Patents

Literature

88results about How to "Guaranteed zero leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

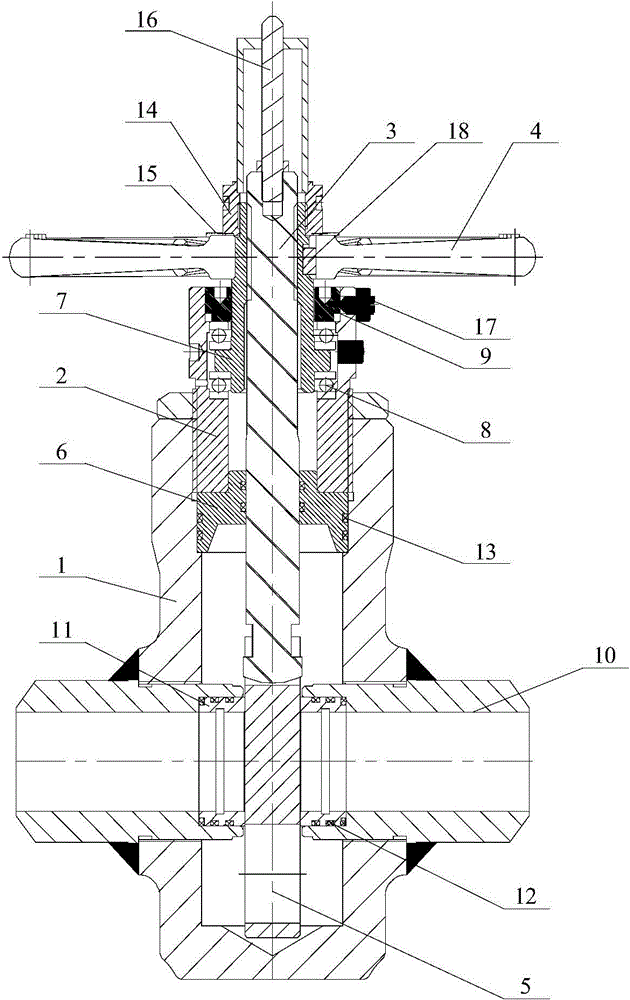

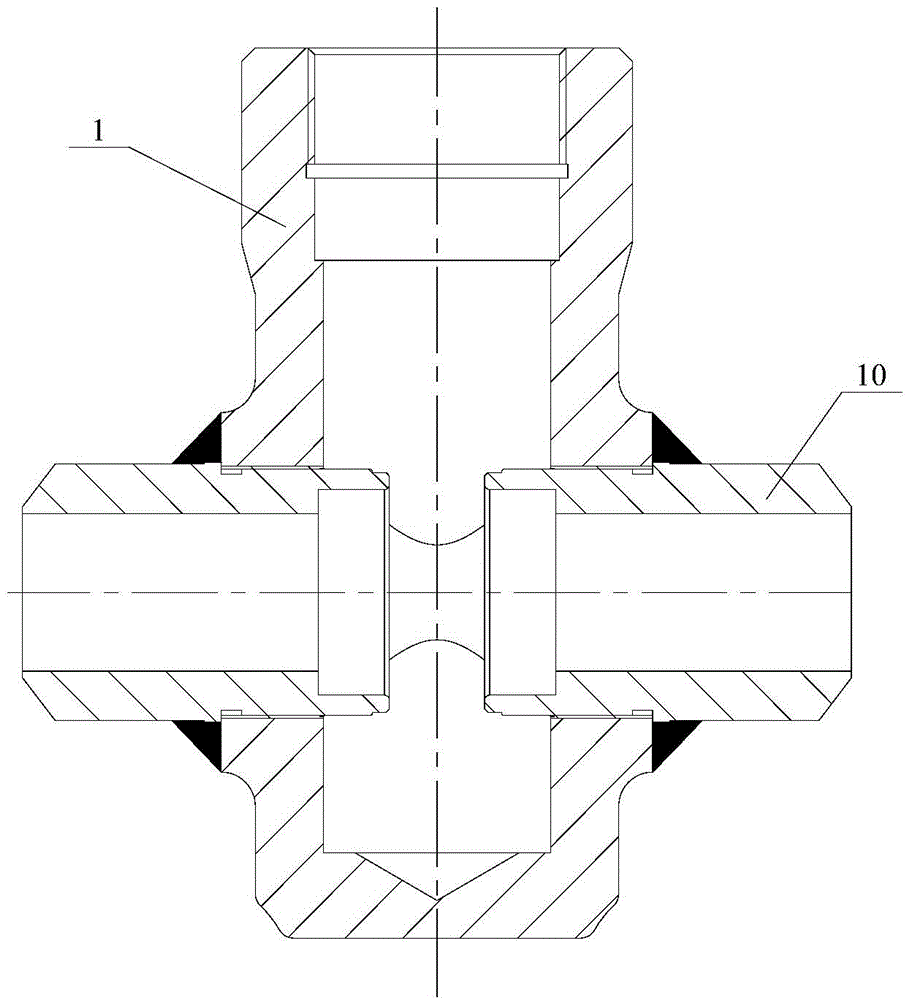

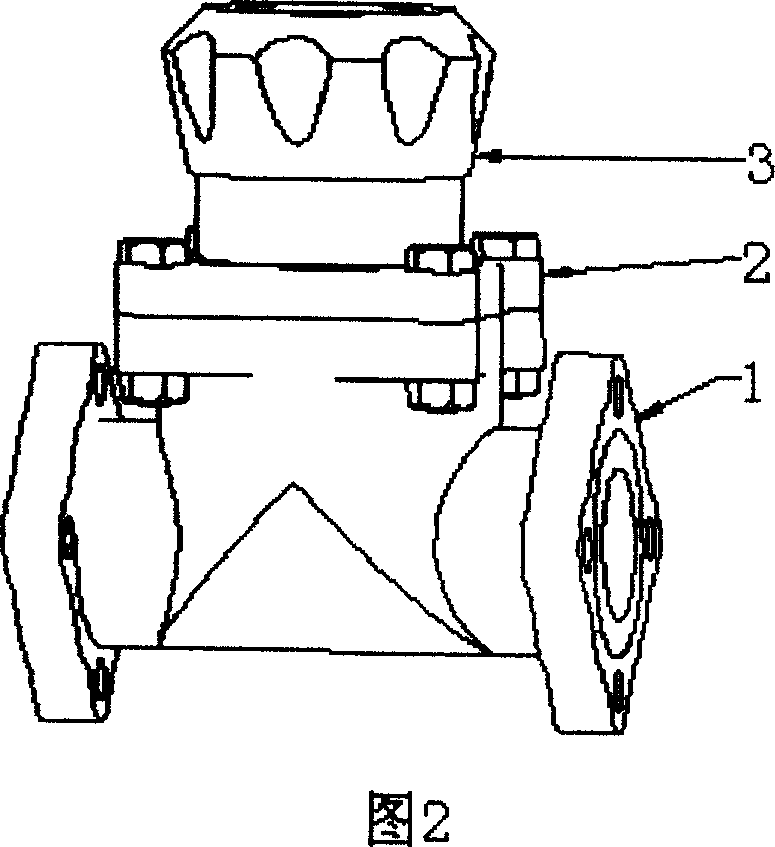

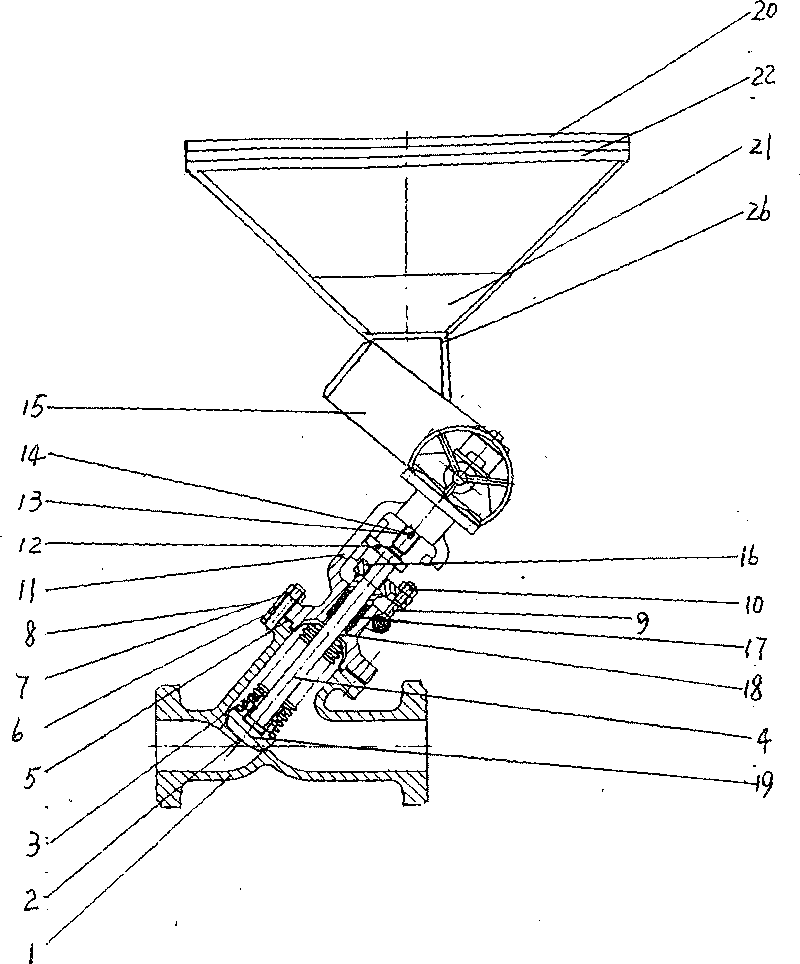

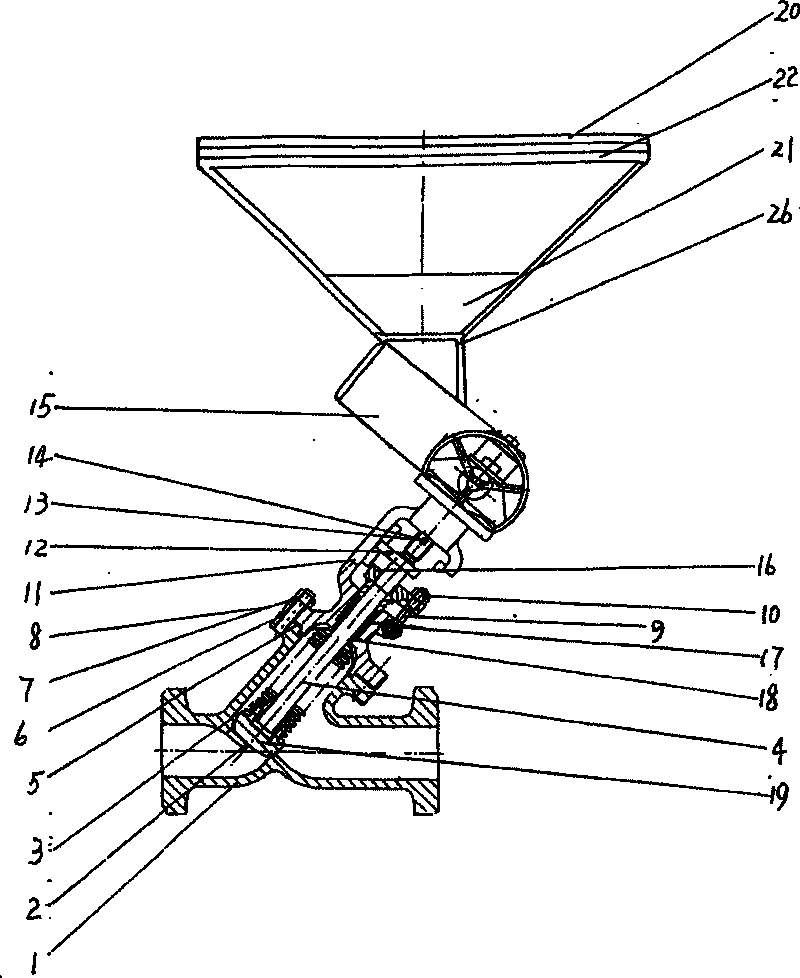

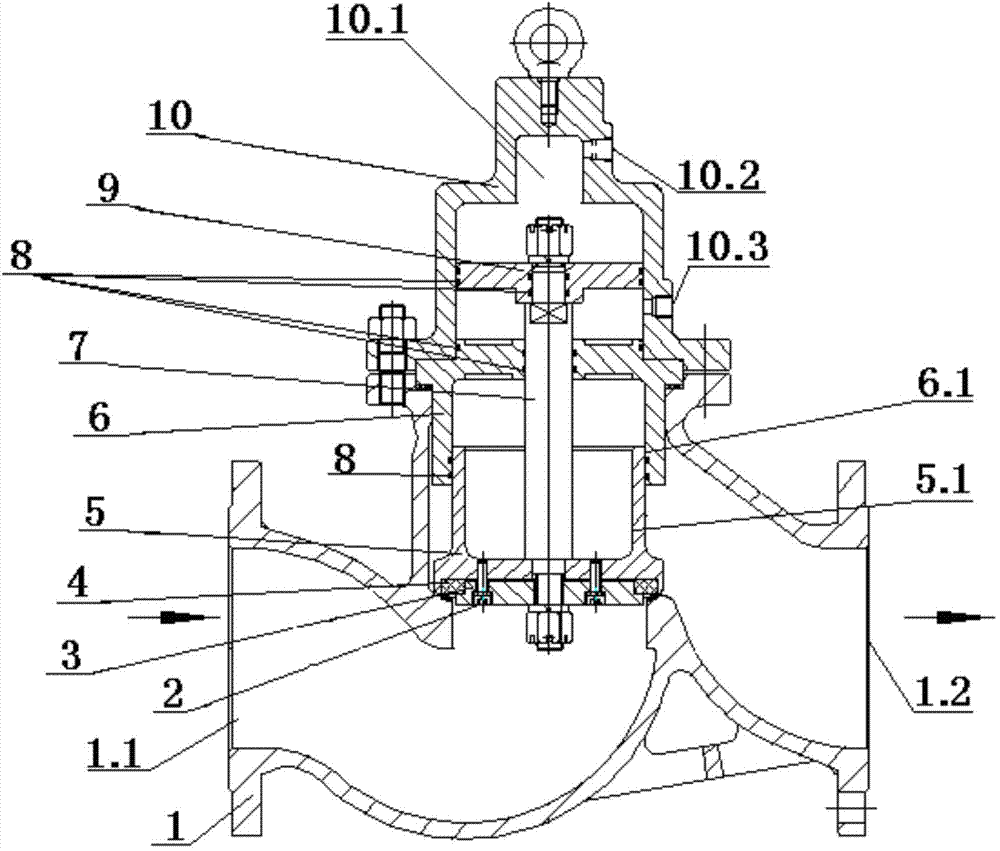

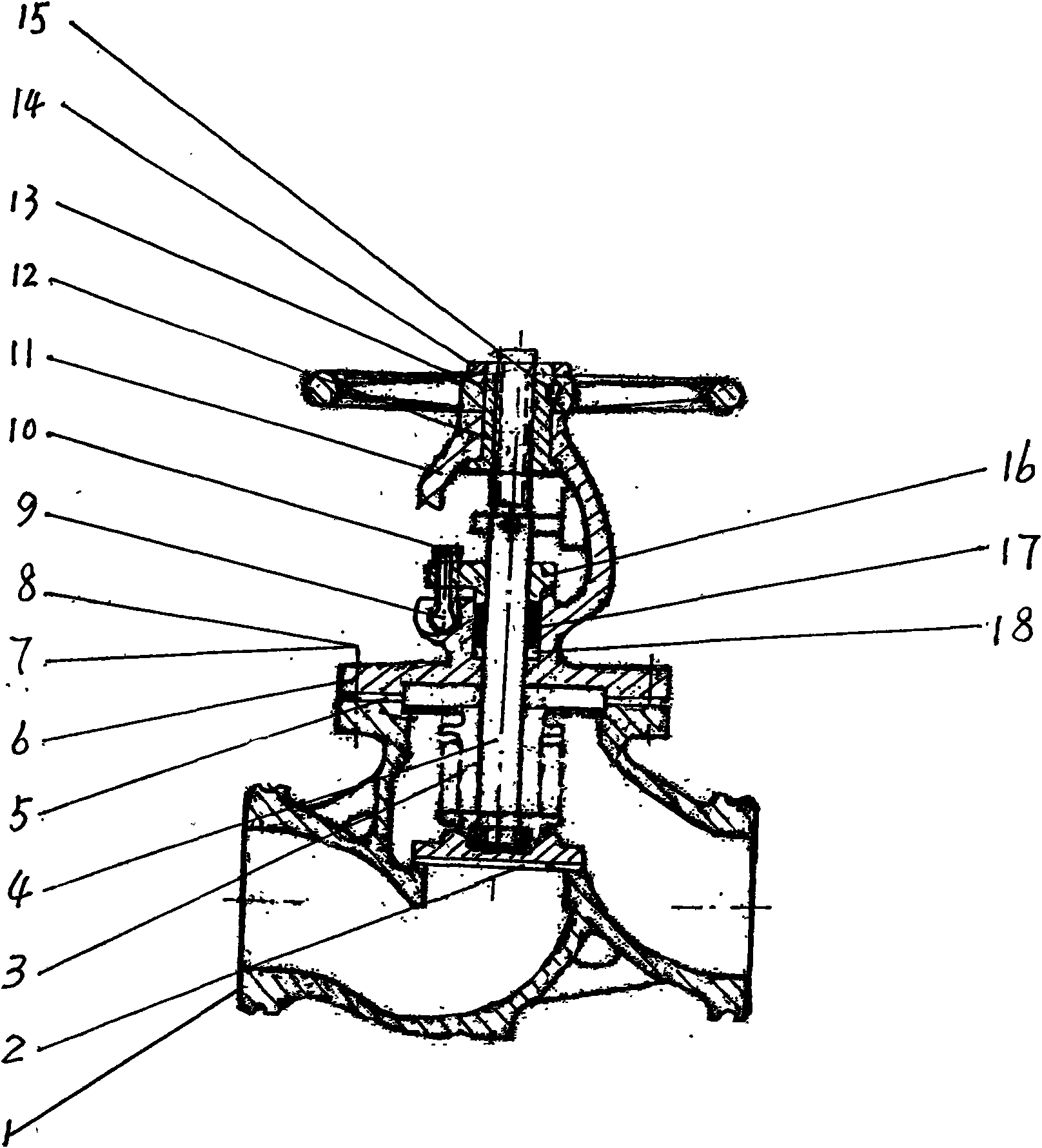

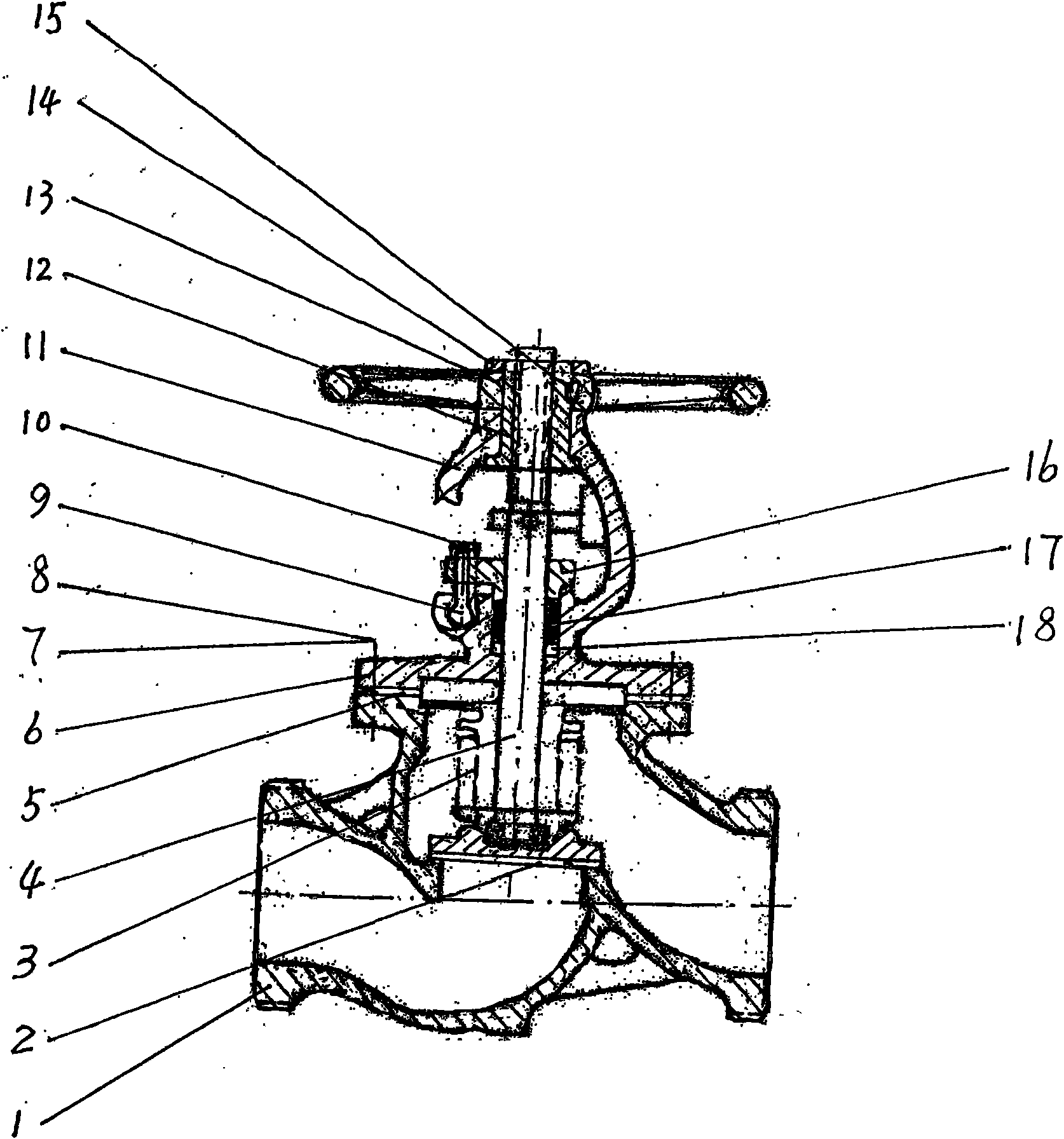

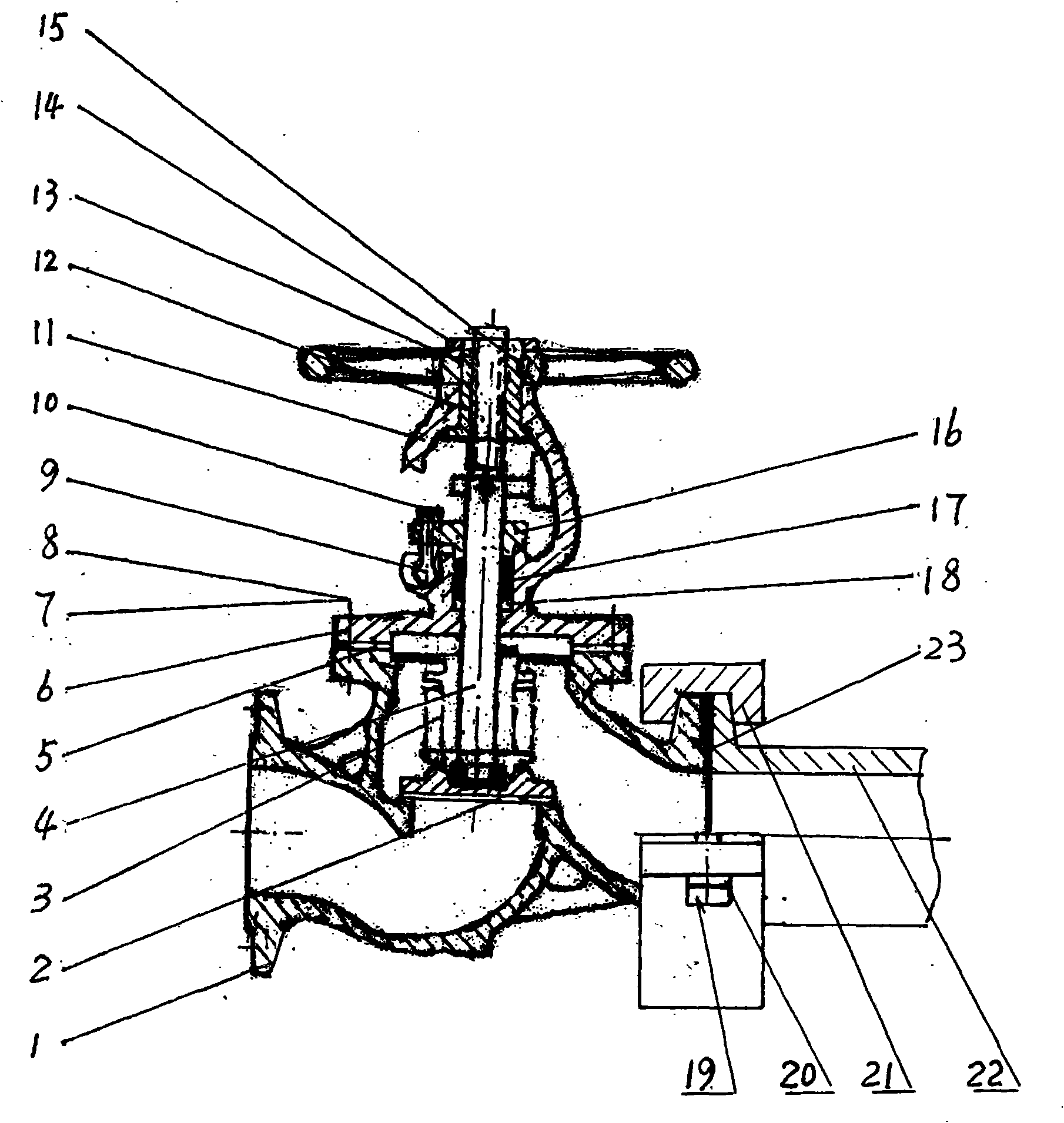

Gate valve and manufacturing process thereof

The invention discloses a gate valve and a manufacturing process thereof. The gate valve comprises a valve body with a T-joint structure, wherein an opening in the upper end of the valve body is connected with a valve cover; a valve stem penetrates into the valve body; the upper end of the valve stem is vertically connected with a handwheel, and the lower end of the valve stem is connected with a valve plate used for controlling opening and closing; a left connecting pipe and a right connecting pipe are respectively inserted into opposite openings on the left and right of the lower end of the valve body; the inner ends, adjacent to the valve plate, of the left connecting pipe and the right connecting pipe are respectively provided with a valve base; the peripheral surfaces of the left connecting pipe and the right connecting pipe are respectively welded and fixed together with the left and right side surfaces of the lower end of the valve body. Components, such as the valve body, the left connecting pipe and the right connecting pipe, in the gate valve are forged and molded, then are respectively processed and finally assembled without special fixtures, so that the labor strength is reduced, and the machining time is shortened.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

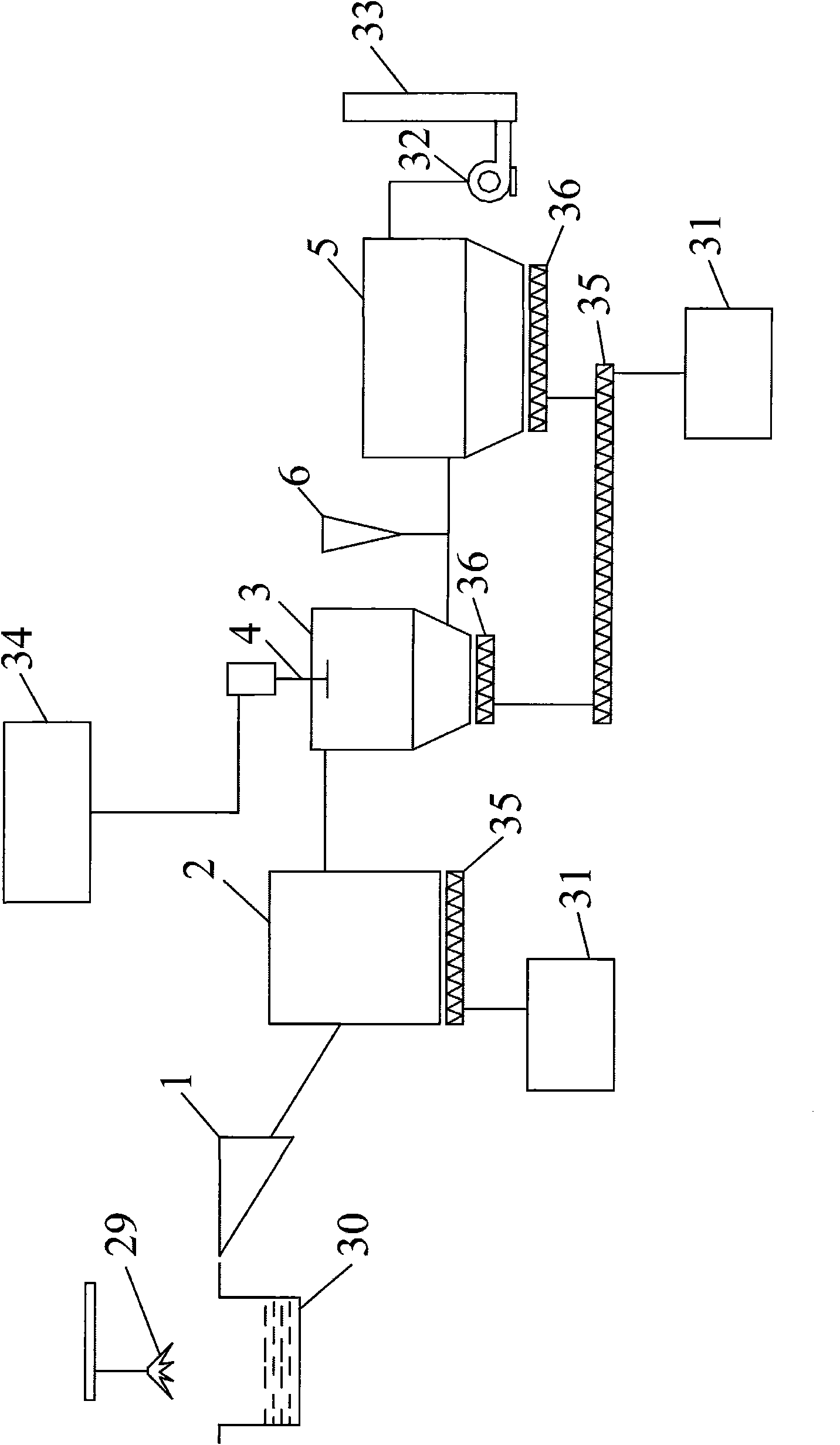

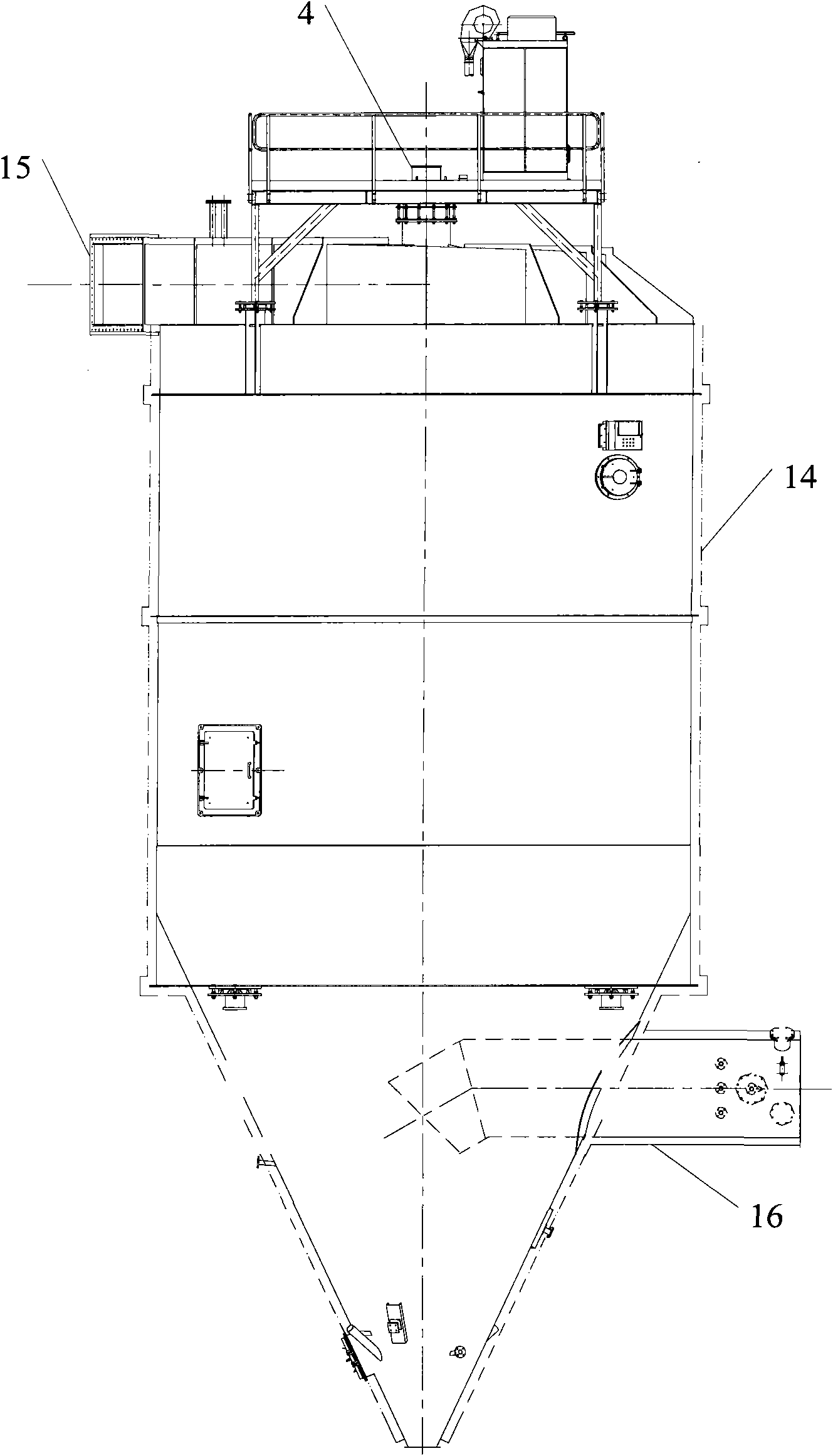

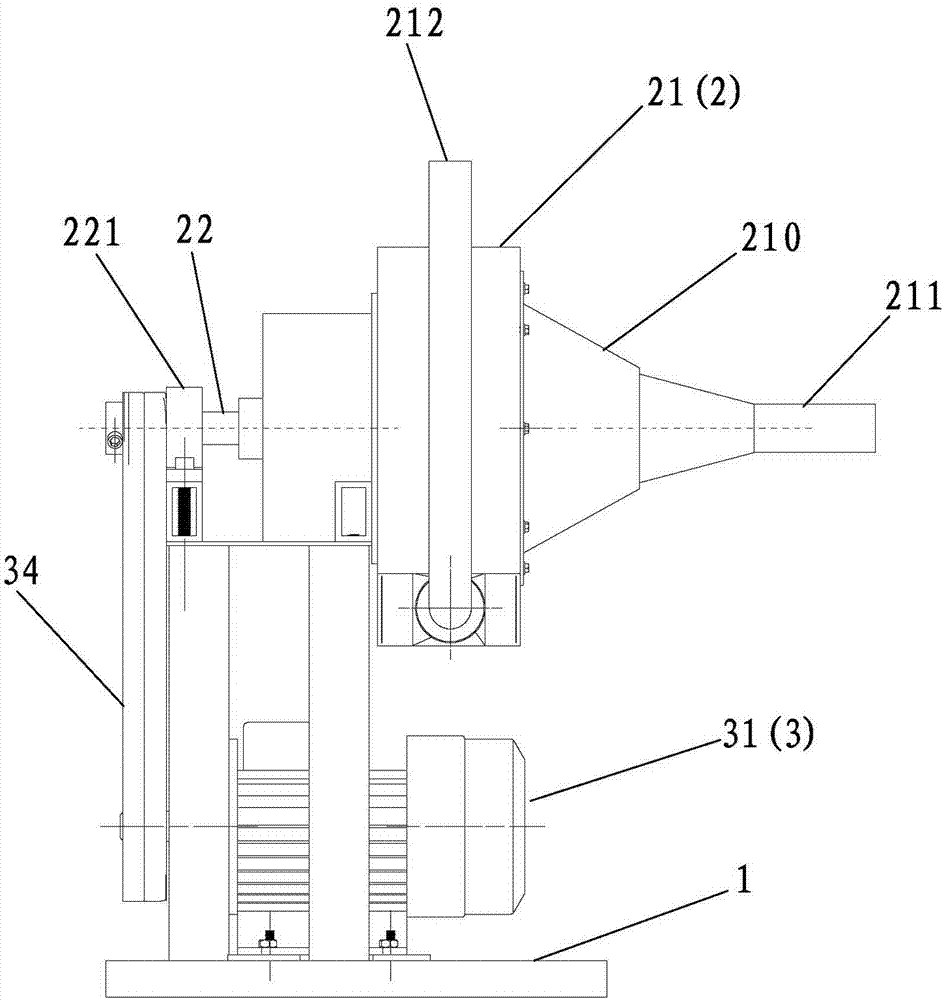

Flue gas purifying system and method

ActiveCN101644437ASimple structureEasy maintenance and operationOperating means/releasing devices for valvesDispersed particle separationCombustionFlue gas

The invention discloses a flue gas purifying system and a method. The system comprises a feed bin, a reaction tower and a deduster, wherein, the feed bin is used for transporting the garbage to a garbage incinerator when the garbage amount meets the primary combustion amount of the garbage incinerator; the reaction tower is connected with the garbage incinerator by a pipeline to be used for the flue gas to react with the lime slurry ejected from a rotary sprayer; the deduster is connected with the reaction tower by the pipeline to be used for dedusting of the flue gas treated by the reaction tower. The system of the invention is high in safety, simple in operation, high in purification efficiency and durable in use.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

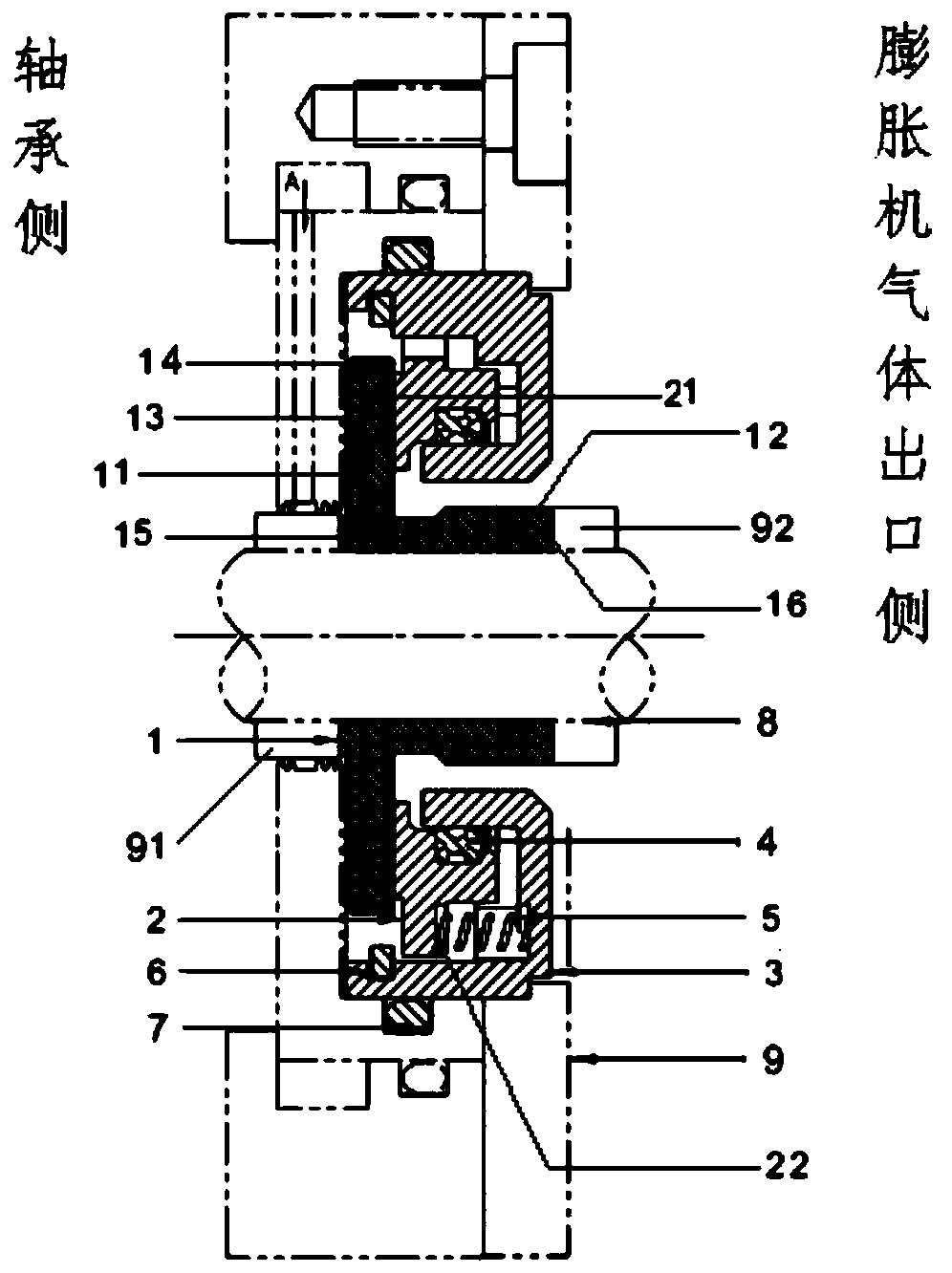

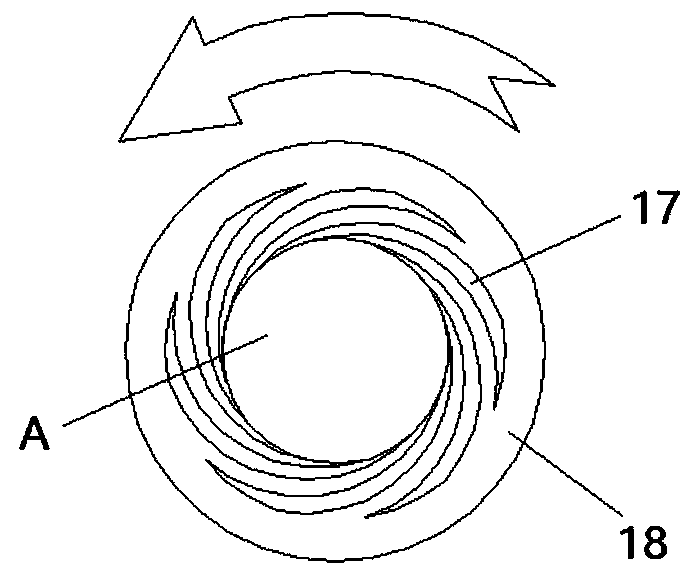

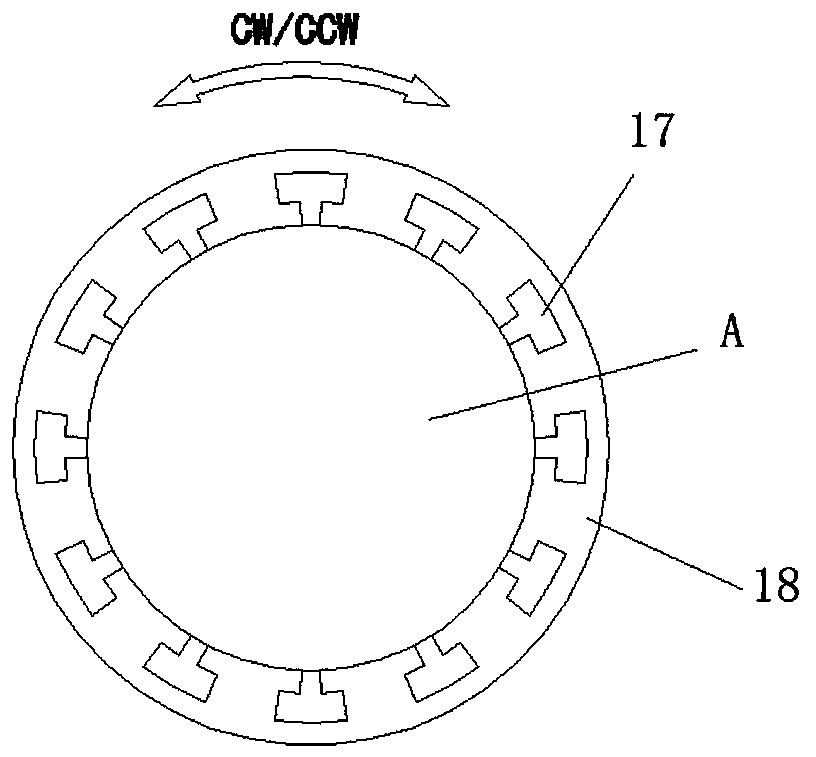

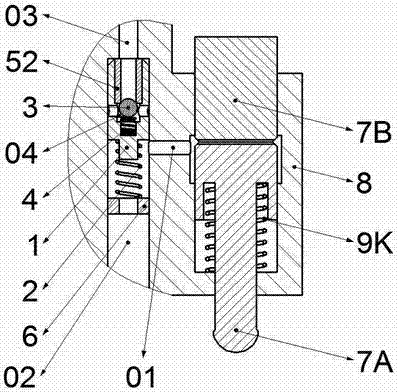

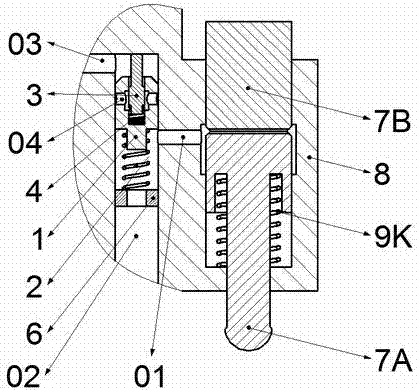

Gas lubrication hydrodynamic sealing device used for miniature high-speed turbo expander

PendingCN111188653AIncrease stiffnessGuaranteed zero leakageLeakage preventionMachines/enginesImpellerGas lubrication

The invention discloses a gas lubrication hydrodynamic sealing device used for a miniature high-speed turbo expander. The miniature high-speed turbo expander comprises a shell, wherein a main shaft and an impeller component are arranged in the shell; the impeller component is fixed on the main shaft; a bearing component is arranged out of the impeller component; the bearing component is sheathed to the main shaft; the sealing device is positioned between the impeller component and the bearing component and comprises a movable ring and a static component; the movable ring is sheathed to the main shaft; two ends of the movable ring are clamped between the impeller component and the bearing component; the static component is fixed on the shell; one end surface of the static component and themovable ring form a sealing surface; an end surface, which is laminated with the static component, on the movable ring is provided with a fluid hydrodynamic groove. Compared with the prior art, the sealing device disclosed by the invention is applied to the high-speed turbo expander, the zero leakage of bearing side lubricating oil to an exit side of the expander can be realized, and in addition,the internal gas loss of the expander is extremely small.

Owner:上海优赛密封科技有限公司

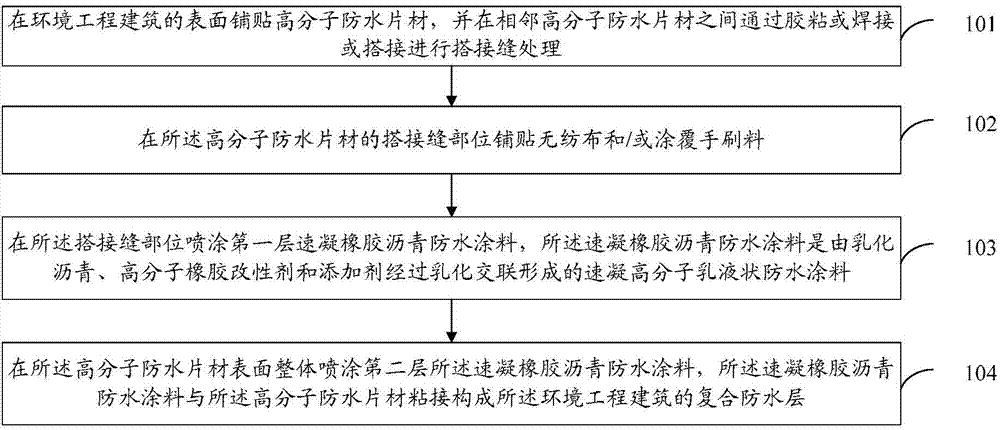

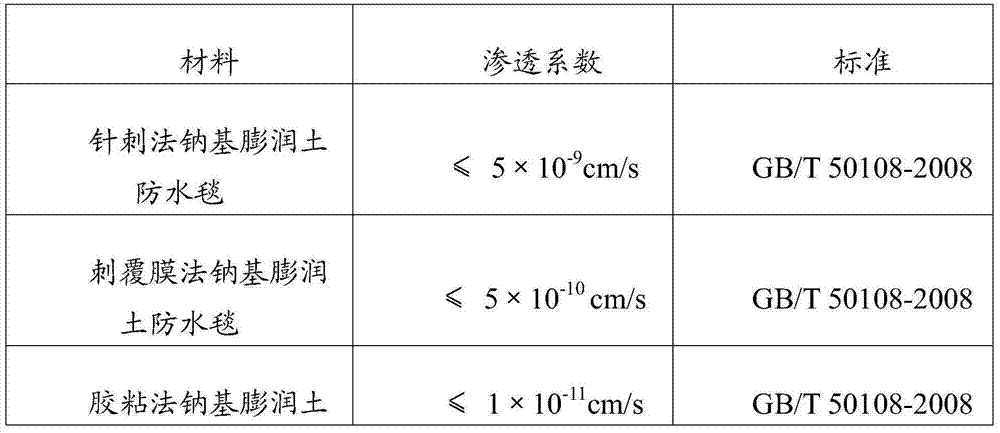

Composite waterproof layer for environmental engineering and preparing and constructing method thereof

ActiveCN104264715AMake up for deficienciesReduce the risk of water leakageLamination ancillary operationsLaminationLap jointEngineering

The invention provides a composite waterproof layer for environmental engineering and a preparing and constructing method thereof. The preparing and constructing method comprises the steps that polymer waterproof sheets are laid on and attached to the surface of an environmental engineering building, and lap joint seam processing is conducted between the adjacent polymer waterproof sheets in a glue bonding or welding or lap joint mode; the lap joint seam parts of the polymer waterproof sheets are provided with non-woven fabric in a laying and attaching mode or is coated with hand brush materials; first layers of rapid hardening rubber asphalt waterproof coatings are sprayed on the lap joint seam parts, and the rapid hardening rubber asphalt waterproof coatings are rapid hardening polymer emulsion state waterproof coatings formed by emulsified asphalt, a polymer rubber modifier and an additive in an emulsification crosslinking mode, a second layer of rapid hardening rubber asphalt waterproof coating is integrally sprayed on the surfaces of the poly waterproof sheets.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

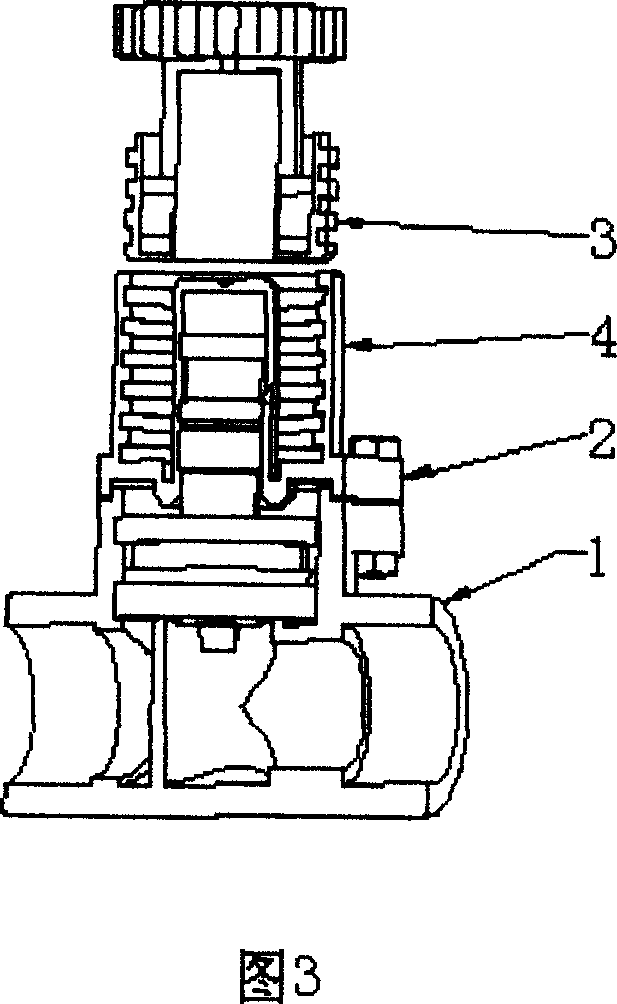

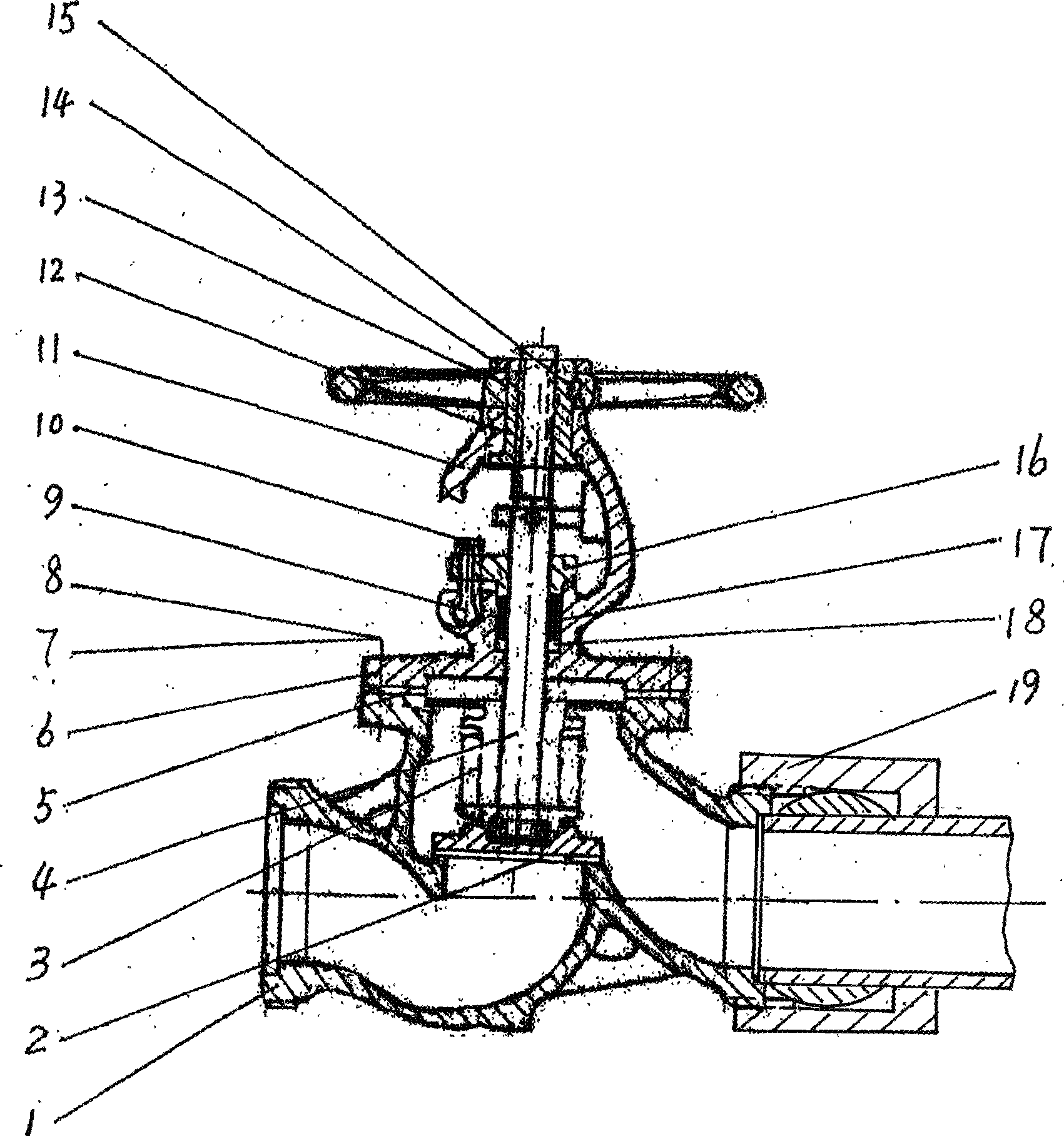

Preparation method of PPR plastic permanent magnet cut off valve

InactiveCN1948794AKeep static closedNo wearing partsLift valveValve housingsSingle injectionEngineering plastic

A PPR plastics permanent-magnet stop valve comprises a valve seat single-injection moulded of PPR plastics, a valve deck made of high-strength engineering plastics and metal connected with the valve seat via a flange plate and a bolt and an operating handle forming a threaded connection with the outside guide cover on the valve deck.

Owner:钟荷清

Composite graphite burning torch

ActiveCN104180394ASimple structureReduce volumeMake-and-break ignitionCombustion chamberAuto ignition

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

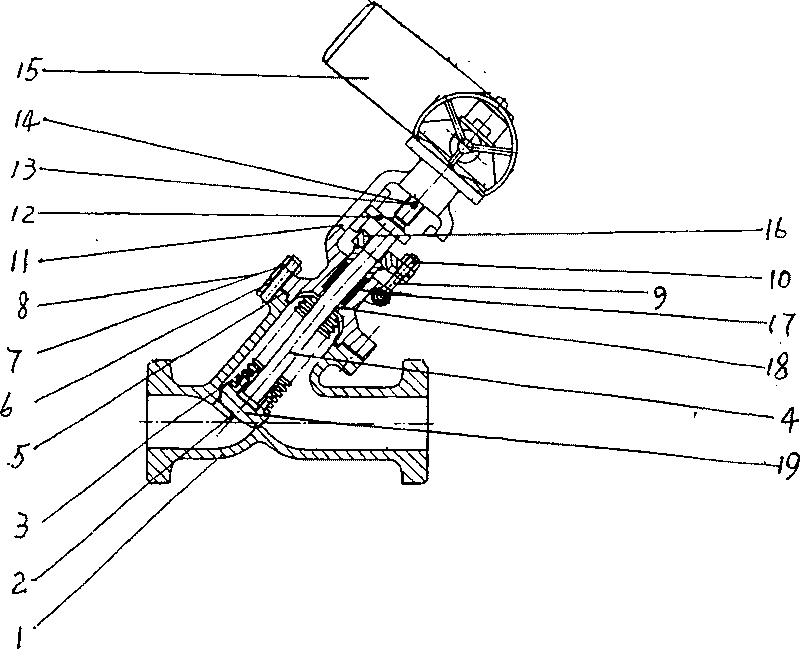

Photovoltaic motor-driven inclined bellow welding type stop valve

InactiveCN101749472AEasy connection and disassemblyEasy to disassembleSpindle sealingsOperating means/releasing devices for valvesChemical industryBody contact

The invention discloses a photovoltaic motor-driven inclined bellow welding type stop valve, and relates to a stop valve, which is characterized in that: an inclined welding type valve body is overlaid with a Co base hard alloy seal ring; a titanizing austenite stainless steel bellow device is movably and mechanically connected between the lower part of a valve rod and the upper part of a valve flap; gaskets are embedded into convex-concave positions of the inclined welding type valve body contacting with a valve cover, and the valve cover are mechanically connected with the inclined welding type valve body through bolts, spring gaskets and nuts; the top of a motor is provided with a silicon solar panel; the silicon solar panel, the top rack of the motor and the top of the motor are mechanically connected; the electric-energy output end of the silicon solar panel is electrically connected with the two ends of a storage battery device; the electric-energy output end of a storage battery is electrically connected with a voltmeter and an ammeter; and the storage battery is electrically connected with an electric control device. The stop valve is applicable to pipelines of the oil industry, the chemical industry, the pharmaceutical industry, the power industry and the like under various working conditions.

Owner:SHANGHAI HAIXING VALVE FACTORY

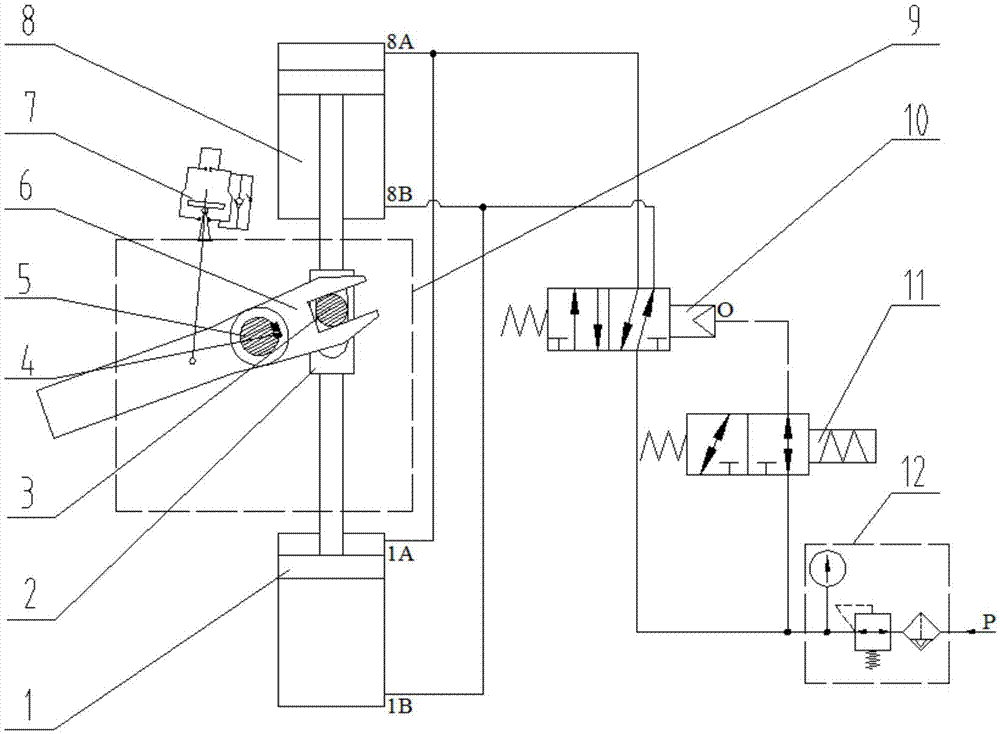

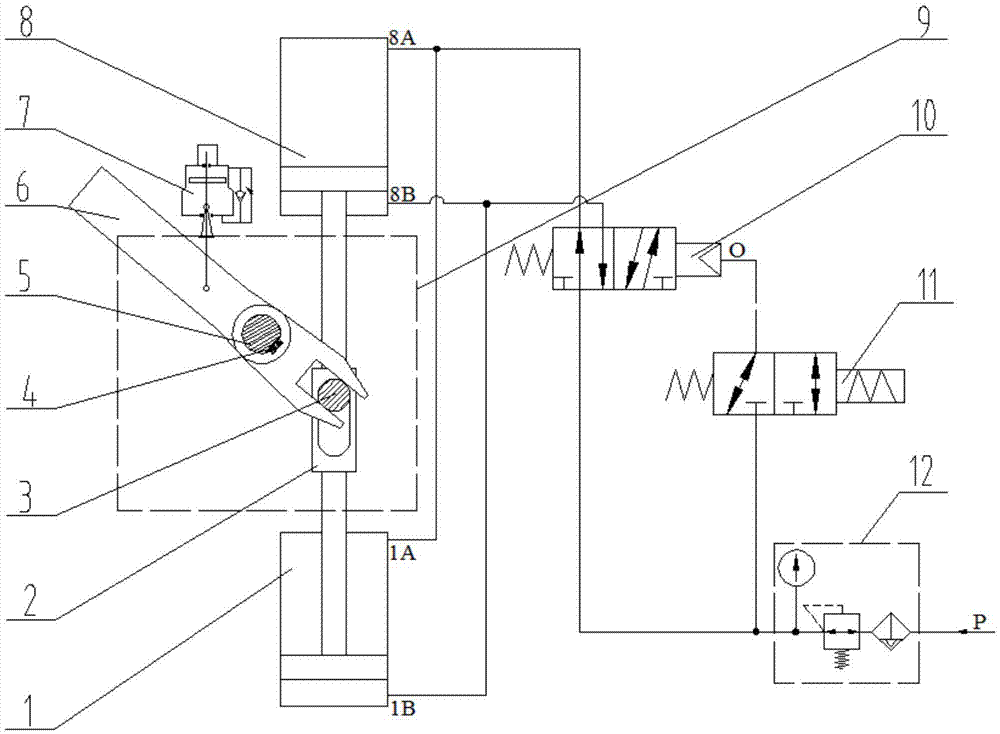

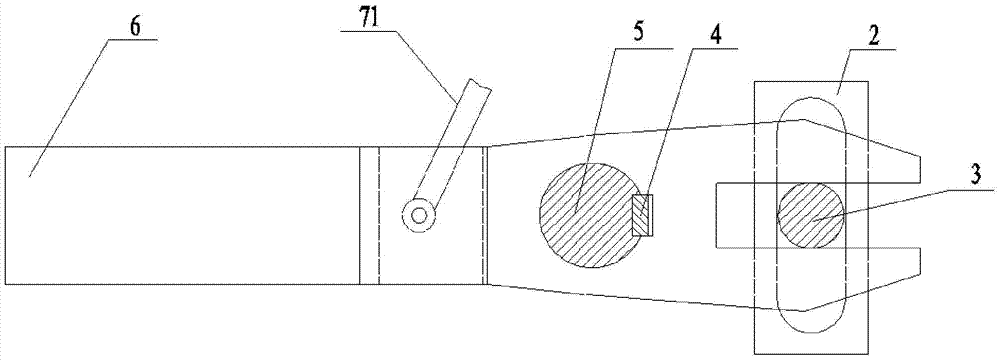

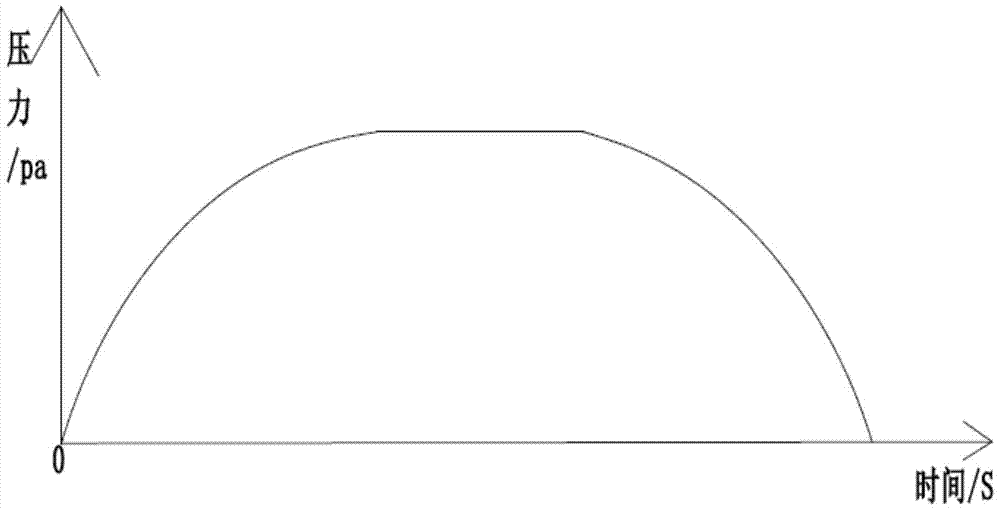

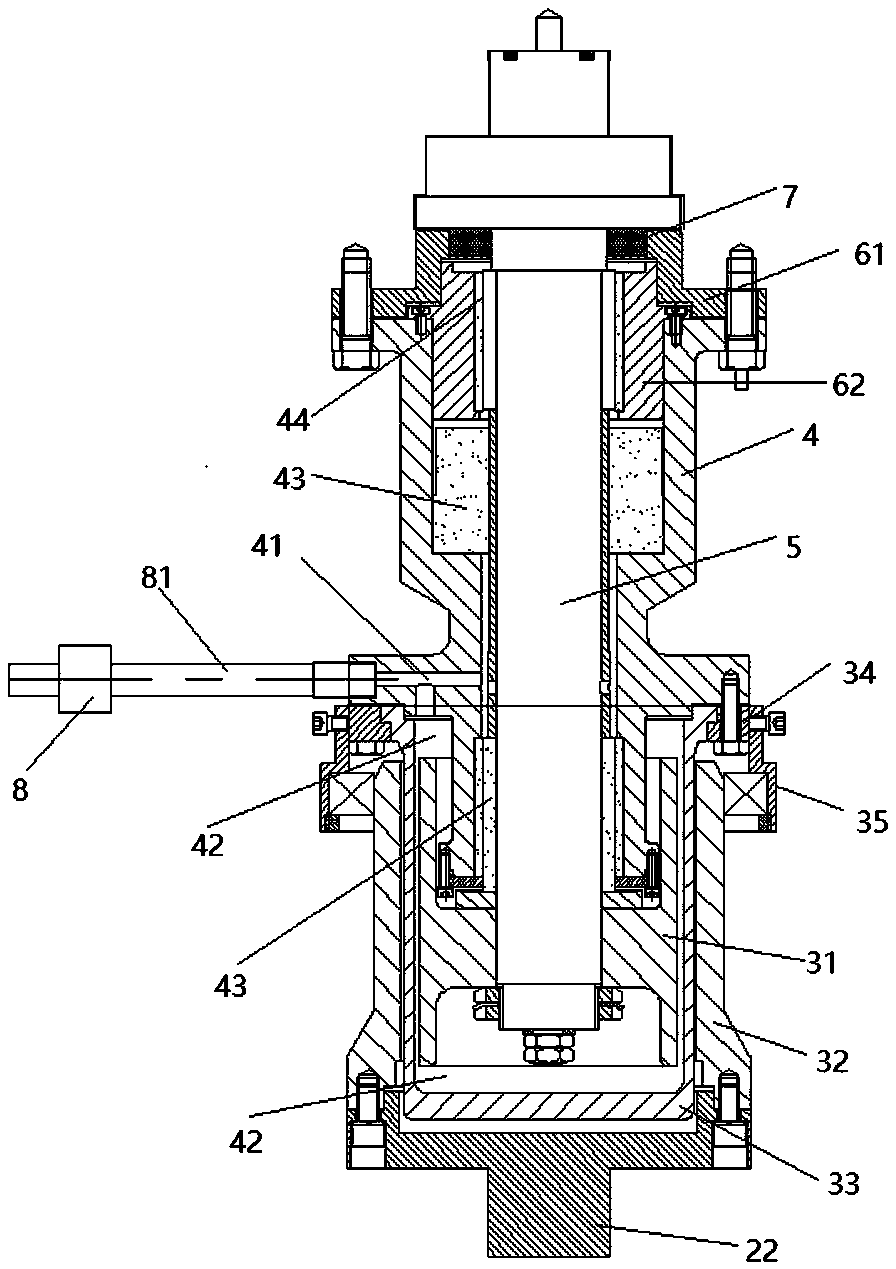

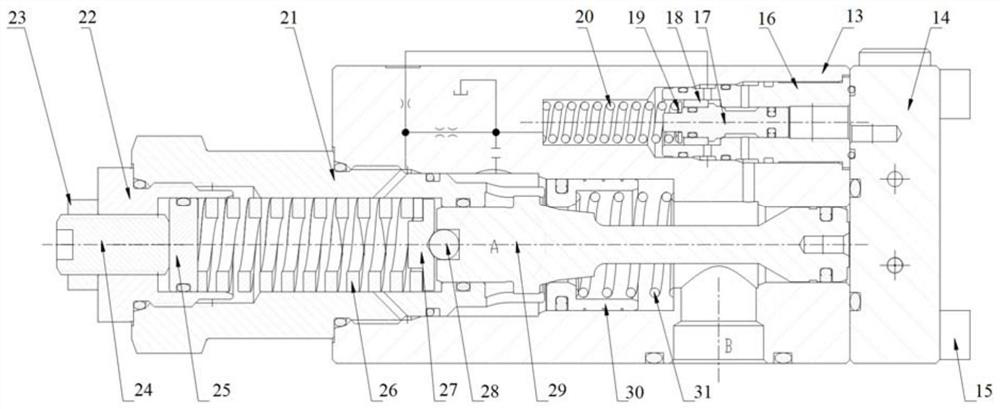

Pneumatic actuating mechanism for one-way damping valve

ActiveCN106917907AGuaranteed to shut downGuaranteed zero leakageOperating means/releasing devices for valvesCheck valvesLinear motionEngineering

The invention discloses a pneumatic actuating mechanism for a one-way damping valve and belongs to the technical field of catalytic cracking units of the petrochemical industry. The pneumatic actuating mechanism for the one-way damping valve comprises a first air cylinder, a second air cylinder, a shifting fork shaft, a shifting fork and an air cylinder reversing control unit. The rod portion of the shifting fork is fixedly connected with a valve shaft of the one-way damping valve. The air cylinder reversing control unit is used for controlling reversing of the first air cylinder and the second air cylinder. The pneumatic actuating mechanism further comprises an engagement and disengagement mechanism which is a cylinder body. The engagement and disengagement mechanism is provided with a guide groove in the longitudinal length direction. The two ends of the engagement and disengagement mechanism are fixedly connected with a piston rod of the first air cylinder and a piston rod of the second air cylinder correspondingly. The shifting fork shaft extends into a U-shaped opening formed in the end of the shifting fork and the guide groove in the engagement and disengagement mechanism. The shifting fork shaft can slide in the U-shaped opening and can conduct linear motion in the guide groove at the same time. The pneumatic actuating mechanism can improve the energy efficiency, guarantees that the one-way damping valve is closed under an emergency condition and protects the seal face of the one-way damping valve at the same time.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Motor-driven bellows inclined type welded valve-body stop valve

InactiveCN101749482AEasy connection and disassemblyEasy to disassembleSpindle sealingsOperating means/releasing devices for valvesChemical industryMotor drive

The invention discloses a motor-driven bellows inclined type welded valve-body stop valve and relates to a motor-driven stop valve, which comprises an inclined type welded valve body. The motor-driven bellows inclined type welded valve-body stop valve is characterized in that: a Co-based hard alloy sealing ring is formed on the inclined type welded valve body by surfacing; a titanized austenitic stainless steel bellows device is flexibly and mechanically connected below a valve rod and above a valve clack; pads are embedded into convex and concave contact positions of the inclined type welded valve body and a valve cap, so that the inclined type welded valve body and the valve cap are mechanically connected by springs, bolts, pads and nuts; a packing pad is arranged in a packing box on the valve cap, the packing is covered by a packing gland, and the packing gland is mechanically connected with the valve cover by a jacking screw and a jacking nut on the valve cover; and the upside of the valve rod is arranged in a mandrel sleeve of a motor driving head and mechanically connected with the same, and the lower head of the valve rod is flexibly and mechanically connected with the valve clack. The motor-driven bellows inclined type welded valve-body stop valve is applicable to pipes of various working conditions such as petroleum industry, chemical industry and the like to switch on and off a pipe medium.

Owner:SHANGHAI HAIXING VALVE FACTORY

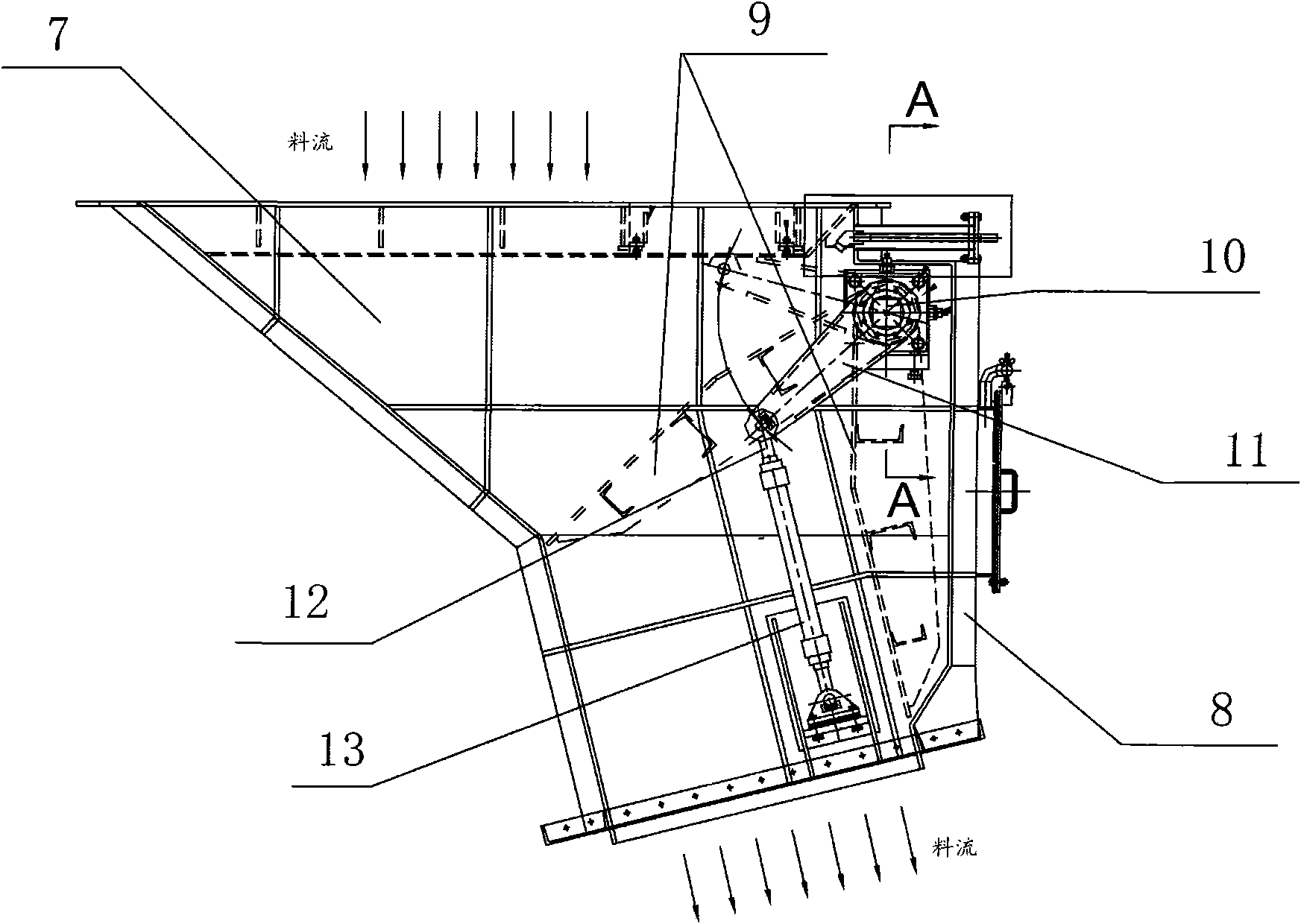

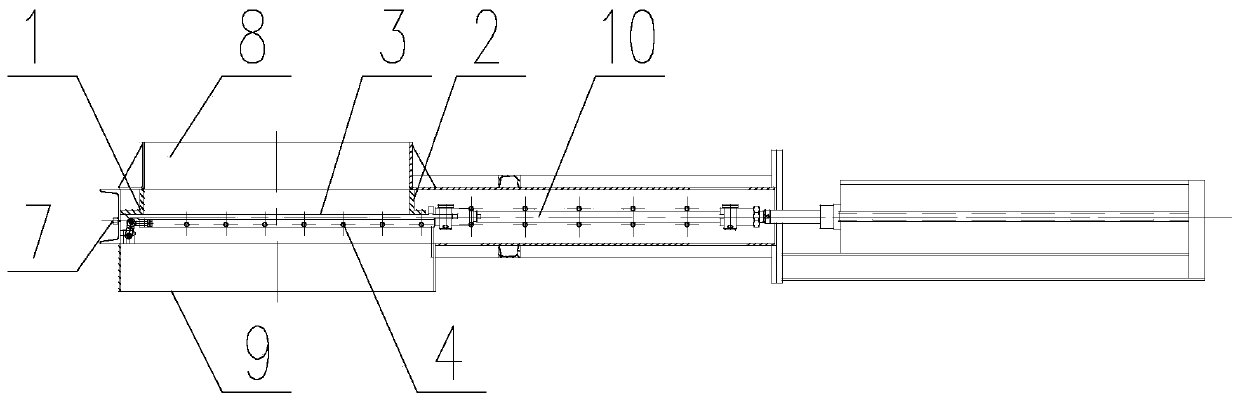

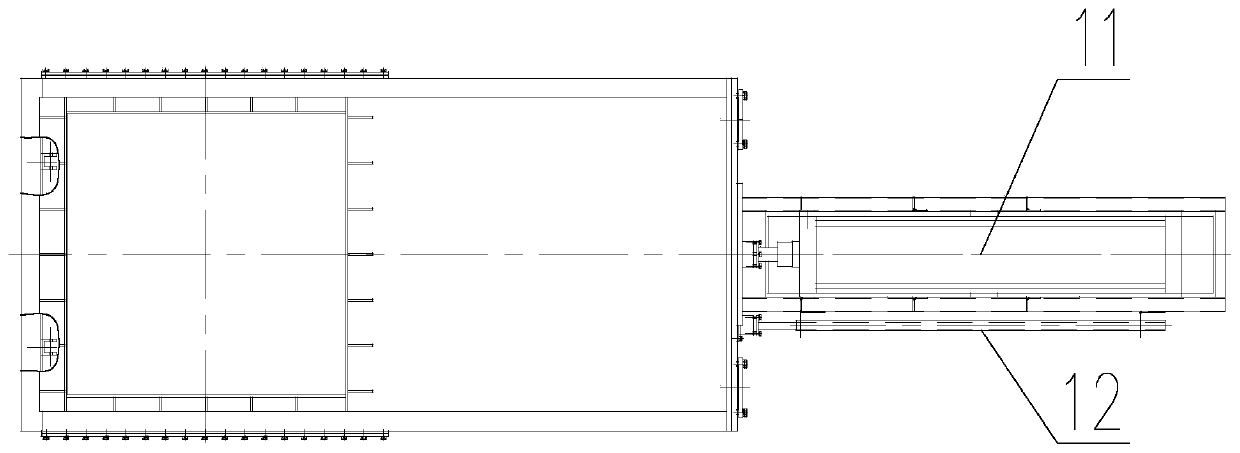

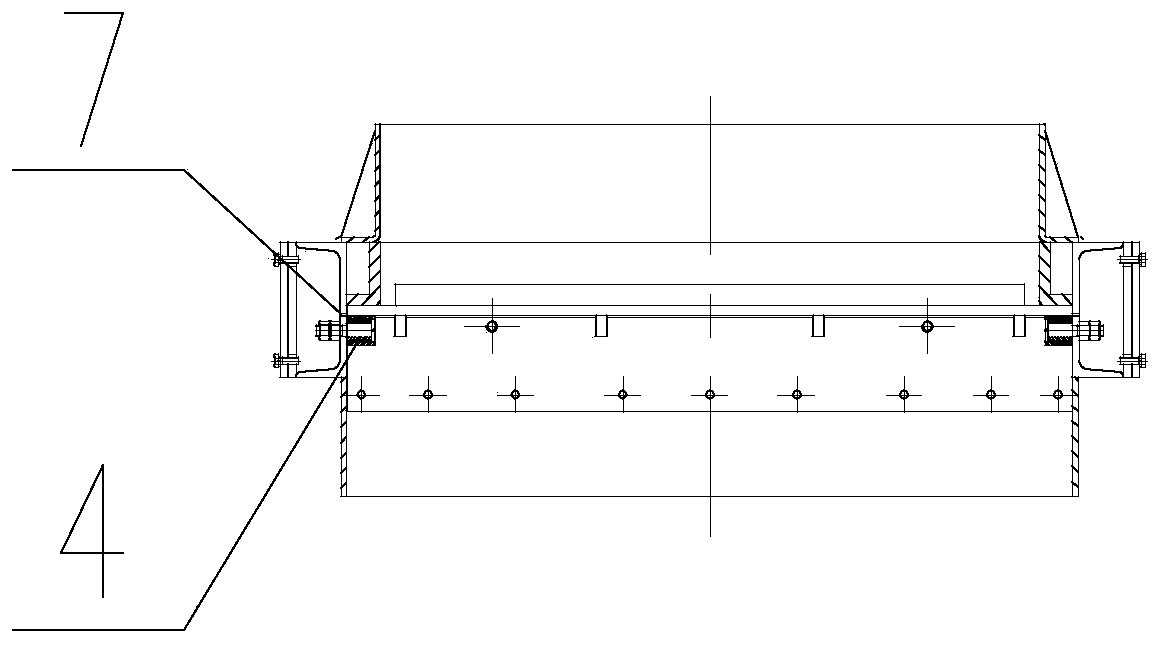

Sealing flashboard door for biomass feeding

PendingCN111473125AAnti-channelingGuaranteed zero leakageOperating means/releasing devices for valvesSlide valveStructural engineeringMechanical engineering

The invention relates to a sealing flashboard door, in particular to a sealing flashboard door for biomass feeding, and solves the problems of poor sealing effect, unsmooth opening and closing, jamming and blockage of an existing flashboard door. The sealing flashboard door for biomass feeding comprises a valve body front end, a valve body rear end, a feed port and a discharge port, wherein the valve body front end and the valve body rear end are both positioned at the front end and the rear end inside a valve body, the feed port is fixedly installed between the front end of the valve body andthe rear end of the valve body and located on the upper portion of the valve body, and the discharge port is located on the lower portion of the valve body. The sealing flashboard door for biomass feeding also comprises a plugboard assembly and a locking assembly, the plugboard assembly is in sliding connection with the bottom of the front end of the valve body and the bottom of the rear end of the valve body, and the locking mechanism is connected with the plugboard assembly. The sealing flashboard door can effectively solve the problems of unsmooth opening and closing, jamming, blocking, high failure rate and the like after frequent opening and closing.

Owner:HARBIN BOILER

Dynamic sealing structure suitable for high-differential pressure environment

InactiveCN108488391AAvoid pollution of high-pressure working medium and other problemsGuaranteed zero leakageEngine sealsMagnetic bearingDifferential pressure

The invention discloses a dynamic sealing structure suitable for a high-differential pressure environment, which is used for dynamic seal between a rotor and stators in the high-differential pressureenvironment. The stators include a first stator and a second stator, an antithrust positioning block is arranged on the rotor, the antithrust positioning block is located in a radial groove between the first stator and the second stator and comprises a radial electromagnetic bearing, an antithrust electromagnetic bearing and a magnetic fluid sealing device, the radial electromagnetic bearing sleeves the stators and is located between the stators and the rotor, the magnetic fluid sealing device sleeves the stators and is located between the stators and the rotor, and the antithrust electromagnetic bearing is arranged on the stators and is located in the radial groove. Because the electromagnetic bearing technique is introduced, the problems of conventional bearing grease lubrication and thelike are solved, and the problems of pollution of oil gas to high-pressure media and the like are solved; additionally, a magnetic fluid sealing technique is adopted, so that zero leakage or less leakage of the high-pressure media in the whole high-pressure system is guaranteed, and the purposes of support of the rotor in the high-pressure system and dynamic seal between the rotor and the statorsare achieved.

Owner:BEIHANG UNIV

Low-energy-consumption braking switch

ActiveCN107060943AReduce energy consumptionCompact structureValve arrangementsMachines/enginesEngineeringEngine valve

The invention discloses a low-energy-consumption braking switch and belongs to the field of engine valve driving and auxiliary braking. The low-energy-consumption braking switch comprises two hydraulic pistons arranged on a fixing part, a sliding valve body, a sliding valve return spring, a one-way valve core, a one-way valve return spring and the like. The driving modes and the braking modes are switched through a braking switch; and through match with different valve driving systems, the different schemes of various modes including the four-stroke driving mode, the two-stroke driving mode, the four-stroke braking mode, the two-stroke braking mode and the like can be achieved, and high-power, low-oil-consumption, low-emission and efficient graded braking is achieved. The low-energy-consumption braking switch is simple and compact in structure, high in reliability and low in cost.

Owner:DALIAN UNIV OF TECH

Motor-driven high-temperature-resistant corrugated pipe stop valve

InactiveCN101598238ASimple structureEasy to installSpindle sealingsOperating means/releasing devices for valvesChemical industryAustenitic stainless steel

The invention provides a motor-driven high-temperature-resistant corrugated pipe stop valve and relates to a motor-driven stop valve. The clamp connection type high-temperature-resistant corrugated pipe stop valve comprises a valve body. A titanizing austenitic stainless steel corrugated pipe device is movably and mechanically connected between the lower part of a valve rod and the upper part of a valve clack, the upper part of the valve rod is arranged in a motor drive head mandrel sleeve and is mechanically connected with the motor drive head mandrel sleeve, a lower head of the valve rod is movably and mechanically connected with the valve clack, the motor drive head mandrel sleeve is arranged in a motor drive head mandrel and is mechanically connected with a motor drive head device, the motor drive head mandrel is rotated to enable a lifting rod of the valve rod to drive the titanizing austenitic stainless steel corrugated pipe device to lift by the motor drive head mandrel sleeve, the motor drive head mandrel sleeve is arranged in an interior hole above a valve cover and is mechanically connected with the interior hole, and the motor drive head mandrel is arranged in the motor drive head mandrel sleeve and is mechanically connected with a traverse pin of the motor drive head mandrel sleeve. The dual firm and durable corrugated pipes have convenient disassembly and reliable sealing, and the motor-driven high-temperature-resistant corrugated pipe stop valve is suitable for pipelines with various working conditions in the petroleum industry, the chemical industry, the electric power industry, and the like.

Owner:SHANGHAI HAIXING VALVE FACTORY

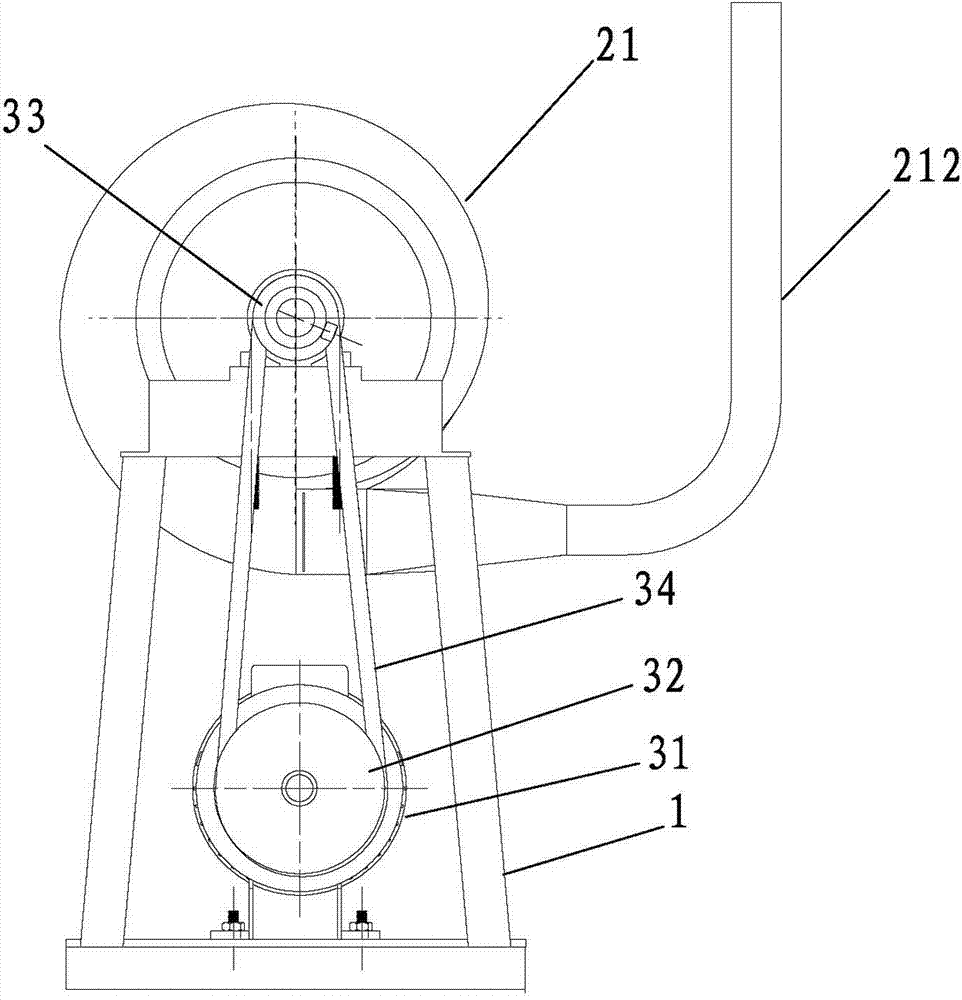

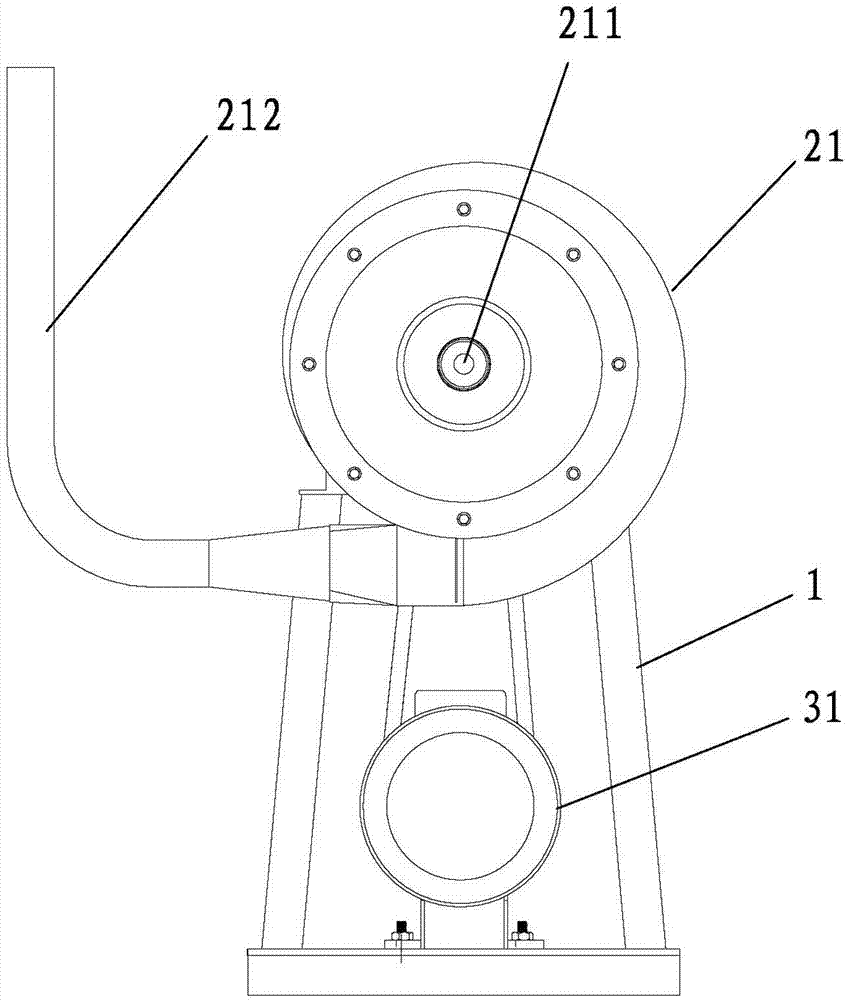

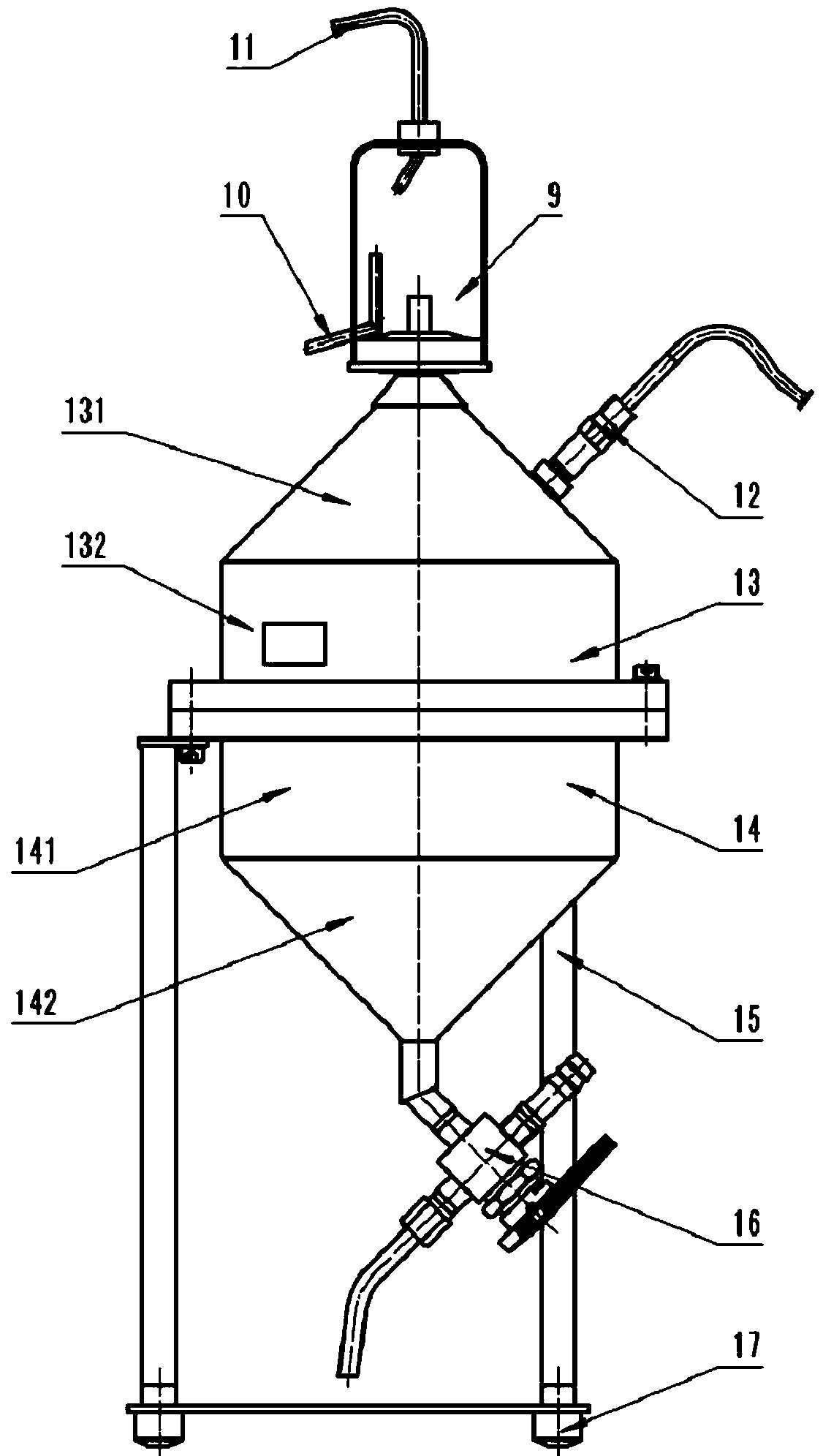

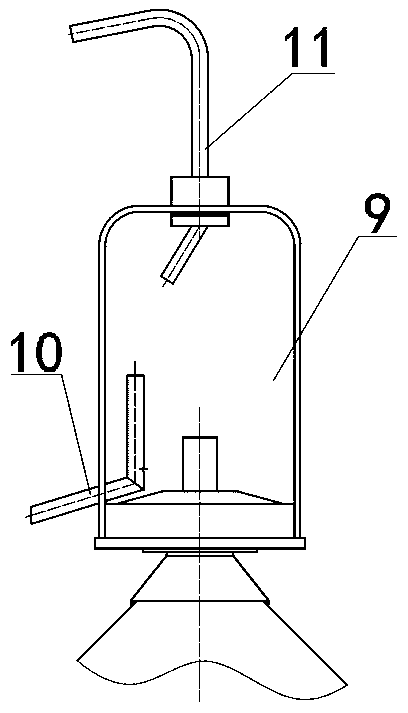

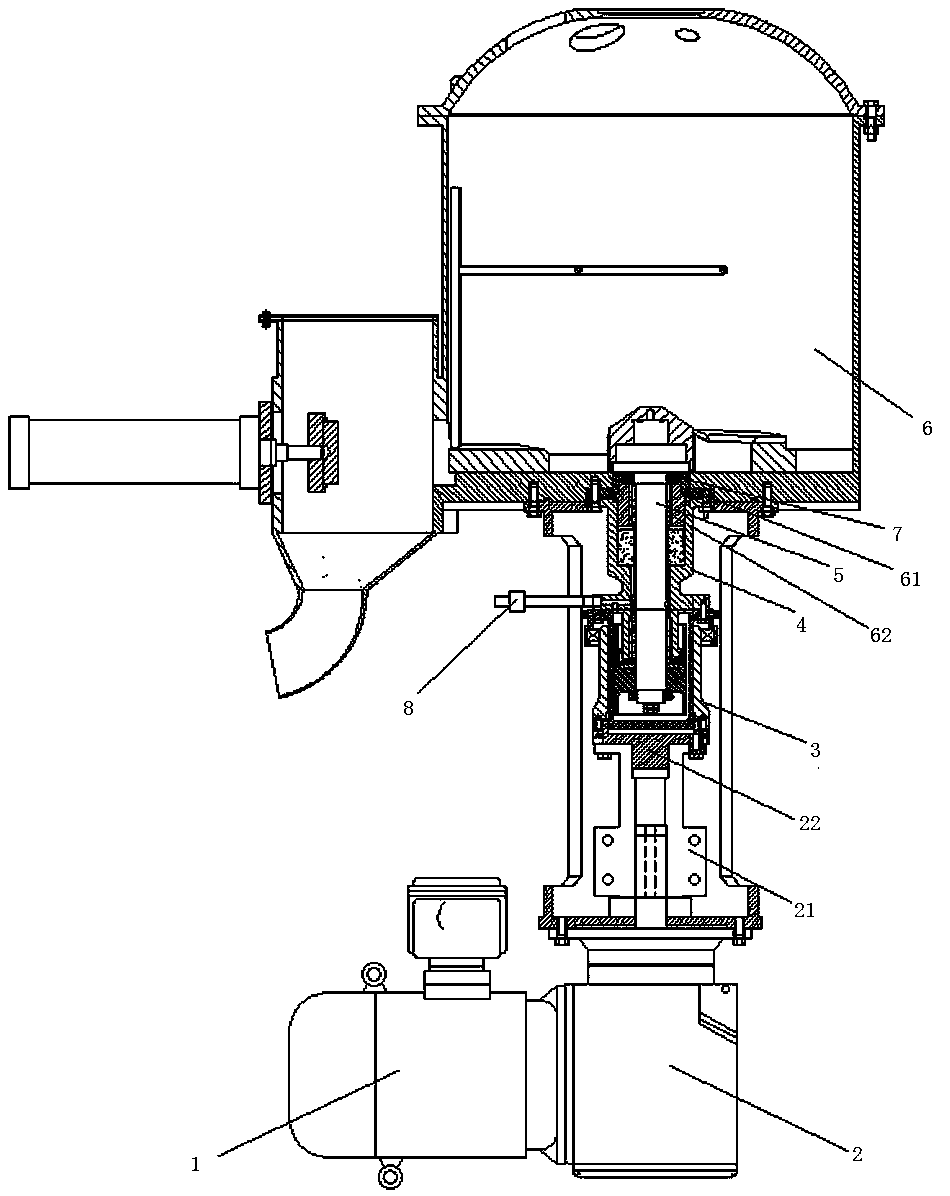

Zero-leakage alkali discharging device

InactiveCN104847669ARealize continuous transportationReduce pollutionSpecific fluid pumpsPump componentsImpellerChemical solution

The invention discloses a zero-leakage alkali discharging device, which comprises a rack, a device body arranged on the rack and a driving mechanism, wherein the device body comprises a housing, an impeller and a main shaft; the housing is volute-shaped, and the side surface and the spiral tail end are provided with an alkali inlet pipeline and an alkali outlet pipeline; one end of the main shaft is in transmission connection with the driving mechanism, the other end of the main shaft extends into the housing along the axial direction of the housing, the impeller is arranged in the housing and axially arranged at the other end of the main shaft, and the impeller is driven to rotate by the driving mechanism through the main shaft. Compared with the prior art, the alkali discharging device disclosed by the invention has the advantages of zero leakage, high efficiency, environment protection, no residual solution, ability of reducing resource waste and environmental pollution and the like, has great economic values and application values and is wide in application prospect, thereby being an optimal choice for transporting chemical solutions in each industry.

Owner:XIAMEN UNIV OF TECH

Pneumatic interior thread connection type high-temperature-resistant corrugated pipe stop valve

InactiveCN101598236AEasy to disassembleEasy connection and disassemblySpindle sealingsOperating means/releasing devices for valvesConnection typeEngineering

The invention provides a pneumatic interior thread connection type high-temperature-resistant corrugated pipe stop valve and relates to a pneumatic stop valve. The pneumatic interior thread connection type high-temperature-resistant corrugated pipe stop valve comprises an interior thread connection type valve body, wherein a Co-based hard alloy sealing ring is resurfaced and welded on the interior thread connection type valve body. A titanizing austenitic stainless steel dual-corrugated-pipe device is movably and mechanically connected below a valve rod, a lower head of the valve rod is movably and mechanically connected with a valve clack, and a pneumatic head mandrel is rotated to enable a lifting rod of the valve rod to drive the titanizing austenitic stainless steel dual-corrugated-pipe device to lift by a pneumatic head mandrel sleeve. The dual firm and durable corrugated pipes are convenient to disassemble, the interior thread connection is convenient to disassemble, the product structure is reasonable, the sealing is reliable, and the zero leakage of the valve rod is ensured. Co-based hard alloy resurfaced and welded on a sealing face and titanizing austenitic stainless steel of the corrugated pipes have good properties of abrasion resistance, erosion resistance and friction resistance and long service life, and the pneumatic interior thread connection type high-temperature-resistant corrugated pipe stop valve is suitable for switching off or switching on pipeline media on pipelines with various working conditions in the petroleum industry, and the like.

Owner:SHANGHAI HAIXING VALVE FACTORY

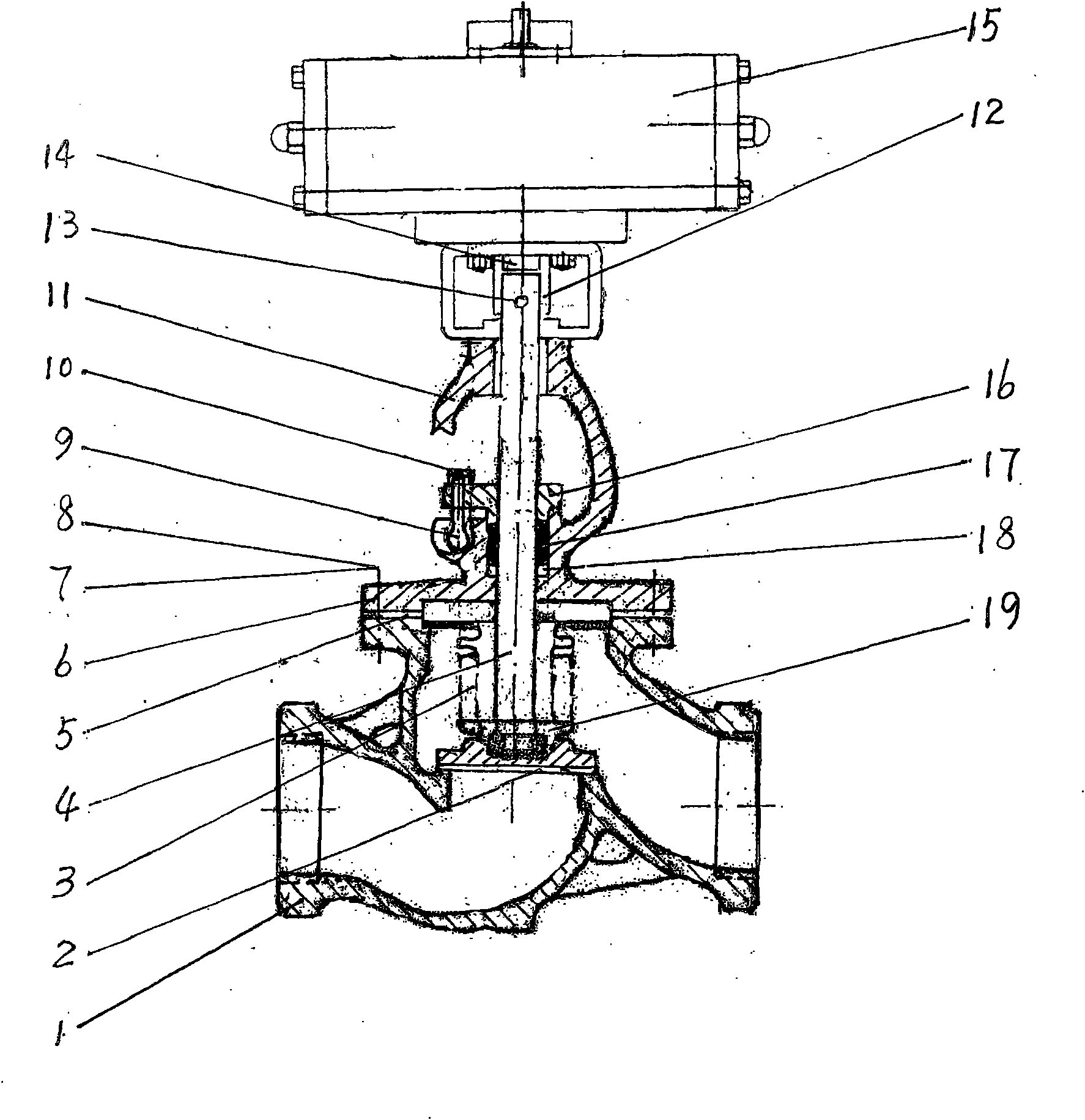

Low and medium-pressure pneumatic balanced stop valve

InactiveCN104747743AGuaranteed coincidenceGuaranteed zero leakageSpindle sealingsOperating means/releasing devices for valvesInlet channelDifferential pressure

The invention relates to a low and medium-pressure pneumatic balanced stop valve which comprises a valve body provided with a water inlet channel and a water outlet channel, wherein a valve seat is arranged on the valve body; a sealing gasket is arranged at the contact part of the valve seat and the valve body; a valve clack is fixedly connected to the valve seat. The stop valve also comprises a cylinder seat and a cylinder barrel provided with an upper air source through hole and a lower air source through hole. A piston and a piston rod are arranged in the cylinder barrel. The bottom end of the cylinder barrel is fixedly connected with the valve body. One end of the piston rod is fixedly connected with the piston while the other end of the piston rod is fixedly connected with the valve seat. A guide platform is arranged below the cylinder seat. A guide barrel is arranged on the upper part of the valve clack. The guide platform and the guide barrel are in sealing cup joint. Under the conditions with any pressure difference of a water current medium, the opening and the closing of the stop valve are convenient, free, easy and labor-saving; the integral size of the valve is reduced; and the service life of the valve is prolonged.

Owner:HUBEI HIGH & HIGH PRESSURE VALVE CO LTD

Buckling connection type high-corrosion resisting bellow cut-off valve

InactiveCN101586696AEasy to disassembleEasy connection and disassemblySpindle sealingsOperating means/releasing devices for valvesConnection typeChemical industry

The invention relates to a buckling connection type high-corrosion resisting bellow cut-off valve which belongs to cut-off valves. The buckling connection type high-corrosion resisting bellow cut-off valve comprises a buckling connecting type valve body on which a Co-based hard alloy seal ring is welded, a titanized austenitic stainless steel bellow device is movably connected to the lower part of a valve rod, a handwheel is rotated to enable a lifting rod of the valve rod to drive the titanized austenitic stainless steel dual bellow device to ascend and descend by a valve rod nut, the dual bellow which is firm and durable is assembled conveniently, the buckling connection and disassembly are convenient, and the product has reasonable structure and reliable sealing; and the Co-based hard alloy and the bellow titanized austenitic stainless steel which are welded on a sealing face have good properties of wearing resistance, corrosion resistance, abrasion resistance and long service life. The invention is suitable for cutting or communicating mediums on pipelines of various working conditions, such as petroleum and chemical industries, and the like.

Owner:SHANGHAI HAIXING VALVE FACTORY

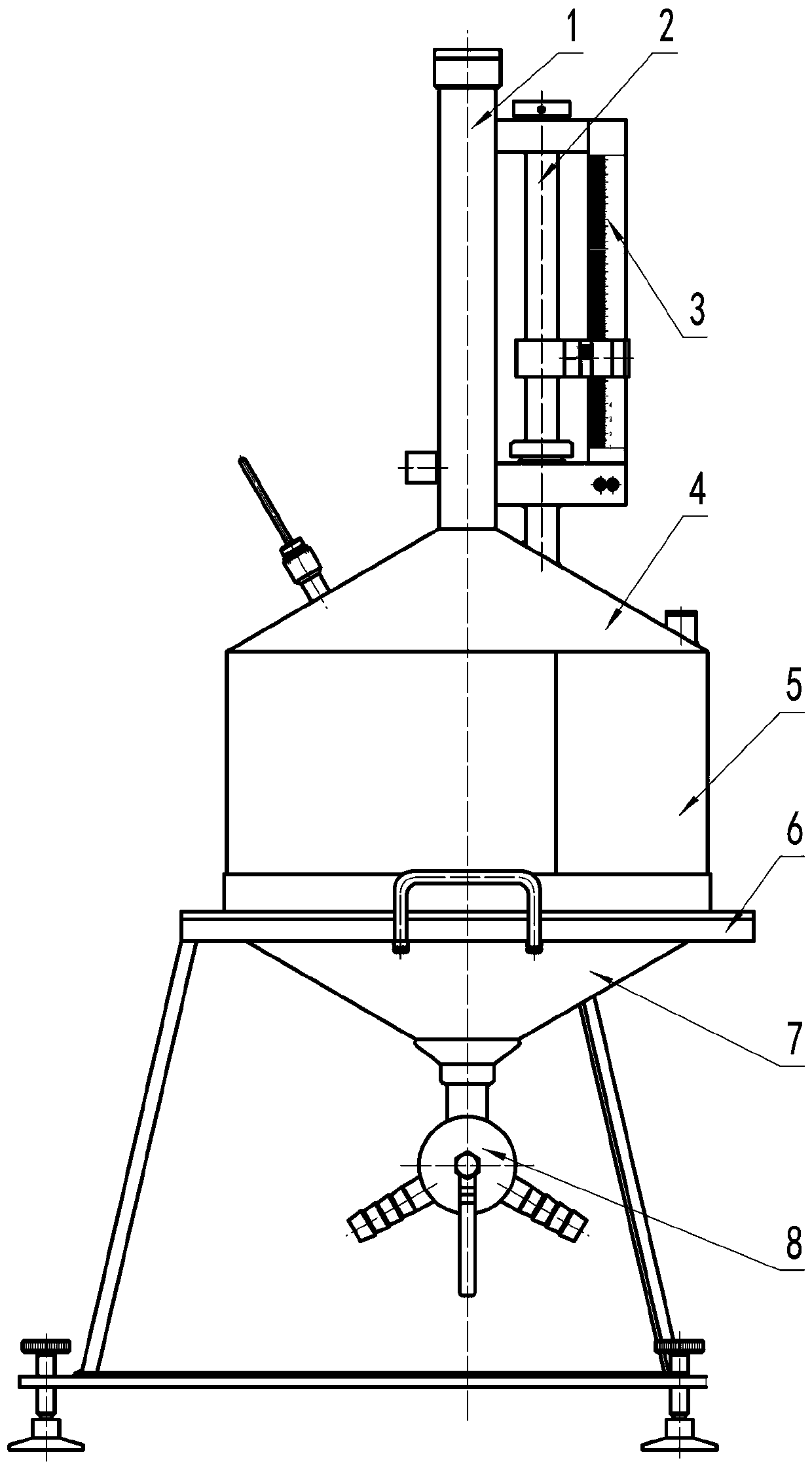

A first-class standard metal measure

ActiveCN104897251BHigh precisionShorten the timeTesting/calibration apparatusCapacity measurement calibrationPlatinum resistanceRepeatability

The invention discloses a first-class standard metal measuring instrument, the main body of which is formed by connecting the upper part of the measuring instrument and the lower part of the measuring instrument. The top of the upper part of the measuring instrument is connected with an overflow device. The overflow device includes a and the casing of the overflow pipe, the upper opening of the overflow pipe is set in the casing and is not lower than the water outlet at the top of the gauge, the lower opening of the overflow pipe is set outside the casing; there is also a Bending, the bending position is lower than the water outlet at the upper top of the measuring device, and an overflow hole is arranged at the bending position. The overflow device adopted in the present invention avoids the error caused by artificially observing the liquid level scale of the metering neck, and improves the measurement accuracy; it is easier to process and transport, and it is convenient to disassemble the measuring device for cleaning; the measurement accuracy and repeatability are improved, and the annular hard seal is more accurate. It is easy to ensure the sealing performance; the imported three-way valve is used to avoid the error caused by the switching valve; the platinum resistance temperature measuring device is used, which has the advantages of high precision and short response time.

Owner:KAIFENG INSTR +1

Valve with double sealing pairs

InactiveCN1644967AHigh mechanical strengthExtended service lifePlug valvesLift valvePower stationWater turbine

The valve with double sealing couple is ball valve or butterfly valve, which consists of valve body and valve core inside valve body. There is a metal sealing couple consisting of the valve core metal seal ring set in external circle of valve core and the valve body metal seal ring set in internal circle of valve body in between valve body and valve core; there is a flexible sealing couple consisting of the valve body flexible seal ring set in internal circle of valve body and above valve core metal seal ring in between valve body and valve core. In this invention, the sealing couples in between valve body and valve core include the metal sealing couple and the flexible sealing couple. The metal sealing couple has strong mechanical strength, long life, and can be used as the main sealing tool, that is working sealing; the flexible sealing couple has good sealing performance, after close the valve, make sure no leak, can be used as turnaround sealing tooo. This invention is applicable for the inlet valve of water turbine in the hydroelectric power station.

Owner:TIELING SPECIAL VALVE

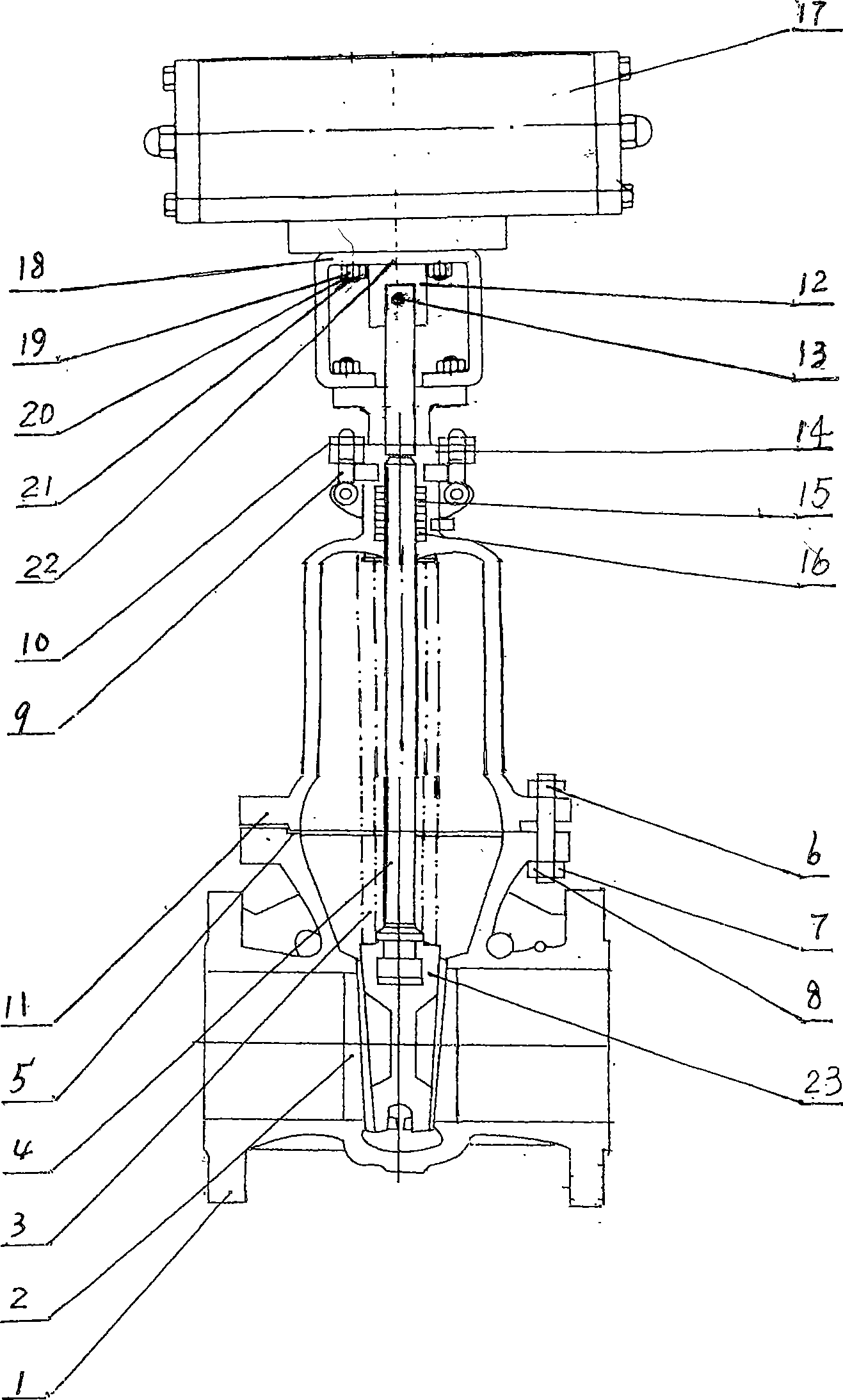

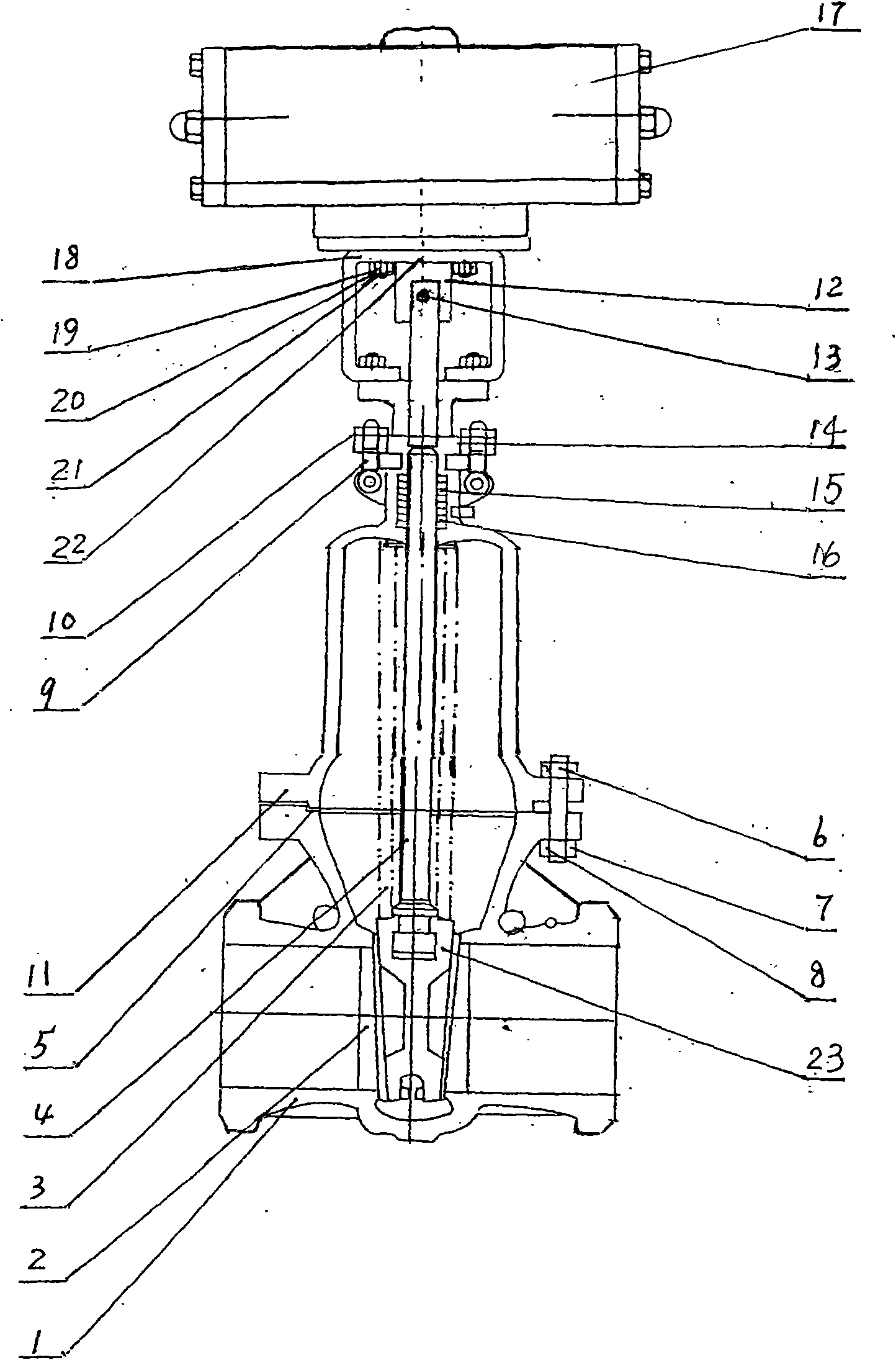

Hydraulically driven high temperature resistant bellows gate valve

InactiveCN101469781AEasy to disassembleGuaranteed zero leakageSpindle sealingsOperating means/releasing devices for valvesAutomatic controlAustenitic stainless steel

A hydraulic drive high-temperature resistance corrugated pipe gate valve, relating to a hydraulic drive gate valve, comprises a valve body, wherein a hydraulic drive head device is mechanically connected with a hydraulic drive head device frame; the hydraulic drive head device frame is mechanically connected with a valve cover through a bolt, a spring gasket and a nut; a hydraulic drive head mandrel; the upper part of a valve rod and a hydraulic drive head mandrel sleeve are mechanically connected through a transverse pin; a Ti-plated austenitic stainless steel corrugated pipe device is movably connected between the lower part of the valve rod and the upper part of a gate plate, the lower part of the valve rod is mechanically connected with the gate plate, the Ti-plated austenitic stainless steel corrugated pipe device is driven to lift through a lifting rod of the valve rod. The hydraulic drive head can be used for automatic controlled pipelines, the flange connection is convenient to be disassembled, and the corrugated pipe with dual-firmness and durability is convenient to be disassembled, the sealing design of the corrugated pipe with dual-firmness and durability guarantees zero leakage of the valve rod. Due to no fluid loss, energy loss is reduced, and the safety of factory equipment is improved.

Owner:SHANGHAI HAIXING VALVE FACTORY

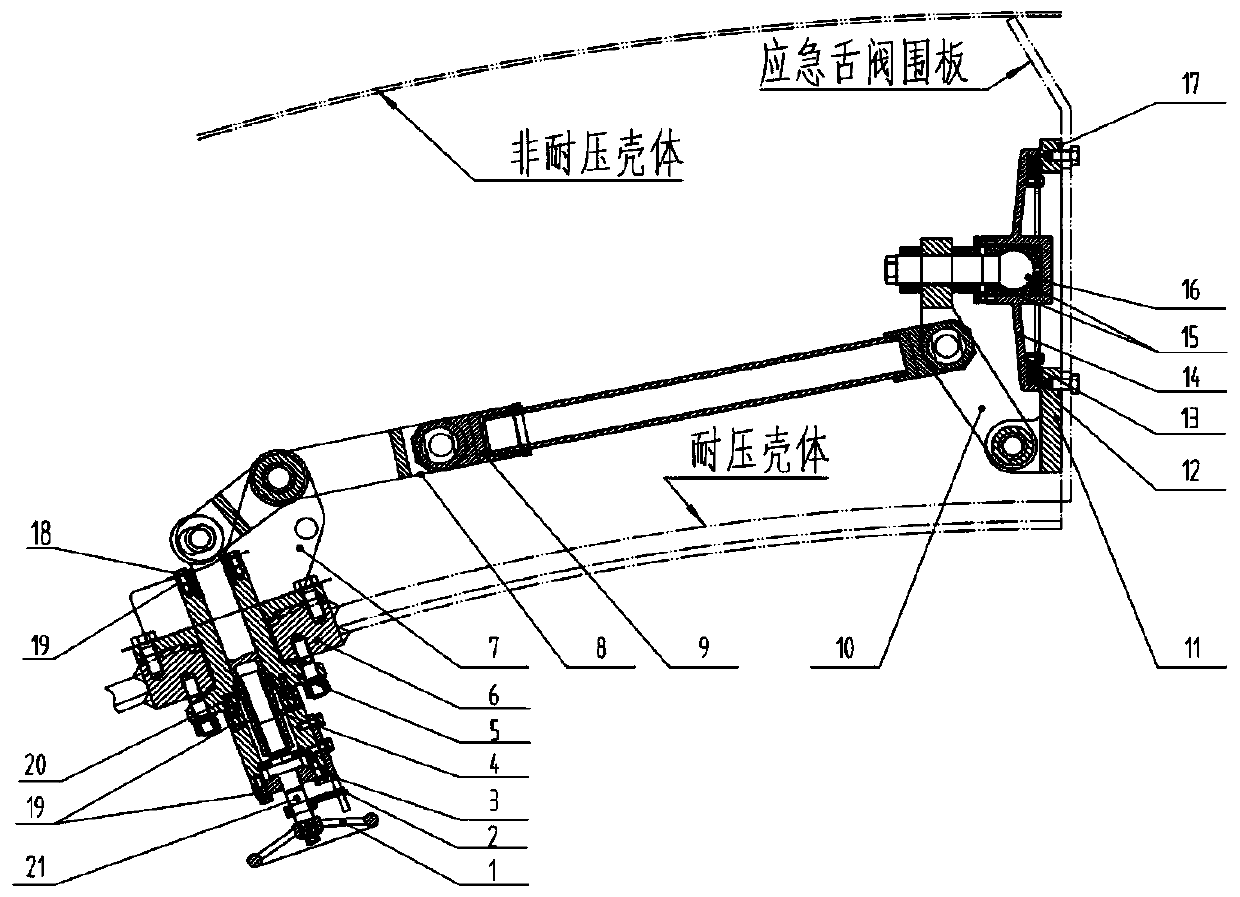

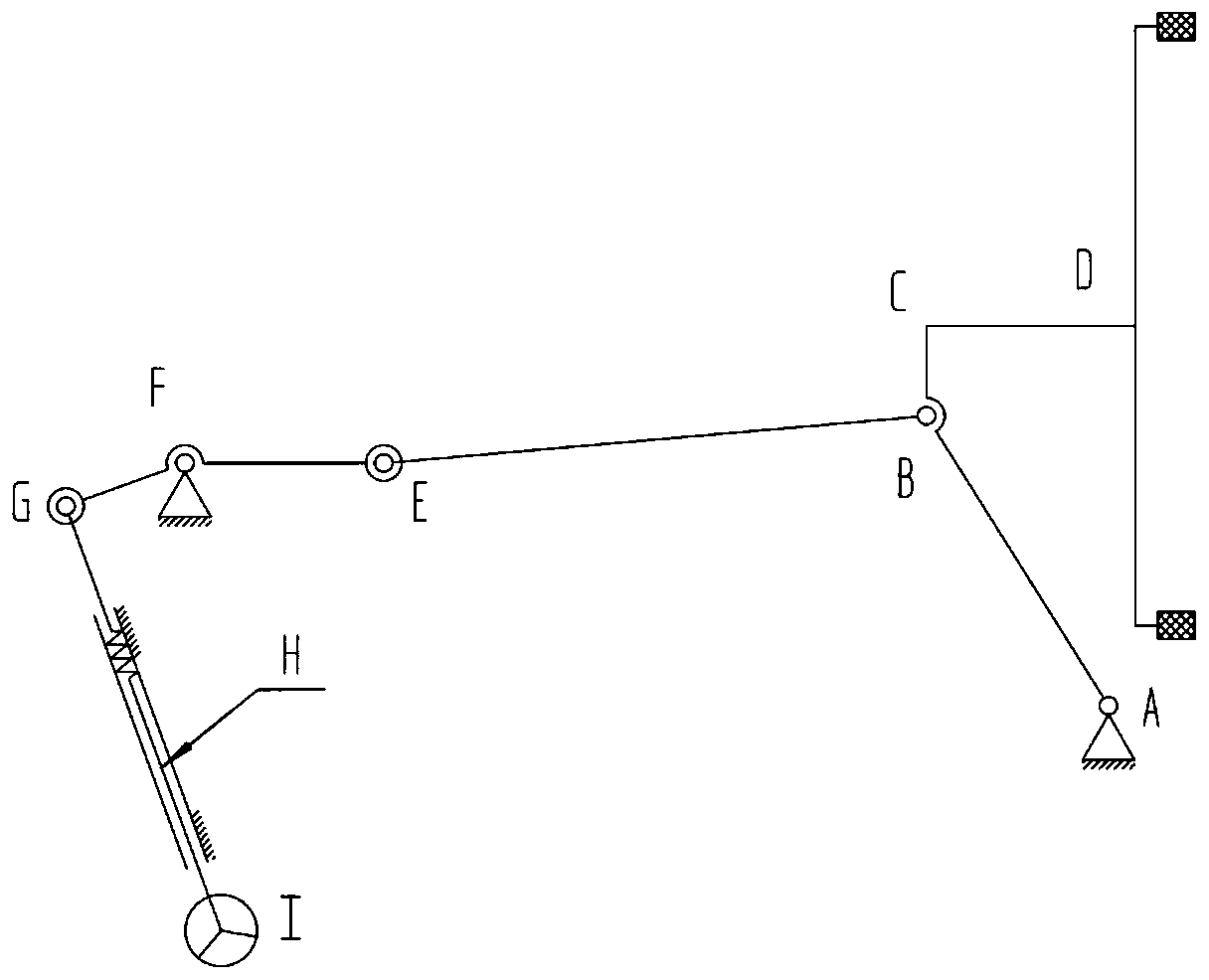

Emergency flap valve

ActiveCN110296268AEasy to operateStrong anti-aging abilityOperating means/releasing devices for valvesLift valveRocker armEngineering

The invention discloses an emergency flap valve. The emergency flap valve comprises a valve body, a supporting seat, a valve plate assembly and a valve seat, wherein the valve body is mounted on the supporting seat; the valve plate assembly is matched with the valve seat. The emergency flap valve is characterized by further comprising a transmission device assembly; the transmission device assembly comprises a force applying mechanism, a swinging rotating mechanism and a rocker arm; the force applying mechanism and the valve body are arranged in a sealing manner; the force applying mechanism penetrates through the valve body and supplies driving force to the swinging rotating mechanism; the tail end of the swinging rotating mechanism is hinged with the rocker arm; and one end of the rockerarm is fixedly connected to the valve plate assembly while the other end of the rocker arm is hinged with the valve seat. The emergency flap valve is convenient to operate and remains zero leakage within certain underwater depth range; the transmission device is adaptive to the deformation of a ship body structure; a sealing material is resistant to abrasion, and high in ageing resistance; partsof hinging points are flexibly oppositely moved and are prevented from falling off.

Owner:CHINA SHIP DEV & DESIGN CENT

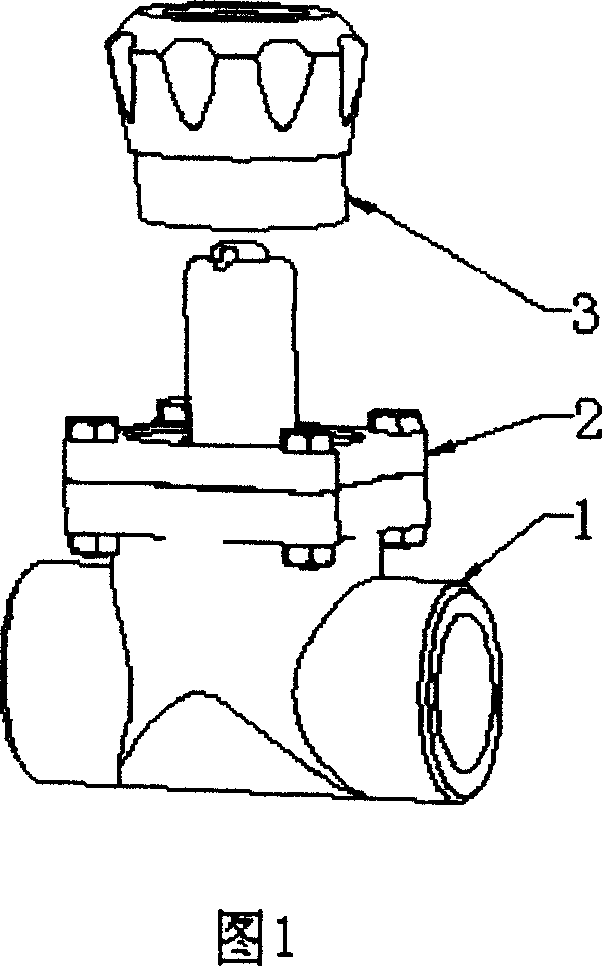

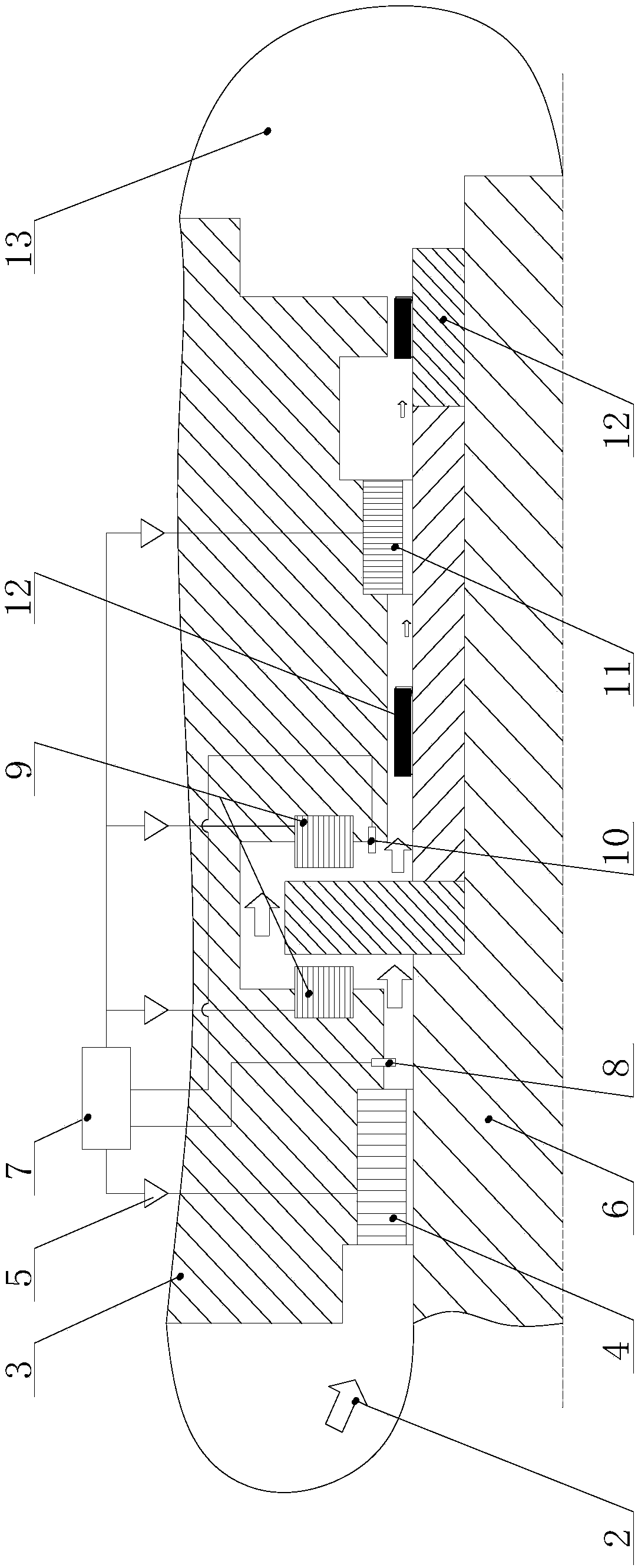

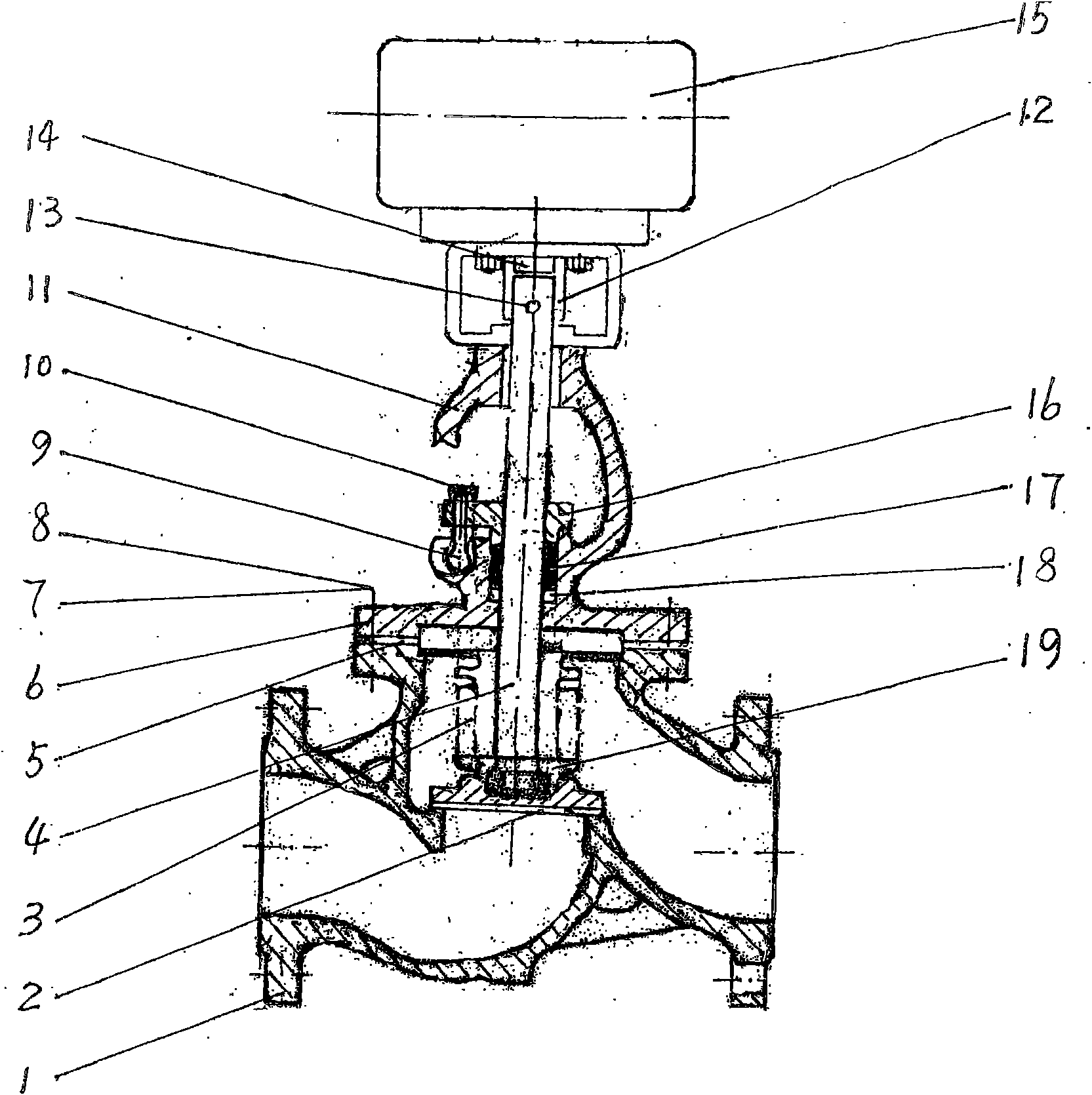

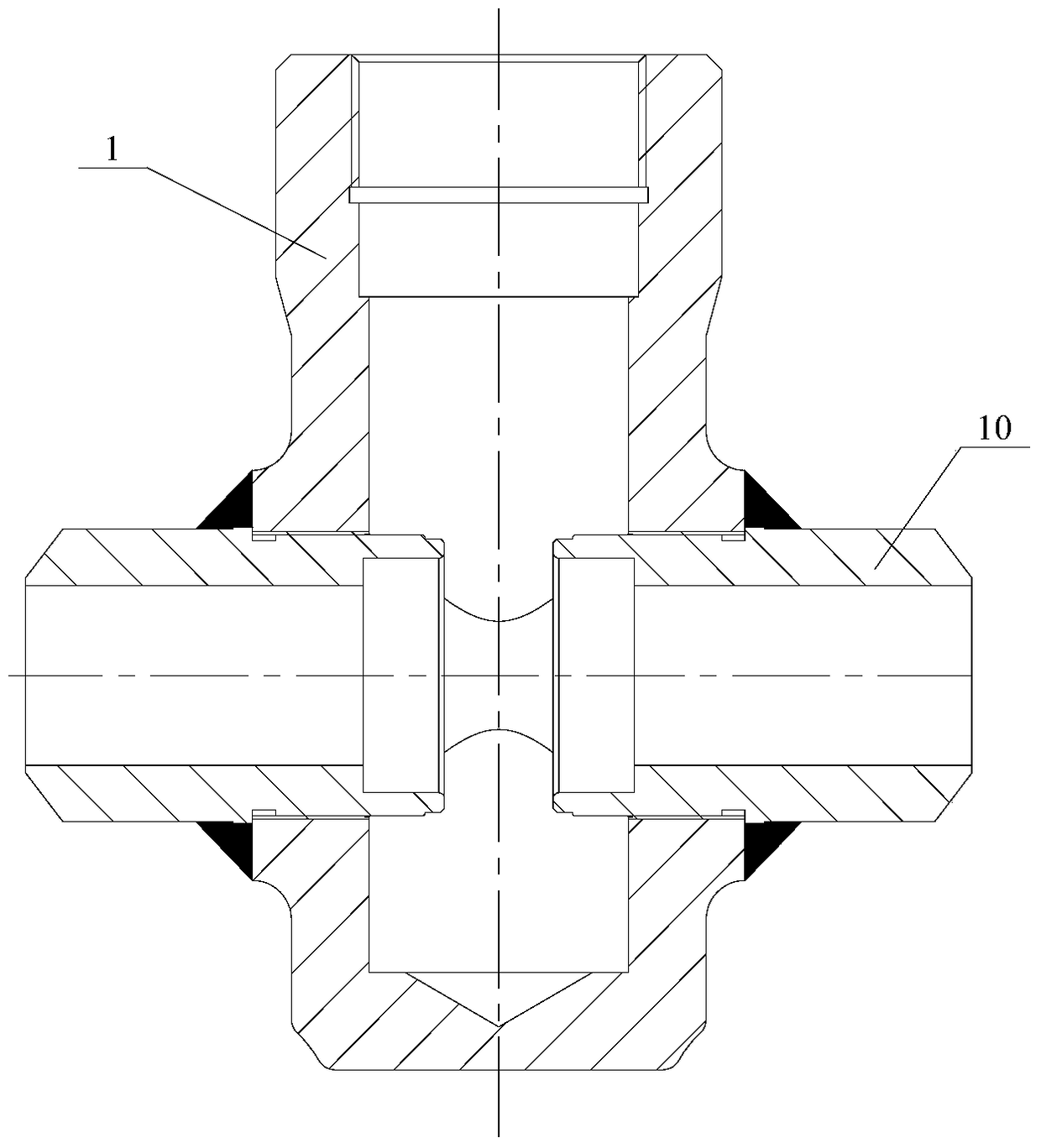

Gate valve and its manufacturing process

The invention discloses a gate valve and a manufacturing process thereof. The gate valve comprises a valve body with a T-joint structure, wherein an opening in the upper end of the valve body is connected with a valve cover; a valve stem penetrates into the valve body; the upper end of the valve stem is vertically connected with a handwheel, and the lower end of the valve stem is connected with a valve plate used for controlling opening and closing; a left connecting pipe and a right connecting pipe are respectively inserted into opposite openings on the left and right of the lower end of the valve body; the inner ends, adjacent to the valve plate, of the left connecting pipe and the right connecting pipe are respectively provided with a valve base; the peripheral surfaces of the left connecting pipe and the right connecting pipe are respectively welded and fixed together with the left and right side surfaces of the lower end of the valve body. Components, such as the valve body, the left connecting pipe and the right connecting pipe, in the gate valve are forged and molded, then are respectively processed and finally assembled without special fixtures, so that the labor strength is reduced, and the machining time is shortened.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

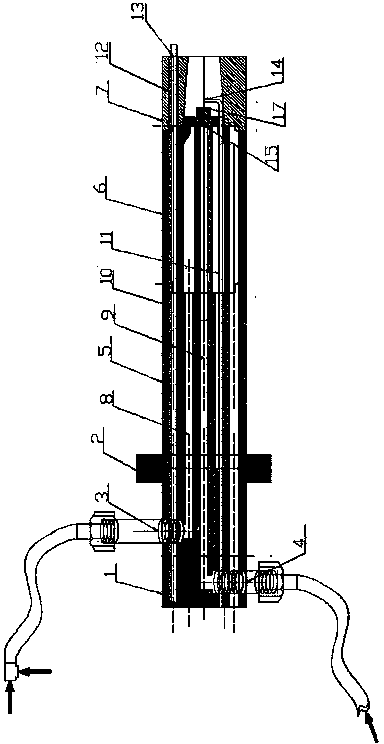

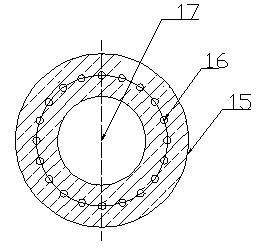

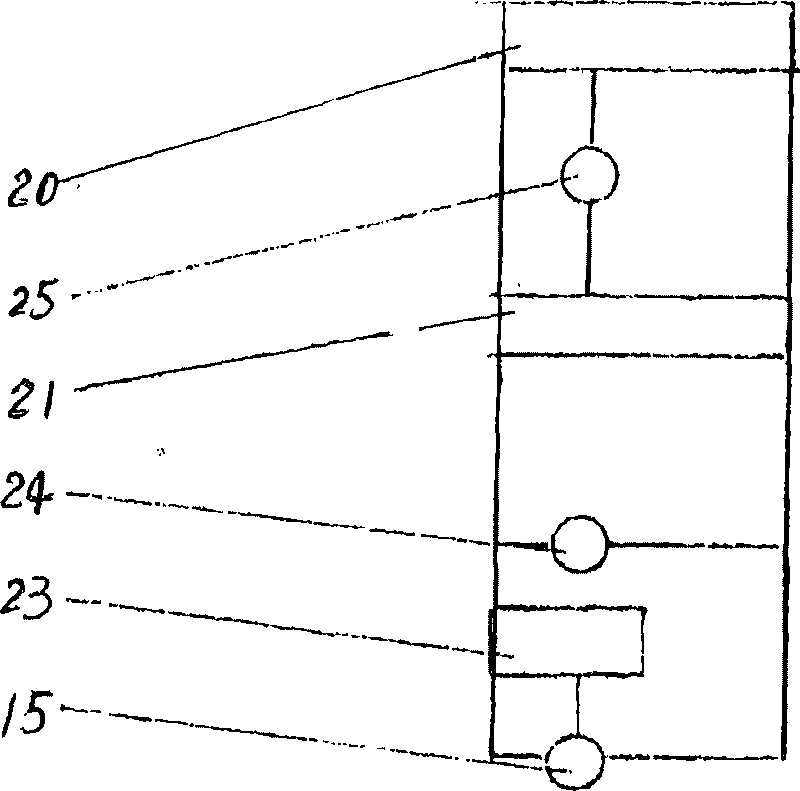

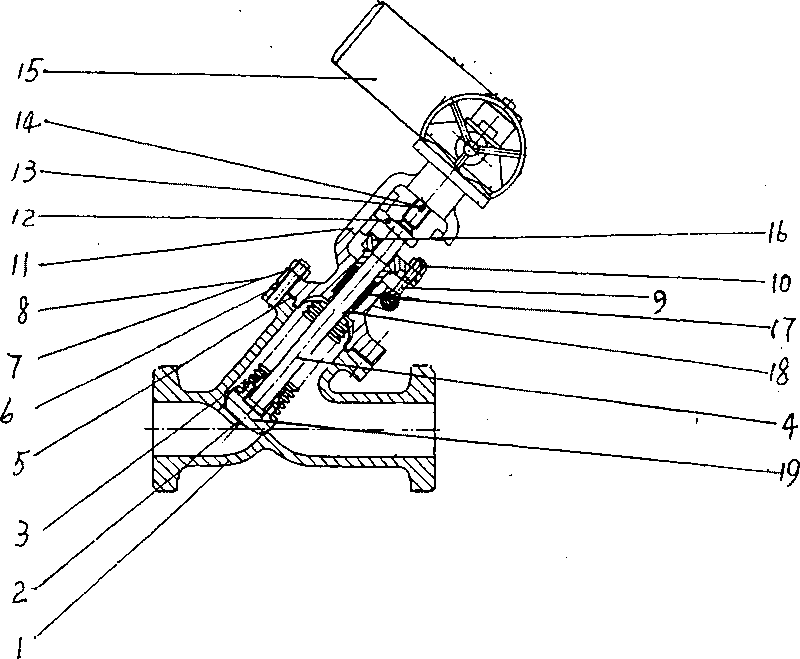

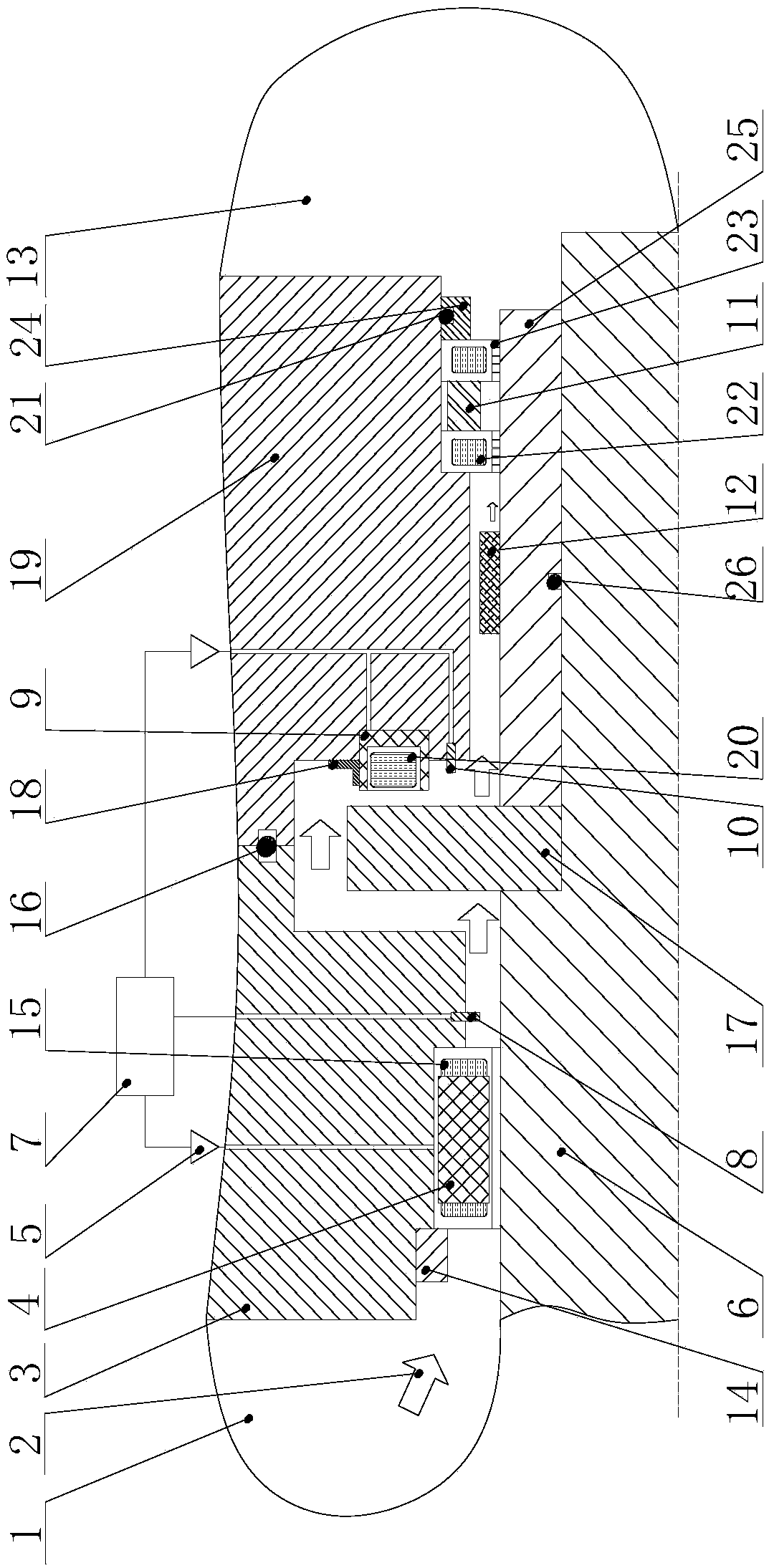

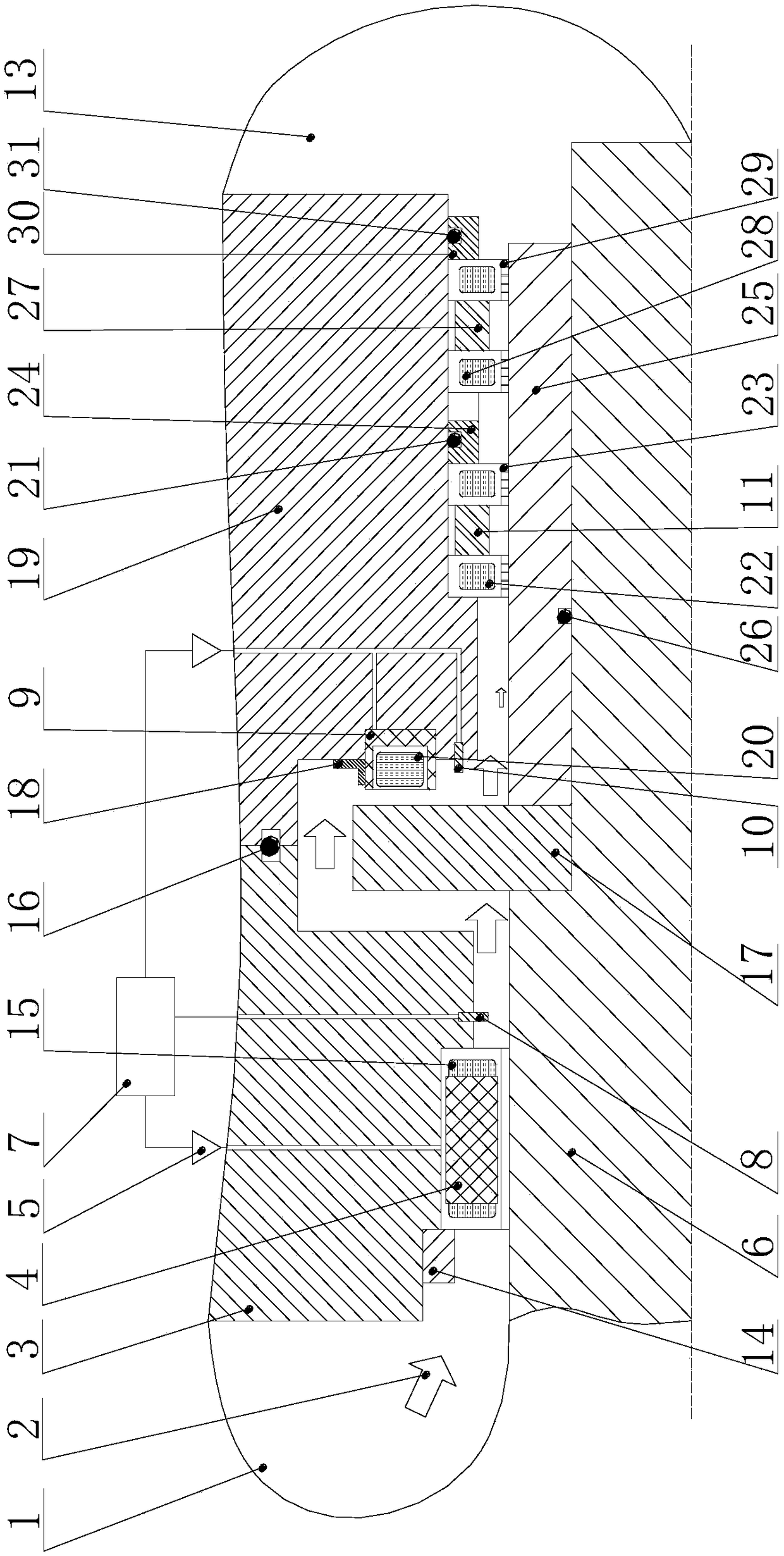

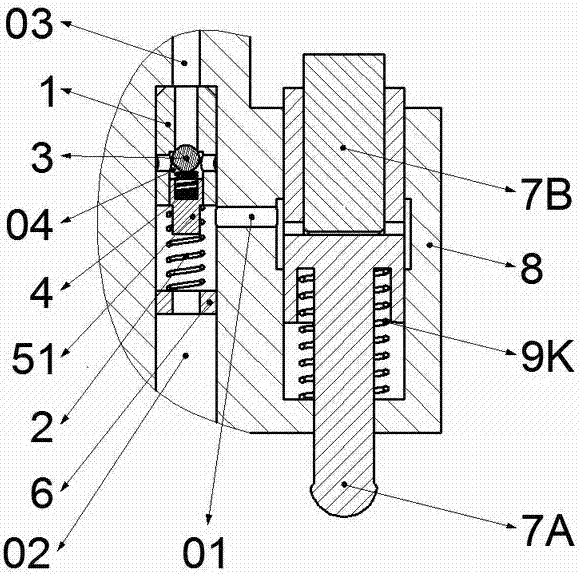

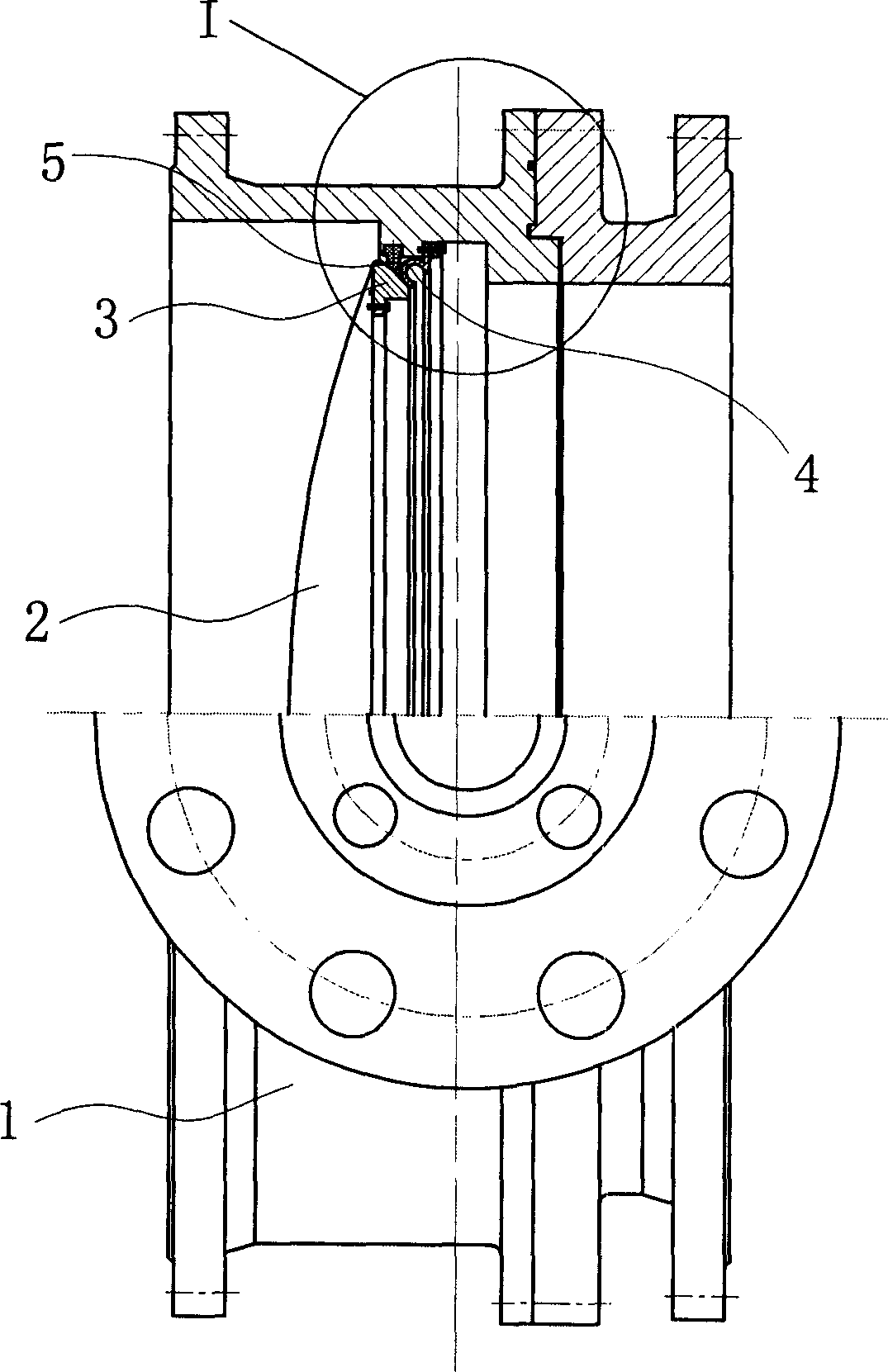

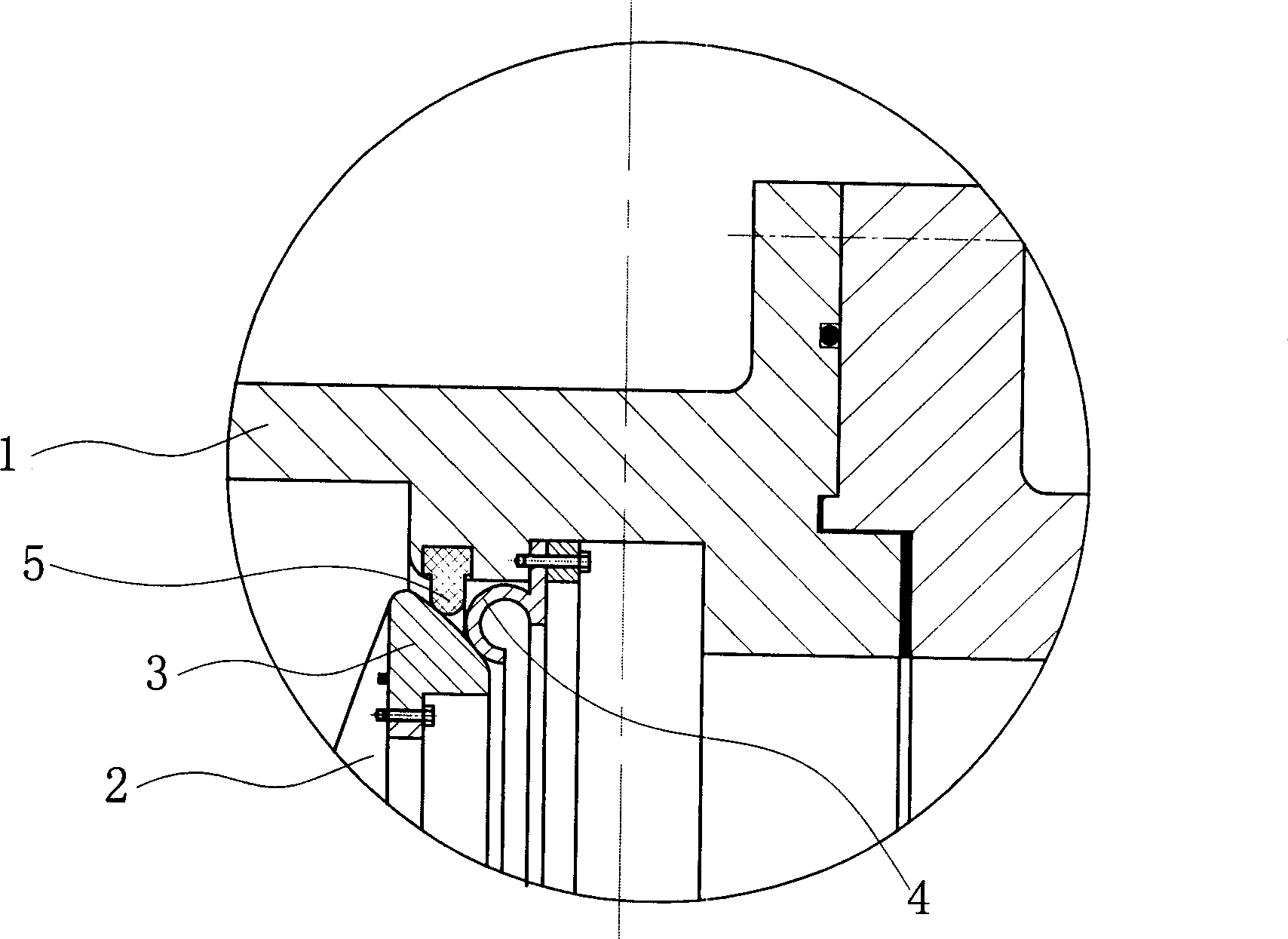

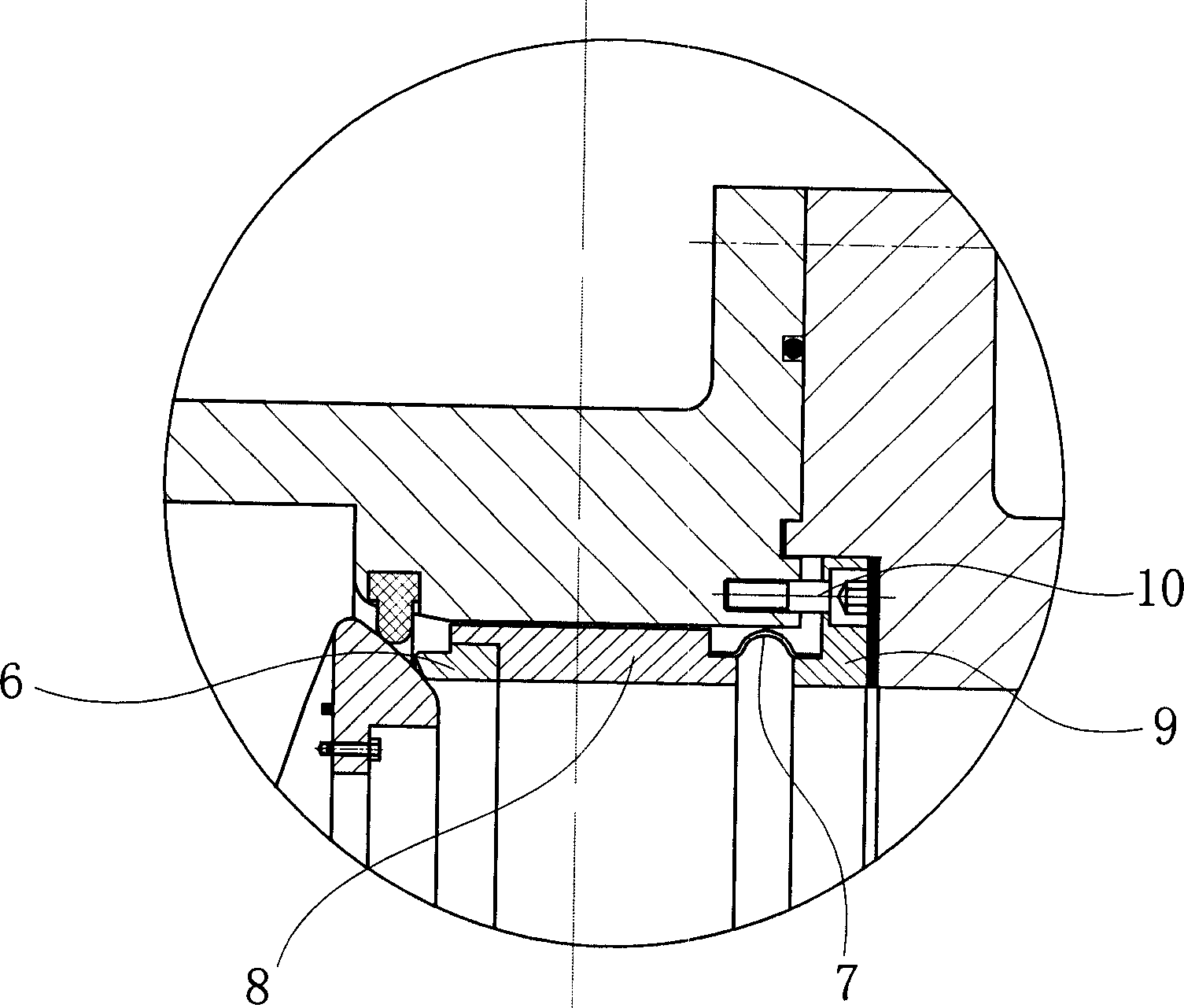

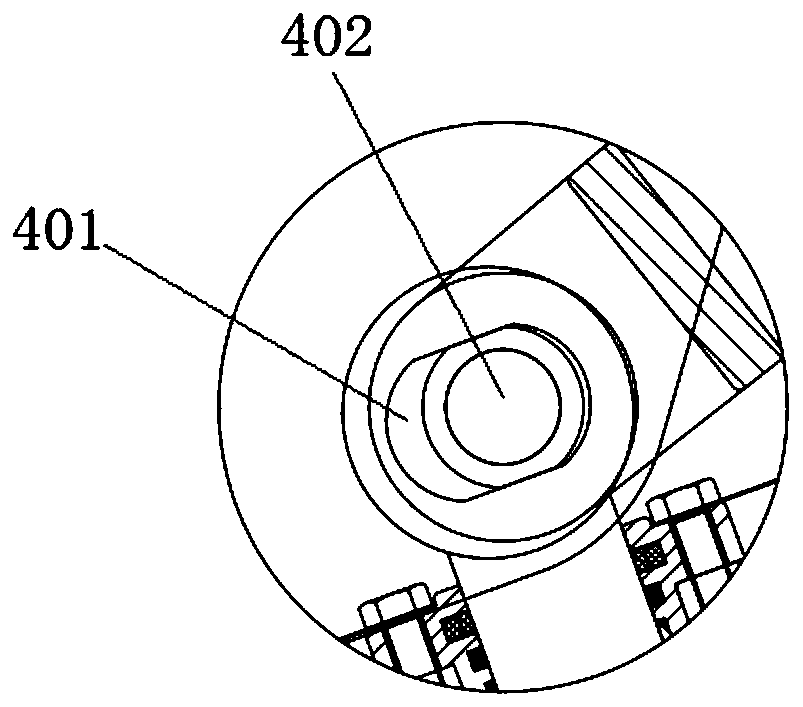

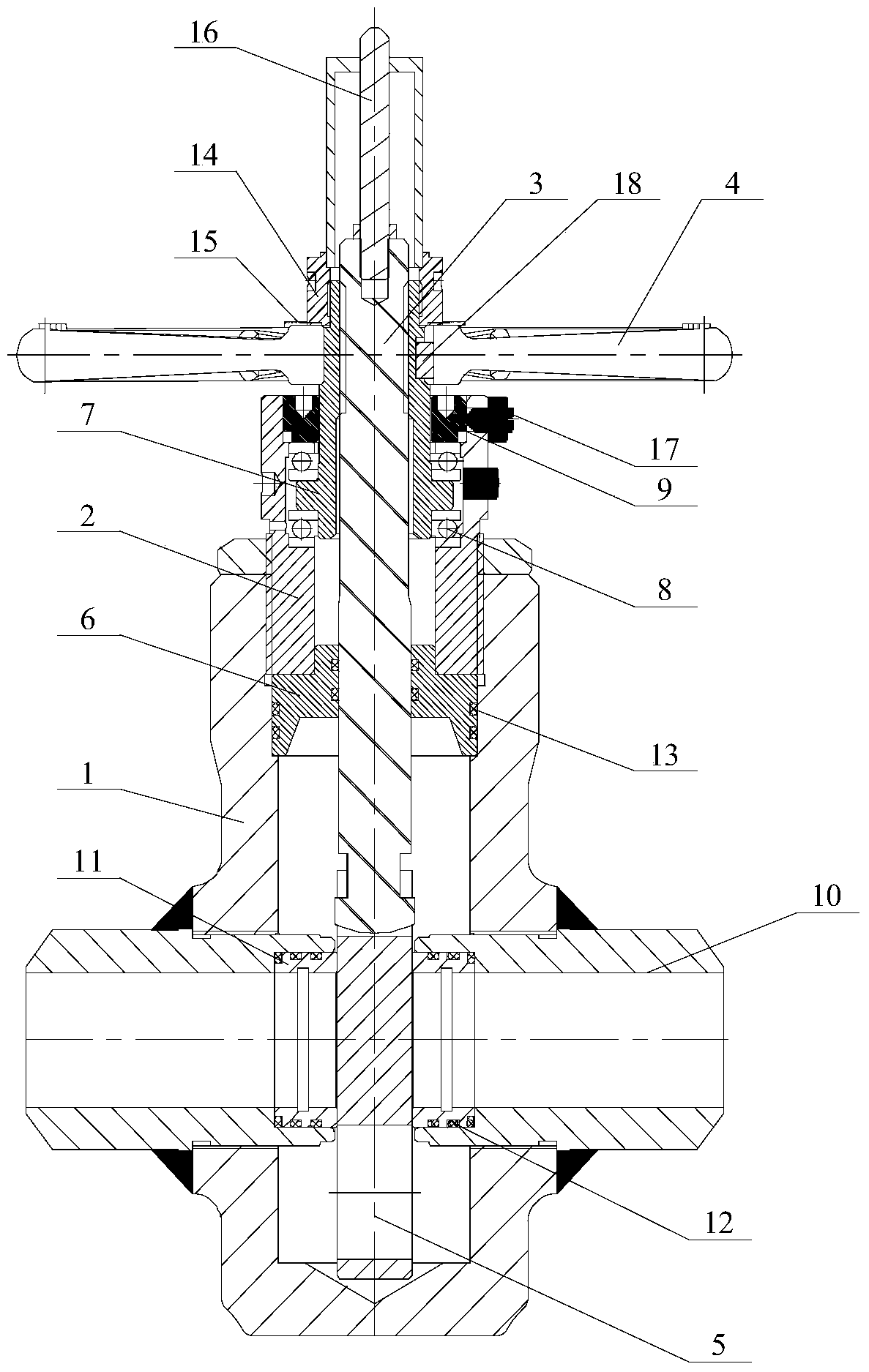

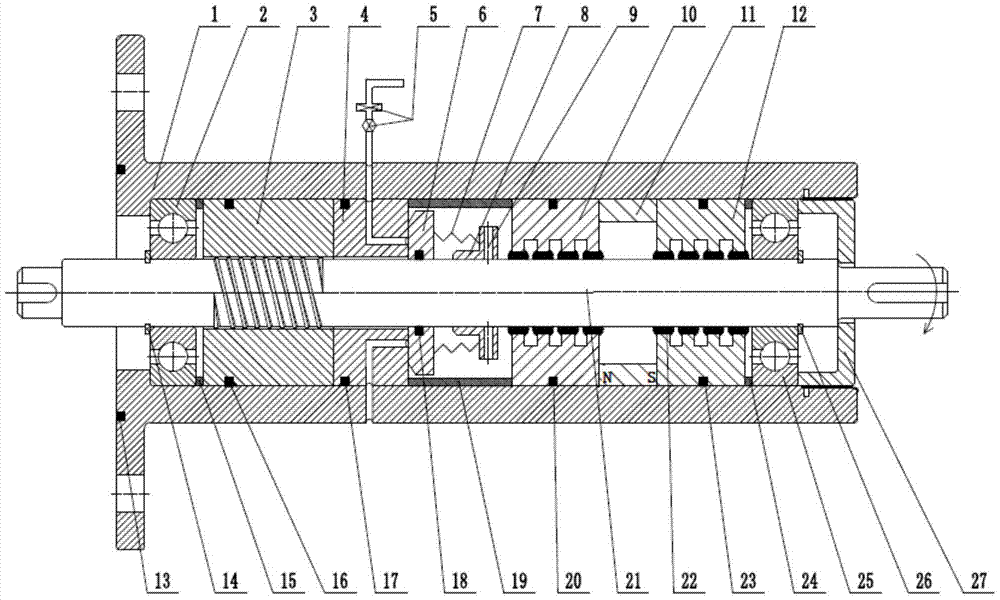

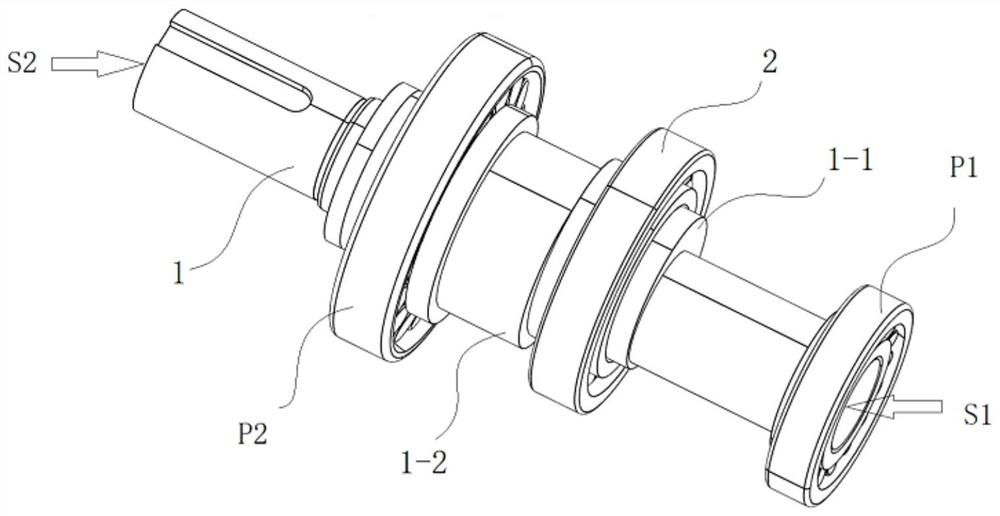

A multi-stage magnetic liquid sealing device

The invention belongs to the field of mechanical engineering sealing, and discloses a novel multi-stage magnetic liquid sealing device. The novel multi-stage magnetic liquid sealing device successfully solves the problem that an existing sealing mode can not avoid mutual dissolution or mutual contamination between magnetic liquid and a liquid medium to be sealed. The device comprises a first-stage seal and a second-stage seal, wherein the first-stage seal is formed by a static ring (4), a pressure control valve (5), a movable ring (6), a spring (7), a spring base (8) and a set screw (9), and the second-stage seal is formed by a left pole shoe (10), a permanent magnet (11) and a right pole shoe (12). The first-stage seal is mainly used for sealing a liquid medium to be sealed in a seal cavity and preventing the liquid medium to be sealed from making contact with magnetic liquid (22), the second-stage seal is mainly used for sealing gas charged into a cavity between the movable ring (6) and the left pole shoe (10), and even when a shaft (21) does not rotate, the novel multi-stage magnetic liquid sealing device can reliably seal the liquid medium to be sealed.

Owner:BEIJING JIAOTONG UNIV

External thread connecting type high-temperature resistant corrugated pipe stop valve

InactiveCN101571198AEasy to disassembleEasy connection and disassemblySpindle sealingsOperating means/releasing devices for valvesChemical industryAlloy

The invention discloses an external thread connecting type high-temperature resistant corrugated pipe stop valve and relates to a stop valve which comprises an external thread connecting type valve body, wherein a Co-based hard alloy seal ring is welded on the external thread connecting type valve body; a titanizing austenite stainless steel dual corrugated pipe device is loosely and mechanically connected under a valve rod; and a handwheel rotates and causes a lifting rod of the valve rod to drive the titanizing austenite stainless steel dual corrugated pipe device to lift by a valve rod nut. A dual, hard and durable corrugated pipe is convenient for disassembly, external threads are convenient for connection and disassembly, a product has reasonable structure and reliable seal, and the zero leakage of the valve rod is ensured. The external thread connecting type high-temperature resistant corrugated pipe stop valve has the advantages of Co-based hard alloy welded on the seal surface, good abrasion resistance, corrosion resistance and friction resistance of corrugated pipe titanizing austenite stainless steel and long service life, is suitable for switching off or on a pipeline medium on a pipeline under various working conditions of petroleum, chemical industry, pharmacy, fertilizer, power industry, and the like and is particularly used for conduction oil boiler pipeline engineer.

Owner:SHANGHAI HAIXING VALVE FACTORY

Clamp connection type high-temperature-resistant corrugated pipe stop valve

InactiveCN101598237ASimple structureEasy to installSpindle sealingsOperating means/releasing devices for valvesAustenitic stainless steelEngineering

The invention provides a clamp connection type high-temperature-resistant corrugated pipe stop valve and relates to a stop valve. The clamp connection type high-temperature-resistant corrugated pipe stop valve comprises a clamp connection type valve body, wherein a Co-based hard alloy sealing ring is resurfaced and welded on the valve body. A titanizing austenitic stainless steel dual-corrugated-pipe device is movably and mechanically connected below a valve rod, and a handwheel is rotated to enable a lifting rod of the valve rod to drive the titanizing austenitic stainless steel dual-corrugated-pipe device to lift by a valve rod nut. The dual firm and durable corrugated pipes are convenient to disassemble, the clamp connection is convenient to disassemble, and an exterior connection pipe and the sealing ring screw down a clamp component by a clamp fastening bolt through a spring shim so as to enable a pipeline to be rapidly sealed and connected. The clamp connection type high-temperature-resistant corrugated pipe stop valve is suitable for switching off or switching on pipeline media on pipelines with various working conditions in the petroleum industry, the pharmaceutical industry, the chemical fertilizer industry, and the like.

Owner:SHANGHAI HAIXING VALVE FACTORY

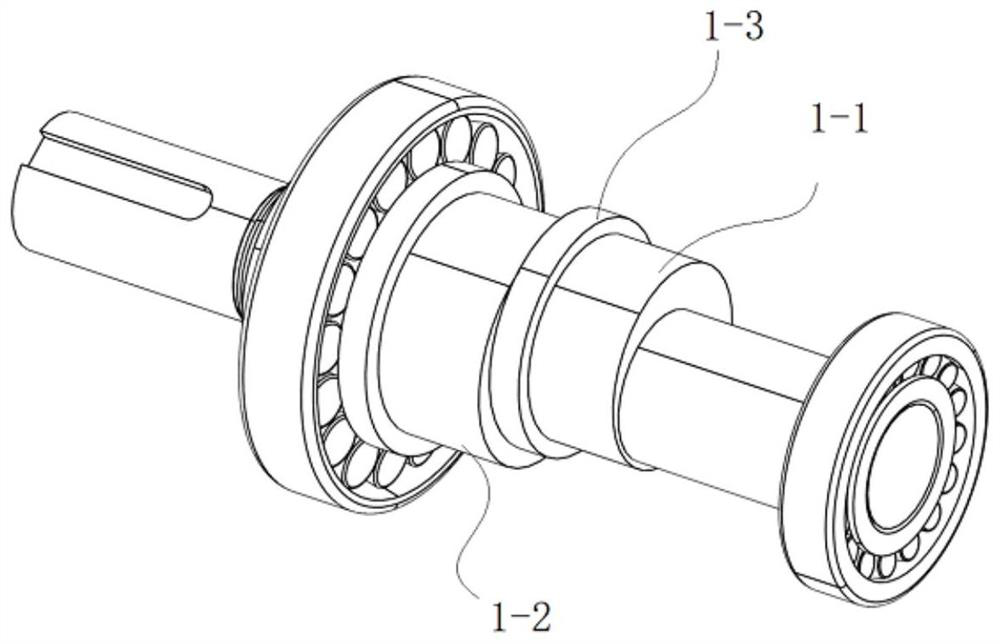

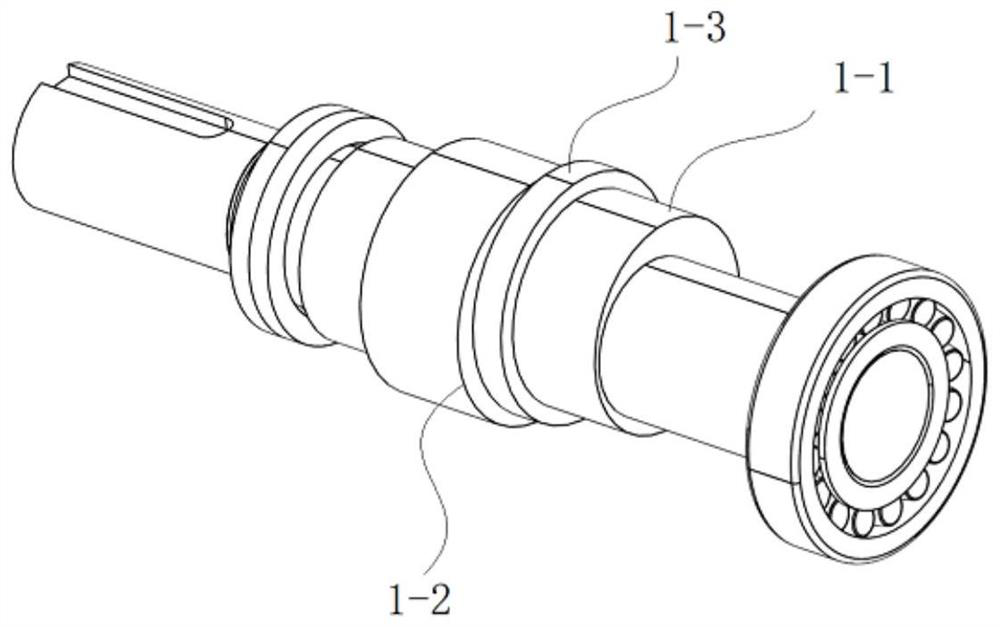

Hydraulic linkage type plunger pushing mechanism and plunger diaphragm pump using same

PendingCN114576126ASo as not to damageGuaranteed zero leakagePositive displacement pump componentsFlexible member pumpsDiaphragm pumpCompression action

The invention discloses a hydraulic linkage type plunger pushing mechanism and a plunger diaphragm pump using the same, the mechanism is provided with a crankshaft which is installed in a low-pressure liquid cavity of a plunger diaphragm pump body through a bearing assembly, the crankshaft is provided with an eccentric part, and the eccentric part of the crankshaft is sleeved with a bearing. According to the plunger diaphragm pump, the hydraulic linkage type plunger pushing mechanism is arranged, so that the problem that mechanical abrasion of a swash plate pushing head driving type hydraulic unit in a traditional plunger diaphragm pump is large is solved through the crankshaft, bearing and eccentric design, the bearing is arranged at the eccentric position of the crankshaft, and the outer ring of the bearing and the pushing head are tightly attached and do not generate relative movement; relative movement is achieved through the rolling bearings, the crankshaft pushes the corresponding plungers through the rolling bearings to complete compression action, outer rings of the bearings are not directly abraded with the plungers, factors of oil temperature rise caused by large mechanical action range of a traditional swash plate pushing head and large mechanical abrasion caused by sliding friction are avoided, the oil temperature in a low-pressure liquid cavity is greatly reduced, and the service life of the crankshaft is prolonged. And the oil temperature of the low-pressure liquid chamber is not obviously increased in the actual operation process.

Owner:SHANGHAI NIKUNI FLUID SYST CO LTD

Cement curing line mixing stirrer

ActiveCN110103335AAvoid OverloadingExtended service lifeEngine sealsCement mixing apparatusRadioactive wastePolymer chemistry

The invention discloses a cement curing line mixing stirrer, and relates to the field of cement curing equipment. The cement curing line mixing stirrer comprises a power device, a stirring box, a bearing box, a stirring shaft, an inner magnetic rotor, an outer magnetic rotor and a distance sleeve. The distance sleeve is arranged in the outer magnetic rotor, the inner magnetic rotor is arranged inthe distance sleeve, and the outer magnetic rotor is coupled with the inner magnetic rotor. One end of the outer magnetic rotor is fixedly connected with the output end of the power device, the innermagnetic rotor is fixedly connected with one end of the stirring shaft, the other end of the stirring shaft penetrates through the stirring box, and a movable seal is arranged between the stirring shaft and the stirring box. The bearing box sleeves the stirring shaft, one end of the bearing box is fixedly connected with the open end of the distance sleeve, the other end of the bearing box is fixedly connected with the stirring box, and sealing gaskets are arranged between the stirring box and the bearing box and between the distance sleeve and the bearing box. The sealing effect of the mixingstirrer is reliable, the problem of radioactive waste leakage is completely solved, the life health of staff is guaranteed, and meanwhile the cement curing line mixing stirrer is reasonable in structural design, convenient to dismount and mount and easier to overhaul and maintain.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

Pneumatic gate valve for welding type high-temperature resistant bellows

InactiveCN101608708AEasy to disassembleGuaranteed zero leakageSpindle sealingsOperating means/releasing devices for valvesAutomatic controlEngineering

The invention relates to a pneumatic gate valve for welding type high-temperature resistant bellows, in particular to a pneumatic gate valve. The pneumatic gate valve comprises a welding type valve body, wherein a pneumatic head device is connected with a pneumatic head device frame; the pneumatic head device frame is mechanically connected with a valve cap through a bolt, a spring spacer and a nut; a pneumatic head mandrel and the upper side of a valve stem are mechanically connected with a pneumatic head mandrel sleeve through a cross-bolt; a Co-based hard alloy seal ring is arranged on the welding type valve body in a mode of surface welding; an adjustable mechanism of titanizing austenitic stainless steel bellows is connected between the lower side of the valve stem and the upper side of a gate plate; and a head part below the valve stem is connected with an adjustable mechanism of the gate plate so that the titanizing austenitic stainless steel bellows are driven to lift by a lifting rod of the valve stem. The pneumatic gate valve has the advantages of simple structure and convenient installation; the pneumatic head can be used for an automatic control pipeline; the dual sturdy and durable bellow is conveniently disassembled; the hermetical design for the dual sturdy and durable bellows ensures the zero leakage of the valve stem.

Owner:SHANGHAI HAIXING VALVE FACTORY

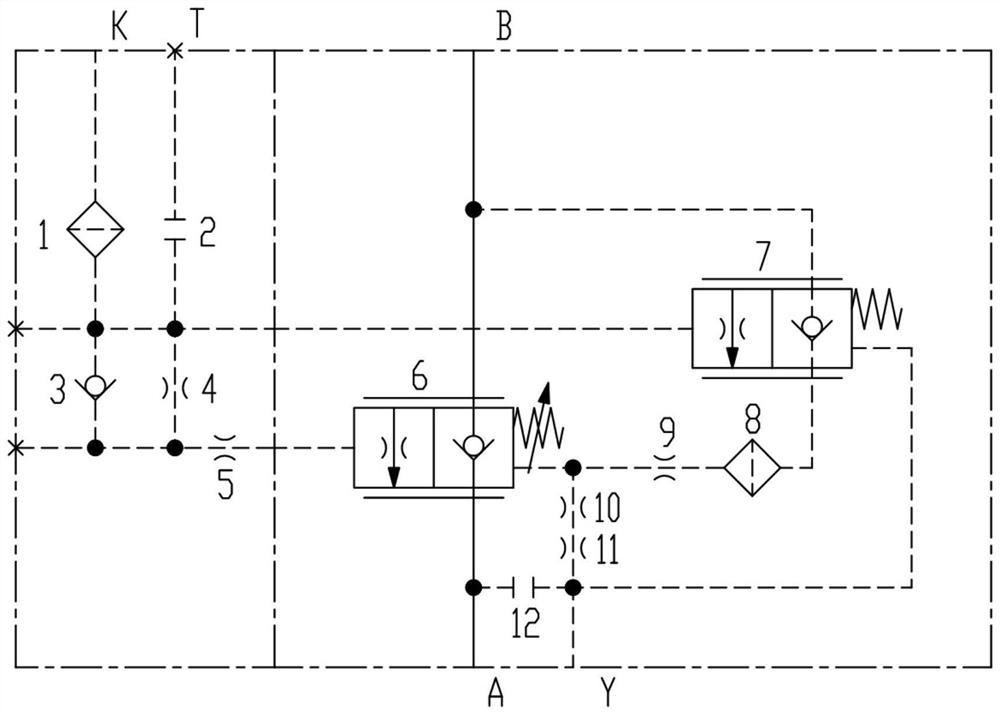

Loading pressure-flow compensation balance valve

ActiveCN111810481AEasy to replaceEasy to assemble and disassembleServomotor componentsCranesEngineeringDamper

The invention discloses a loading pressure-flow compensation balance valve. The loading pressure-flow compensation balance valve comprises a balance valve body, wherein a control end cover is installed on the balance valve body, an opening K of the control end cover is used for receiving control pressure from variable-amplitude falling, and is connected with a one-way valve, a first damper, one end of a first screwed plug and a two-position two-way reversing valve through a first filter screen, the one-way valve and the other end of the first damper are connected together and connected to a control cavity of a balance valve through a second damper, one end of the balance valve is connected with a variable-amplitude oil cylinder through a balance valve opening B, the other end of the balance valve is connected with a control valve through a balance valve opening A, spring cavities of the balance valve are connected with one end of a third damper and one end of a fourth damper correspondingly, the other end of the fourth damper and a fifth damper are connected in series and then are connected with one end of a second screwed plug, a spring cavity of the two-position two-way reversingvalve and a balance valve opening Y, and one oil end of the two-position two-way reversing valve is connected with the balance valve opening B. The loading pressure-flow compensation balance valve has the advantages of being simple in product structure, low in cost, good in compensation effect and capable of being adjusted conveniently.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Fastener connecting bellows stop valve

InactiveCN101398088AEasy to disassembleEasy connection and disassemblySpindle sealingsLift valveClamp connectionHeat conducting

The invention discloses a clamp-connecting globe valve of a corrugated tube, relating to a globe valve. The clamp-connecting globe valve comprises a clamp-connecting valve body; Co-based cemented-carbide sealing ring is welded on the valve body in a resurfacing manner; a double corrugated tube device coated with austenitic titanium stainless steel is detachably and mechanically connected to the lower part of a valve stem; and when a hand-wheel is turned, a lifting poker of the valve stem drives the double corrugated tube device coated with austenitic titanium stainless steel to rise and fall through a valve stem nut. The strong durable double corrugated tube is convenient to detach, a clamp connection is also convenient to detach, a product is simple in structure and reliable in sealing, and zero leakage of the valve stem is guaranteed. The clamp-connecting globe valve has no fluid loss, reduces energy loss and increases safety to the plant equipment. The sealing surface is welded with Co-based cemented carbide in a surfacing manner; the corrugated tube is coated with austenitic titanium stainless steel, thereby being wear-proof and corrosion-poof and having good anti-friction performance and long service life; the clamp-connecting globe valve is applicable to engineering pipelines with clamp-connecting nut externally connecting a conduit under various engineering conditions in petroleum industry, chemistry industry, pharmacy industry, fertilizer industry, electricity industry and the like to cut off or connect the pipeline media, particularly to the engineering of a heat-conducting oil boiler pipeline.

Owner:SHANGHAI HAIXING VALVE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com