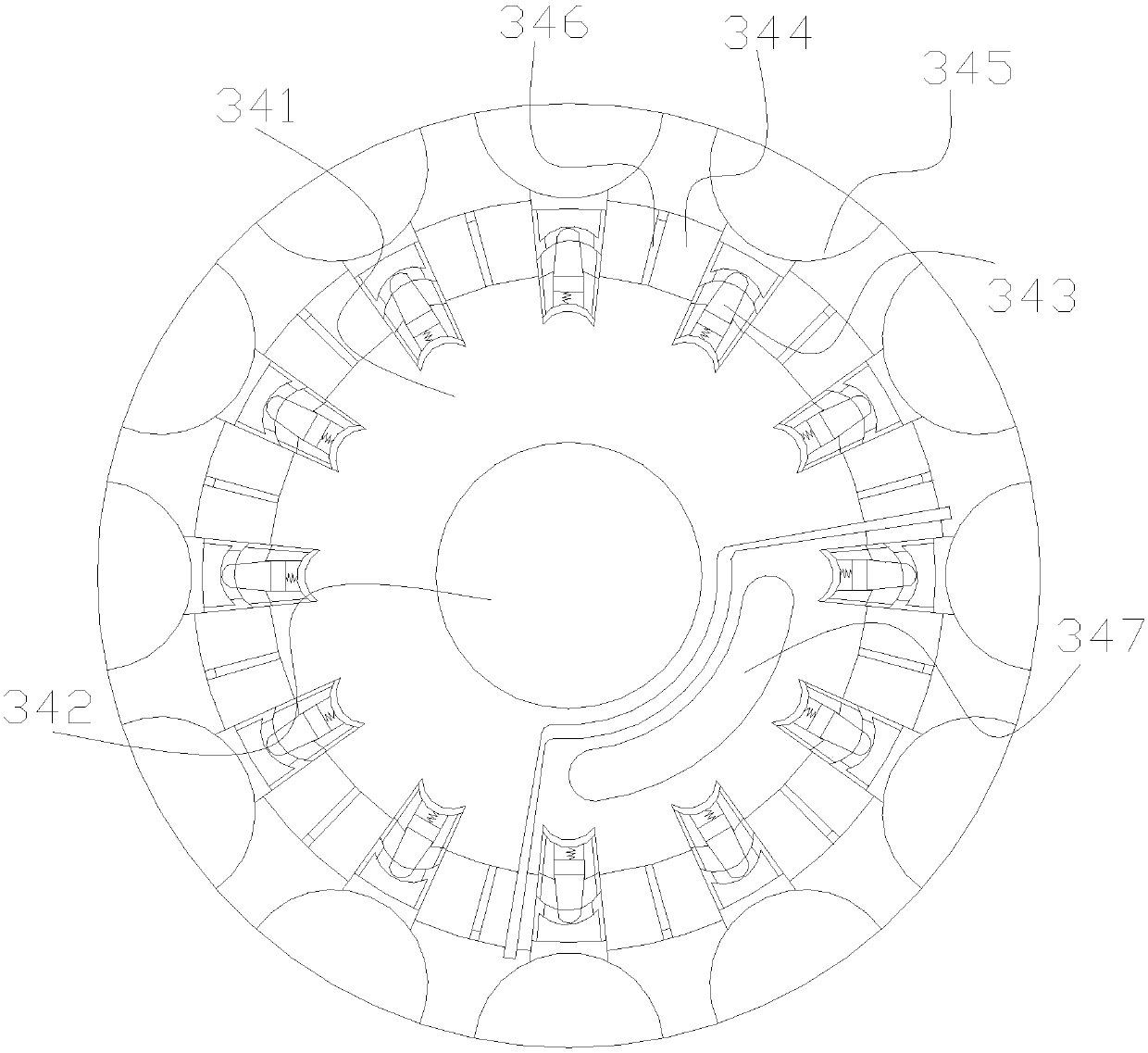

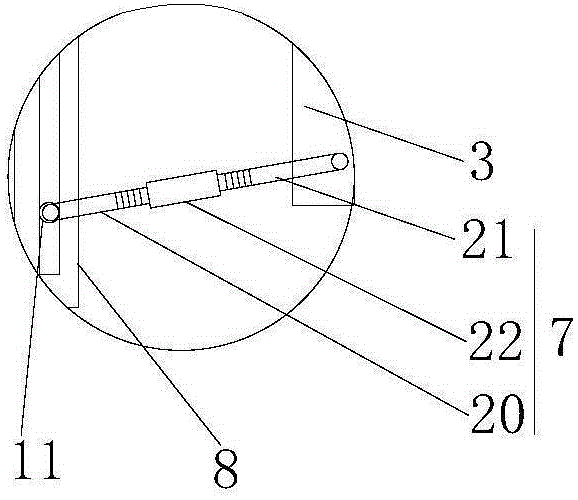

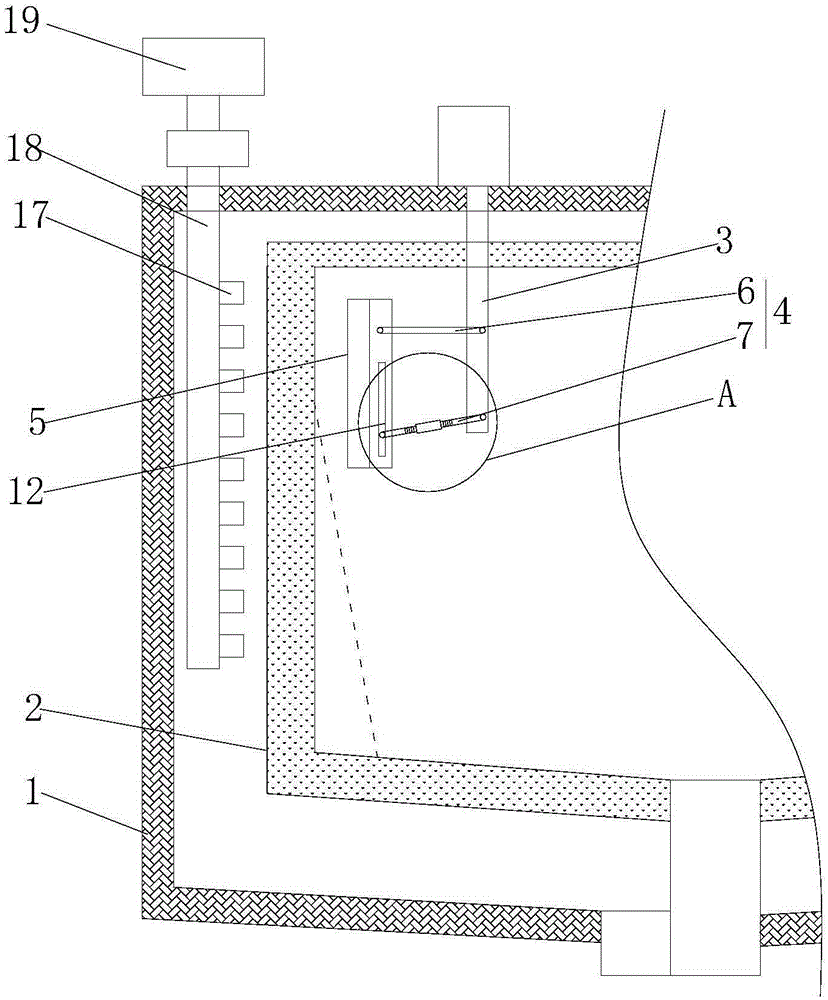

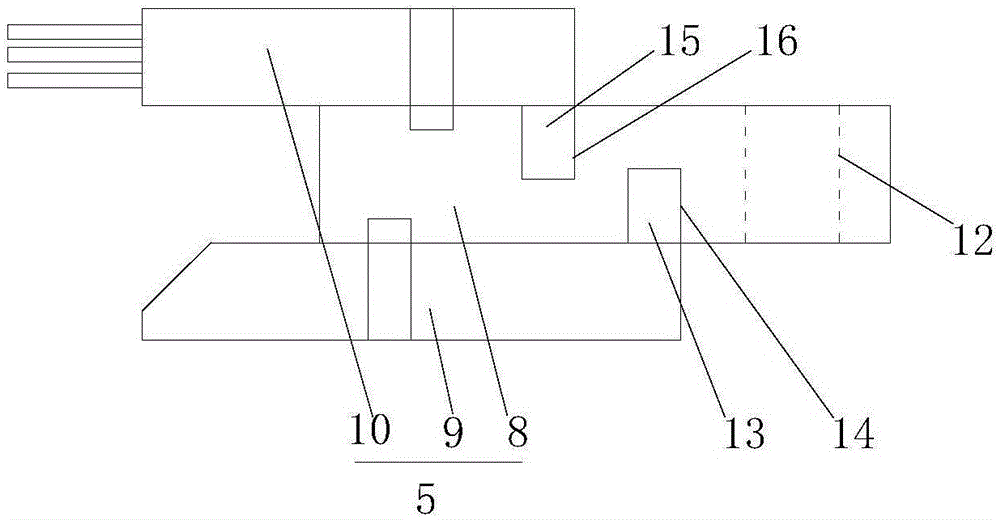

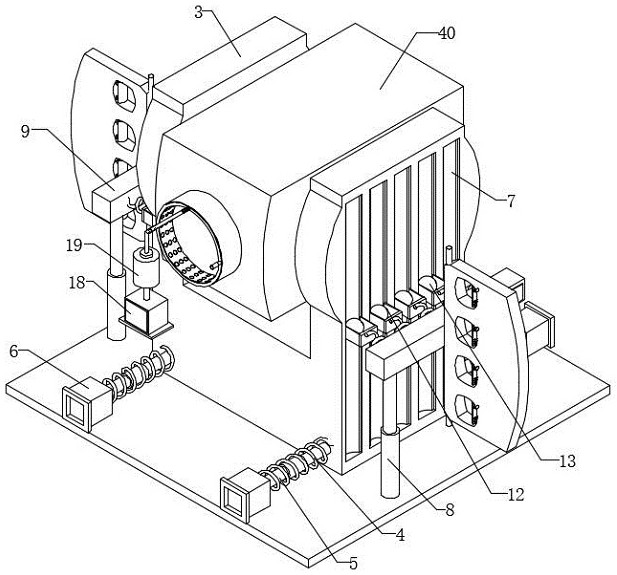

Multi-tangential-flow combined rape threshing, separation and stalk crushing integral device

The invention relates to a multi-tangential-flow combined rape threshing, separation and stalk crushing integral device. The device comprises a feeding and preliminary threshing device, a main threshing device, a re-threshing device, a stalk crushing device, a clamping belt loss monitoring device and a notch board clearance adjusting device. The device is applicable to graded threshing of rape which is inconsistently matured, the threshing and separation efficiency is high, the loss is small, and notch board clearance can be adjusted in real time through a feedback system of the clamping belt loss monitoring device. The multi-tangential-flow combined rape threshing, separation and stalk crushing integral device has the advantages that not only can the agricultural mechanical and intelligent level in China be improved, but also the rape harvesting quality can be improved and the market space is wide.

Owner:JIANGSU UNIV

Method and equipment for extracting fiber from stalks

The invention is a method and device for extracting stalk fiber, characterized by comprising the steps of: (1) stock preparationú(2) cuttingú(3) cookingú(4) dehydratingú(5) extracting fiberú and (6) filtering, and the device comprises a stalk fiber extractor and a filter, where the stalk fiber extractor comprises a steel wire wheel whose peripheral surface is bestrewed with projecting points; and the filter comprises a screen wheel whose outer surface is of a steel wire sieve bestrewed with sieve pores and which is below the steel wire wheel, and one axial end of the screen wheel is connected with an exhaust fan. And the device can be driven by tractor through drive mechanism to directly extract and outputting the fiber. And the invention can synthetically utilize stalks, reducing wood consumption and beneficial to environmental improvement and applied to town and country.

Owner:徐丕义

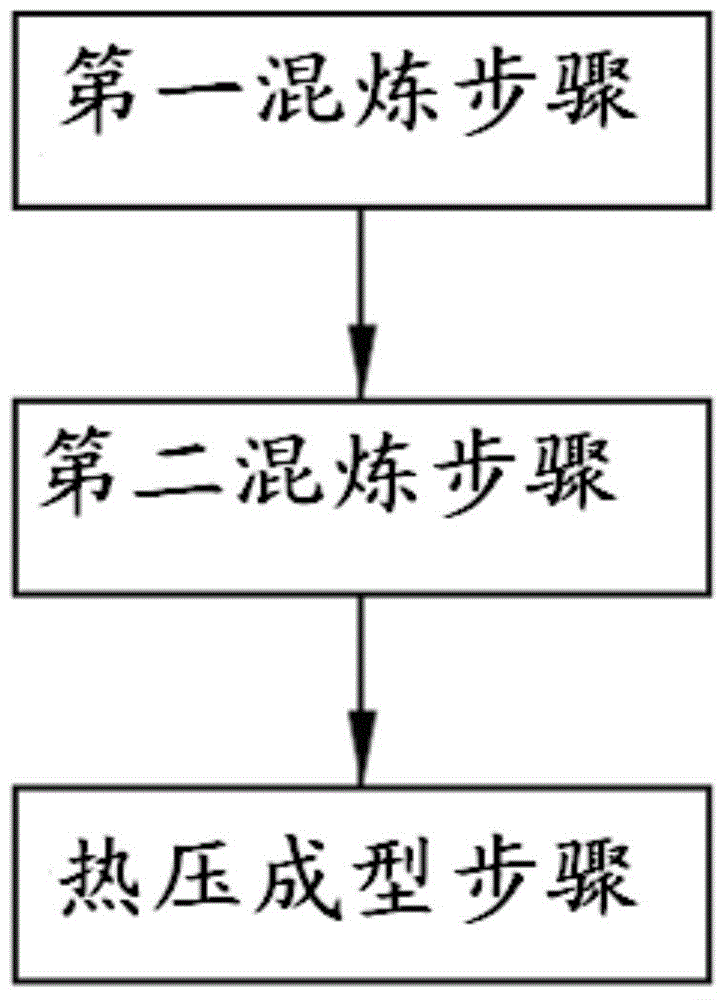

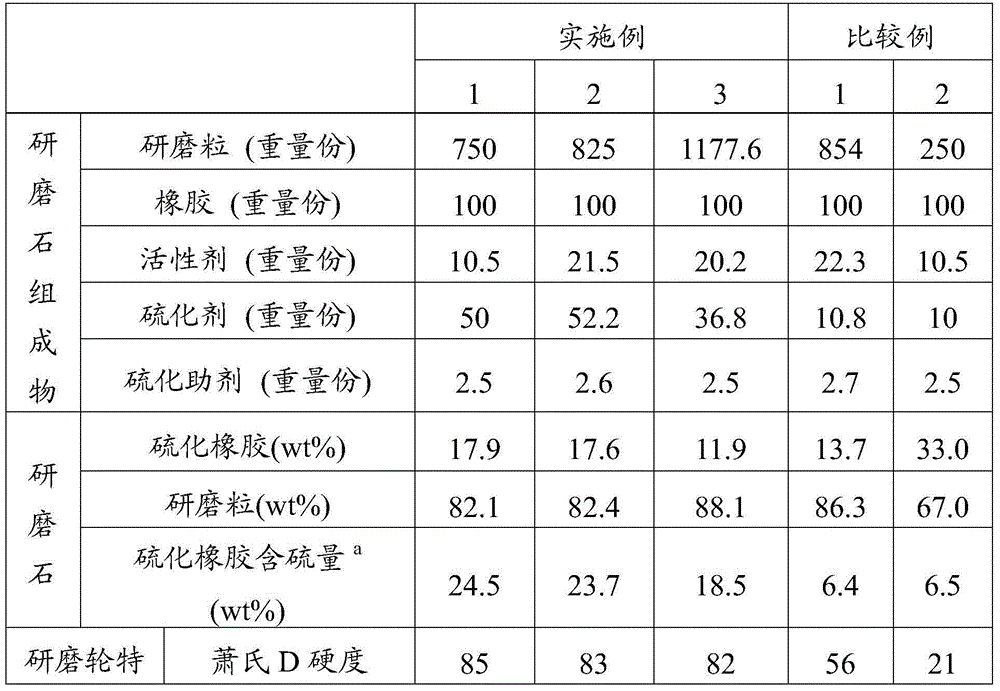

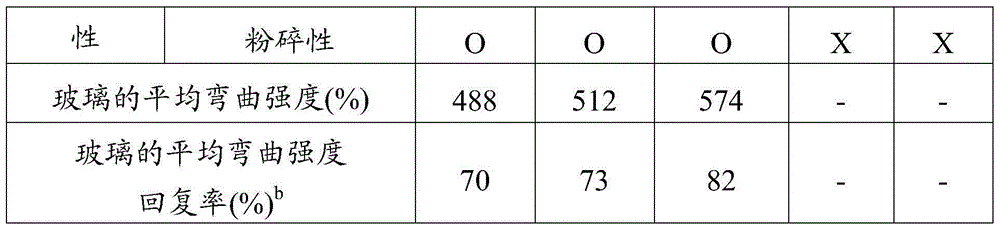

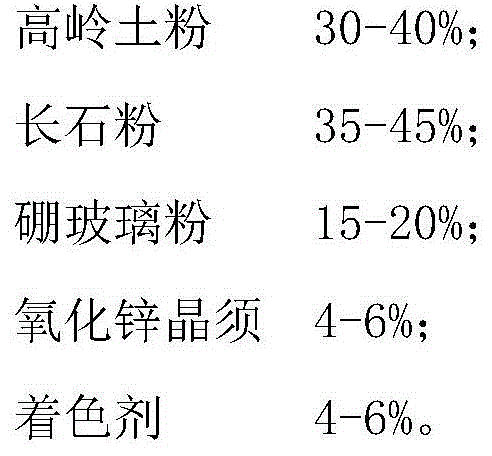

Grinding stone, grinding member including the same, and manufacturing method of grinding member

InactiveCN103909476AShedding evenlyProper bindingAbrasion apparatusGrinding devicesStone compositionFlexural strength

The invention provides a piece of grinding stone, a grinding member including the grinding stone, and a manufacturing method of the grinding member. The grinding stone is formed by a grinding stone composition through mixing and hot compression and includes perduren and a plurality of grinding particles dispersed around the perduren, the sulphur content of the perduren in the range of 10-30 wt%. The manufacturing method of the grinding member includes a first mixing step, a second mixing step, and a hot compression forming step. The manufacturing method, by means of controlling the sulfuration crosslinking of the perduren, enables the grinding particles of the grinding stone to be properly come off, when the formed grinding member grinds an article to be grinded which is less in bending strength caused by cutting, and therefore, the polishing strengthening of the article to be grinded is facilitated and the bending strength of the article to be grinded can be recovered.

Owner:DAXIN MATERIALS

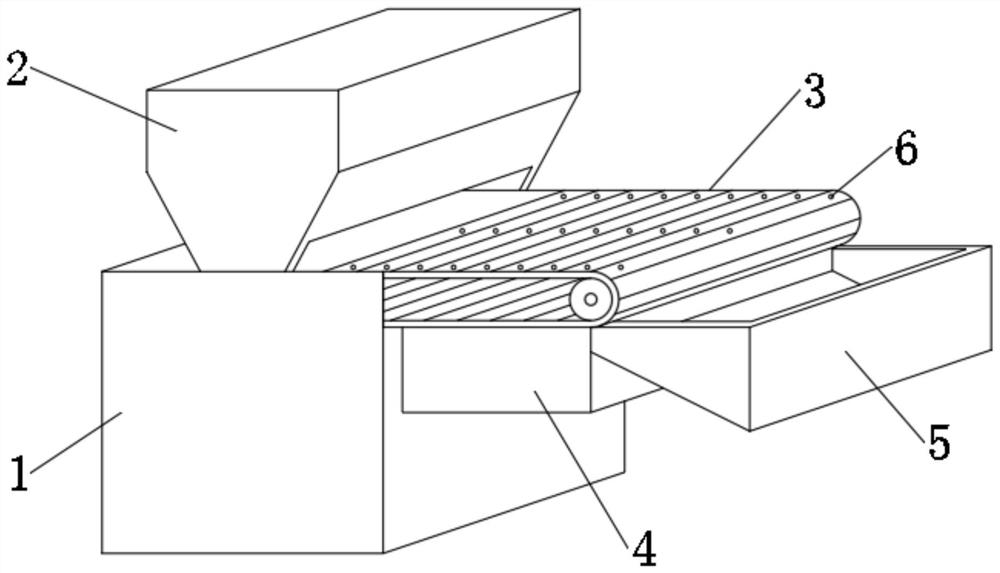

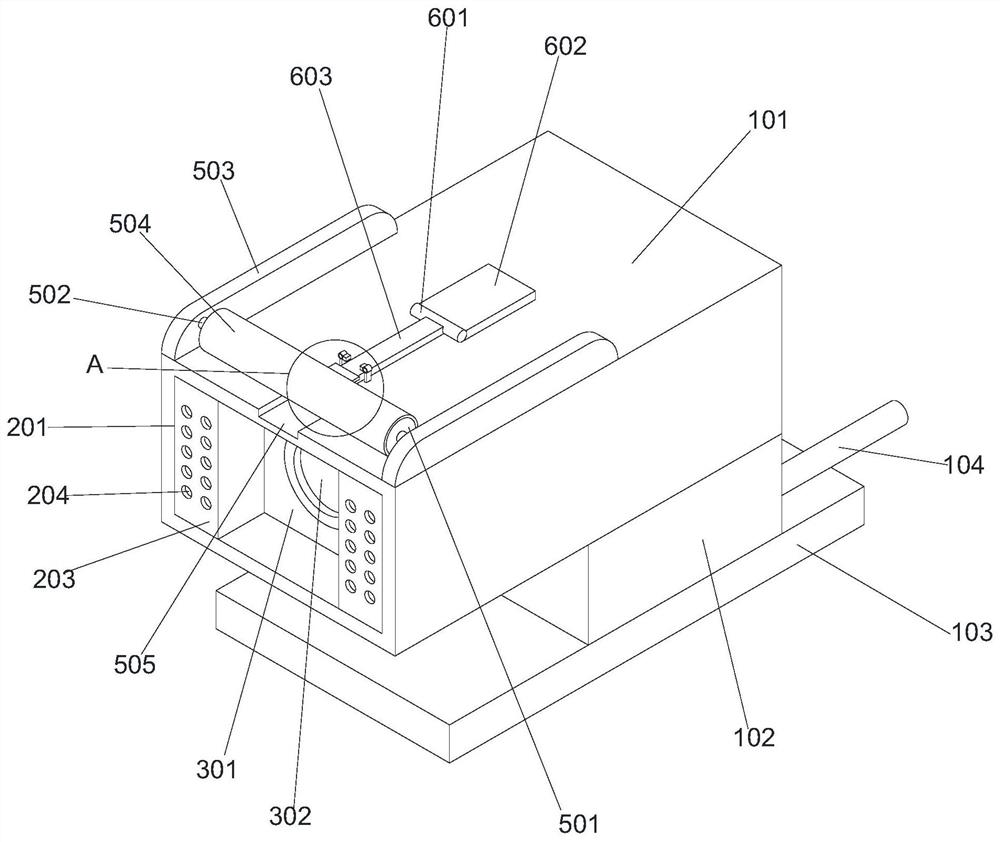

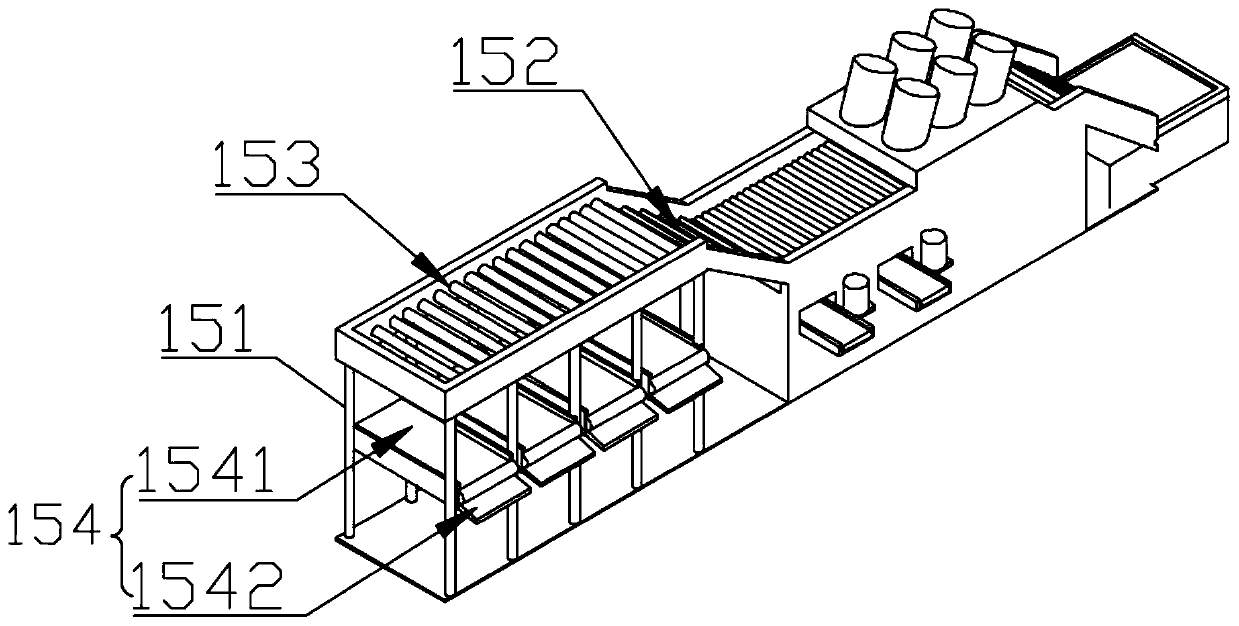

Automatic printing and conveying device for tempered glass

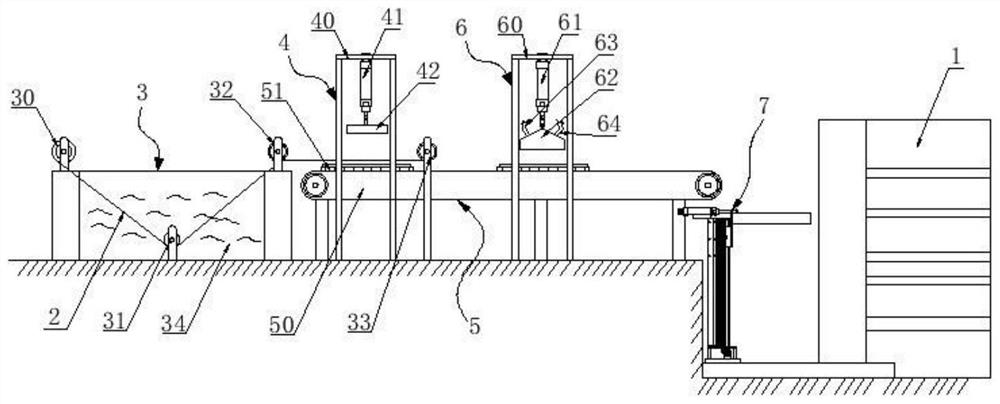

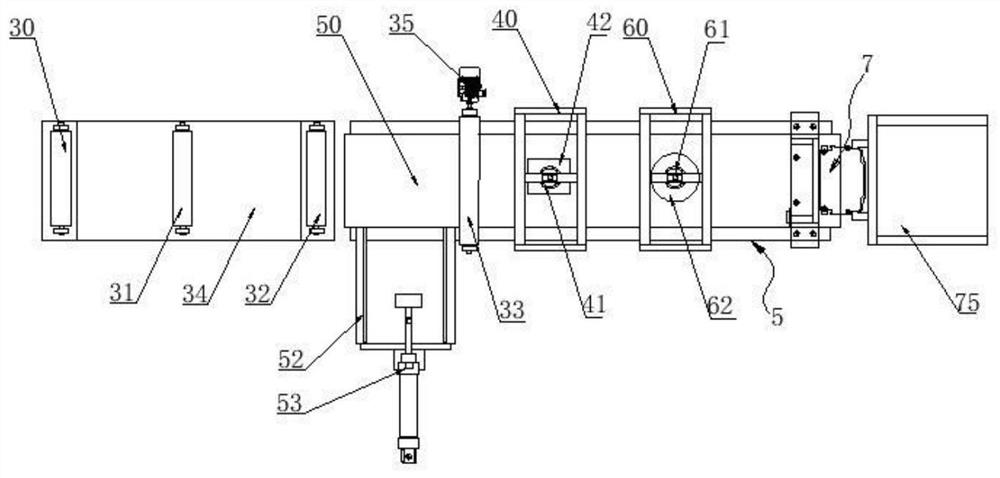

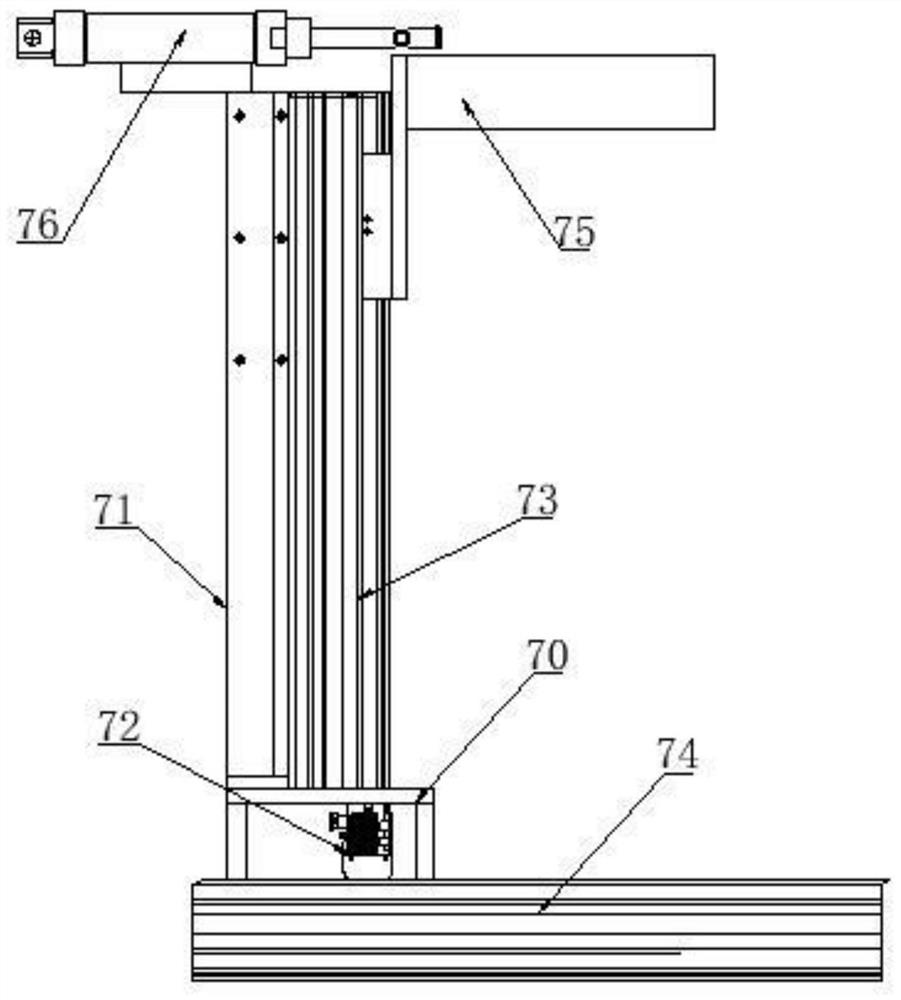

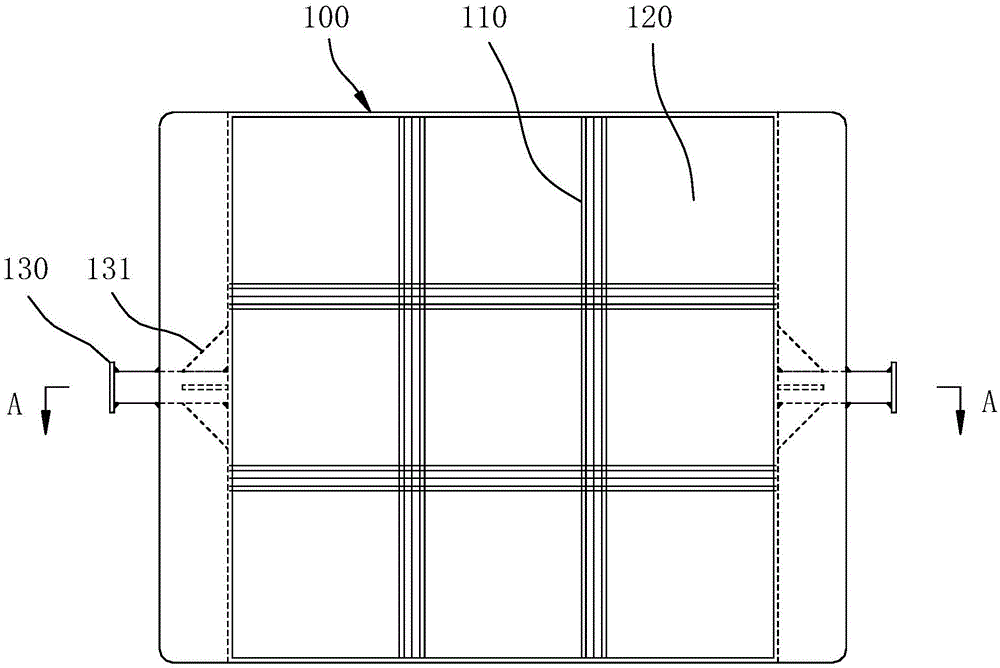

ActiveCN112278860AShedding evenlyImprove alignment accuracyTransfer printingCharge manipulationTextile printerProduction line

The invention relates to the field of glass printing, and particularly relates to an automatic printing and conveying device for tempered glass. The automatic printing and conveying device comprises adecorating furnace, a printing paper roll, a soaking and pattern removing mechanism, a pattern pasting mechanism, a horizontal conveying mechanism and a pasting and printing mechanism, wherein the soaking and pattern removing mechanism is arranged at the upstream end of the horizontal conveying mechanism and used for soaking pattern pasting paper; the pattern pasting mechanism is located over thehorizontal conveying mechanism and used for enabling the pattern pasting paper to be pasted to the pattern pasting position of a glass sheet; the pasting and printing mechanism is located over the horizontal conveying mechanism, located at the downstream end of the pattern pasting mechanism and used for enabling pattern sheets in the pattern pasting paper to be disengaged and fall onto the glasssheet; and the downstream end of the horizontal conveying mechanism is right opposite to the inlet end of the decorating furnace, and the horizontal conveying mechanism of the automatic printing and conveying device is used for conveying the glass sheet. According to the device, the pattern pasting process and the baking process are connected through an automatic production line, manual usage is reduced, the pattern pasting production efficiency and the pattern pasting precision are improved, the damage degree caused by manual glass conveying is avoided, and the glass printing product percentof pass is increased.

Owner:湖南天秀科技有限公司

Mold release agent and preparation method thereof

ActiveCN107570660AGood release performanceExtended service lifeFoundry mouldsFoundry coresCast ironCoal slurry

The invention relates to the technical field of ironmaking agents, in particular to a mold release agent. The mold release agent is prepared by mixing and stirring a dry material and water, the dry material comprises, by weight, 0.5-1.5% of carboxymethylcellulose, 10.0-15% of sodium bentonite, 50-60% of low carbon coal slurry, 15-20% of aluminum-magnesium refractory mortar, 10-15% of coal powder and the balance water, wherein the weight of the water is 9-11 times of the total weight of the dry material. The preparation method comprises the steps that when being poured, the mold release agent forms a sintered layer of 1-2 mm under the high temperature of molten iron, an isolation layer can be effectively formed between the molten iron and a cast iron mold, a cast iron block can smoothly fall off from the cast iron mold, the mold release performance of the mold release agent is good, the mold release rate is up to 100%, the cast iron mold can be protected and is not easily deformed, theservice life of the cast iron mold can be remarkably prolonged, the low carbon coal slurry is generally thrown away as waste, the low carbon coal slurry is used as the main component of the mold release agent, and waste using is achieved, so that the cost of the release agent is low, and popularization is facilitated.

Owner:PANGANG GROUP TITANIUM INDAL

Milltailing collecting and transportation device and core shooter milltailing recovery method

InactiveCN106270416AImprove sticking situationReduce labor intensityMoulding machine componentsMould handling/dressing devicesRecovery methodEngineering

The invention discloses a milltailing collecting and transportation device and a core shooter milltailing recovery method, and aims at solving the problem that milltailings transported by a trolley cannot be directly used for sand regeneration treatment in a used sand regeneration system after the curing. The milltailing collecting and transportation device comprises a milltailing collecting box, wherein each of the top and the bottom of the milltailing collecting box is provided with an opening; at least one separation plate with the V-shaped cross section is arranged in the milltailing collecting box; the inner cavity of the milltailing collecting box is separated into at least two sand storage spaces by the separation plate. According to the core shooter milltailing recovery method, a forklift, a travelling crane, the milltailing collecting and transportation device, a sand falling shaking belt and the sand regeneration system are used for recovering core shooter milltailings. The sand storage space is formed through the separation of the separation plate; the milltailings are enabled to be in a certain size range after the curing; the milltailings can be directly conveyed to a roasting furnace to complete the sand regeneration process; the link of sand breaking through manual knocking is avoided; the work intensity of workers is greatly reduced; the milltailing recovery and treatment efficiency is high.

Owner:重庆机电控股集团铸造有限公司 +1

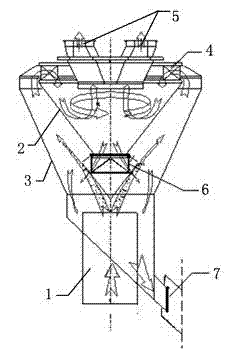

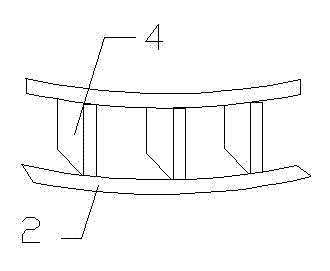

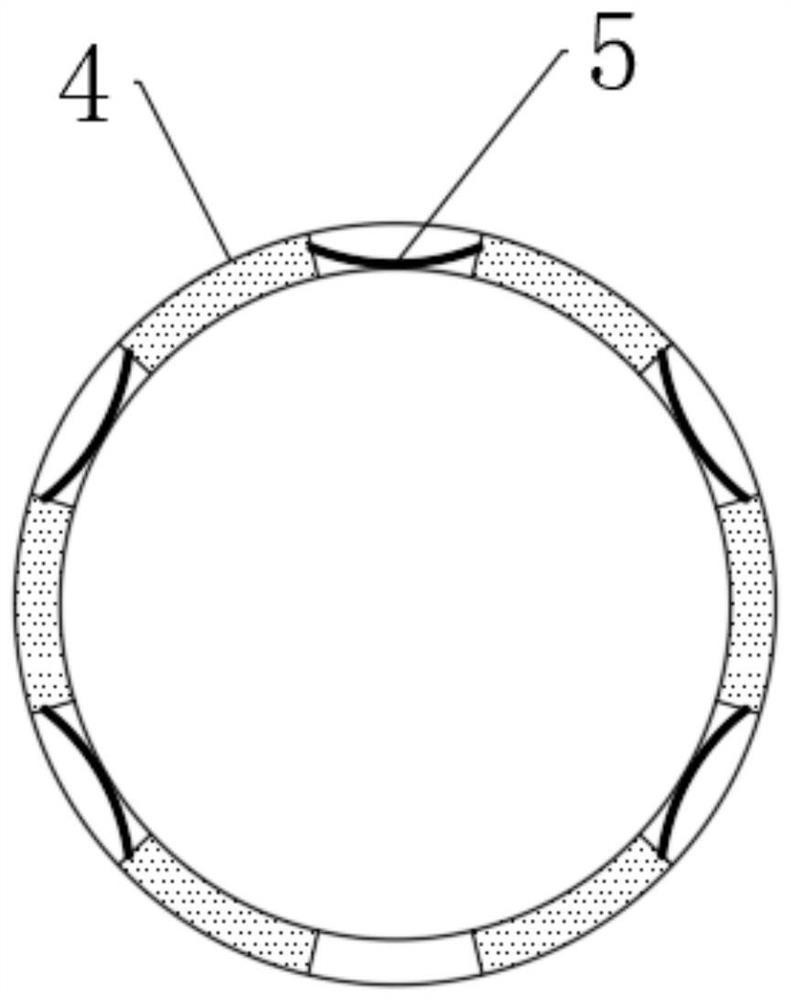

Anti-blocking device for double-in and double-out ball type coal pulverizer separator

The invention discloses an anti-blocking device for a double-in and double-out ball type coal pulverizer separator. The anti-blocking device for the double-in and double-out ball type coal pulverizer separator comprises an outer conical barrel, an inner conical barrel and separator inlet radial baffles which are arranged on the inner conical barrel, wherein the end side surfaces of the separator inlet radial baffles and the outer edge of the upper end face of the inner conical barrel are positioned at the same height. According to the device, the end side surfaces of the separator inlet radial baffles and the outer edge of the upper end face of the inner conical barrel are positioned at the same height, so that the upper end face of the inner conical barrel is effectively prevented from supporting impurities which are attached to the separator inlet radial baffles, and the impurities can smoothly fall off under the action of gravity and airflow; and furthermore, a plurality of axial separation baffles are also uniformly arranged between the walls of the outer conical barrel and the inner conical barrel for preliminarily separating the rising pulverized coal air flow, the number of the separator inlet radial baffles are reduced, the distances between the separator inlet radial baffles are increased, the lengths of the separator inlet radial baffle are increased, furthermore, the double-out ball type coal pulverizer separator is prevented from being blocked, and the pulverized coal fineness and uniformity are ensured.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Limestone crushing device

The invention discloses a limestone crushing device in the mining mechanical field. The limestone crushing device comprises a shell, a crushing roller and a negative-pressure fan; a feed port is formed above the shell, and a dust removing port is formed below the shell; the crushing roller is arranged in the shell, and is positioned rightly below the feed port; the negative-pressure fan is mountedin the dust removing port; screening mechanisms are arranged on two sides and the lower side of the crushing roller; the screening mechanisms comprise screening nets made of steel foils and with elasticity; a rotating roller, fixedly connected through a fixed frame, is arranged in the shell; the screening nets are in transmission connection to the outer surface of the rotating roller; the screening nets and the rotating roller form a U-shaped conveying channel; a cleaning column matched with meshes of the screening nets is arranged on the surface of the rotating roller; multiple screening nets are connected to the rotating roller side by side; and cutters are arranged between the adjacent screening nets, and are fixed on the surface of the rotating roller. The problem of worse dust accumulation of limestone remained in the crushing device can be effectively prevented; and the crushing device can normally work.

Owner:遵义汇恒环保科技有限公司

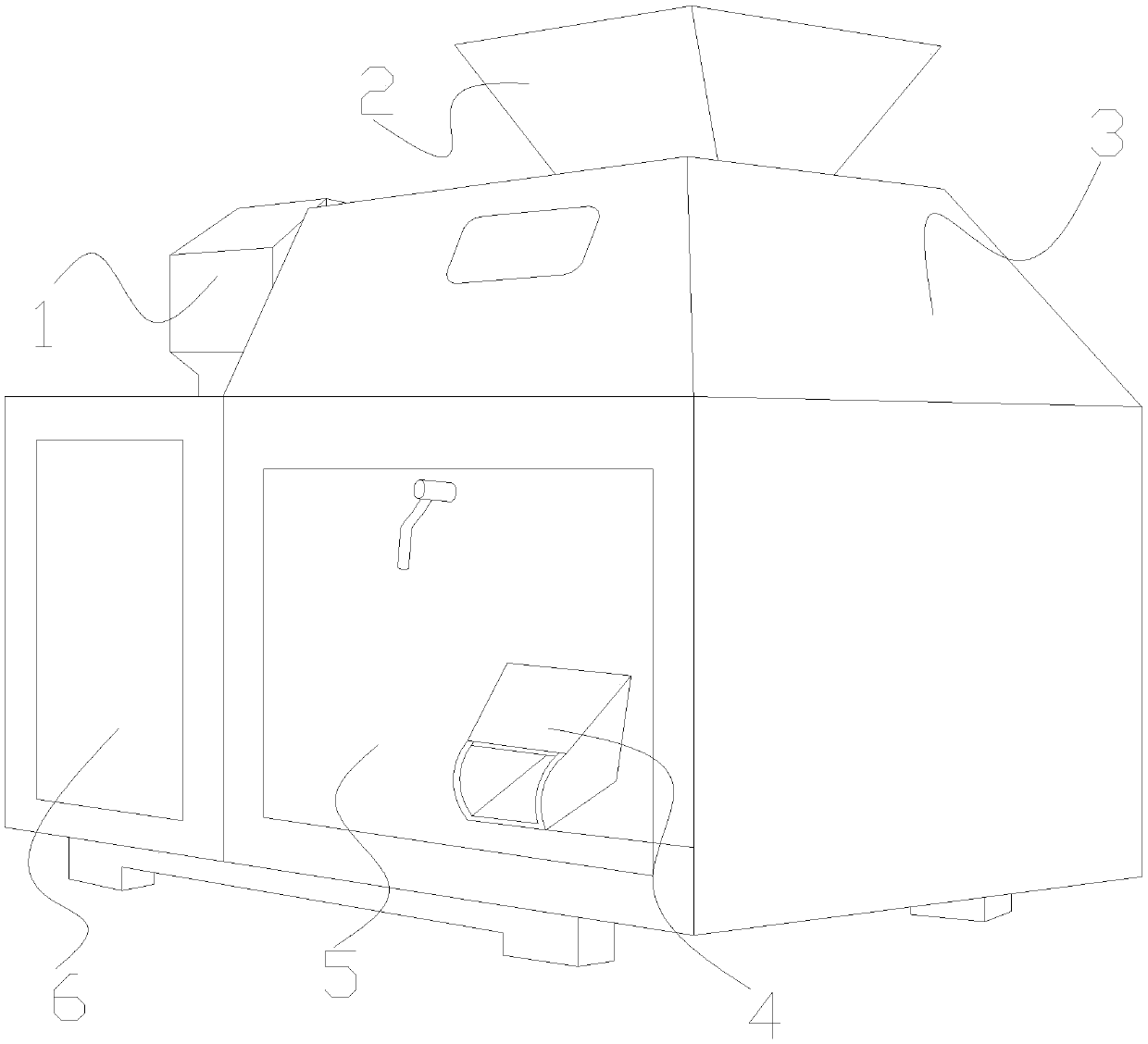

Plant nutrient granulator using piston gas jet to prevent wall-sticking

InactiveCN109647281AReduce gapShedding evenlyGranulation in stationary drums/troughsProduct gasEngineering

The invention discloses a plant nutrient granulator using a piston gas jet to prevent wall-sticking. The structure includes a driving device, a charging hopper, an wall-sticking preventing granulationdevice, a discharging port, a maintenance door, and a control cabinet. The driving device is mounted on the control cabinet and is connected to the control cabinet by bonding. The charging hopper isconnected to the wall-sticking preventing granulation device by welding. According to the invention, a gas guiding chamber and a gas pressure guiding chamber which are separated by a separating platefor preventing pressure release communicate with each other through the rotation of a main wheel. Meanwhile, a heat conduction layer and a pressing element heat and pressurize gas inside the pressureguiding chamber. A clearance between a self-weight piston and a valve port slowly decreases due to the gravity action of the piston, and so the pressure speed of sprayed hot air gradually increases. Agranulation groove and the surface of nutrient balls are pre-heated to reduce the moisture and viscosity, the thrust of the sprayed gas is used to smoothly separate the nutrient balls from the granulation groove, and then the sprayed hot gas dries the surface of the dropped nutrient balls to prevent the nutrient balls from sticking to each other.

Owner:简胜坚 +2

Special sand mold coating material produced from alumina powder as main raw material

The invention relates to a special sand mold coating material produced from alumina powder as a main raw material. The technical scheme is as follows: the special sand mold coating material comprisesthe following raw materials by weight: 5.3kg to 6.7kg of water, 10.75kg to 14.75kg of alumina powder, 6g to 10g of xanthan gum and 38g to 42g of polyethylene. According to the special sand mold coating material, the production cost of an electrically-fused brick sand mold coating material is greatly reduced, and the coating material cost of electrically-fused bricks per ton can be saved by about 200 RMB; the alumina powder has refractoriness capable of reaching 2,010 DEG C to 2,050 DEG C, and thus, the requirements of high-temperature resistant coating materials of electrically-fused brick sand molds on high-temperature resistance can be met; the market price of the alumina powder per ton is 3,200 RMB, and the use cost of the coating material can be greatly reduced as the electrically-fused brick sand mold coating material; and by using the alumina powder as the sand mold coating material, the fitness is higher, a layer of crust is formed after the coating material is sintered, thus, gas generated from resin combustion is prevented from polluting brick faces, crusts formed by the coating material at high temperatures will successfully and naturally fall off during brick discharging, the brick faces are more convenient in cleaning, and the efficiency of cleaning of the brick faces is increased.

Owner:郑州远东耐火材料有限公司

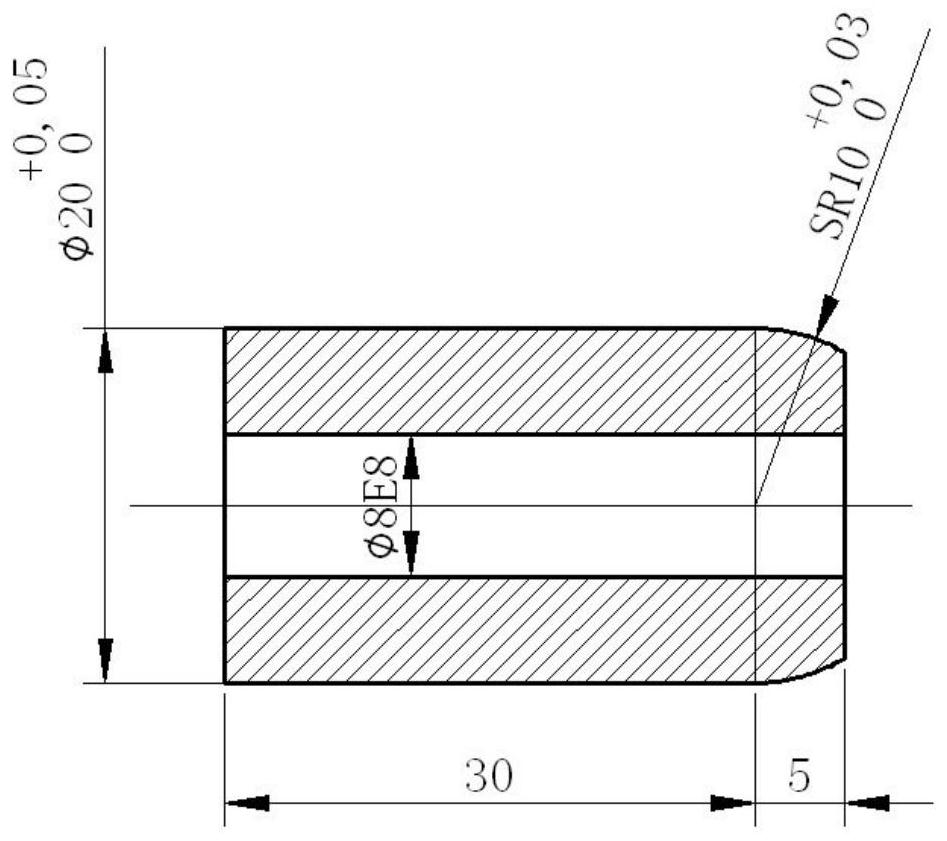

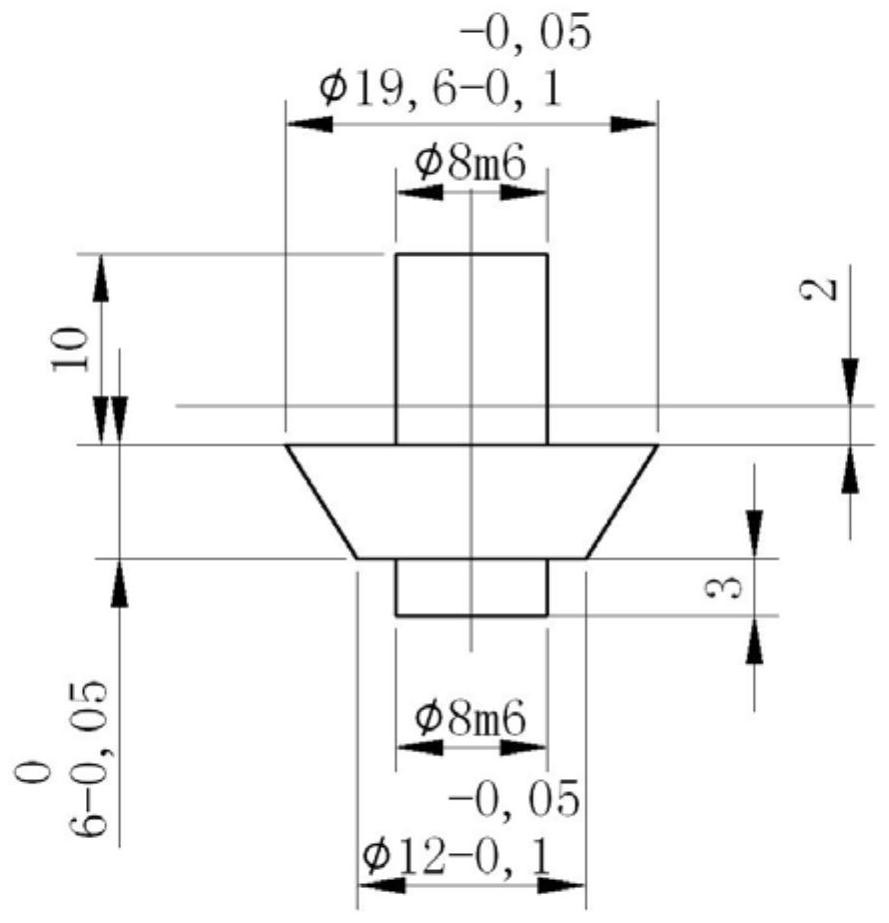

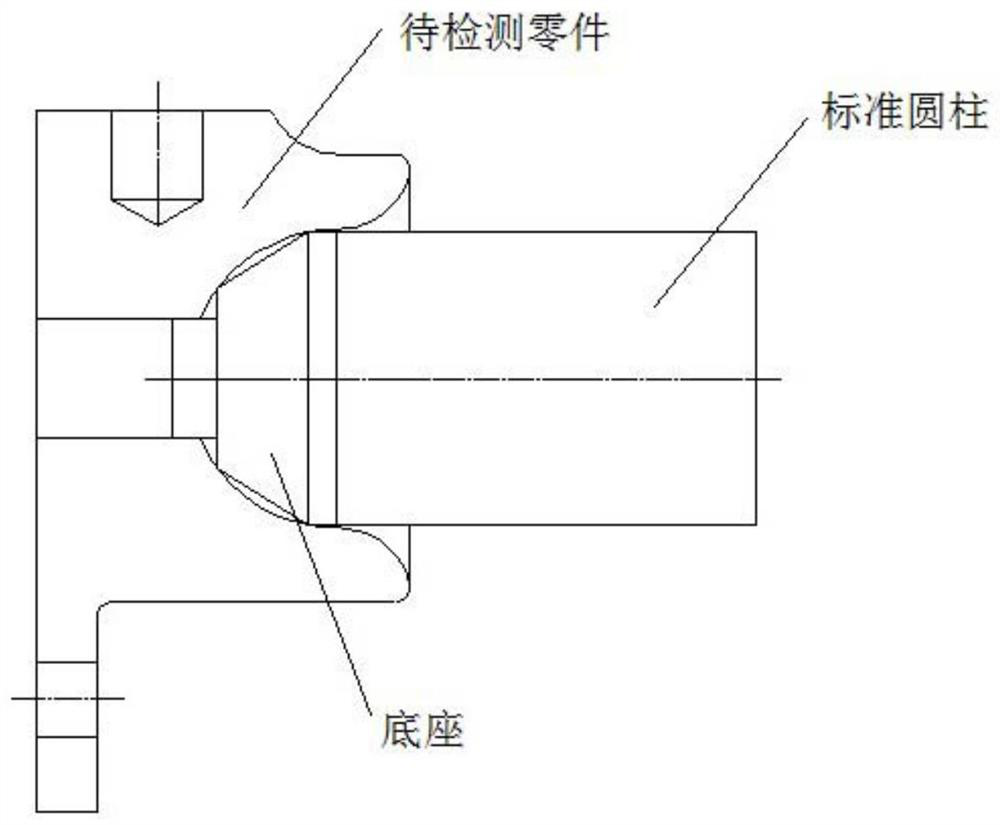

Spherical surface detection method of ball socket part

PendingCN112683220AImplement dimension verificationShedding evenlyMeasurement devicesLower borderEngineering

The invention discloses a spherical surface detection tool of a ball socket part, and the spherical surface detection tool comprises a standard cylinder and a base, the base comprises a positioning pin shaft, a circular truncated cone and a guide column which are coaxial from bottom to top, a through hole is formed in the center of the standard cylinder, the center hole is matched with the guide column, and the diameter of the upper end face of the circular truncated cone is matched with the diameter of a lower boundary section circle of a detection area. The height of the circular truncated cone and the diameter of the lower end face meet the standard that the base does not interfere with the spherical surface when placed into the ball socket. The size verification of the transition area between the ball socket spherical surface and an R5 rounded corner is realized, the out-of-tolerance phenomenon of the area is avoided, and the smooth falling of a booster ball head is further ensured.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

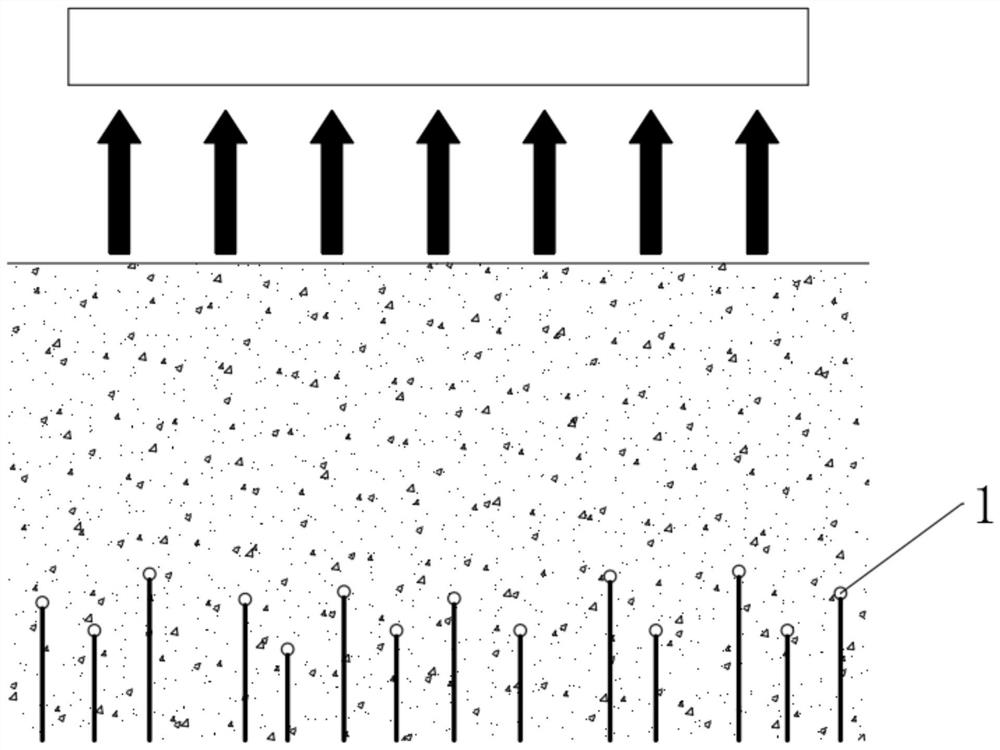

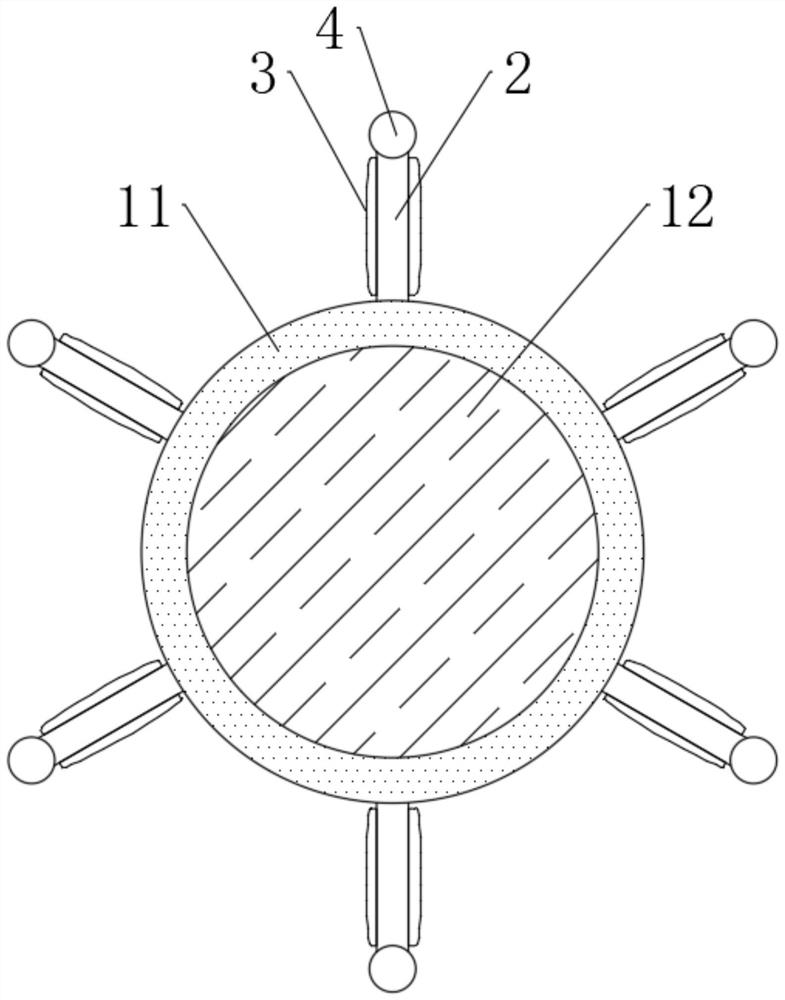

Gap forming type hardened soil treatment method

InactiveCN112385349ANot easy to accidentally fall offImprove the porosity effectSoil-working methodsEdaphicMagnetic field effect

The invention discloses a gap forming type hardened soil treatment method, and belongs to the technical field of soil remediation. Hardened soil is pre-softened, gap forming main balls are thrown intothe deep part of the soil in a ploughing manner, a magnetic field effect is applied above the soil to force the gap forming main balls to migrate to the surface from the deep part of the soil, a macroscopic gap forming phenomenon is formed, in addition, in the process of migrating the gap forming main balls to the soil surface, due to the structural characteristics, the gap forming main balls canbe partially inserted when encountering hardened soil blocks, gas is forced to expand through extrusion action to trigger release of gas making microspheres, and the gas making microspheres are dissolved and react to release a large amount of gas after making contact with residual moisture in the soil; and the soil blocks are loosened and disintegrated by using sharply increased gas in the soil blocks to form a microscopic gap forming effect, and meanwhile, the dissolved and residual gas making microspheres also migrate upwards under the action of a magnetic field to assist in improving the gap forming effect, so that the loosening and gap forming effect on the hardened soil can be greatly improved in a short time.

Owner:李变利

Discharge device adjustable centrifugal machine

The invention provides a discharge device adjustable centrifugal machine which comprises a chassis, a rotating drum, an inner discharge device and an outer discharge device, wherein the rotating drum is rotationally mounted in the chassis and is driven to rotate by a first driving device; the inner discharge device comprises a second driving device, a driving rod, a connecting assembly and a cutter assembly; the driving rod stretches into the rotating drum from the upside; the second driving device drives the driving rod to move up and down; the outer discharge device comprises a vent pipe stretching into a part between the chassis and the rotating drum; a plurality of nozzles are formed on the vent pipe; the vent pipe is communicated with a blower; the nozzles face towards the rotating drum; the cutter assembly comprises a cutter rest, a cutter and a hair brush; and the cutter and the hair brush are respectively arranged on the two sides of the cutter rest. The discharge device adjustable centrifugal machine discharges more easily and cleanly, and the service life is increased.

Owner:湖南捷瑞化工有限公司

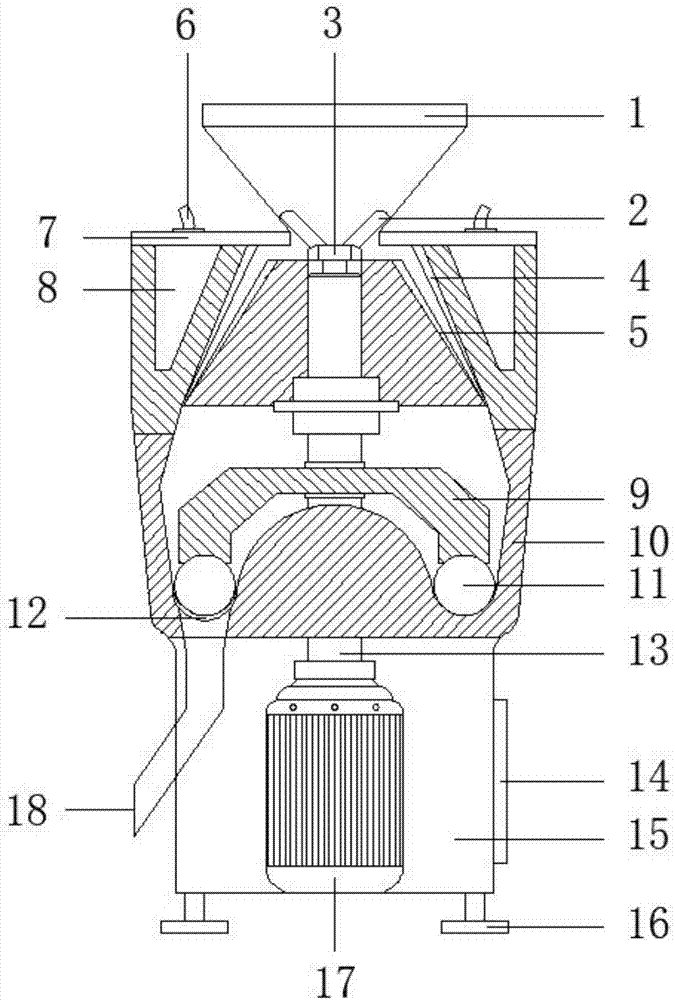

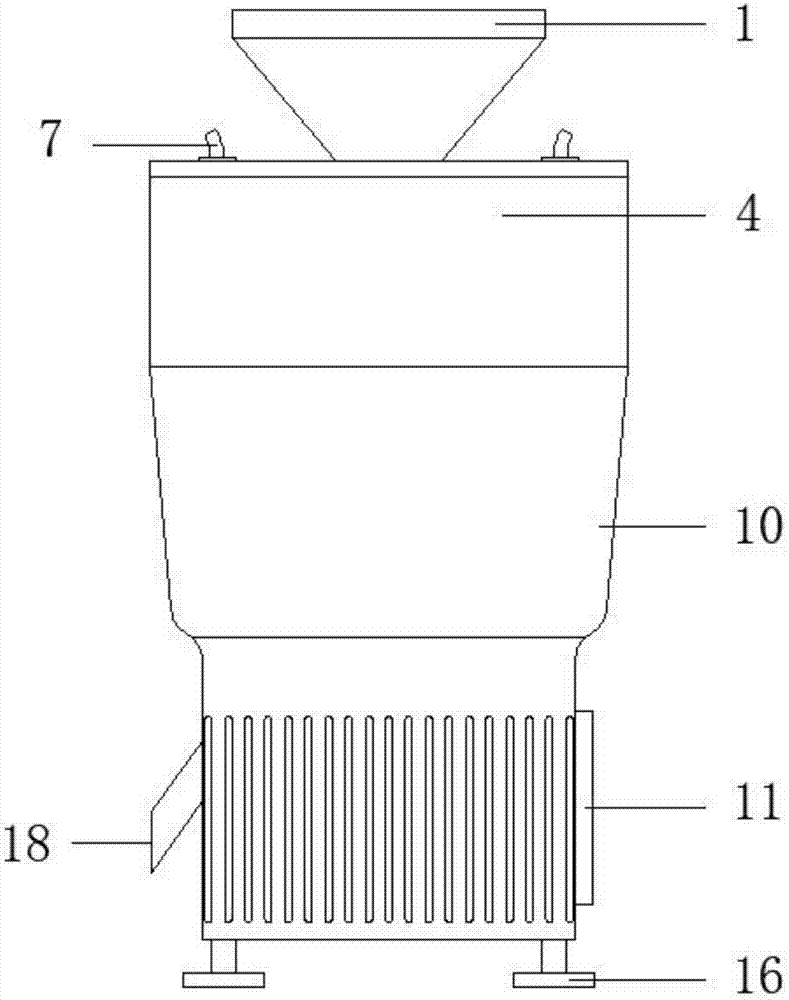

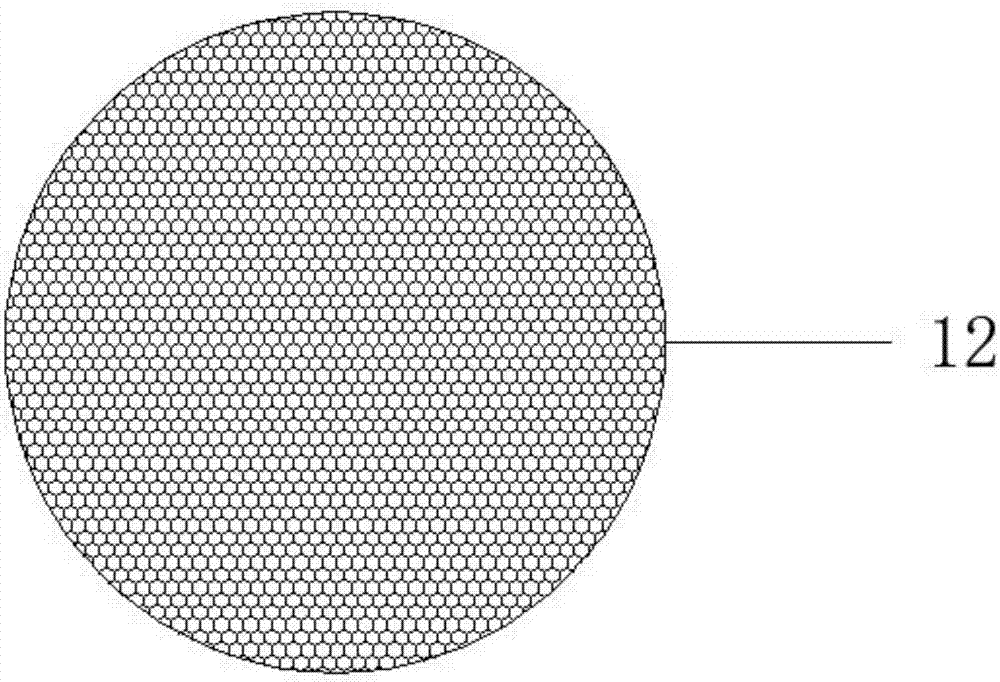

Particle mechanical grinding device of metallic paint

The invention relates to the technical field of paint production equipment, in particular to a particle mechanical grinding device of metallic paint. The particle mechanical grinding device comprisesa hopper, a vane blade and a tool apron. The hopper is arranged on the upper portion of a top cover, and the hopper and the top cover are connected in an embedded manner. A static grinding disc is located on the lower portion of the top cover, and the static grinding disc and the top cover are connected through a fixed bolt. A cooling tank is arranged in the static grinding disc, and the cooling tank and the static grinding disc are connected in an inlaid manner. A cooling circulating pipe is arranged on the upper portion of the top cover in a penetrating manner, and the bottom of the coolingcirculating pipe is connected with the cooling tank. A dynamic grinding disc is located below the hopper, and the tool apron is arranged at the top of the dynamic grinding disc. Through the structuralimprovement, the particle mechanical grinding device has the advantages that integrated design is achieved, coarse grinding and fine grinding can be carried out at the same time, the structure is simple, the grinding process is simple and convenient, the grinding efficiency is high, and creativity is high; and therefore the problems and defects existing in existing devices are effectively solved.

Owner:惠州市广源钢结构工程有限公司

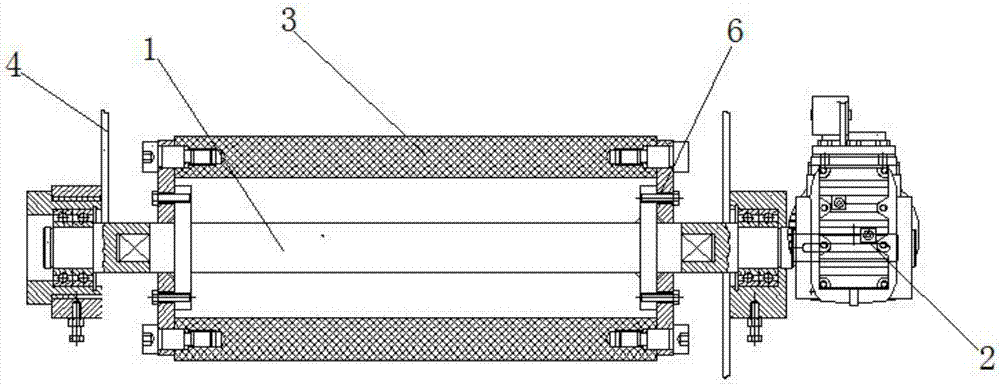

Corrugated roller grinding wheel and manufacturing method thereof

ActiveCN104889894AUniform hardnessUniform tissueAbrasion apparatusGrinding devicesGranularityGrinding wheel

The invention belongs to the field of grinding wheels and manufacturing method thereof and particularly relates to a corrugated roller grinding wheel and a manufacturing method thereof. The grinding wheel is characterized in that raw material component and weight percentage of grinding parts are that 68-80% of grinding materials with granularity of 36 [mu]m-120 [mu]m; 8-15% of ceramic bond; and 10-15% of pore-forming materials. The manufacturing method comprises following steps of 1) mixing materials; 2) forming; 3) drying; 4) kiln placing; 5) sintering; and 6) blank drying and size processing. The grinding wheel is advantageous in that the grinding wheel is high in rotation strength, rigidity, structure uniformity, static balance performance, heat radiation performance, grinding performance, grinding efficiency and grinding precision.

Owner:QINGDAO SISA ABRASIVES CO LTD

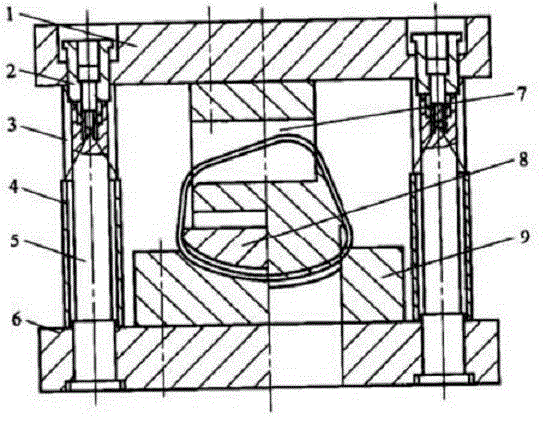

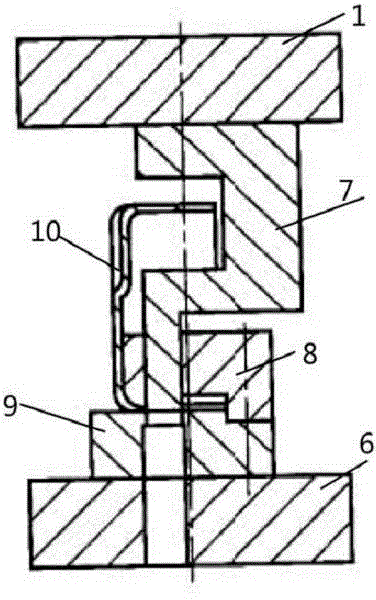

Floating side hole punch die

InactiveCN104550431AImprove distance accuracyShedding evenlyPerforating toolsStripping-off devicesStructural engineeringMechanical engineering

The invention belongs to a punch die and particularly relates to a floating side hole punch die. The floating side hole punch die comprises an upper die base, a lower die base, a first elastomer and a guide post, wherein the lower surface of the upper die base is connected with the first elastomer; the first elastomer is positioned in the guide post; the lower end of the guide post is arranged in the lower die base; a male die is fixed to the lower end of the upper die base; a workpiece groove is formed in the male die; the upper end of a workpiece is arranged in the workpiece groove; the workpiece can move up and down with an upper die and punch work is finished; the lower end of the workpiece is positioned in a gap between a female die and a discharging plate; the lower surface of the female die is arranged on the lower die base; the discharging plate is fixed to the upper surface of the female die, so that the machined position is convenient to position. The bottom of a shell part is relatively slightly punched, so that the machining efficiency is high, and the floating side hole punch die is safe and convenient to use.

Owner:重庆信奇建材机械制造有限公司

Fall-off portable holding rod

InactiveCN102322173AIncrease the bearing areaReduce labor intensityTowersEngineeringMechanical engineering

The invention discloses a fall-off portable holding rod, which is characterized by comprising a holding rod body consisting of two long rods, jackets arranged on the tops of the long rods, fall-off top sleeves sleeved outside the jackets, and a connecting ring which is connected with the top sleeves and used for a pulling rope to pass through, wherein a foot pad is arranged at the bottom of each long rod and connected with each long rod through a buckle ring. The fall-off portable holding rod has the advantages that: human resources are greatly saved, and time and waste in the transportation process and in the electric pole assembling process are reduced; safety, reliability and flexibility in the electric pole assembling process are enhanced; and the labor load of personnel is reduced, and actual work efficiency is improved.

Owner:国网江苏省电力有限公司南通市海门区供电分公司 +1

Automatic material collecting device for film cutting machine

PendingCN113213235AReduce frictional resistanceReduce wearMetal working apparatusArticle deliveryThin membraneEngineering

The invention discloses an automatic material collecting device for a film cutting machine, and belongs to the technical field of film cutting machines. The automatic material collecting device can automatically discharge materials through a transmission crawler belt, a plurality of uniformly distributed transfer balls are attracted from the lower side by virtue of the magnetic attraction effect of magnetic control bags, the magnetic attraction force of the magnetic control bags is automatically lost after the transmission crawler belt rotates to the upper side, the transfer balls are in contact with a thin film and then are adhered to the thin film, the thin film normally slides down when reaching an inclined collecting box, the transmission crawler belt always attracts the transfer balls in a reciprocating manner and then enables the transfer balls to be adhered to the thin film, the thin film can realize automatic collecting under the action of gravity, and meanwhile, due to the existence of the transfer balls, frictional resistance of the thin film during sliding down can be greatly reduced, and possibly appearing wear between thin films can be reduced. Compared with the prior art, the device has the advantages that the thin films can be automatically collected, arranged and stacked by means of the transfer balls, the collecting efficiency is greatly improved, and the device is suitable for large-scale production of products.

Owner:深圳市质立科技有限公司

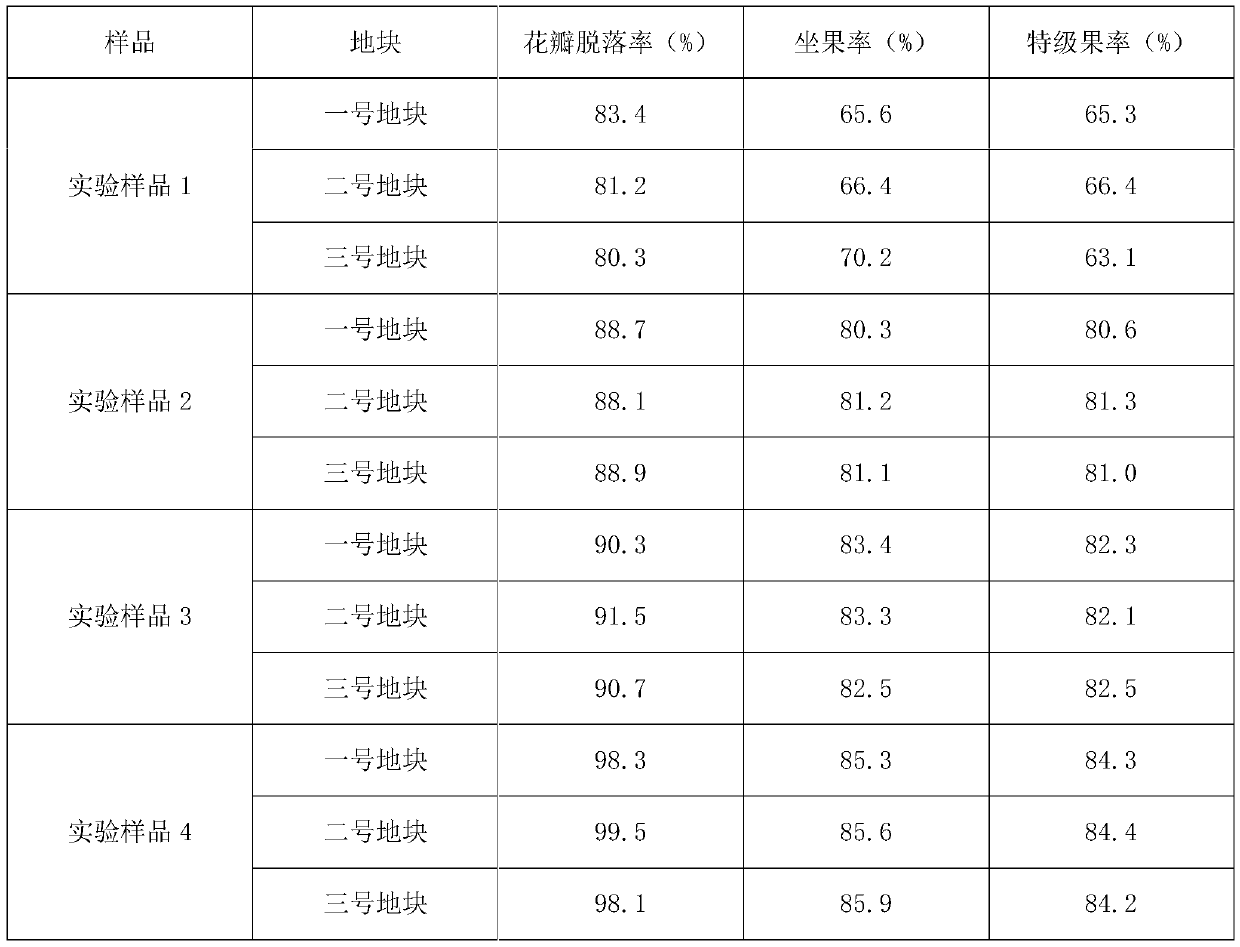

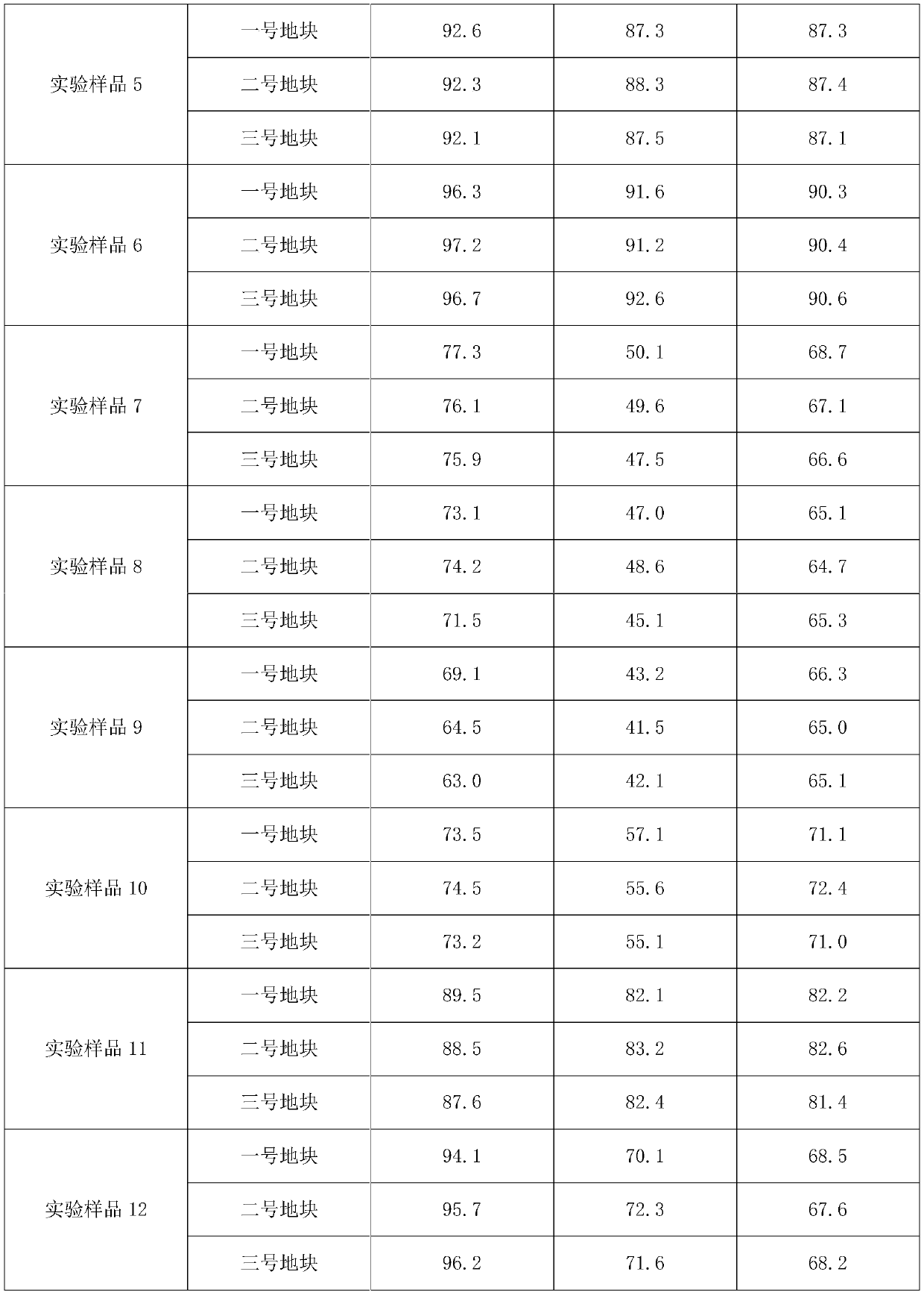

Fruit retention method of Fortunella Crassifolia Swingle

ActiveCN111357523AImprove fruit preservation effectSave resource costAircraft componentsPlant growth regulatorsFruit treeFortunella crassifolia

The invention provides a fruit retention method of Fortunella Crassifolia Swingle, and specifically relates to the technical field of agricultural plant protection. The fruit retention method can enhance the fruit retention effects of Fortunella Crassifolia Swingle, uniformly standardizes the time, frequency and means of flower thinning of the Fortunella Crassifolia Swingle and stipulates the flower thinning time and petal dropping rate of each blooming. The flower thinning using external force to shake branches can be manually carried out or can be carried out through the remote operation ofa plant protection unmanned aerial vehicle; and the plant protection unmanned aerial vehicle is optimally selected to carry out flower thinning operation, which is more time- and labor-saving than manual force applying, so that labor resources and labor costs can be saved to a great extent. Through the fruit retention method, the petal dropping rate of Fortunella Crassifolia Swingle trees can reach more than 80%, fruit setting rate can be stabilized at more than 65%, and special grade fruit rate can reach up to more than 63%; and especially through the adopting of the plant protection unmannedaerial vehicle to perform flower thinning, petal shedding rate can reach more than 88%, and both the fruit setting rate and the special grade fruit rate can reach more than 80%.

Owner:RONGAN LIANGFENG SEEDING CO LTD

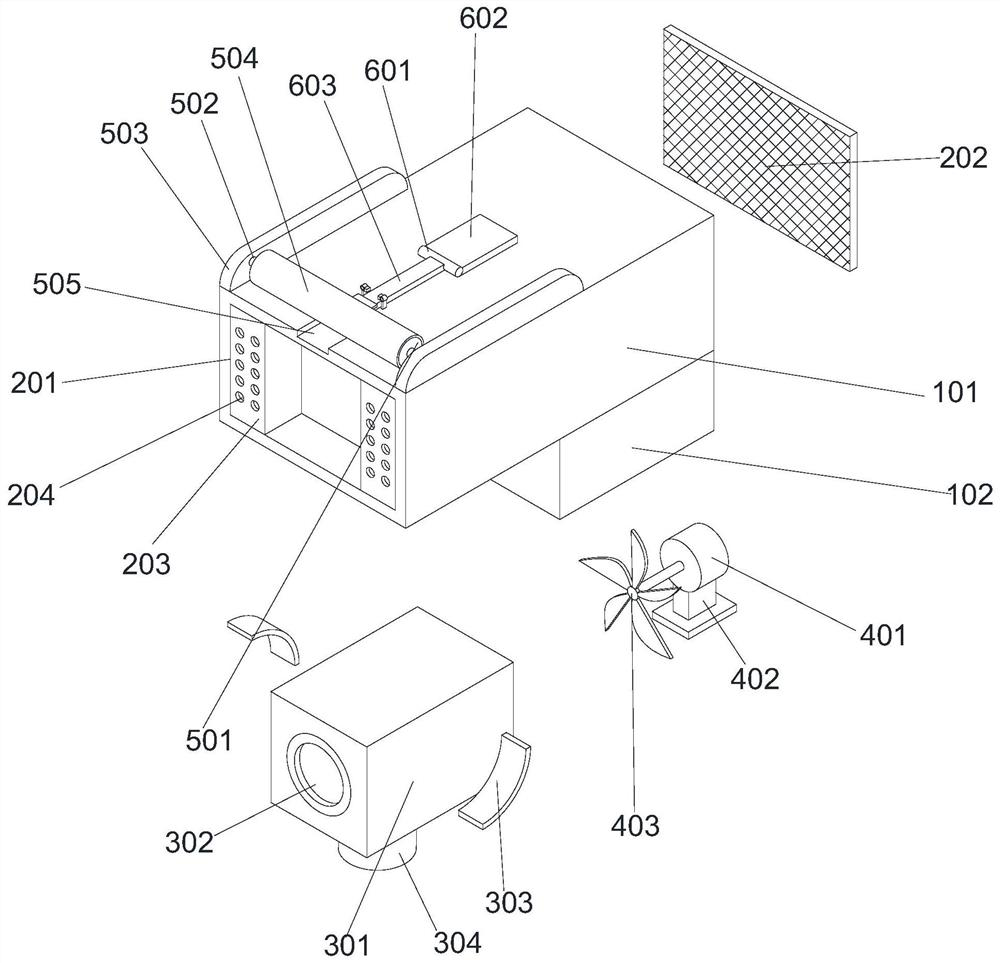

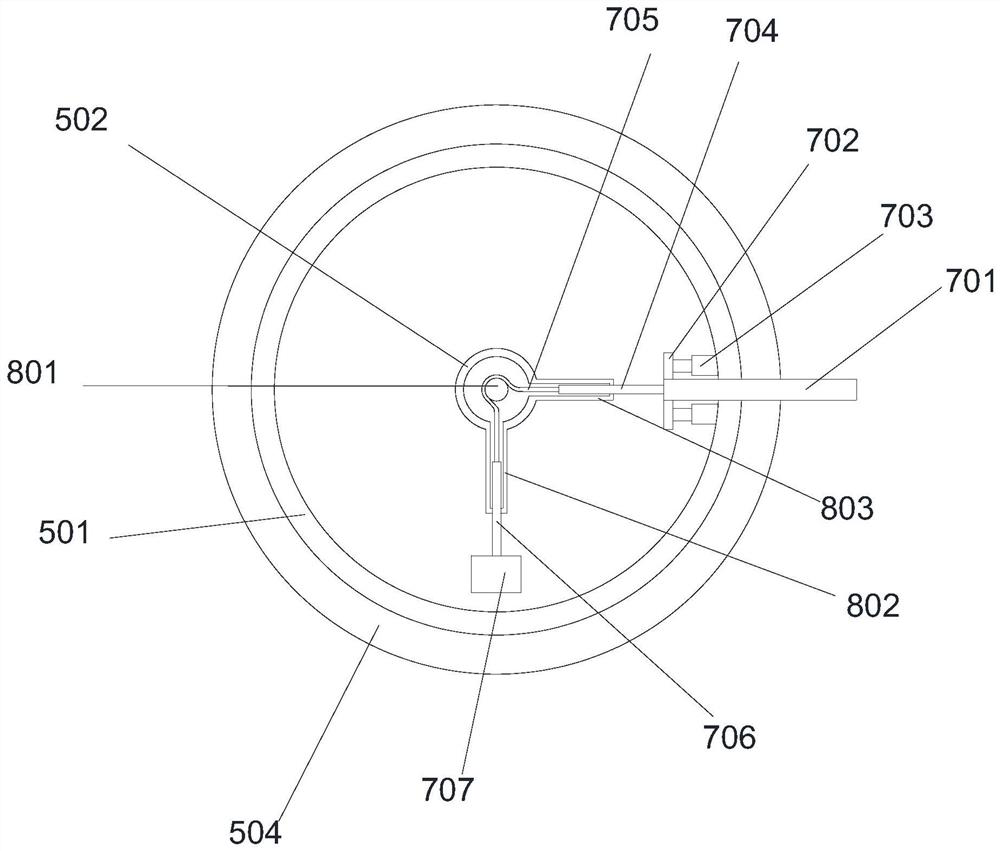

Multifunctional security and protection equipment device for intelligent property management

InactiveCN113095961AEffective coolingAvoid failureData processing applicationsBurglar alarmStructural engineeringFan blade

The invention discloses a multifunctional security equipment device for intelligent property management, and relates to the technical field of security equipment. The multifunctional security and protection equipment device for the intelligent property management comprises an equipment shell; a battery bin is fixedly connected to the right end of the lower surface of the equipment shell, a mounting bottom plate is fixedly connected to the lower surface of the battery bin, and a power line is fixedly connected to the right side face of the battery bin; and a shooting port penetrates through the left side surface of the equipment shell. side covers are fixedly connected to the front and rear ends of the inner wall of the shooting port; an air inlet penetrates through the left side surface of the side cover; a port is formed in the right side face of the equipment shell, and a dustproof net is fixedly connected to the inner wall of the port; a camera device is arranged in the device shell; a fan blade is arranged at the right end of the camera equipment; the left end of the upper surface of the equipment shell is provided with a rolling shaft, and the right side of the rolling shaft is provided with a transverse plate. According to the technical scheme, the problem that illegal persons investigate camera shielding in advance to cause potential safety hazards is avoided.

Owner:杭州中荷智慧城市科技有限公司

Precise and durable handheld measuring device for engineering surveying and mapping and surveying and mapping method thereof

The invention belongs to the technical field of engineering surveying and mapping, and particularly relates to a precise and durable handheld measuring device for engineering surveying and mapping and a surveying and mapping method of the precise and durable handheld measuring device. And the outer walls of one sides of the two sliding openings are each fixedly connected with two first telescopic air cylinders, and the outer walls of one sides of the two first telescopic air cylinders located on one side are fixedly connected with the same sliding block. Through the arrangement of the dust suction cover, the dust suction hole, the dust suction pump, the telescopic hose and the dust collection box, when the measuring instrument is collected into the protection frame, a second telescopic rod is adjusted to enable the dust suction cover to move to an observation opening of the measuring instrument, then the dust suction pump is started, and dust around the observation opening is adsorbed through the dust suction hole in the dust suction cover on the telescopic hose; and then the dust is uniformly discharged into the dust collection box, so that dust at an observation opening of the placed measuring instrument can be effectively isolated, and the situation that the dust corrodes the measuring instrument, and the service life of the device is affected is prevented.

Owner:董雨晴

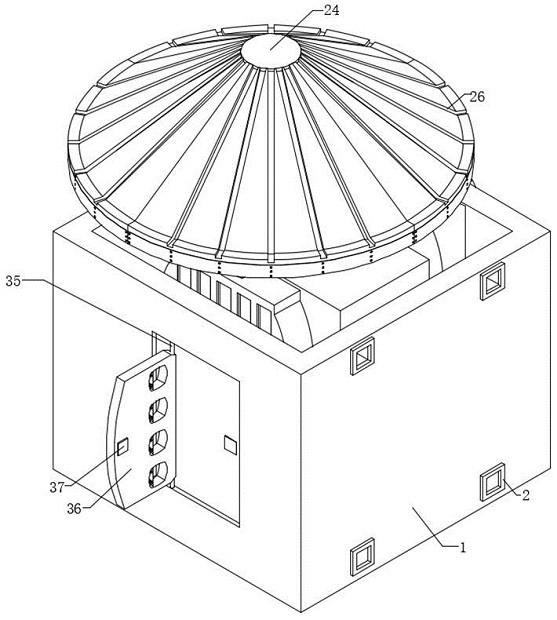

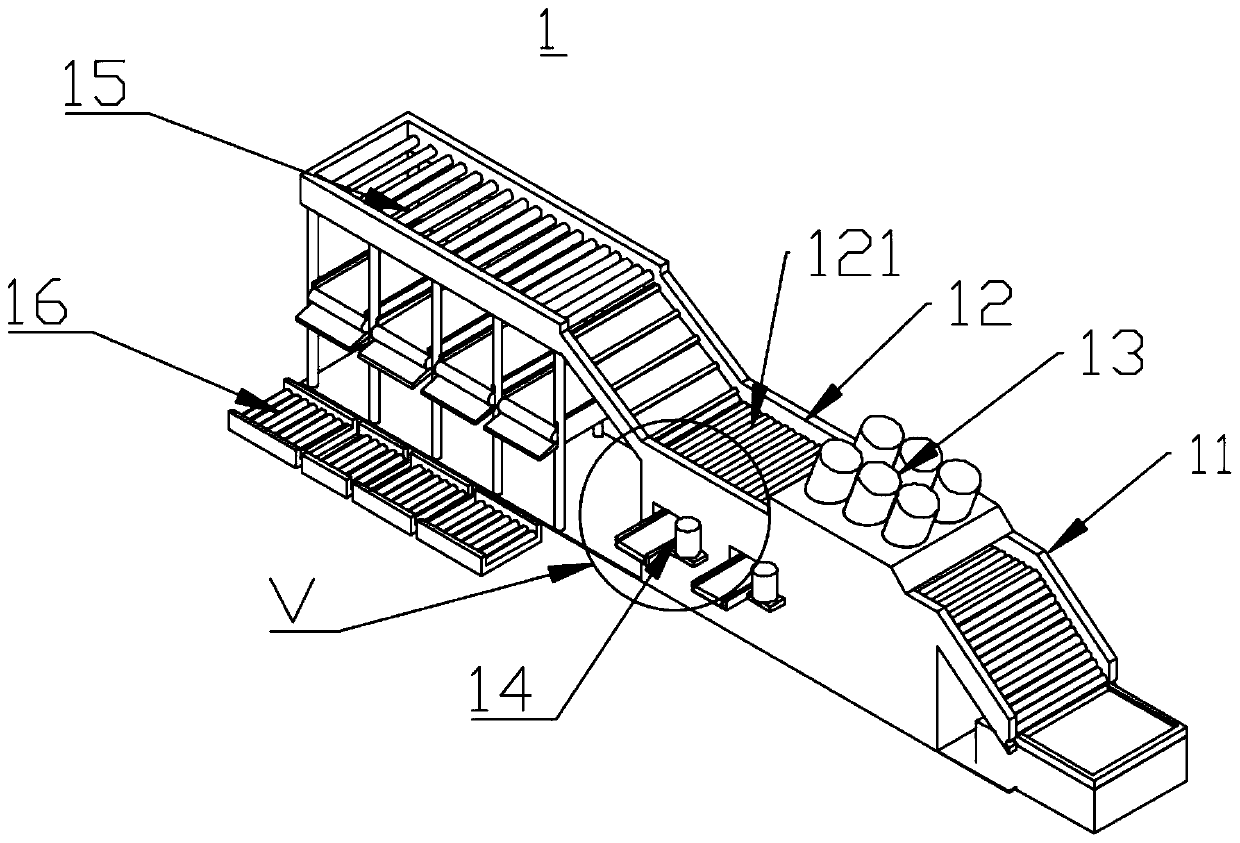

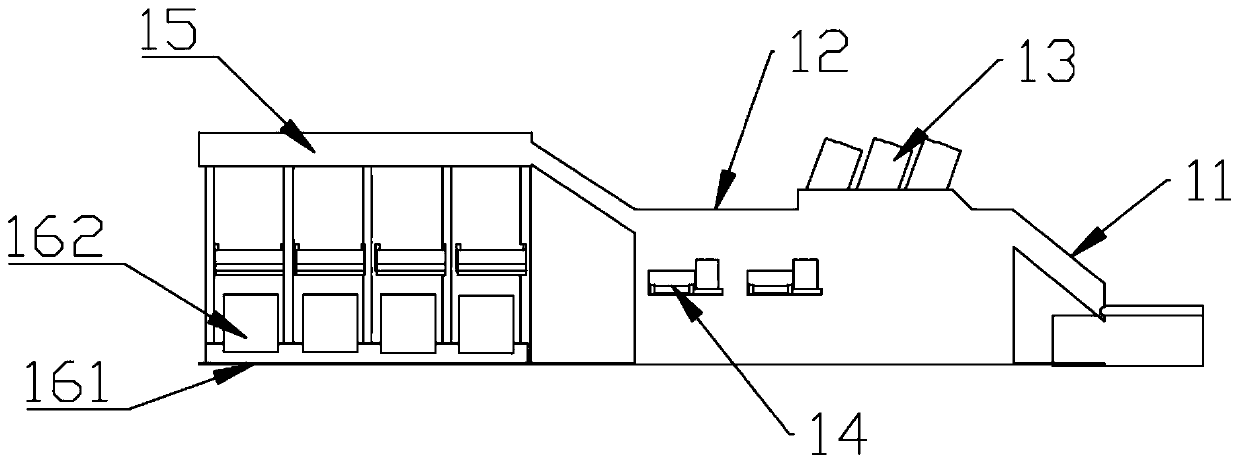

Full-automatic potato grader

InactiveCN110026331AShedding evenlyMinimizeSievingScreeningAgricultural engineeringSolanum tuberosum

The invention provides a full-automatic potato grader, and relates to the field of agricultural instruments. The full-automatic potato grader comprises a lifting device, a conveying device, an air-drying device, a cleaning device, a grading device and a weighing device, wherein the lifting device is connected with one end of the conveying device; the grading device is connected with the other endof the conveying device for grading potatoes; the cleaning device is arranged at the bottom of the conveying device for cleaning the potatoes on the conveying device; the air-drying device is arrangedon the top of the conveying device for drying the potatoes on the conveying device; and the weighing device is arranged at the outlet end of the grading device for receiving the potatoes. Compared with the prior art, according to the full-automatic potato grader, soil on the potato surfaces can be air-dried by the air-drying device, and then the soil on the potato surfaces can fall off smoothly by the cleaning device, so that the influence of the soil on the subsequent grading process is avoided, and the grading effect is improved.

Owner:CHONGQING ACAD OF AGRI SCI

A sleeve type fork ear support rod structure for a booster

Owner:JIANGXI HONGDU AVIATION IND GRP

Patting sweeping device for belt of cigarette manufacturing machine

The invention discloses a patting sweeping device for a belt of a cigarette manufacturing machine. The patting sweeping device comprises a rotating spindle, a decelerating motor and two patting rollers. The rotating spindle is in transmission connection with the decelerating motor and arranged on the upper portion of the belt of the cigarette manufacturing machine through a rack; the two patting rollers are symmetrically arranged on the two axial sides of the rotating spindle through mounting supports connected with the rotating spindle; and the axial direction of the patting rollers is parallel to the axial direction of the rotating spindle. The structure is simple and novel, and the patting rollers pat the belt continuously and circularly so as to enable viscous matter to fall off successfully. After using, it is proved that the patting sweeping device has the obvious removing effect.

Owner:安徽飞翔烟机配套有限公司

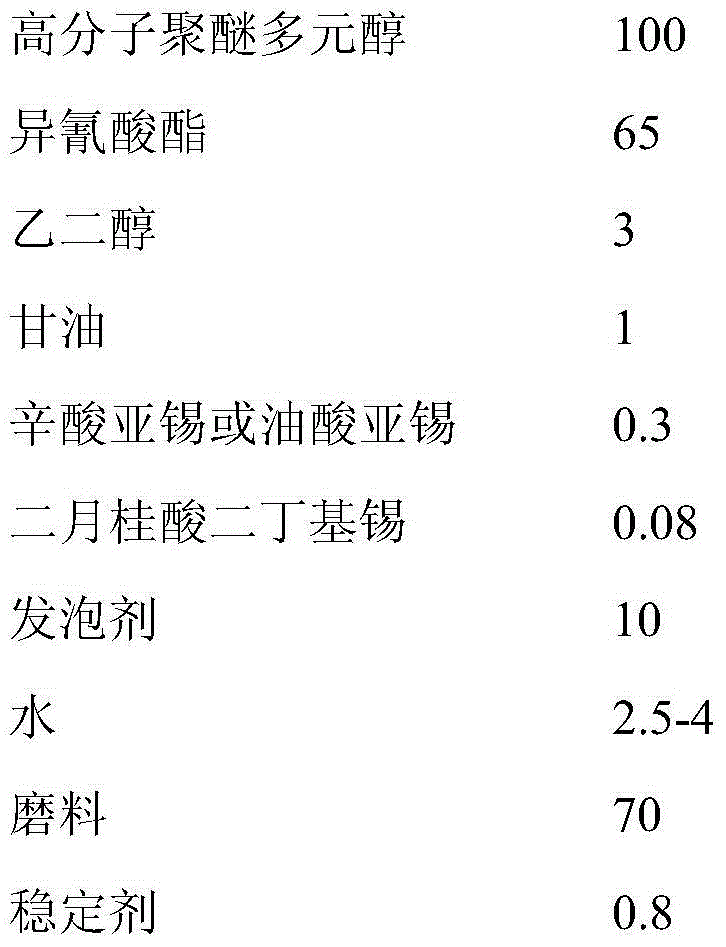

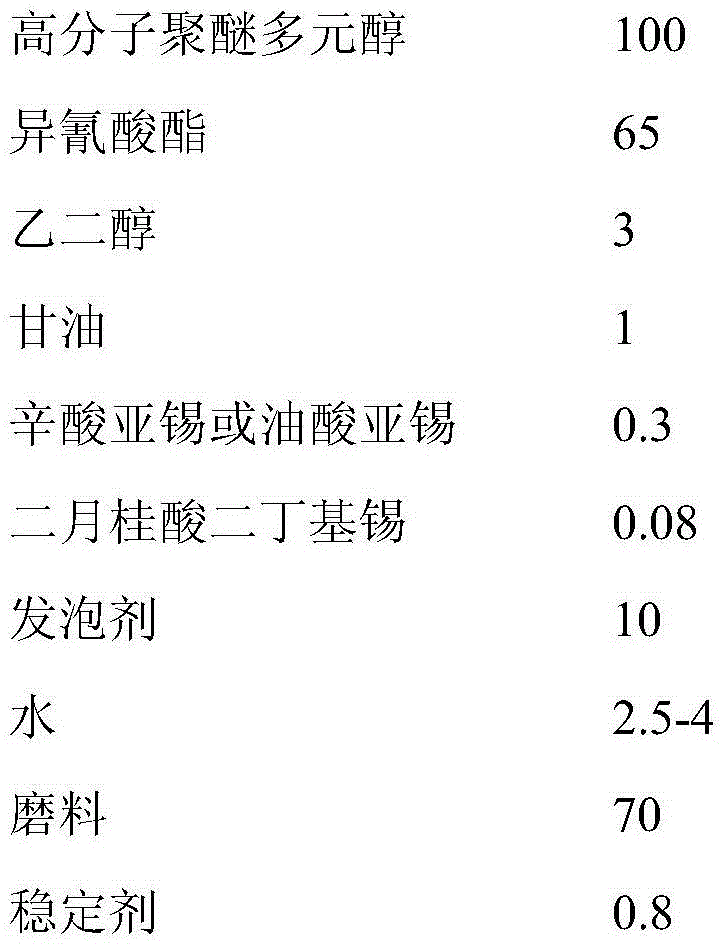

Material of polyurethane wet type polishing wheel

The invention discloses a material of a polyurethane wet type polishing wheel. The material has the advantage that the material is manufactured into the wet type polishing wheel; by utilizing the wet type polishing method, the accuracy of traditional grinding is greatly improved, the dustless or slight-dust polishing is realized, the cost of precision grinding is greatly reduced, and the material after precision grinding can be applied to multiple production fields in a large-scale way.

Owner:台山市远鹏研磨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com