Cement curing line mixing stirrer

A technology of mixing and mixing and cement curing. It is applied in cement mixing devices, chemical instruments and methods, and engine sealing. It can solve the problems of life and health threats to maintenance personnel, short effective sealing time period, and poor dynamic sealing reliability. Maintenance cycle, guaranteed service life, and the effect of maintaining the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

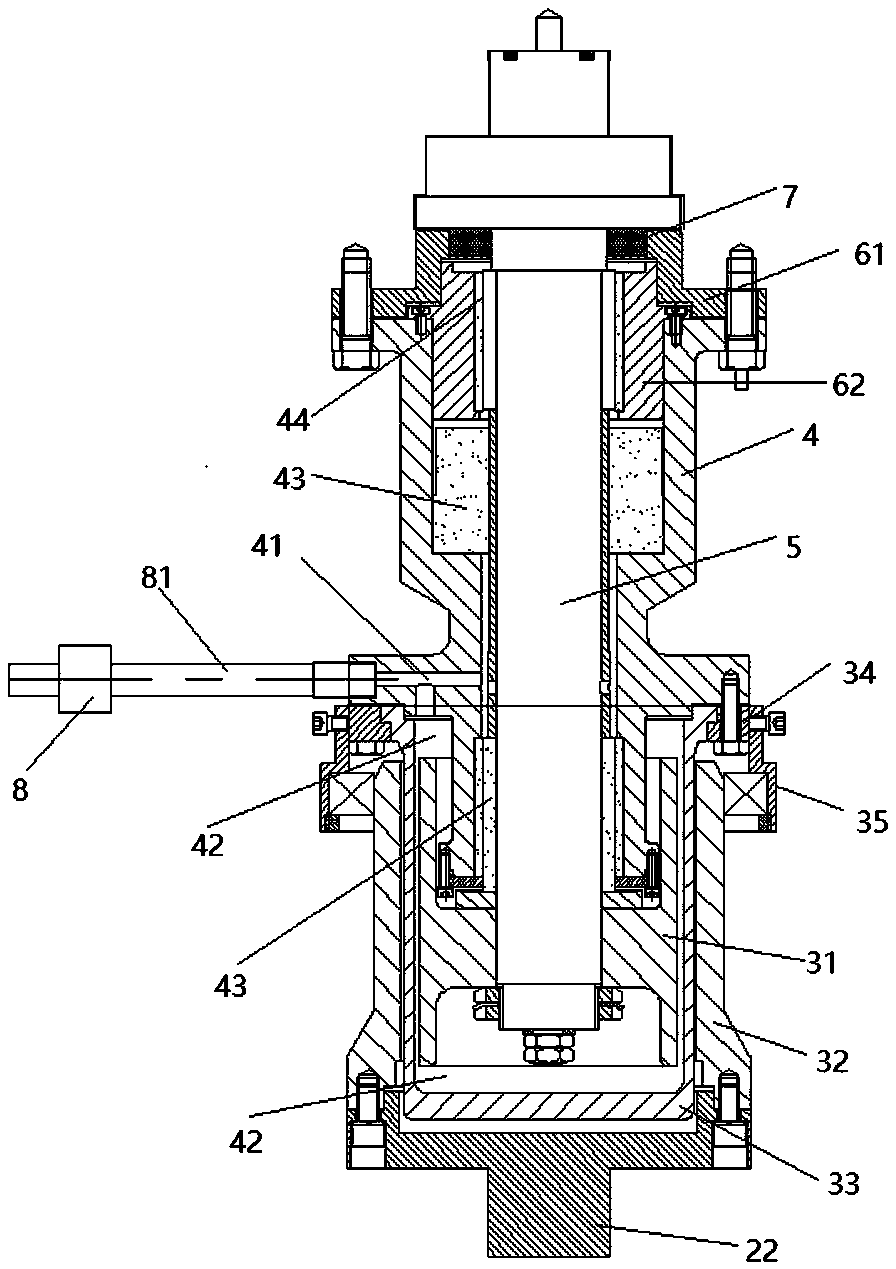

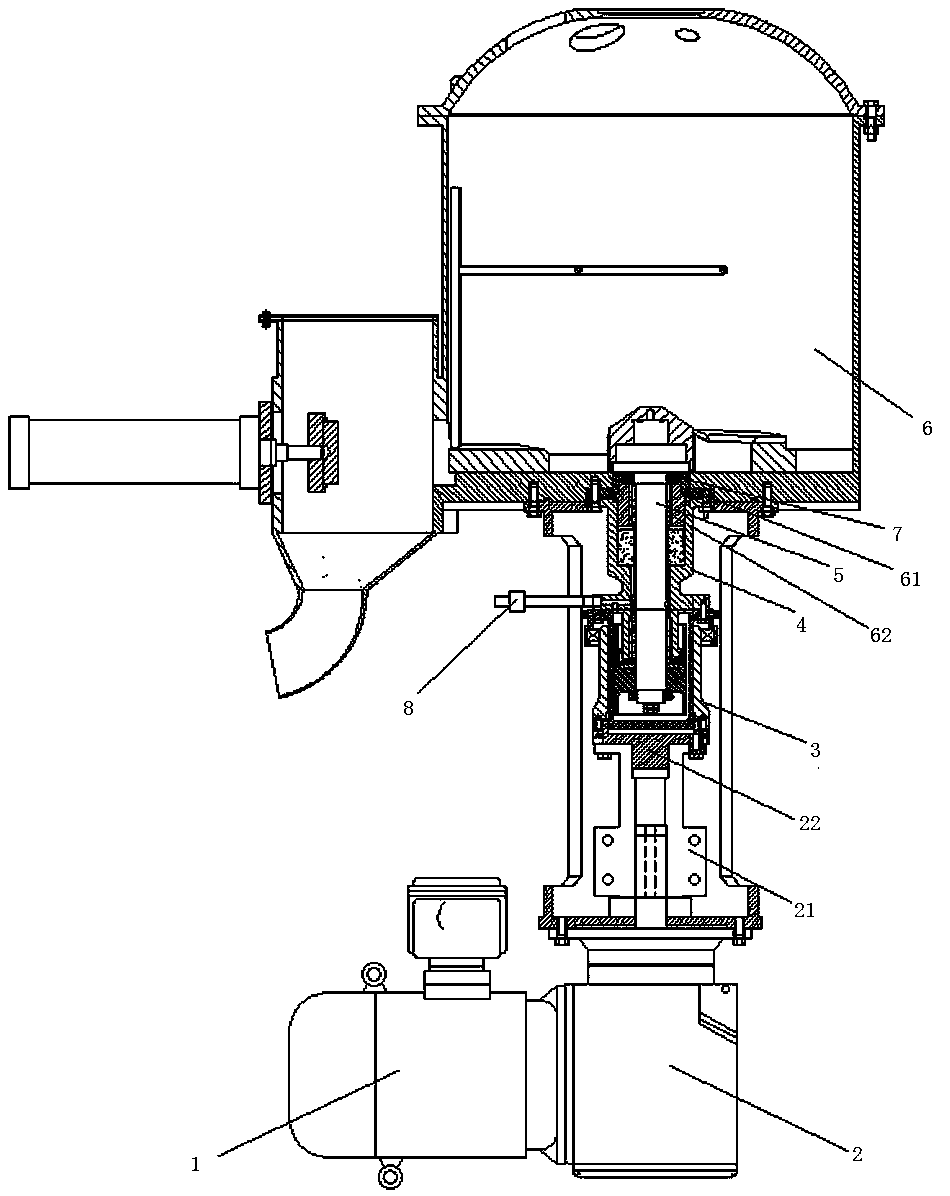

[0032] like figure 1 , figure 2 As shown, a cement curing line mixing mixer includes a power unit, a shaft assembly and a mixing box 6 .

[0033] The shaft assembly includes a magnetic drive 3 , a bearing housing 4 and a stirring shaft 5 . The magnetic transmission 3 includes an inner magnetic rotor 31 , an outer magnetic rotor 32 and an isolation sleeve 33 . The isolation sleeve 33 is a hollow cylinder structure with one end closed. The isolation sleeve 33 is arranged in the outer magnetic rotor 32 , the inner magnetic rotor 31 is arranged in the isolation sleeve, and the outer magnetic rotor 32 is coupled with the inner magnetic rotor 31 . The inner magnetic rotor 31 is fixedly connected to one end of the stirring shaft 5 , the bearing housing 4 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com