Patents

Literature

149results about How to "Solve the jam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

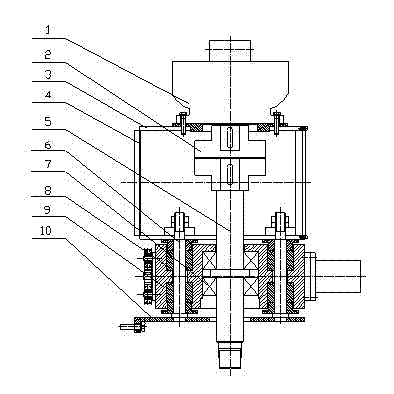

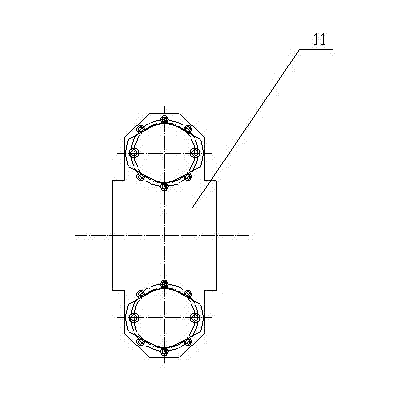

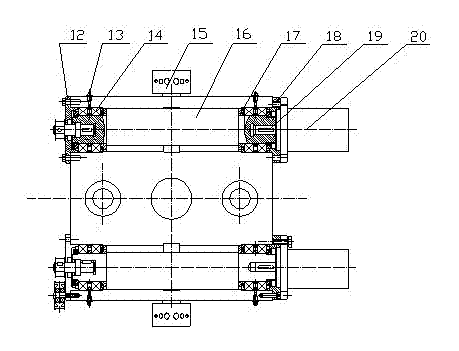

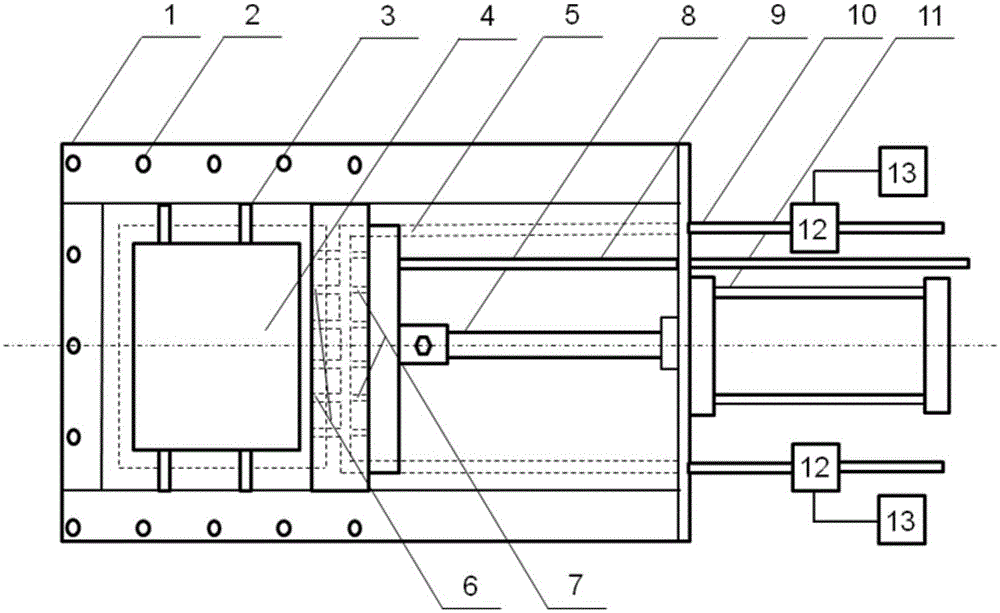

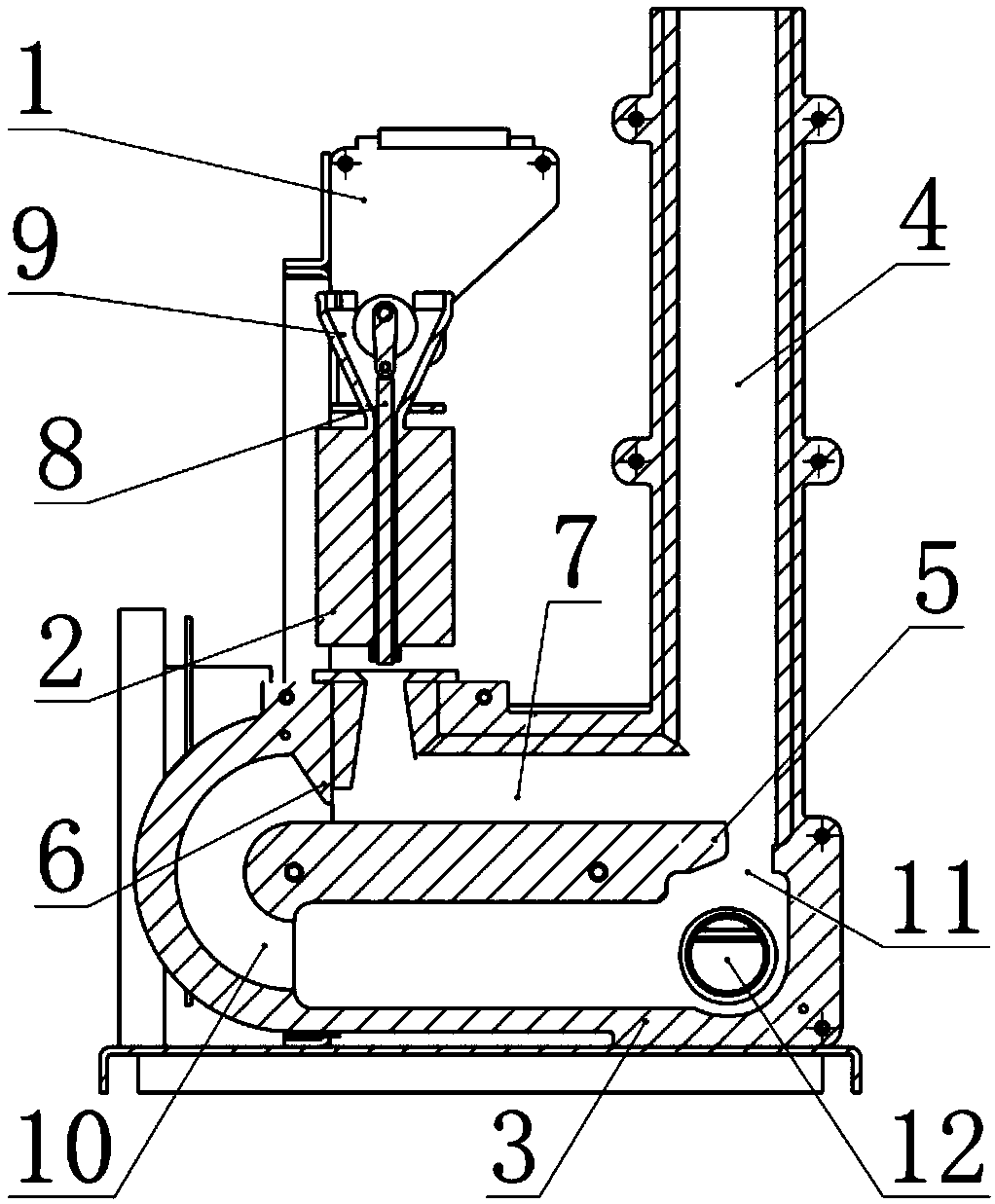

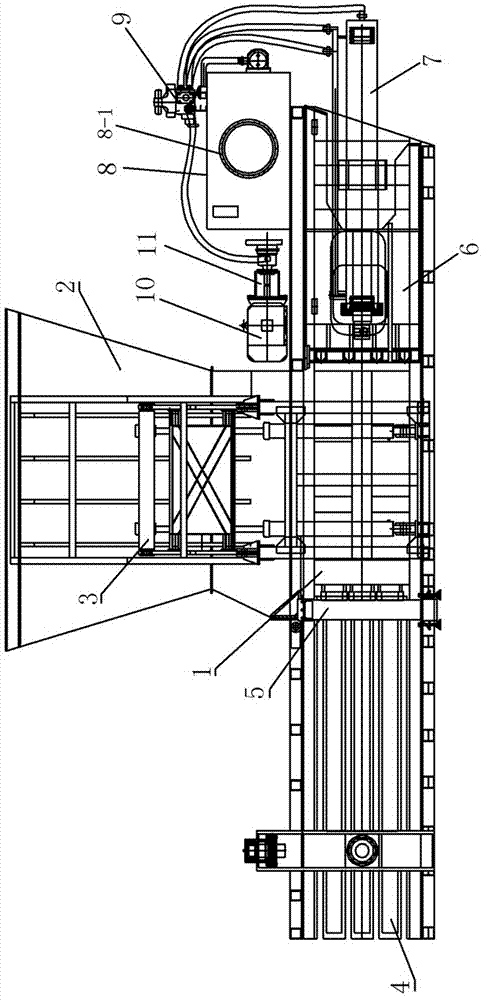

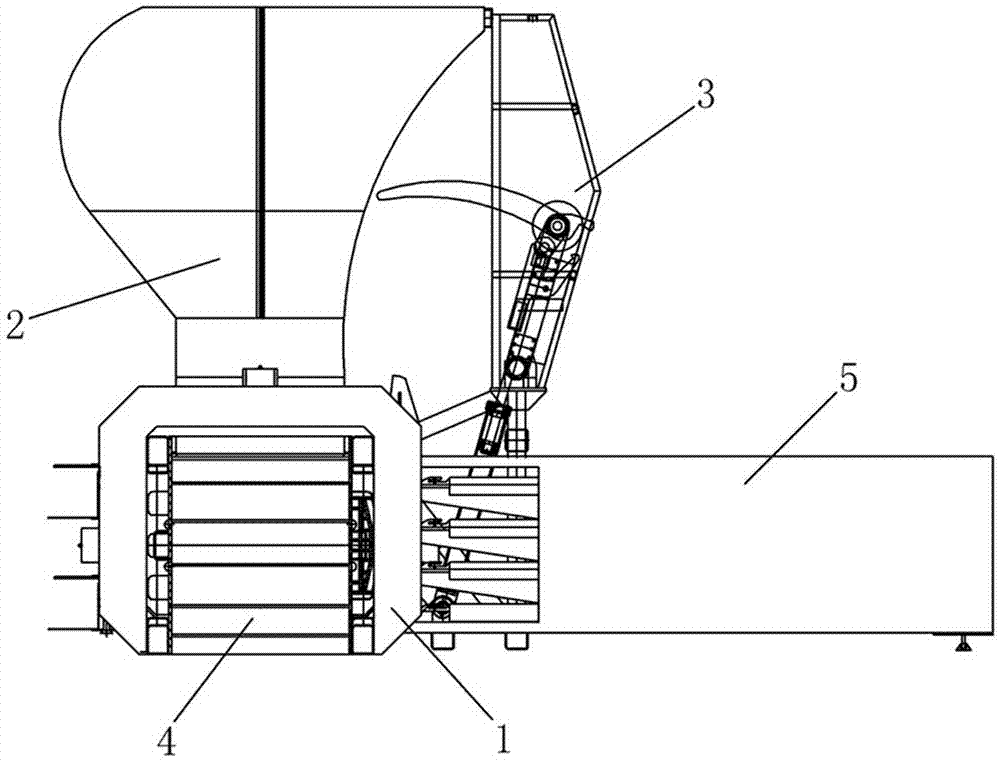

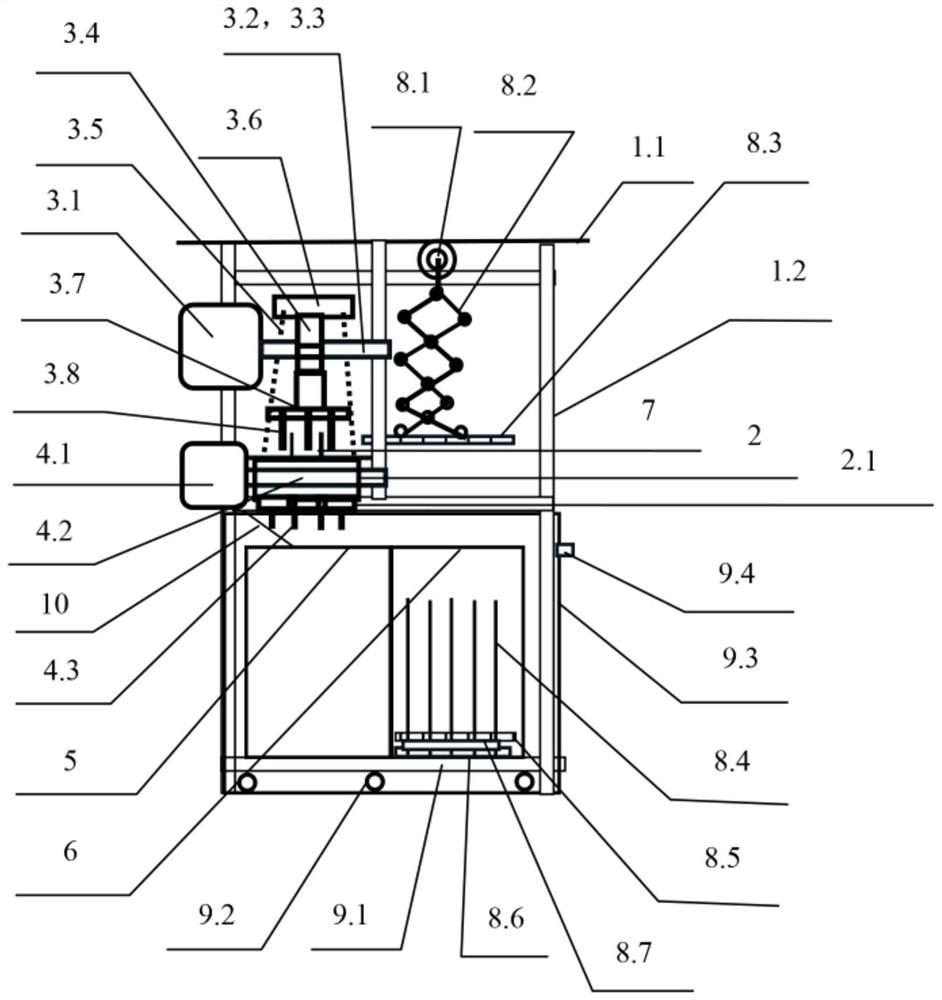

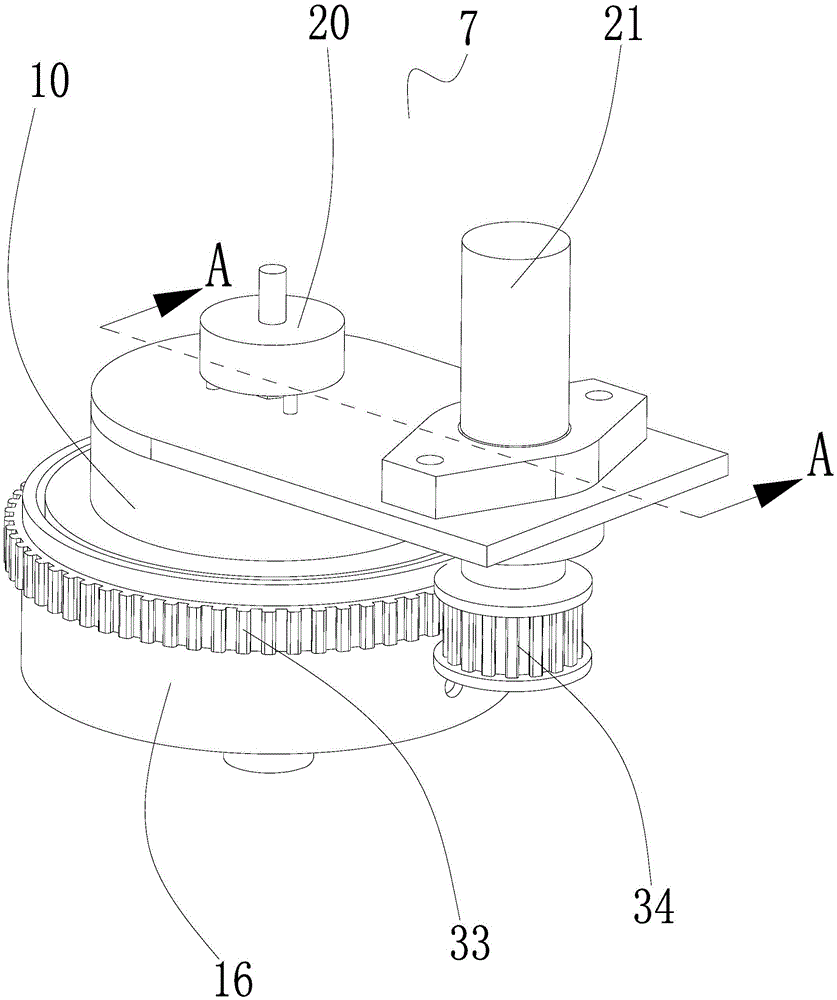

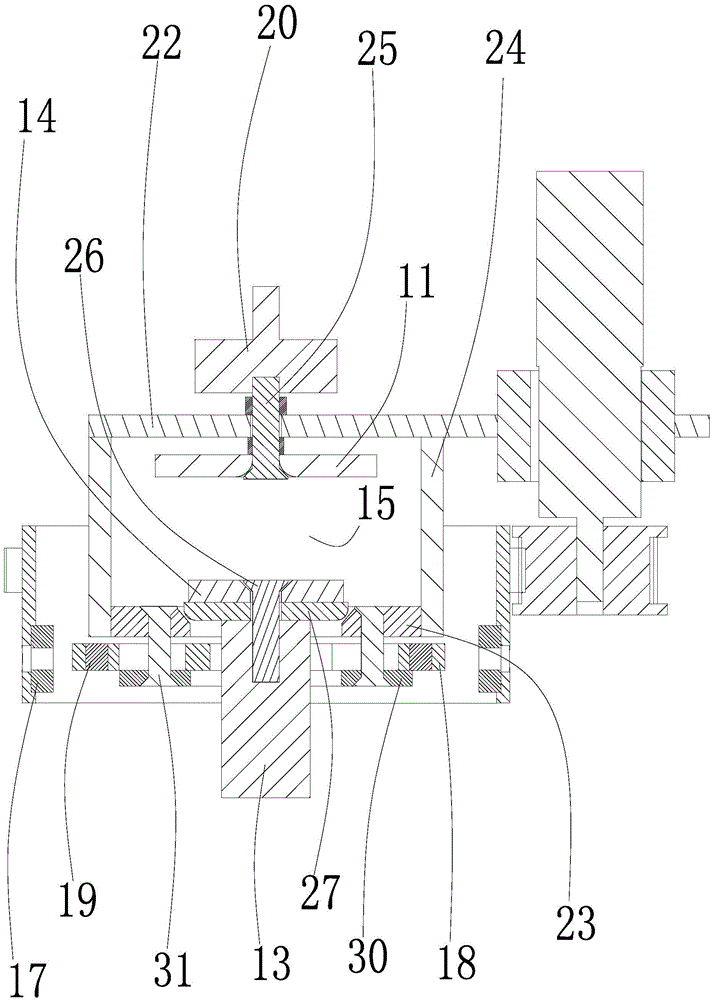

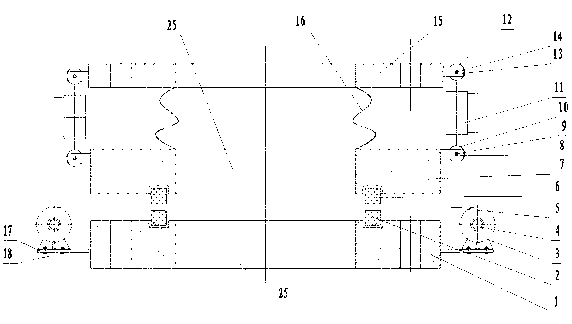

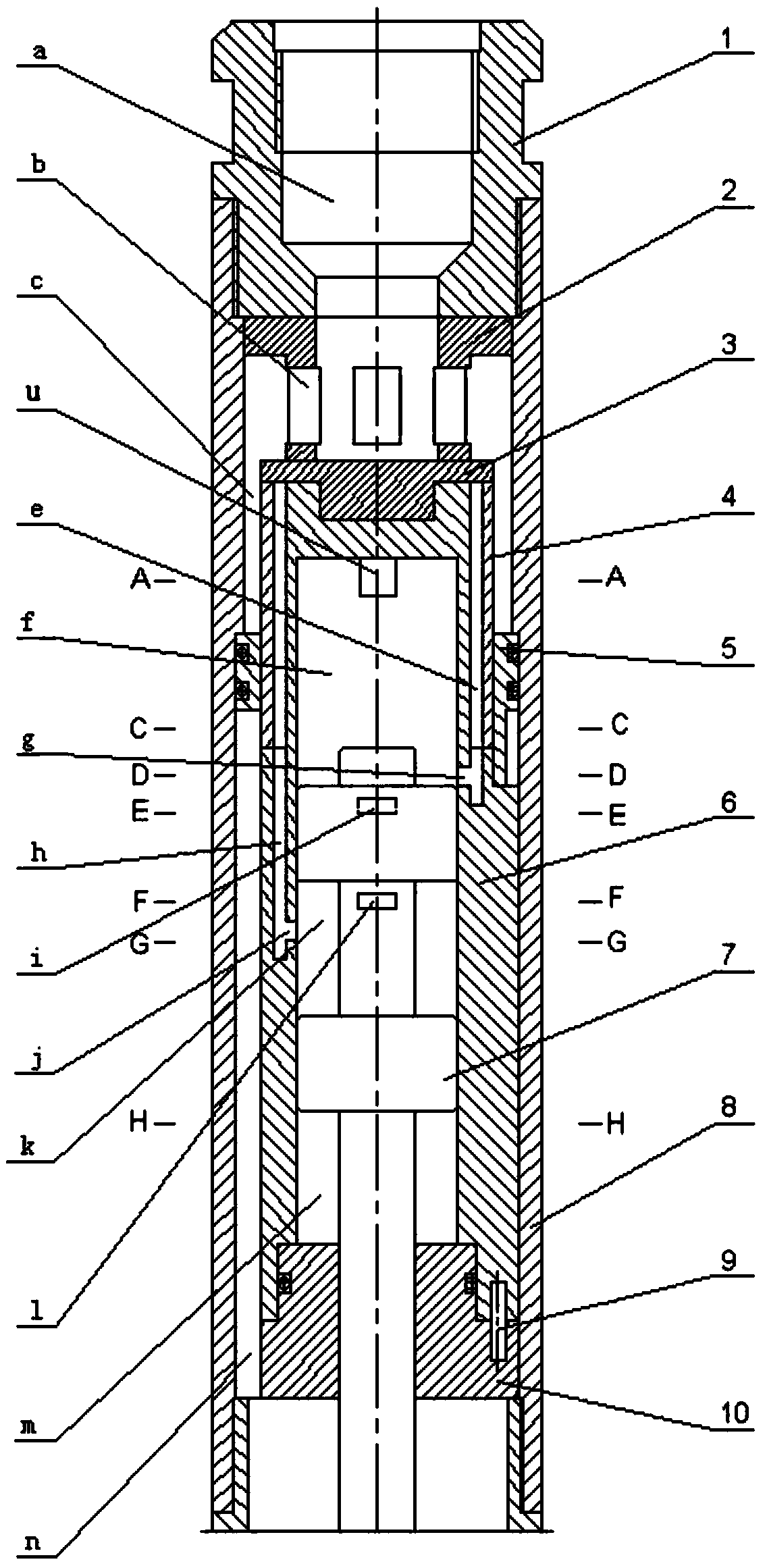

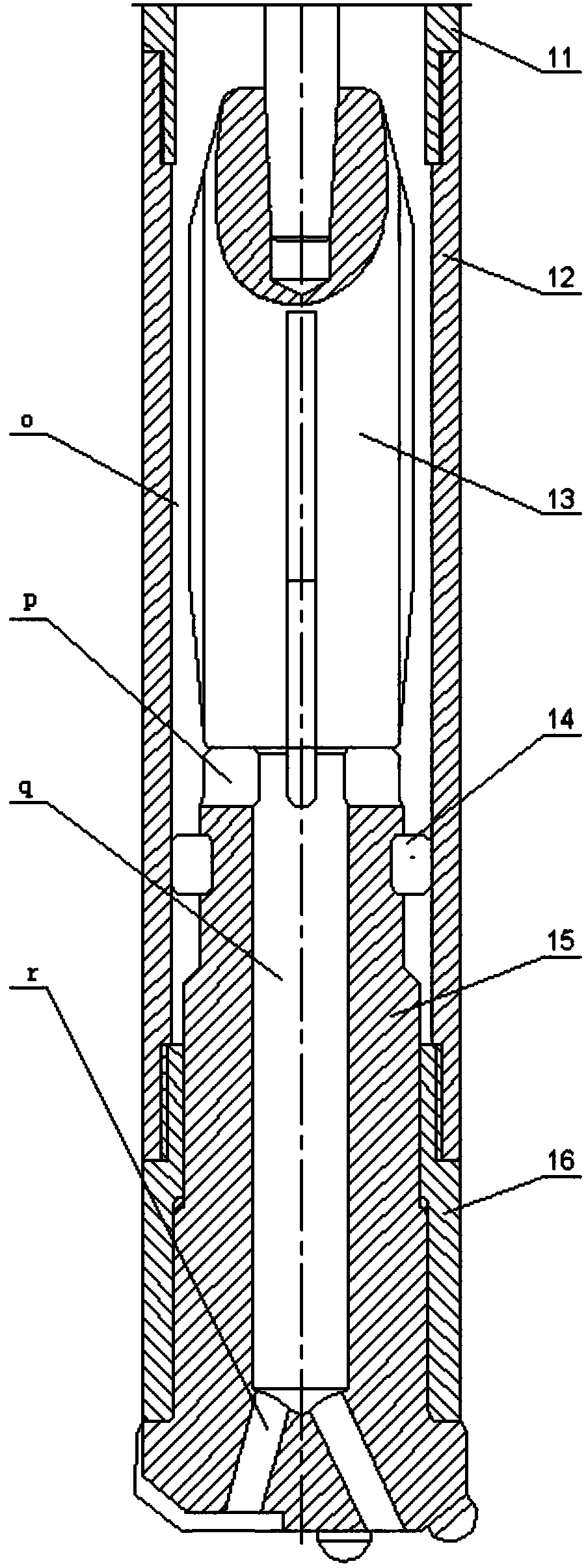

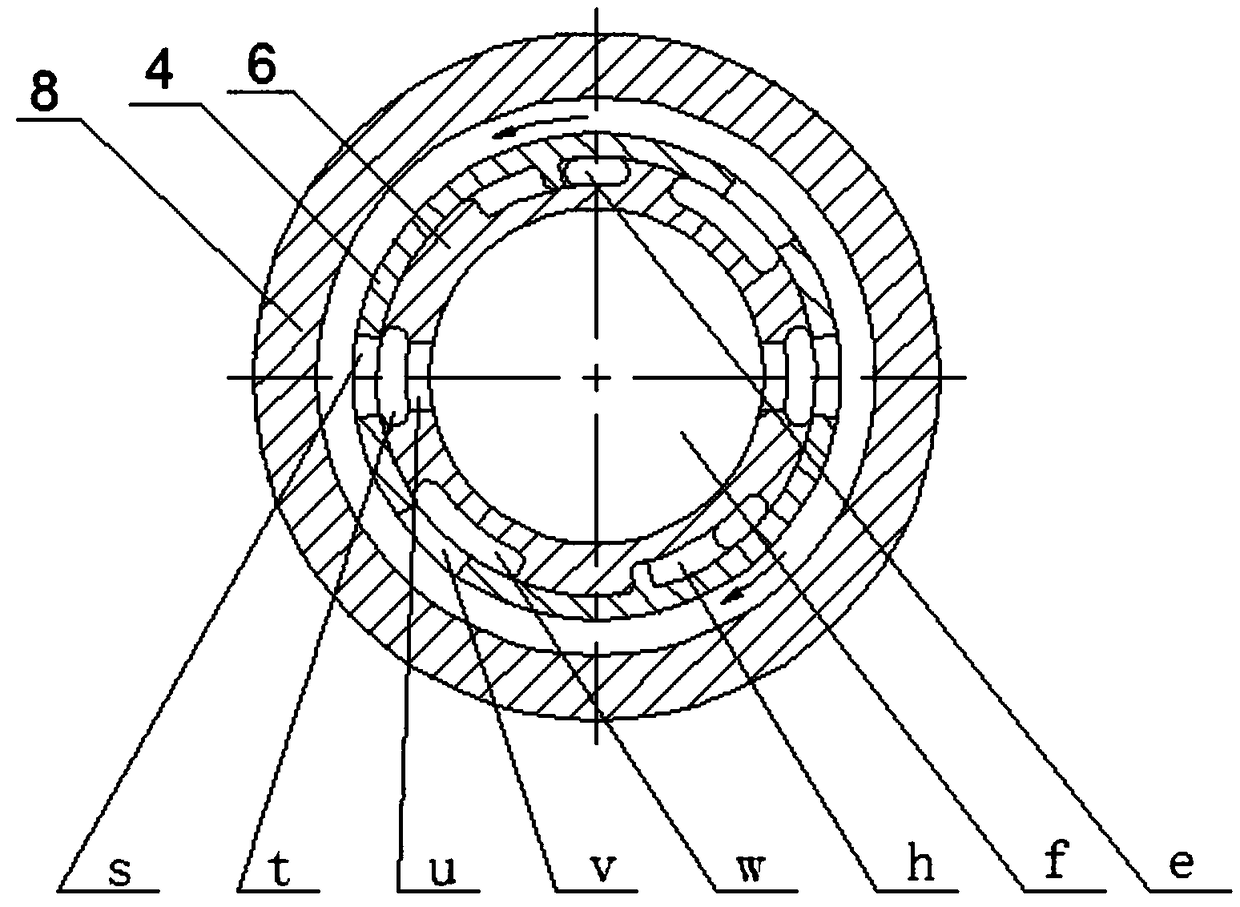

Hydraulic superhigh-frequency vibrating power head

InactiveCN102900354AAvoid harmVibration frequency stepless adjustmentReciprocating drilling machinesConstructionsUltrahigh frequencyDrill hole

The invention discloses a hydraulic superhigh-frequency vibrating power head and belongs to the field of shallow drilling and sampling. The hydraulic superhigh-frequency vibrating power head comprises a rotary motor, a coupler, a coupler box, a vibrator, a vibration damper, a spindle, a power head back plate and a support plate, wherein the rotary motor is connected with the upper end of the spindle via the coupler, and the spindle is vertically penetratingly arranged in the vibrator. The vibrator is connected with a bottom plate of the coupler box via the vibration damper and comprises a vibrator box, two groups of high-speed hydraulic motors, two eccentric shafts, a synchronous belt / synchronous wheel forced synchronizing mechanism and a high-speed bearing cooling and lubricating device, wherein the two groups of high-speed hydraulic motors are symmetrically arranged on two sides of the spindle, the high-speed hydraulic motors drive the eccentric shafts to rotate via key joint, and the two eccentric shafts can realize synchronous running via the synchronous belt / synchronous wheel forced synchronizing mechanism. The hydraulic superhigh-frequency vibrating power head is capable of conveniently and effectively realizing shallow drilling and sampling on various overburden layers, drilling speed is improved, and popularization is facilitated.

Owner:中煤地第二勘探局集团有限责任公司 +1

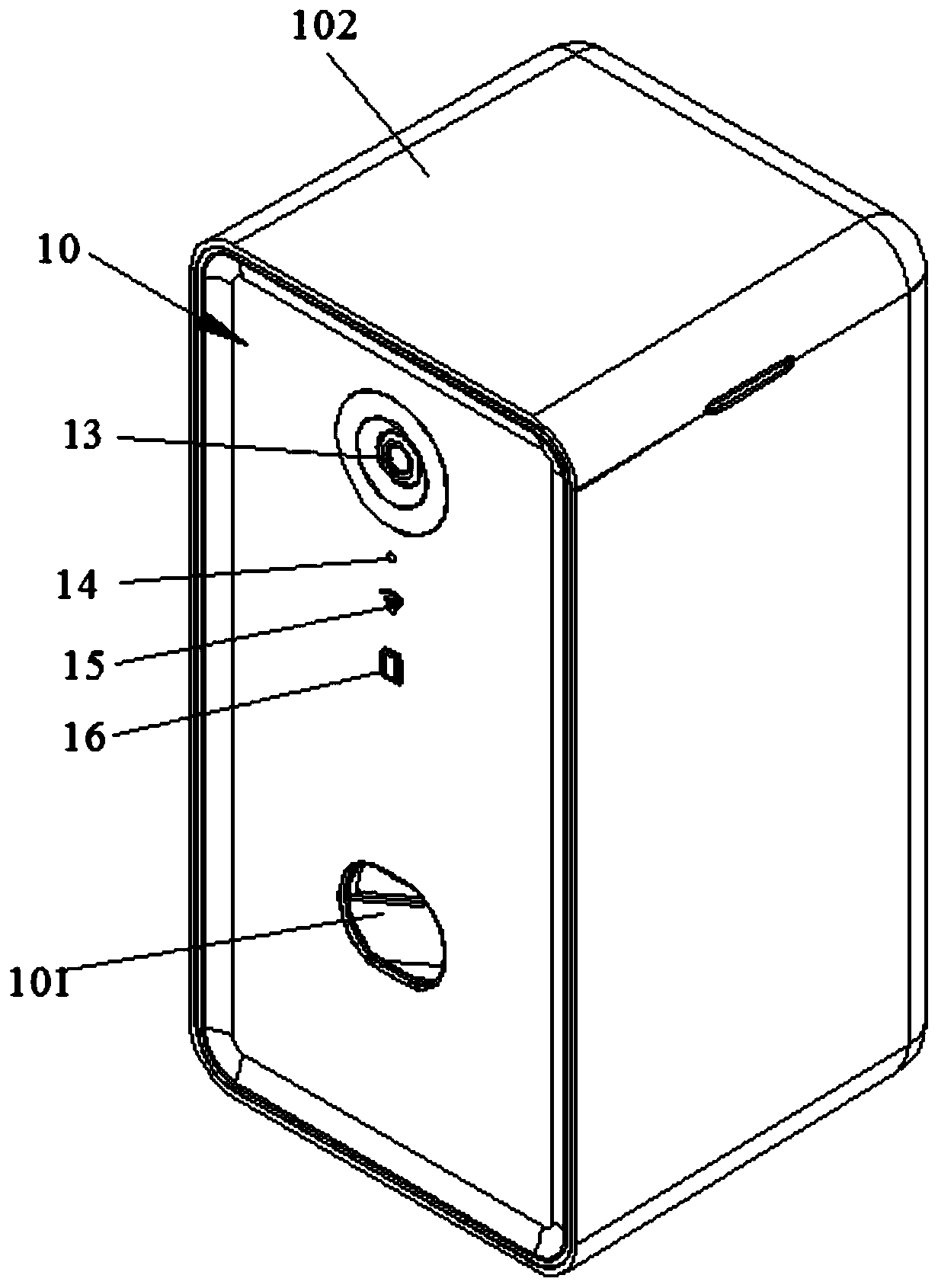

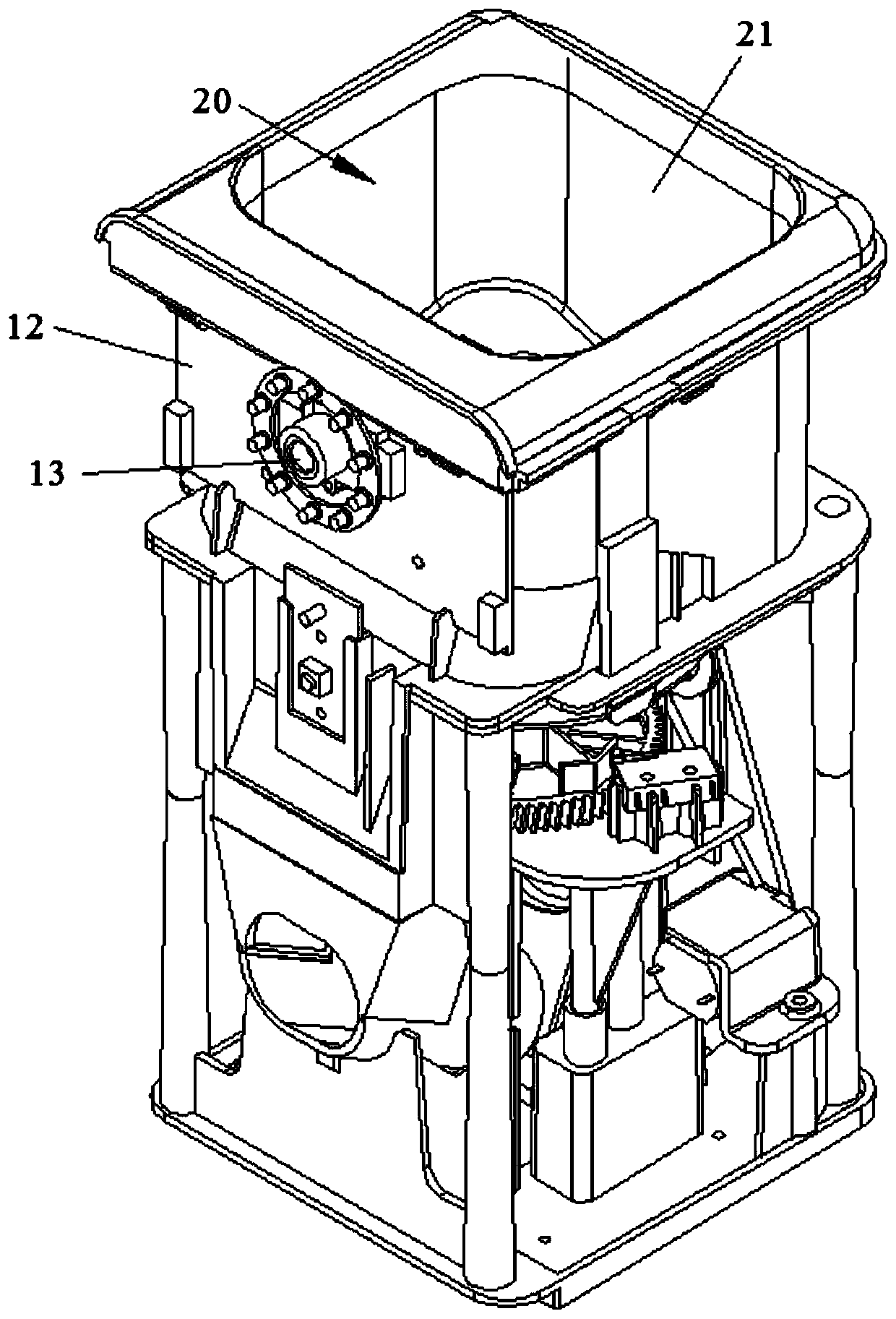

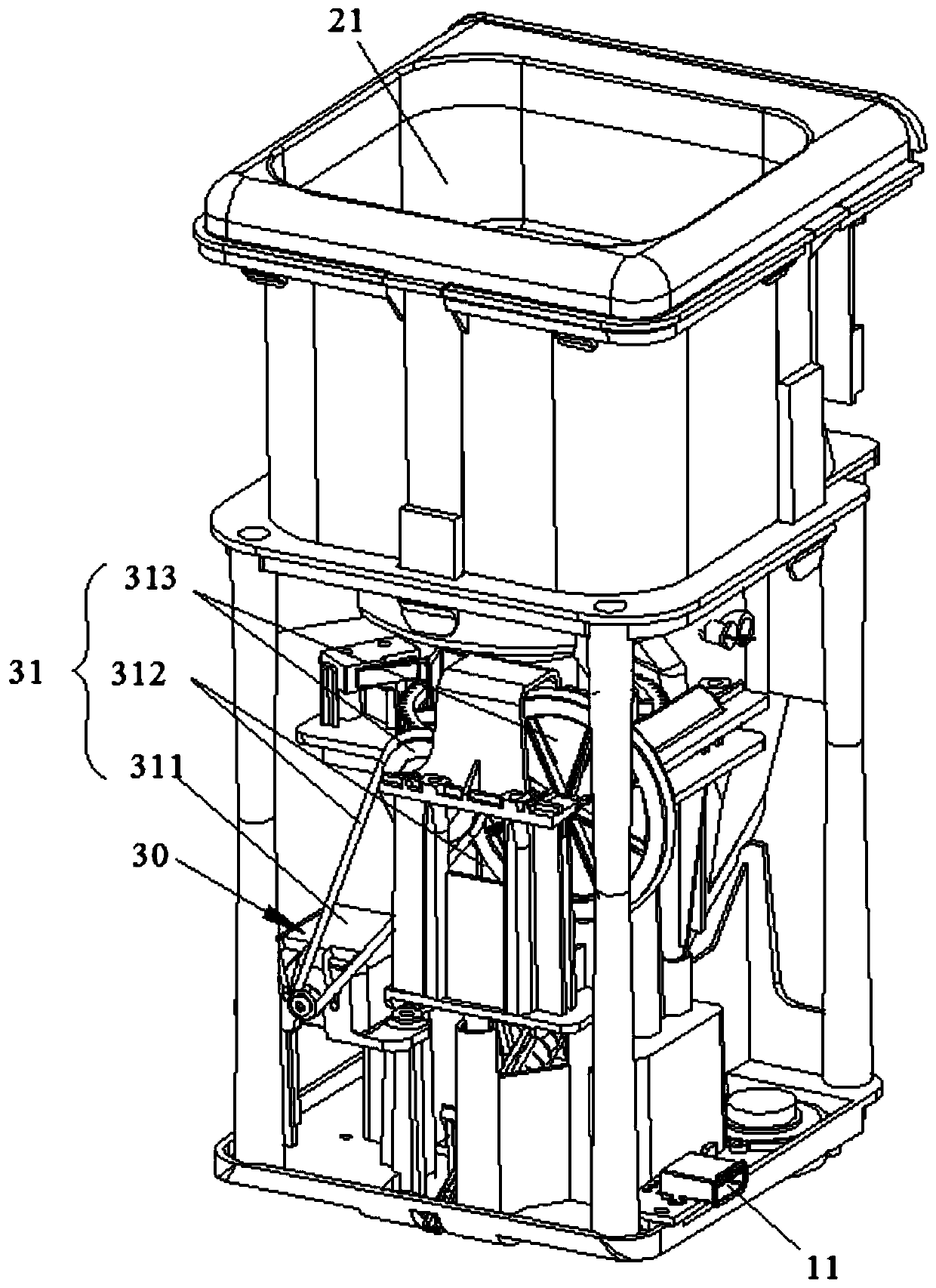

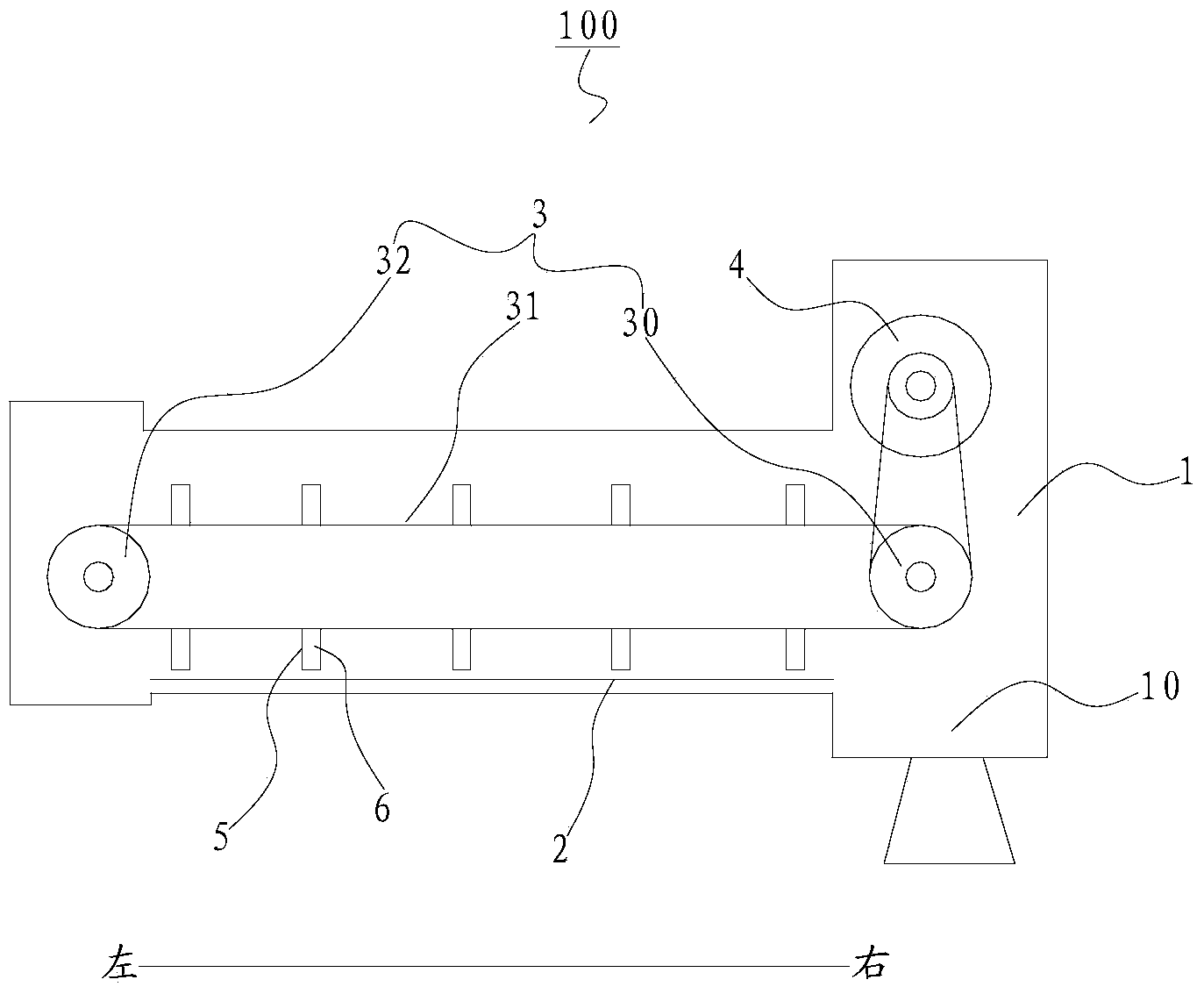

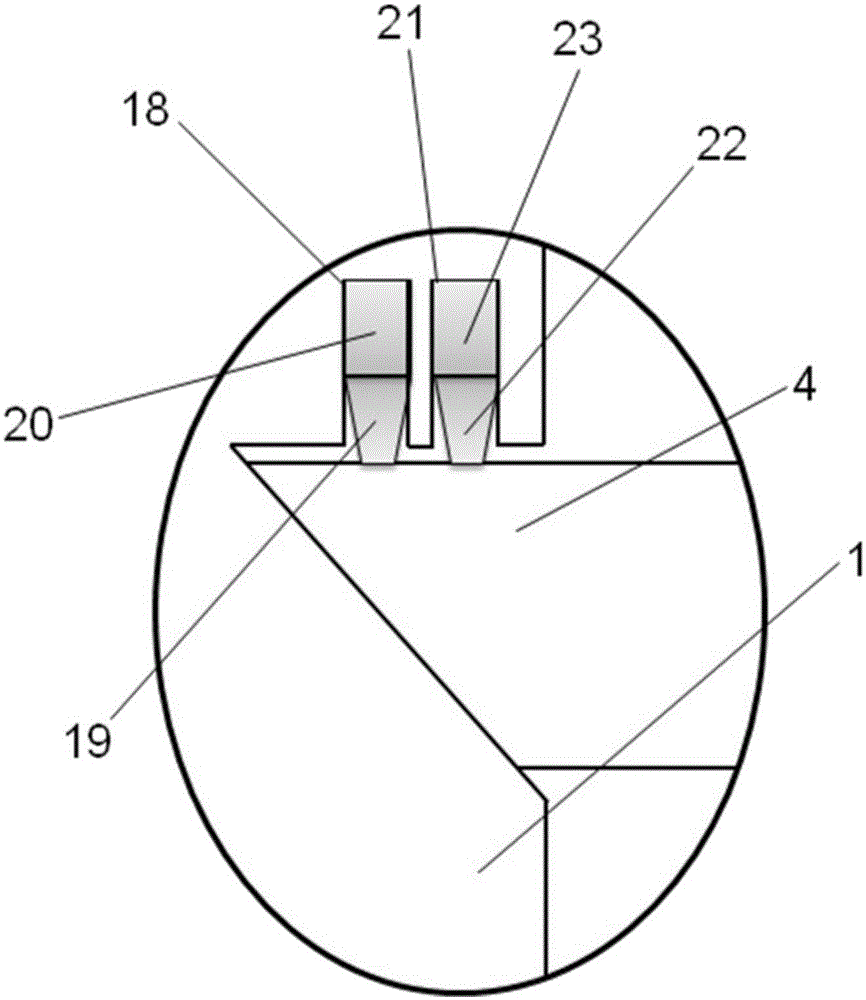

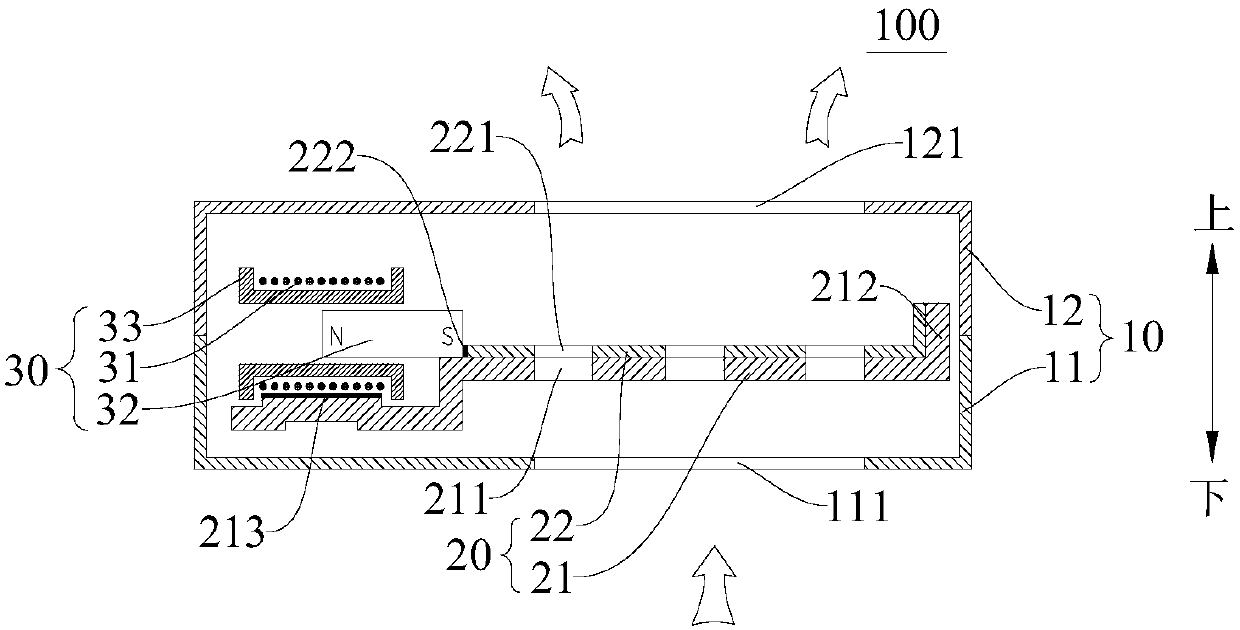

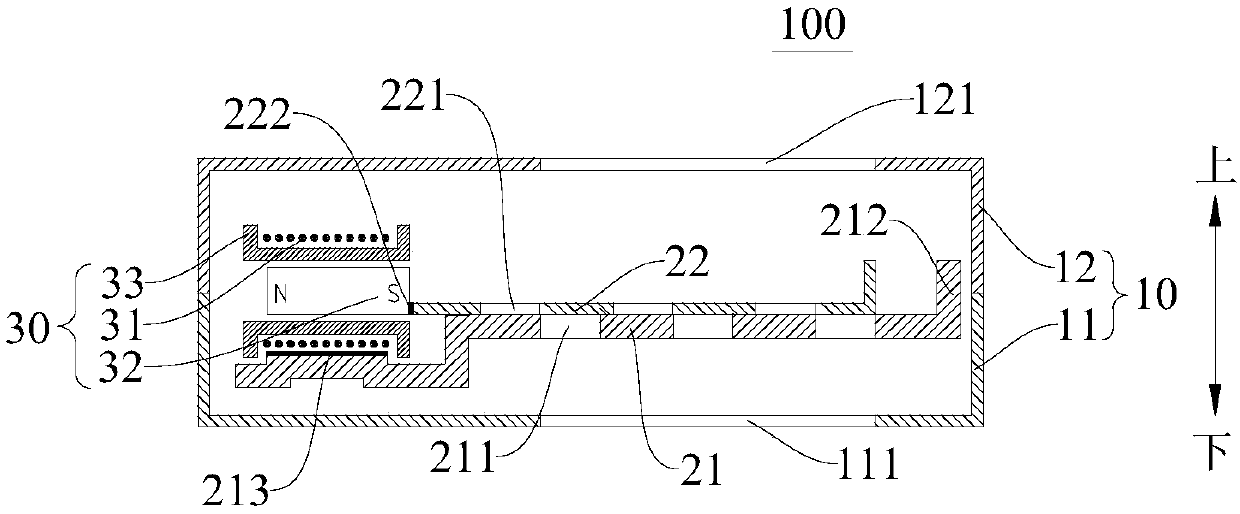

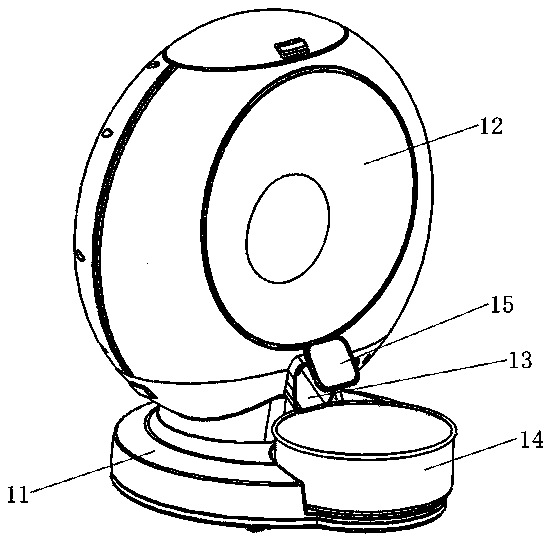

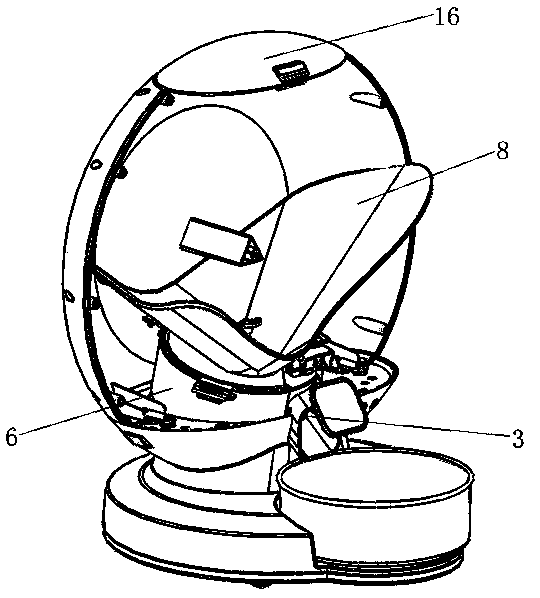

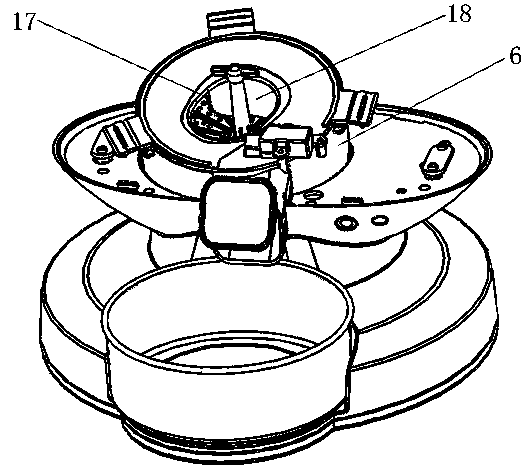

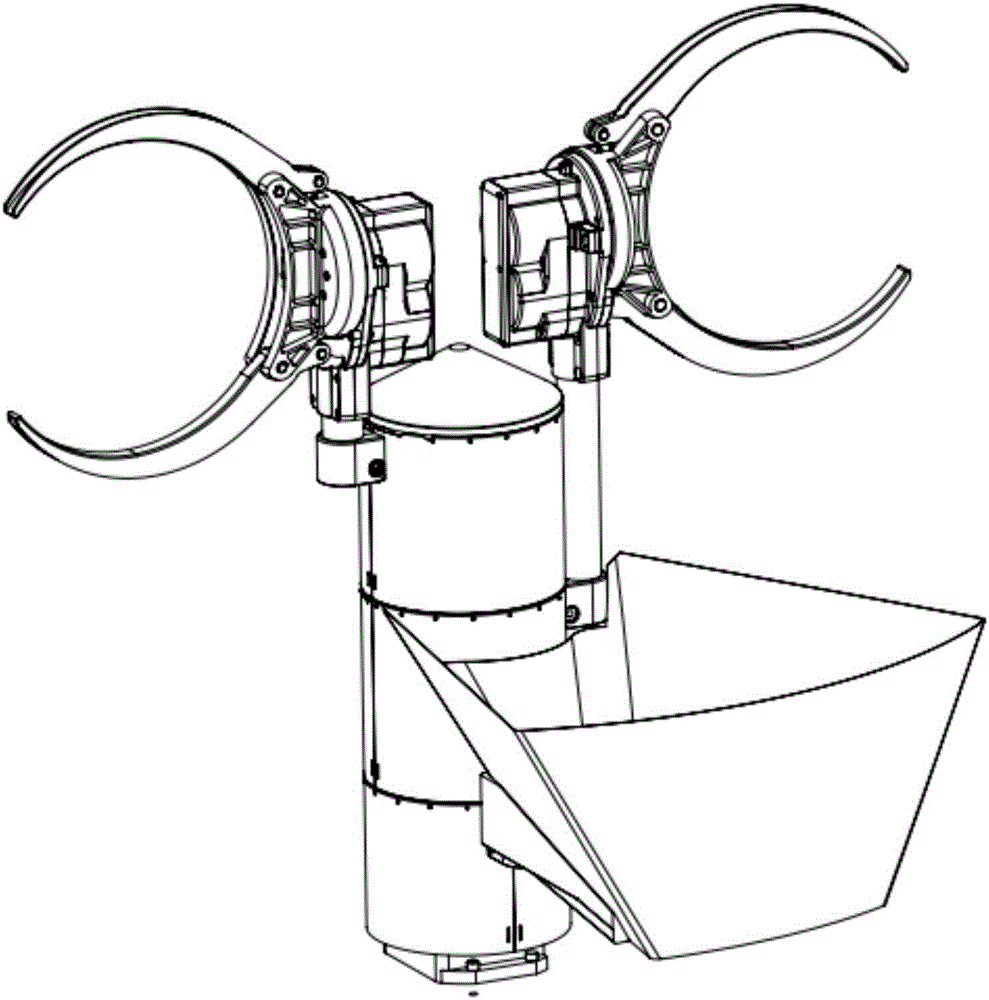

Intelligent pet amusing device for camera shooting of pets

PendingCN110050722ASolve the jam"Material jam" problem solvedTelevision system detailsAnimal feeding devicesEngineeringSilo

The invention discloses an intelligent pet amusing device for camera shooting of pets. The intelligent pet amusing device for the camera shooting of the pets comprises a charging barrel, a blanking device and a power device, wherein the blanking device is provided with a storage silo, a blanking channel and a feeding barrel; the storage silo is positioned at the upper part, and the feeding barrelis positioned at the lower part; the blanking channel is communicated with the storage silo and the feeding barrel; the storage silo is provided with a blanking rotor which can open and close the blanking channel; the blanking rotor is a soft rubber rotor; a block piece is arranged between the storage silo and the blanking channel; the block piece is soft rubber block piece; a blanking sensor is installed on the wall surface of the blanking channel. Due to the arrangement of the soft rubber blanking rotor and the soft rubber block piece, collision with food is avoided during blanking, and theproblem of material blockage is prevented. The intelligent pet amusing device for the camera shooting of the pets is longer in service life and easier to use.

Owner:GUANGDONG LIN SHENG INTELLIGENT TECH LTD

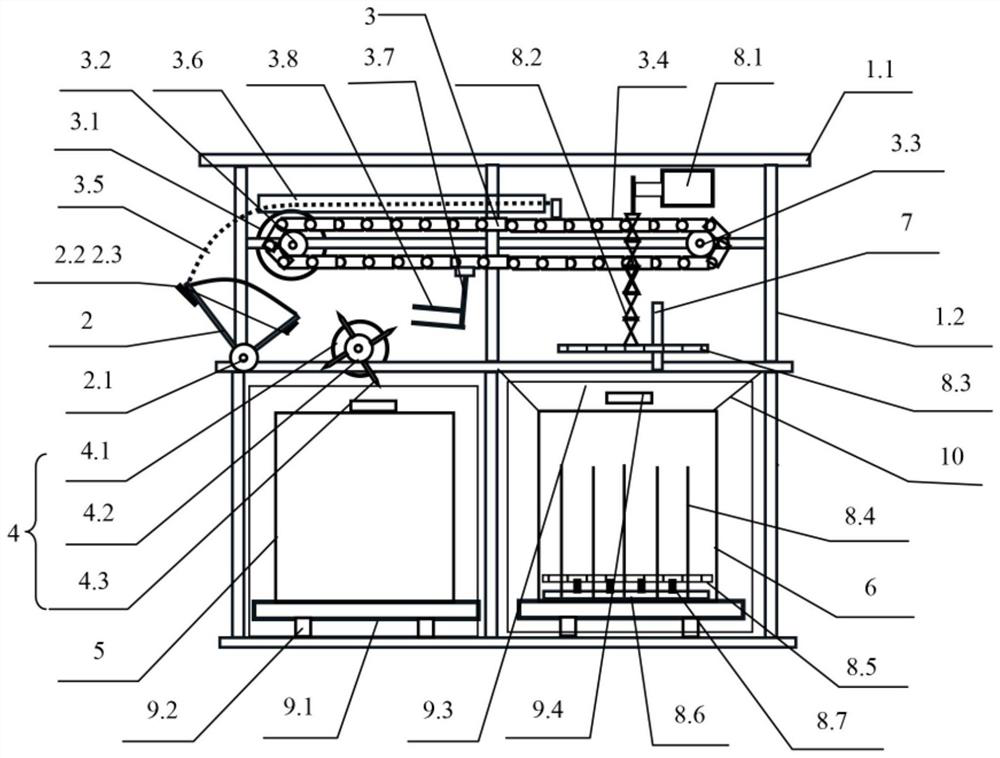

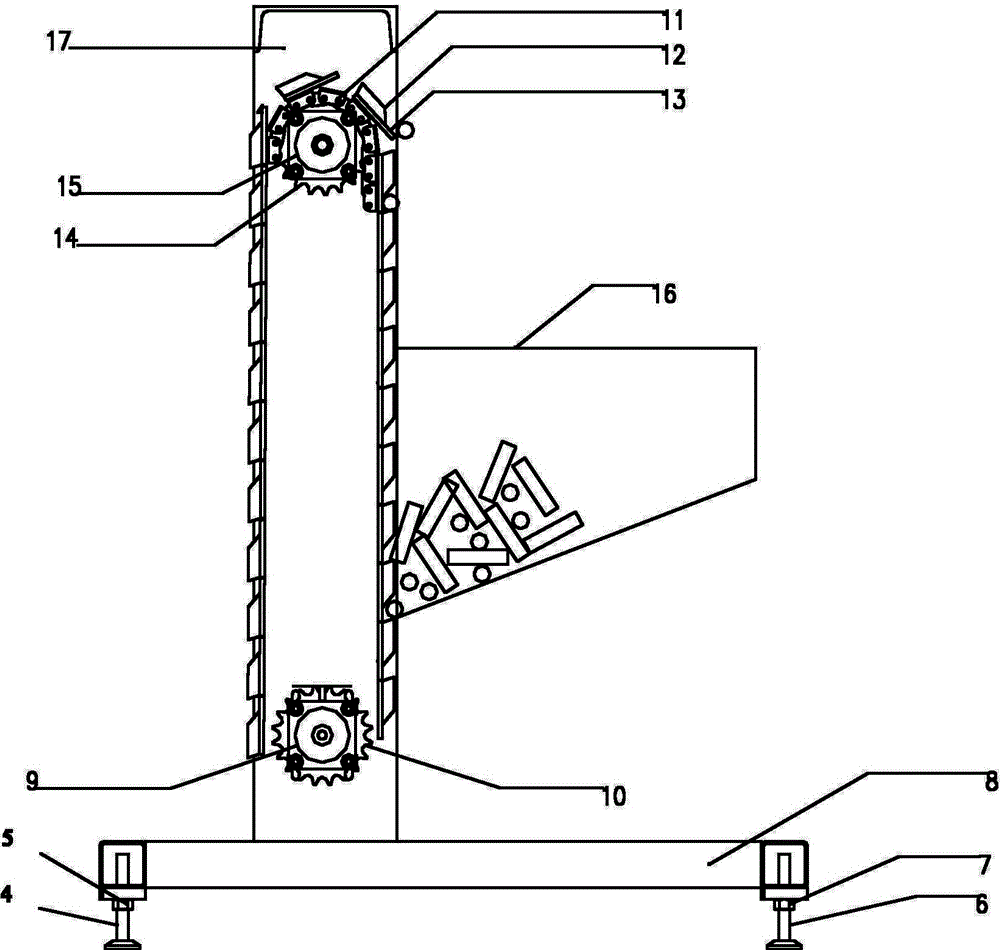

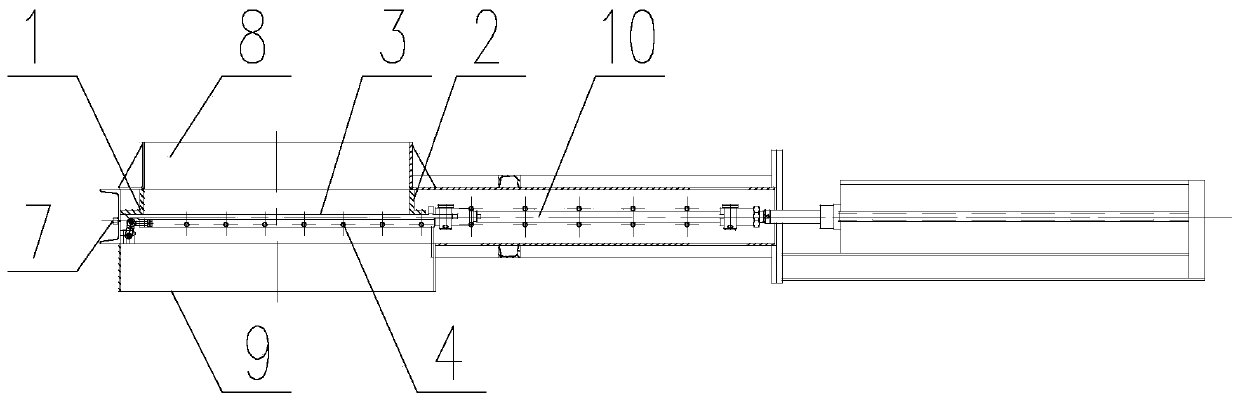

Discharging device for heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of junked tire

ActiveCN103672923ADoes not destroy physical propertiesFacilitate subsequent processingIncinerator apparatusDecompositionEngineering

The invention discloses a discharging device for a heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of a junked tire. The discharging device comprises a shell, a material laying plate used for containing the solid products, a chain board wheel transmission assembly, a driver and a plurality of material scraper blades. A discharge opening is formed in the shell. The material laying plate is movably arranged inside the shell. The chain board wheel transmission assembly is arranged inside the shell and placed above the material laying plate. The driver drives the chain board wheel transmission assembly to operate. The material scraper blades are respectively arranged on a transmission chain of the chain board wheel transmission assembly, the transmission chain drives the material scraper blades to move, and the material scraper blades push the solid products to the discharge opening. According to the discharging device, the traditional problems of material clamping, blocking and the like are solved, the continuous discharging purpose is achieved, the operating cost caused by abnormal maintenance and overhauling is greatly lowered, carbon black can be effectively prevented from being ground into powder, the potential risk caused by raised dust is avoided, and meanwhile the physical property of the solid products can not be damaged.

Owner:北京节净环保科技有限公司

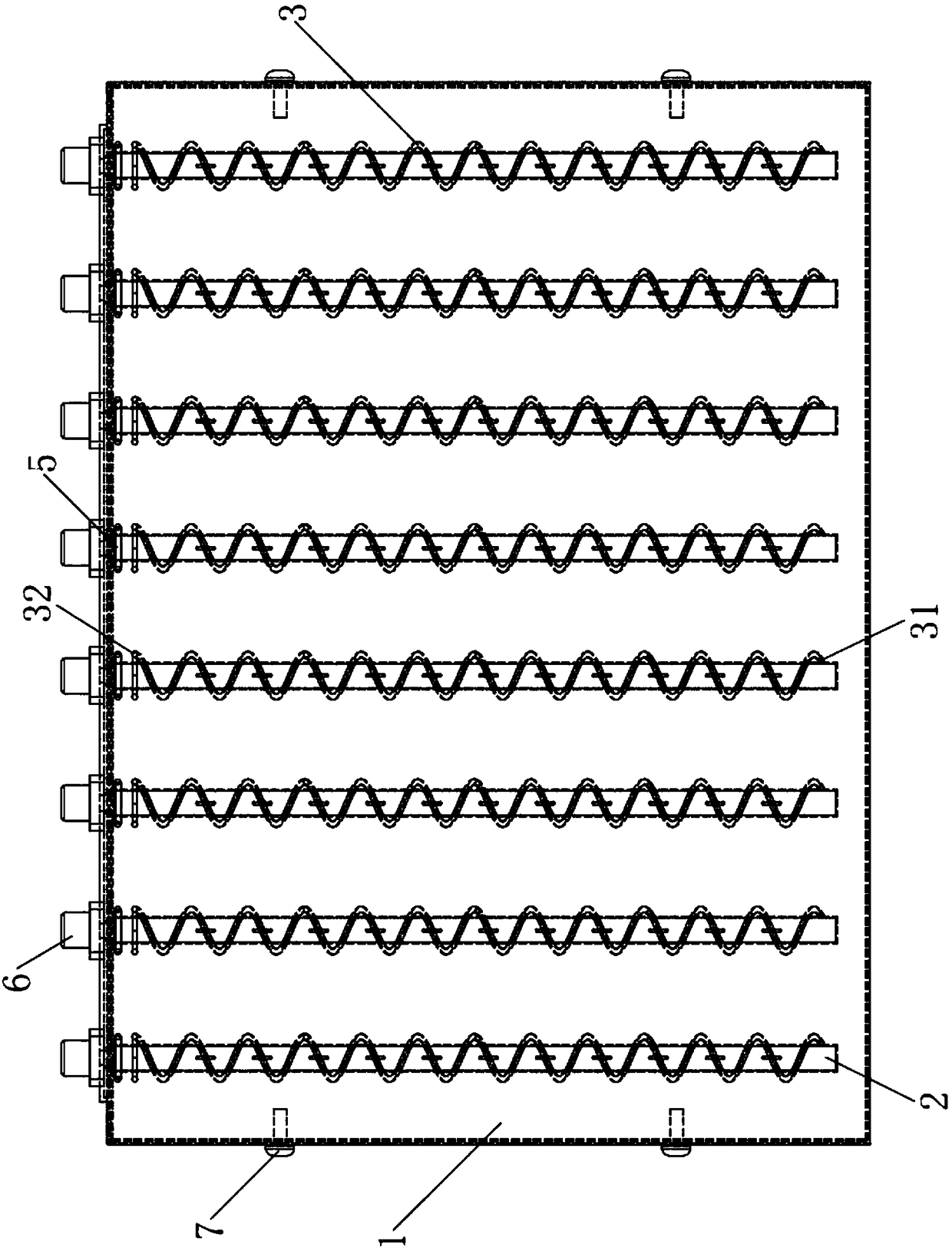

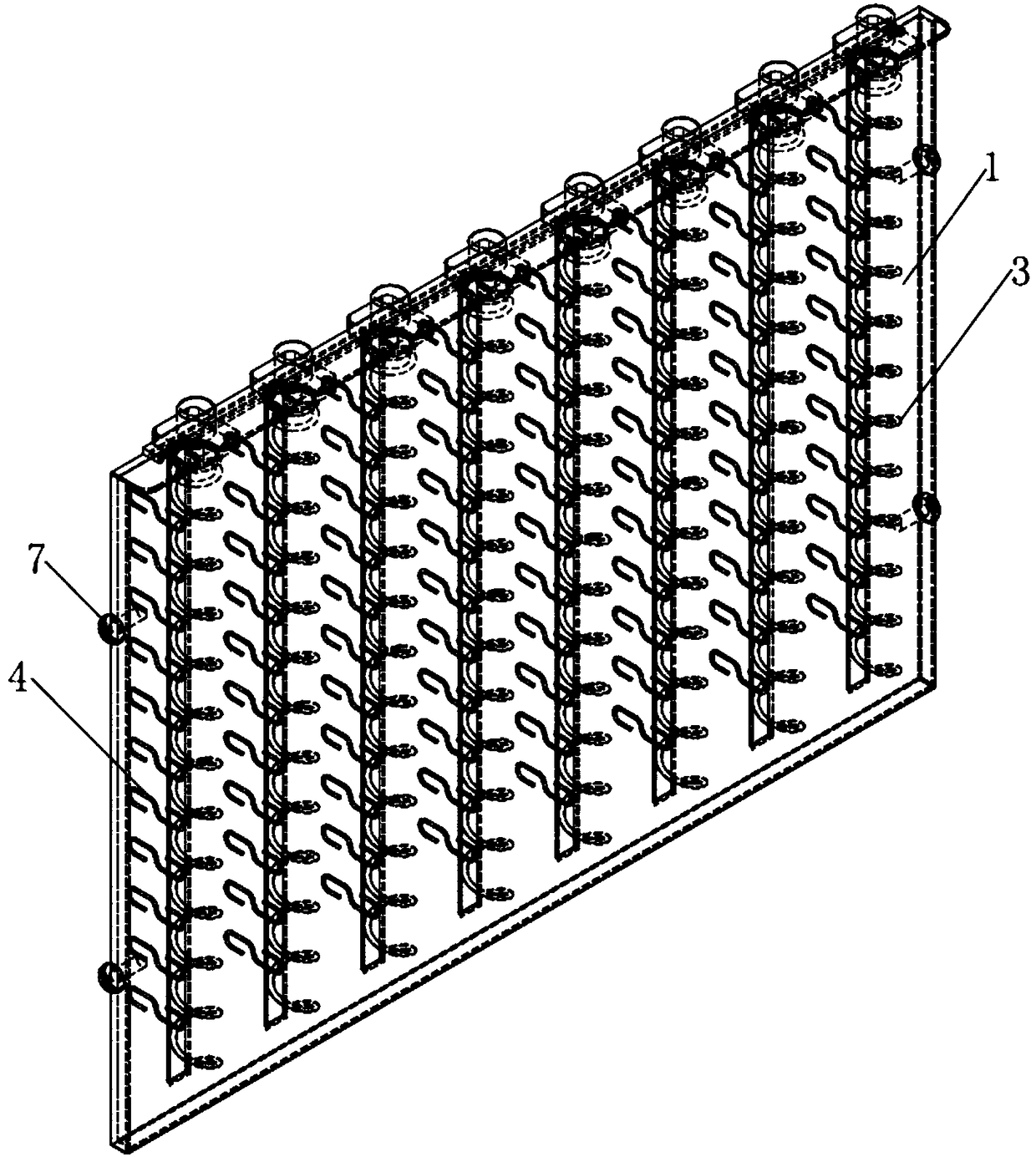

Automatic vending machine and delivery device thereof

PendingCN108492463ASolve the jamNot easy to slip offCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineDrive motor

The invention provides a delivery device of an automatic vending machine. The delivery device comprises a tray provided with a plurality of delivery channels; each delivery channel is provided with asending mechanism connected with a drive motor which is fixed on the tray; the delivery device further comprises hangers for hanging goods above the sending mechanisms correspondingly. Correspondingly, the invention further provides the automatic vending machine. With the arrangement, application range of the automatic vending machine to selling goods is expanded, jamming of the goods due to non-standard packages of the goods is avoided. Besides, the automatic vending machine is through from top to bottom and is easy to be filled with the goods; the goods are not easy to slip off during pushing of helix tubes; a direct-dropping manner is utilized so that dropping points of the goods are positioned accurately, which is different from the rolling or slipping delivery manner of conventional automatic vending machines (provided with spring delivery channels, S-shaped delivery channels or crawler-belt channels).

Owner:徐州峰行驱动技术有限公司

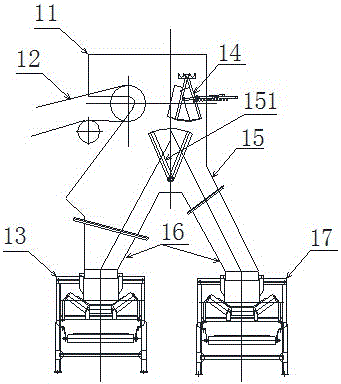

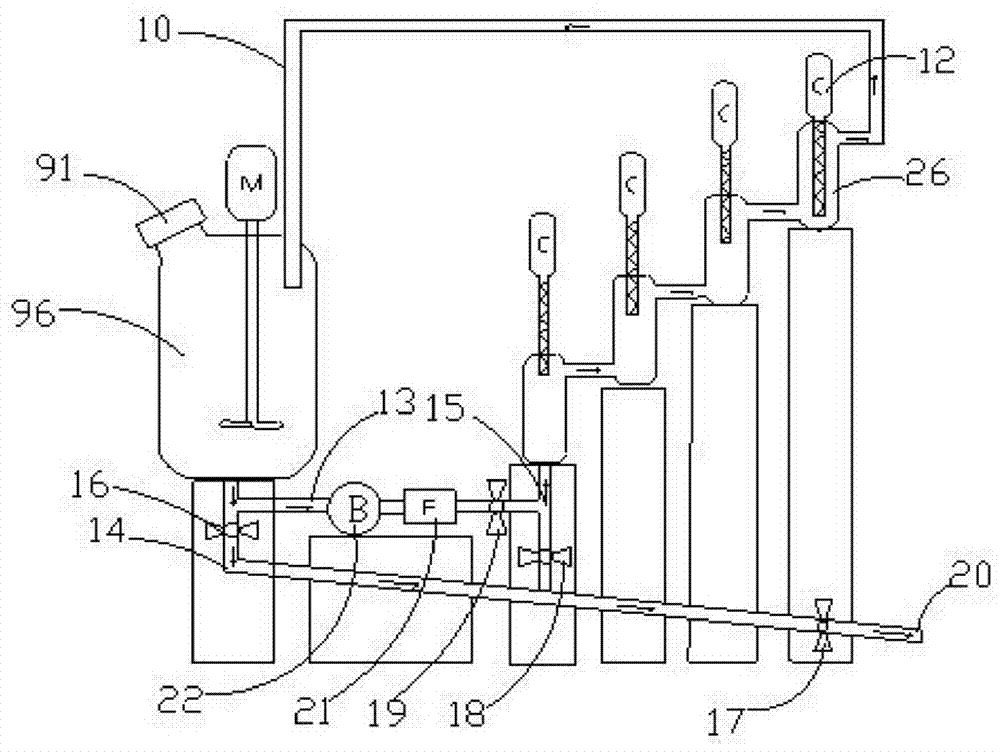

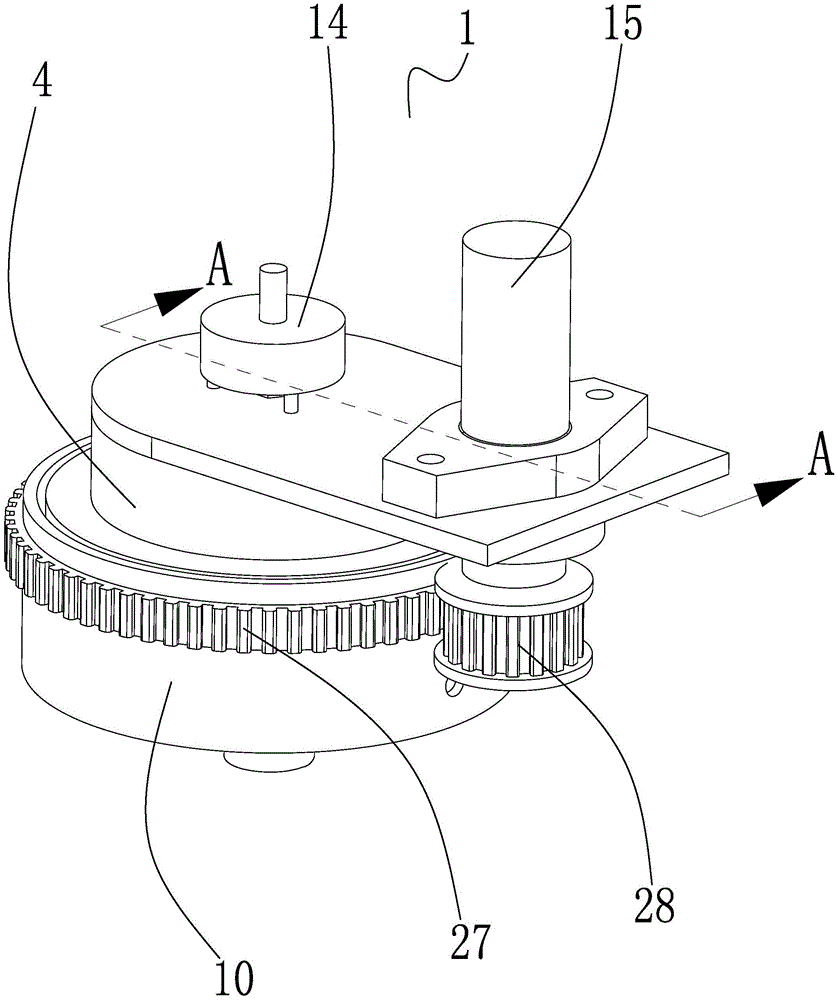

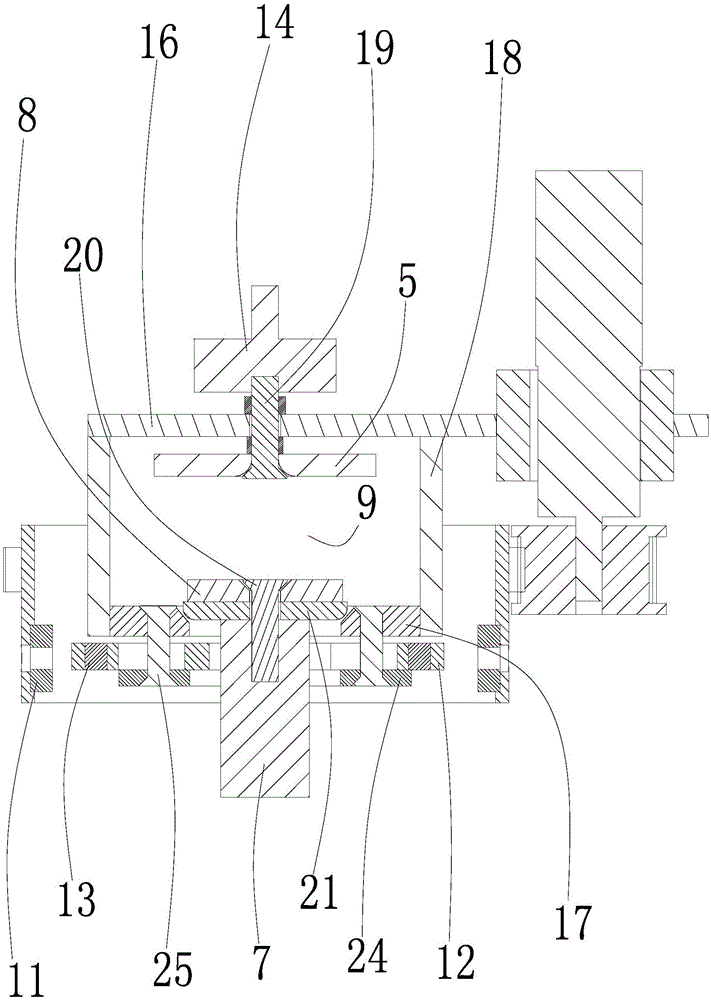

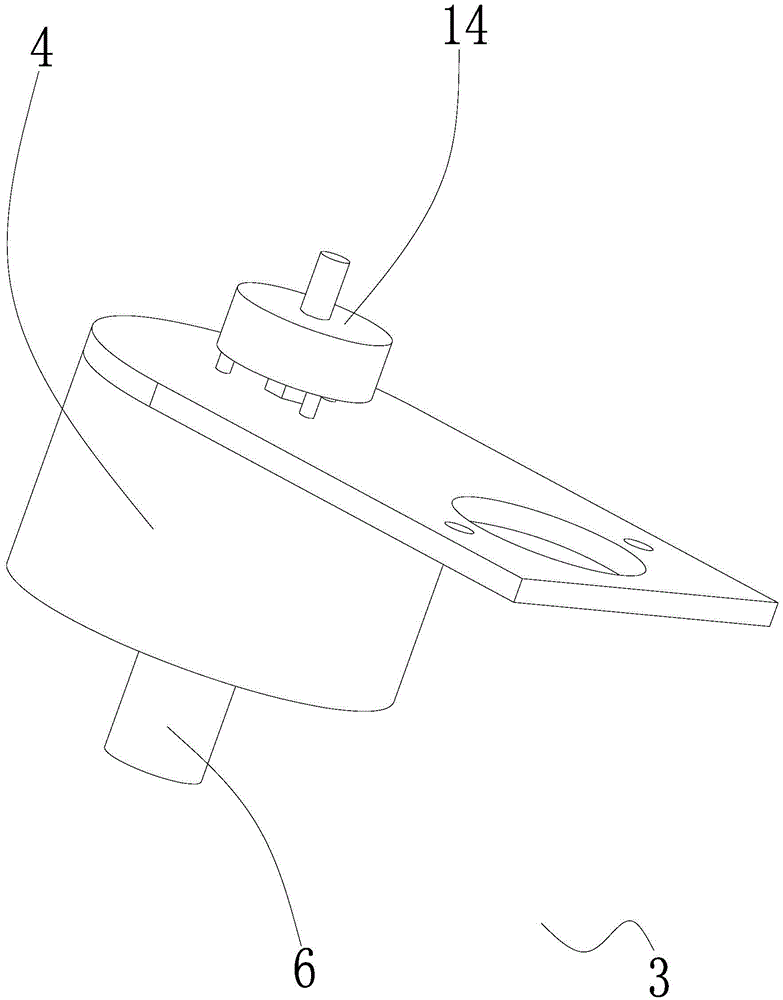

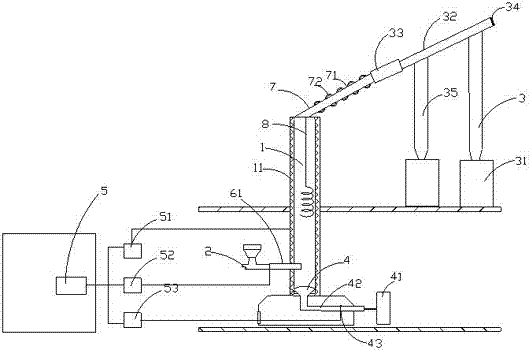

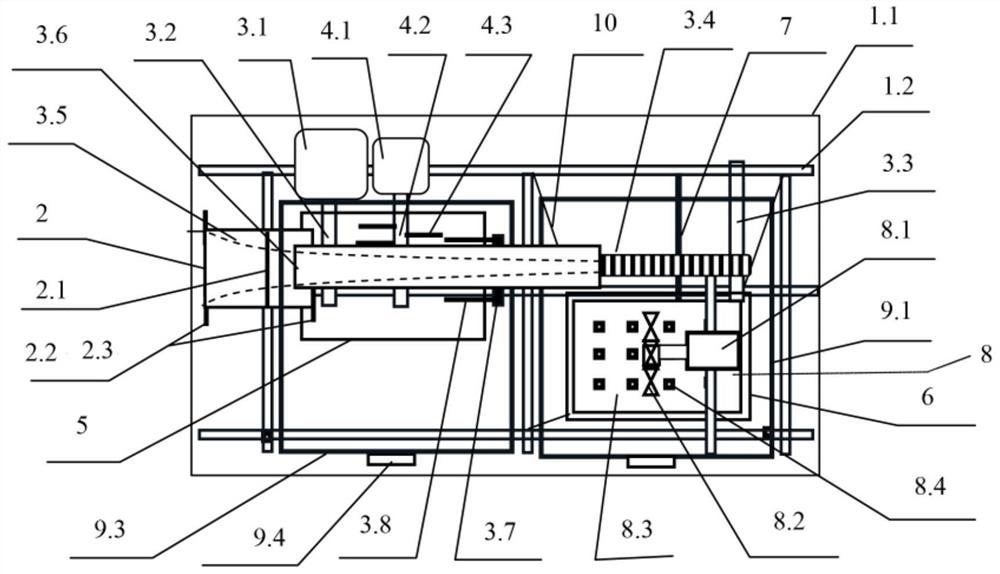

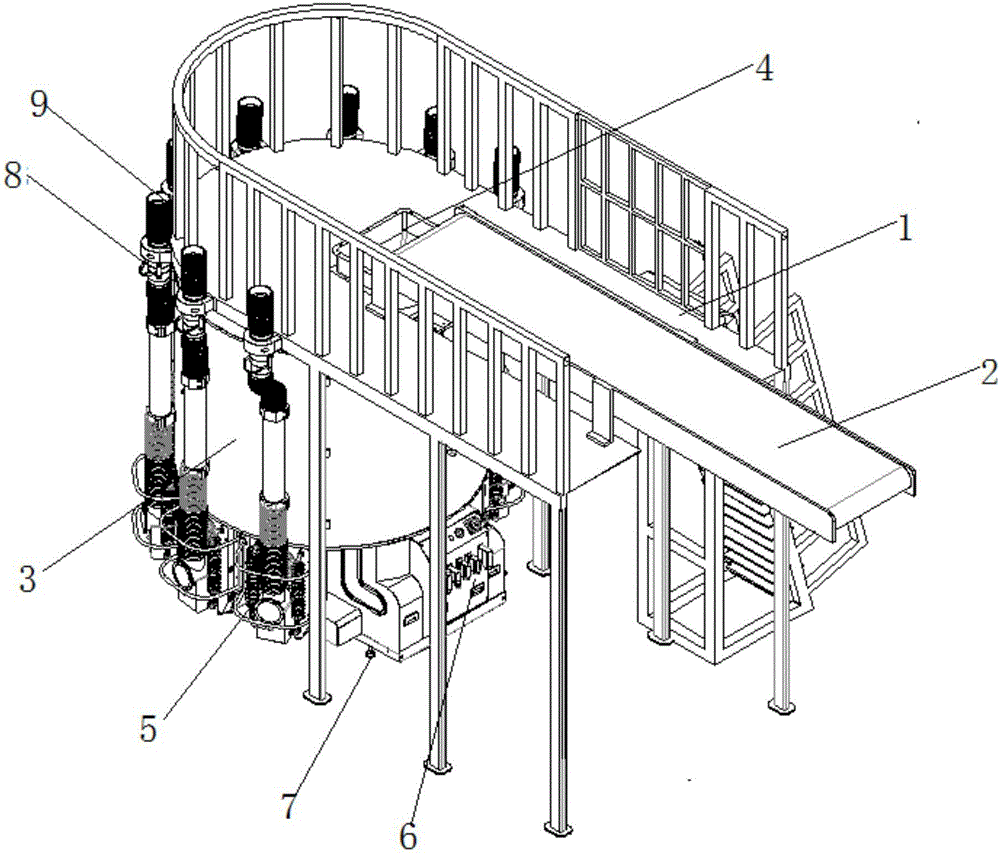

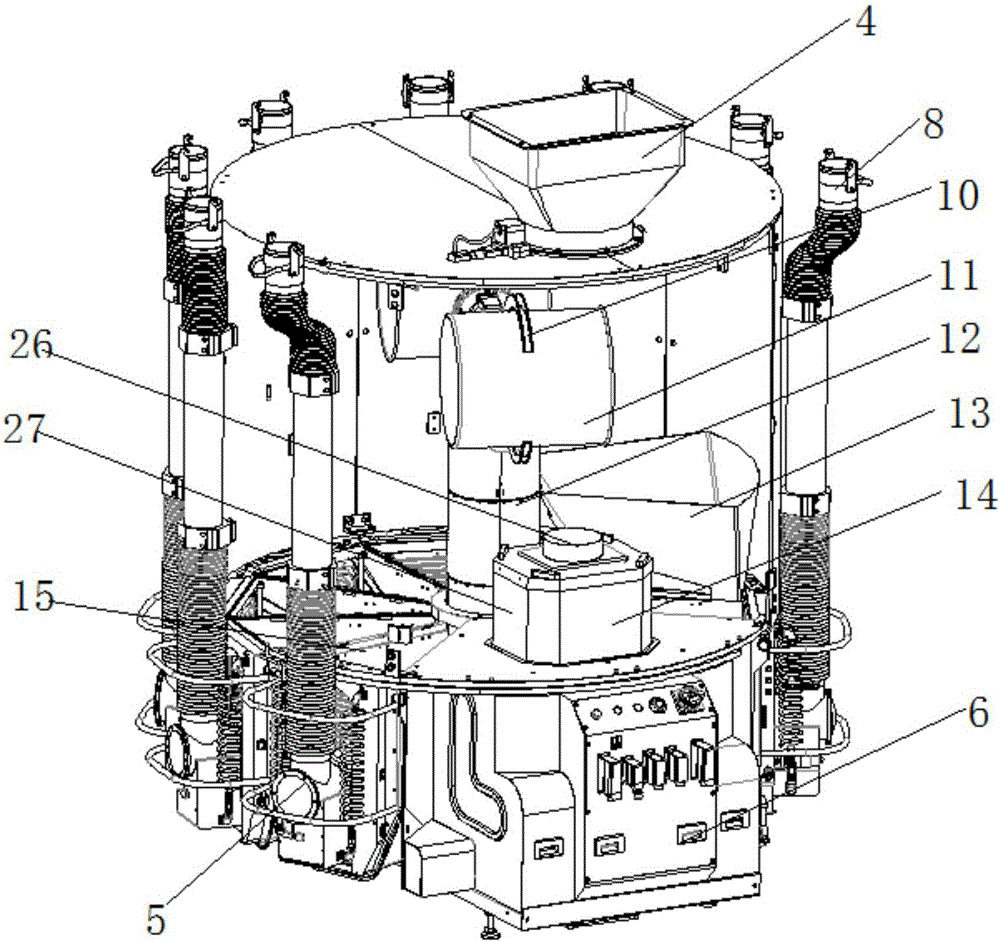

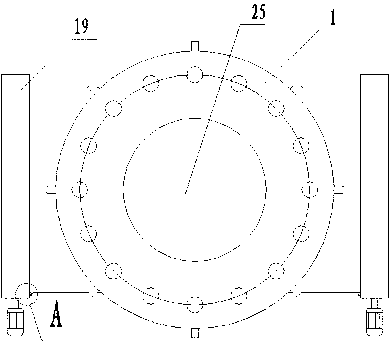

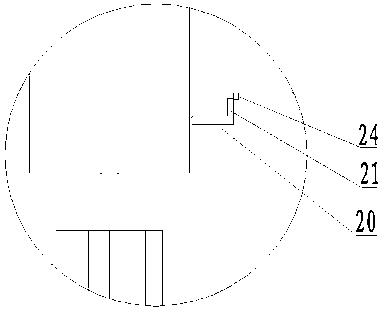

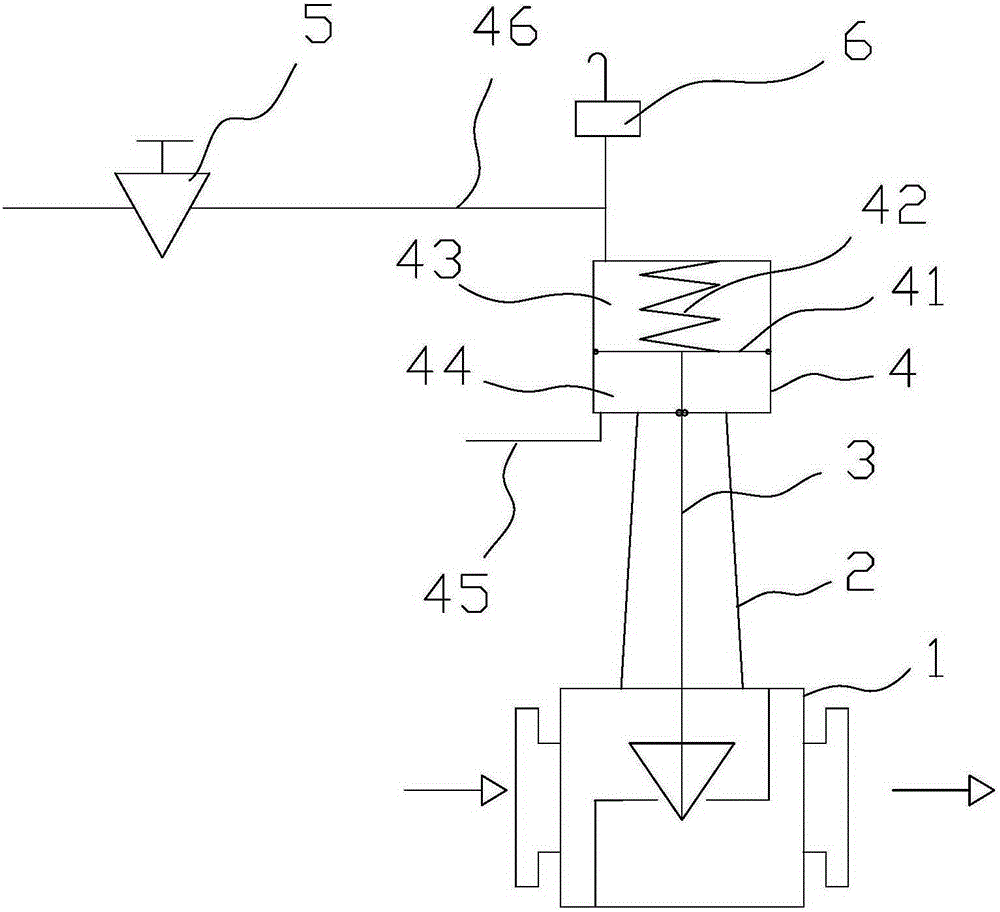

Rotating disk type feeding system of biomass burner

PendingCN104165376APrevent flashbackAdjust the feeding speed at any timeLump/pulverulent fuel feeder/distributionCombustionDrive shaft

The invention provides a rotating disk type feeding system of a biomass burner. The rotating disk type feeding system of the biomass burner comprises a material rack, a speed governor, a feeding disk and a discharging disk. The feeding disk and the discharging disk are connected and fixed to the material rack through a transmission shaft, a through hole in the middle of the feeding disk and a through hole in the middle of the discharging disk. A round through hole is formed in the middle of the feeding disk, and an upper bearing end cover is arranged on the through hole. A ring is welded to one side of the discharging disk, and a rotating disk is arranged in the ring. Through the rotating disk type feeding system, materials can be fed evenly and continuously, and the feeding speed can be adjusted at any time; compared with traditional spiral feeding, very large friction force cannot be generated, accumulation is avoided, the material jamming problem can be solved, the backfire phenomenon of a hopper in combustion can be effectively avoided, and the rotating disk type feeding system of the biomass burner runs safely and reliably.

Owner:ZHEJIANG MEDITERRANEAN NEW ENERGY EQUIP

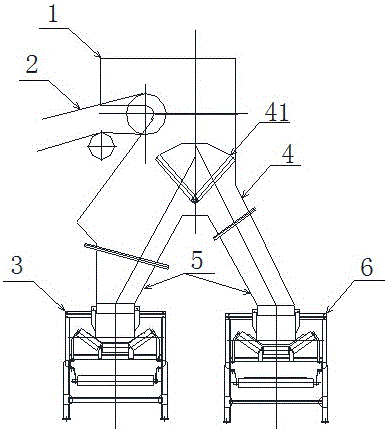

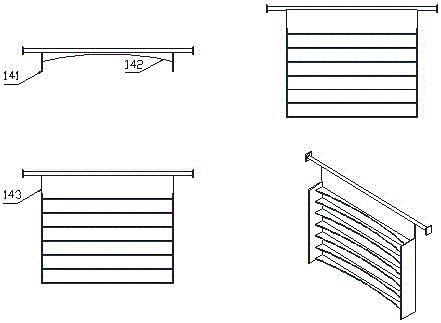

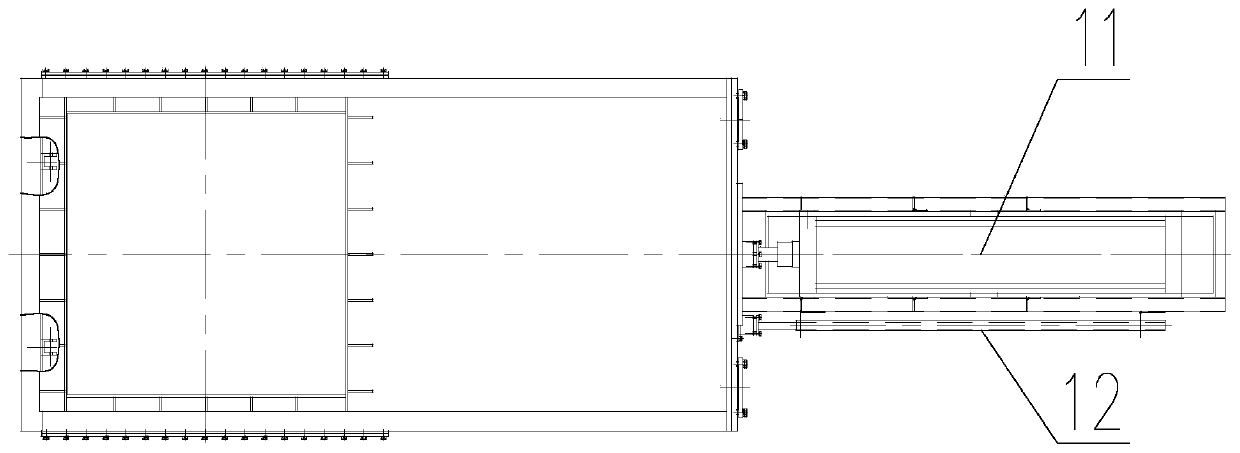

System and method for three-way material distribution of belt conveyor

A system for three-way material distribution of a belt conveyor comprises an upstream belt conveyor, a downstream belt conveyor I, a downstream belt II, a housing, a stream guide baffle, a three-way material distributor, chutes and a three-way material distributor turning flip plate, wherein the upstream belt conveyor is connected to one side of the upper end of the housing; the three-way material distributor is disposed under the housing; the three-way material distributor flip plate is fixed in the three-way material distributor; the lower end of the three-way material distributor flip plate is connected to the upper end of the middle part of a fork hole in the three-way material distributor by a rotation shaft; two fork tubes of the three-way material distributor flip plate are connected to corresponding chutes respectively; the downstream belt conveyor I and the downstream belt II are disposed on the bottom ends of the two chutes respectively; the stream guidance baffle is installed in the housing; lateral baffles are installed on two sides of the stream guidance baffle; at least two horizontal baffles are installed on the stream guidance baffle; and the middle part of each horizontal baffle is lower, and two ends of the horizontal baffle are higher. The invention provides the system and method for the three-way material distribution of the belt conveyor. The system and the method solve the problems in the prior art that material sedimentation and flip plate jamming take place in a three-way material distribution system of a belt conveyor.

Owner:NANJING MEISHAN METALLURGY DEV +2

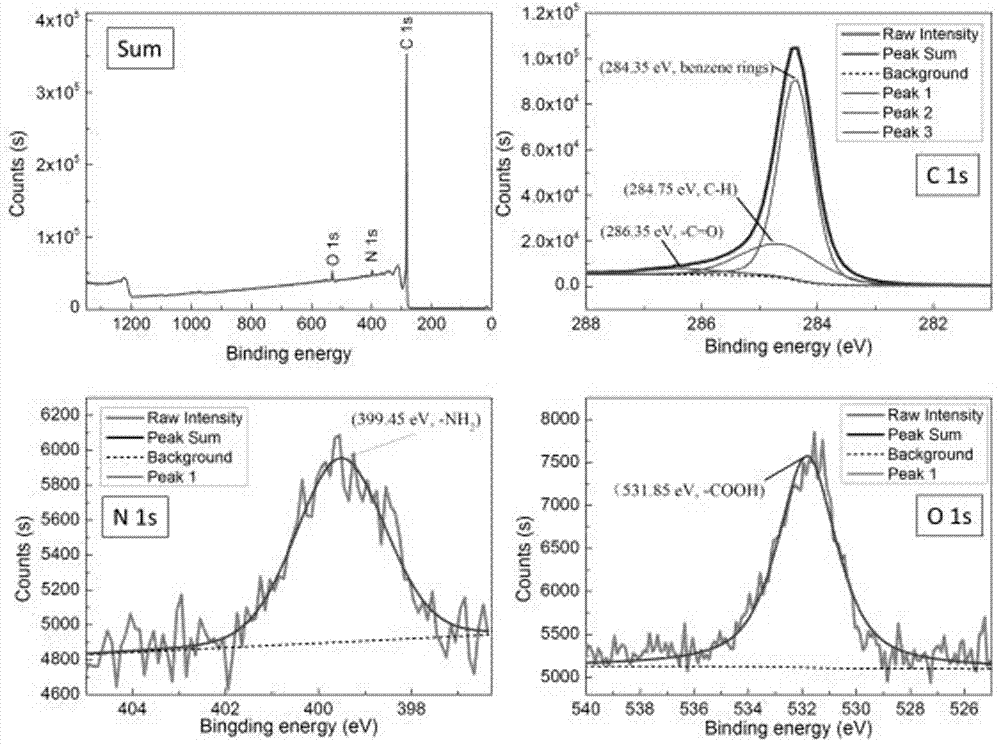

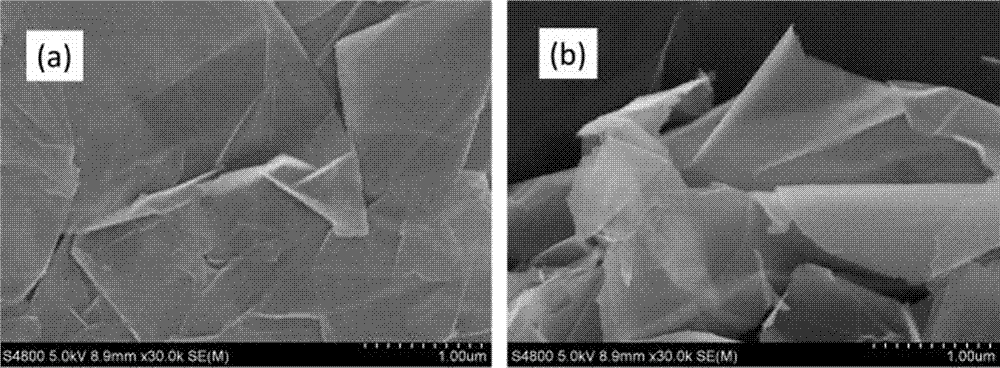

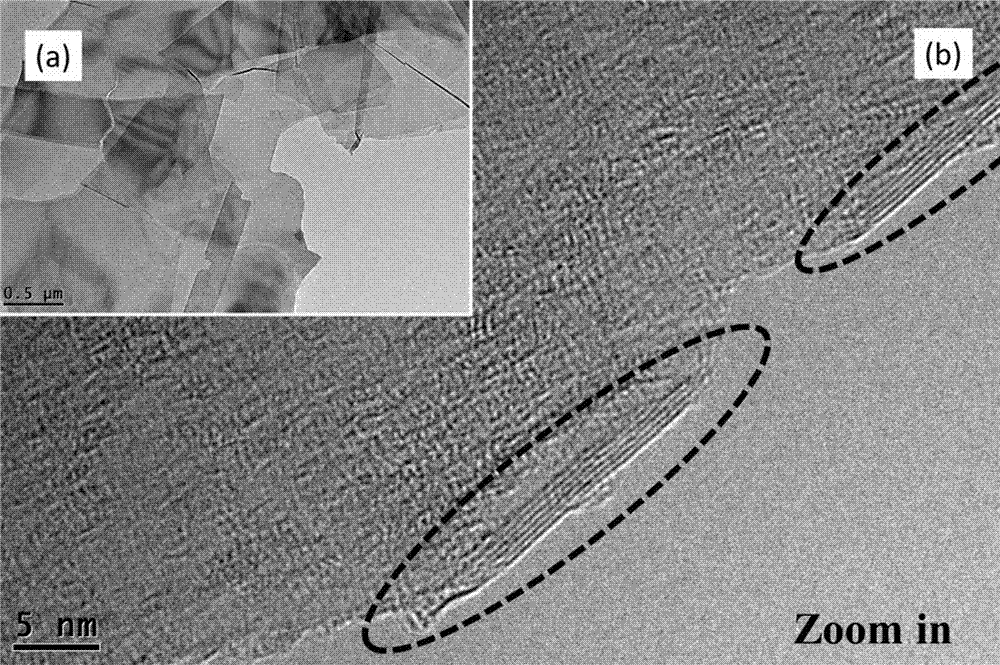

Method for preparing graphene from microcrystalline graphite

The invention belongs to the technical field of preparation of materials and particularly relates to a method for preparing graphene from expanded graphite. Microcrystalline graphite serving as a raw material is subjected to first chemical intercalation treatment, first high-temperature expansion treatment, second intercalation treatment and second high-temperature expansion treatment sequentially, second expanded microcrystalline graphite is obtained and subjected to ultrasonic treatment twice, and a peeling material is obtained and subjected to press filtering, separation and washing, and graphene is obtained. According to the method, the microcrystalline graphite is taken as the raw material, the production technology process is short, and the method is low in cost, produces no sulfur and can be used for mass production of graphene materials.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

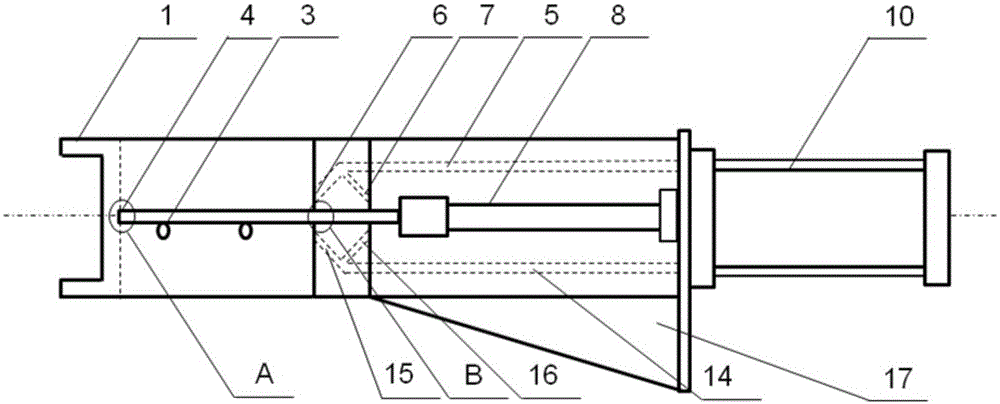

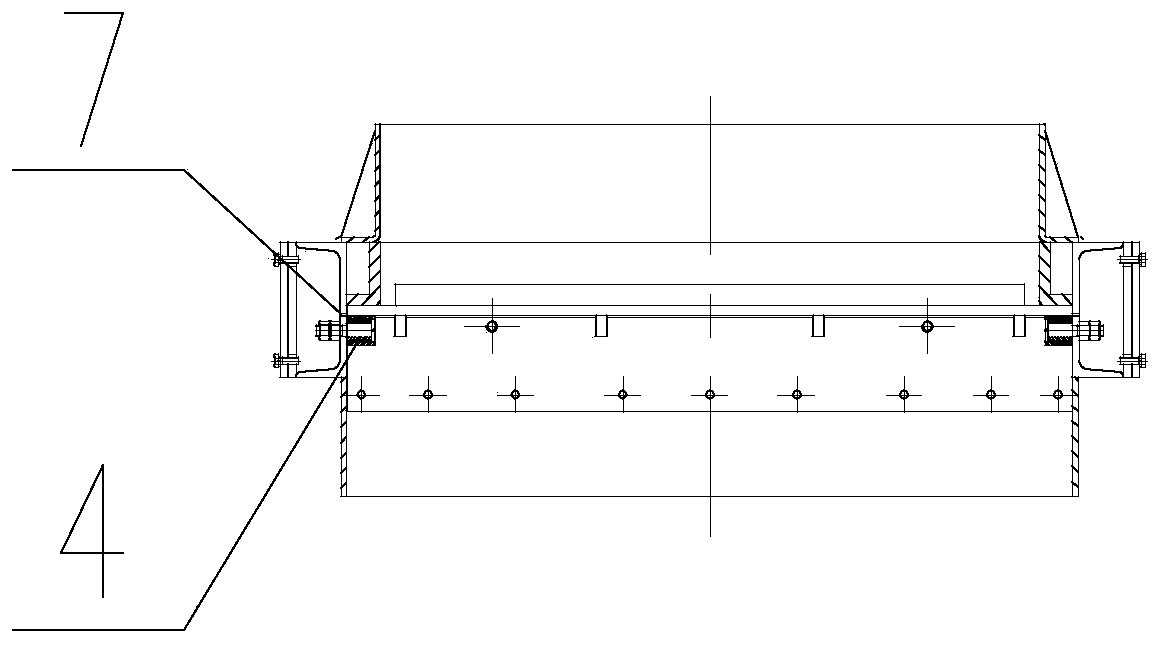

Anti-jamming pneumatic slide plate gate of pulverized coal pipeline and work method based on anti-jamming pneumatic slide plate gate

ActiveCN105135034ASolve the jamAvoid influenceOperating means/releasing devices for valvesSlide valveAnti jammingCoal pipeline

The invention discloses an anti-jamming pneumatic slide plate gate of a pulverized coal pipeline and a work method based on the anti-jamming pneumatic slide plate gate. The anti-jamming pneumatic slide plate gate comprises a rectangular frame which is connected with the pulverized coal pipeline through fixing bolts, wherein a slide plate which can block airstreams in the pulverized coal pipeline is arranged in the center of the rectangular frame; the rectangular frame comprises a front side frame, a rear side frame, a left side frame and a right side frame; the left and right side frames are separately provided with a sliding rail, so that the slide plate can slide along the sliding rails of the rectangular frame; the slide plate is connected with a slide plate draft device; asymmetrical chevron air passages are arranged above the rear side frame; symmetrical chevron air passages are arranged below the rear side frame; the air passages are all connected with compressed air pipelines; the compressed air pipelines are connected with a compressed air source; electromagnetic valves are arranged on the compressed air pipelines; the electromagnetic valves are connected with compressed air control systems; and in processes of inserting the slide plate into the rectangular frame and pulling the slide plate out of the rectangular frame, dust accumulated on the upper part, the lower part, the front part and the rear part of the slide plate is cleaned through airstreams in the compressed air pipelines, so that the problem of jamming of the slide plate caused by large friction force of the dust is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

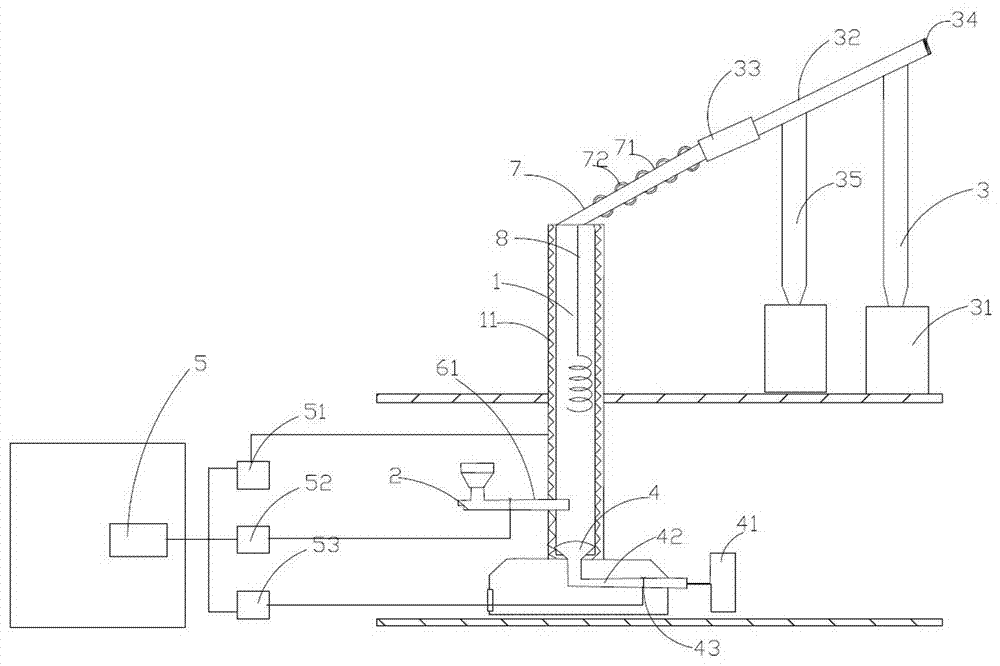

Batch preparation method of graphene and production system therefor

InactiveCN107500279AImprove stripping rateImprove stabilitySingle layer grapheneGraphiteCvd graphene

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

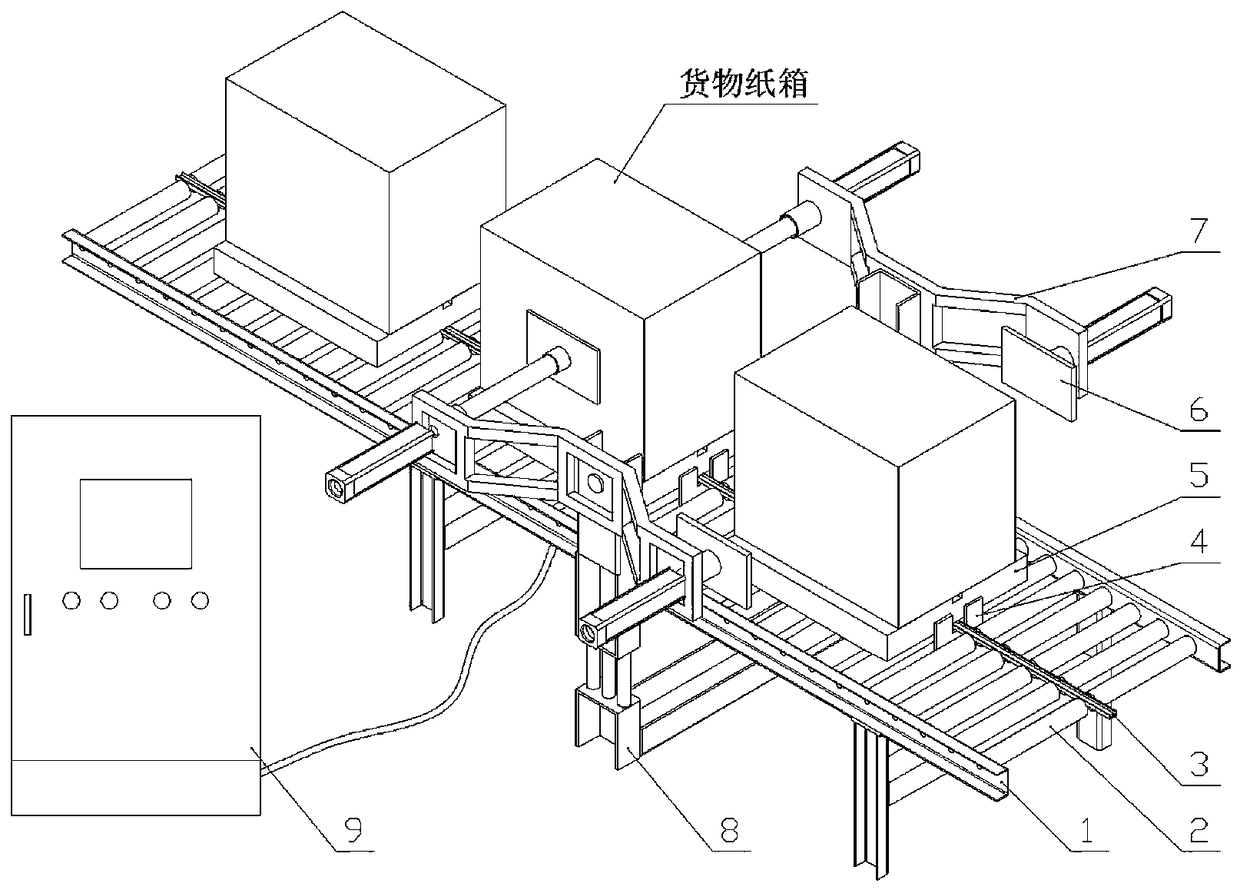

Conveying device capable of achieving automatic turnover of box type goods

InactiveCN108455244ARich varietySolve the jamConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a conveying device capable of achieving automatic turnover of box type goods, and particularly relates to the technology of conveying and automatic turnover of goods irradiatedby industrial electron accelerators. The conveying device is characterized by comprising a conveying line support, accumulation and release type rollers, a guide groove, tray baffles, goods trays, box chucks, turnover arms, a turnover support and a control box. The conveying line support is used for allowing other parts to be installed and bearing the parts, so that a conveying face is formed. Aplurality of accumulation and release type rollers are installed on transverse beams of the conveying line support. The guide groove is fixed to the center of the conveying face of the conveying linesupport. The tray baffles and driving cylinders of the tray baffles are installed on the conveying line support. The box chucks and cylinders at the rear ends of the box chucks are installed on the turnover arms. The turnover support strides over the two sides of a conveying line machine frame to be fixed to the ground, and is used for achieving installation of the turnover arms. The conveying device has the following advantages that the irradiated goods can smoothly move forward, packages can be free of wear, and 180-degree selective automatic turnover of the box type goods can be achieved.

Owner:SHANDONG LANFU HIGH ENERGY PHYSICS TECH CO LTD

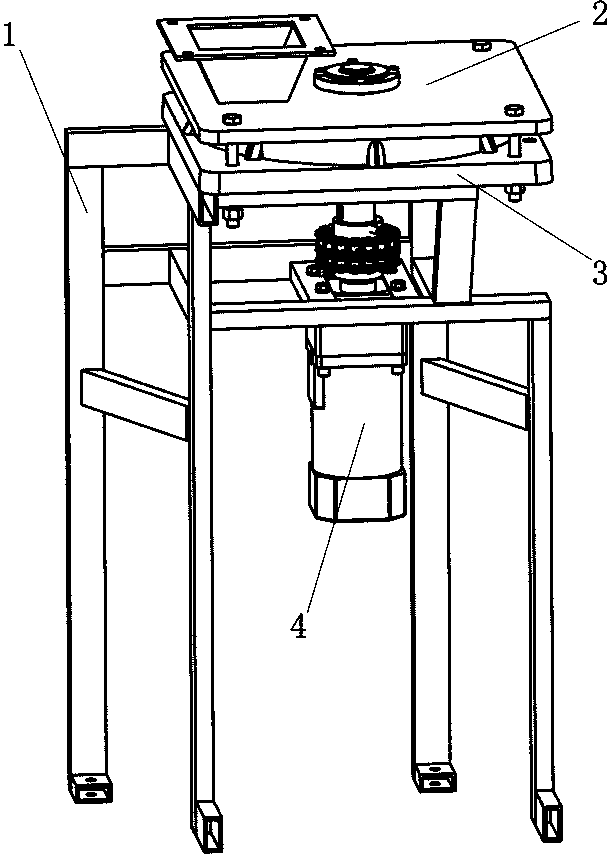

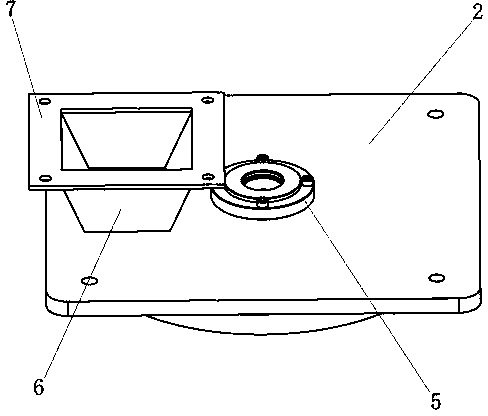

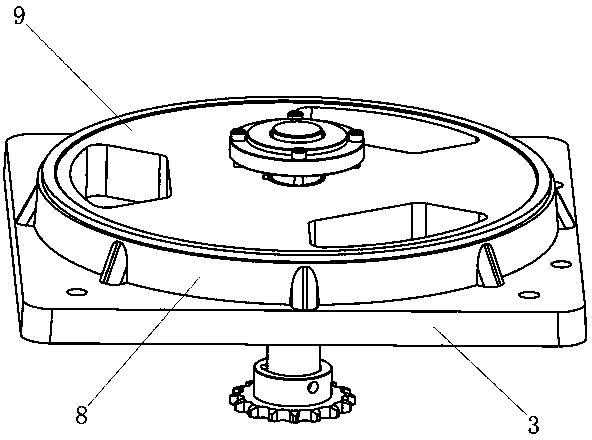

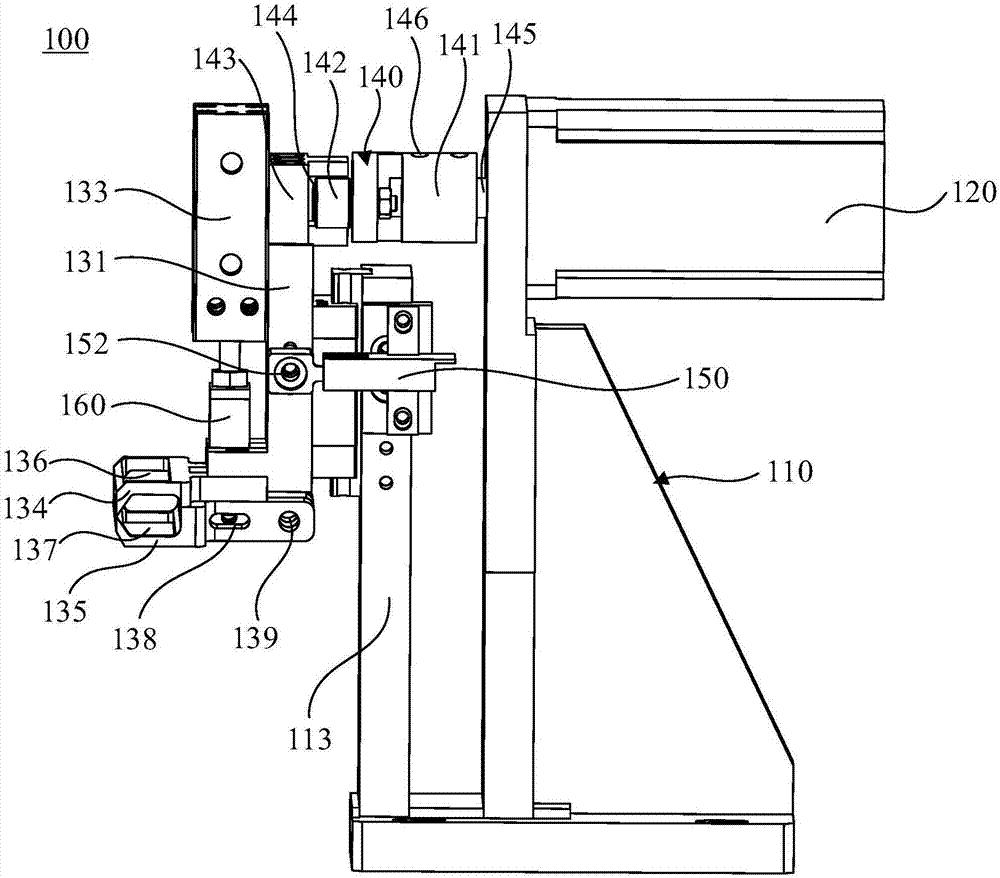

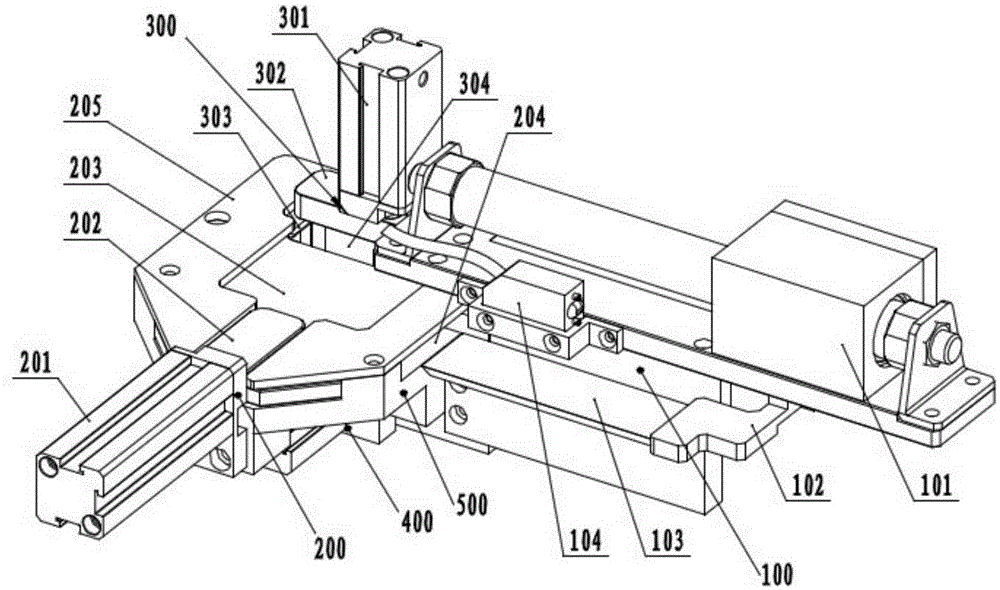

Compliant device and method for realizing peg-in-hole assembly

InactiveCN105522369ASolve the jamImprove quality and efficiencyMetal working apparatusEngineeringPeg in hole

The embodiment of the invention provides a compliant device for realizing peg-in-hole assembly and a method for realizing peg-in-hole assembly through the compliant device. The compliant device comprises an active compliance part and a passive compliance part, peg-in-hole assembly is realized through the driving effect of magnetic field force to an assembly shaft, the jamming problem generated when assembly hole walls are smooth or rough is mainly solved, the magnetic field force is adopted in the assembly work, the shortcomings of traditional position control in high-quality and high-accuracy assembly work are overcome, and the assembly quality and the work efficiency are greatly improved.

Owner:中山市工业技术研究中心 +1

Breaking device

ActiveCN107088604ASolve the jamQuickly move outStripping-off devicesEjection devicesWaste management

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

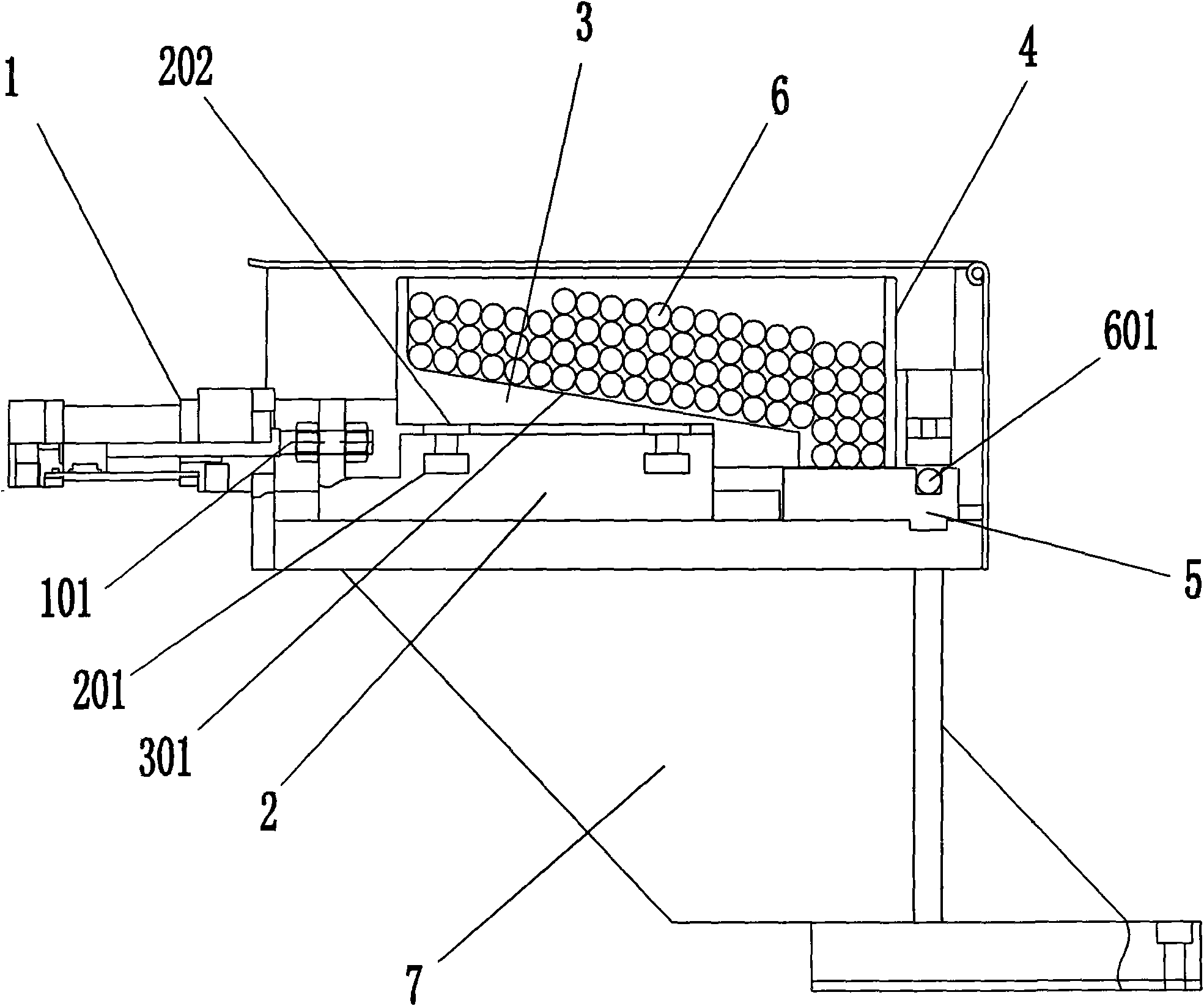

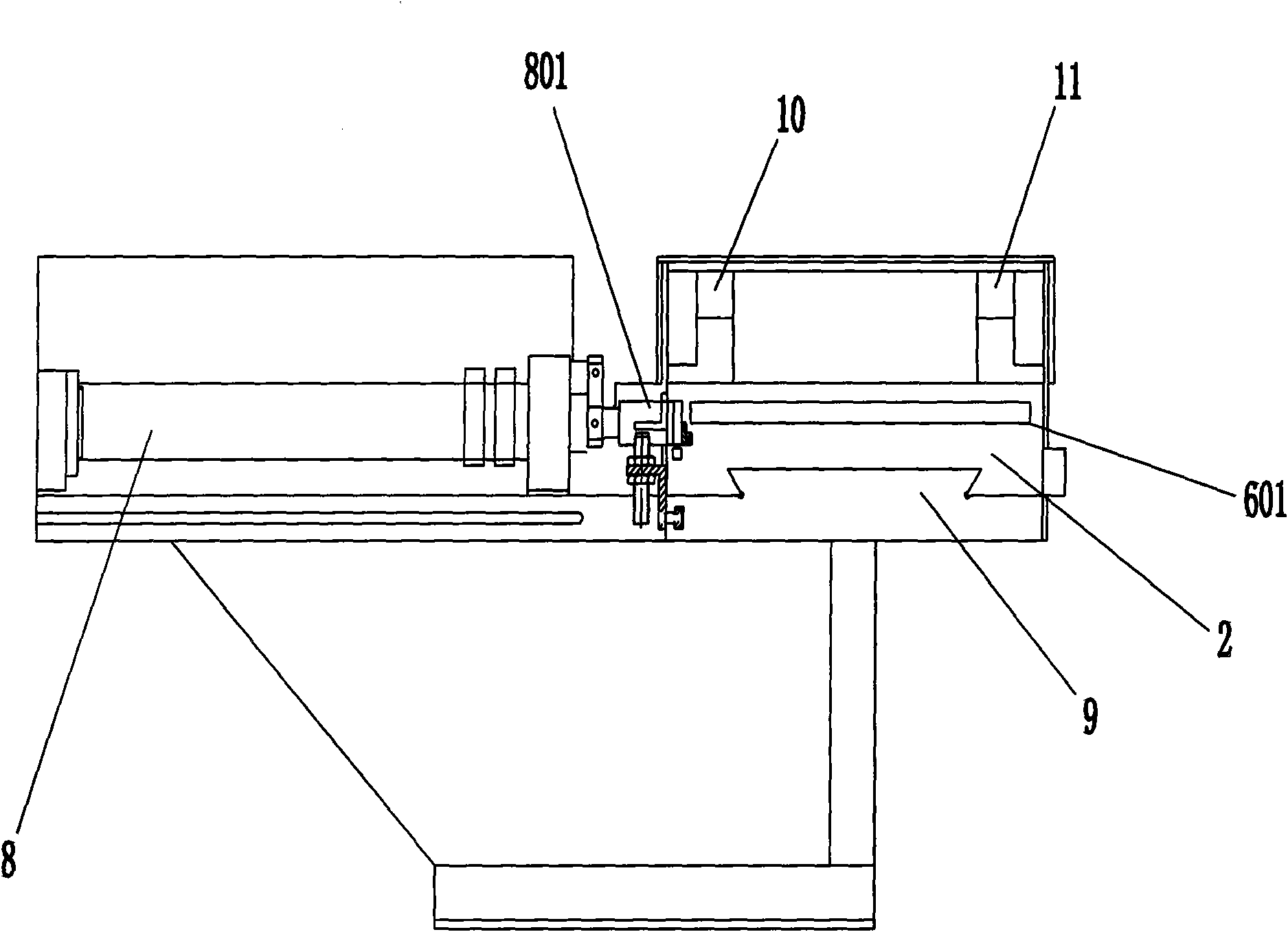

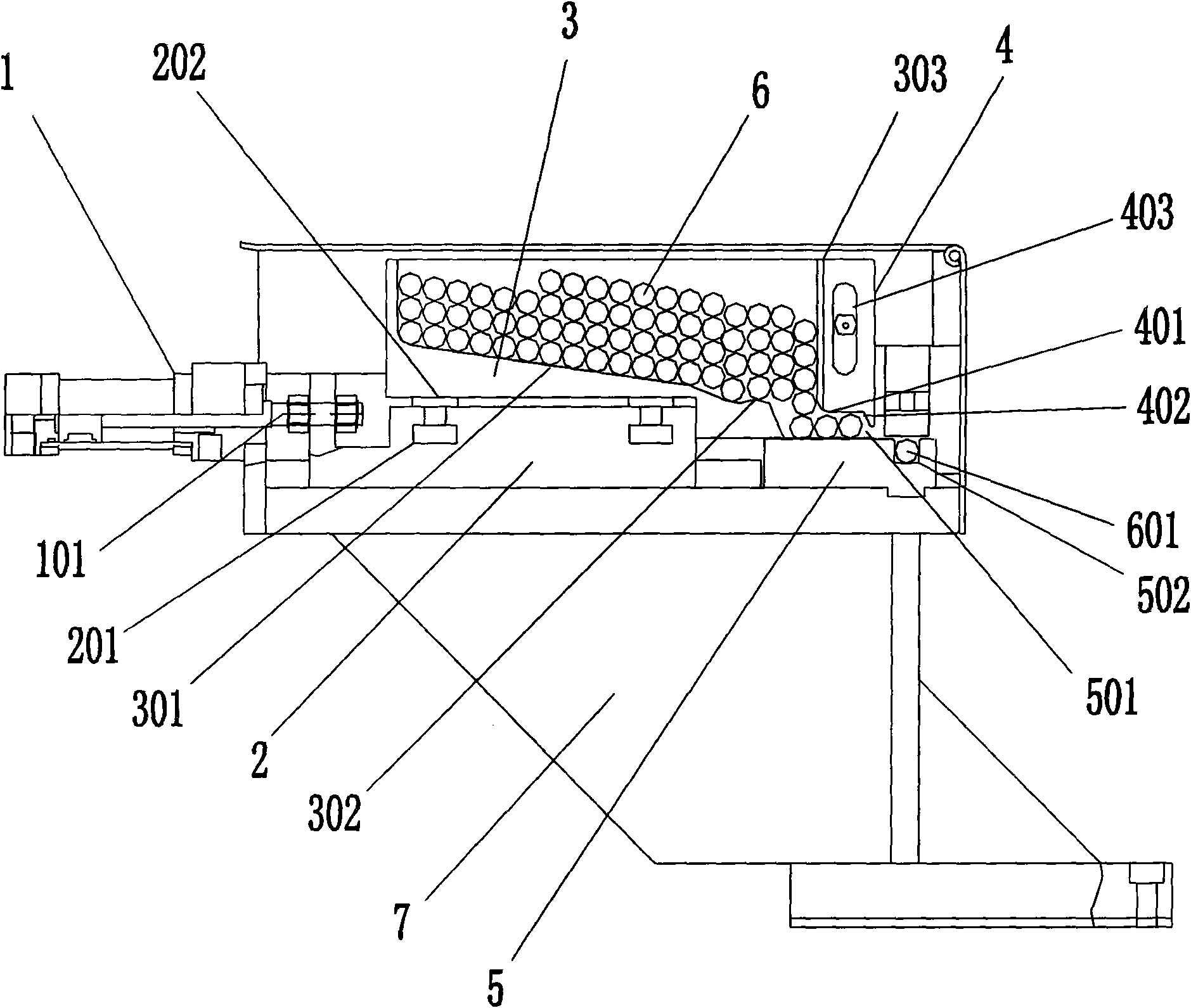

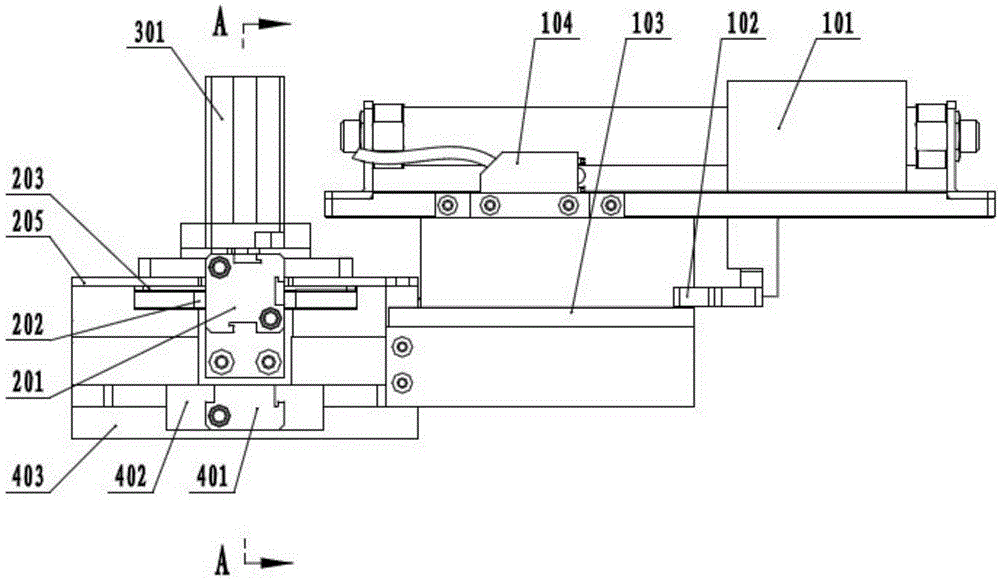

Automatic feed mechanism of numeric-control drill tip grinder

InactiveCN101590617AReduce manufacturing costThere will be no material jamDrilling toolsDrillEngineering

The invention discloses an automatic feed mechanism of a numeric-control drill tip grinder, which comprises a base, a hopper base arranged on the base and a guide block, wherein a feed bin is fixedly arranged on the hopper base, a guide board is movably fixed on the side wall of the discharge hole of the feed bin, the lower end of the guide board is provided with a gap, and an open slot is formed between the gap and the guide block. The automatic feed mechanism of the invention can effectively solve a jamming problem in feeding, and has the advantages of quick feeding, good feeding stability, high feeding efficiency, simple structure, and the like. A plurality of grinders can be simultaneously operated for production by one person, and production cost can be greatly reduced for companies.

Owner:SHENZHEN GOLD DRILL TOOLS & MFR TECH

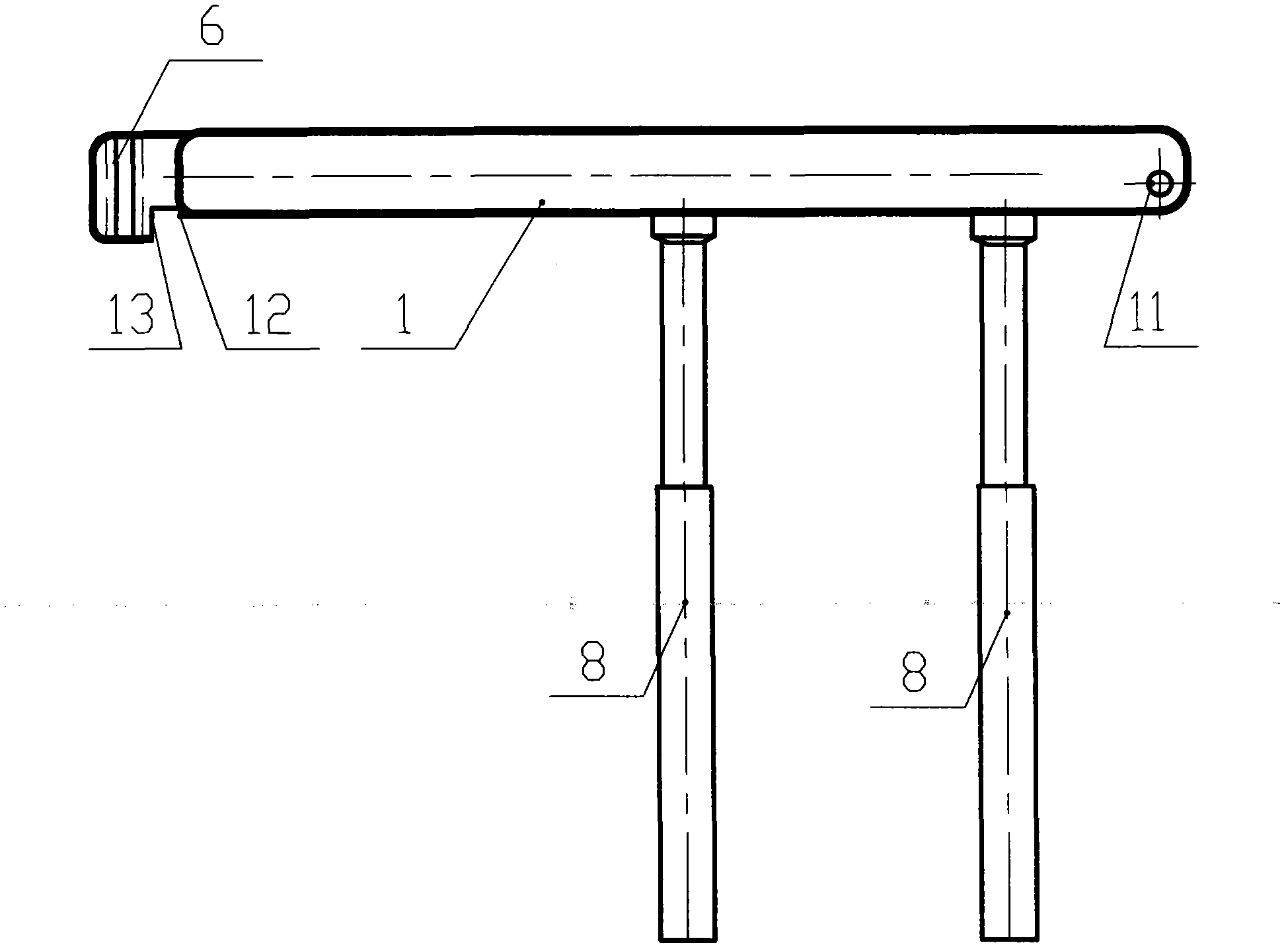

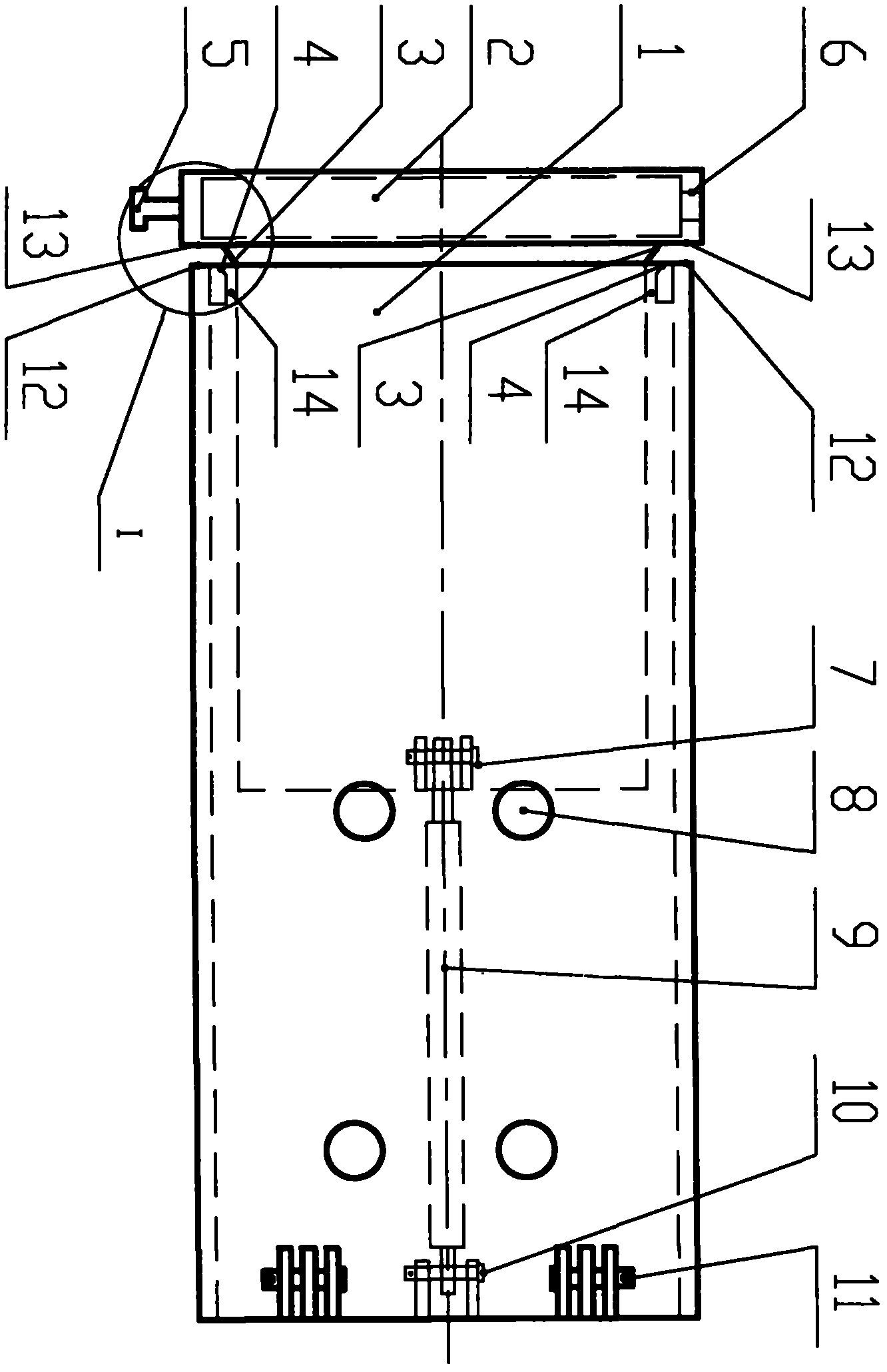

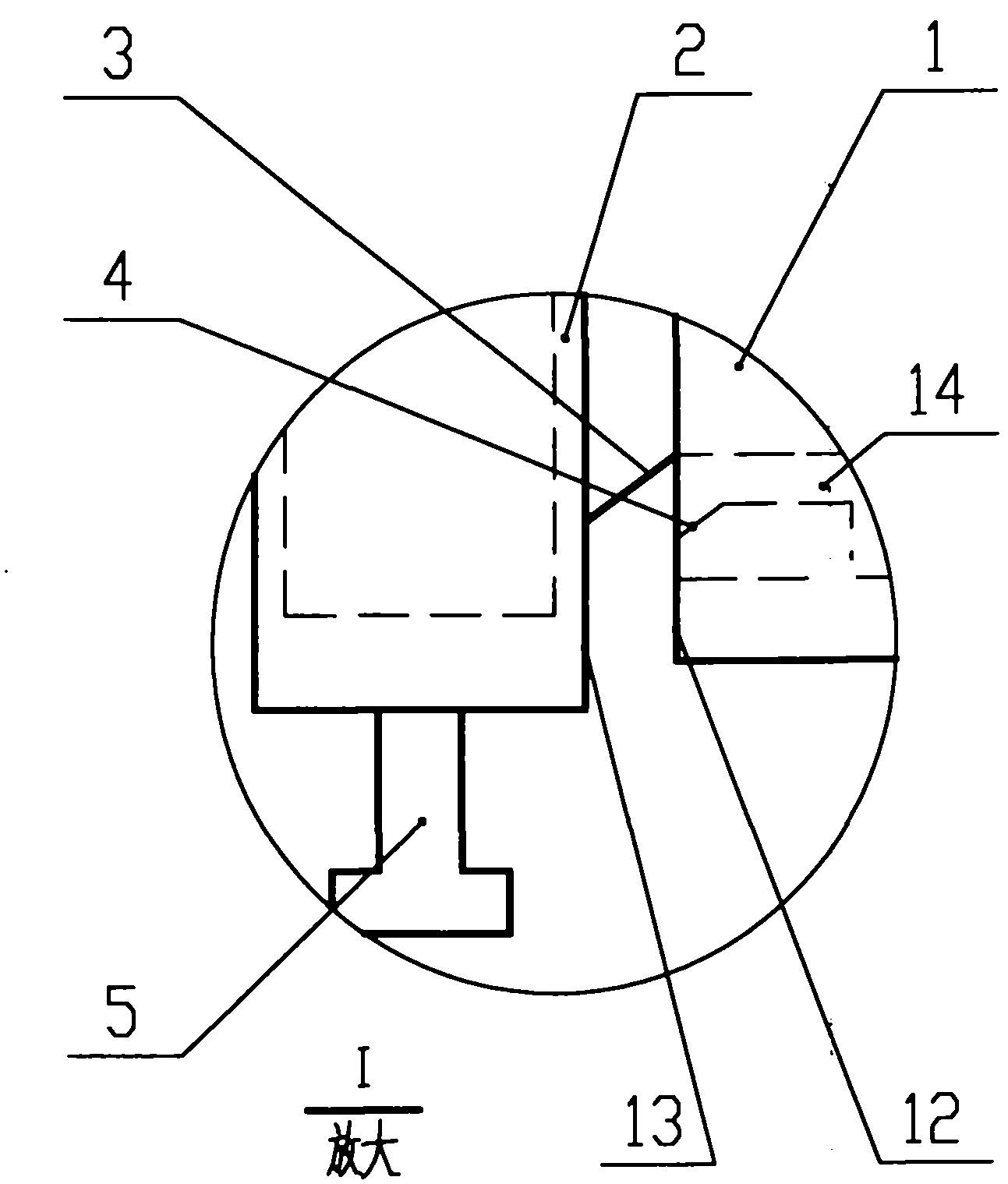

Supports

ActiveCN103174447ASave time for frame adjustmentOvercoming dumping problemsMine roof supportsMechanical engineeringSoft Coals

The invention discloses supports which are applied to face timbering top plates of underground coal mines. The supports comprise top beams and hydraulic props, wherein the hydraulic props droop downwards. The group of supports comprises forward extending beams which are connected in sequence and synchronously extend out, and thrust cylinders, wherein one ends of the thrust cylinders are connected with the forward extending beams, and the other ends of the thrust cylinders are connected with the top beams. The supports are characterized in that top beam automatic centering devices and top beams nonparallelism suitable devices are arranged in the supports in the support transferring process. Through adoption of the structure, the supports can achieve rapid support transferring and automatic centering, is free from support adjustment, and further capable of achieving support connection, fall prevention and support transferring on the condition that a roof is not empty. The supports are especially suitable for full-seam mining breaking roofs, three-soft coal seam working faces and super-soft top coal caving working faces.

Owner:李薇薇

Novel cold flame spraying decoration device

The invention provides a novel cold flame spraying decoration device. The device comprises a feeding mechanism, a heating mechanism, a feeding and blowing mechanism and a spraying mechanism which areconnected in sequence, an airflow sent by the feeding and blowing mechanism is divided into two paths, one path and the feeding mechanism are communicated, and the other path is communicated with thespraying mechanism. The device has the advantages that the structure is simpler, the design is more reasonable, and the spraying decoration effect is better.

Owner:CHANGSHA SPARK TECH ELECTRONICS CO LTD

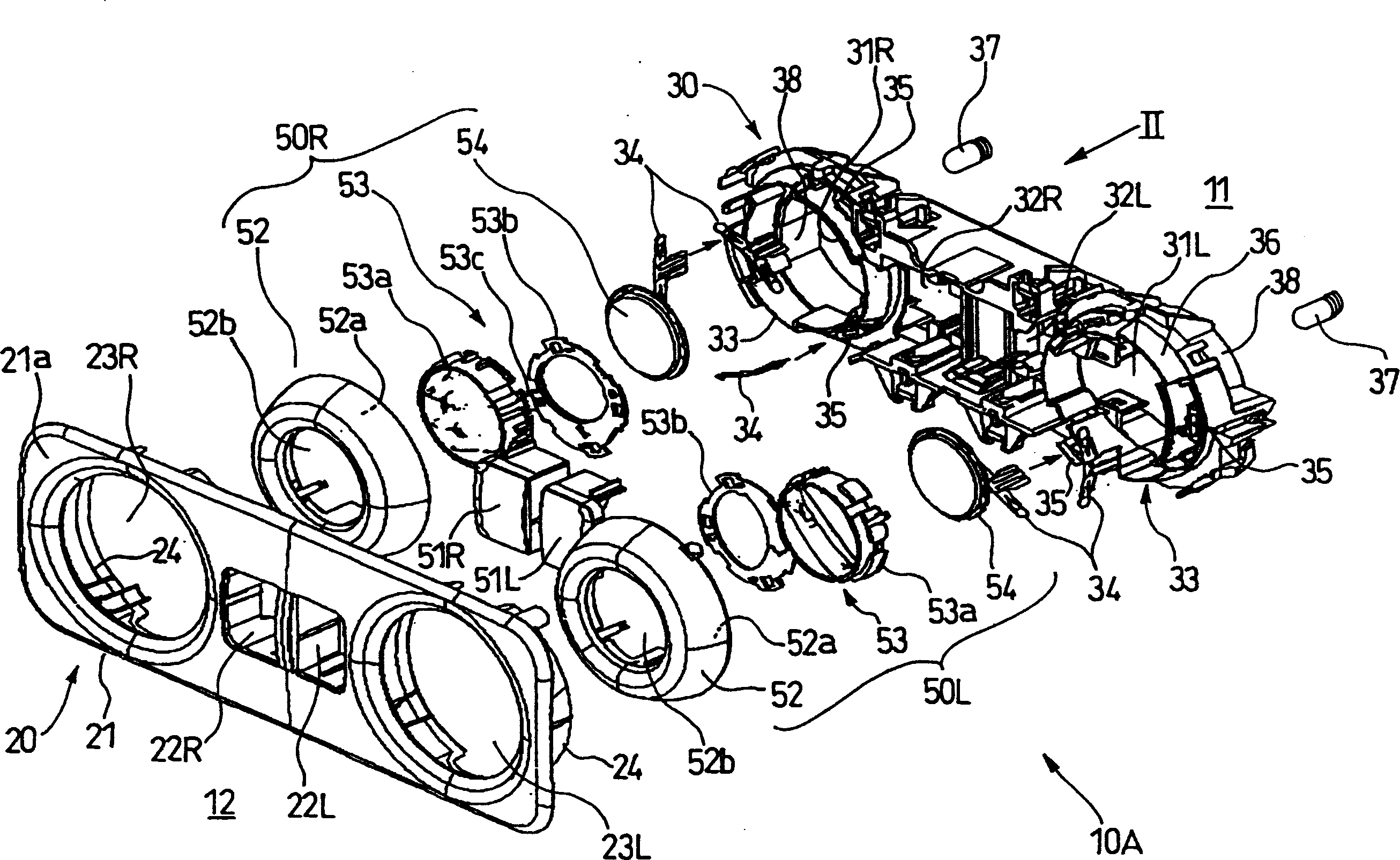

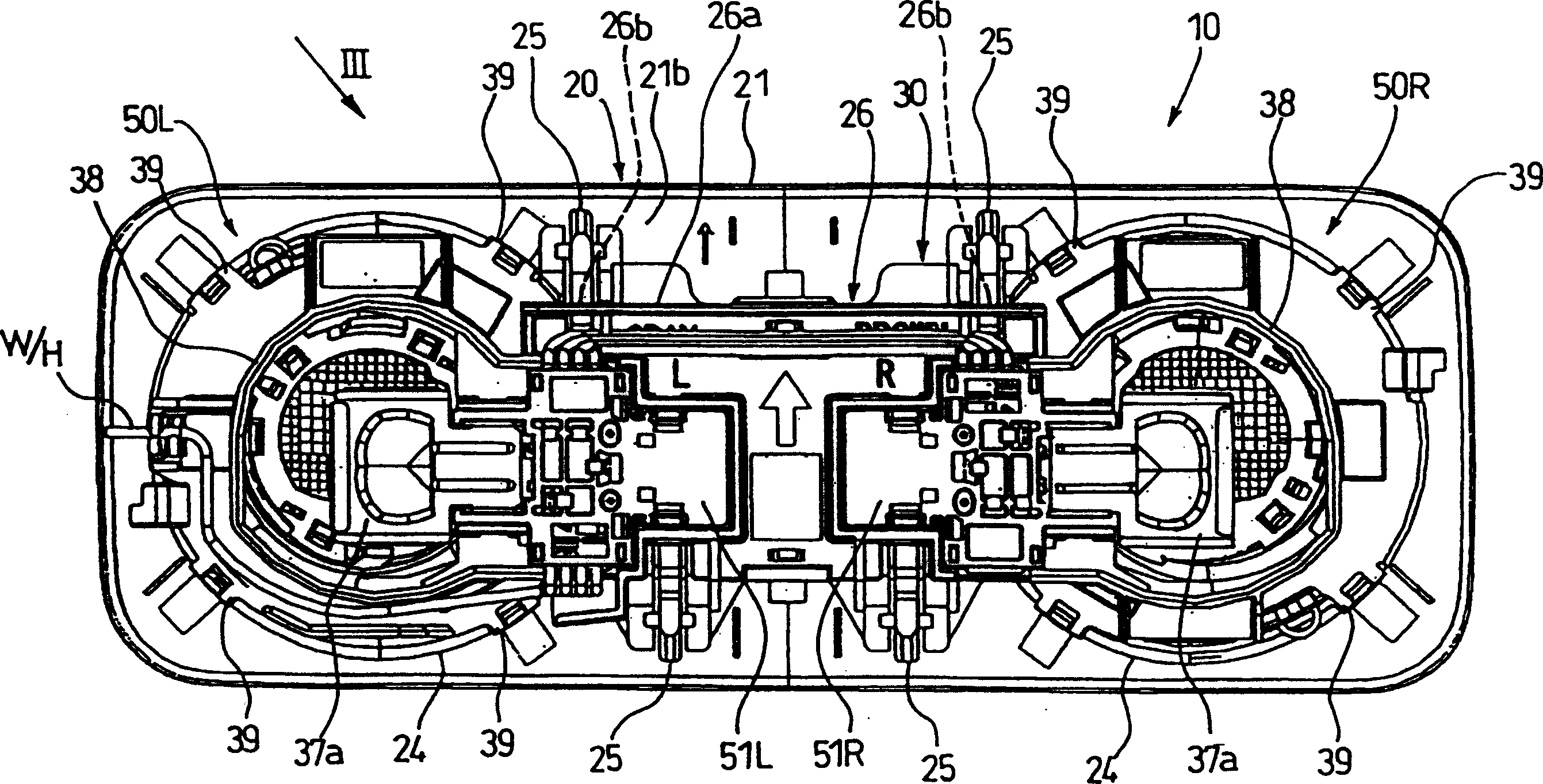

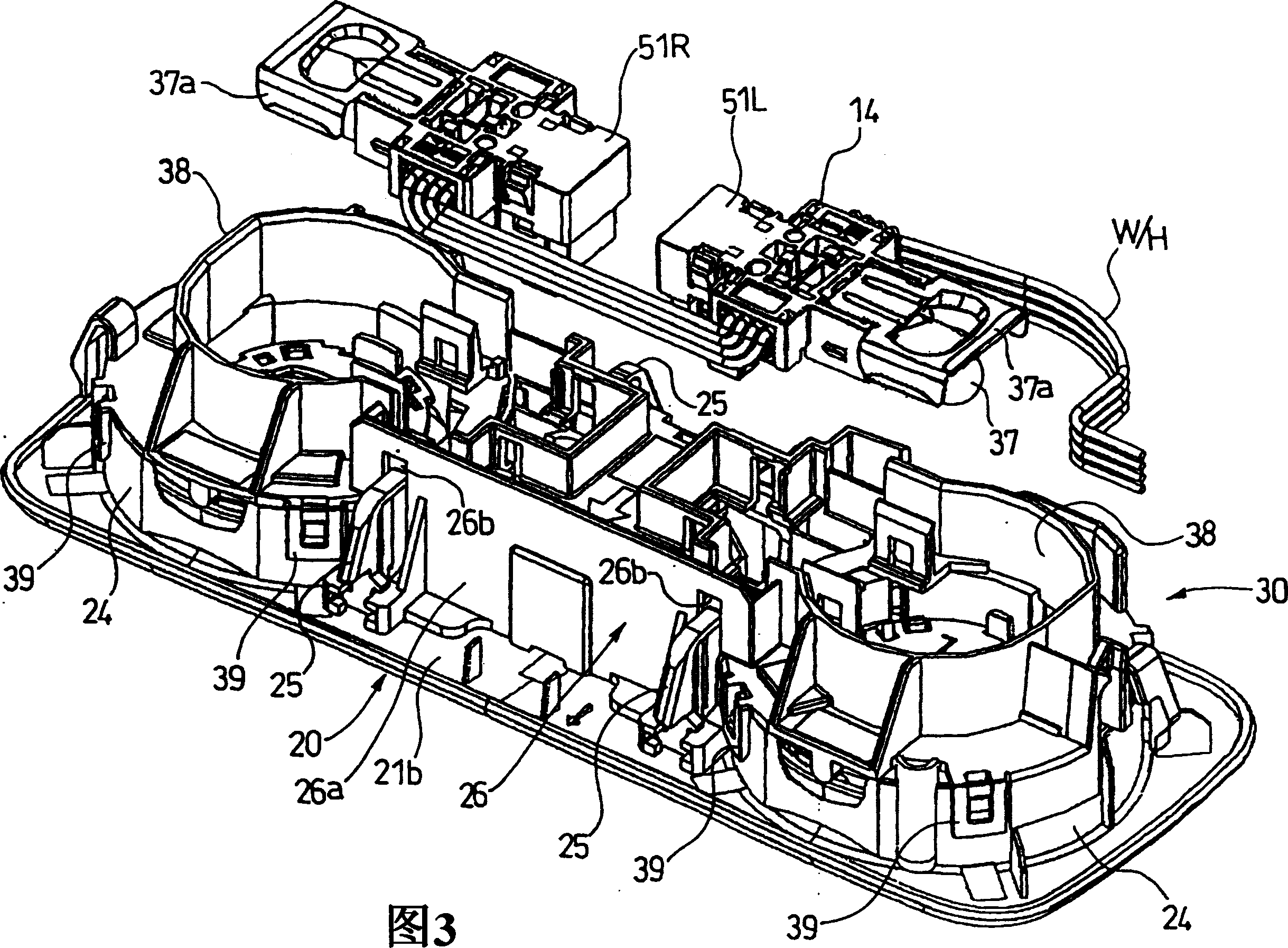

Internal illuminating lamp

InactiveCN1609504ATroubleshoot miswiringSolve the problem of wire clamping during installationLighting circuitsLight mounting arrangementEngineeringElectric wire

An interior illumination lamp 10 including a design portion 20 in which a lens 54 is fixed to a bezel 22 of a housing 21 capable of being attached to an opening 13 a provided at an interior member 13 of a vehicle 11 , a functional portion 30 arranged to a rear side of the interior member 13 by being supported by the design portion 20 and having a light source 37 , and a guide portion 26 in a groove-like shape provided for guiding an electric wire W / H connected to the functional portion 30 , in which a clip 25 is arranged to a notched portion 26 b provided at a wall portion 26 a of the guide portion 26 and front ends of the wall portion 26 a interposing the notched portions 26 b are connected to ride over the notched portions 26 b. That is, upper portions of the notched portions 26 b of the clips 25 provided at the guide portion 26 are connected and therefore, the electric wire W / H wired along the guide portion 26 can be prevented from extruding from the notched portion 26 b to be bit thereby Further, erroneous wiring can be prevented by wiring an electric wire along the guide portion 26.

Owner:YAZAKI CORP

Air door assembly control method and control device as well as equipment

PendingCN109798718ASolve the icingSolve the jamLighting and heating apparatusCooling fluid circulationEngineeringOpening - action

The invention discloses an air door assembly control method and control device as well as equipment. An air door assembly comprises a shell, an air door and electromagnetic driving parts; an air ductis defined in the shell, and the shell is provided with an air outlet and an air inlet; the air door is used for communicating or dis-communicating the air inlet with the air outlet, and the air dooris completely or partially made of a heat conduction material part; and the electromagnetic driving parts are connected with the air door and drives the air door to be switched between an opened stateand a closed state. The control method comprises the following steps that whether the air door is abnormal or not is judged; and if the air door is abnormal, the electromagnetic driving parts are controlled to alternately execute opening actions and closing actions both with the preset period duration. The novel control method is provided for the electromagnetically-driven air door, so that the freezing or blocking plugging conditions at the air door can be quickly eliminated, normal operation of the air door is ensured, and the reliability is high.

Owner:HEFEI HUALING CO LTD +2

Clinging arm horizontal packing machine

ActiveCN103693228AIncreased efficiency of access to material binsImprove work efficiencyBinding material applicationEngineeringMaterial resources

The invention relates to the field of packing machines, in particular to a clinging arm horizontal packing machine which comprises a machine box, a material box arranged at the middle position of the machine box, a packing block outlet arranged at one end of the machine box and a power mechanism arranged at the other end of the machine box. An inlet at the top of the material box is communicated with a hopper, an outlet of the material box is communicated with the machine box, a pushing disc is arranged in the machine box at the other end opposite to the material box outlet, a clinging arm mechanism is arranged on one side of the hopper, a clamping arm mechanism is arranged at the position of the packing block outlet of the machine box, and a hook rope device is arranged at the joint of one side of the machine box and the material box outlet. According to the clinging arm horizontal packing machine, the problems that in the material packing process, feeding of loose and fluffy materials is difficult, the materials are blocked easily, and compression efficiency of formed packing blocks is low are solved, the packing cost is low, production efficiency is improved, and manpower and material resources are saved.

Owner:ZHENGZHOU XIELI CONSTR EQUIP

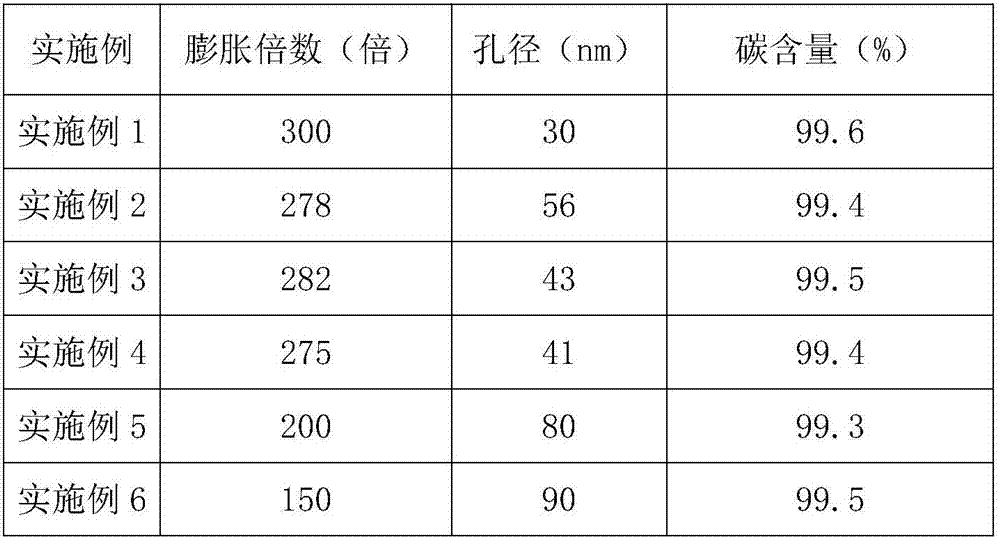

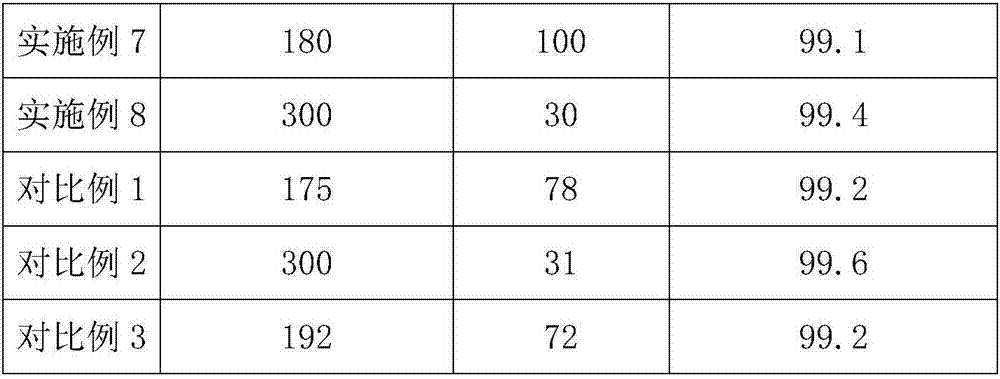

Expanded graphite and preparation method thereof

InactiveCN107311169AImprove stabilityControllable expansion ratioCarbon compoundsGas protectionWind speed

The invention relates to an expanded graphite material, and discloses expanded graphite and a preparation method thereof. The traditional high-temperature expansion method is combined with a graphite expansion furnace; the optimal expansion temperature is used; the product stability can be effectively improved through controlling the raw materials and the process parameters at the expansion temperature, so that the large-scale preparation of stable expanded graphite with controllable expansion times is realized; the expansion times is 200 to 300; the bore diameter is 30 to 100nm; the carbon content is stable. The temperature region is formed by defining the temperature of a feeding opening and a discharging opening; the expansion time is controlled by setting the feeding speed and the wind speed; then, the separation and collection are realized through wind speed; the large-scale preparation is realized; the inert gas protection is not needed; the graphite high-temperature oxidation caused by too high expansion temperature can be prevented, so that the expansion volume of the graphite is reduced.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Feeding structure and feeder applying same

The invention belongs to the technical field of material conveying, and particularly relates to a feeding structure. The structure comprises a rotating body, one side of the rotating body is arranged to be a feeding surface which is oblique, the feeding surface forms a downward curved surface from the center to the periphery, a feeding passage extending in the rotating direction of the rotating body is formed in the feeding surface, a feeding hole of the feeding passage is located on the first low side of the feeding surface, a discharging hole of the feeding passage is located on the second low side of the feeding surface, the first low side is isolated from the second low side, and the feeding surface is provided with multiple raised lines and / or strip-shaped grooves which extend to the periphery along the center. Accordingly, by means of oblique arrangement of the feeding surface, it can be guaranteed that when the rotating body drives the feeding surface to rotate, material particles on the feeding surface can rotate along with the feeding surface under the action of the raised lines and / or the strip-shaped grooves, and can slide along the obliquely arranged feeding surface to the discharge hole to drop down in the rotating process, and the material jamming phenomenon is not likely to occur.

Owner:MANGO IOT CHANGZHOU CO LTD

Automatic bag breaking and collecting device and method for resident household garbage

PendingCN113816045ASolve the jamAvoid entanglementRefuse receptaclesBags openingProcess engineeringDomestic waste

The invention discloses an automatic bag breaking and collecting device and method for resident household garbage. The device simultaneously has three functions of garbage classified throwing, automatic bag breaking and sorting of garbage and garbage compression and volume reduction, and an integrated scheme of manual classified throwing, automatic mechanical bag breaking and sorting, compression and volume reduction, packaging and clearing and intelligent induction is adopted. The effects of classified throwing, automatic bag breaking and sorting and classified packaging and clearing of the household garbage of community residents are achieved, meanwhile, the dual characteristics of humanization and mechanization are achieved, source classification and sorting of the household garbage are facilitated, and garbage recycling and source volume reduction are facilitated. The automatic bag breaking and collecting device and method for the resident household garbage solve the problems of high management difficulty, high management cost and difficulty in realizing effective garbage source classification in the existing community resident household garbage source only depending on the consciousness of residents, and also solves the problems that source classified garbage is not compressed and subpackaged, high garbage clearing cost, heavy pollution on the way of transportation, mixed loading and terminal mixed processing in the garbage classification process and the like are caused.

Owner:徐州无废城市技术研究院有限公司

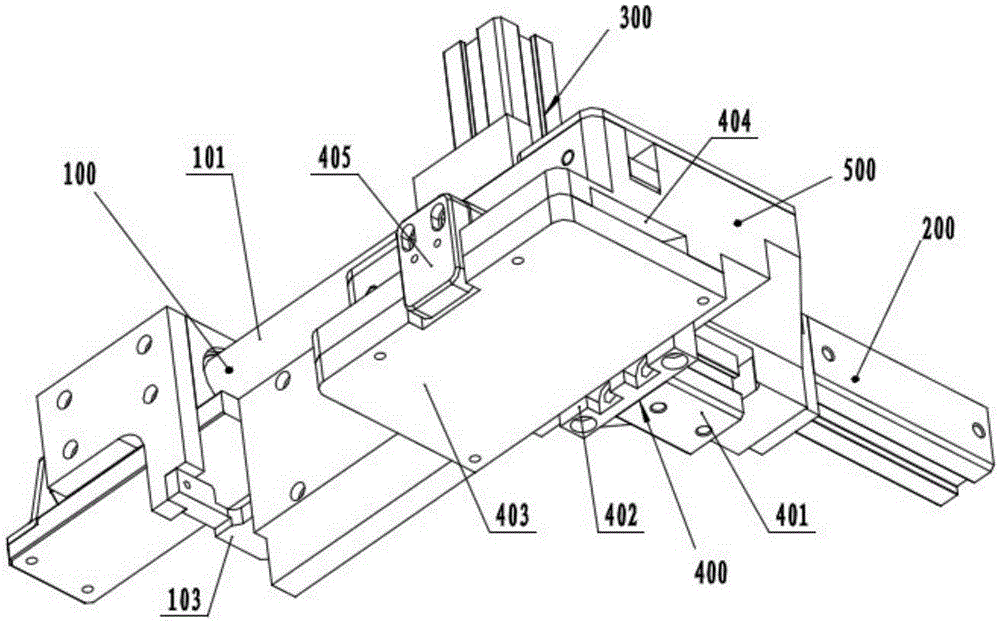

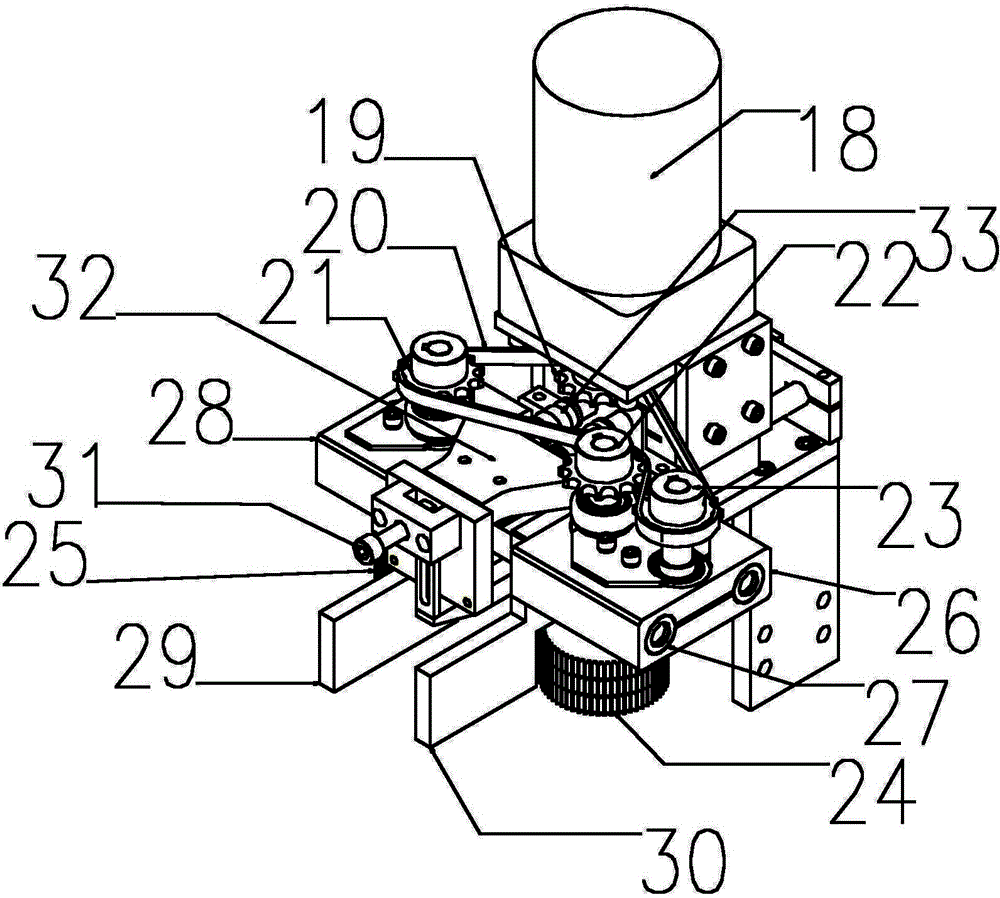

Positioning, punching and assembling device

ActiveCN105382114AIncrease success ratePositioning stamping assembly is accurateMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a positioning, punching and assembling device which is used for punching and assembling an upper material and a lower material together. The positioning, punching and assembling device comprises a first pushing mechanism, a punching mechanism and a positioning mechanism. The first pushing mechanism comprises a horizontal first pushing rail. A first pushing part is arranged in the first pushing rail in a slide fit mode. The first pushing part pushes the upper material to the tail end of the first pushing rail. The punching mechanism comprises a punching rail arranged at the tail end of the first pushing rail and intersecting with the first pushing rail. A punching part is arranged in the punching rail in a slide fit mode. The punching part pushes down the upper material along the punching rail. The positioning mechanism comprises a horizontal positioning rail perpendicular to the punching rail. A positioning part is arranged in the positioning rail in a slide fit mode. The positioning part makes the lower material positioned below the punching rail. The positioning, punching and assembling device is accurate in positioning and high in assembling success rate, the material blockage problem is solved, and assembling efficiency is improved.

Owner:SHANGHAI KINBIO TECH

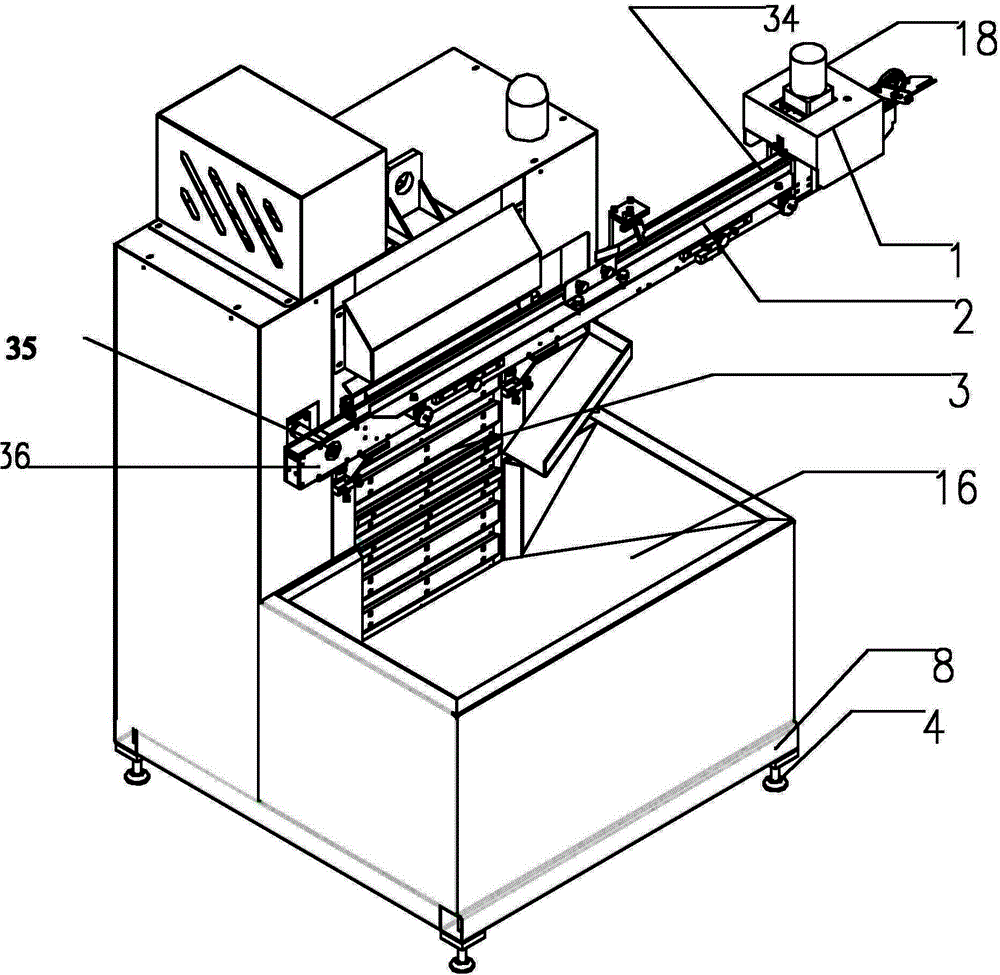

Lifting and oppositely clamping loader

ActiveCN104648965ASolve the jamIncrease flexibilityConveyorsConveyor partsProduction lineEngineering

The invention discloses a lifting and oppositely clamping loader and belongs to the field of automatic production. The loader mainly comprises a material cabin, a scraper structure, a conveying structure and an oppositely clamping mechanism, wherein the scraper structure is used for lifting a material to the conveying structure from the material cabin; the scraper structure is used for conveying the material falling from the scraper structure to the oppositely clamping mechanism; the oppositely clamping mechanism pushes a rod material through a left rolling wheel and a right rolling wheel to enter the next procedure, and the distance between the left rolling wheel and the right rolling wheel is adjusted through an adjusting block so as to adapt to materials with different sizes. The lifting and oppositely clamping loader provided by the invention is more suitable for an automatic production line and is higher in flexibility.

Owner:江苏海渡教育科技集团有限公司

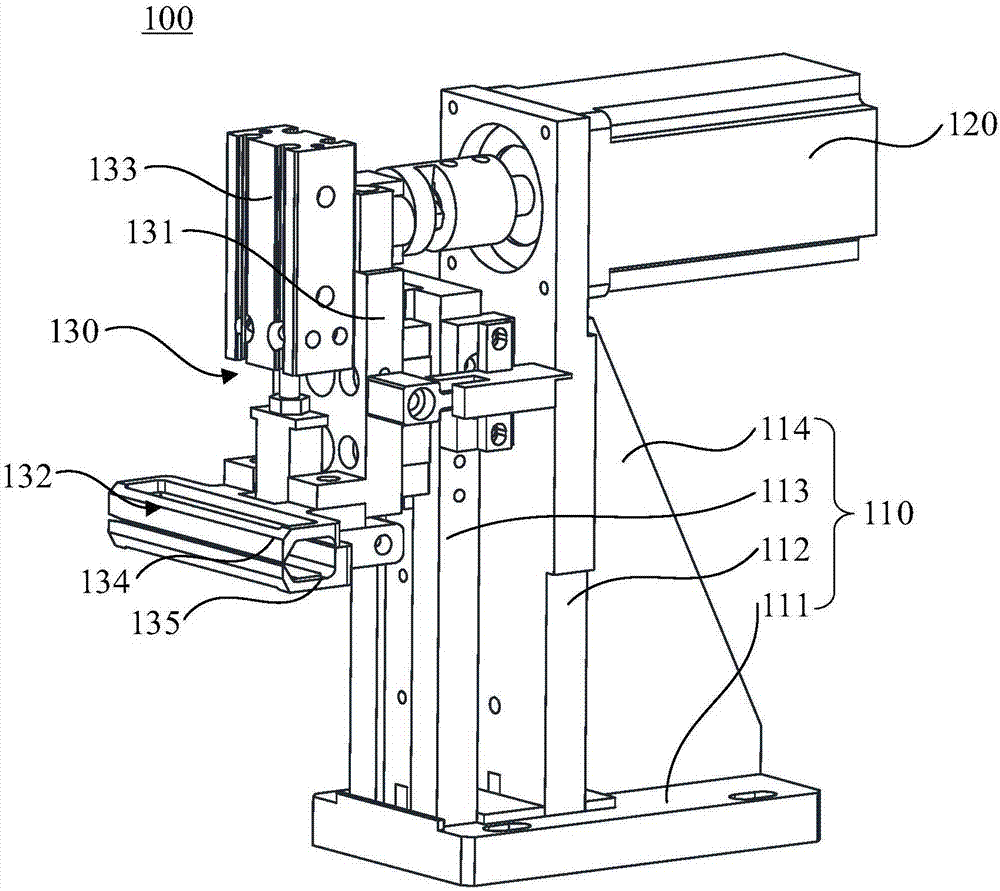

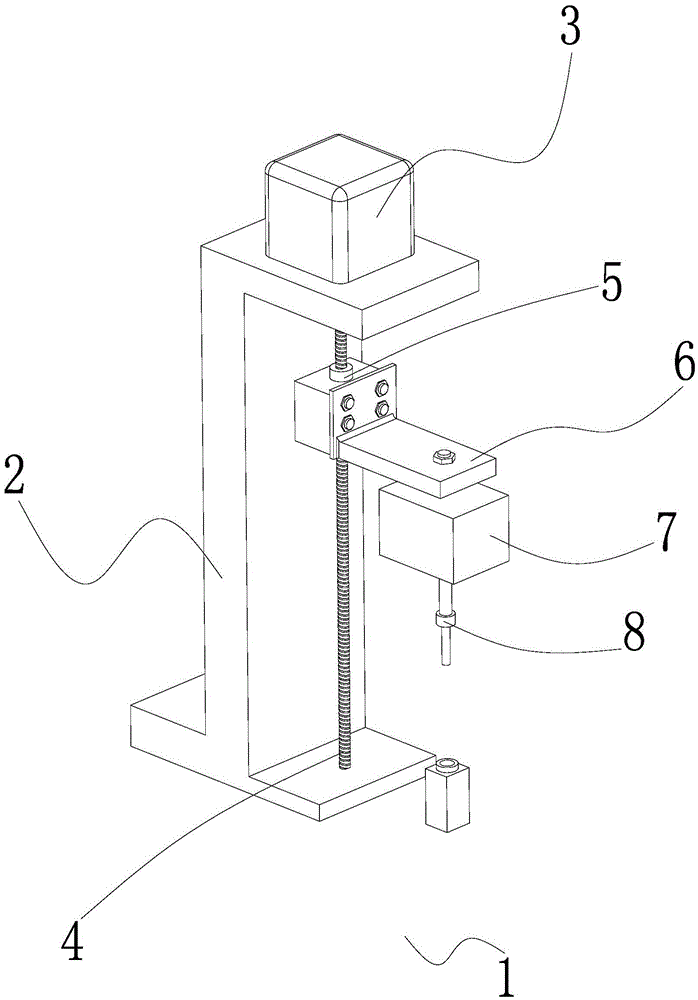

Equipment and method for achieving shaft hole assembly

InactiveCN105479146AImprove work efficiency and assembly qualitySolve the jamMetal working apparatusEngineeringMechanical engineering

The embodiment of the invention provides equipment for achieving shaft hole assembly and a method for achieving shaft hole assembly through the equipment. The equipment comprises a support and a power device fixedly arranged on the support. The support is provided with a lead screw capable of being driven by the power device to rotate. The lead screw is sleeved with a lead screw nut capable of vertically moving along the lead screw. A connecting plate is arranged on one side of the lead screw nut. The connecting plate is provided with a smoothening device for achieving shaft hole assembly based on magnetic field force, and a clamping mechanism connected with the smoothening device is arranged below the smoothening device. When the lead screw is driven by the power device to rotate, the lead screw nut can vertically move along the lead screw and meanwhile drives the smoothening device connected with the lead screw nut to move downwards. The jamming problem generated when an assembly hole wall is smooth or coarse is mainly solved, the magnetic field force is integrated in assembly work, the defects of traditional position control in high-quality and high-precision assembly work are overcome, and the assembly quality and working efficiency are greatly improved.

Owner:中山市工业技术研究中心 +1

Novel shred feeding machine

The invention relates to a novel shred feeding machine which comprises a machine body, a shred absorbing device and a power supply device. The novel shred feeding machine is characterized in that a feeding port is formed on the machine body; a conveyer belt is arranged above the feeding port; the conveyer belt is fixedly arranged on a machine frame; the machine body is equipped with the power supply device and the shred absorbing device; a shred absorbing port is formed on the shred absorbing device; the shred absorbing device is connected with a shred absorbing pipe; a fast joint is arranged on the shred absorbing pipe; a discharging slot and a manipulator fixer are arranged in the machine body; a manipulator is arranged on the manipulator fixer; a charging barrel can be clamped by the manipulator; a weighting device is also arranged on the machine body; and the weighting device is used for weighting the charging barrel. The novel shred feeding machine disclosed by the invention has the beneficial effects that the tobacco shreds used by each cigarette making machine can be counted and recorded; the problem of material blocking of the shred feeding machine can be effectively prevented; when the shred feeding machine is in fault or is maintained, the shred feeding machine under a working state is wholly and quickly replaced by its standby machine under the condition of no influence on normal downstream process.

Owner:玉溪市新特科技有限公司

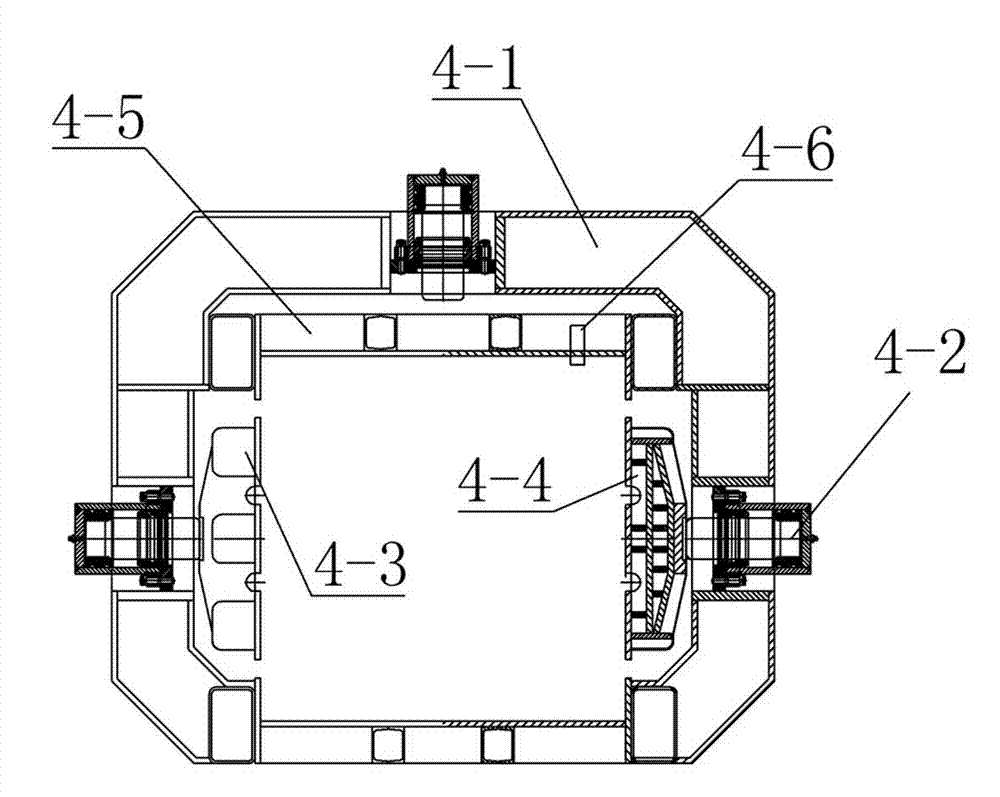

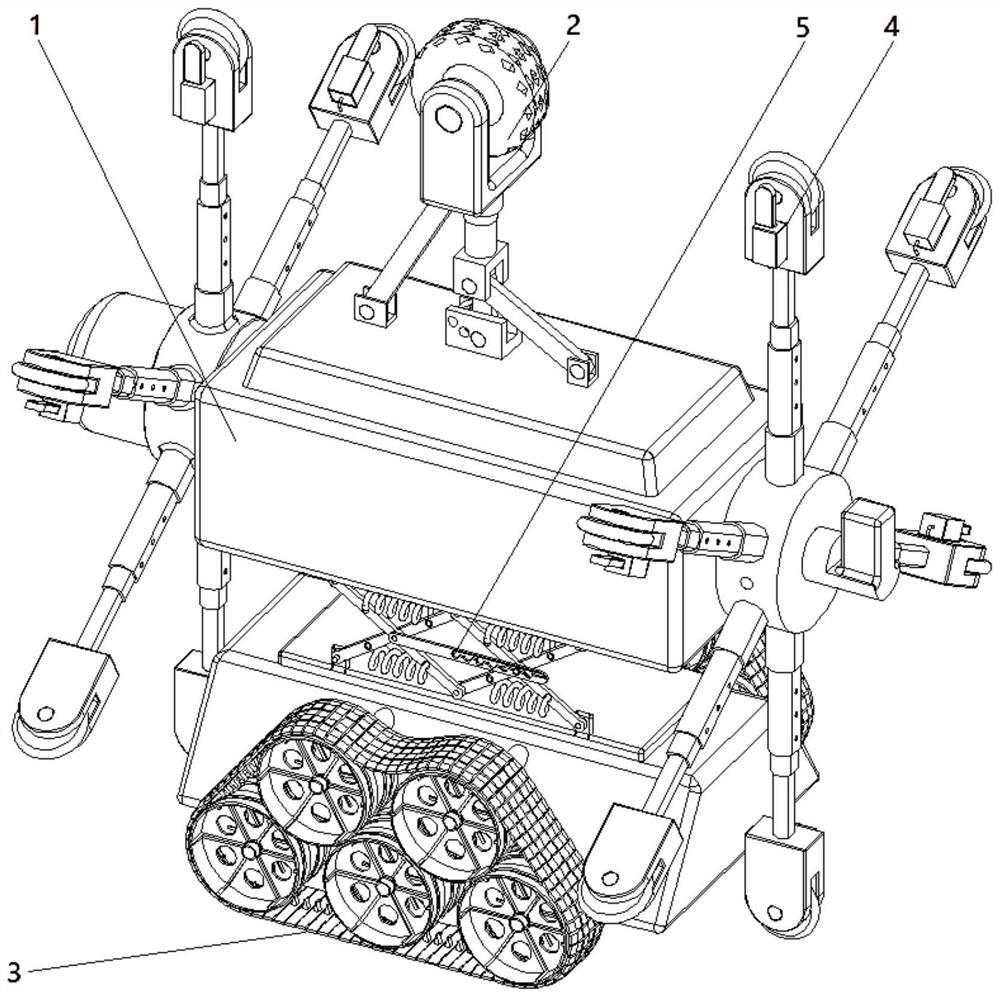

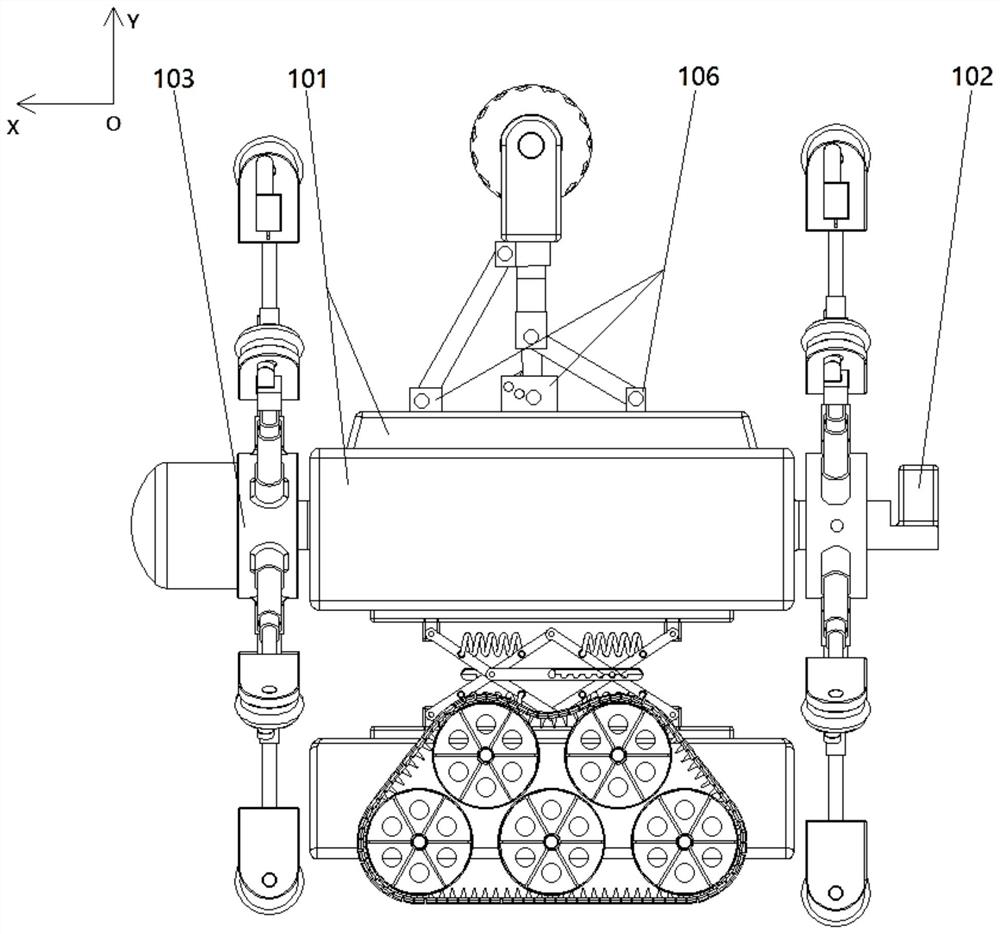

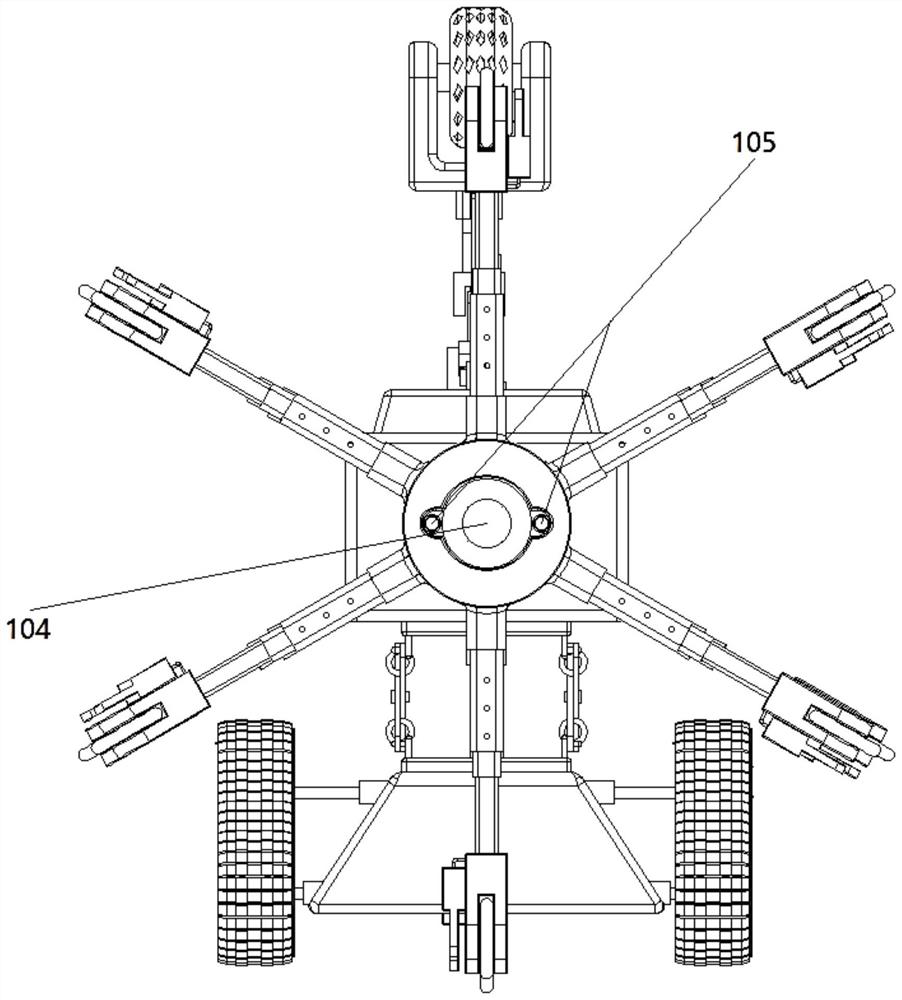

Magnetic memory detection robot for buried pipeline

The invention provides a magnetic memory detection robot for a buried pipeline in order to solve the problem that an existing robot can only detect the formed macro defects and is prone to being stuckand blocked. The magnetic memory detection robot is characterized in that the magnetic memory detection robot comprises a robot main structure, a foldable third-foot stabilizing system, a variable-angle track crawling system, an adaptive variable-diameter magnetic memory detection system and a double-X-shaped multi-spring suspension system; the foldable third-foot stabilizing system is used for maintaining the stability of the robot during advancing in a pipeline and adapting to the working conditions of the variable-diameter pipeline; the variable-angle track crawling system is used for realizing close contact between a crawling mechanism and the inner pipe wall; the adaptive variable-diameter magnetic memory detection system is used for realizing the magnetic memory detection function of a sensor for different pipe diameters; and the double-X-shaped multi-spring suspension system is used for adjusting the height of the robot and ensuring that the center of the magnetic memory detection system coincides with the center of the pipeline. The magnetic memory detection robot can carry out full-life and all-round magnetic memory detection on early stress concentration, hidden damage and macro defects of the pipeline.

Owner:NORTHEAST GASOLINEEUM UNIV

Pipeline valve

The invention discloses a pipeline valve which comprises an upper valve body and a lower valve body. Two valve body holes as large as each other are formed in the upper valve body and the lower valve body respectively. A strip valve element is disposed between the upper valve body and the lower valve body. A valve element hole is formed in the strip valve element. The valve element moves to allow overlap parts of the valve element hole and the valve body holes to change so as to achieve open and close of the valve element, simultaneously dust falling on the valve bodies and the valve element can be cleaned, and accordingly the problem of valve blockage caused by dust accumulation on the valve is solved effectively. A cylinder is disposed on the upper valve body, high-pressure air is fed into the cylinder to allow the upper valve body seal, the strip valve element and lower valve body seal to be compressed under pretightening force of the cylinder, and accordingly smoke leakage on the upper seal face and the lower seal face of the strip valve element is avoided, and production safety is increased. A telescopic joint is disposed on the upper valve body, so that the upper valve body can move flexibly. By the structure, the service life of the valve is prolonged greatly, production cost is saved, and huge economic benefits are brought to enterprises.

Owner:JINCHUAN GROUP ENGINEERING AND CONSTRUCTION CO LTD

Sealing flashboard door for biomass feeding

PendingCN111473125AAnti-channelingGuaranteed zero leakageOperating means/releasing devices for valvesSlide valveStructural engineeringMechanical engineering

The invention relates to a sealing flashboard door, in particular to a sealing flashboard door for biomass feeding, and solves the problems of poor sealing effect, unsmooth opening and closing, jamming and blockage of an existing flashboard door. The sealing flashboard door for biomass feeding comprises a valve body front end, a valve body rear end, a feed port and a discharge port, wherein the valve body front end and the valve body rear end are both positioned at the front end and the rear end inside a valve body, the feed port is fixedly installed between the front end of the valve body andthe rear end of the valve body and located on the upper portion of the valve body, and the discharge port is located on the lower portion of the valve body. The sealing flashboard door for biomass feeding also comprises a plugboard assembly and a locking assembly, the plugboard assembly is in sliding connection with the bottom of the front end of the valve body and the bottom of the rear end of the valve body, and the locking mechanism is connected with the plugboard assembly. The sealing flashboard door can effectively solve the problems of unsmooth opening and closing, jamming, blocking, high failure rate and the like after frequent opening and closing.

Owner:HARBIN BOILER

Pneumatic valve using air cylinder as actuator

InactiveCN105351600AIncrease forceSolve the jamOperating means/releasing devices for valvesSpring forceEngineering

The invention discloses a pneumatic valve using an air cylinder as an actuator. The pneumatic valve comprises a valve body, a valve rod, and the air cylinder for controlling the valve rod to reciprocate, wherein the air cylinder is fixed to the valve body through a bracket; one end of the valve rod is connected to a piston rod of the air cylinder; a returning spring is arranged in one working chamber of the air cylinder, and another working chamber of the air cylinder communicates with a control air channel through an air tube; an air feeding tube at the air exhausting port of the working chamber, provided with the returning spring, of the air cylinder, communicates with the control air channel; a pressure releasing valve is mounted on the air feeding tube. According to the pneumatic valve, a stable pressure air source is charged to the returning spring side of the air cylinder, thus the acting force of the returning spring to a piston of the air cylinder can be increased, and as a result, the problem of blocking of the valve due to insufficient spring force can be solved, the valve can be smoothly operated, and the potential risk can be removed.

Owner:ANHUI LIUGUO CHEM CO LTD

Rotating-valve-type hydrodynamic impactor

The invention discloses a rotating-valve-type hydrodynamic impactor. An upper connector of the rotating-valve-type hydrodynamic impactor is connected with an upper outer pipe through a thread, a glandand a valve cover are sequentially fixed to the upper end face of a cylinder body through the upper connector, the cylinder body is sleeved with the upper outer pipe, and the periphery of the upper end of the cylinder body is sleeved with a freely-rotating rotor sleeve. Various vertical and radial fluid channels are formed in the cylinder body, a piston is formed by means of the method that an upper piston head and a lower piston head are connected to a piston rod in series, and according to the piston, the upper piston head and the lower piston head are machined on the piston rod. An end cover is inserted into the lower end of the cylinder body and positioned by a positioning pin, a middle connector is connected with an upper outer pipe and a lower outer pipe through threads, and the piston rod penetrates through the end cover to be connected with a hammer body to form a movement whole. A spline sleeve is connected with the lower outer pipe through a thread, a spline on a drill bit body is matched with a spline groove in the spline sleeve, an assembled body capable of axially moving is formed, and the lower bottom face of the hammer body makes contact with the top face of a drillbit. The rotating-valve-type hydrodynamic impactor has the advantages that the clamp-blocking problem caused by a slide valve is avoided, the structure is simple, impacting energy is large, and the service life is long.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com