Spherical surface detection method of ball socket part

A ball socket and component technology, applied in the field of spherical surface detection, can solve the problems of ball head and ball socket stuck, out of tolerance, unmeasurable spherical size accuracy, etc., to achieve the effect of ensuring smooth falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

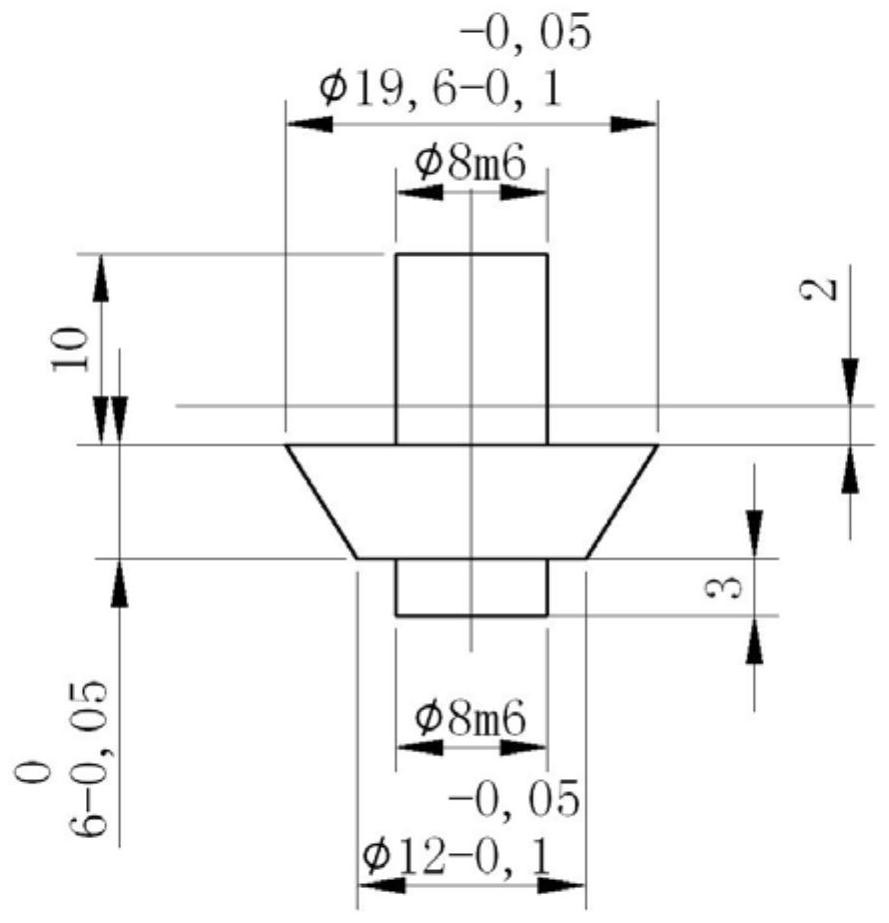

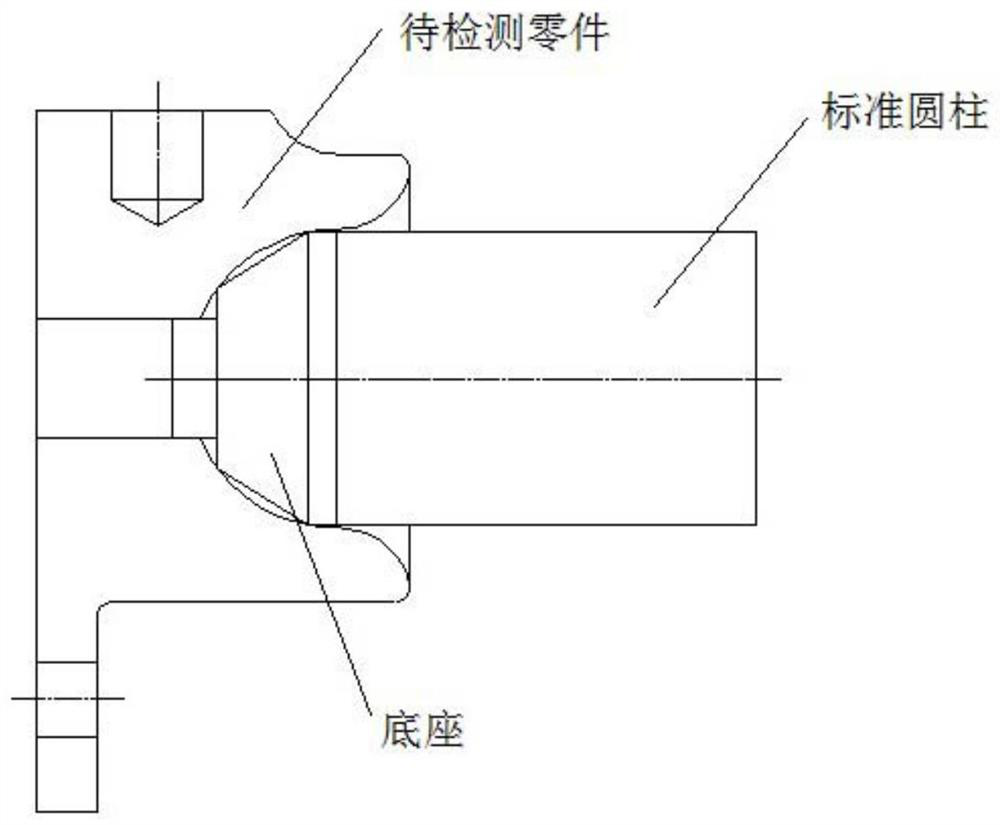

[0018] Aiming at the unmeasurable problem of the spherical surface, the present invention designs a spherical surface detection tool for ball socket parts, which detects and verifies the transition area between the spherical surface and the R5 fillet to ensure that the spherical surface size meets the design requirements and the ball head can fall off smoothly.

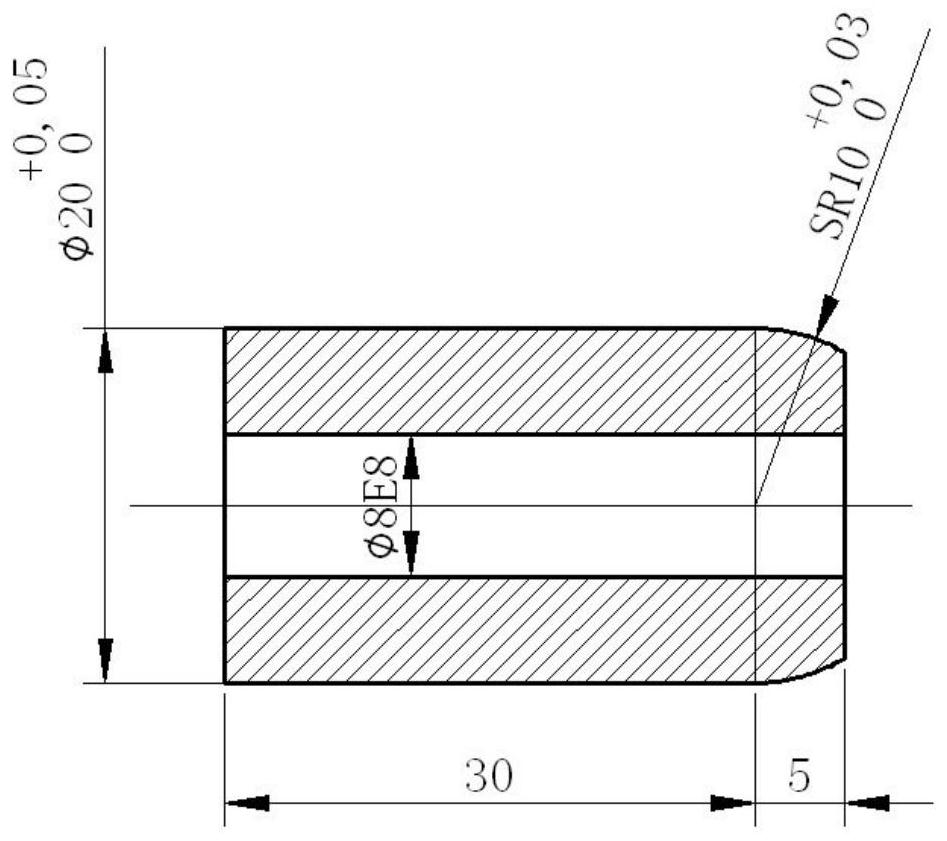

[0019] The spherical inspection tool for ball and socket parts consists of two parts, one is a standard cylinder, and the outer diameter of the cylinder can be made according to the diameter of the cross-sectional circle of the spherical area to be inspected, such as figure 1 As shown, the front end of the standard cylinder is made as an arc surface, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com