Circulating fluidized bed boiler for purely burning furfural residues

A technology of circulating fluidized bed and fluidized bed, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, and combustion methods, etc., can solve problems such as difficulty in meeting national environmental protection requirements and pollution, and achieve enhanced self-cleaning ability, avoid corrosion, and prevent the effect of poor feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

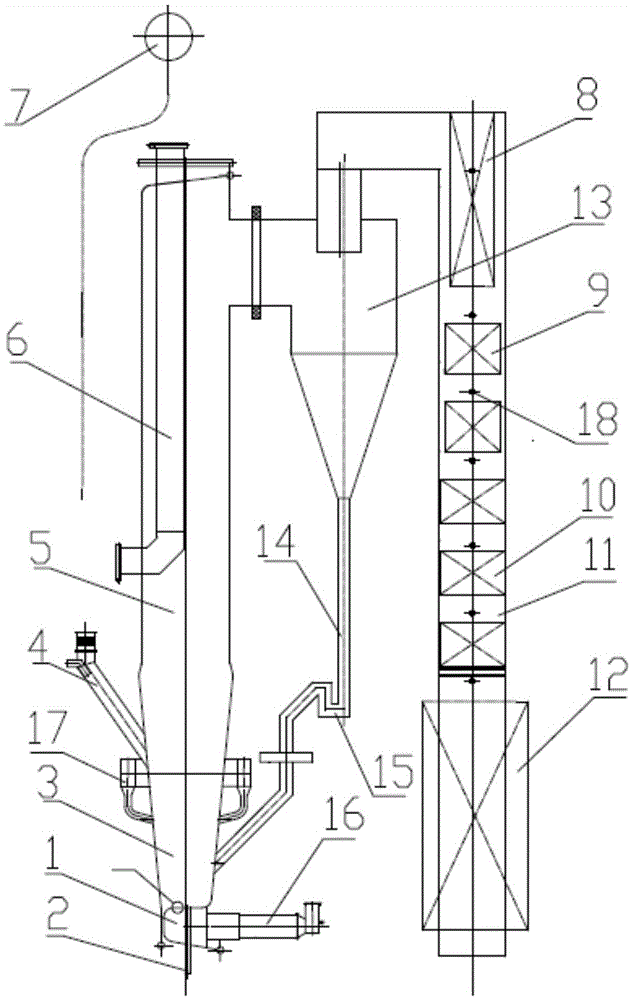

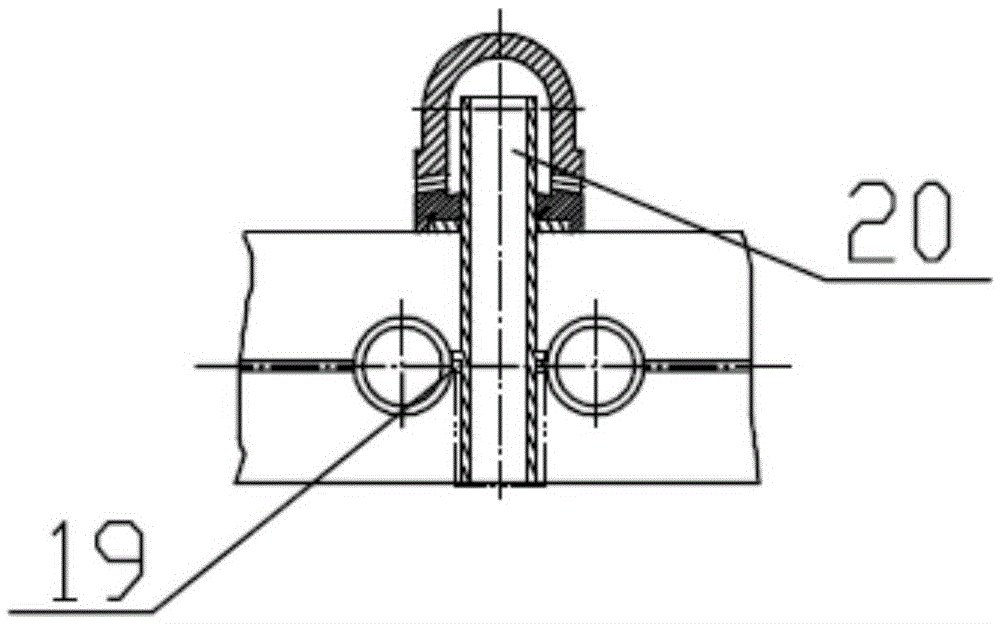

[0014] Such as figure 1 and figure 2 As shown, a circulating fluidized bed boiler for purely burning furfural slag includes a drum 7, a membrane water-cooled hearth 5, a high-temperature panel superheater 6 and a fluidized bed combustion chamber 3, wherein: it also includes a secondary hot air inlet Furnace branch pipe 17, water-cooled air chamber 1, water-cooled slag discharge pipe 2, ignition device 16, adiabatic cyclone separator 13, material return system 14, evaporation tube bundle 8, low-temperature superheater 9, economizer 10, shaft flue 11, air Preheater 12, low energy consumption self-balancing return valve 15, water-cooled air distribution plate 19 and bell-type hood 20, the high-temperature panel superheater 6 is arranged in the upper part of the membrane-type water-cooled hearth 5, and the fluidized bed The combustion chamber 3 is arranged at the lower part in the membrane type water-cooled hearth 5, and the furfural slag fuel inlet 4 communicating with the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com