Pneumatic gate valve for welding type high-temperature resistant bellows

A welded, bellows technology, applied in the field of pneumatic gate valves, to achieve good anti-corrosion and anti-friction performance, good anti-friction performance, and improve the safety of factory equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

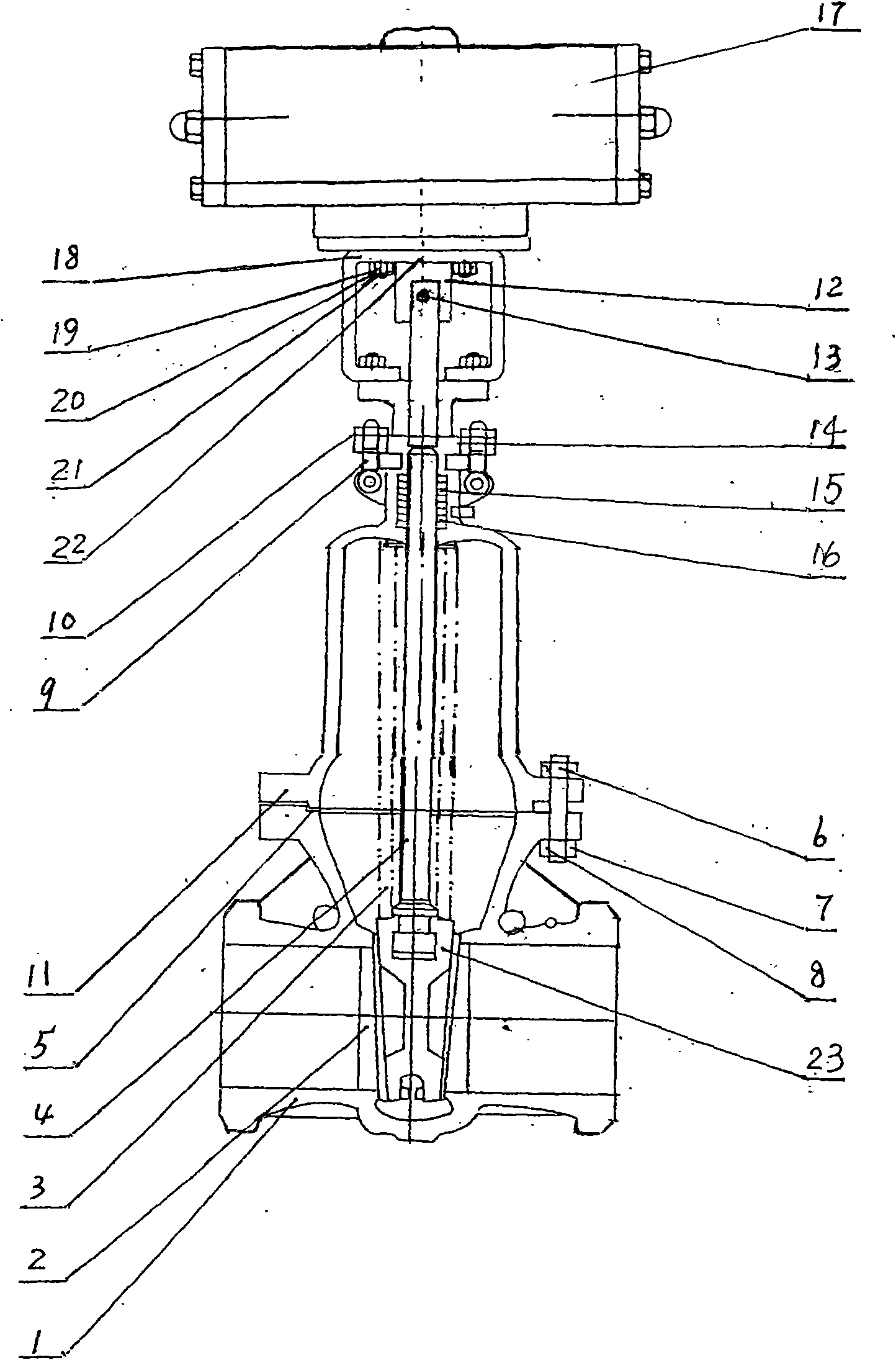

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0008] In the figure: 1. Welded valve body, 2. Overlay welding Co-based hard alloy sealing ring, 3. Titanium-plated austenitic stainless steel bellows device, 4. Valve stem, 5. High temperature resistant gasket, 6. Bolt , 7. Spring washer, 8. Nut, 9. Jack screw, 10. Jack nut, 11. Valve cover, 12. Pneumatic head mandrel sleeve, 13. Cross bolt, 14. Packing gland, 15. Packing, 16 .Lower packing pad, 17. Pneumatic head device, 18. Pneumatic head device frame, 19. Bolt, 20. Spring washer, 21. Nut, 22. Pneumatic head mandrel, 23. Gate.

[0009] exist figure 1 In the shown example: the pneumatic head device 17 is mechanically connected with the pneumatic head device frame 18, the pneumatic head device frame 18 and the valve cover 11 are mechanically connected by bolts 19, spring washers 20, nuts 21, the pneumatic head mandrel 22 is connected with the valve st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com