Material of polyurethane wet type polishing wheel

A technology of wet polishing and polyurethane, applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of high cost, poor grinding accuracy, large dust, etc., and achieve high cost performance, uniform shedding, and high elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

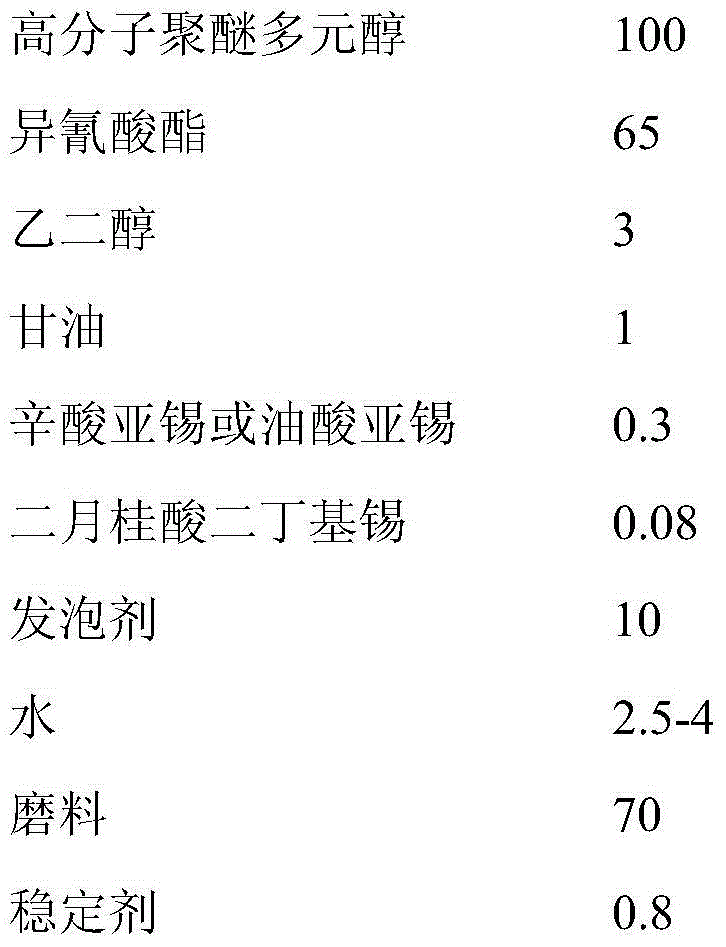

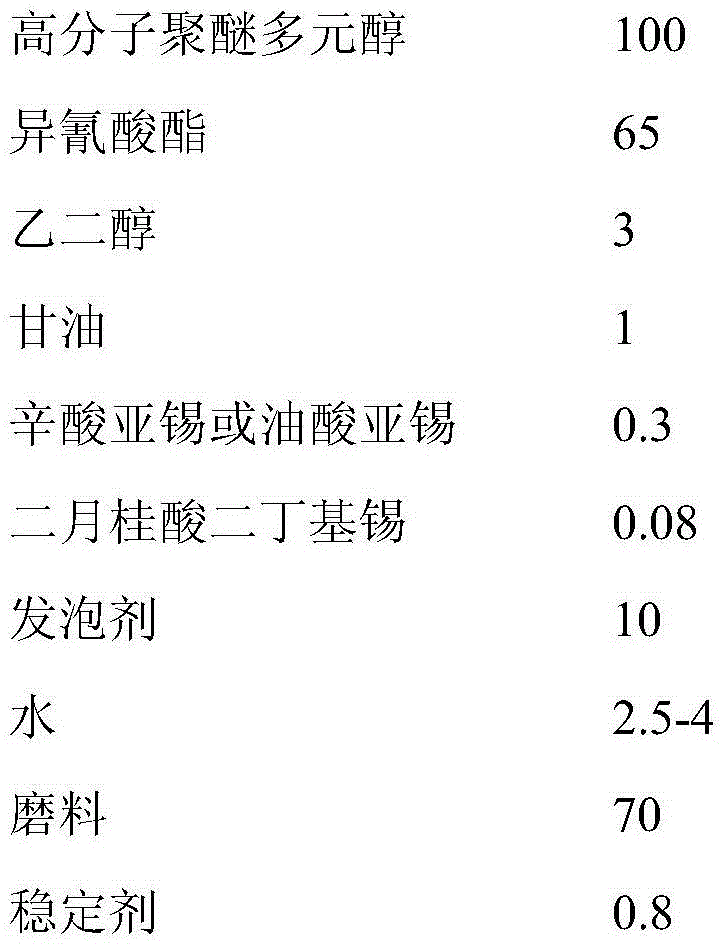

[0018] Materials used in the examples are as follows:

[0019] raw material name

parts by mass

CAS registration number

100

diphenylmethane diisocyanate

13

5101-68-8

Triphenylmethane triisocyanate

52

2422-91-5

Ethylene glycol

3

107-21-1

Glycerin

1

56-81-5

0.3

301-10-0

0.08

201-039-8

10

water

2.5-4

70

Os-15 (fatty alcohol polyoxyethylene ether)

0.8

111-09-3

[0020] 1) Mix the materials in the above weight ratio, and use a high-speed mechanical arm to even them at a high speed of 1200 to 1500 revolutions per second.

[0021] 2) Pour the mixed raw materials into the mold to complete the pouring. Before pouring, the mold needs to be coated with a layer of wax and grease as a release agent.

[0022] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com