Low-energy-consumption braking switch

A brake switch, low energy consumption technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of easy damage to contact parts, large inertial force of rocker arm movement, leakage of HPD mechanism, etc. The effect of expanding the scope of application and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

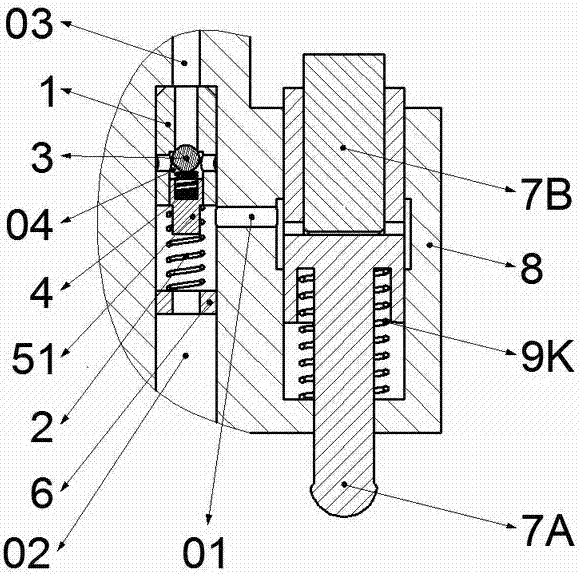

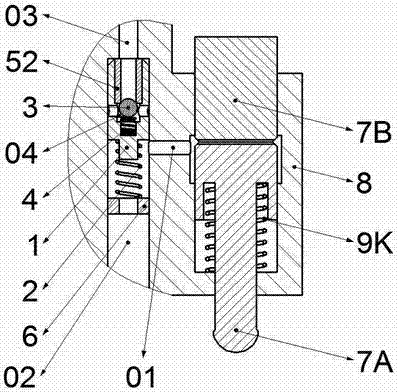

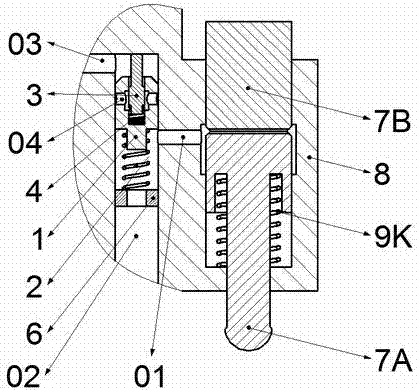

[0018] The invention relates to a low energy consumption braking switch. Figure 1-4 They are schematic diagrams of the four implementations of the brake switch. It also includes a first hydraulic piston 7A, a second hydraulic piston 7B, a spool valve body 1 , a spool return spring 2 , a one-way valve spool 3 and a one-way valve return spring 4 . A mounting hole, a driving oil passage 01 , an oil draining oil passage 02 and a control oil passage 03 are arranged in the fixing part 8 . Both the first hydraulic piston 7A and the second hydraulic piston 7B are installed in the fixed part 8 or the piston bushing T2 fixed on the fixed part 8, or after the first hydraulic piston 7A and the second hydraulic piston 7B are nested, they are installed In the fixed part 8 or in the piston bushing T2 fixedly arranged on the fixed part 8 . The oil chamber between the first hydraulic piston 7A and the second hydraulic piston 7B is connected with the driving oil circuit 01 . The spool valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com