Sealing flashboard door for biomass feeding

A technology of biomass and sliding doors, which is applied in the direction of valve operation/release devices, sliding valves, valve details, etc., can solve problems such as poor switching, jamming, and blockage, so as to avoid reverse channeling, continuous and reliable switching, and Guaranteed non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

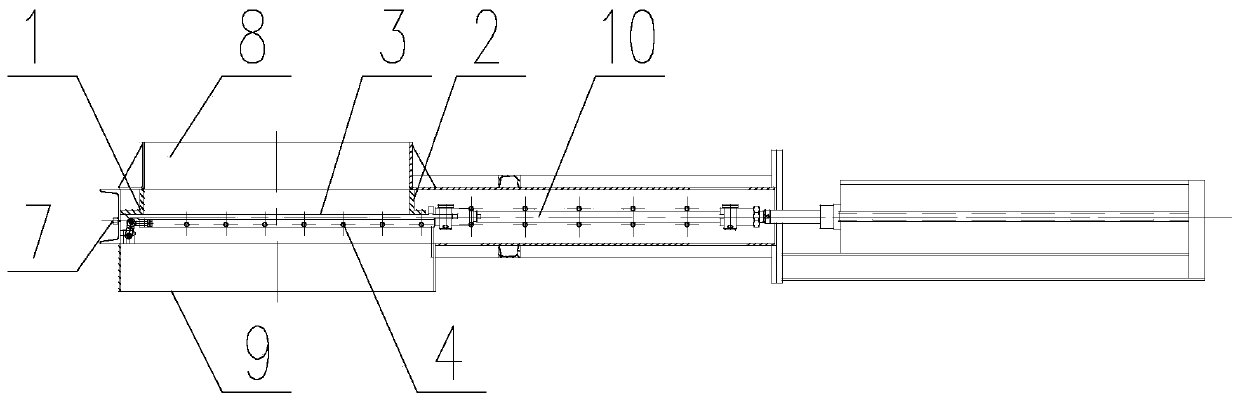

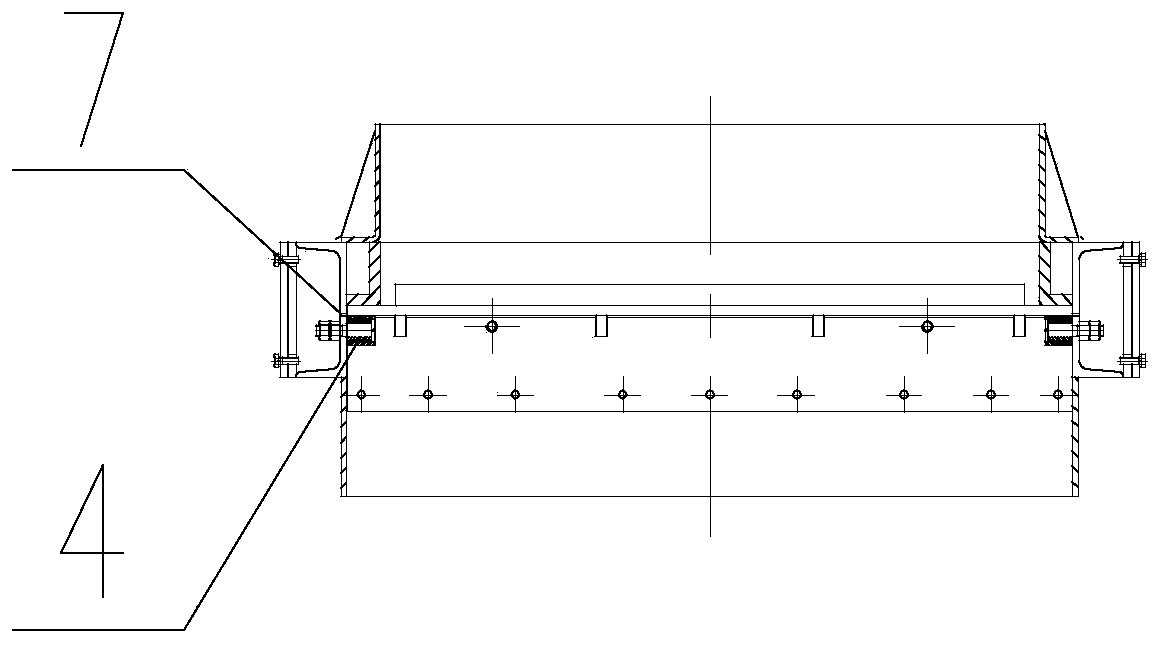

[0024] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment is a kind of sealing gate for biomass feeding, which includes the front end 1 of the valve body, the rear end 2 of the valve body, the feed port 8, the discharge port 9, the front end 1 of the valve body and The rear end 2 of the valve body is located at the front and rear ends of the valve body, and the feed inlet is fixedly installed between the front end 1 of the valve body and the rear end 2 of the valve body. The sealed gate for biomass feeding also includes The flashboard assembly and the locking assembly, the flashboard assembly is slidingly connected to the bottom of the valve body front end 1 and the valve body rear end 2 respectively, the discharge port 9 is located at the bottom of the flashboard assembly, and the locking mechanism is connected to the flashboard assembly.

[0025] After the valve body is manufactured, the sealing surface of the valve body...

specific Embodiment approach 2

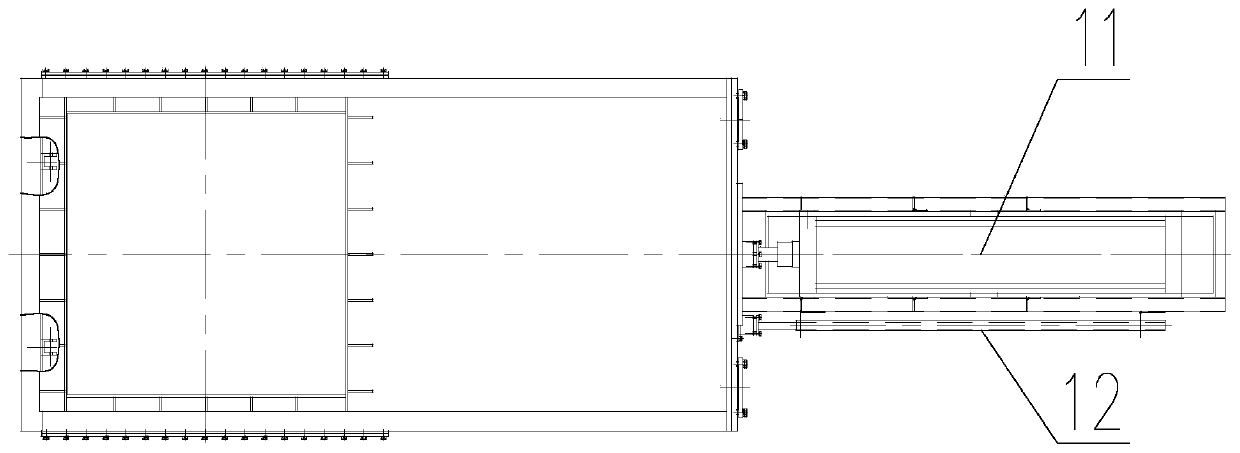

[0026] Specific implementation mode two: combination figure 1 Describe this embodiment, the flashboard assembly described in this embodiment includes a flashboard 3, a connecting rod 10, and a cylinder 11. Slidingly connected, one end of the connecting rod 10 is hinged with the flashboard 3, and the other end of the connecting rod 10 is connected with the cylinder 11. The limiting device 12 is in sliding connection with the cylinder 11 .

[0027] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 To describe this embodiment, the front end of the board 3 described in this embodiment is a wedge-shaped structure 3-1.

[0029] Such setting can effectively remove materials and impurities stuck on the sealing surface of the valve body, ensure reliable sealing of the sliding door in the closed state, and prevent material jamming.

[0030] Other components are the same as those in the second embodiment in terms of connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com